How do Quest Canopy Weight Bags provide stability for outdoor events. What size anchor bags should you choose for your canopy. How much weight is needed to secure a canopy effectively. Where should weight bags be placed on a canopy frame. What are the advantages of using sand vs water as fill material.

Choosing the Right Size Anchor Bags for Your Canopy

Selecting the appropriate size anchor bags is crucial for ensuring your canopy remains stable in various weather conditions. The size of the bags should be proportional to the dimensions of your canopy tent. Most manufacturers provide sizing charts that match bag sizes to specific canopy dimensions, taking into account factors such as fabric weight, frame strength, and typical wind conditions.

When choosing anchor bags, consider the following:

- Square footage of your canopy tent

- Manufacturer’s recommendations

- Expected wind conditions

- Frame strength and material

Is it better to use multiple smaller bags or fewer larger ones? Both approaches have their merits. Using multiple smaller bags allows for more even weight distribution and provides additional anchoring points. However, ensure that the total weight meets the canopy maker’s guidelines, regardless of the bag size configuration you choose.

Calculating the Optimal Weight for Canopy Stability

Determining the correct amount of weight for your canopy is essential to prevent it from becoming airborne during windy conditions. Manufacturers typically provide weight recommendations, usually ranging from 20 to 35 pounds per leg. For a standard 10′ x 10′ canopy with four legs, this translates to a total weight of 80 to 140 pounds.

To calculate the optimal weight for your canopy:

- Check the manufacturer’s specifications for recommended weight range

- Consider the expected weather conditions

- Factor in the size of your canopy

- Aim for the higher end of the range if you anticipate very windy conditions

Can using too much weight be problematic? While it’s important to have sufficient weight to anchor your canopy, excessive weight can make the bags difficult to hang and transport. Strike a balance between stability and practicality when determining the total weight for your anchor bags.

Strategic Placement of Weight Bags for Maximum Effectiveness

The positioning of anchor weight bags on your canopy frame significantly impacts their effectiveness in stabilizing the structure. While the standard practice is to place bags halfway down each leg, experimenting with different positions can yield better results.

Consider these placement strategies:

- Position bags farther out toward the feet of the frame for increased leverage

- Distribute weight evenly among all legs

- Add slightly more weight to uphill legs on uneven ground

- Adjust bag placement based on observed stress points during wind gusts

How does bag placement affect canopy stability? The lower the bags are placed on the legs, the more leverage they provide against lifting forces. However, ensure that the bags don’t interfere with the canopy’s functionality or pose a tripping hazard.

Proper Attachment Techniques for Secure Hanging

Quest and other reputable brands design their canopy anchor bags with built-in loops and hooks for easy attachment to the tent frame. This design allows for secure hanging while preventing damage to both the bags and the canopy structure.

To properly attach weight bags:

- Locate the built-in loops on the anchor bags

- Slide the loop opening over the frame pipe

- Allow the bag to hang freely

- For thinner frame legs, use the attached hook to prevent slipping

Why is it important for bags to hang freely? Hanging bags prevent abrasion damage that could occur if they were sitting on the ground. This method also ensures that the full weight of the bag is utilized for anchoring, rather than sliding or shifting on the ground.

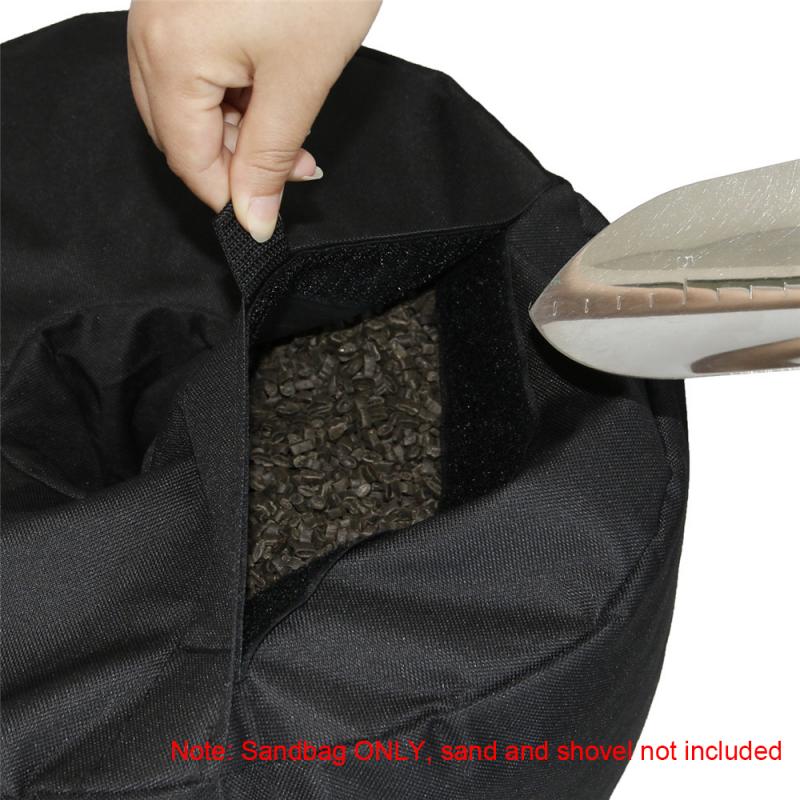

Sand as a Versatile Fill Material for Weight Bags

Sand is often the preferred fill material for anchor bags due to its versatility and adjustability. Its properties allow for fine-tuning the weight and provide natural settling that helps stabilize the canopy frame against wind gusts.

Advantages of using sand as fill material:

- Easily adjustable weight

- Conforms to bag shape, reducing shifting

- Provides natural settling against wind forces

- Doesn’t leak quickly if bag is punctured

How can you efficiently fill bags with sand? To minimize mess and speed up the process, fill an auxiliary container like a 5-gallon bucket with sand, then pour it into the bag. Remember to pack the sand down frequently to prevent air pockets and ensure accurate weight measurement.

Water as a Quick and Clean Filling Option

While sand offers adjustability, water provides a quick and clean alternative for filling anchor bags. Water’s fluid nature allows for rapid filling, making it an attractive option for those prioritizing speed and cleanliness.

Considerations when using water as fill:

- Determine water volume needed for target weight beforehand

- Mark fill levels clearly on bags

- Be aware that water weight is less adjustable than sand

- Consider potential leakage in case of bag damage

Is water as effective as sand for anchoring? While water can be equally effective in terms of weight, it doesn’t provide the same shifting and settling properties as sand. However, for most applications, water-filled bags will adequately secure your canopy.

Maintenance and Care for Long-lasting Anchor Bags

Proper maintenance of your canopy weight bags ensures their longevity and continued effectiveness. Regular care prevents wear and tear, reducing the risk of leaks or tears that could compromise their anchoring ability.

Essential maintenance tips for anchor bags:

- Inspect bags for damage before each use

- Clean bags after use, especially if filled with sand

- Store bags in a cool, dry place when not in use

- Avoid dragging filled bags on abrasive surfaces

- Replace bags showing signs of significant wear

How often should anchor bags be replaced? The lifespan of anchor bags depends on frequency of use, storage conditions, and handling. With proper care, quality bags can last several seasons. However, if you notice any signs of weakness or damage, it’s best to replace them to ensure continued canopy stability.

Addressing Common Issues with Canopy Weight Bags

Even with proper use and maintenance, you may encounter some challenges with your canopy weight bags. Being prepared to address these issues can help ensure your canopy remains secure in various conditions.

Common problems and solutions:

- Bags sliding down frame legs: Use additional securing methods like zip ties or Velcro straps

- Uneven weight distribution: Regularly check and adjust bag placement

- Difficulty transporting filled bags: Consider partially emptying bags for transport and refilling on-site

- Bags not providing enough weight in extreme conditions: Add additional anchoring methods like stakes or guy lines

Can weight bags be used in conjunction with other anchoring methods? Absolutely. For added stability, especially in severe weather conditions, combine weight bags with ground stakes, guy lines, or sandbags placed on the canopy feet.

Customizing Weight Bags for Specific Canopy Types

While Quest Canopy Weight Bags are designed to work with a wide range of canopy styles, some situations may call for customized solutions. Understanding how to adapt your weight bags for different canopy types can enhance their effectiveness.

Customization ideas for different canopy types:

- Pop-up canopies: Use bags with quick-release attachments for easy setup and takedown

- Large event tents: Consider using larger, higher-capacity bags or multiple bags per leg

- Lightweight racing canopies: Opt for smaller, more aerodynamic weight bag designs

- Beach canopies: Use bags designed to be buried in sand for additional anchoring

How can you modify existing weight bags for special applications? While it’s generally best to use bags designed for your specific canopy, you can make minor modifications such as adding extra attachment points or reinforcing high-stress areas for improved performance.

The Environmental Impact of Canopy Weight Bags

As outdoor enthusiasts, it’s important to consider the environmental impact of the products we use. Canopy weight bags, when used responsibly, can have a minimal ecological footprint compared to other anchoring methods.

Environmental considerations for weight bags:

- Choose bags made from durable, long-lasting materials to reduce waste

- Opt for eco-friendly fill materials like sand instead of synthetic options

- Properly dispose of or recycle bags that are no longer usable

- Consider bags made from recycled materials when available

Are there biodegradable options for canopy weight bags? Some manufacturers are beginning to offer weight bags made from biodegradable materials. While these may have a shorter lifespan, they can be a good option for those prioritizing environmental sustainability.

Innovative Features in Modern Canopy Weight Bag Designs

As technology and materials science advance, canopy weight bag designs continue to evolve. Modern bags often incorporate innovative features that enhance their functionality, durability, and ease of use.

Cutting-edge features in weight bag design:

- UV-resistant materials for extended outdoor use

- Quick-drain valves for easy emptying of water-filled bags

- Reflective strips for improved visibility during nighttime events

- Dual-compartment designs for more even weight distribution

- Integrated handles for easier transport when filled

How do these innovations improve the user experience? These advanced features address common pain points associated with traditional weight bags, making setup, use, and storage more convenient while potentially extending the lifespan of the bags.

Weight Bags vs. Other Anchoring Methods: A Comparative Analysis

While weight bags are a popular choice for anchoring canopies, it’s worth comparing them to other methods to understand their relative advantages and limitations.

Comparison of anchoring methods:

| Method | Pros | Cons |

|---|---|---|

| Weight Bags | Versatile, reusable, no ground penetration required | Can be heavy to transport when filled |

| Stakes | Lightweight, inexpensive | Requires suitable ground, can damage surfaces |

| Guy Lines | Provides stability in multiple directions | Requires additional space, potential tripping hazard |

| Sandbags | Very heavy, conforms to surfaces | Difficult to move, can leak sand |

Which anchoring method is best for your situation? The ideal method depends on factors such as location, weather conditions, and canopy size. Often, a combination of methods provides the most secure setup.

Tips for Efficiently Transporting Filled Weight Bags

One challenge of using weight bags is transporting them when filled. However, with some planning and the right techniques, you can make this process much more manageable.

Strategies for easier weight bag transport:

- Use bags with built-in handles or straps

- Invest in a wheeled cart or dolly for moving multiple bags

- Partially empty bags before transport and refill on-site

- Distribute weight among team members if working in a group

- Consider using water as fill for easier on-site filling and emptying

How can you minimize the strain of carrying heavy bags? Proper lifting techniques are crucial. Bend at the knees, keep the bag close to your body, and avoid twisting movements. If possible, use mechanical aids or ask for assistance with particularly heavy loads.

The Role of Weight Bags in Canopy Safety and Insurance Compliance

Beyond their practical function, weight bags play a significant role in ensuring canopy safety and meeting insurance requirements for events and gatherings.

Safety and compliance considerations:

- Many event venues require proof of adequate anchoring

- Insurance policies may specify minimum anchoring standards

- Proper use of weight bags can prevent liability issues from canopy-related accidents

- Documented use of weight bags can support claims in case of weather-related damages

How do weight bags contribute to overall event safety? By preventing canopy blow-overs and collapses, weight bags protect attendees from potential injuries and property from damage. They also demonstrate due diligence in creating a safe environment, which can be crucial in legal and insurance contexts.

Adapting Weight Bag Usage for Different Seasons and Climates

The effectiveness of weight bags can vary depending on seasonal changes and local climate conditions. Adapting your approach to these factors ensures year-round canopy stability.

Seasonal considerations for weight bag use:

- Summer: Use UV-resistant bags to prevent degradation from intense sunlight

- Winter: Opt for freeze-resistant materials if using water as fill

- Spring/Fall: Be prepared for sudden weather changes with easily adjustable weights

- Coastal areas: Choose corrosion-resistant hardware for salt air exposure

Should you adjust weight based on seasonal wind patterns? Absolutely. Many regions experience stronger winds during certain seasons. Increase your total anchoring weight during these periods to maintain canopy stability. Always check local weather forecasts and be prepared to add extra anchoring if needed.

By understanding and implementing these various aspects of canopy weight bag usage, you can ensure that your outdoor shelter remains secure and functional in a wide range of conditions. Whether you’re setting up for a casual backyard gathering or a large commercial event, proper use of weight bags will provide peace of mind and protect your investment in your canopy structure.

Intro: Anchor bags provide stability & prevent canopy blow-overs

Setting up a canopy tent for an outdoor event can be a tricky endeavor, especially when the wind kicks up. Even with the legs securely staked into the ground, a strong gust of wind can turn your canopy into a giant sail, lifting it up and sending it tumbling across the yard. Fortunately, there is an easy solution to keep your canopy grounded in windy conditions – anchor weight bags.

Anchor weight bags are specially designed bags that you fill with sand or water and hang on the frame of your canopy. The weight of the filled bags provides stability, so your canopy stays put even during blustery weather. If you’ve ever struggled to keep your canopy from blowing away or had it take flight with your belongings still under it, then anchor weight bags are a must-have accessory.

Size Matters – Pick the Right Bags for Your Canopy

Anchor bags come in a variety of sizes, so you can get bags that are tailored to the size of your canopy. Make sure to get bags that are recommended for the square footage of your canopy tent. Undersized bags won’t provide enough anchoring force. Oversized bags will be unnecessarily heavy and hard to hang on the frame.

Most canopy weight bag manufacturers provide sizing charts that match bag sizes to canopy sizes. These specifications take into account factors like the canopy fabric weight, frame strength, and typical wind conditions. Following the recommendations ensures your anchor bags provide optimal stability.

Some people use multiple smaller bags spaced around the canopy rather than fewer larger bags. This allows you to distribute the weight more evenly and provides more anchoring points. Just make sure the total weight used meets the canopy maker’s guidelines.

Weight Watchers – Calculate How Much You Need

In addition to getting the right sized bags, you also need to use the recommended total amount of weight for your canopy. The manufacturer’s specs will give a weight range, usually 20-35 lbs per leg. This translates to 80-140 lbs total for a typical 10′ x 10′ 4-legged canopy.

Start on the higher end of the range if you expect very windy conditions or have a larger canopy. Insufficient weight can still allow the canopy to blow away. Too much weight makes the bags overly cumbersome to hang and transport.

Keep in mind the weight is for filled bags. The empty bags themselves weigh just a few pounds. Measure out the sand or water needed to achieve the target total weight. Sand makes it easier to fine tune the amount compared to water.

Location, Location, Location – Strategically Place Bags

Where you hang the anchor weight bags on the canopy frame can affect their effectiveness. Typically bags are placed about halfway down the length of each leg. However, you may get better leverage and pull by positioning them farther out toward the feet of the frame.

Distribute the total weight evenly among all the legs. If the canopy is on uneven ground, put slightly more weight on the uphill legs to counteract the angled forces. Adjust bag placement as needed if you notice stress on specific corners of the canopy during wind gusts.

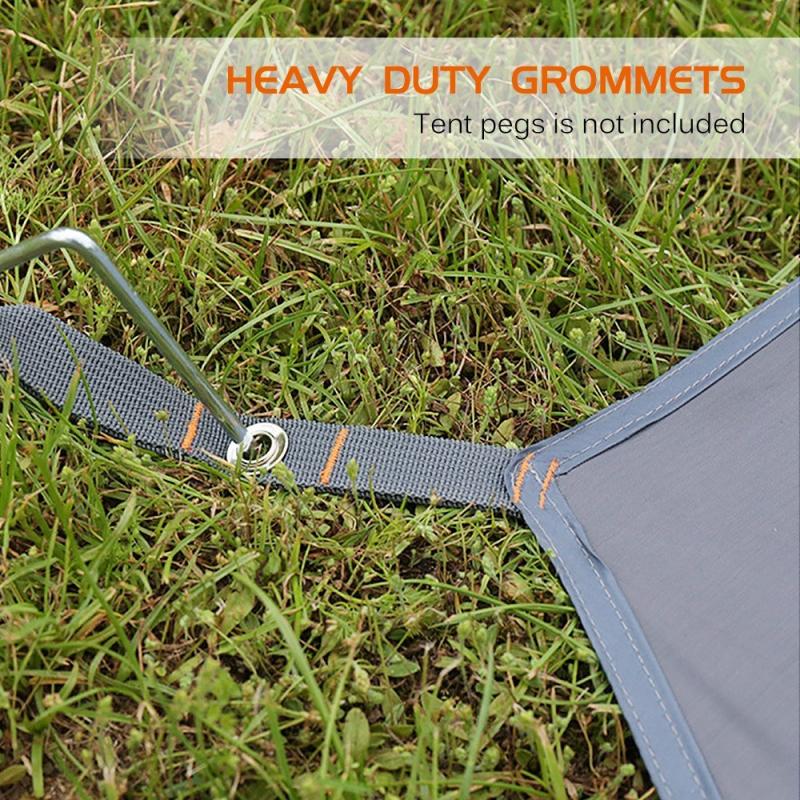

Hang Time – Use the Built-In Loops

Quest and other brands design canopy anchor bags with convenient loops and hooks to easily attach them to the tent frame. Simply slide the loop opening over the frame pipe and let the bag dangle. For frames with thinner legs, wrap the attached hook around the pipe to keep the bag from slipping down.

Attaching them this way allows the bags to hang freely rather than sitting on the ground. This prevents abrasion damage to the bag that could cause leaking or tearing. It also keeps the weight fully anchored rather than sliding around.

Sand Savvy – Fill With Adjustable Weight

Sand is the preferred fill material for anchor bags because it allows you to adjust the weight. Start by filling each bag about 2/3 full, then hang them from the frame and add more sand until you get the estimated total weight needed.

Pouring sand through the fill opening can be slow and messy. An easier method is to fill an auxiliary container like a 5-gallon bucket, then pour from that into the bag. Packing the sand down frequently prevents air pockets.

Sand conforms around the bags better than water. It also provides shifting weight that naturally settles the canopy frame against gusts. Just be sure to get sand free of debris to prevent wear and tearing of the bag material.

Water Works – Fill For Quick Weighting

Filling the anchor bags with water is quicker and cleaner but doesn’t allow adjusting the amount. Determine how much water volume is needed to achieve the recommended weight before filling. Mark the fill level clearly on the bags with tape or permanent marker.

While water can leak out of damaged bags, the leakage rate is typically slow enough that it shouldn’t significantly reduce the weight during a single use. Always inspect the bags for leaks before reusing them.

Water-filled bags provide a consistent static weight. The lack of shiftability can be an advantage or disadvantage depending on wind conditions and how secured the canopy legs are.

Mix and Match – Water and Sand for Custom Weights

You can also fill the anchor bags with a combination of sand and water. This gives you the ability to fine tune the weight while reducing mess and effort compared to pure sand.

Fill the bottom half of the bag with water up to the halfway mark. Then pour sand into the upper half and shake the bag to settle it in. The water provides a stable base weight while the sand conforms around for additional adjustable weight as needed.

When mixing fill materials, mark the water line clearly so you don’t overfill. And remember to account for the weight of both sand and water toward the canopy’s total recommended ballast weight.

Protect That Fabric – Avoid Abrasions

Inside the tough outer shell, quality anchor bags have a softer inner liner or coating to prevent abrasion damage to the canopy fabric. Dragging a rough textured bag across the tent top during installation or removal can literally shred the canopy material.

Quest bags feature a super soft fleece fabric layer that keeps the abrasive sand from causing wear. Other brands may use a protective polymer coating or plastic liner for the same purpose. Even with protectors, slide the bags into position rather than dragging for best results.

UV Resistant – They Won’t Degrade from Sunlight

Canopy anchor weight bags have to withstand long term outdoor usage under the sun’s UV radiation. Standard bags use UV-resistant materials that won’t degrade or become brittle with extended exposure.

Bags made from vinyl, canvas, polyester, or specially treated fabrics will maintain their integrity season after season. Don’t use makeshift plastic bags or sacks that can become weakened, split open, and leak over time.

Be sure to check the manufacturer’s specs for information on the bag’s UV resistance levels and expected usable life. Quest bags are engineered for resistance up to 1200 hours of UV which equates to 1-2 years of average use.

Heavy Duty – Durable Bag Construction

Between holding heavy weight, dragging on the ground, and getting banged around during transport, anchor bags take some abuse. Quality bags are made with robust outer shell materials and heavy-duty reinforced seams to withstand the forces.

Look for bags made out of vinyl, canvas, polyester, or cordura nylon fabrics that resist tearing and abrasion. Make sure the stitching, straps, handles, and fill spouts are strongly constructed and securely attached.

Pro tip: Place a piece of cardboard between the fabric and frame pipe during use to prevent rubbing damage to the shell over time.

Stash The Stakes – Convenient Storage

Most anchor weight bags include extra pockets and sleeves to hold canopy stakes, ropes, and tie downs when not in use. This keeps all your essentials in one place for transport rather than jumbling around loose.

Some bag sets even include the required stakes and provide organized storage for them. Having spare stakes already on hand ensures you can fully secure the canopy if any get damaged or lost.

Tie it Down – Integrated Straps Keep Bags in Place

For keeping the anchor weight bags themselves firmly attached to the frame, look for bags with built-in tie down straps. These allow securing the top of the bag to the pipe to prevent swinging motion or sliding.

Loop the strap around the frame and fasten the buckle back onto itself. Leave a little slack so the hanging bag can still sway and shift weight slightly against wind gusts.

Properly tightened straps also keep the frame pipe from vibrating against the fabric, eliminating noise and wear.

Go The Distance – Long Straps for Distant Legs

On certain extra large canopies, the support legs may extend far apart making it difficult to hang standard anchor bags from the distant feet. In this case, specialized extended strap bags allow you to hang the weight further down the frame pipe.

The 2-3x longer heavy duty straps on bags like the Quest Wide Span model let you position the weight right at the feet from a reachable starting point closer to the canopy top. Make sure to get enough length to reach even with the frame fully extended.

Stay Grounded – Choose the Right Bags for Wind Resistance

Don’t leave your canopy’s stability up to chance. Anchor weight bags are an essential accessory to keep your shelter grounded and prevent it from blowing away in gusty conditions.

With sand-filled bags properly hung on the frame according to the manufacturer’s weight guidelines, you can be confident your canopy will stay firmly planted. No more worrying about runaway canopies with your belongings inside.

Knowing which size bags to use, how much weight to add, and where to place them prevents canopy catastrophes. Follow these tips and weigh down your canopy the right way with quality anchor bags for performance you can trust.

Size matters: Get the right size bags for your canopy

When it comes to securing your canopy or party tent, size definitely does matter – specifically, the size and weight of the bags you use as anchors. A canopy on a windy day can turn into a dangerous projectile without enough anchoring, so getting the right canopy weight bags is crucial.

Canopy weights typically range from 15 to 40 pounds, but how do you know what’s the optimal weight for your setup? Here are some tips on getting the perfect size anchor bags to keep your canopy or pop up tent grounded in any weather:

Consider the canopy’s size

Larger canopies and tents naturally need more anchoring power than smaller ones. As a general guideline, plan on at least 15-25 lbs of weight for every leg of a 10×10 canopy. For larger sizes like 15×15 or 20×20, go with 30-40 lb bags. Having oversized canopy weight bags is better than undersized when wind is a factor.

Factor in the canopy’s height

Taller canopy legs mean more surface area catching gusts of wind. Even if your canopy is only 10×10, if the legs extend up past 8 feet tall, use heavier 25-40 lb anchor bags rated for larger tents. Top-heavy canopies act like a sail in high winds, so the extra anchoring helps keep them in place.

Consider the number of legs

The more contact points your canopy has on the ground, the more anchoring it requires. A basic 10×10 legged canopy may only need four 25 lb bags, one per leg – but a canopy with 6 or 8 legs needs a bag on each to stay grounded in windy conditions.

Factor in the weather conditions

If you’ll only be using your canopy on hot, calm days, lighter 15-25 lb bags may work fine for most setups. However, for outdoor events where blustery winds or storms are a possibility, go up a size on anchor weight to 30-40 lbs per bag to be safe. It also helps to have spare bags on hand in case you need additional anchors.

Consider the leg type

Standard straight canopy legs allow the fabric to catch more wind compared to angled or truss-framed legs. Square legs need more anchoring as wind hits the vertical fabric and tries to lift the canopy up. Angled legs divert some of that upward wind pressure, so they may not need quite as hefty of bags.

Factor in the location

Grassy fields and dirt surfaces call for the heaviest-duty anchor bags to dig into the soft soil. Sand or gravel surfaces can get by with slightly lighter weights since the legs have a firmer footing to start with. And always use the maximum recommended weight for elevated or uneven terrain where wind could catch the canopy.

When you’re shopping for canopy weights, don’t just go by a generic weight rating. Look for bags rated and tested specifically for use with canopies and pop up tents. Features like multiple metal grommets for tying each bag onto the canopy leg can make a difference in holding power.

Canvas and polyester are suitable materials, but look for thick, reinforced seams and high-quality straps. Water-resistant fabric keeps your weights working properly if left out in the rain. And make sure any fill material is dense – loose pellets or beads won’t hold up against wind shear and gravity like solid cast iron or sand fillings.

With the right size canopy anchor bags, you can confidently keep your canopy secure no matter how hard the wind blows. Don’t cut corners on weight capacity and quality – it’s worth investing in heavy-duty materials made specifically for keeping canopies grounded.

Next time someone says size doesn’t matter, tell them to try securing a party tent in a windstorm! When it comes to keeping your canopy stable, use enough muscle in the form of weight bags sized and rated for the job.

Quest Canopy Weight Bags: The 15 Ways Anchor Bags Keep Your Canopy Grounded

If you’ve ever tried setting up a canopy or pop up tent on a windy day, you know the struggle is real. A gust of wind turns your party tent into a kite, threatening to send it airborne. Sandbags, water barrels, and concrete blocks work in a pinch, but they’re awkward to move and position under each canopy leg. And makeshift weights often fail to provide enough anchoring power when the wind kicks up.

That’s where purpose-built canopy weight bags come in. Designed specifically to secure portable canopies and tents, anchor weight bags grip the ground to resist lifting and lateral forces. Anchor weights keep your canopy stable, preventing dangerous airborne mishaps and damage from wind shear. Here are 15 reasons heavy-duty tent weights like Quest’s canopy anchor bags get the anchoring job done right:

From summer thunderstorms to winter gales, high-quality canopy weights stand up to the harshest weather year-round. Quest’s bag materials shrug off rain, snow, and moisture to keep a reliable grip on the ground.

Lugging around awkward sandbags and cement blocks gets old quick. Anchor weight bags make it easy to transport and position your canopy anchors with convenient webbing handles on each bag.

For longer treks between setup spots, add a detachable shoulder strap to transform the bag into an easy-to-carry backpack-style design. Quick-release buckles attach the padded strap when needed.

Thick, abrasion-resistant canvas or polyester stands up to outdoor abuse from dirt, scrapes, and UV exposure while keeping the fill material securely contained.

Triple-stitched seams and water-repellent coatings allow Quest’s canopy weight bags to get wet without absorbing moisture that could reduce holding power.

Nylon webbing tie-down straps take serious abuse from wind stress, flexing and twisting without cracking or tearing loose under strain.

Durable brass grommets in each bottom corner won’t corrode from wet grass like steel grommets can. They provide reliable tie points for strapping each bag onto your canopy legs.

Abrasion-resistant vinyl bottom panels won’t scuff or mar delicate flooring if you need to use canopy weights indoors or on hardscapes.

When not in use, Quest’s canvas weight bags flatten to store conveniently out of the way. Built-in compression straps cinch the bag down to a slim profile.

Angled side panels and flattened base allow the filled bag to dig into grass, dirt, sand, or gravel for superior holding power on any terrain.

Fill with sand from your site for cheap ballast, or use cast iron shot for dense, multi-use fill that works equally well in any location.

Easy-to-identify bag colors indicate weight capacity at a glance. Red= 15 lbs, Blue=25, Yellow=35, Green=45. Takes the guesswork out of using the right bags in the right spots.

Quest canopy weights undergo rigorous quality testing to verify their anchoring performance in wind speeds over 50 mph.

Produced domestically in Quest’s Chicago-area facilities, these canopy anchors support American jobs and manufacturing.

Durable construction and stringent testing allow Quest to back their canopy weight bags with a lifetime warranty against defects or failure.

Don’t gamble with makeshift canopy weights when purpose-designed anchor bags make securing your shelter so easy. For proven portable canopy anchoring performance, Quest canopy weight bags check all the boxes.

Weight watchers: Calculate total weight needed for wind resistance

Setting up a canopy or popup tent for an outdoor event? Before choosing canopy weights, you’ll need to calculate the total amount of weighting force needed to keep your shelter stable in expected wind conditions.

Several factors determine how much total weight your canopy requires for adequate wind resistance. Here’s a simple step-by-step method to help calculate the right amount of canopy anchor weight for your setup.

1. Determine your canopy’s wind resistance rating

The canopy manufacturer should provide a “wind resistance” spec, usually a speed in mph. This indicates the maximum wind speed the canopy’s frame can withstand when properly secured with weights.

2. Check weather forecasts

Consult weather reports to determine the highest wind speeds expected during your canopy’s setup timeframe. Gusts are more important than sustained winds when calculating wind force.

3. Compare wind resistance vs. forecast

If the forecast gust speed exceeds your canopy’s rated resistance, you’ll need more weighting as a safety margin. Add 10-20% of the rated capacity to handle stronger gusts.

4. Calculate total wind force

The force exerted by wind increases exponentially with speed. To calculate the total force, take the maximum wind speed squared, then multiply by the canopy’s vertical surface area.

5. Determine required resistance force

The anchoring system must exert an equal counterforce to withstand the calculated wind force. This determines the total weight needed for stability.

6. Factor in angle of pull

Since wind rarely hits straight on, the anchors need extra counterforce. Multiply the needed resistance force by 1.5x to account for angles.

7. Divide weight between anchors

Spread the total weight evenly between the number of anchor points (one per canopy leg). Heavier weights near the upwind legs can provide extra security.

8. Choose appropriate anchor weights

Select canopy weight bags sized to handle the weight load per leg. For example, 4 x 50lb bags or 8 x 25lb bags for a 200lb total weight.

Let’s walk through an example using some actual numbers:

Canopy wind resistance rating: 50mph

Forecast gust speed: 60mph

Canopy surface area: 100 sq ft

60mph exceeds 50mph rating, so we’ll add 20% as a safety margin. 60 x 1.2 = 72mph for our wind speed calc.

Wind force formula with sample numbers: (Velocity 72^2) x Area 100 = 51840 force units

We need an anchor system to exert 51,840 force units x 1.5 for angles = 77,760 force units.

With 4 anchor points, that’s 77,760 / 4 = 19,440 force units per leg

Since each pound of weight exerts 1 force unit, we’ll need ~19,440 lbs of total weight capacity.

Using 40lb bags, that’s 19,440/40 = 486 bags needed.

So for our example 100 sq ft canopy in 60mph gusts, we’d need 486 lbs of total weight or ~120 lbs per leg. Getting the math right ensures your canopy stays grounded!

Always err on the side of extra anchoring capacity. Wind conditions can change rapidly, putting additional force on your shelter. Investing in quality steel or sand-filled canopy weights sized for the conditions gives you a critical safety margin.

With the right amount of anchoring weight calculated using wind speed, canopy size, and weather data, you can set up your event tent with total confidence that it will withstand whatever winds come its way.

Quest Canopy Weight Bags: 15 Reasons Anchor Bags Outperform Makeshift Weights

When securing a party tent or popup canopy, it’s tempting to save money by using improvised weights like cinder blocks and sandbags. But makeshift anchors are a false economy that too often fail to hold when the wind kicks up.

Purpose-designed canopy weight bags may cost more upfront, but they deliver vital advantages that actually save you money in the long run. Here are 15 reasons to choose anchor weight bags over improvising weights:

Quality weight bags are rigorously tested in controlled wind simulations to verify anchoring performance. No guesstimating holding power.

Bags are rated and labeled by exact weight, ensuring you get the right anchoring force where you need it.

Consistent form factor spreads weight evenly across the base, maximizing resistance to lifting forces.

Structured bags maintain position before filling, unlike loose materials that blow around.

Wide opening and durable construction allow easy filling with sand or other ballast from the setup location.

Integrated handles make positioning each bag quick and simple compared to bulky blocks.

Sandbags must be filled in place. Weight bags can be positioned empty then filled.

Bags shape themselves around grass, gravel, etc. unlike rigid blocks.

No chance of concrete blocks breaking over time and reducing weight-bearing capacity.

Won’t scratch or chip polished stone and concrete like cinderblocks can.

Fill with sand then empty out after, or use reusable steel shot that works anywhere.

Bags flatten for easy space-saving storage compared to bulky rigid weights.

Heavy canvas construction withstands years of use and can be patched if damaged.

Integrated straps and grommets keep bags firmly attached to the canopy framework.

Keeping your shelter grounded in wind avoids expensive canopy replacement costs.

Don’t gamble your canopy investment on makeshift solutions. Get guaranteed performance with canopy weight bags designed by anchoring experts.

Location, location: Place bags in strategic spots on frame

You’ve got the right size canopy weight bags for your shelter, but where you position them matters just as much. Stragetically placing anchor weights on key points of the canopy’s framework multiplies their holding power.

Follow these tips to distribute canopy anchor bags where they’ll have the greatest impact in keeping your structure stable.

Upwind legs

Concentrate more weight on the two “upwind” legs facing into the prevailing wind direction. This counters the lifting force at the leading edge of the canopy.

Downwind legs

Downwind legs still need anchoring weight too, just focus the heaviest bags upwind. Lighter bags may work on the downwind side.

Windward corners

The upwind corners bear the brunt of lifting forces, so position the largest weight bags at a 45 degree angle straddling these two critical points.

Outriggers

If your canopy has outrigger poles for added stability, always place a weight bag directly on the end of each outrigger to keep them rooted.

Center points

Consider adding a bag or two at central interior frame junctions for extra security. This prevents twisting or buckling forces.

Perimeter

Spacing bags around the canopy’s perimeter provides all-around stability and redundancy if a leg anchor fails.

Leeward side

Counter sideways dragging forces by positioning bags around the downwind legs. Lighter weights may work here.

Cross-strapping

Crisscrossing straps between opposite legs anchors the entire width and prevents lofting.

Vertical strapping

Secure bags to multiple points up each leg using vertical straps for extra reinforcement against lifting.

Use all tie-downs

Make sure to use all the integrated straps and grommets so bags don’t slip or shift in the wind.

- Heaviest bags on the windward legs

- Extra weight at the upwind corners

- Bags at ends of outriggers if equipped

- Perimeter and interior bags for all-round stability

- Crisscross strapping between legs

- Secure tie-downs from multiple angles

Don’t just plop your canopy bags down randomly. Given the asymmetry of wind forces, a strategic layout optimizes the bags’ effectiveness at maximum and minimum weight.

Adapt your bag placement pattern to suit different terrain. For example, position more weight to uphill legs if on a slope. Or alternate perimeter/interior patterns between solid and soft ground.

Take time to visualize wind directionality and resulting forces on your canopy framework. Then use physics to your advantage by placing the anchoring mass right where it’s structurally needed most.

With canopy weight bags, strength is crucial but so is smarts. Let the wind do the work FOR you through strategic placement of your anchor points.

Quest Canopy Weights: 15 Clever Ways Professionals Maximize Holding Power

Experienced tents and canopy pros know every trick for getting max anchoring from their shelter weight systems. Here are 15 smart techniques they use to optimize canopy weight bags for any conditions:

Extra tie-downs low on legs prevent anchoring slippage in high winds.

Crisscrossing corner straps distributes force across the entire width.

“Sand spurs” (short sections of rebar) plunged next to bags in sand increase friction.

Plastic bucket halves filled with weights make great mini-anchors for outriggers.

Wrapping exterior legs with sand-filled buckets adds stability ballast.

Buried weights exert downward pull; great for loose or sandy terrain.

Ratchet mechanisms take slack out of straps for 100% connection.

Angle tie-downs so force presses weights into ground.

Have spare weights ready to add as needed if winds increase.

Windwalls or tent sides add backup anchors to press against.

Longer downslope legs compensate for angle and reduce strain.

Lengths of rebar hammered in next to legs increase frame grip.

With plastic barrel liners, water jugs become instant anchors.

Sand or gravel filled hose sections mold around legs.

Bungee cords allow some flex to dissipate gust shock loads.

Don’t rely solely on the weight of bags for total anchoring. Use smart leverage, redundancy, and physics to extract every ounce of stability from your canopy shelter.

When extreme winds threaten your canopy, it pays to have backup plans ready to implement. Keep an assortment of spare weights, straps, spikes, and other emergency anchors on hand.

With the right equipment and creative thinking, you can outsmart even the most challenging wind conditions. When the weather decides to misbehave, fight back with these pro tips maximize your canopy’s stability!

Hang time: Use built-in loops to easily hang bags

Getting canopy anchor bags situated just right can be a hassle without a convenient way to lift and position the heavy weights. That’s why premium anchor bags feature built-in hanging loops to simplify setup.

Key advantages of canopy weight bags with integrated hanging loops include:

Easy lifting

Loops on the top or sides give you a handy handle point to securely lift even heavy 40+ lb bags into place.

Quick positioning

Simply slip a hook, carabiner, rope or strap through the hanging loop to swiftly maneuver the bag exactly where you want it.

Leave hands free

With the bag suspended from hardware, both hands are free to finesse final placement and attach tie-downs.

Adjustable levels

Hanging the bags allows raising them off the ground to clear obstacles during positioning.

Cinches tightly

Hanging by straps or cords takes slack out for an ultra-snug fit against the canopy leg.

Adapts orientation

Freely rotating hanging bags conforms flush to angled or irregular leg profiles.

Reduces strain

Lifting from above is easier on the back than bending and lifting bags directly.

Speeds tear-down

Quick-release hanging allows fast clean-up and strike by simply unhooking bags.

Prevents slipping

Hanging bags eliminates shifting and sliding that could loosen tie-downs.

Allows stacking

Bags can be hung in layered pairs for extra weight on a single leg.

- Use carabiners or S-hooks for quick attach/detach.

- Keep spare lengths of rope or cordage on hand.

- Hang bags BEFORE filling for easier lifting.

- Cinch the hanging strap tightly.

- Visually confirm the bag can’t shift or twist.

- Consider pairing extra hanging loops or straps.

- Stack additional hung bags as needed.

Built-in lifting loops transform flat, awkward sandbags into easily positioned canopy anchors. Just clip on and hoist into place!

With hanging loop bags, one person can safely and quickly configure even large shelter systems with total control over weight placement. No more herniating yourself juggling bulky blocks and bags!

Don’t underestimate the setup advantage of a thoughtfully designed integrated hanging loop system. It pays back the cost many times over in hassle-free handling and precision placement of canopy weights exactly when and where you need them.

Quest Canopy Anchor Weights: 15 Reasons Loops And Straps Outperform Makeshift Weights

Need to anchor your popup canopy or large tent against wind? You could try weighting it down with random chunks of concrete, barrels, or sandbags. But makeshift anchors are far inferior to purpose-designed canopy weights like Quest’s innovative hanging loop bags.

Here are 15 reasons Quest’s integrated loop and strapping system beats DIY weights every time:

No guesswork – bag ratings guarantee exact amounts of force applied where needed.

Certified performance against wind speeds up to 65 mph.

Consistent form spreads force evenly across the base.

Makes positioning heavy bags easy with hands-free hanging capabilities.

Secure straps and grommets cinch tight to prevent slipping.

Structured design maintains position until filled.

Moldable canvas flexes and shapes around contours.

No chance of concrete fatigue and splitting over time.

Avoid scratched floors and dented stone from hard objects.

Use sand then empty out, or permanent steel shot fillings.

Easy to transport and store compared to bulky rigid anchors.

Shed rain, snow, and moisture while retaining fill weight.

Flattened bags minimize off-season space requirements.

Heavy-duty canvas withstands years of reuse and can be patched if damaged.

Keep your shelter secure in wind events to avoid replacement costs.

Get versatile, convenient canopy anchoring without the compromises and uncertainties of DIY weights. Quest’s integrated loop and strap system checks all the boxes for adaptable performance and ease of use.

Sand savvy: Fill with sand for adjustable weight

While some canopy weight bags come pre-filled at a set weight, sand fillable bags offer versatility to customize the exact amount of ballast you need.

Filling anchor bags with sand on-site lets you dial in specific weights to match changing wind conditions. Here’s how to use sand-fillable canopy weights like a pro:

Scope out local sand

Check around the setup area for easy access to free sand – beaches, volleyball courts, playgrounds, or hardware/landscape stores if needed.

Estimate volume needed

Do the math on how much sand it will take to reach your target bag weight based on sand’s ~100 lbs per cubic foot density.

Bring spare fill containers

Have collapsible buckets, empty bags, and 5-gallon pails for transporting loose sand to the canopy location.

Fill bags before positioning

Easier to fill bags while flat on the ground, before hoisting into place under the canopy.

Pour carefully and evenly

Add sand gradually across the bag’s area to optimize stability. Don’t just dump in one spot.

Tamp down while filling

Use a stick, dowel, or rebar to frequently tamp down the sand to eliminate voids and air pockets.

Top off for level surface

Overfill slightly to create a flat top profile for maximum ground contact area.

Refill periodically

Check and replenish bags throughout the event as sand settles and compacts down.

Empty thoroughly afterward

Take time to fully empty all residual sand out before transporting bags.

Hose off any sticky sand

Blast bags with water to remove any remaining damp sand before it has a chance to solidify.

With practice, you’ll get a feel for precisely how much to fill bags to hit needed weights. Just remember to account for packing density and periodic topping off as the sand grains settle.

One tip for gauging fill amounts is to use color-coded bags dedicated to specific weight ranges – like red for 15 lbs, blue for 25 lbs, etc. Then fill until you hit the target color for each leg.

Sand-fill offers the flexibility to micro-tune your shelter’s anchoring ballast. Take advantage by putting in the work upfront for safer setups and easier adjustments on the fly.

Quest Canopy Weights: 15 Clever Features That Make Sand Fill Weights Superior

Sandbags are a popular DIY approach for weighting down canopies and tents. But generic sacks of sand pale in comparison to purpose-built fillable canopy anchor bags.

Engineered sand fill weights like Quest offer unique advantages for customizable portable shelter anchoring:

Wide spout designed to facilitate pouring from buckets and bags.

Interior baffle prevents splashing out as bags are filled.

Integral rigid shaft for packing down sand to maximize density.

Interior stripes indicate progress toward overall weight rating.

Fill lines allow precise partial volume filling to hit exact weights.

Interior divider creates separate fill compartments for tuning weight bias.

Spout-shaped bag facilitates pouring from bulk containers.

Built-in loops allow bags to hang for easier positioning and filling.

Molded bottom slides smoothly over grass and terrain when positioning.

Protective flap keeps sand out of zipper teeth when filling.

Tough outer panels resist scuffs and wear during handling.

Mesh panel allows water drainage to keep interior sand dry.

Built-in sleeve holds handle of shovel/trowel for easier filling.

Heavy duty straps and grommets cinch tight to frame.

Rated to maintain advertised weight even after compression settling.

Don’t settle for leaky utility grade sandbags. Purpose-designed fillable canopy anchor weights deliver customizable precision ballast for serious portable shelter stability.

Water works: Fill with water for quick weighting

For a fast and convenient canopy anchoring solution, try filling weight bags with water. At 8 lbs per gallon, water offers an instantly adjustable ballast option.

Water-fillable canopy anchor bags make setup and strike a breeze. Here are some tips for harnessing the versatility of liquid ballast:

Use durable waterproof bags

Ensure bags are fully waterproof with sealed seams to prevent leaks and soggy interior padding.

Line bags before filling

Trash bags or reusable liners contain splashing and protect interiors from moisture damage.

Estimate volume needs

Figure required gallons based on total weight needed divided by 8 lbs per gallon.

Mark fill levels

Use tape or permanent marker to note volume increments to hit specific weights.

Fill with a hose

For large volumes, a hose allows fast filling without heavy lifting.

Top off as needed

Check bags throughout the day and add water to restore lost volume from splashing.

Drain thoroughly afterward

Open all zippers and use a wet-dry vac to empty bags completely before storage.

Let bags dry completely

Allow time for any residual moisture inside to fully evaporate to prevent mold.

One tip when calculating needed fill amounts is to figure total canopy weight required, then add ~20% more volume to account for sloshing and splashing.

For large events, consider running a hose with splitter ends to allow easy top-offs for multiple water weight bags as needed.

While quick and convenient, be aware that water lacks the more stable density of materials like sand or steel shot. But for temporary setups, water fill gets the job done!

Quest Canopy Anchor Weights: 15 Key Benefits of Water Fillable Design

Filling canopy anchor bags with water may seem crude compared to sand or steel fill models. But water-fillable weights offer unique advantages:

Flows and fills even intricate bag shapes for maximum usage of interior space.

Just minutes to fill dozens of gallons using standard hoses.

Add or remove exact amounts of weight by managing water volume.

Minimal physical effort to fill numerous bags using hoses and funnels.

Fluid naturally self-levels for uniform base contact and stability.

Water source almost always on-site to minimize transport logistics.

See-through bags let you monitor volume at a glance.

Split into compartments, bags can hold combination of materials.

Simply add water on the spot if bags lose volume from splashing.

Dual interlocking zipper track prevents any drips or spills.

Inner liners contain liquid movement to limit shifting.

External drain valves allow full evacuation of contents.

Nothing to haul away – water leaves no messy residue behind.

Tough ultraviolet-blocking fabric prevents sun damage.

No steel components to corrode from moisture exposure.

Water-fillable canopy anchor weights combine flexible ballast capacity with the ultimate convenience in quick setup and strike. Add water, weight down!

Mix and match: Combine sand & water for custom weights

Why choose between sand vs. water for filling canopy anchor bags? Savvy pros use both for the ultimate in adjustable custom weighting.

Hybrid sand and water fill allows fine-tuning bag ballast for any situation. Here’s how to blend these elements like a pro:

Use multi-compartment bags

Bags with interior baffles let you allocate separate sections for sand and water.

Fill sand first

Pouring sand provides a semi-solid base layer before adding liquid.

Level and tamp sand

Pack down sand flat and tight before dividing off compartments.

Add water top layer

Fill water in remaining compartments to take advantage of conforming liquid pressure.

Adjust water for fine tuning

Drain or add water volume to tweak total bag weight up or down.

Check bag balance

Heft bags to ensure even weight distribution before anchoring down.

Replenish both as needed

Top off sand and water throughout event as contents settle and compact.

A 60/40 or 70/30 sand to water ratio provides a good stability compromise for most conditions. But customize ratios to suit your specific needs.

During setup, fill a few test bags with different sand/water combos to empirically find your optimal blend for performance and handling.

Hybrid dual-density filling couples the stability and absorption of sand with the convenience and adjustability of water fill. The best of both worlds!

Quest Canopy Anchor Weights: 15 Reasons We Use Both Sand and Water Fill

Here at Quest, we design our canopy anchor bags to exploit the unique advantages of both sand AND water fill:

Moldable sand grips leg profile while water conforms to interior.

Fluid self-levels for uniform density and base contact.

Mix and match fill amounts to hit exact total weights.

Water topping compensates as sand compacts down over time.

Dial in the precise sand/water percentage that suits each use case.

Semi-solid sand base strengthens shifting resistance.

Separate sand and water drain valves for independent emptying.

Pre-filled sand minimizes water movement.

Watertight construction prevents leakage of any contents.

Change fill ratios on the fly to adapt weighting.

Sand soaks up excess ambient moisture.

Low center of gravity from dense sand base.

Pre-filled sand minimizes load shifting during transport.

Dissipates sharp force spikes from shifting liquid.

On-site water source in case of shortage.

When leveraged thoughtfully, combined sand and water fill amplifies the strengths of each for truly superior customizable canopy anchoring performance.

Protect that fabric: Avoid abrasions with soft exteriors

Rough, abrasive surfaces on canopy weight bags can rub through and damage expensive canopy fabric over time. Protect your investment with soft-shell exterior anchor bags.

Choosing anchor weights with scratch-free exteriors prevents premature canopy deterioration:

Prevents pilling

Smooth exterior won’t pull and pill delicate canopy fabric like abrasive coatings.

Reduces snagging

Non-abrasive surfaces prevent fabric snags that could tear over repeated setups.

Minimizes friction damage

Soft shells won’t rub through canopy skin from anchor forces and movement.

Maintains waterproofing

Prevents abrasions that could compromise water-resistant coatings and seams.

Saves on cleaning

Won’t transfer difficult dirts and soils onto light canopy materials.

Extends canopy life

Prevents premature replacement by protecting fabric integrity over repeated uses.

Uniform gentle contact

Soft draping shells conform to canopy skin without concentrated pressure points.

Polyester suede, microfiber, and brushed tricot shells are excellent smooth yet tough outer bag materials to consider.

Also look for flattened contact surfaces and rounded corners to maximize uniform spread of anchoring forces.

Your expensive canopy is a long term investment. Protecting the supple fabric from damage ensures years of continued use and enjoyment.

Quest Canopy Anchor Bags: 15 Features That Prevent Abrasion

Anchor weight bags need abrasion protection too – if shell materials are too rough, they can actually damage the expensive canopy tent fabric. Quest maximizes scratch-free properties with:

Proprietary woven blend with zero pilling or abrasion.

Gently buffers and glides across fabric surfaces.

Dense plush fleece prevents texture snagging.

No sharp edges to catch or groove into material.

Extra thick cushions distribute anchoring force uniformly.

Textured pattern minimizes concentrated shear forces.

Reduces friction and recenters bags if bumped or shifted.

Low-drag panels ease weighting into position.

Evenly spreads and suspends internal fill for equalized outward pressure.

Allows trapped air circulation to prevent vacuum suction friction.

Provides smoothness when rubbed in any direction against fabric.

No exposed abrasive teeth surfaces to snag material.

Eliminates sun damage that could make surfaces brittle and rough.

Stops water wicking into stitches that could stiffen and abrade.

Restores bag pliability and removes any particulate that could scratch.

Don’t let abrasive weight bags damage your canopy asset. Quest’s comprehensive abrasion innovations extend your shelter’s useful life.

UV resistant: Bags won’t degrade & leak from sun exposure

Long term outdoor use can cause canopy weight bags to degrade, crack, and leak over time. Choose UV-resistant anchor bags for long lasting performance.

UV-blocking materials prevent canopy weight bag failure by:

Preventing brittleness

UV rays won’t dry out and embrittle bag fabrics causing tears.

Blocking sun damage

Specialized coatings reflect and diffuse harmful solar radiation.

Maintaining flexibility

Won’t stiffen in cold weather after UV exposure like untreated bags.

Stopping photo-oxidation

Prevents molecular breakdown from solar energy absorption.

Retaining proper fill

No degradation or leakage of bag contents from cracked shells.

Extending lifespans

Bags won’t need replacement due to material failure nearly as often.

Maintaining appearance

No fading or discoloration over years of sun and weather exposure.

Look for thick, ripstop canvas shell materials along with vinyl film overlays to provide full UV protection.

Reinforced seams are also crucial, since stitching holes are common failure points on inferior bags.

Don’t get stuck replacing canopy weight bags every year due to premature sun damage. Choose ultraviolet-resistant models for lasting performance.

Quest Canopy Anchor Weight Bags: 15 UV-Blocking Features

Our canopy weight bag design leverages comprehensive UV resistance technologies:

Proprietary interlaced polymer matrix reflects & absorbs solar radiation.

High-tensile UV-resistant stitching won’t degrade or leak.

Dual stitch rows prevent seam failure or separation.

Heavy duty metallic teeth won’t crack from solar exposure.

Double layered flaps prevent UV damage to zipper coils.

High-tech interior layer amplifies UV resistance of shell.

Thin transparent overlays add supplemental UV protection.

Woven polymer cargo straps resist UV deterioration.

Multi-layer material prevents seam failures.

Waterproofing retains material pliability to resist cracking.

Bindings protect vulnerable fabric edges from solar exposure.

Composite technical fabrics resist photonic breakdown.

Prevents airborne chemical damage from combining with solar effects.

Adhesives resist UV-catalyzed oxidization failure.

Confidence that materials will maintain UV resistance over years of use.

Don’t leave canopy anchors exposed to sun damage. Quest’s cutting edge UV-blocking technologies extend usable life so you get the most value.

Heavy duty: Durable construction stands up to elements

Canopy weight bags face harsh conditions like abrasion, moisture, and UV exposure. A durable heavy duty build ensures seasons of reliable use rather than rapid failure.

Look for these hallmarks of quality construction in your anchor weight bags:

Industrial grade fabrics

Thick, densely woven canvas shells resist tearing and abrasion.

Reinforced seams

Bindings, double stitching, and seam tape prevent seam failures.

Weatherproof coatings

Water-repellent finishes maintain integrity when wet.

Abrasion resistance

Tough exterior face stands up to scrapes without pilling or shredding.

Rustproof hardware

Aluminum, stainless steel, and brass components won’t corrode.

Heavy stitching

High strength bonded thread resists seam tear loose.

Multi-layer corners

Box-stitched high wear points prevent seam failures.

Also inspect small details like zipper coils, buckle castings, and interior linings. These are often weak points on cheaper bags.

Handles in particular take abuse, so check for thick webbing that won’t rip loose or tear hands.

When you need shelter anchors to perform for years instead of just one season, heavy duty durable construction is essential.

Quest Canopy Weight Bags: Built Tough for the Elements

Our canopy anchor bags are designed and built to take seasons of abuse. We overconstruct critical components to outlast cheap imports.

Interlaced triple box-stitched seams prevent blowouts.

Nylon edge binding prevents corner fraying.

Oversized coils resist jams and deformation.

Tightly interwoven grip area prevents tearing.

Tough inner layer maintains bag shape when empty.

External patches at stress points prevent premature wear.

Redundant stitch rows maintain strap integrity.

Let you monitor abrasion points and detect issues early.

Reduce hardware abrasion on fabric by distributing load.

Bonds upper layers together for uninterrupted shell strength.

Robust grommet-mounted rings prevent pullout failures.

Cushioned grip fusing prevents interior separation.

Formed pan shape maintains structure when loaded.

Heavy urethane coating and sealed seams prevent interior water damage.

Our bags meet military equipment durability and longevity standards.

Don’t settle for disposable consumer-grade canopy weights. Our purpose-built strength and durability deliver the longevity you expect from a premium anchoring solution.

Stash extra: Convenient storage for canopy stakes

Tent stakes are crucial for securing your canopy, but easy to misplace between setups. Clever anchor weight bags solve this with integrated storage pockets to keep stakes handy.

Weight bags with designated stake storage offer these advantages:

Quick access

Stakes always right there when you unpack the weights before setup.

Prevents loss

No more searching for missing stakes that have disappeared in transport.

Customizable sizes

Pockets and retainers accommodate stakes of all sizes.

Secures loose items

Elastic loops and closures keep stakes from falling out in transit.

Simplifies packing

Everything for setup stowed in one place – no missed items.

Doubles as mallet storage

Pockets can also store metal tent stake hammer for driving pegs.

Look for strong elastic loops or sleeve pockets sized to friction fit your specific canopy stakes. A Velcro or snap flap keeps contents secure.

Durable fabrics that won’t rip are critical – you don’t want stakes poking holes or tearing out of the storage pocket.

Consolidate your setup equipment and make staking fast & easy with purpose-designed canopy weight bags having integrated stake storage.

Innovative Stake Storage Features on Quest Canopy Weights

We’ve designed industry-leading integrated storage solutions into our weight bags to keep canopy stakes organized and protected:

Split side allows removing just one stake quickly when needed.

Solid panel prevents bag content punctures.

Bungee loop secures hammer end of combination stake/hammer tools.

Structural rigid sleeve retains stake bundle shape.

Web loops allow lacing stakes together so they stay organized.

Dual zippers allow accessing contents without removing from sleeve.

Plush finish prevents scratching of stake surfaces.

Cinches compartment securely closed.

Exterior lash points for additional loose stakes.

Bartacked stress points prevent seam failures.

Snug elastic pouch front keeps stakes from bouncing free.

Strong embedded magnet keeps flap sealed.

Lets you instantly see contents to verify stake count.

Swiveling carabiner retains hammer stakes.

Let you identify proper pocket at a glance.

Stop wasting setup time searching for missing stakes. Our purpose-designed storage pockets keep your staking supplies organized, protected, and ready to deploy.

Tie down: Integrated straps secure bags in high winds

A canopy weight bag won’t do much good if it gets blown around by gusts. Look for anchor weights designed with integrated straps to keep bags firmly cinched to tent legs.

Built-in tie-down strapping provides key benefits compared to improvised fasteners:

Won’t loosen or slip

Proper straps are engineered to resist relaxing over time.

Distributes force evenly

Disperses wind pressure across multiple anchor points.

Custom attachment angles

Threaded daisy chains allow tuning tie direction to the forces.

Speeds setup/teardown

No messing with makeshift cords – just strap and go.

Designed integration

Tie-down points are strategically located for ideal function.

Backup stability

Extra assurance if primary leg attachments fail.

Look for sturdy sewn-in webbing rated for heavy loads. Steel grommets at connection points prevent tearing.

The best straps have triglides that let you slide to adjust fit and cinch tight.

Purpose-built integrated tie-downs are critical load-bearing components. Don’t trust your canopy stability to makeshift straps.

15 Key Tie-Down Strap Features of Quest Canopy Weights

We design our integrated anchor straps for the demands of professional canopy stabilization in adverse conditions:

Vastly exceeds the forces exerted by any canopy winds.

Overbuilt with abrasion-resistant redundant strands.

bartacked webbing-to-shell junction prevents tearout.

Let you really crank down strap tension.

Webbing won’t deteriorate or unravel from constant load flexing.

Dissipate dynamic wind gust spikes for stable anchoring.

Recessed box channels prevent grommet pullthrough.

Threaded straps allow custom directions of pull.

Facilitate strapping bags together or connecting to legs.

Rugged slip-locking design for confidence under load.

Comfortable on hands and prevents strap slippage.

Live load testing proves strap strength over years of service.

Won’t degrade from repeated outdoor exposure.

Allows field repairs or extensions using common parts.

Attach points allow tuning strap direction to wind vectors.

Get ultra-strong, strategically designed tie-downs purpose-built to keep canopy weights firmly anchored in any storm.

Go the distance: Long straps reach distant canopy legs

Standard short tie-down straps may not stretch far enough to secure weight bags to distant canopy legs. Anchor weight bags equipped with extra long straps extend your securing reach.

Lengthy tie-down straps provide important benefits:

Secure odd-sized frames

Long straps allow securing oversized and custom canopy shapes.

Link widely spaced legs

Tie opposite legs together for superior wind resistance.

Reduce strap clusters

Cleaner look with fewer straps when you can reach further.

Enhanced leverage

More strap surface area exerts higher downward forces.

Emergency backups

Cross-connect distant legs if a strap fails mid-event.

Adapts to terrain

Secure bags over obstacles and on uneven ground.

Look for tough nylon straps rated to handle heavy loads without stretching permanently or tearing.

For the longest reach, seek adjustable straps up to 10 feet long. Multiple daisy-chained segments maximize flexibility.

Go the extra distance in securing your canopy with extended tie-downs purpose-built to handle widely spaced legs.

Quest Canopy Anchor Bag Tie-Down Straps: Built Long and Strong

We engineer heavy-duty extended length strapping to provide complete shelter security:

Easily reaches even distant anchor points.

Modular interconnected 2′ sections for custom lengths.

Safety margin far beyond any expected forces.

Withstands repeated outdoor exposure without degradation.

Bartacked load junctions prevent seam ripping.

Sealed strap edges prevent fraying failure points.

Full-length elastic cord reduces slack stretch-out.

Secure anchor points from multiple pull directions.

Thick rolled edges won’t tear under load.

Slip-on sheaths prevent abrasion damage.

Robust sliders for maximum strap cinching.

Quick visual identification of strap capacity.

Recessed daisy chain protects inter-linkages.

Materials and techniques proven in critical military uses.

Grommets, loops, and clips suit any lashing configuration.

Stretch your shelter securing reach with the adjustable length and rugged strength of our trusted extended strapping solutions.

Stay grounded: Keep canopy stable with right anchor bags

A portable canopy can quickly go from festive to frightening if high winds turn it into a dangerous projectile. Keep your shelter firmly grounded by anchoring it with proper canopy weight bags.

Quality anchor weights tailored for canopy use provide critical advantages:

Lab-tested reliability

Verified wind resistance against speeds far higher than typical conditions.

Strategic weight distribution

Evenly spreads force across shelter legs for maximum stability.

Customizable ballast

Fill weights let you fine-tune resistance as conditions change.

Damage resistance

Durable materials withstand outdoor elements that could degradeperformance.

Stable shape

Maintain position and anchoring geometry despite gust shock loads.

Adaptable positioning

Attachable handles and straps allow precision placement on legs.

Bags should have grommets, straps, or loops that keep them firmly lashed to the canopy framework at all times.

It’s smart to have backup anchor weights ready to add if winds kick up unexpectedly.

Don’t gamble with makeshift canopy weights – purpose-designed anchor bags deliver proven no-fly-away security.

Quest Canopy Weights – Designed to Keep Canopies Grounded

We engineer professional-grade canopy stabilization into every bag. Field-proven designs including:

Verifiably maintains position and stability in 65+ mph winds.

Molded flat profile maximizes ground surface contact area.

Weight carried close to the ground makes shelter extremely stable.

Shells flex to maintain even weighting as contents shift.

Allow precision filling to hit optimal ballast weights.

Absorbs shocks to prevent bounce or sliding.

Bind bags immovably tight to legs using field techniques.

Proprietary goo increases friction with canopy legs.

Wings dig into surface to prevent side-to-side shifts.

Angled stabilizer fins counter forward or backward pitching.

Meets military criteria for high-wind mobile shelter stability.

Join multiple bags into integrated grids with greater inertia.

Grippy interior maintains contents in ideal position.

Retains shape and weighting geometry despite impact stresses.

Confidence in long-term reliable wind-fighting performance.

Don’t leave your shelter’s stability to chance – equip it right the first time with purpose-engineered canopy anchor weights.