How to choose the right replacement cleat studs for football. What factors to consider when selecting new studs for your cleats. Why screw-in cleats offer more versatility than molded options. How to properly install and break in new cleat studs.

Understanding the Importance of Proper Cleat Studs

Football players know that worn-out cleats can significantly impact performance on the field. Slipping and sliding due to rounded-over studs can be frustrating and potentially dangerous. Revitalizing your cleats with fresh studs can make a substantial difference in your game.

Choosing the right replacement studs is crucial for optimal performance. Several factors come into play when selecting new studs, including material, type, length, shape, and compatibility with your specific cleat model.

Metal vs. Plastic Studs: Weighing the Pros and Cons

When it comes to cleat studs, one of the primary decisions is choosing between metal and plastic options. Each material has its advantages and drawbacks:

Metal Studs

- Extremely durable, lasting through multiple seasons

- Provide excellent traction on various field conditions

- Generally more expensive than plastic options

Plastic Studs

- More budget-friendly option

- Lighter weight, potentially reducing fatigue during long games

- May wear down faster, requiring more frequent replacement

Are metal studs worth the higher price tag? For players who prioritize durability and consistent performance, metal studs can be a worthwhile investment. However, if you’re on a tight budget or prefer a lighter feel, plastic studs can still provide adequate performance at a lower cost.

The Advantages of Screw-In Cleats

When selecting new cleats or replacement studs, the choice between screw-in and molded options is crucial. Screw-in cleats offer several benefits that make them a popular choice among experienced players:

- Versatility: Easily swap out studs for different field conditions

- Customization: Adjust stud length and shape to suit your playing style

- Longevity: Replace worn studs without needing to buy entirely new cleats

While molded cleats may be lighter and require less maintenance, the flexibility provided by screw-in cleats often outweighs these advantages for serious players.

Selecting the Ideal Stud Length for Optimal Traction

Stud length plays a critical role in determining traction and stability on the field. Choosing the right length can significantly impact your performance:

Longer Studs

- Ideal for soft, muddy fields

- Provide better grip in wet conditions

- May reduce stability on firm surfaces

Shorter Studs

- Best for firm, dry fields

- Offer improved acceleration and quick movements

- Provide better stability on hard surfaces

How do you determine the right stud length for your needs? Consider the typical field conditions you play on and measure your current studs before ordering replacements. Matching the length of your old studs ensures a proper fit and familiar feel.

Matching Stud Shape to Your Position and Playing Style

The shape of your cleat studs can significantly impact your performance on the field. Different positions and playing styles benefit from specific stud shapes:

Conical Studs

- Ideal for quick lateral movements

- Preferred by running backs and defensive backs

- Offer excellent maneuverability for cutting and pivoting

Bladed Studs

- Provide superior straight-ahead traction and speed

- Favored by linemen for powerful forward drives

- Offer stability for positions requiring strength and power

Hybrid Studs

- Combine elements of conical and bladed studs

- Suitable for versatile positions like quarterbacks and wide receivers

- Offer a balance of maneuverability and straight-line speed

How can you determine the best stud shape for your position? Consider your typical movements on the field and consult with experienced players or coaches in your position for recommendations.

Adapting to Different Field Conditions

Field conditions can vary greatly depending on weather, maintenance, and surface type. Adapting your cleat studs to these conditions can give you a significant advantage:

Soft, Muddy Fields

- Use longer studs with multiple conical ends

- Provides better grip and prevents slipping in wet conditions

Dry, Hard Fields

- Opt for shorter bladed studs

- Offers stability and prevents sliding on firm surfaces

Artificial Turf

- Use specialized turf studs

- Designed to grip artificial surfaces without causing damage

How often should you change your studs based on field conditions? For players with screw-in cleats, it’s beneficial to have multiple sets of studs on hand. This allows you to adjust your cleats quickly based on the field conditions you encounter on game day.

Choosing Quality Brands and Ensuring Compatibility

When purchasing replacement studs, it’s crucial to prioritize quality and compatibility:

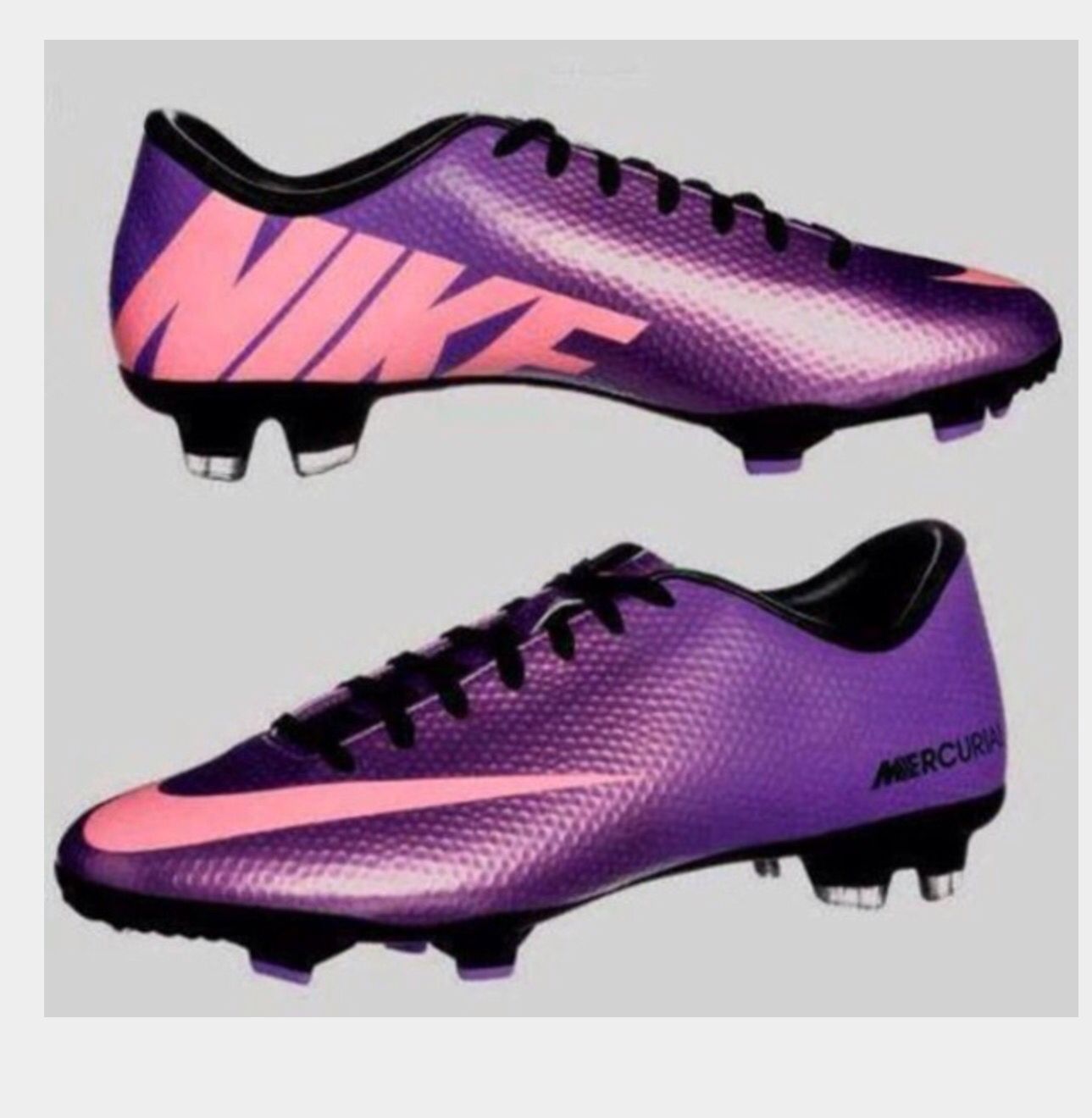

- Stick with trusted brands known for quality cleats (e.g., Nike, Adidas, Under Armour, New Balance)

- Look for studs specifically designed for your cleat model

- Be cautious of “universal” studs that may not fit properly

How can you ensure you’re getting compatible studs? Always search for replacement studs using your exact cleat brand and model number. This approach minimizes the risk of ordering studs that don’t fit correctly.

Proper Installation and Breaking In New Studs

Installing new cleat studs is a straightforward process when you have the right tools and approach:

Tools Needed

- Stud wrench (specific to your cleat brand)

- Lubricant (e.g., WD-40) for loosening stuck studs

Installation Steps

- Remove old studs using the stud wrench

- Clean the threaded holes in the cleat sole

- Insert new studs and tighten with the wrench

- Ensure all studs are securely fastened

Breaking In New Studs

New studs can be extremely sharp and may require an adjustment period. To prevent potential injuries:

- Start with light practices to get accustomed to the new feel

- Gradually increase intensity over several sessions

- Pay attention to any discomfort or unusual strain on your feet and ankles

How long does it typically take to break in new studs? Most players find that 2-3 light practice sessions are sufficient to adjust to new studs. However, this can vary based on the individual and the type of studs installed.

Maximizing the Lifespan of Your Cleat Studs

Proper care and maintenance can significantly extend the life of your cleat studs:

- Clean studs after each use, removing dirt and debris

- Check for loose studs regularly and tighten as needed

- Rotate between multiple pairs of cleats if possible

- Store cleats in a cool, dry place to prevent rust (for metal studs)

How often should you replace your cleat studs? The frequency of replacement depends on various factors, including usage, field conditions, and stud material. As a general rule, inspect your studs every few games and replace them when you notice significant wear or reduced traction.

Enhancing Performance Through Proper Cleat Maintenance

While replacing worn studs is crucial, overall cleat maintenance also plays a vital role in on-field performance:

Regular Cleaning

- Remove excess dirt and mud after each use

- Use a soft brush and mild soap for thorough cleaning

- Allow cleats to air dry completely before storage

Addressing Wear and Tear

- Inspect cleats for damage to the upper material

- Use appropriate adhesives or patches for minor repairs

- Consider professional repair for more significant damage

Proper Storage

- Store cleats in a well-ventilated area

- Use shoe trees or stuff with newspaper to maintain shape

- Avoid extreme temperatures that can damage materials

How does proper maintenance impact cleat performance? Regular cleaning and maintenance not only extend the life of your cleats but also ensure consistent performance. Well-maintained cleats provide better support, comfort, and traction, potentially reducing the risk of injuries.

Innovative Cleat Technologies and Future Trends

The world of football cleats is constantly evolving, with new technologies and designs emerging to enhance performance:

Adaptive Studs

- Studs that adjust length based on applied pressure

- Provides optimal traction across various field conditions

3D-Printed Customization

- Personalized stud configurations based on player data

- Tailored to individual playing styles and foot shapes

Sustainable Materials

- Eco-friendly cleat and stud materials

- Biodegradable options for reduced environmental impact

How might these innovations change the future of football cleats? As technology advances, players may have access to highly personalized cleats that adapt to their specific needs and playing conditions in real-time. This could lead to improved performance, reduced injuries, and a more sustainable approach to sports equipment.

The Psychological Impact of Well-Maintained Cleats

While the physical benefits of properly maintained cleats are evident, the psychological impact should not be overlooked:

- Increased confidence in movement and traction

- Reduced anxiety about slipping or equipment failure

- Improved focus on gameplay rather than equipment concerns

How does equipment confidence affect on-field performance? Players who trust their equipment are often more willing to push their limits and take calculated risks during play. This confidence can translate into improved performance and a more aggressive playing style.

Balancing Cost and Performance in Cleat Maintenance

For many players, especially at amateur levels, budget considerations play a significant role in equipment choices:

Cost-Effective Strategies

- Invest in high-quality, durable cleats initially

- Maintain cleats properly to extend their lifespan

- Consider purchasing replacement studs in bulk

Performance Trade-offs

- Assess the impact of lower-cost options on your game

- Consider the long-term costs of frequent replacements

- Weigh the benefits of premium features against their cost

How can players find the right balance between cost and performance? Prioritize the features that most directly impact your playing style and position. Invest in quality where it matters most, and look for cost-saving opportunities in less critical areas.

The Role of Proper Footwear in Injury Prevention

Well-maintained cleats with appropriate studs play a crucial role in preventing on-field injuries:

- Reduced risk of slips and falls

- Improved stability during quick movements

- Better shock absorption and foot support

How significant is the impact of proper footwear on injury rates? While exact statistics vary, studies consistently show that appropriate, well-maintained footwear can significantly reduce the risk of common football injuries, particularly those related to the lower extremities.

Adapting Cleat Choices to Player Development

As players progress in their football careers, their cleat needs may evolve:

Youth Players

- Focus on comfort and proper fit

- Consider multi-purpose cleats for various surfaces

- Prioritize affordability as feet may still be growing

High School and College Players

- Invest in position-specific cleats

- Consider multiple pairs for different conditions

- Pay attention to advanced features that enhance performance

Professional Players

- May have access to custom-designed cleats

- Often use multiple specialized pairs for training and games

- Focus on minute details that can provide a competitive edge

How should players adjust their cleat choices as they advance in their careers? As skill levels increase, players should become more attuned to the specific features that enhance their individual playing style. This may involve more specialized equipment and a greater willingness to invest in premium options that offer performance benefits.

Choose the Right Type of Replacement Cleat Studs

As an avid football player, I know the frustration of worn out cleats all too well. There’s nothing worse than slipping and sliding across the field because your cleat studs are rounded over. Revamping your cleats with fresh studs can make a world of difference in your performance. But with so many replacement stud options out there, how do you choose the right ones?

Based on my own experience replacing cleat studs over the years, here are some tips to find the ideal studs for your specific needs:

Go Metal or Plastic?

The first big choice is metal versus plastic studs. Metal studs are extremely durable and will last through seasons of play. I’ve had the same set of screw-in metal studs on my cleats for years. However, metal can be pricier than plastic. If you’re on a tight budget, plastic studs can still get the job done at a lower cost. Just know you may need to replace them more often as they tend to wear down faster in my experience.

Screw-In for Versatility

Choosing between screw-in versus molded cleat studs is another key consideration. I prefer screw-in cleats because you can easily swap out the studs whenever you want. This comes in handy when I need to adjust my studs for different field conditions. Molded cleats don’t give you that flexibility – the studs are permanent. However, molded cleats tend to be lighter weight.

Pay Attention to Stud Length

Stud length makes all the difference for getting optimal traction. Longer studs are great for really soft, muddy fields to dig into the ground. But on firm fields, longer studs may actually reduce your stability. Shorter studs are best for getting acceleration and traction on harder surfaces. Measure the old studs on your cleats before ordering replacements. Getting new studs with the same length will ensure proper fit.

Match Stud Shape to Your Position

The shape of your cleat studs should complement your position and style of play. For quick lateral movements, pointed conical studs are ideal. As a running back, I rely on conical studs to cut and pivot on the field. Bladed studs are better for straight-ahead traction and speed. Linemen who drive forward often favor bladed cleat studs. While quarterbacks and wide receivers may opt for a hybrid mix of conical and bladed studs.

Consider Your Typical Field

Factor in the usual conditions of the fields you play on too. I always get longer screw-in studs with multiple conical ends once the rainy season hits. They dig into those thick, muddy fields well. For drier harder fields, I switch to shorter bladed studs that prevent sliding around in the dirt. Turf fields may require complete different turf studs. Evaluate your usual field scenarios before picking replacement studs.

Shop Trusted Brands

When it’s time to order new replacement studs, stick with brands known for quality cleats like Nike, Adidas, Under Armour, and New Balance. I’ve had great luck finding compatible screw-in studs from the same manufacturer as my cleats. Their metal studs stand up to seasons of heavy use too. Generic discount studs may not fit properly or last as long in my experience.

Find Your Cleat Model

Speaking of proper fit, be sure to find replacement studs made specifically for your cleat model. I learned this lesson the hard way, ordering screw-in studs that were supposedly “universal”. Turns out they didn’t line up with the threaded holes on my Under Armour Highlights precisely. I had to return them. Search for your exact cleat brand and style to find guaranteed compatible replacement studs.

Use the Right Tools

Installing new cleat studs is a quick process with the proper tools on hand. You’ll need a stud wrench to safely remove the old studs and tighten the new ones. Applying some lubricant like WD-40 helps loosen up any stuck studs too. Taking your time and having the right stud wrench makes replacement easy. I keep one in my football bag at all times.

Break Them In

Finally, take it slow at first with new cleat studs. The stud tips are ultra sharp right out of the package. I made the mistake of going full speed my first practice with new studs and ended up straining my ankle. Give your body a chance to get accustomed to the feel and increased traction over a few light practices before going all out. Your ankles will thank you.

Finding the ideal replacement cleat studs involves some trial and error. But paying attention to factors like stud material, length, shape and your field conditions will set you up for success. With the right studs, you’ll be blowing by defenders in no time this season. Just take it easy while you break those fresh studs in!

Opt for Screw-In Cleats for Versatility

As a lifetime football player, I’ve gone through my fair share of cleats. And when those studs wear down, I’ve learned that screw-in cleats are the most versatile option for replacing them. Here’s why switchable screw-in studs can optimize your performance in any conditions.

In my early days, I used molded cleats with permanent studs. They served me well for a season or two until the studs rounded over. When it came time to replace them, I decided to try screw-in cleats instead. It opened up a whole new level of customization that I soon realized was crucial for adapting to different fields.

Adjust Your Studs on the Fly

The main perk of screw-in cleats is the ability to swap studs whenever needed. Heading into a big rainy game? I can quickly screw in longer studs for more traction in the mud. Then for dry conditions, I’ll opt for shorter studs that grip the firm ground better. With molded cleats, you’re stuck using the same studs in any situation.

Optimize Your Studs for Each Position

I also love that I can customize my studs as I transition between positions. As a running back, pointed studs are ideal for cutting and changing direction. But when I switch to receiver, I may opt for more bladed studs to maximize speed and acceleration off the line. The flexibility of screw-ins allows me to tailor my cleats to how I need to perform.

Match Your Studs to Each Field

Every field has its unique quirks and conditions. With permanent molded studs, you just have to make do. But screw-ins let me adjust for each field I play on. For the sodden grass field with thick mud, I’ll screw in my longest conical studs to dig in. On the harder artificial turf field, I’ll go with rubber turf studs instead to prevent slipping. Screw-ins give you the agility to match your cleat studs to each field’s individual nuances.

Carry Studs for Any Occasion

I always come prepared with extra screw-in studs in my bag. That way, I can swiftly swap my studs if conditions suddenly change during a game. When a surprise downpour hit at halftime in the playoffs last year, I quickly changed into longer conical studs while the team was in the locker room. It made all the difference in maintaining traction in the second half monsoon. With screw-ins, you can adapt your studs to anything game day throws at you.

Extend the Life of Your Cleats

The other big benefit of screw-in cleats is the longevity. When my molded cleat studs wore down, my only option was buying new cleats. But with screw-ins, I can just replace the studs to make them like new again. Some of my cleat bases are 5+ years old – I’ve just kept them going with fresh screw-in studs. Being able to swap out studs is much less wasteful and saves money in the long run.

At this point, I won’t even consider molded cleats again. The versatility and adaptability of screw-in studs are essential for optimal performance in changing conditions. They allow me to fine-tune my studs for every situation. While molded cleats lock you into one stud configuration, screw-ins let you adjust on the fly. Any player serious about grip and traction should join me in switching to screw-in cleats.

Once you experience the difference customizable studs make, you’ll become a believer too. So next time your cleat studs are due for replacement, do yourself a favor and go screw-in. Your ankles and performance will thank you!

Go for Metal Studs for Durability

As an avid football player, I’m tough on my cleats. I need studs that can stand up to seasons of hardcore use on the field. That’s why when it comes time to replace my worn out cleat studs, I always turn to rugged metal for maximum durability.

In my early days, I would just grab whatever cheap plastic studs I could find. But I quickly learned they don’t last. The plastic would round off or snap after just weeks of play. That’s when I switched to metal replacement studs and never looked back.

Metal Studs Are Virtually Indestructible

The first benefit I noticed with metal cleat studs was the sheer durability. The solid metal construction holds up to the most intense forces. Where plastic studs would bend and break under pressure, my metal studs took hit after hit without blinking. I’m still using some of my original metal studs several seasons later since they show barely any wear.

They Maintain Their Shape Season After Season

Another perk of metal is that the stud shape doesn’t degrade over time. The sharp, defined edges continue gripping the turf just like when they were new. Compare that to plastic studs that quickly get rounded off as the material wears down. The tip shape of my metal studs stays razor-sharp for optimal traction season after season.

Metal Provides the Strongest Threaded Grip

You also can’t beat the holding power of metal threads. They cut clean, robust threads into the cleat base that keeps the studs firmly anchored game after game. With plastic threads, I’d have issues with the studs slowly loosening over time as the threads got stripped. Not so with sturdy metal – the studs screw in tight every time.

They Stand Up to All Field Conditions

While weather can wreak havoc on plastic studs, my metal studs power through rain, snow, mud or heat. Where plastic might expand, contract or grow brittle in extreme conditions, titanium studs laugh it off. No matter how cruddy the field, I never worry about my metal studs holding strong.

Metal Studs Provide Next-Level Traction

Let’s not forget the stellar grip and traction of metal cleat studs. With plastic, the grip deteriorates as the studs wear down. But razor-sharp metal continues digging into even the hardest turf for maximum acceleration and stability. I notice a big performance difference with metal over plastic in both speed and maneuverability.

For me, only metal studs check off all the must-have boxes for serious play. The exceptional durability and traction mean I can just screw them in and not worry the rest of the season. While plastic studs failed me time and again, you can always rely on uncompromising metal to have your back.

Next time your cleat studs need some new life, skip the plastic and go for hardy metal replacements. Your ankles and performance will thank you. Once you try metal, you’ll never go back. These studs are in it for the long haul – just like you need your equipment to be when game day comes knocking!

Consider Plastic Studs for Affordability

As an avid football player on a budget, I’m always looking for ways to save money on gear. When it comes time to replace my worn out cleat studs, affordable plastic studs can provide quality traction at a fraction of the cost of metal.

Early on, I would only use metal studs. They lasted forever, but boy were they expensive to replace. When money got tight one season, I decided to give plastic studs a shot. I was skeptical at first, but quickly realized you can get impressive performance out of quality plastic studs without breaking the bank.

Plastic Cleat Studs Cost Less Upfront

The main advantage of plastic studs is clearly the lower price. A set of plastic screw-in studs can run 50% or less than a comparable set of metal. When you play as much as I do, those savings add up over time. While the metal studs last longer, the upfront cost savings of plastic make them appealing.

You Can Replace Them More Frequently

With plastic studs, I don’t feel bad replacing them a bit more often. When they start rounding over after a season or two of play, I can easily swap in fresh plastic studs affordably. With costly metal studs, I try to stretch them as long as possible before replacing. The lower cost of plastic studs gives me flexibility to freshen them up regularly.

They Get the Job Done for Most Positions

While positions like lineman may require the durability of metal, plastic studs perform admirably for many roles. As a running back and receiver, they give me the traction I need to cut, accelerate and sprint downfield. The stud shape stays crisp long enough for effective performance for a season or two.

Plastic Bladed Studs Grip Well in Dry Conditions

One area where plastic truly excels is dry field grip. The bladed plastic studs dig into hard, dry grass and turf better than rounded metal in my experience. The blades give that extra bite to launch out of your stance on rock-hard fields.

You Can Stock Up on Reserves

Finally, the low cost lets me keep plenty of reserves on hand. I can stock up on several sets of plastic studs for the price of one metal set. That way, I have replacements ready to go whenever my current studs start wearing over.

While serious players often default to metal studs, don’t overlook affordable plastic as an option. For many positions and conditions, they can provide the stud sharpness and grip you need at a fraction of the price. If you take care of them, quality plastic studs will give you good mileage for the money.

So next time you need fresh cleat studs, consider giving plastic a fair shot. You might find they offer everything you need for peak performance without breaking your budget. The lower cost gives you flexibility to readily swap them out when they wear down too. For positions where metal may be overkill, plastic studs hit that sweet spot of affordability and function.

Measure Your Current Stud Length

When it’s time to replace your worn out cleat studs, the stud length is a crucial factor to get right. The height impacts your stability, traction and performance. That’s why carefully measuring your existing studs before ordering new ones is a must.

In my early days, I would just guess at the stud length or figure most replacements were standard. But I learned the hard way that even small differences in height completely change how your cleats perform. Now I always precisely measure so I get replacements that match the feel I’m used to.

Stud Height Impacts Traction and Stability

The main reason to copy your stud length is the dramatic effect it has on traction and stability. Longer studs dig deeper to provide grip in soft conditions. But on hard turf, longer studs can make you feel wobbly and unstable. Getting the height wrong can really throw off your game.

Measure from Multiple Points on the Cleat

To get an accurate read, I measure studs at the heel, midfoot and forefoot areas. You want replacements that match the profile across your whole cleat. Studs often vary slightly across the sole, so multiple measurements give you the full picture.

Note Measurements for Each Stud Type

I also note down the specific lengths of each stud type – conical, bladed, etc. Some positions may mix stud types, so you want your replacements to mirror the original combo and shape. Stud material (metal, plastic) can also impact height.

Account for Any Wear on Current Studs

When measuring worn studs, note the original length before rounding occurred. This will give you the true height for new replacements. If current studs are very worn, reference unworn studs to estimate original length.

Confirm Compatibility with Manufacturer

Once I have precise measurements, I check with the cleat manufacturer that new studs in those sizes will properly fit my cleat model. That confirmation ensures I get an exact match to the stud profile I’m accustomed to.

It may sound tedious, but taking the time to carefully measure stud length avoids unpleasant surprises. I once failed to measure, and the longer replacements totally changed my stability. Don’t just guess – measure! Dialing in your ideal stud height through careful measurement helps transfers your stud feel and performance to new replacements.

Pick the Proper Stud Shape for Your Position

When replacing your football cleat studs, the stud shape you choose can make or break your performance. Each position requires studs tailored for how you move on the field. Taking the time to match stud shape with your position ensures your replacements optimize traction and control.

Early on, I would just slap in whatever random stud shape was available. It wasn’t until I started paying attention to stud design for my position that my performance really improved. Here are some tips on picking studs shaped for your role:

Conical for Quick Cuts and Changes of Direction

As a running back, pointed conical studs are essential for my role. Their narrow shape allows for swift side-to-side cuts, pivots and acceleration in any direction. The pointed ends provide grip when pushing off in lateral motions.

Bladed for Speed and Forward Drive

For linemen who need to explode forward, bladed studs are ideal. The blade design offers enhanced traction for driving off the line and winning the point of attack. Blades also deliver straight-ahead speed for pulling guards and tackles.

Mix of Both for Balanced Versatility

For versatile positions like quarterback and receiver, combining conical and bladed studs provides the best of both worlds. The conicals aid agile routes and cuts, while the blades add speed when blasting downfield for a pass.

Consider More Conical Studs for Maneuverability

Defensive backs can opt for higher concentrations of conical studs to mirror wide receivers. The conical grip assists backpedaling, transitions and blanketing receivers on routes. Just enough blades maintain forward speed when needed.

Turf Studs for Synthetic Fields

On artificial turf, rounded rubber turf studs get the most traction without damaging the surface. Pointed studs may stick and cause injury on turf, so go with rounded plastic or rubber.

Don’t settle for generic stud shapes. Take the time to match your stud profile to how you perform your position. Dialing in proper stud shapes tailored to your movements gives you a big competitive edge. The right stud shape for your role enhances what you do best on the field.

Choose Between Conical and Bladed Studs

When replacing your football cleat studs, one of the biggest decisions is conical versus bladed studs. The shape you choose impacts traction, speed, and maneuverability. Understanding the pros and cons of each will ensure you pick the stud profile that complements your playing style.

Early on, I just used whatever random stud shape was available. It wasn’t until I actually compared bladed to conical studs head-to-head that I realized the huge performance differences. Here’s what I learned from testing out both options:

Conical for Agility and Changes of Direction

The main advantage of conical studs is multidirectional traction and grip. Their narrow, pointy shape allows for quick cuts, pivots and changes of direction. As a running back, conicals provide the agility I need in open space.

Bladed for Straight Line Speed

Bladed studs excel at forward acceleration and top speed. The blade design offers enhanced traction when blasting off the line or rushing the passer. For positions like receiver and linebacker, bladed studs enable explosive linear speed.

Conical Grips on Sideways Pushes

A big difference I noticed was conical’s superior grip on lateral movements. When pushing off sideways, the conical points dig in for traction where blades can slip. Defensive backs benefit from this conical grip when mirroring wideouts.

Bladed Excels on Hard, Dry Fields

On the flip side, bladed studs outperform conicals on drier, firmer fields. The blades provide bite when accelerating on rock-hard grass. For these conditions, bladed studs get you up to speed faster.

Most players choose a blend of conical and bladed studs to get the best of both. But understanding where each excels allows you to tailor the ratio to your position and playing style. Precisely balancing conical grip and bladed speed gives you a customized stud profile built for how you play the game.

Select Studs for Your Field Conditions

One overlooked factor when replacing cleat studs is tailoring them to your usual field conditions. The stud profile that performs great on firm natural grass may falter on muddy, thick turf. Choosing studs matched to the fields you play on most optimizes traction and minimizes slippage.

Early on, I would just use the same generic studs regardless of the field. But after experiencing poor grip on certain surfaces, I learned to adapt my studs to each field’s unique demands. Here are some tips for stud selection based on field conditions:

Longer Conical Studs for Soft, Muddy Natural Grass

When games are played on rain-soaked and muddy natural grass fields, longer conical studs dig through the thick turf best. The extended length and pointed shape provide enhanced traction when sinking into soft, soggy earth.

Shorter Bladed Studs for Firm Natural Grass

For drier natural grass fields, shorter bladed studs deliver optimal grip and acceleration. The blades take hold in densely packed earth for stable cuts and speed. Avoids overly long studs getting stuck in firm ground.

Molded or Detachable Turf Studs for Synthetic Fields

On artificial turf, specialized turf studs work best. Rounded molded cleats or short rubber detachable studs provide the surest footing with less potential to stick in synthetic fibers. Avoid long or metal studs that can damage fake turf.

While most players use one stud profile for everything, customizing for your home field’s conditions gives you an edge. The right stud shape, material and height for your surface reduces slippage while providing responsive traction. Let your field determine your football cleat studs.

Get Studs for Firm Natural Grass

When I’m gearing up to replace my worn out football cleat studs, the firmness of my home field’s natural grass has a big impact on the stud profile I choose. Hard, compacted earth requires a different stud shape and length than soft, thick grass. Dialing in studs optimized for firm natural turf ensures I get maximum grip and acceleration on game day.

In my early days of swapping cleat studs, I didn’t factor in my field conditions much. But after slipping around on hard packed earth, I learned proper stud setup makes all the difference. Here are my tips for stud selection on firm natural grass fields:

Shorter Bladed Studs Grip Better

On compacted natural earth, shorter bladed studs provide the best traction and bite in my experience. The blades excel at digging into tightly packed ground, especially on older fields. Longer studs can actually reduce stability on very firm turf.

Avoid Long Conical Studs That Get Stuck

While longer conical studs work well in muddy conditions, they can be a liability on hard fields. I’ve had issues where overly long conicals get temporarily lodged in rock-solid earth and alter footing stability. Shorter studs avoid this.

Metal Tips Maintain Shape Longer

The unforgiving compacted ground can quickly dull and round plastic stud tips. For consistent grip over time, metal tipped studs hold their shape longer in firm natural grass. Just avoid overly long metal studs.

Enhance Stud Grip with Cleat Prep Tools

Some players use cleat sharpening or cleaning tools before games on hard fields. These prep the studs for extra bite to prevent slippage. I keep a simple cleat brush in my bag for pre-game grip boosts.

It may take some trial and error to dial in your optimal stud combo. But once you get it right for hard, dry natural grass, you reap the benefits in stability and quickness. Don’t just default to your muddy field stud setup – customize for firmness!

Use Longer Studs for Soft Natural Grass

When I’m gearing up to replace my football cleat studs, soft, muddy natural grass calls for a very different stud profile than firm fields. Soggy, rain-soaked earth requires extended studs to penetrate the ground and provide traction. Choosing longer studs tailored for soft natural turf prevents slipping on game day.

Early on, I’d use the same short studs regardless of conditions. But the first time I hit a thick, muddy field in those, I was sliding all over the place. That taught me to adjust my studs based on softness and moisture. Here are my tips for studs in soft natural grass:

Look for Removable Studs that are At Least Half an Inch Long

For heavy soft turf, I look for replaceable studs that are no less than a half inch in length. This increased extension helps them dig through the ground better for enhanced traction and control.

Opt for Conical Studs to Penetrate Thick Grass

Conical stud shapes fare best when sinking into super soft earth. The tapered tip pierces the ground while the wide base provides stability. I go with an all conical profile on swampy fields.

Carry Replacements in Case Conditions Change

I always carry extra longer studs in my bag for soft games in case it starts raining heavily. This allows me to swap my normal studs for extended traction as needed.

Check League Rules on Maximum Stud Length

While you want longer studs in soft grass, most leagues limit how long they can be for safety. I verify regulations before using any studs over 3/4 an inch long on game days.

Dialing in that ideal longer stud profile may take some tinkering, but it makes all the difference in soft turf traction. Don’t get caught flat-footed – let wet conditions determine your stud setup!

Opt for Turf Studs for Synthetic Fields

When preparing to replace my worn out football cleat studs, the type of field surface is a huge factor. Synthetic turf fields require a totally different stud profile than natural grass to optimize stability and prevent injury risk. Specialized turf studs are essential for reliable grip on artificial playing surfaces.

Early on, I would just use my regular studs designed for grass on turf fields. But the poor traction and foot lock-ups I experienced taught me that turf requires adaptable studs. Here are some tips on selecting studs for synthetic fields:

Turf Studs Are Shorter with Rounded Tips

The optimal stud profile for artificial turf has shorter length and rounded tips. This prevents the studs from sticking in the synthetic fibers while providing grip. Conical and bladed studs can latch.

Look for Molded or Detachable Turf Studs

Most brands offer cleats designed just for turf use, usually with permanent molded studs. For versatility, go with removable turf studs that can be swapped in when needed.

Rubber Studs Provide Durability and Traction

Rubber stud material works well for striking a balance of turf grip and durability. The rubber compounds provide firm footing without excessive surface wear.

Avoid Long or Metal Studs to Prevent Damage

Lengthy or metal studs can really dig into and tear up turf fabric. Using corrosive metals like aluminum also damages the surface. Short, rounded plastic or rubber studs are safest.

It pays to invest in specialized turf studs if artificial fields are your primary playing surface. The proper stud shape and material makes all the difference in optimizing synthetic turf traction and control.

Shop Popular Cleat Stud Brands

When searching for replacement cleat studs, sticking with known high-performance brands ensures you get maximum durability and compatibility. The top football cleat companies make studs specifically designed to optimize traction and grip in their shoe models. Here are some of the top stud brands to look for:

Nike

As the athletic wear giants, Nike offers a deep selection of screw-in and molded replacement studs engineered for their popular cleat models. I’ve had great luck finding compatible metal and plastic Nike studs for my Vapor line cleats.

Adidas

Adidas has replacement stud sets tuned for their Freak, Adizero and other cleat models. Their screw-in options come in multiple lengths and materials to customize your stud profile. I use Adidas’ bladed studs for added acceleration.

Under Armour

With their growing football presence, Under Armour has studs designed for UA Highlight, Spotlight and other cleats. I rely on their titanium and plastic screw-ins to keep my Highlight cleats fresh season after season.

New Balance

Known for performance running shoes, New Balance also makes football stud replacements for their 4000v and other cleat models. I use their wider bladed studs for drive blocking leverage in the trenches.

While cheaper generic studs are available, I stick with stud replacement options directly from the top brands. This ensures 100% compatibility and the same quality construction as my original cleats. For optimizing cleat stud performance, you can’t beat replacements designed specifically for your shoe model.

Find Your Cleat Size and Model

Searching for the right replacement cleat studs starts with identifying your specific cleat brand, model and size. With so many stud options out there, zeroing in on the exact match for your current cleats ensures flawless compatibility and fit.

In my early days, I’d just order the first set of random studs that seemed close enough. But I quickly learned that taking the time to precisely identify my cleat specs gets you replacement studs that slide right into place and perform like OEM parts.

Check Inside the Shoe for Brand and Model

The easiest place to find your cleat details is printed directly inside the shoe tongue or side walls. There you should see the brand, model name, size and other specifics to guide your replacement stud purchase.

Search Online for Your Model if Unclear

If the text inside is worn off, search your cleat brand and description online to identify. Looking up images can provide visual matches to hone in on the right model.

Measure Studs for Sizing Specifics

Stud sizing and lengths can also help identify your model for replacement purposes. Carefully measuring current studs provides size parameters when searching for stud alternatives.

Confirm Fit with Manufacturer or Retailer

Once I’ve identified possible replacement studs, I always verify with the manufacturer or retailer that they are guaranteed to fit my cleat model. This added confirmation ensures stud compatibility.

Identifying those key cleat details takes some legwork upfront. But doing your homework to find the perfect replacement stud match pays off in ideal performance. Don’t settle for close enough – replacement studs should feel custom built for your cleats!

Use Proper Tools for Installation

When it’s time to swap in fresh replacement cleat studs, having the right tools makes the process smooth and simple. Rushing through stud installation without the proper equipment can damage the studs or your cleats. Investing in a stud wrench and lubricant ensures quick, easy stud replacement.

In my early days, I’d try to force and muscle off old studs with pliers or whatever I had lying around. This led to stripped studs and cleat damage. Learning to use the proper specialized tools transformed my stud swaps.

Stud Wrench

A stud wrench is essential to safely remove and install screw-in cleat studs without damage. The wrench grips the stud perfectly for maximum torque and control. I use mine every time I tweak my stud profile.

Lubricant

A penetrating lubricant like WD-40 helps loosen up any studs seized in place from grime or corrosion. This allows you to remove them without shearing off the stud. I apply it liberally on any stubborn studs.

Brushes

A stiff brush clean stud holes and preps the cleat for new studs. Removing compacted dirt allows the new studs to seat and tighten fully. I give my cleats a good scrub beforehand.

Replacement Stud Kit for Your Model

Stud kits made for your exact cleat model contain all necessary hardware, including replacement lock nuts for screw studs. Brand name kits ensure compatible components.

With the right tools and parts on hand, cleat stud replacement takes just minutes. Don’t improvise – use purpose-made gear and stud kits to avoid damage and optimize your traction.

Break in New Studs Slowly

Once I’ve got fresh replacement cleat studs installed, the final step is gradually breaking them in to avoid injury. Brand new studs are razor sharp right out of the box. Taking it slow those first few times out allows your body to adjust to the increased traction.

In my younger days, I’d excitedly sprint full throttle into my first practice on new studs. But rolling an ankle taught me the importance of pacing yourself while the cleats fully break in. Here are my tips for safely transitioning to new studs:

Begin With Light Jogging and Short Sprints

For the first few sessions on new studs, stick to easy jogs, light cuts and short accelerations at half or 3/4 speed. Giving your ankles time to adapt prevents strains and rolls.

Avoid Sharp Changes of Direction at First

Cutting and pivoting aggressively too soon on fresh studs can lead to ankle or knee issues as your joints adjust. Take it slow on lateral moves until your tendons strengthen to the new stud grip.

Tighten Studs Fully so They Don’t Loosen Up

Having studs gradually loosen during break-in leads to instability and slipping. Using a stud wrench to crank them down tight prevents any loosening as you work them in.

Transition to Full Speed Over 2-3 Sessions

For most cleat models, I find 2-3 practices is enough transition time before going all out in new studs. The gradual ramp up prevents injury without excessively prolonging break-in.

It can be tempting to rush into max intensity on fresh studs. But taking a patient approach pays off by getting your body fully adapted for peak performance. Slowly work those new studs into game shape!

Consider Plastic Studs for Affordability

As another football season approaches, many players may be dismayed to find their cleats worn down from the year before. Purchasing a fresh pair can be an expensive endeavor, especially for youth and school teams on a budget. However, with a little creativity and elbow grease, you can revive those old cleats and save big bucks. Let’s explore some of the easiest and most cost-effective ways to get your cleats back in playing condition this season.

Assess the Damage

Start by thoroughly examining your cleats to identify problem areas. Look for studs that are loose, worn down, or missing completely. Check the upper for rips, tears, or holes that need patching. Don’t forget to inspect the inside of each shoe for protrusions, rough spots, or detached lining that could irritate your feet or ankles. Being methodical now will help you pinpoint everything that needs addressed.

Replace Metal Studs

If your cleats have detachable studs, replacing any that are bent, dull, or missing is a great way to refresh traction on a budget. Most sporting goods stores sell replacement studs in plastic or metal for just a few dollars per piece. Plastic studs are more affordable and lower profile, providing slightly less grip than metal. However, for youth in particular, plastic may be a smarter choice to reduce risk of injury from overly aggressive traction. Install new studs with a stud key by twisting them into the sole until securely fastened.

Repair Upper Damage

Use vinyl repair kits to patch any small holes or tears in the upper material of your cleats. Thoroughly clean the area first, apply adhesive to both surfaces, allow to become tacky, then press together firmly. For larger damaged sections, cut a patch out of spare vinyl or leather at least 1 inch wider than the hole all the way around. Adhere into place the same way. You can also stitch around the edges for added durability.

Replace Detached Lining

If the lining inside your cleats has come loose, don’t just tape it down. The constant friction will quickly wear through tape and cause blisters. Carefully peel off the detached section. Cut a replacement patch out of soft, flexible material like suede or moleskin. Make sure it’s large enough to cover the spot with at least 1/2 inch margin all around. Use a flexible adhesive like Shoe Goo to attach the new lining patch securely.

Add Traction with Spray

For studs that are merely dull rather than damaged, traction spray can restore grip. Lightly scuff the contact surface of the studs with sandpaper to help the spray adhere better. Apply 2-3 even coats, allowing to dry in between. Spray adds texture for better field bite without altering stud shape. Re-apply as needed throughout the season to maintain enhanced traction.

Fill with Shoe Goop

If you have studs that are badly worn down or missing sections, filling them in with rubberized compound creates new tread. Shoe Goo works great for this. Thoroughly clean and dry each stud, then overfill slightly with the adhesive. Allow to cure fully. Once hardened, use a sharp blade to slice off any excess that protrudes past the original stud shape. Buff smoothly. The new rubber will provide grip almost as good as new metal or plastic.

Cover with Soft Spikes

An alternative solution for worn studs is applying soft spikes. These are short traction cleats that screw into adapters placed over top of your existing studs. Install adapter bases using adhesive, allowing to dry completely. Then simply twist in the threaded soft spikes. No modifications to your cleats required. Soft spikes come in many lengths and materials to fine tune grip. Easily swap them out as needed when they wear down.

Reinforce the Sole

If the sole plate of your cleats is cracked or separating from the upper, the shoes are unfortunately beyond full repair. However, you can still get more use by adding reinforcement. Clean and dry the soles completely. Apply flexible rubberized adhesive generously over all interior surfaces. Press the upper and sole back into place firmly. Allow the adhesive to fully cure and repeat as needed until the sole feels solid.

Get Creative with DIY Traction

If funds are extremely tight, get creative with household items to make your own traction. Try meticulously gluing on small squares cut from rubber matting or bike tire treads. For a bold statement, adhere Legos, magnets, or gravel for unique bite. Secure anything firmly with flexible glue interfacing made for shoe repair. Test traction and comfort before game use.

With a bit of ingenuity and effort, you can bring new life to old cleats without breaking the bank. Address all visible issues for maximum safety and performance. Don’t be tempted by quick-fix tape jobs that won’t last. Take time to make quality repairs so you can dig in confidently all season long without slips, discomfort, or injuries.