How do Cascade CPV heating and cooling systems work. What are the technical specifications of Cascade CPV units. How to properly size Cascade CPV systems for optimal performance. Why are R-sizing charts crucial for Cascade CPV installations. What are the key benefits of Cascade CPV technology in HVAC applications. How to maintain and troubleshoot Cascade CPV systems for longevity. What factors should be considered when installing Cascade CPV units in residential and commercial settings.

Understanding the Basics of Cascade CPV Technology

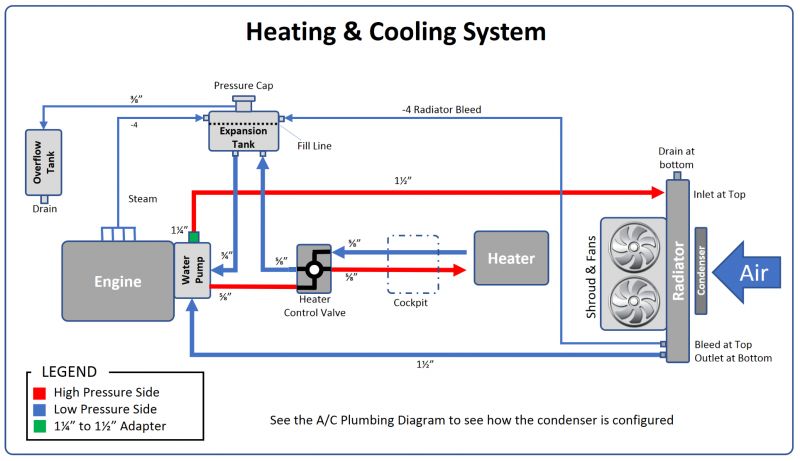

Cascade CPV (Condensing Pressure Valve) technology represents a significant advancement in heating and cooling systems. This innovative approach to climate control offers improved efficiency and performance compared to traditional HVAC systems. But how exactly does it work?

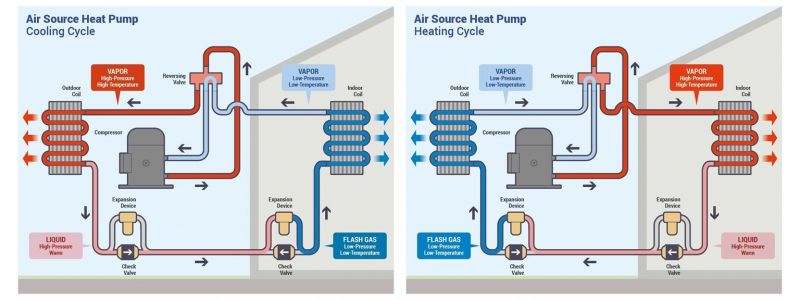

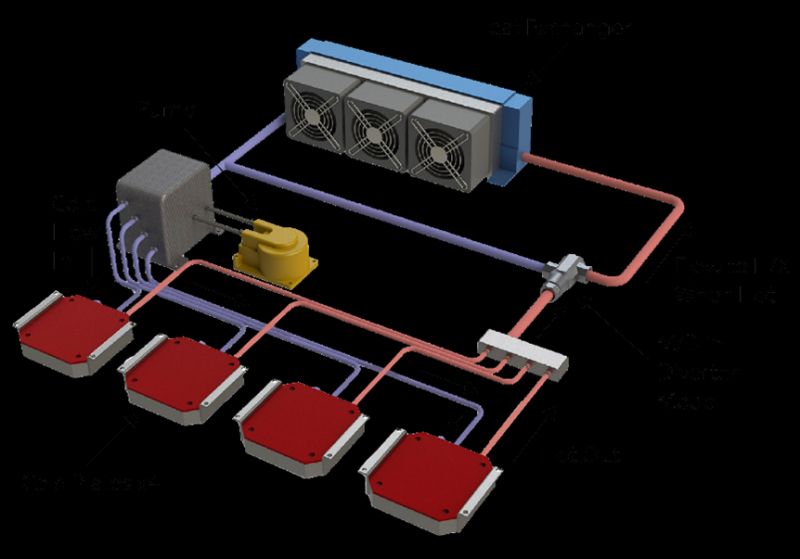

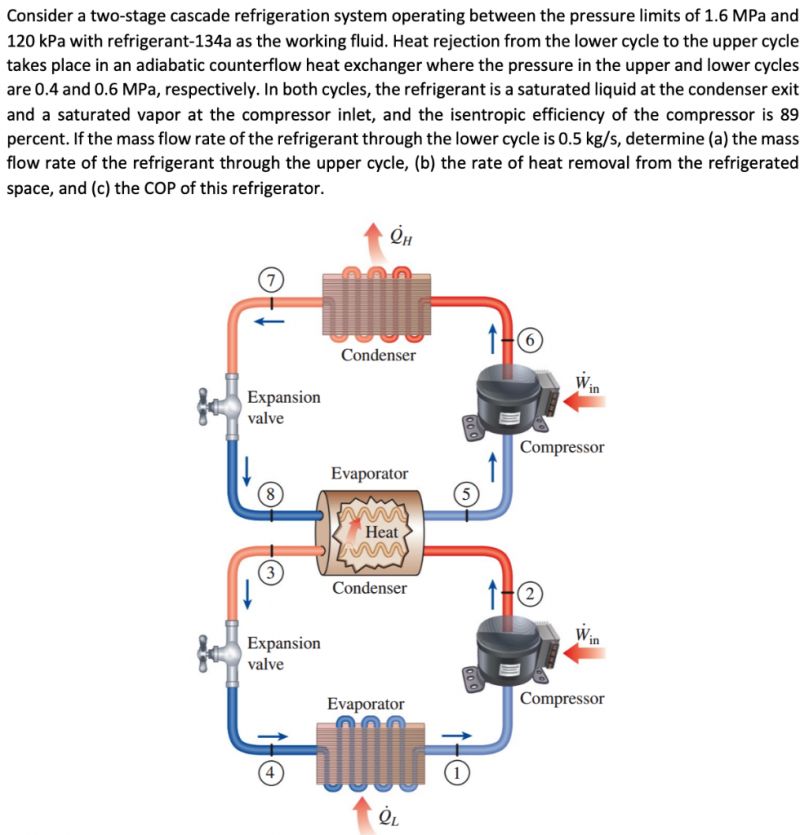

At its core, Cascade CPV technology utilizes a series of interconnected heat exchangers and compressors to transfer heat more effectively. This cascade effect allows the system to achieve higher temperature differentials, making it particularly suitable for applications requiring extreme heating or cooling.

Key Components of Cascade CPV Systems

- Multiple compressors arranged in stages

- Intercoolers between compression stages

- Condensing pressure valves for precise control

- Advanced control systems for optimal operation

By employing these components in a carefully engineered configuration, Cascade CPV systems can achieve remarkable efficiency gains. This translates to lower energy consumption and reduced operating costs for users.

Technical Specifications of Cascade CPV Units

When considering a Cascade CPV system for your heating and cooling needs, it’s essential to understand the technical specifications that define its performance. These specifications vary depending on the specific model and intended application, but several key parameters are common across the product line.

Capacity and Efficiency Ratings

What capacity range do Cascade CPV systems offer? Typically, these units are available in capacities ranging from 2 to 20 tons for residential and light commercial applications, with larger custom systems available for industrial use. The efficiency of these systems is often measured using the Seasonal Energy Efficiency Ratio (SEER) for cooling and Heating Seasonal Performance Factor (HSPF) for heating. High-end Cascade CPV models can achieve SEER ratings of up to 20 and HSPF ratings of 10 or higher, indicating exceptional energy efficiency.

Operating Temperature Range

One of the standout features of Cascade CPV technology is its ability to operate effectively across a wide temperature range. Many models can provide heating in ambient temperatures as low as -22째F (-30째C) and cooling in temperatures up to 125째F (52째C). This broad operating range makes Cascade CPV systems suitable for diverse climates and applications.

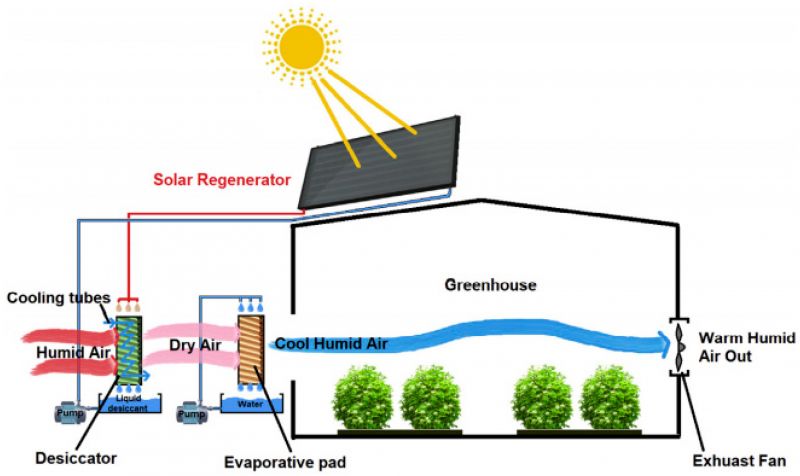

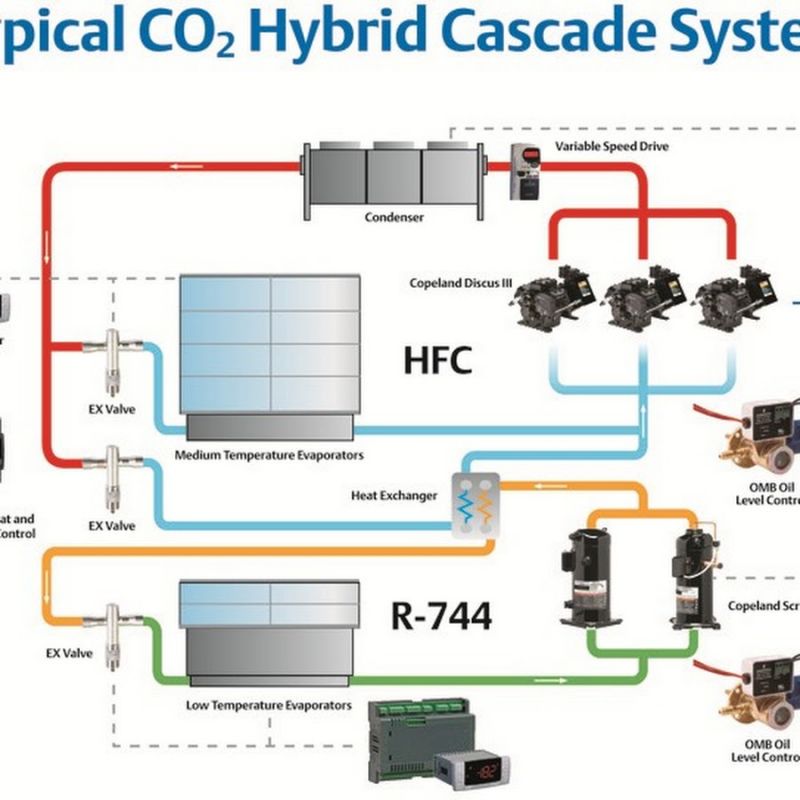

Refrigerant Types and Environmental Impact

Cascade CPV systems typically use environmentally friendly refrigerants with low Global Warming Potential (GWP). Common choices include R-410A for residential systems and R-134a or R-1234yf for larger commercial installations. The use of these refrigerants helps minimize the environmental impact of HVAC operations.

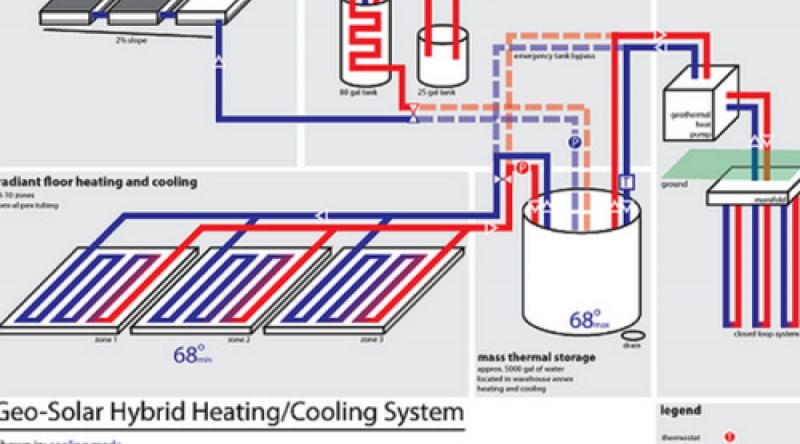

Proper Sizing Techniques for Cascade CPV Systems

Accurate sizing is crucial for the optimal performance of any HVAC system, and Cascade CPV units are no exception. Undersized systems may struggle to meet heating and cooling demands, while oversized units can lead to inefficient operation and poor humidity control. How can you ensure proper sizing for your Cascade CPV installation?

Load Calculation Methods

The first step in sizing a Cascade CPV system is to perform a thorough load calculation. This process takes into account various factors that affect heating and cooling requirements:

- Building size and layout

- Insulation levels

- Window area and orientation

- Local climate conditions

- Occupancy patterns

- Heat-generating equipment and lighting

Professional HVAC contractors typically use software based on industry-standard methods like ACCA Manual J for residential applications or more complex tools for commercial projects. These calculations provide a detailed breakdown of heating and cooling loads for each space in the building.

Matching System Capacity to Load Requirements

Once the load calculations are complete, the next step is to select a Cascade CPV system with a capacity that closely matches the calculated loads. As a general rule, the system’s capacity should be within 15% of the peak load requirements. This margin allows for some flexibility without risking significant over- or under-sizing issues.

It’s important to note that Cascade CPV systems often have modulating capabilities, allowing them to adjust their output to match varying load conditions. This feature can help improve efficiency and comfort, especially in applications with fluctuating heating or cooling demands.

Exploring Cascade CPV R-Sizing Charts

R-sizing charts are essential tools for ensuring proper component matching in Cascade CPV systems. These charts provide guidance on pairing compatible indoor and outdoor units, taking into account factors such as refrigerant flow rates and system capacities.

Interpreting R-Sizing Chart Data

How do you read and apply the information in a Cascade CPV R-sizing chart? These charts typically organize information by product family and nominal cooling capacity. For each outdoor unit, they list compatible indoor coils and provide important details such as:

- Cooling capacity at various operating conditions

- Heating capacity (for heat pump systems)

- Airflow requirements

- Refrigerant charge specifications

By referencing these charts, installers can ensure that all system components are properly matched for optimal performance and efficiency.

The Importance of Proper Component Matching

Why is it critical to follow R-sizing charts when installing Cascade CPV systems? Mismatched components can lead to a range of issues, including:

- Reduced system capacity and efficiency

- Improper refrigerant flow and distribution

- Increased wear on compressors and other components

- Poor temperature and humidity control

- Potential for premature system failure

By carefully adhering to the manufacturer’s R-sizing guidelines, installers can avoid these problems and ensure that Cascade CPV systems operate as intended, delivering maximum comfort and efficiency.

Benefits of Cascade CPV Technology in HVAC Applications

Cascade CPV systems offer several advantages over conventional HVAC technologies. Understanding these benefits can help building owners and managers make informed decisions about their climate control solutions.

Enhanced Energy Efficiency

One of the primary advantages of Cascade CPV technology is its superior energy efficiency. By utilizing multiple compression stages and advanced heat exchange techniques, these systems can achieve higher Coefficients of Performance (COP) compared to single-stage systems. This translates to lower energy consumption and reduced operating costs over the system’s lifetime.

Improved Temperature Control and Comfort

Cascade CPV systems excel at maintaining precise temperature control, even in challenging conditions. The multi-stage compression process allows for finer adjustments to heating and cooling output, resulting in more stable indoor temperatures and improved occupant comfort.

Versatility in Extreme Climates

The wide operating temperature range of Cascade CPV systems makes them particularly well-suited for use in regions with extreme climates. Whether dealing with scorching summer heat or frigid winter temperatures, these systems can maintain efficient operation and deliver reliable heating and cooling performance.

Maintenance and Troubleshooting of Cascade CPV Systems

Proper maintenance is essential for ensuring the longevity and optimal performance of Cascade CPV heating and cooling systems. Regular upkeep can prevent many common issues and help identify potential problems before they escalate.

Routine Maintenance Tasks

What are the key maintenance activities for Cascade CPV systems? A comprehensive maintenance program typically includes:

- Regular inspection of all system components

- Cleaning or replacement of air filters

- Checking and adjusting refrigerant levels

- Lubricating moving parts as needed

- Verifying proper operation of safety controls

- Cleaning coils and heat exchangers

- Inspecting and tightening electrical connections

These tasks should be performed by qualified technicians according to the manufacturer’s recommended maintenance schedule.

Common Troubleshooting Scenarios

Even with proper maintenance, occasional issues may arise with Cascade CPV systems. Some common problems and their potential causes include:

- Insufficient cooling or heating: Could be due to low refrigerant levels, dirty filters, or malfunctioning compressors.

- Unusual noises: May indicate loose components, worn bearings, or refrigerant leaks.

- Short cycling: Often caused by incorrect thermostat settings, oversized equipment, or refrigerant issues.

- Frozen evaporator coils: Can result from low airflow, dirty filters, or low refrigerant charge.

When troubleshooting these issues, it’s important to follow a systematic approach and consult the manufacturer’s documentation for specific guidance.

Installation Considerations for Cascade CPV Units

Proper installation is crucial for the performance and longevity of Cascade CPV systems. Several factors must be considered to ensure optimal system operation in both residential and commercial settings.

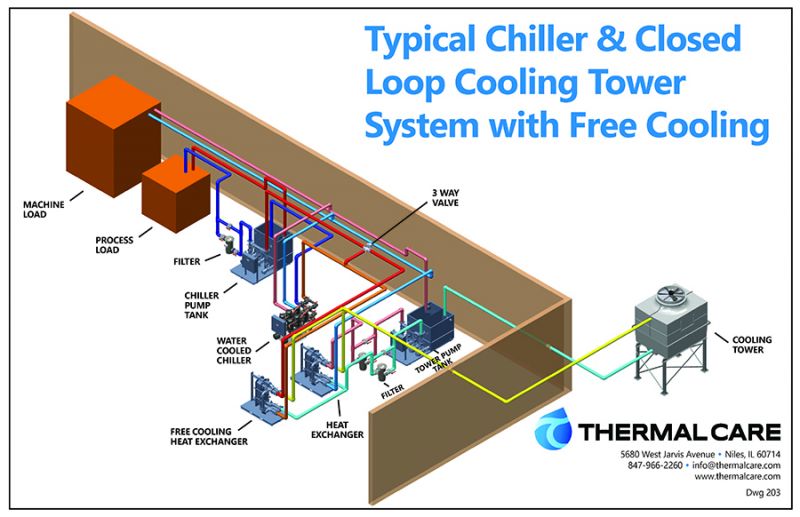

Site Preparation and Equipment Placement

Careful planning of the installation site is essential. Key considerations include:

- Adequate clearance around outdoor units for airflow and maintenance access

- Proper drainage to prevent water accumulation near equipment

- Structural support for rooftop installations

- Noise considerations for compressor and fan placement

- Protection from extreme weather conditions

Indoor components should be installed in easily accessible locations to facilitate maintenance and repairs.

Electrical and Control System Integration

Cascade CPV systems often require sophisticated control systems to manage their multi-stage operation effectively. How can installers ensure proper integration with building management systems? It’s crucial to:

- Verify compatibility with existing control infrastructure

- Properly size and install electrical circuits to meet equipment requirements

- Configure control parameters for optimal system performance

- Implement appropriate safety interlocks and monitoring systems

Collaboration between HVAC technicians and building automation specialists may be necessary to achieve seamless integration and operation.

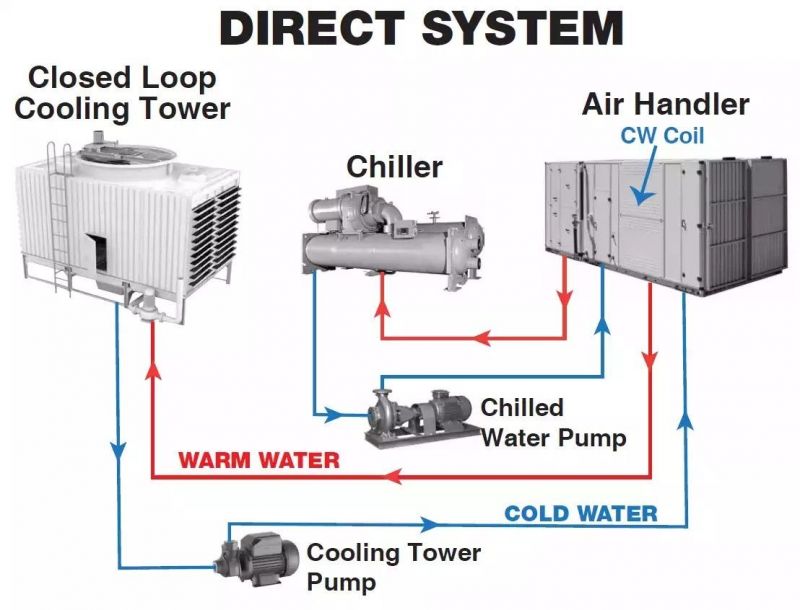

Refrigerant Piping and Charging

Proper design and installation of refrigerant piping are critical for Cascade CPV system performance. Considerations include:

- Correct pipe sizing to ensure proper refrigerant flow

- Minimizing pipe length and bends to reduce pressure drops

- Proper insulation of refrigerant lines to prevent energy loss

- Accurate system charging according to manufacturer specifications

Leak testing and evacuation procedures should be meticulously followed to ensure system integrity and optimal performance.

By carefully addressing these installation considerations, contractors can help ensure that Cascade CPV systems deliver on their promise of efficient and reliable heating and cooling performance. Proper installation sets the foundation for years of trouble-free operation and satisfied end-users.

Technical Specifications of Cascade Cpv Units

Cascade Cpv systems are available in a wide range of capacities and configurations to meet the needs of residential and commercial applications. Here are some key technical specifications to be aware of when selecting and sizing Cascade Cpv units:

Understanding the key specifications is critical when comparing and selecting the ideal Cascade Cpv system for your home or building. Consult the Cascade Cpv product brochures or website for full technical details on all models.

How to Properly Size Cascade Cpv Systems

Properly sizing a Cascade Cpv heating and cooling system is crucial for optimal performance, efficiency, and comfort. With both undersized and oversized units, you may end up with higher energy bills, uneven cooling or heating, and premature system failure. Follow this guide for tips on sizing Cascade Cpv units correctly:

The first step is to calculate the accurate heating and cooling loads for the space. For cooling, factors like square footage, building orientation, window area, insulation level, and climate will impact loads. Heat gain from sunlight, appliances, and occupants must also be included. A load calculation provides the required BTU/hr of heating and cooling needed. HVAC pros use ACCA Manual J for residential load calcs and more complex versions for commercial settings.

Once accurate heating and cooling loads are determined, refer to Cascade Cpv product literature for equipment capacities. Match the loads calculated with a unit that can meet but not drastically exceed those values. Oversizing leads to short cycling and moisture buildup. A unit with capacity within 15% of calculated peak loads is ideal. An HVAC contractor can help select the properly sized Cascade Cpv model.

Be sure to account for any future additions, renovations, or changes in use that may impact heating/cooling requirements. A conservatively sized unit allows for future flexibility. Also consider potential occupancy increases for a commercial space when choosing capacity.

Use Cascade Cpv R sizing charts to pick the correct indoor evaporator coil and outdoor condenser match. Mismatched or improperly sized components lead to system problems. Refer to the Cascade Cpv Application Guide for detailed sizing guidelines and r-values for approved system combinations.

Consider efficiency ratings like SEER and HSPF when choosing the Cascade Cpv model. A higher efficiency unit may have a higher upfront cost but save substantially on energy expenses over the lifetime of the equipment.

Work closely with an experienced HVAC contractor during the Cascade Cpv sizing process. An expert can help select the ideal capacity by factoring in all the relevant variables for your specific project requirements. Improper sizing can lead to premature failure, so get it right the first time.

Carefully sizing and selecting the correct Cascade Cpv system for your home or commercial space is crucial to getting the most out of the advanced heating and cooling technology. Follow professional protocols to accurately match the unit capacity to the calculated loads. Over time, a properly sized Cascade Cpv system will deliver comfort, reliability, and efficiency.

Exploring Cascade Cpv R Sizing Charts

Properly matching system components is critical for optimal performance of Cascade Cpv heating and cooling equipment. Cascade Cpv provides detailed r-sizing charts to pair compatible indoor and outdoor units for a seamless system.

Cascade Cpv r-sizing charts provide the approved evaporator coil and condenser combinations across the Cascade Cpv product line. The evaporator coil must be matched to a condenser unit with the proper refrigerant flow rate, or r-value, for the system to work correctly.

Mismatched components lead to a variety of system issues such as reduced capacity, increased operating costs, equipment cycling problems, loss of humidity control, and even premature component failure. Following the Cascade Cpv r-sizing charts helps prevent these problems.

The Cascade Cpv Application Guide provides comprehensive r-sizing tables covering all air conditioners, heat pumps, cased coils, fan coils, and packaged units in the Cascade Cpv offering. There are tables organized by product family as well as by nominal cooling capacity.

For example, the 2-3 ton cooling capacity chart shows approved matches like the 24ABC6 2-ton air conditioner paired with the CHPF2430A 3-ton cased coil. The r-values align for optimal refrigerant flow. Consult the notes below each chart for additional sizing considerations.

When sizing Cascade Cpv systems, always reference the r-sizing charts for the specific product series you have selected. For example, the Elite Series EX units have separate approved combinations versus the Builder Series BX models. Matching evaporator and condenser within the same product line is critical.

If you require an r-combination outside what is listed in the published sizing charts, consult a Cascade Cpv representative for special approval. Never combine non-approved coils and condensers without explicit guidance.

Installation contractors should have access to printed or digital versions of the latest Cascade Cpv r-sizing charts when configuring an HVAC system. Relying on outdated materials may result in improper sizing. Stay current with the newest recommendations.

Following Cascade’s approved r-value pairings in the sizing charts ensures your heating and cooling system operates at maximum efficiency and capacity. Take the guesswork out of system design by leveraging Cascade’s deep product expertise.

Installing Cascade Cpv Heating and Cooling

Properly installing Cascade Cpv heating and cooling equipment is essential to achieving optimal performance and longevity from these advanced HVAC systems. Follow best practices for installing Cascade Cpv:

Carefully read the Cascade Cpv installation manual for the specific model series being installed. Follow all equipment guidelines and clearances to ensure proper operation and serviceability. Cascade Cpv Elite Series, for example, has different requirements than Builder Series.

Ensure the installation location allows for required clearances around the indoor and outdoor units. Minimum clearances for ventilation, refrigerant piping, electrical connections, air flow, and service access must be maintained. Consult the manual for details.

Use Cascade Cpv factory-approved indoor evaporator coils and outdoor condenser units only. Mixing non-approved or mismatched components voids the warranty and causes performance issues. Follow Cascade’s r-sizing guidelines.

Install the outdoor condenser on a firm, level foundation like a concrete pad. Secure the base to the pad per Cascade Cpv specifications to avoid vibration and noise. Keep condenser clear of plants, debris, fences or structures that restrict air flow.

Mount the evaporator coil inside on the furnace or air handler per Cascade’s instructions. Properly slope horizontal drain lines to ensure condensate flows away freely. Leaks can cause major property damage if drain lines are incorrect.

Connect refrigerant lines between the evaporator and condenser per Cascade’s guidelines. Avoid kinks, overtightening, overbending, or undersized refrigerant piping. Pressure test lines once connected to check for leaks.

Provide proper electrical wiring between the units following all local building codes. Use copper wiring of sufficient gauge to avoid voltage drops during start-up. Undersized wiring causes system damage.

Once installation is complete, thoroughly evacuate air from refrigerant lines using proper pump-down procedures. Failure to evacuate all moisture leads to acid formation and corrosion inside the system.

Carefully follow each step outlined in the Cascade Cpv commissioning procedures, including refrigerant charging, control configuration, and system test operation. Improper start-up voids the warranty.

Be sure to register the Cascade Cpv equipment for warranty coverage once installation and start-up are complete. This provides proof of purchase and installation date.

Following Cascade’s published guidelines for properly installing Cascade Cpv HVAC systems ensures you maximize performance and longevity. Taking shortcuts risks voiding the warranty and causing early failures.

Programming and Controlling Cascade Cpv

One of the advantages of Cascade Cpv heating and cooling systems is the flexibility and precision of control they provide. Properly programming and controlling Cascade Cpv unlocks the full potential of these advanced HVAC units.

Cascade Cpv systems come with integrated, configurable touchscreen controllers that allow complete command of the equipment. Technicians can digitally dial in custom settings for modes, schedules, setpoints, and advanced parameters.

For example, the controller can be set to cycle the system in heating or cooling mode based on desired temps. Fan speeds, humidification levels, and dehumidification limits can be precisely tuned as well. Night setback temperatures automatically conserve energy.

Cascade Cpv controllers also provide monitoring capabilities like temperature logs, runtime histories, and error reporting for simplifying diagnostics and maintenance. Data can be downloaded to analyze performance.

For home installations, Cascade offers consumer-friendly comfort controllers with digital thermostats, touchpads, and apps. Homeowners can easily override schedules, change modes, and view settings from mobile devices.

Cascade’s commercial controllers integrate with sophisticated building automation systems using BACnet or Modbus protocols. This allows remote monitoring and operation across multiple zones in large facilities.

Technicians should take full advantage of the setup wizards and control menus offered by Cascade Cpv systems.inputs tailored to the application ensure ideal comfort and efficiency.

Be sure to set minimum runtimes, cycle rates, and temperature differentials appropriately to avoid overcycling or rapid fluctuations. Built-in diagnostics help optimize calibrations.

Consider enabling weather compensation or demand-controlled ventilation based on occupancy patterns. Smart programming minimizes costs while maintaining comfort.

Train staff and end users on the capabilities of the Cascade Cpv controller. This empowers them to customize comfort and efficiency to match changing needs.

With programmable precision controls, Cascade Cpv delivers the ultimate in HVAC performance, flexibility, and energy savings. Properly leveraging the system controls is key to unlocking the full potential.

Maintenance Tips for Cascade Cpv Equipment

Regular maintenance is essential to keep Cascade Cpv heating and cooling systems operating at peak efficiency and maximize the useful life of the equipment. Here are key maintenance tips for Cascade Cpv units:

Clean or replace air filters regularly, at least every 3 months. Clogged filters reduce airflow, lower system capacity, and strain the blower motor. Use filters with a MERV rating recommended by Cascade.

Keep evaporator and condenser coils free of dirt, debris and buildup. Gently clean coils with an approved foaming coil cleaner to maintain air flow. Avoid damaging the delicate aluminum fins.

Clear debris and overgrowth away from the outdoor condenser unit and make sure vents aren’t obstructed. Allow a minimum clearance for airflow around the condenser.

Check refrigerant charge yearly and top off if needed to meet Cascade’s charging specifications. Low refrigerant reduces cooling capacity and strains the compressor.

Inspect and tighten electrical connections to avoid problems from vibration or moisture. Check capacitors, contactors, and wires for damage or burn marks.

Listen and watch for abnormal noises, smells or vibrations that could indicate problems like motor wear, refrigerant leaks, or loose parts.

Drain pans and condensate lines should be checked for obstructions to prevent clogs and water damage, especially before summer cooling season.

Have an HVAC technician do a complete annual tune-up to ensure the system is operating safely and efficiently to Cascade’s parameters.

Record maintenance and repairs to track service history. Well-documented records help diagnose problems and justify repairs if needed.

Consider enrolling in a Cascade maintenance agreement program to receive regularly scheduled professional care for your Cascade Cpv system.

Following the maintenance guidelines in your Cascade Cpv owner’s manual is essential to keeping your system running efficiently for years to come. Proper maintenance saves money and prevents costly breakdowns.

Comparing Cascade Cpv to Competing Brands

With so many HVAC system brands on the market, it’s important to understand how Cascade Cpv compares to competitors when selecting new heating and cooling equipment. Here’s an overview of how Cascade stacks up:

Efficiency Ratings – Cascade Cpv offers some of the highest SEER and HSPF efficiency ratings in the industry, up to 26 SEER for cooling and 13 HSPF for heating on premium models. This results in lower energy costs compared to less efficient brands.

Reliability Reputation – With over 50 years in the business, Cascade has earned a reputation for reliability and durability. Their compressor warranties are among the longest at 10 years.

Technology – Cascade is an innovation leader, using advanced compressor and heat exchanger designs, multi-stage operation, and precision controls for optimal performance.

Operating Range – Cascade Cpv operates efficiently down to 0°F in heating mode and up to 115°F in cooling mode, ideal for extreme climates.

Resale Value – Cascade’s reputation adds resale value. A Cascade Cpv HVAC system can positively impact your home’s value compared to lesser known brands.

Noise Levels – Cascade Cpv units operate quieter than many competitors thanks to swept fan blades, isolated compressors, and insulated panels.

IAQ Options – Cascade’s Evolution air purifiers, whole-home humidifiers, UV lights, and ventilators improve indoor air quality better than basic competitors.

Warranties – Cascade comprehensive warranties surpass basic parts and compressor coverage from bargain brands to provide greater long-term protection.

Service Availability – Cascade’s nationwide network of dealers makes finding maintenance and expertise easy compared to brands with limited representation.

Smart Controls – Cascade Cpv controls allow much more precision in optimizing settings for efficiency and comfort than basic thermostats.

When you compare Cascade’s offerings to other HVAC brands on key factors, it’s easy to see why Cascade Cpv is considered an industry leader within the heating and cooling marketplace.

Cascade Cpv Warranty Information

One of the key advantages of choosing Cascade Cpv heating and cooling systems is the strong warranty coverage to protect your investment. Here are key details on Cascade Cpv warranties:

All Cascade Cpv equipment comes with a 10-year parts limited warranty. This covers any defects in materials or workmanship on internal components such as compressors, coils, fans, controls and heat exchangers.

Cascade also provides a 10-year compressor limited warranty, one of the longest in the industry. This covers compressor failure due to defects. Labor charges may apply for replacement.

For the first 5 years, Cascade provides an additional compressor parts warranty to cover any shipping costs for providing replacement compressor parts.

The Cascade Cpv lifetime limited warranty on the stainless steel heat exchanger reflects the outstanding durability and longevity of these units.

Cascade Elite Series come with an Upgraded Compressor Limited Warranty of 12 years to provide even greater long-term protection.

All Cascade warranties apply to the original owner only and cannot be transferred. Proof of purchase and installation date are required.

Warranty coverage is contingent on proper registration, installation, and maintenance by a licensed contractor per Cascade guidelines. Alterations or misuse void the warranty.

Labor charges may apply for repairs and replacements covered under warranty after the first year. Check warranty terms for details.

Optional extended warranties are available from Cascade to go beyond the standard warranty terms. Extended coverage can be cost-effective given the lifespan of the equipment.

See the Cascade Cpv warranty certificate for full details on coverage, limitations, exclusions, and requirements. Contact Cascade with any warranty-related questions.

Frequently Asked Questions About Cascade Cpv

Cascade Cpv heating and cooling systems are highly advanced pieces of technology. Here are answers to some of the most common questions about Cascade Cpv:

How often should I replace my Cascade air filter? Cascade recommends replacing filters every 3 months for optimal performance. Clogged filters reduce system efficiency. Use Cascade filters sized correctly for your unit.

What temperature range can Cascade Cpv heat and cool to? Cascade systems can heat down to 0°F outdoor ambient and cool up to 115°F ambient. Performance is optimized within those operating ranges.

Do Cascade heat pumps work well in cold climates? Yes, Cascade heat pumps provide reliable heating down to 0°F thanks to multiple stage compression, variable speed fans, and advanced defrost capabilities.

Is a Cascade heat pump the same as an air conditioner? Cascade heat pumps provide both heating and cooling from one outdoor unit. An air conditioner only provides cooling. A furnace is needed for heating.

How long should a Cascade system last? With proper maintenance, a Cascade unit can provide 20 years or more of reliable service. The stainless steel heat exchanger and 10-year compressor warranty reflect the durability.

What maintenance does a Cascade Cpv need annually? Cascade recommends an annual tune-up, refrigerant check, coil cleaning, filter change, and inspection of electrical connections and drain lines.

Can I control a Cascade with my smartphone? Yes, Cascade controllers integrate with smart home platforms and have apps that allow remote access from iOS and Android mobile devices.

Does Cascade offer lifetime warranties? Cascade provides a lifetime limited warranty on stainless steel heat exchangers, but not a lifetime warranty on the entire unit.

What is the SEER rating on the most efficient Cascade unit? Cascade Elite Series heat pumps are rated up to 26 SEER, among the highest ratings in the HVAC industry.

What is the difference between Cascade’s Builder, Premium, and Elite series? The Cascade series differ in terms of efficiency ratings, sound levels, capacities, warranty terms, and advanced features.

Cascade Cpv Vs. Traditional HVAC Systems

Cascade Cpv systems differ in several key ways compared to traditional HVAC equipment. Understanding these differences allows homeowners to make informed decisions when replacing heating and cooling units.

Efficiency – Cascade Cpv heat pumps offer much higher SEER and HSPF ratings versus old-technology units, leading to lower monthly energy bills. Multi-stage compression improves efficiency across operating ranges.

Controls – Cascade Cpv systems have sophisticated digital controls for precision temperature, humidity, and ventilation control. This allows customization for efficiency and comfort.

Refrigerant – Cascade uses the eco-friendly R-410A refrigerant, which replaces older ozone-depleting refrigerants being phased out due to environmental regulations.

Compressors – Cascade Cpv compressors use scroll and inverter-driven variable speed technology for quieter, more reliable, and more efficient operation.

Convenience – Cascade controllers and apps allow homeowners to easily monitor and adjust their HVAC system remotely from smart devices.

Air Quality – Cascade Cpv can integrate with humidity controls, air cleaners, UV lights, and ventilators for improved indoor air quality.

Reliability – Between the stainless steel heat exchanger, protected compressor, and heavy-duty components, Cascade Cpv units are built to last longer than traditional HVAC systems.

Resale Value – Cascade Cpv units can positively impact your home’s resale value more than outdated equipment. Homebuyers appreciate updated systems.

Warranties – Cascade’s 10-year compressor and 10-year parts warranties provide greater protection than the basic 5-year coverage offered by most older units.

Operating Range – Cascade Cpv units can heat and cool across a wider ambient temperature range, providing year-round comfort in more climates.

When selecting new heating and cooling equipment, Cascade Cpv systems offer significant advantages in terms of efficiency, features, and long-term value compared to outdated technology. The higher upfront investment pays dividends for years to come.

Decorating Cascade Cpv Units With Mohawk Decals

One way that homeowners personalize the look of their Cascade Cpv heating and cooling units is by adding decorative decals or wraps. Mohawk is one leading provider of custom decals for HVAC equipment.

Mohawk offers hundreds of decorative decal options ranging from solid colors and faux finishes to stylized patterns, brick effects, sports themes, and custom photography. This allows you to match your outdoor condenser to your home’s colors and architecture.

The Mohawk decals are cut from high performance vinyl films that resist fading, peeling, and damage from weather, UV rays, and time. Choose from finishes like gloss, matte, textured, or metallic.

Since Cascade Cpv condenser cabinets are made from heavy-gauge galvanized steel, they provide an ideal surface for Mohawk decals to adhere to securely. Proper prep and installation is key.

Be sure the Cascade Cpv condenser surface is clean before decal application. Remove any dirt, oils, or flaking paint so the vinyl film can bond tightly.

Measure the dimensions of your Cascade condenser cabinet and order a Mohawk decal customized to those specifications for perfect coverage. Larger units may require multiple decal panels.

Carefully apply the Mohawk decal according to the included instructions, smoothing the vinyl as you go while removing any air pockets or wrinkles.

Once applied, the Mohawk decals should hold up to intense UV, rain, snow, and temperature extremes. However, inspect for lifting edges or wear annually.

Make sure the decorative decal does not block condenser intake vents or air flow. Leave proper clearance space around the unit.

Consider coordinating your custom Cascade decal with other exterior elements like home siding color, paint, or yard landscaping for a cohesive aesthetic.

With so many design options, Mohawk decals allow you to transform a bland Cascade Cpv condenser into an artistic focal point reflecting your personal style.

Cascade Cpv For Commercial Vs Residential Use

One of the benefits of Cascade Cpv heating and cooling systems is that they can flexibly serve both residential and commercial HVAC applications with proper product selection and sizing.

For residential use, Cascade Cpv split-system heat pumps ranging from 1.5-5 ton capacity are ideal for keeping homes comfortable. Larger homes may utilize multi-zone systems.

Cascade Cpv heat pumps include variables like multi-stage scroll compressors, copper tube aluminum fin coils, MERV 13 filtration, and insulated cabinets suited for homes.

WiFi-enabled Cascade thermostats allow homeowners to adjust temperatures and humidity remotely. Advanced controls optimize residential efficiency and comfort.

For commercial settings, Cascade offers packaged rooftop units up to 30 tons for large spaces like offices, retail, schools, and hospitals.

Commercial Cascade Cpv units include high-efficiency compressors, stronger structural framing, and BAS integration for smart zoned control across large facilities.

Features like economizers, CO2 sensors, and demand-control ventilation provide commercial energy savings and meet building codes.

The installation process also differs between residential and commercial Cascade Cpv applications in terms of structural requirements, ductwork, wiring, and accessing equipment.

While sizing principles remain the same, commercial load calculations use Manual J for residential and more complex methodologies for larger spaces.

Maintenance for commercial Cascade units often requires contracting qualified HVAC service providers rather than periodic homeowner DIY care.

When selecting Cascade Cpv heating and cooling, work closely with experts to ensure your commercial or residential application is properly designed, equipped, and supported based on your specific needs.

The Future of Cascade Cpv Technology

Cascade has been innovating and evolving their Cpv heating and cooling technology for over 50 years. Here is an outlook on what the future may hold for Cascade Cpv systems:

Efficiency – Expect Cascade to continue pushing the boundaries on energy efficiency. SEER ratings approaching 30+ are on the horizon along with ultra low-watt furnace fans to minimize power use.

Refrigerants – Cascade is investing heavily in the testing and approval of new lower global warming potential refrigerants to replace R-410A as environmental regulations evolve.

Controls – Cascade Cpv controls will integrate deeper with home automation and building management systems. Voice commands, geofencing, self-monitoring, and AI optimization will likely expand.

Connectivity – Remote access and control of Cascade systems will improve through upgrades to the CascadeLink platform and integration of 5G wireless communication in HVAC equipment.

Electrification – Cascade is developing all-electric HVAC solutions to align with trends in sustainable, zero-emission buildings. Expect advances in heat pump water heating too.

Air Quality – Look for more sophisticated filtration, UV disinfection, humidification control, air monitoring sensors, and ventilators to be integrated into Cascade equipment.

Design – Cascade outdoor units will continue getting smaller, lighter, and quieter through advances like vacuum-insulated compressor jackets and smaller condenser coil designs.

Installation – Cascade aims to enhance accessibility of equipment, simplify wiring and controls, reduce refrigerant piping, and speed up modular installation timeframes.

Reliability – To extend operating lifetimes, Cascade is focused on connected diagnostics, automated maintenance alerts, and component designs that enable easy field repairs.

Cascade has exciting innovations in development to ensure their Cpv systems continue leading the industry. Investing in a Cascade unit means your HVAC is future-ready as technology evolves.

Cascade Cpv For Commercial vs Residential Use

One of the benefits of Cascade Cpv heating and cooling systems is that they can flexibly serve both residential and commercial HVAC applications with proper product selection and sizing.

For residential use, Cascade Cpv split-system heat pumps ranging from 1.5-5 ton capacity are ideal for keeping homes comfortable. Larger homes may utilize multi-zone systems.

Cascade Cpv heat pumps include variables like multi-stage scroll compressors, copper tube aluminum fin coils, MERV 13 filtration, and insulated cabinets suited for homes.

WiFi-enabled Cascade thermostats allow homeowners to adjust temperatures and humidity remotely. Advanced controls optimize residential efficiency and comfort.

For commercial settings, Cascade offers packaged rooftop units up to 30 tons for large spaces like offices, retail, schools, and hospitals.

Commercial Cascade Cpv units include high-efficiency compressors, stronger structural framing, and BAS integration for smart zoned control across large facilities.

Features like economizers, CO2 sensors, and demand-control ventilation provide commercial energy savings and meet building codes.

The installation process also differs between residential and commercial Cascade Cpv applications in terms of structural requirements, ductwork, wiring, and accessing equipment.

While sizing principles remain the same, commercial load calculations use Manual J for residential and more complex methodologies for larger spaces.

Maintenance for commercial Cascade units often requires contracting qualified HVAC service providers rather than periodic homeowner DIY care.

When selecting Cascade Cpv heating and cooling, work closely with experts to ensure your commercial or residential application is properly designed, equipped, and supported based on your specific needs.

The Future of Cascade Cpv Technology

Cascade has been innovating and evolving their Cpv heating and cooling technology for over 50 years. Here is an outlook on what the future may hold for Cascade Cpv systems:

Efficiency – Expect Cascade to continue pushing the boundaries on energy efficiency. SEER ratings approaching 30+ are on the horizon along with ultra low-watt furnace fans to minimize power use.

Refrigerants – Cascade is investing heavily in the testing and approval of new lower global warming potential refrigerants to replace R-410A as environmental regulations evolve.

Controls – Cascade Cpv controls will integrate deeper with home automation and building management systems. Voice commands, geofencing, self-monitoring, and AI optimization will likely expand.

Connectivity – Remote access and control of Cascade systems will improve through upgrades to the CascadeLink platform and integration of 5G wireless communication in HVAC equipment.

Electrification – Cascade is developing all-electric HVAC solutions to align with trends in sustainable, zero-emission buildings. Expect advances in heat pump water heating too.

Air Quality – Look for more sophisticated filtration, UV disinfection, humidification control, air monitoring sensors, and ventilators to be integrated into Cascade equipment.

Design – Cascade outdoor units will continue getting smaller, lighter, and quieter through advances like vacuum-insulated compressor jackets and smaller condenser coil designs.

Installation – Cascade aims to enhance accessibility of equipment, simplify wiring and controls, reduce refrigerant piping, and speed up modular installation timeframes.

Reliability – To extend operating lifetimes, Cascade is focused on connected diagnostics, automated maintenance alerts, and component designs that enable easy field repairs.

Cascade has exciting innovations in development to ensure their Cpv systems continue leading the industry. Investing in a Cascade unit means your HVAC is future-ready as technology evolves.