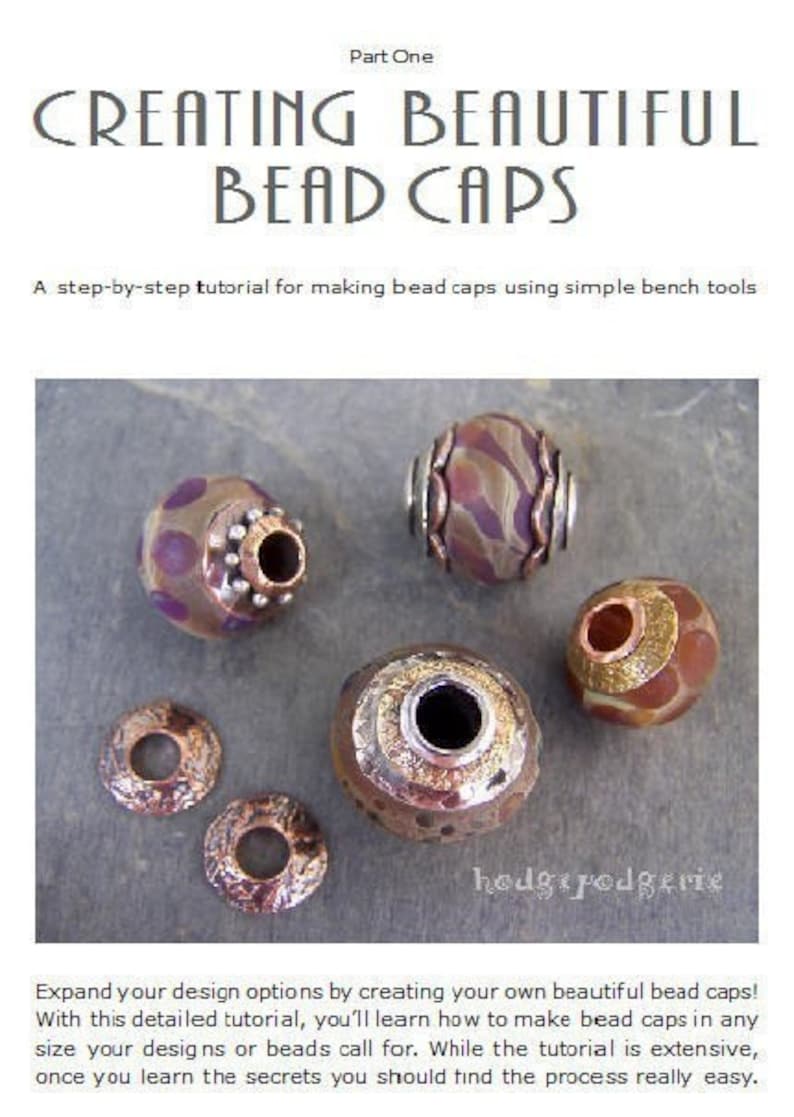

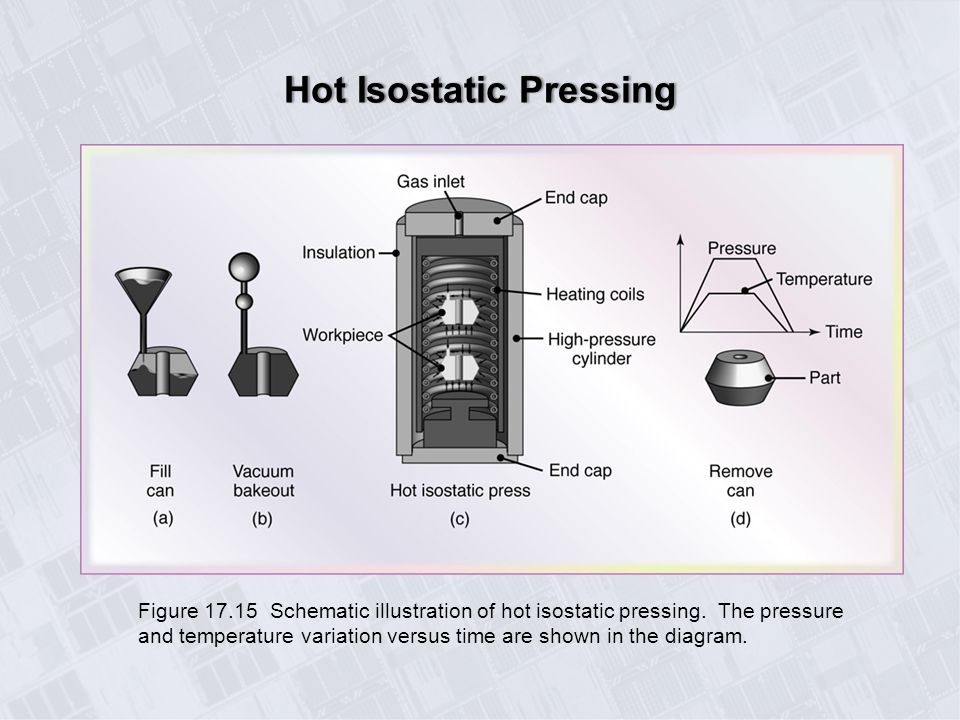

How do you create professional-looking end caps for jewelry projects. What materials and tools are needed for making custom end caps. Why should you consider making your own end caps instead of buying pre-made ones. How can homemade end caps enhance your jewelry designs.

Understanding the Importance of End Caps in Jewelry Making

End caps play a crucial role in jewelry design, particularly when working with cords, cables, or flexible materials. They serve multiple purposes, including:

- Providing a polished finish to bracelet or necklace ends

- Securing cords and preventing fraying

- Creating attachment points for clasps or other findings

- Adding a decorative element to the overall design

By learning to make your own end caps, you gain greater control over your jewelry’s appearance and functionality. This skill allows you to customize your pieces and potentially reduce costs compared to purchasing pre-made components.

Essential Materials and Tools for DIY End Cap Creation

Before diving into the end cap making process, gather the following materials and tools:

- Metal discs or squares (silver, copper, or brass)

- Tubing that fits your cord or cable

- Solder and flux

- Torch or soldering iron

- Files and sandpaper

- Pliers (round nose and flat nose)

- Safety equipment (gloves, goggles, ventilation)

- Pickle solution for cleaning

- Jump rings

Having these items on hand ensures a smooth crafting process and professional results.

Step-by-Step Guide to Creating Custom End Caps

Follow these steps to create your own custom end caps:

- Cut tubing to size (minimum 5mm, ideally 10mm for better security)

- File or sand one side of the tubing flat for a stronger solder joint

- Cut a small square of metal slightly larger than the tube’s diameter

- Place solder inside the tubing to prevent excess on the exterior

- Solder the tubing and bottom piece together

- Trim excess metal and file to match the tubing’s curve

- Clean the soldered piece in a pickle solution

- Attach an appropriately sized jump ring to the end cap

By following these steps carefully, you’ll create professional-looking end caps tailored to your specific jewelry designs.

Incorporating End Caps into Jewelry Designs

Once you’ve mastered the art of making end caps, consider these creative ways to incorporate them into your jewelry:

- Use them to finish leather or cord bracelets

- Create multi-strand necklaces with coordinating end caps

- Design interchangeable pendants that attach to end-capped cords

- Craft earrings using end caps as decorative elements

The versatility of custom end caps allows for endless design possibilities, limited only by your imagination.

Tips for Working with Different Cord Materials

Different cord materials require specific considerations when creating end caps:

Buna’N Cord

This synthetic rubber co-polymer is flexible and durable. Ensure your end caps have a snug fit and consider using a strong adhesive like Loctite for added security.

Metal Cable

When working with metal cable, choose end caps with slightly larger inner diameters to accommodate the cable’s structure. You may need to use a wire brush to clean the cable ends before attaching the caps.

Leather Cord

For leather cords, consider creating end caps with a slightly flared opening to prevent fraying. A dab of leather glue can help secure the cord within the cap.

Advanced Techniques: Creating Decorative End Caps

Once you’ve mastered basic end cap creation, explore these advanced techniques to add unique flair to your designs:

- Texturing: Use hammers or stamps to add texture to the end cap surface

- Stone setting: Incorporate small gemstones into the end cap design

- Filigree work: Add delicate wire designs to create intricate end caps

- Mixed metals: Combine different metals for a two-tone effect

These techniques can elevate your jewelry pieces and set them apart from mass-produced items.

Troubleshooting Common End Cap Issues

Even experienced jewelers encounter challenges when making end caps. Here are solutions to common problems:

Solder not flowing properly

Ensure your metal is clean and flux is applied evenly. Check that your torch is providing adequate heat.

End caps coming loose

Use a strong adhesive in addition to the mechanical fit. Consider creating a slightly tapered interior for a tighter grip.

Difficulty attaching jump rings

Pre-solder a small loop onto the end cap before attaching it to the tubing for easier jump ring connection.

Safety Considerations for DIY Jewelry Making

When creating end caps and other jewelry components, prioritize safety:

- Work in a well-ventilated area, especially when soldering or using chemicals

- Wear protective eyewear and heat-resistant gloves

- Keep a fire extinguisher nearby when using open flames

- Store chemicals properly and label all containers

- Tie back long hair and avoid loose clothing that could catch on tools

By following these safety guidelines, you’ll create a secure working environment for your jewelry-making projects.

Exploring Alternative End Cap Designs

While traditional end caps are versatile, consider these alternative designs for unique jewelry pieces:

Clamshell End Caps

These hinged end caps fold over the cord, providing a secure closure without soldering. They’re ideal for delicate materials or quick changes.

Coiled End Caps

Create a spiral wire design that wraps around the cord end, offering a bohemian or nature-inspired look.

Tapered End Caps

Craft end caps with a gradual taper for a sleek, modern appearance that transitions smoothly into the cord.

Experimenting with these alternatives can lead to distinctive jewelry designs that stand out in the market.

Maintaining and Caring for Jewelry with Custom End Caps

To ensure the longevity of your handcrafted jewelry pieces featuring custom end caps, follow these care instructions:

- Store pieces individually to prevent scratching or tangling

- Clean regularly with a soft cloth to remove dirt and oils

- Avoid exposing jewelry to harsh chemicals or extreme temperatures

- Check end caps periodically for signs of wear or loosening

- Re-tighten or reapply adhesive as needed to maintain security

Proper care ensures that your custom-made jewelry remains beautiful and functional for years to come.

Sourcing Quality Materials for End Cap Creation

The success of your end cap projects depends largely on the quality of materials used. Consider these factors when sourcing supplies:

Metal Quality

Choose metals appropriate for jewelry-making, such as sterling silver, gold-filled, or jewelry-grade brass. Avoid base metals that may cause skin reactions.

Tubing Options

Experiment with different tubing diameters and wall thicknesses to find the perfect fit for your designs. Consider seamless tubing for a more polished look.

Solder Selection

Use solder specifically designed for jewelry-making, matching the metal type of your end caps for the strongest bond.

Investing in high-quality materials ensures durable, professional-looking end caps that enhance the overall value of your jewelry pieces.

Incorporating Custom End Caps into Your Jewelry Business

For jewelry makers looking to turn their craft into a business, custom end caps can be a valuable addition to your offerings:

- Create a signature line of end caps that sets your brand apart

- Offer customization options to clients for truly unique pieces

- Use end caps as a upselling opportunity for repair or redesign services

- Develop workshops to teach end cap creation as an additional revenue stream

By mastering end cap creation, you not only enhance your jewelry designs but also open up new business opportunities in the competitive jewelry market.

Eco-Friendly Approaches to End Cap Production

As sustainability becomes increasingly important in jewelry making, consider these eco-friendly approaches to end cap production:

Recycled Metals

Use recycled silver or gold to create your end caps, reducing the environmental impact of mining.

Upcycled Materials

Repurpose old jewelry or metal objects to create unique, one-of-a-kind end caps with character.

Low-Impact Techniques

Explore cold connections or friction-fit designs that eliminate the need for soldering and harsh chemicals.

By adopting these eco-friendly practices, you can appeal to environmentally conscious consumers and reduce your carbon footprint.

Leveraging Technology in End Cap Design and Production

While traditional metalworking techniques remain valuable, modern technology offers new possibilities for end cap creation:

3D Printing

Design complex end cap shapes using CAD software and create prototypes or final pieces with 3D printing in metal or resin.

Laser Cutting

Utilize laser cutting technology to create precise, intricate designs for flat end cap components.

CNC Machining

For larger-scale production, CNC machines can efficiently produce consistent end caps with high precision.

Embracing these technologies can streamline your production process and open up new design possibilities for your jewelry line.

The Future of Custom End Caps in Jewelry Design

As jewelry making continues to evolve, the role of custom end caps is likely to expand:

- Integration of smart technology for wearable tech jewelry

- Development of biocompatible materials for health-monitoring accessories

- Exploration of nano-materials for ultra-strong, lightweight end caps

- Customization through augmented reality design tools

Staying informed about these trends can help you position your jewelry business at the forefront of innovation.

By mastering the art of custom end cap creation, you unlock a world of design possibilities and set yourself apart in the jewelry-making community. Whether you’re a hobbyist or a professional jeweler, the ability to craft bespoke end caps allows you to create truly unique pieces that reflect your personal style and meet the specific needs of your clients. As you continue to refine your skills and explore new techniques, remember that each end cap you create is not just a functional component, but a tiny work of art that contributes to the overall beauty and integrity of your jewelry designs.

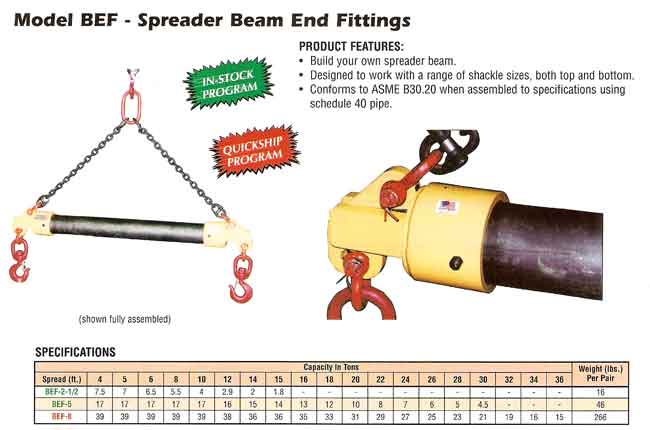

Tubes, Clips and End Caps

Bracelet made with clip back and hand woven silver cable

Remember: Take all safety precautions – it is YOUR responsibility to know what they are. I will list some, as I think of them. But, please, please, please use common sense and caution. Ventilate when using chemicals, burning things or soldering, wear gloves when using chemicals, don’t put strange things in your mouth and tie back your hair. Wear a mask when sanding. Don’t wear loose, flowing clothing, especially things with long sleeves or fringe (I’m talking to you, hippies (my sister) and wear closed toe shoes. Think smart. Live long.

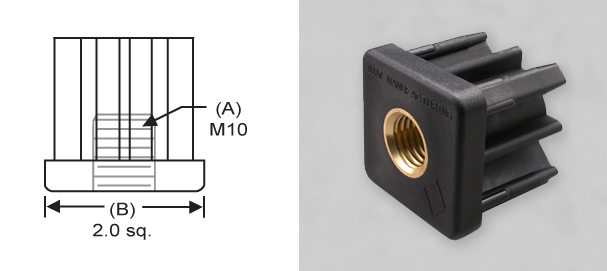

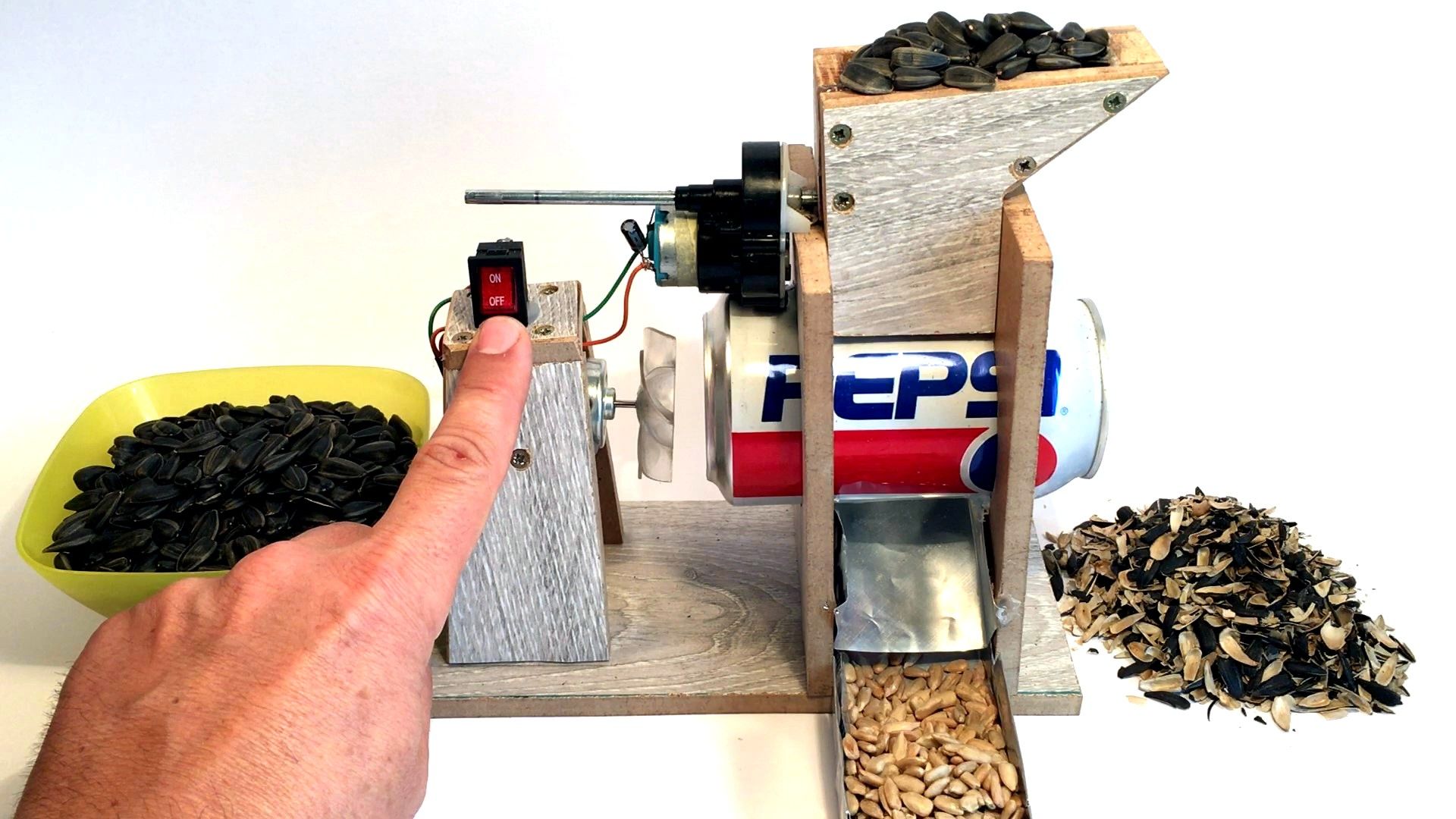

This drawing illustrates how to construct a bracelet using tubing in combination with Buna cord, metal cable or any other thing you want. Reasons to do this are to: 1. keep copper or brass off of the skin to eliminate that green skin thing (tubes are silver) 2. a way to make a flexible, linked bracelet 3. ’cause you want to.

a way to make a flexible, linked bracelet 3. ’cause you want to.

Ensure that your cord fits through the tube! Cut tubing to size. Sand or file one side of tubing flat. (Gives you more metal to solder to and makes the join stronger.) Solder the tubing to the back of your piece. Pickle, neutralize and clean.

Tube with flat side

Thread the Buna’N (a synthetic rubber co-polymer – see Wikipedia explanation here) or cable through the tubing. Glue on your end caps. If you don’t own pre-made end caps and want to make your own, STOP HERE and read a few paragraphs below on how to make them.

If you desire, you can use little “O” rings as spacers. These spacers can also keep the pieces from shifting around. You can also add a drop of Loctite, into the tube, to stop all movement. Don’t do this until you are almost completely finished with your bracelet, as soldering is now NOT AN OPTION.

Don’t do this until you are almost completely finished with your bracelet, as soldering is now NOT AN OPTION.

Here’s an exciting little bit of information (ugh- too perky), Wow – you can make your own “O” Rings by cutting Buna cord and using super glue or Loctite’s Quick Set 404, and gluing the ends together. Try it! It’s a very strong join and you can make them whatever size you want. Although, I must say, those teeny, tiny ones are easier to buy!

“O” Rings – VERY, very blown up.

Polymer Clay Express sells Buna’N cord and a bunch of other cool stuff. They have the “O” Rings too. Here’s a link to different kinds of Buna/O-Ring cord.

You can also use clips to hold Buna’N or Cable instead of tubing. Here is a brief tutorial on how to make these clips:

1. Cut your metal to size – that’s up to you – experiment!

Cut your metal to size – that’s up to you – experiment!

2. Curl the ends of the metal with round nose pliers. CURLED METAL

3. Bend the metal around a dowel, shank of a dapping punch or round nose pliers.

4. Now flatten the bottom of that curve so that you have a flat surface to solder or rivet into. You can use parallel or flat nose pliers , square stock or a square bezel mandrel to do the job.

5. Solder or Rivet the clip to your piece.

6. After pickling, rinsing, etc and when you are almost completely done with your piece, insert the cord or whatever, into the clip. Squish (a technical jewelry term) the top of the clip together and smoosh (another one) it down. You can also drop a bit of Loctite Super Glue (my favorite is their “Ultra Gel Control”) or some other type of super glue, onto the bottom of the Buna, (the part in the clip) – if, you don’t want it to ever move, again! Wasn’t that fun?

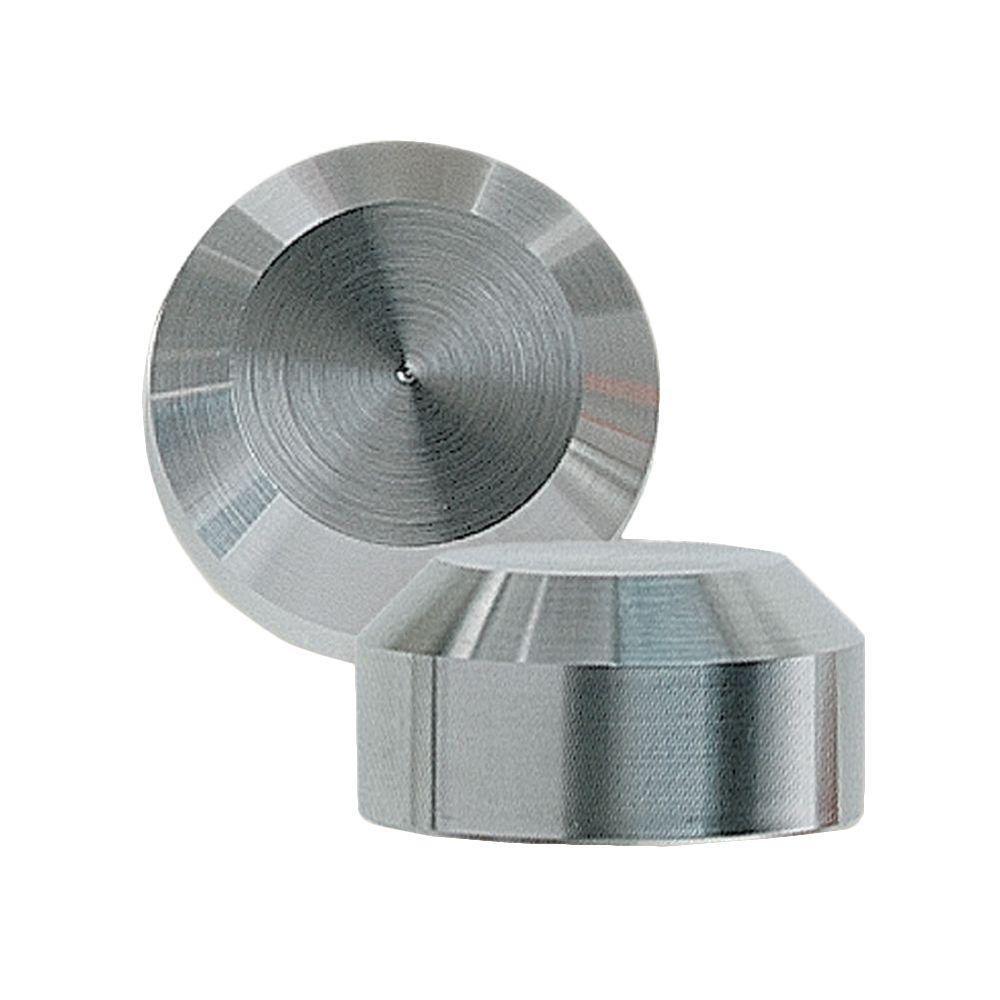

Making End Caps for the cords.

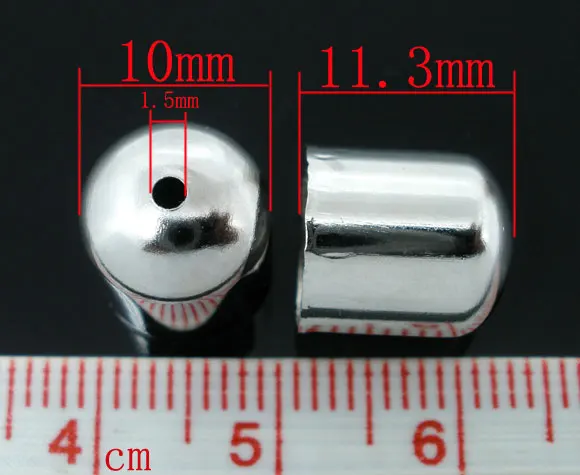

Now, if you are only using one cord, with the tubes or clips running down the middle, you only need to make two of these – one for each end. The following directions are for the basic, single end cap.

You need tubing that fits your cable – as tightly as possible. Try to match outer diameters of cord with inner diameters of tubing. You can come close. If the fit is very tight, you can, using a round file, file down the interior walls of the tubing. The tubing should be, at a minimum, 5mm long. You want that tubing to stay in the end cap so, a little longer is better – say, 10mm (or 1 centimeter, for those who get this metric thing).

Ensure that the ends of your tubing are filed or sanded flush and are clean. Cut a small square of metal, larger than the tube. The cut can be rough, but the metal should be flat – I use scrap metal for this step.

As the above picture says, put the solder INSIDE the tubing – that way it doesn’t run up the outsides of the tube and it SAVES YOU TIME as you don’t have to sand off the solder! Yippeee! Solder tubing and bottom piece together.

Trim excess metal with French shop shears or some other hand held metal cutting gizmo. File and sand to match the curve of the tubing.

Make or find jump rings that fit the tubing – a little Goldilocks and the 3 bears here – choose the one that is neither too big nor too small – you want it… “just right”. Make certain that the two ends of the jump ring fit together tightly and cleanly. Sand or file the edge where the two halves of the ring meet (the seam), flat.

Now, take that flat edge and solder it to the CENTER (not as easy as it sounds) of the end of the tubing with the cap on it. You can use a third hand or using, cross lock tweezers, freehand it. I usually flux both pieces, place the solder on the tubing and, as soon as it flows, drop the jump ring, FLAT SIDE DOWN, right smack in the middle of the cap! Of course, that “right smack in the middle” thing happens 6 out of 10 times. I spend a bit of time re-flowing and re-positioning. Jewelry making is such fun! Don’t forget to solder a jump ring on the other cap. If you are doing double cording you will do something different but similar. See below.

I usually flux both pieces, place the solder on the tubing and, as soon as it flows, drop the jump ring, FLAT SIDE DOWN, right smack in the middle of the cap! Of course, that “right smack in the middle” thing happens 6 out of 10 times. I spend a bit of time re-flowing and re-positioning. Jewelry making is such fun! Don’t forget to solder a jump ring on the other cap. If you are doing double cording you will do something different but similar. See below.

Attach your clasp with a jump ring (or not) – made with a heavy gauge wire, like 14g, if you’re not soldering it – any other gauge jump ring will do if you are soldering. Don’t use anything less than 18g for bracelets, they just don’t hold up.

Pull out your Loctite, either plop some into your tube or using a tooth pick, dab the glue into the cap (this is the “ladylike” version).

Side bar rant warning:

DON’T USE a cotton swab to apply Cyanoacrylate glues (super glues) supposedly, the combination of cotton, OR WOOL, and the glue causes an exothermic reaction – fire! So, don’t do it. Now, back to work. Grab your cording and shove that puppy into the cap. (Make sure that you have threaded the cording or cable through your tubes first). Carefully, so as to not glue your fingers to the tubing, wipe away the glue that has gotten everywhere. If that fails and you are stuck to the cap, stick a Q-tip or paper towel into some Acetone (not in the glue – remember!) and gently apply to your finger. Don’t get the Acetone into the tubing and try to keep it off the Buna’N or Buna’V . Wash with soap and water and slather with hand lotion to ensure soft and lovely fingertips! Ah hem. Others recommend using W-D 40 to remove your fingers from foreign objects. I wouldn’t know. Super Glue Corp. can tell you all about it as can this link from our favorite, Wikipedia. The glue takes two hours for final bonding. It is waterproof.

Now, back to work. Grab your cording and shove that puppy into the cap. (Make sure that you have threaded the cording or cable through your tubes first). Carefully, so as to not glue your fingers to the tubing, wipe away the glue that has gotten everywhere. If that fails and you are stuck to the cap, stick a Q-tip or paper towel into some Acetone (not in the glue – remember!) and gently apply to your finger. Don’t get the Acetone into the tubing and try to keep it off the Buna’N or Buna’V . Wash with soap and water and slather with hand lotion to ensure soft and lovely fingertips! Ah hem. Others recommend using W-D 40 to remove your fingers from foreign objects. I wouldn’t know. Super Glue Corp. can tell you all about it as can this link from our favorite, Wikipedia. The glue takes two hours for final bonding. It is waterproof.

Here’s an UNTRIED tip: According to the stats on super glues, they dissolve at low temperatures. I have read that to disassemble something that is glued with a cyanoacrylate (super glue), one simply places it into a household freezer for several hours and pulls apart. Going to try it soon!

I have read that to disassemble something that is glued with a cyanoacrylate (super glue), one simply places it into a household freezer for several hours and pulls apart. Going to try it soon!

Untried tip two: Vaseline is rumored to remove dried super glues from your skin. Now, don’t pour glue on your hands just to test this! I’ll do that for you. NOT.

Okay, enough already on the glue! Let’s finish this.

If you are not using a flammable/melt-able substance but instead are using silver cable or something similar, you can just solder the cable in place. Flux interior of the cap and spread solder pallions around the interior. Torch, quench, pickle and neutralize. Dance around the house naked. First though, pull the blinds and lock the door. This step is a suggestion, not a requirement.

So on to the problem of the double cord. Here you may ask, Nancy, what do I do if I have double cords?

Well, start out by making four tubes instead of two. Follow all of the steps above – EXCEPT for soldering on the jump ring and attaching the clasp.

Follow all of the steps above – EXCEPT for soldering on the jump ring and attaching the clasp.

Now, solder two tubes together. Best to sand a flat spot on both tubes, put the flat spots together and then solder. You can also, insert the tubes into a decorative (metal) box that you fabricate or add a metal spacer or whatever you want. How you handle this part depends on how far apart you want the cording AND what you want the end of your bracelet to look like. Solder the other set of tubes together.

After soldering the parts together, create a loop or use a jump ring (sand one side flat) and solder onto the center of the two caps.

Hook on or solder on, your clasp. Follow directions on inserting and gluing cords in place.

Lock doors, pull shades…etc.

Here’s two bracelets made with this system:

We can’t seem to find that page

(* {{l10n_strings. REQUIRED_FIELD}})

REQUIRED_FIELD}})

{{l10n_strings.CREATE_NEW_COLLECTION}}*

{{l10n_strings.ADD_COLLECTION_DESCRIPTION}}

{{l10n_strings.COLLECTION_DESCRIPTION}}

{{addToCollection.description.length}}/500

{{l10n_strings.TAGS}}

{{$item}}

{{l10n_strings.PRODUCTS}}

{{l10n_strings.DRAG_TEXT}}

{{l10n_strings.DRAG_TEXT_HELP}}

{{l10n_strings. LANGUAGE}}

LANGUAGE}}

{{$select.selected.display}}

{{article.content_lang.display}}

{{l10n_strings.AUTHOR}}

{{l10n_strings.AUTHOR_TOOLTIP_TEXT}}

{{$select.selected.display}}

{{l10n_strings.CREATE_AND_ADD_TO_COLLECTION_MODAL_BUTTON}}

{{l10n_strings.CREATE_A_COLLECTION_ERROR}}

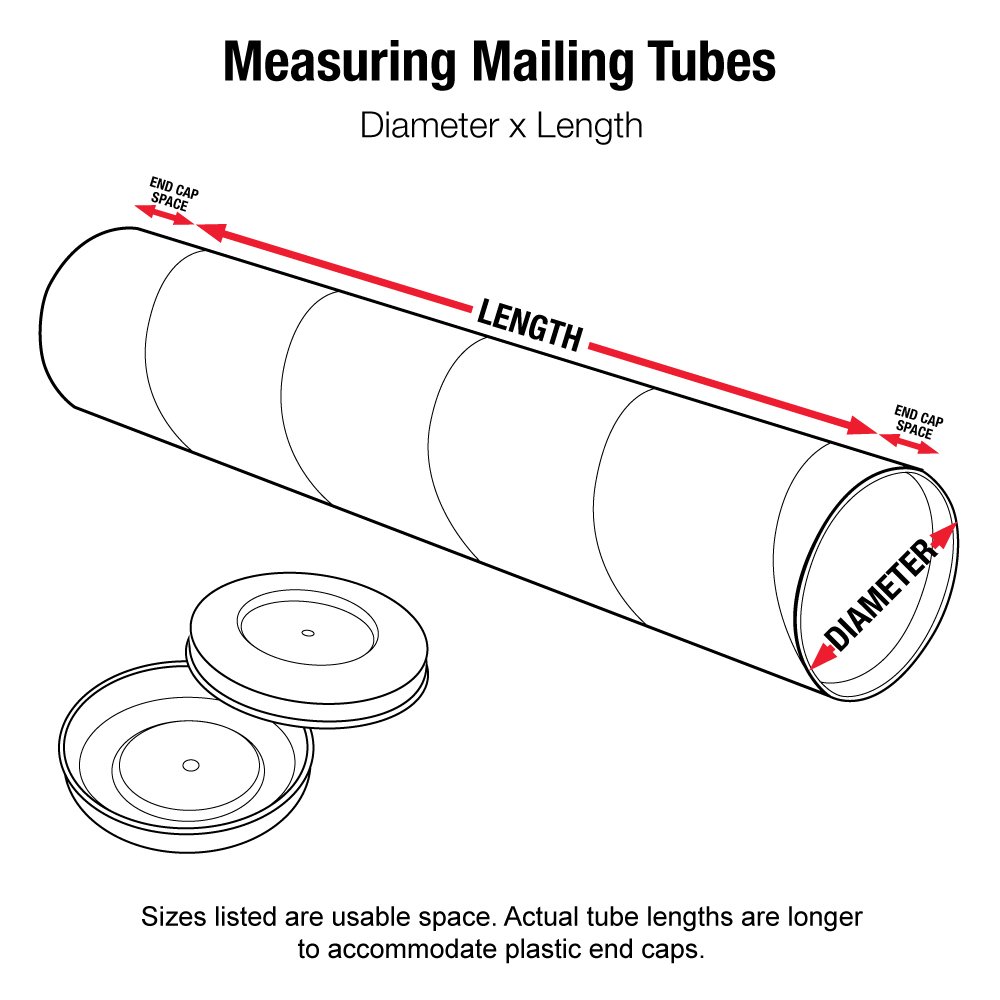

How to Use an End Cap with Ribbon

End caps create professional finishes for your jewelry designs. Adding them to the ends of silk ribbon can be tricky. Read this tutorial to learn how to quickly and easily add an end cap to your silk ribbon in a secure and stylish way

Adding them to the ends of silk ribbon can be tricky. Read this tutorial to learn how to quickly and easily add an end cap to your silk ribbon in a secure and stylish way

Step 1

Place an eye pin on the end of your silk ribbon.

Step 2

Fold the silk ribbon around the eye pin and tie cord around the ribbon at the base of the eye pin to secure it. Make a knot.

Step 3

Wrap the cord several times around the ribbon, ensuring that it stays in place around the base of the eye pin loop.

Step 4

Tie another knot for even more security.

Step 5

Add a dab of adhesive to the cord and allow to dry. Trim the cord.

Step 6

Slide an end cap onto the eye pin and over the cord around the silk ribbon.

Step 7

Add a bead of your choice onto the eye pin and create a tight wrapped loop to secure the end cap in place.

Add all available items to your cart at once or edit the quantities below.

Nice choice! All or most of the products needed for this project are shown

below with quantities. Sometimes we sell out of components and aren’t able to order more from

the manufacturer (we know, it is very disappointing to us, too). Use the opportunity to mix up

the design and make it yours by substituting similar products or altering the entire color

scheme—it’s up to you!

ADD ALL AVAILABLE TO CART

RESET DEFAULT QUANTITIES

Bead Wraps as End Caps

Bead Wraps as End Caps

Free instructions for making a end cap link using beads and jewelry wire.

These instructions will document how to make a wrapped bead cap as shown at right. This technique is a decorative way to embellish a bead using wire.

Step 1: Cut a segment of 22 gauge wire about 6″ long. Straighten this wire using your nylon jaw pliers.

Step 2: Bend the wire 90 degrees about 2 1/2″ from one end. Make a wrapped loop at this point, but do not cut the excess wire. You should have about 1 3/4″ of excess wire. Make the wrapped loop with about two wraps of wire around the stem. You can view our free instructions for making a wrapped loop here. After you have completed the wrapped loop add an 8mm or larger bead to the wire. At this point your wire and bead should appear as shown at right.

Step 3: Using your bent chain nose pliers, grasp the wire immediately above (or below as shown at left) the bead and bend the wire about 90 degrees

Step 4: Using your round nose pliers, make a loop in the wire centered on the wire inside the bead. Make the loop as close to the 90 degree bend in the wire as possible so that the final loop will be centered on the wire inside the bead. At this point your wire and bead should appear as shown at right.

Make the loop as close to the 90 degree bend in the wire as possible so that the final loop will be centered on the wire inside the bead. At this point your wire and bead should appear as shown at right.

Step 5: If you are connecting this bead in a chain, you can connect this segment to the rest of the chain at this point, before you complete the second wrap. When you are ready, grasp the new loop with your bent chain nose pliers and wrap the wire tail around the wire coming out of the bead. At this point you will have a wrapped loop above and below the bead with about 2 wraps of wire on both sides.

Step 6: Grasp the loop on one end in your bent chain nose pliers and hold the loop while you continue to wrap the wire. At this point the wire should begin to make a spiral on the side of the bead. Complete about 4 loops of wire on either side of the bead. See the pictures below for how this should appear.

Step 7: Using your flush cutter, cut the excess wire. Squeeze the cut end of the wire with your bent chain nose pliers so that it lays flat. See the picture at right for a completed bead with end cap wraps.

See the picture at right for a completed bead with end cap wraps.

How to Make the Most of End Cap Displays

Of all the “geographic” locations within your store, end caps are proven winners when it comes to selling merchandise. It’s easy for shoppers to zero in on end cap displays as they scan the store, and they pass end caps as they make their way around. Every type and size retail operation has aisles, and every aisle has an end. That gives you multiple opportunities to maximize sales.

So, are you making the most of those opportunities? Keep in mind that the reason internet-addicted customers still love to shop in-store is because of the comprehensive, multi-sensory experience. Happily, those experience-seekers are also dedicated impulse shoppers. Well-designed end cap displays will attract them like bees to honey. Here are some best practices to create lucrative displays.

Strong Color and Eye-Catching Design

To be big sellers, end cap displays must stand out and shout “buy from me!” The less it looks like a stack of stuff, the more intriguing it will be for shoppers. Try these tips when it comes to color and design.

Try these tips when it comes to color and design.

- You don’t have to use fixtures with shelves to create stunning end cap displays. Anything that will hold your merchandise has potential. For back-to-school, use old school desks and chairs to hold larger items, book bags or colorful “wastebaskets” to hold smaller loose items. Or make your display look like a huge crayon box.

- If you’re using product cartons as the foundation of your display, repeat the key colors in your signage, too. Consistency makes your end cap bolder and more attractive.

- Signage should be big, bold, and instructive, with a clear call to action. Not “New Bath Towels,” but “Feel Me!” Or make them an offer they can’t refuse: “30% Off, While They Last.”

Less Variety, More Depth

Much like a mall kiosk, end caps perform best when they offer less variety, more depth. Don’t just throw anything on your end cap. Too much choice confuses shoppers. There needs to be a point to your end cap. So, choose a variety of the same product or similar products. Here are some other tips, too.

So, choose a variety of the same product or similar products. Here are some other tips, too.

- Feature items that aren’t too large, and stock them deeper than usual, to avoid having to restock frequently.

- Stock wide, too, for can’t-miss visual impact. Multiple facings or an entire shelf of one item will create a strong horizontal effect — a “banner” made of the products themselves.

- Remove an item or two from the facings, so it appears shoppers are already snapping up your excellent offer. That motivates others to follow suit before it’s all gone.

Go Digital

Electronic endcaps can be ultra-effective for two reasons — they draw the eye with visual movement, and they practically beg for interaction. In this digital world, we just can’t help but reach out to use available electronics. End caps are the ideal location for this stop-and-check-it-out option because there is more room for shoppers to comfortably spend time without blocking an aisle. By using technology, you can:

By using technology, you can:

- Incorporate digital displays or how-to-use-me videos.

- Provide touchscreens to look up product information or custom-assemble a product.

- Strategically position a free-standing kiosk as an end cap.

Keep it Fresh

Shoppers quickly go blind to displays they’ve seen before. So, change up the merchandise and offers often. You can also create a sense of movement and excitement throughout your store by moving successful end cap displays around from time to time. That ensures customers who typically frequent only one area will have an opportunity to shop your end cap.

Shoppers want good deals, they want to be first to buy new products, and they want to feel, smell, taste, and try the products. End cap displays can capitalize on all that, in a big way. Don’t settle for mediocre end caps that get passed by. Create one that stops shoppers in their tracks.

Here’s Everything You Need to Know

There are many good reasons why you need to pay close attention to any end cap display in your store. For one, they allow you to create visually appealing spaces to draw in shoppers. If you’ve set them up right, they also allow you to be more efficient with your retail space. But, how do you create these displays?

For one, they allow you to create visually appealing spaces to draw in shoppers. If you’ve set them up right, they also allow you to be more efficient with your retail space. But, how do you create these displays?

Also, what is their purpose? Who looks after them? Moreover, what are the common elements of successful and effective end cap displays?

What is the purpose of an end cap display [and who is responsible for them]?

Before we look at how you can go about setting up a profitable end cap, it’s worth unpacking its purpose. Why? It’s only once you fully understand the meaning of something that you can then use it effectively.

Also, while we have written articles about end caps and why you need to be strategic when setting them up, we haven’t yet touched on its purposes.

Here it is: end caps are unique display fixtures with two purposes that feed into each other.

Firstly, they display items, drawing customers into your store or to a specific aisle. The items displayed could be on promotion, or you might want to highlight a particular product. The choice is up to you. Secondly, an end cap display aims to sell more products.

The items displayed could be on promotion, or you might want to highlight a particular product. The choice is up to you. Secondly, an end cap display aims to sell more products.

Another way of explaining it is to say it’s like bundling your marketing and sales efforts into one. Visually, an end cap display captures attention, and functionally it can help you to convert browsers into buyers.

As for who is responsible for stocking and maintaining your end cap displays, it depends.

If you’re a retailer and a supplier purchased the end cap from you, it’s their responsibility. They’d need to maintain the stock levels and ensure it looks good at all times. The merchandiser attached to that specific company might also get involved here to act on behalf of the supplier in-store.

On the other hand, if your head office chose the items you display, it is your responsibility as a store to manage it.

Of course, that doesn’t mean these are your only options. You could also co-manage it with your supplier.

For example, you could sell the space to one of your suppliers. However, the supplier might not have the workforce to do everything. In that case, you make a deal. As part of the agreement, the supplier must provide the stock. In return, you could implement the layout of the end cap display and maintain it.

Key questions to ask yourself when setting up an end cap display

Before you begin building any end cap display for your store, it’s essential that you place yourself in your customers’ shoes. After all, if you want to captivate them and entice them to buy, you must think like them.

So, the next time you visit a store, be that your own if you run one, or one of your competitors, observe the end cap displays. Which ones grab your attention? Ask yourself why it makes you take notice.

If you look at a variety of effective end caps across multiple stores, you’ll find they all have common elements. They take advantage of colour, clear messaging, vertical structure, and lighting, amongst others. We’ll touch on a few more key elements below.

We’ll touch on a few more key elements below.

They also consider answering a variety of questions. As with anything, they are the 5 W’s – who, what, when, where, and why.

Who:

For this question, the ‘who’ could refer to multiple people, depending on who is responsible for the display. We have already touched on it briefly above.

For example, it could refer to the person in your store who sets up the display. It could also refer to the brand displayed and the supplier who was involved.

What:

The next question focuses on the items that you place on the display. What items are you going to display? It is rare to stock an entire range of items unless the range itself is small.

For example, there might be a promotion on Brand A, which is a mouthwash product. The entire range consists of 10 SKUs, but the promotion is only on four of those items. In that case, it wouldn’t make sense to stock everything. Instead, you’d only stock those on promotion on your end cap to increase awareness.

Instead, you’d only stock those on promotion on your end cap to increase awareness.

Increasing the awareness of these items can lead to increased attention on the rest of the range, which can lead to category growth.

When:

If ‘what’ refers to the items displayed, it’s just as critical to ensuring you stock them at the right time. That’s where this question plays a role. It refers to seasonality.

After all, it is counterproductive to promote air conditioners or fans during the middle of winter. Promoting hot chocolate during summer is just as bad. You’d be better off matching your promotions to the season. So, in this instance, an end cap display with a hot chocolate special would work well during autumn or winter.

Where:

Next up is ‘where’. This question refers to the location of your display. Where do you place your end caps? Shelf space is one of your most valuable assets as a retailer. However, it becomes worthless if you don’t use it effectively.

Of course, we’re not referring to the most plausible location – at the end of an aisle. Instead, we’re referring to which aisle.

With end caps, if you fail to match them to your category adjacencies, you only confuse your customers.

Why:

The last question is a straight-forward question which we have already alluded to earlier in this piece.

Why should you set up an end cap display? Simple: to please customers and increase your sales.

Regardless of who set up the end cap display, it is a profit-generating vehicle. Without it in your store, you lose out on opportunities to increase your sales.

Key elements of successful end cap displays

1. They keep a theme in mind

The first key element of any successful end cap display is that they all keep one theme in mind. In reality, that goes for anything merchandising-related. And, it comes back to looking at your displays and gondolas as a customer.

What will catch their attention? A themed display that is visually appealing will entice them to browse for longer and even add more items to their basket. Meanwhile, a disorganised display with no common theme will give off the impression that it is a dumping ground for merchandise that you don’t know where else to place.

For example, a pharmacy could merchandise a gondola end with cold and flu items. An auto parts store could set up a do-it-yourself display with all the necessary items to do an oil change. Regardless of the theme you choose, make it obvious to the customer as that can lead to an increase in your sales.

2. They showcase your branding

Gondola end caps are the perfect place to showcase your brand. You might find a customer wanders through your store to find out more about a product or brand.

Of course, allowing your customers to wander your store is not necessarily a bad thing – it could lead to exposure for other products. However, you wouldn’t want them to do it aimlessly or become frustrated.

However, you wouldn’t want them to do it aimlessly or become frustrated.

Merchandising your end cap display with items that highlight your brand is key to driving interest.

Let’s consider the example of a local craft store that might feature merchandise that matches the current school schedule or how a grocery store could feature a s’mores end cap with all store brand items.

With an end cap display, you have the opportunity to offer customers a taste of your overall selection.

3. They highlight new products with cross merchandising

If you have an exciting new product that you want to display, one option to you is to place it on display before the shelf that stocks that category.

Another option is to cross-merchandise throughout your store. While the first option is a given, the second is a must if you want to capitalise. What’s more, shoppers who don’t come in looking for that particular product could place it in their basket because you cross-merchandised it.

For example, if you stock coffees and teas from around the world, you could merchandise the latest arrival of locally roasted coffee beans in a gondola run that stocks your brewing devices or mugs. It’s the same if you have a new brewing device.

By placing it on display at the end of your coffee and tea aisle, you’re guaranteed to have customers walk past it and consider buying it.

4. They entice shoppers down aisles

Merchandising your end caps to feature items from corresponding aisles is a smart and subtle way to remind shoppers of a product they might need. That’s why cross-merchandising is so effective.

That said, as stated above, the key to success is all about visual appeal. If you can use the right colour, package the product in a way that naturally draws the eye, and complete that with a well-designed display, you can draw customers into an aisle that they might otherwise have not considered shopping.

There is also the point that your end caps function as signposts, subconsciously telling customers what they can expect within an aisle. The average shopper doesn’t spend a lot of time wandering around. Thus, every minute they spend in-store is an opportunity for you to make a lasting impression and gain a sale.

The average shopper doesn’t spend a lot of time wandering around. Thus, every minute they spend in-store is an opportunity for you to make a lasting impression and gain a sale.

Conclusion

DotActiv’s planogram software is used by over 1500 retail professionals in more than 60 countries across the globe. Interested in finding out more about how we can enable you to use your business data to create better product layouts, localised assortments, advanced retail analytics and more?

You can visit our online store here or click below to find out more.

Crimping Beads Jewelry Making – Use Memory Wire End Caps

HOW TO USE MEMORY WIRE END CAPS

Finish off Remembrance Memory Wire designs with End Caps for a professional, polished finish. End Caps are open on one side and are available in a variety of shapes in either silver or gold plate, a perfect complement for any Remembrance and Plated Steel Memory Wire design.

|

See also: Resource Center | Mastering Memory Wire | Memory Wire | Tips and Techniques

How to make secure phone covers

Technological openings of the phone are the most vulnerable parts of the device. First of all, water will rush there, when the device falls into water, dust gets there, if, for example, you do not use headphones for a long time. In the end, anything can get there in an elementary way; seeds, tobacco, pellets, etc. remaining in your pocket. In order to protect the phone, or any other device, from external aggressive influences, a wide variety of protective cases, bumpers, glasses and similar accessories are sold.Some cases have silicone plugs to seal the holes, others do not. Which one to buy is an individual matter for everyone. And not for every phone model (or other gadget), you can find a cover with plugs. Personally, for my phone, no matter how I looked, I did not find this anywhere. Not on the free market, not even on the Internet. Therefore, I decided to make the plugs myself. And at the same time he will share this master class with other users who, perhaps, also faced such a problem.

remaining in your pocket. In order to protect the phone, or any other device, from external aggressive influences, a wide variety of protective cases, bumpers, glasses and similar accessories are sold.Some cases have silicone plugs to seal the holes, others do not. Which one to buy is an individual matter for everyone. And not for every phone model (or other gadget), you can find a cover with plugs. Personally, for my phone, no matter how I looked, I did not find this anywhere. Not on the free market, not even on the Internet. Therefore, I decided to make the plugs myself. And at the same time he will share this master class with other users who, perhaps, also faced such a problem.

Needed

- Scissors.

- Pliers.

- File or file.

- Stationery knife.

- Seconds glue.

- Insulating tape.

- A piece of plastic 2 × 10 × 10 millimeters.

- Bur machine, with 2mm drill and cutting disc.

- 3.5 mm mini jack plug.

- Micro usb plug.

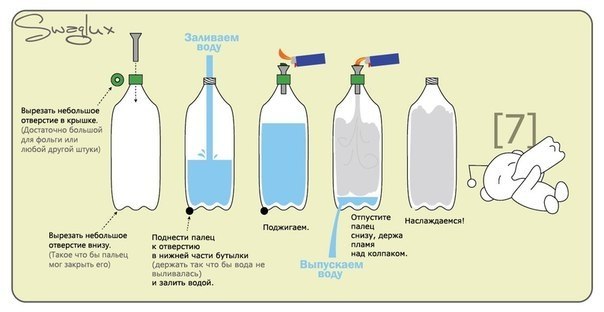

Manufacturing of plugs

I will make plugs for my phone, and therefore I took the plugs that fit the connectors for this model.

The headphone jack is the same for everyone, but the charging connectors may differ, so before manufacturing you should make sure that the plug fits the jack. So, first you need to remove the brass plug itself from the rubber sheath. To do this, we will make cuts along the entire length of the shell with a technical scalpel (or a clerical knife). Then, using pliers, rip off the shell from the plug.

There is a bulge at the base of the plug, something like a brass skirt, or a ring.We need to cut off the bur with a machine all the roots of the plug, flush with this very ring. Like this:

It is also necessary to cut off the top, in the thinnest place:

When removing the “root” of the plug, it can stratify into separate parts, this can be seen in the video:

It’s not scary; everything is perfectly fixed in place with a second glue. Next, sand the sawn-off top and spine with sandpaper. Then the spine must be insulated – apply a drop of second glue to it, and stick a piece of insulating tape.Next, carefully separate the excess fields of the duct tape with a scalpel.

Next, sand the sawn-off top and spine with sandpaper. Then the spine must be insulated – apply a drop of second glue to it, and stick a piece of insulating tape.Next, carefully separate the excess fields of the duct tape with a scalpel.

This completes the plug for the headphone jack. Now we will make a plug for the charging connector. The principle of action for the manufacture of this plug is not very different from the first option – we stick the plug into the connector, measure the desired length, and cut off the excess bur with a machine.

Do not forget to remove all thin brass contacts from the segment. There should be four of them. We, of course, will insulate the cut off place, but just in case, it is better to remove the contacts.Further, there is a small snag: having measured the length of the plug we need, we will not have any protrusions on it, for which it will be possible to remove it from the connector in the future, if necessary. Therefore, the plug should be sawn off by 1 millimeter longer. This will be needed when we glue the plug to the plastic base. Making a base takes 10 minutes! To do this, in a piece of plastic, 2 mm thick, we make a groove with a drill (or a thin cutter) for the thickness and width of the plug. One millimeter deep.

This will be needed when we glue the plug to the plastic base. Making a base takes 10 minutes! To do this, in a piece of plastic, 2 mm thick, we make a groove with a drill (or a thin cutter) for the thickness and width of the plug. One millimeter deep.

In this groove we will put that extra millimeter of the plug length. Next, we cut the edges of the base to the parameters you need, and process them with a file.

Now, with the help of a second glue, we install a piece of the plug into the groove of the base.

Now you’re done. We install plugs in the connectors, and use them with pleasure.

As you can see from the video, the phone does not react to plugs in any way – nothing is displayed in the quick access panel.Of course, maybe these plugs are not as effective against water as silicone ones, but they will perfectly protect the connectors from dust and debris. This is quite enough to keep the phone from breaking. In addition, they are much more durable than silicone ones.

Watch video

The right plug for a round pipe with your own hands | Manual arc welding

Friends, I welcome everyone to our channel dedicated to all those who master welding on their own, or think about it.Here we try to give real information based on many years of welding practice, which you will not find in welding textbooks.

Sooner or later, all self-taught beginners will have to deal with a round pipe, and therefore today I will tell you such a necessary topic, how to make a plug for a round pipe with your own hands.

As an example, I will take a piece of a round pipe, for the end of this pipe we need to make a plug.

But we will make the plug of such a diameter that it goes inside the pipe. I think that doing this is much more aesthetically pleasing and more convenient if you suddenly have to repair a pipe in this place.

I think that doing this is much more aesthetically pleasing and more convenient if you suddenly have to repair a pipe in this place.

After all, if you weld the plug with an overlap along the outer diameter of the pipe, then, for example, the place near the wall will be difficult in terms of repair, and if the plug is inside the pipe, then the approach to the end is free in any position of the pipe.

yandex image source

yandex image source

You can use a caliper, or buy a ready-made plug at a metal base, but if this is not possible, then you can use this clever method!

You just need any piece of paper, apply it to the end of the pipe, tap the paper around the circumference with a hammer.

And here it is, a ready-made paper mold with the required diameter.

We circle this pattern from paper on a piece of sheet metal, cut it out with a small grinder, if suddenly there is a surplus in the diameter of the cut-out plug, we just grind it off.

So we got a plug with the required diameter, which goes into the inside of the pipe. Now we take the magnetic pen, insert the plug into the pipe, grab it, and then scald it.

Friends, let’s watch a video with this method, there is information in a more expanded and detailed form

Do-it-yourself plugs for profile pipes: photo and video

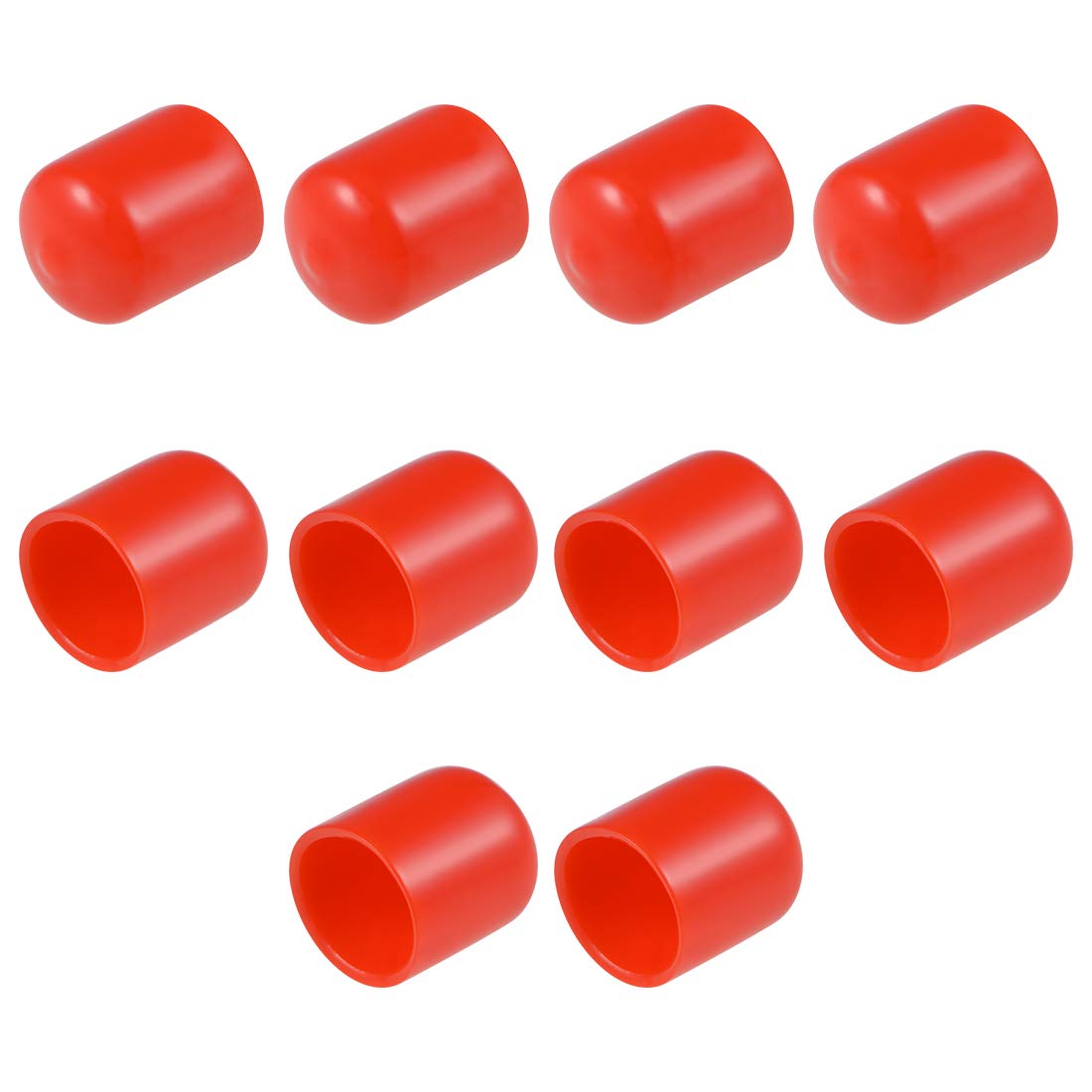

Caps for profile pipes are a necessary element in order for the structure to be tight and safe.In addition, these products fulfill a number of other important functions. In particular, plugs are needed in order to:

- Protect the system from moisture and corrosion;

- Protect the system from accumulation of debris and insects;

- To give the system a more aesthetic appearance.

The plugs are usually selected according to the profile pipe configuration. You can see how they look through the photo. In addition, it is important to select the appropriate plug size.

Types of plugs

Which material to choose from? Usually the material from which the products are made is selected in accordance with the material from which the pipes are made. What to buy in a particular case? For profile pipes, metal plugs are selected made of ordinary steel or stainless steel, aluminum, and various alloys. Installation can be done by hand, without using a welding machine. You can see how the installation is performed in the photo.

A steel pipe plug is a suitably sized iron plate that is welded to the end of the structure. There are also plastic products made from polymers. It makes sense to choose plugs made of polyethylene, since this material is resistant to mechanical damage. They allow the structure to be sealed and at the same time ennoble its appearance.

External plastic caps for profile pipes provide sealing of both the end and the upper part of the structure.When installing with their own hands, they are put on the element. Among the disadvantages of the product is low strength. The installation of such elements is often carried out during the transportation of profile structures.

The inner plug provides an inconspicuous closure of the structure, as only a small part of the product is visible from it. Thus, a decorative function is provided. The product has special stiffening ribs that provide strength and reliability of fastening. Their specific configuration is aimed at making a do-it-yourself installation investment.

In the case when structures are planned to be operated in complicated areas with increased loads, increased requirements are imposed on the plugs. In particular, they have to withstand a high temperature range. For this reason, metal-plastic products are most often used.

Double elements are commercially available, reinforced, made of robust alloys. In some cases, it is necessary that the products are resistant to corrosion.In this case, plastic elements are used. Products made of special polymers are used for aggressive chemical environments.

For the correct installation of these elements for profile pipes, we recommend that you view the relevant information materials: photos, videos.

Page not found – Master in the house

It looks like nothing was found at this location. Maybe try a search or one of the links below?

Archives

Select month October 2021 September 2021 August 2021 July 2021 June 2021 May 2021 April 2021 March 2021 February 2021 January 2021 December 2020 November 2020 October 2020 September 2020 August 2020 July 2020 June 2020 May 2020 April 2020 March 2020 February 2020 January 2020 December 2019 November 2019 October 2019 September 2019 August 2019 July 2019 June 2019 May 2019 April 2019 March 2019 February 2019 January 2019 December 2018 November 2018 October 2018 September 2018 August 2018 July 2018 June 2018 May 2018 April 2018 March 2018 February 2018 January 2018 December 2017 November 2017 October 2017 September 2017 August 2017 July 2017 June 2017 May 2017 April 2017 March 2017 February 2017 January 2017 December 2016 November 2016 October 2016 September 2016 August 2016 July 2016 June 2016 May 2016 April 2016 March 2016 February 2016 January 2016 December 2015 November 2015 October 2015 September 2015 August 2015 July 2015 June 2015 May 2015 April 2015 March 2015 February 2015 January 2015 December 2014 November 2014 October 2014 September 2014 August 2014 July 2014 June 2014 May 2014 April 2014 March 2014 February 2014 January 2014 December 2013 November 2013 October 2013 September 2013 August 2013 July 2013 June 2013 May 2013 April 2013 March 2013 February 2013 January 2013 December 2012 November 2012 October 2012 September 2012 August 2012 July 2012 June 2012 May 2012 March 2012 January 2012 December 2011 90,085

HeadingsChoose a headingHouse ideasTools and gadgetsInteresting thingsInformation and guidesMaterialsKitchen furnitureDiy CraftsBathroom RepairKitchen RepairDo-it-yourself PlumberWe will make for a summer residenceDiy furnitureTips for home craftsmanJoinery work

How to create a beautiful stub for a website

A stub is a page that is placed on a website when it is unavailable for one reason or another. For example, when you are finalizing or changing the design of a site and at this time it is not available or is displayed somehow incorrectly. It will be advisable to put a dummy page for this time, on which it will be written that the site is under maintenance.

For example, when you are finalizing or changing the design of a site and at this time it is not available or is displayed somehow incorrectly. It will be advisable to put a dummy page for this time, on which it will be written that the site is under maintenance.

So let’s get started …

We will make a simple stub with a background image and text that the site is under maintenance.

Let’s create a folder on the computer where we will place all the necessary files for our stub.

In this folder, create another folder called images . In it we will place our background image and, possibly, other pictures that may be needed in the course of work.

Open the Notepad ++ program (or similar, for example Notepad). Create a new document. Next – File – Save As, select our folder with a stub and save the document with the name index.html

This is what should be in our folder now:

Open the index. html (you should have it open after saving). Now we need to make sure that the encoding of this file is set correctly. To do this, go to the “Encodings” menu item and click on “Convert to UTF-8”

html (you should have it open after saving). Now we need to make sure that the encoding of this file is set correctly. To do this, go to the “Encodings” menu item and click on “Convert to UTF-8”

In order not to accidentally lose the achieved result during work, I recommend that you periodically save the document while you work. This can be done in the “File” menu or by the keyboard shortcut “Ctrl + S”.

Write the following code in the editor:

Any web page consists of these tags.

Now let’s add a title to our page, because it won’t be very nice when someone opens it and sees index.html in the title of the browser tab (you can open the page in a browser and watch what happens). To do this, add the following code between

and:

Background picture

Now let’s add a background image to our stub, and then go back to editing the page.

To do this, go to Google Pictures and look for an interesting picture that could serve as a background for our page. It is important to select a picture with a width of at least 1920 pixels so that our page looks good on large screens. I entered 1920 backgrounds into the search box and selected one of the pictures.

Open the picture in full size and save it to the folder images . Then we rename it. Let’s call it bg (don’t forget about the image format, in my case it’s jpg).

Here’s what I picked up. This is a photo of the city of Chicago. In my opinion, it is quite suitable for the background image of the site.

Attach a background image to the page, for this we use CSS styles:

Also above, I added styles for the text, namely, set the font Arial and white text color.

Next, let’s create a 900px wide block, into which we will place our text. Let’s center this block.

Let’s center this block.

The text will consist of a heading and, in fact, a paragraph of text.

This site is under maintenance, check back later!

Currently, the site is undergoing technical work. Please come back later or contact us in one of the following ways:

Here’s what happened:

Now we will add our contacts so that visitors can immediately contact us, and not wait until the site is finished working.

Let’s add 3 blocks, which will contain phone, email and skype.

This site is under maintenance, check back later!

Currently, the site is undergoing technical work. Please come back later or contact us in one of the following ways:

Tel .: 333-33-33

E-mail: admin @ site. ru

ru

Skype: admsite

It remains to work with the styles.

Enlarge the title, center it and move it closer to the center of the screen.

Increase the font of the paragraph of text to twenty pixels and indent a little from the heading. We will also make a border at the bottom of the text, which will separate it from the contacts.

Let’s make blocks with contacts in 3 columns, increase the font, align each block in the center and change the color of the text.

This site is under maintenance, check back later!

Currently, the site is undergoing technical work. Please come back later or contact us in one of the following ways:

Tel .: 333-33-33

E-mail: admin @ site.ru

Skype: admsite

The result is a stub page that we can use when the site is undergoing maintenance.

What happened can be downloaded from this link.

Try professional hosting for your website

90,000 short description, benefits, photos.How to make plugs for sockets with your own hands

If small children live in your house, then the use of this item becomes a necessity. What is it about? This is a plug for an outlet that is an effective protection against electric shock. With it, adults need not worry about the safety of young researchers. The product is sold in electrical stores and has a variety of models.

Despite the impressive assortment in which the plug for the socket is presented, you should take the choice of the product seriously.In most cases, it looks like a cork with a flat surface and includes several pins made of special plastic. The forceful effect of an electric current does not threaten the child if the above-described object is installed everywhere in the house.

Children sometimes show miracles of ingenuity. In particular, parents talk about cases when primitive modifications were easily opened by restless kids. If you suspect that your child will give you a similar unpleasant surprise, it is better to opt for special models.Such a plug for an outlet is supplied with a key. Behind him, too, you need an eye and an eye. It should be left where the child cannot find it under any circumstances.

In particular, parents talk about cases when primitive modifications were easily opened by restless kids. If you suspect that your child will give you a similar unpleasant surprise, it is better to opt for special models.Such a plug for an outlet is supplied with a key. Behind him, too, you need an eye and an eye. It should be left where the child cannot find it under any circumstances.

Classification

Why are socket plugs needed? You can expect anything from children, especially those who are restless and curious. They are able to find trouble where, it would seem, they are not in danger. One of the most dangerous objects is the electrical outlet. To protect the child from electric shock, they resort to the help of the devices we are considering.Products are conventionally divided into three types:

- internal;

- swivel;

- lock.

The first version consists of a plastic device that secures the socket by snapping it into place. The second type lends itself to extraction by physical pressure. The third modification opens only after using a special key.

The second type lends itself to extraction by physical pressure. The third modification opens only after using a special key.

Models with the simplest design are in the lowest price segment. A plug for an outlet with a more complex device will cost more.The highest cost is for high strength locking systems.

On the market of electrical goods are presented not only plugs for outlets from children. There are also the following types:

- Waterproofing. They are distinguished by increased density. Made of plastic. Equipped with additional protection made of rubber or silicone. After their installation, the flow of moist air to the inner parts of the outlet is completely blocked.

- Decorative plugs for sockets. It is best to hide the keys from children who are curious about these bright and beautiful details.Otherwise, attempts to open products with their help will not be long in coming. The function of such models is to make the interior of the room more attractive.

The samples are distinguished by unusual colors and shapes. Allows you to mask the outlet.

The samples are distinguished by unusual colors and shapes. Allows you to mask the outlet. - Plugs for the socket outlet. They are designated as a variation of the previous type of product. If, after renovation, you still have open entrances in the wall, use these models to close them.

Plugs for sockets: photo, recommendations for selection

Thanks to the clear division by type, it will not be difficult to choose the optimal modification.You just need to understand what kind of protection is required in your case.

You must be absolutely sure that you have purchased the correct model. A child cannot cope with such a product. Please note that the swivel mechanisms are the simplest. They are best avoided.

Some modifications of the internal plugs are also not entirely reliable. In general, the older the children are, the easier it is for them to access the outlet.

Locking devices are capable of minimizing contact potential. On the other hand, if your child is still very young, you can limit yourself to simpler options for now. When buying a model with a complex design, the keys are handed over to the disposal. There is always a chance of losing them.

On the other hand, if your child is still very young, you can limit yourself to simpler options for now. When buying a model with a complex design, the keys are handed over to the disposal. There is always a chance of losing them.

Quality is the main criterion!

Choose products made of high quality plastic. Only they provide reliability. What else should you pay attention to?

- Take a closer look at the sealing inserts. They must hold on firmly. The features of the seals play an important role in this case.

- Fastening elements must match the size of the socket outlet. Thus, you eliminate the situation when the purchased product does not fit the existing equipment.

- The criterion, which is not the least important, is the type of electrical outlet. Let’s say you are unlikely to be able to use the plug described in this article for a telephone input. The same can be said about radio points and other similar objects.

Self-creation of products

If desired, it is quite possible to build plugs for sockets with your own hands. This method saves money, although it takes more time and effort. The algorithm is as follows.

This method saves money, although it takes more time and effort. The algorithm is as follows.

- Start from the inside of the socket. Determine its dimensions.

- Prepare a sheet of plastic. Its thickness must be at least 2 mm.

- It is necessary to make a round bar of a certain diameter from it.

- In turn, you need to make a hole in it. It is designed for the entrances and the center screw.

- In the box, remove the existing screw and replace it with a longer one.Its standard types are suitable in some cases.

- It remains to screw the inner strap to the box. Following this, it is necessary to rotate it 90 degrees.

As you can see, in order to make plugs for sockets from children with your own hands, nothing special is required. As a result of simple actions, you get a homemade item that can protect your child from contact with electric shock.

Among other things, it becomes a barrier against various debris. The product is very easy to open. It is enough for this to turn the bar around the axis.

The product is very easy to open. It is enough for this to turn the bar around the axis.

Features

The plugs are strong enough to withstand severe pressure and any other stress. Not all models can provide water resistance. If you want the product to also protect from moisture, you will have to pay extra.

The advantages of this type of product are obvious:

- the ability to stay in peace of mind for the safety of young children;

- high strength;

- More attractive, aesthetic appearance of the socket;

- Possibility of installation in the bathroom by counteracting humidity.

A similar product will not be superfluous in any apartment. It is very cheap and is extremely beneficial. Installation of the plug is extremely simple. For this reason, anyone can handle it.

Installation of products is allowed in any area of the dwelling. The fixation of children’s protective elements is usually carried out using screws. Individual varieties can be simply inserted into the box.

Individual varieties can be simply inserted into the box.

Website stub: examples and templates

Why create a dummy page?

A stub page for a site acts as a temporary home page that informs visitors that a resource is temporarily unavailable.

There can be several purposes for which such a page is installed:

- The site is undergoing technical work and it is necessary to notify the user that this is temporary.

- The site is at an early stage of development and the stub page is serving an advertising role.

- A stub for a domain that is for sale.

In any of these cases, it is important to maintain audience loyalty to the resource, so the stub may contain relevant content.If the user has any questions about the site’s management, then such a page will inform how to contact him.

If a commercial organization’s website development is delayed for a long time, then instead of a simple stub, it is better to publish a page about the company.

Basic elements of a stub page for a site

Before starting to design a dummy page, it is important to determine what elements it should consist of.

- The first thing to understand is that it is not enough to place the inscription “The site is undergoing technical work” or “The site is under construction.”Here it is important to notify the visitor about which particular resource he came to, indicating the name and logo of the company.

- Second, this is contact information, it must also be indicated. Perhaps a potential client came to the site and got to the stub. In this case, if there are no contacts, he will most likely leave the resource and turn to competitors for help. Therefore, contact information should be published on the stub.

- It will not be superfluous to publish brief information about what the company is doing.The main thing here is not to overload the page with data, but to indicate only the key directions.

- Speaking about the previous point, in addition to text and graphic information, you can publish a video about the company. In some cases, this will be more appropriate, for example, if there is a lot of information.

- You can put a form for an email newsletter on a blank, but then you should motivate the visitor to leave his contact. In addition to other newsletters, this function is often used to notify the audience when the site will again be available for visiting.But this option is more suitable for well-known companies that already have regular visitors.

- Notifying users about the timing of technical work. You can approach this element creatively by indicating not just the date of resource activation, but making an animated counter that counts down the time.

- A stub can be used to solve marketing problems, for example, by indicating on it information about a competition, the results of which will be summed up already on a working site.

Thus, you can motivate the visitor to return to the resource.

Thus, you can motivate the visitor to return to the resource. - Speaking of contact information, I would like to highlight links to groups and project pages on social networks as a separate element. This will allow you not to lose potential customers, moreover, there is a chance to increase the number of subscribers on other platforms.

When creating a dummy page according to the above recommendations, you want to fit as much data on it as possible. But the main rule is to publish extremely relevant information, maintaining a balance between the volume and usefulness of the content.At the same time, you should take into account the peculiarities of the audience’s behavior; in some cases, an overly creative page can play a negative role.

How to create and install a stub on a site?

There are several options for creating a stub page. The choice depends, for example, on whether the site works on a ready-made CMS, whether there are corresponding plugins for it, etc.

But in general, the stub is a full-fledged page of the site and it is worth approaching its development in the same way.Initially, a prototype of the template is designed. Elements of the future stub are placed on it in a graphical form, and usability is also being worked out. Next, based on the prototype, a template layout is created with the finished design.

Creating a website stub from a ready-made HTML template

If you do not have the resources or desire to create a prototype and layout of a template from scratch, you can use ready-made solutions.

One of the popular sites where you can download and further edit templates in a convenient graphic editor is Nicepage.com. Here are dozens of ready-made stub pages, before downloading which, you need to install a graphical editor.

Nicepage.com Graphic Editor

After that, a template is selected on the site, on the page of which there is an identifier – we indicate it in the installed editor and the template will be available for editing.

Selecting a template on the site

Search for a template by ID

Every element of the page is editable, so you can create a great placeholder in just 10 minutes.

Editing template

After it is created, it is proposed to export it in various formats.

We export in the format we need

Conveniently, all exported templates from the editor are adapted for various types of devices (mobile, tablet, desktop), and you can see how they will look in one resolution or another in the program itself.

Adaptability test

More details about tariff plans and terms of use of templates can be found on the website.

Examples of stubs based on ready-made templates

We have collected the most successful, in our opinion, ready-made HTML stub templates.

An example of a stub for a site – 1

Ref

Example site stub – 2

Ref

Example of a stub for a site – 3

Ref

Example site stub – 4

Ref

An example of a stub for a site – 5

Ref

Creating a stub using HTML

This method can be used on any site and CMS. Its essence lies in the fact that the page template is laid out in HTML-code, and then installed on the site.

Its essence lies in the fact that the page template is laid out in HTML-code, and then installed on the site.

Create a stub file that contains HTML layout with,

and blocks.

A NEW START IS COMING!

Our site is under construction and we are almost ready to go!

We are preparing something amazing and exciting for you - a special surprise for subscribers

This is how the entire stub page is assembled.176 \ .111 \ .11 \ .22

RewriteRule $ /file. html [R = 302, L]

html [R = 302, L]

The second and fifth lines contain the name of the generated stub file, to which users and crawlers will be redirected. The third and fourth are the IP addresses from which it will be possible to enter the site without redirecting. Usually, the data of administrators and those who work on the site are registered there.

Plugins for CMS

Most popular CMS, such as WordPress and Bitrix, have ready-made plugins that allow you to activate and install stub pages.This greatly simplifies the job for inexperienced webmasters.

For example, WP Maintenance Mode plugin is popular for WordPress, which has more than 800 thousand active installations in the repository. It allows you to create beautiful and modern stub designs, including integrating animated counters, contact forms. At the same time, all templates are adapted for mobile devices.

For Bitrix, you can also find ready-made plugins, for example, the eponymous “Stub: technical work, the site is under development. “The developer company provides all technical support for the paid versions of the plugin.

“The developer company provides all technical support for the paid versions of the plugin.

Examples of design of stubs for sites

Example – 1

Minimalist style stub, links to social networks and a notification sign-up form, as well as a timer before website launch.

Example – 2

This is an extended version of the stub, which includes the first screen with a timer, there is a main navigation menu, because the plug consists of several screens.As blocks, you can use information about the company, an extended feedback form, etc.

Example – 3

Notice of site maintenance and contact information, in some cases this is sufficient.

Example – 4

A stub with an abstract background image, in general, it is advisable to adhere to the style of the site.

Example – 5

The name of the project, a timer with a countdown to launch, and a subscription form are indicated.

Add another drop of BeadFix adhesive to where the End Cap meets the wire.

Add another drop of BeadFix adhesive to where the End Cap meets the wire.

The samples are distinguished by unusual colors and shapes. Allows you to mask the outlet.

The samples are distinguished by unusual colors and shapes. Allows you to mask the outlet.

Thus, you can motivate the visitor to return to the resource.

Thus, you can motivate the visitor to return to the resource.