What are the key features of oil-resistant work shoes. How do they enhance workplace safety. Which components provide maximum comfort during long shifts. Why are breathable designs crucial for foot health. How do slip-resistant soles improve traction on oily surfaces.

The Importance of Breathable Mesh in Oil-Resistant Footwear

Breathability is a crucial factor in oil-resistant work shoes, especially for those who spend long hours on their feet in challenging industrial environments. High-quality oil-resistant footwear often incorporates breathable mesh designs to enhance comfort and foot health.

How does breathable mesh benefit workers? It allows air to circulate within the shoe, effectively wicking away perspiration and keeping feet cool and dry. This feature is particularly valuable in hot work environments where foot sweat can lead to discomfort and potential health issues.

- Promotes air flow around the feet

- Reduces moisture buildup

- Minimizes foot odor

- Enhances overall comfort during long shifts

Where are breathable mesh panels typically located? Manufacturers strategically place these panels around the toes, sides, and tongue of the shoe. This placement ensures maximum ventilation without compromising the shoe’s oil-resistant properties.

Advanced Slip-Resistant Soles: A Cornerstone of Workplace Safety

When it comes to oil-resistant work shoes, slip-resistant soles are not just a feature – they’re a necessity. However, not all slip-resistant soles offer equal protection. Premium oil-resistant footwear often boasts cutting-edge tread compounds and innovative sole designs specifically engineered to provide superior grip on oily and wet surfaces.

What characteristics define high-performance slip-resistant soles?

- Advanced tread compounds

- Pronounced lug patterns

- Flexible comfort

- Specialized designs for industrial conditions

These features work in tandem to create soles that offer an extra margin of safety and stability when navigating slick industrial floors. The result is a significant reduction in the risk of slips and falls, which are among the most common workplace accidents.

Electrical Hazard Protection: A Critical Safety Feature

In many industrial settings, electrical hazards pose a significant risk to workers. This is where the Electrical Hazard Protection (EHP) feature of oil-resistant work shoes becomes invaluable. But why is EHP so crucial?

Electrical shocks through improperly insulated footwear can lead to severe consequences, including nerve damage, tissue injury, or even fatality. High-quality oil-resistant work boots incorporate electrical-shock resistant soles with ample insulation to protect against live wires and circuits.

What should workers look for in EHP-equipped footwear?

- Non-conductive, compression-resistant sole and heel

- Meets or exceeds ASTM F2413-18 standards

- Secondary protection against incidental contact with electrical circuits

It’s important to note that EHP footwear should be used in conjunction with other safety measures and is not intended as primary electrical protection.

Water and Oil Repellent Materials: Keeping Feet Dry and Safe

The core function of oil-resistant work shoes is to protect against wet oils, coolants, drilling fluids, and other liquid hazards encountered in industrial environments. How do manufacturers achieve this protection?

Premium oil-resistant footwear often combines multiple protective elements:

- Water-repellent leather uppers

- Oil-resistant textile components

- Anti-penetration liners

This combination of materials works to keep moisture out and feet dry throughout the workday. The benefits extend beyond comfort – by repelling light oils and preventing stains, these shoes require less maintenance and laundering compared to more absorbent alternatives.

How does this feature impact workplace safety? By keeping feet dry and preventing liquid penetration, these materials significantly reduce the risk of slips and falls caused by wet socks or insoles.

Impact Protection: The Role of Steel Toe Caps

In workplaces with heavy equipment, fabrication processes, or construction activities, impact hazards are a constant concern. Steel toe caps in oil-resistant work shoes provide crucial protection against these risks. But how exactly do they work?

Steel toe caps are designed to deflect force away from the toes, effectively safeguarding against:

- Crushing injuries

- Lacerations

- Fractures

Modern steel toe caps are engineered to be lightweight, ensuring they don’t impede movement or cause undue fatigue. Many manufacturers now offer alloy or composite toe boxes as alternatives, providing similar protection with even less weight.

How do steel toe caps complement other features of oil-resistant shoes? They work in tandem with slip-resistant soles and water/oil protection to create a comprehensive safety package for industrial environments.

Comfort Innovations: Memory Foam Footbeds and Cushioning

Long shifts on hard surfaces can take a toll on workers’ feet, leading to discomfort and fatigue. To address this, many top oil-resistant shoe manufacturers incorporate advanced comfort features into their designs. One such innovation is the use of memory foam footbeds.

What makes memory foam footbeds so effective?

- They mold to the unique shape of each foot

- Provide personalized cushioning and support

- Offer long-lasting comfort throughout the workday

- Can be replaced when worn out, extending the life of the shoe

Beyond memory foam, many oil-resistant work shoes feature additional cushioning elements in the midsole. These often utilize materials like EVA (Ethylene-Vinyl Acetate) or polyurethane to absorb shock and reduce fatigue during long periods of standing or walking.

How do these comfort features impact worker productivity? By reducing foot pain and fatigue, they can help maintain energy levels and focus throughout long shifts, potentially improving overall job performance and satisfaction.

Lightweight Construction: Balancing Protection and Wearability

The weight of work shoes can significantly impact comfort and fatigue levels over the course of a long shift. Recognizing this, manufacturers of oil-resistant footwear have made great strides in developing lightweight construction techniques that don’t compromise on protection.

How do modern oil-resistant shoes achieve this balance?

- Use of synthetic leather or textile uppers

- Implementation of EVA midsoles

- Incorporation of composite safety toes instead of steel

- Strategic use of lightweight, durable materials throughout the shoe

These innovations result in oil-resistant work shoes that provide all the necessary protection without the bulk and weight traditionally associated with industrial footwear. The benefits for workers are clear: reduced fatigue, improved mobility, and increased comfort throughout long shifts.

Does lightweight construction affect durability? Not necessarily. Many modern materials used in lightweight oil-resistant shoes are engineered to be just as durable, if not more so, than their heavier counterparts.

Flexibility: The Key to Natural Movement

Flexibility is another crucial aspect of comfortable oil-resistant work shoes. Rigid footwear can restrict natural foot movement, leading to discomfort and potential foot health issues over time. How do manufacturers address this challenge?

Many high-quality oil-resistant shoes incorporate:

- Flexible leather uppers

- Textile flex panels

- Strategically placed overlay straps

- Sole designs that allow natural foot flexion

These features allow the shoe to move naturally with the foot, reducing pinching, binding, and discomfort. The result is a work shoe that feels good from the first hour of a shift to the last, supporting natural foot mechanics while still providing essential oil and slip resistance.

Shock-Absorbing Midsoles: Protecting Joints and Enhancing Energy

Industrial environments often involve long hours of standing or walking on hard surfaces like concrete. This can lead to significant stress on joints and overall fatigue. To combat this, many oil-resistant work shoes incorporate shock-absorbing midsoles.

What materials are commonly used in these midsoles?

- EVA (Ethylene-Vinyl Acetate)

- Polyurethane

- Proprietary cushioning compounds

These materials work to absorb the impact of each step, reducing the stress on joints and muscles. By dampening these repetitive shocks, shock-absorbing midsoles can help prevent fatigue and potential long-term joint issues.

How does this feature benefit workers beyond comfort? By reducing fatigue and joint stress, shock-absorbing midsoles can help maintain energy levels throughout a shift, potentially improving productivity and reducing the risk of accidents caused by tiredness.

Durable Upper Construction: Built to Last in Tough Conditions

The upper part of oil-resistant work shoes bears the brunt of daily wear and tear in industrial environments. Durability in this area is crucial for both safety and cost-effectiveness. What characteristics should workers look for in upper construction?

- Heavy-duty leather or synthetic blends

- Reinforced toe areas

- Welted seams for added strength

- Abrasion-resistant materials

These features combine to create uppers that can withstand the rigors of industrial environments, including exposure to oils, chemicals, and physical hazards. Durable uppers not only provide consistent protection but also extend the life of the shoe, offering better value over time.

How does upper durability impact safety? Shoes with robust uppers maintain their protective properties longer, ensuring consistent safety performance throughout their lifespan.

Puncture-Resistant Plates: Guarding Against Sharp Objects

In many industrial settings, the risk of stepping on sharp objects like nails, metal shards, or glass is a real concern. Puncture-resistant plates in oil-resistant work shoes provide an essential layer of protection against these hazards.

What materials are commonly used for puncture-resistant plates?

- Steel

- Kevlar

- Composite materials

These plates are typically inserted between the insole and outsole, covering the entire bottom of the foot. They’re designed to prevent sharp objects from penetrating the sole and injuring the foot.

Do puncture-resistant plates affect comfort? Modern plates are engineered to be thin and flexible, minimizing their impact on the shoe’s overall comfort and flexibility. Some materials, like Kevlar, offer excellent puncture resistance while being lighter and more flexible than traditional steel plates.

Anti-Microbial Treatments: Combating Odor and Promoting Foot Health

Given the long hours and potentially sweaty conditions in which oil-resistant work shoes are worn, anti-microbial treatments have become an increasingly common feature. But what exactly do these treatments do?

Anti-microbial treatments in work shoes serve several purposes:

- Prevent the growth of odor-causing bacteria

- Reduce the risk of fungal infections like athlete’s foot

- Extend the freshness and usability of the shoe

- Improve overall foot hygiene

These treatments are typically applied to the shoe’s lining, insole, or both. They work by either inhibiting microbial growth or actively eliminating microorganisms that cause odors and infections.

Are anti-microbial treatments safe for long-term use? Most anti-microbial treatments used in quality work shoes are designed to be safe for prolonged skin contact. However, individuals with sensitive skin or specific allergies should always check the manufacturer’s specifications.

Quick-Dry Linings: Enhancing Comfort in Wet Conditions

While oil-resistant work shoes are designed to repel liquids from the outside, internal moisture from sweat can still be an issue. This is where quick-dry linings come into play. How do these linings benefit workers?

- Rapidly wick moisture away from the foot

- Promote faster drying between uses

- Reduce the risk of blisters and skin irritation

- Enhance overall comfort in hot or humid conditions

Quick-dry linings are typically made from synthetic materials engineered to move moisture away from the skin and towards the outer layers of the shoe where it can evaporate more easily.

Do quick-dry linings affect the shoe’s breathability? In most cases, these linings work in tandem with breathable mesh panels to create a comprehensive moisture management system, enhancing rather than impeding overall breathability.

Customizable Fit Systems: Ensuring Comfort for Every Foot Shape

Recognizing that every foot is unique, many manufacturers of oil-resistant work shoes now offer customizable fit systems. These systems allow workers to adjust the fit of their shoes for optimal comfort and support. What types of customizable fit systems are available?

- Adjustable insoles

- Multiple width options

- Customizable lacing systems

- Removable footbeds for orthotic insertion

These features allow workers to fine-tune the fit of their shoes, addressing individual needs such as high arches, wide forefeet, or the need for additional support in specific areas.

How does a customizable fit impact safety? A well-fitting shoe not only enhances comfort but also improves stability and reduces the risk of accidents caused by ill-fitting footwear. It also encourages consistent wear of protective equipment, as workers are more likely to keep their shoes on if they’re comfortable.

Reflective Elements: Enhancing Visibility in Low-Light Conditions

Many industrial environments involve work in low-light conditions or during night shifts. To address safety concerns in these situations, some oil-resistant work shoes incorporate reflective elements. How do these features enhance worker safety?

- Increase visibility to others in dark or dimly lit areas

- Help prevent accidents involving moving vehicles or equipment

- Provide an additional layer of passive safety

- Often integrated seamlessly into the shoe’s design

Reflective elements are typically placed on the heel, sides, or tongue of the shoe. They’re designed to catch and reflect light, making the wearer more visible to others in the area.

Are reflective elements effective through oil and dirt? High-quality reflective materials used in work shoes are designed to maintain their reflective properties even when exposed to oils, dirt, and other contaminants commonly found in industrial environments.

When it comes to occupational footwear, oil and water resistant work shoes are an absolute must for many professions. As someone who’s spent years on my feet in challenging industrial environments, I can tell you firsthand there are few things more important than having work boots or shoes that can stand up to liquid hazards. The right oil and water resistant footwear can make all the difference in keeping you surefooted, protected and comfortable throughout long workdays. If you’re in the market for new work shoes or boots that repel oils, coolants and other wet contaminants, here’s a close look at 15 impressive features to seek out.

Breathable Mesh Designs Keep Your Feet Cool

Imagine how uncomfortable your feet would get in oil resistant shoes made entirely of rubber and sealed materials. Many brands incorporate breathable mesh fabrics to allow air to flow into the boot and wick away perspiration. Mesh panels placed strategically around the toes, sides and tongue can make your feet feel cooler and drier even after hours of work in hot environments. Good breathability also cuts down on foot odor when you take your shoes off at the end of a long day.

Slip-resistant soles are a basic essential for oil resistant work shoes. But not all slip-resistant soles are created equal. Premium oil resistant shoes from reputable brands often have the most advanced tread compounds and sole designs to really grip oily, wet floors in industrial conditions. Lug soles, pronounced tread patterns and flexible comfort are hallmarks of high-traction oil resistant soles that provide that extra margin of safety and stability for walking on slick surfaces.

You don’t want to learn the hard way how dangerous it can be completing electrical work, repairs or construction without proper EHP (electrical hazard protection). Electric shocks through improperly insulated footwear can lead to severe nerve and tissue damage or worse. The best oil resistant work boots have electrical-shock resistant soles with ample insulation from live wires and circuits. Don’t work around open or concealed power sources without the EHP component of oil resistant shoes.

The oil and water resistant materials give you that protection against wet oils, coolants, drilling fluids and other liquids that can soil footwear and lead to slips and falls. Premium oil resistant work shoes often combine water-repellent leather and textile uppers with anti-penetration liners to keep moisture out and feet dry. Light oils won’t stain the exteriors or leak inside to dampen your socks or insoles throughout the workday. Less maintenance and laundering compared to more absorbent materials.

On worksites with heavy equipment, fabrication and construction, impact hazards abound. Stubbed toes, dropped tools and other sudden blows are painful. Steel toe caps deflect that force to safeguard your feet from crushing injuries, lacerations and fractures. The alloy or composite toe boxes are lightweight so as not to weigh down your steps. And they work in tandem with the slip-resistance and water/oil protection of the boots.

At the end of a long shift during which you’ve been on your feet for hours, sore tired feet are no fun. Many top oil resistant shoes and work boots include replaceable footbeds made of memory foam or similar cushy, shock-absorbing materials. After you mold them to your feet, they continue providing blissful cushioning and support mile after mile. Replace them when they wear out for fresh comfort.

Heavy, clunky boots with thick rubber soles can wear you out quicker. The latest best oil resistant shoes offer surprisingly lightweight builds combining synthetic leather or textile uppers with EVA midsoles or similar materials. The oil and slip resistance remains uncompromised while fatigue from wearing them all day is reduced.

Flexible uppers are also key for oil resistant shoes that move naturally with your feet without any pinching,binding or discomfort. Quality leather paired with textile flex panels, overlay straps and similar functional designs yield that flexibility so your feet feel good at hour ten of your shift as much as they did at hour one.

Oil resistant work environments like factories and mills involve long hours of standing,walking, sometimes on hard concrete floors. Cushioning midsoles integrated into oil resistant shoes absorb the shocks and impacts from all that time on your feet. Look for EVA, polyurethane or comparable midsole materials that protect joints and keep you energized.

The upper part of your oil resistant boots take the most abuse from abrasions, impacts, liquids and more. Heavy-duty leathers and synthetic blends stand up to the hazards and endure season after season of wear. Thick, reinforced toes and welted seams prevent ruptures. Know the materials and components of the uppers before you buy.

Nails, debris, scrap metal and other sharp objects penetrate standard boot soles. Puncture-resistant plates incorporated into high-performance oil resistant shoes and boots safeguard your feet from accidental punctures from underneath. Kevlar, fiberglass and plated designs maintain flexibility while blocking sharp pointy hazards.

Nothing beats dry feet, except maybe dry feet that also smell fresh. That’s where moisture-wicking linings come in for oil resistant footwear. Synthetic linings swiftly draw sweat away from skin to keep your feet drier and prevent odor inside shoes and boots after hours of work and activity.

Surfaces get extremely slick with oils, coolants and greases in industrial environments. Lug soles with deep, multi-directional tread lugs bite down securely on those slippery floors. Paired with true slip-resistant compounds, the deep lugs grip so you keep stable footing. The best oil resistant work shoes have aggressive treads to match their workplace.

Secure footholds and balanced steps are contingent on achieving the right snug fit for your foot in oil resistant shoes. Lace-up closures are tried-and-true for cinching up a good fit and preventing slips when you’re moving and bearing loads. Quick-pull loops let you tighten and loosen laces expediently for dialing in the custom fit.

Low light combined with wet floors is a recipe for slips and falls. Reflective patches and accents integrated onto oil resistant work shoes improve visibility for the wearer and of the wearer from a distance. Passing motorists and heavy equipment operators can spot your reflective feet and avoid mishaps in dim lighting.

As you can see, today’s cutting-edge occupational footwear combined rugged oil/water protection with advanced comfort and safety technologies. When your livelihood depends on steady footing through long workdays on greasy surfaces, oil resistant shoes with features like the above are vital equipment. Don’t cut corners with substandard oil resistant boots only to risk paying the price through slips, fatigue, discomfort or worse. Take these pointers to heart when shopping to discover why premium work shoes are worth the investment!

When you’re on your feet all day in an occupational setting, having reliable traction is paramount. Floors become even more slippery when contaminated with water, oil and other liquids. That’s why slip-resistant soles are such an important feature to look for when shopping for oil and water resistant work shoes.

Slip-Resistant Soles Provide Superior Traction

Not all slip-resistant soles are created equal. The best ones use advanced tread rubber compounds that maintain grip even when walking on oily, wet surfaces. Look for deep lugs, channels, and siping on the outsoles that allow fluids to escape beneath your feet instead of causing hydroplaning. The lugs bite down securely, the siping flexes naturally, and the channels funnel away liquids.

I’ve found over the years that work shoes and boots with Vibram or similar name-brand slip-resistant soles truly live up to their claims. The state-of-the-art traction these soles deliver can mean the difference between surefooted stability and a nasty fall on a slippery floor. Their proprietary tread rubber compounds are engineered specifically to resist oil and water underfoot.

The outsole tread patterns also matter. Multidirectional lugs provide superior traction and braking in all directions – forward, backward, lateral side-to-side. Some oil resistant boots have defined heels to prevent slips when working on ladders. The pronounced lugs grip rungs securely as you climb up and down.

In my experience, slip-resistant soles prevent fatigue as the day goes on. You conserve energy staying firmly planted with each step rather than having your feet slide all over the place. Traction gives you the stability and confidence to walk normally, pivot and go about your tasks without worrying about slippery floors.

Look for CE or similar safety ratings on oil resistant shoes to confirm they meet standardized slip resistance criteria. Lab tests on surfaces like steel coated with glycerol ensure the soles live up to real-world conditions. I opt for oil resistant shoes rated at the SRA or equivalent level for superior wet/dry traction.

While you’re evaluating the slip resistance, also look for flexibility in the sole. Bend it in your hands and make sure it moves with your foot for natural walking motion. Rigid, stiff soles inhibit mobility and can be uncomfortable over time.

Proper traction helps prevent strains and sprains from slips and falls. But a related benefit is minimizing fatigue. Slip-resistant soles with shock absorption reduce the impacts and vibrations your feet, ankles, knees and hips absorb over long days on hard industrial floors.

Don’t take shortcuts here – high quality oil and water resistant work shoes with advanced slip-resistant soles are critical equipment that can protect your safety and comfort hour after hour at demanding jobsites. Give them a test walk and your feet will thank you!

As someone who’s been in the workforce for many years, I always advise investing in work shoes or boots with the best traction technology for your environment. When liquids and other slick contaminants make flooring hazardous, oil-resistant footwear with slip-resistant soles can provide the serious grip and stability needed to get through long shifts surefooted, energized and protected.

Working around live electrical equipment or components requires an added layer of protection that standard work boots just don’t offer. That’s where electrical hazard (EH) rated shoes and boots come in. This key safety feature is something I always look for when picking out oil and water resistant work footwear.

Electrical Hazard Protection for Added Safety

Here are some key things I’ve learned about EH ratings over my years in occupations where contact with live circuits is a risk:

Electrical hazard protection involves using specially engineered soles in footwear that don’t conduct electricity. Rubber and thermoplastic polyurethane are common materials that provide this insulation. The footwear meeting EH standards will have an EH rating marked on it.

This EH rating means the shoes or boots have been tested to meet ASTM safety standards for standing up to live electrical circuits of up to 600 volts in dry conditions and 18,000 volts in wet conditions. That high voltage protection in wet environments is crucial since we often encounter liquids on the job.

EH footwear prevents electric current from flowing to the ground through your feet. Instead, the current flows around the outside of the boots. This protects you from severe nerve damage, internal tissue burning, muscle contractions and other hazards of electrical shock.

I like knowing OSHA mandates EH protection for workers in settings like construction, industrial plants and more where live wires and connections pose risks. EH boots comply with those federal regulations while delivering essential safeguarding.

Features like steel toes, metatarsal guards and shank reinforcement can be incorporated into EH boots without affecting electrical insulation. So you still get protection from impacts, compression and punctures along with the electrical safety.

EH rating testing checks footwear insulation before and after substances like mineral oil are applied to simulate workplace conditions. Properly EH rated boots maintain insulation despite liquids.

Along with electrical hazard protection, today’s top oil resistant work boots also deliver traction, cushioning, breathability and other features to safeguard and support your feet across long shifts.

As an experienced worker, I never take chances with electrical hazards on the job. Protecting against shocks and electrical burns is too important. That’s why proper electrical hazard footwear is a must-have for me and my crew any time our work brings us into contact with live power.

Don’t play games with boot quality and safety ratings. When you need electrical hazard protection along with slip, oil and water resistance for demanding work environments, do your homework to find footwear up to the task.

Oil and Water Resistant Materials Repel Liquids

When it comes to work shoes, having oil and water resistance is a highly desirable feature. Not only does it keep your feet dry and comfortable, but it also enhances safety by preventing slips on wet or oily surfaces. For workers in demanding conditions, oil and water resistant shoes are practically a necessity.

But what exactly makes a shoe oil and water resistant? There are a few key materials and technologies that enable work shoes to repel liquids.

Leather

Full-grain leather naturally repels water and oil to some degree. The dense structure and oils in high-quality leather make it difficult for liquid to penetrate. However, leather alone does not make a fully oil and water resistant shoe. It needs to be specially treated for maximum effectiveness.

Treatment and Coatings

Applying special treatments and coatings to leather enhances its natural liquid-repelling properties. Using hydrophobic and oleophobic chemicals provides an extra barrier against water and oil. The chemicals alter the surface tension of the leather, causing liquids to bead up and roll off instead of soaking in. Popular treatments like Scotchguard utilize these types of chemicals.

Membranes

Advanced membranes like Gore-Tex take liquid resistance a step further. These ultra-thin membranes have billions of pores that are smaller than liquid molecules but larger than water vapor molecules. This construction blocks liquid from passing through while still allowing ventilation. Membranes provide high-performance oil and water resistance without compromising breathability.

Construction

The overall construction of oil and water resistant shoes also plays a role. Sealed seams ensure liquids cannot sneak in through gaps or stitching holes. Gusseted tongues further prevent water from getting down into the shoe. Finally, combining a waterproof interior lining with the external resistant materials provides an impenetrable barrier.

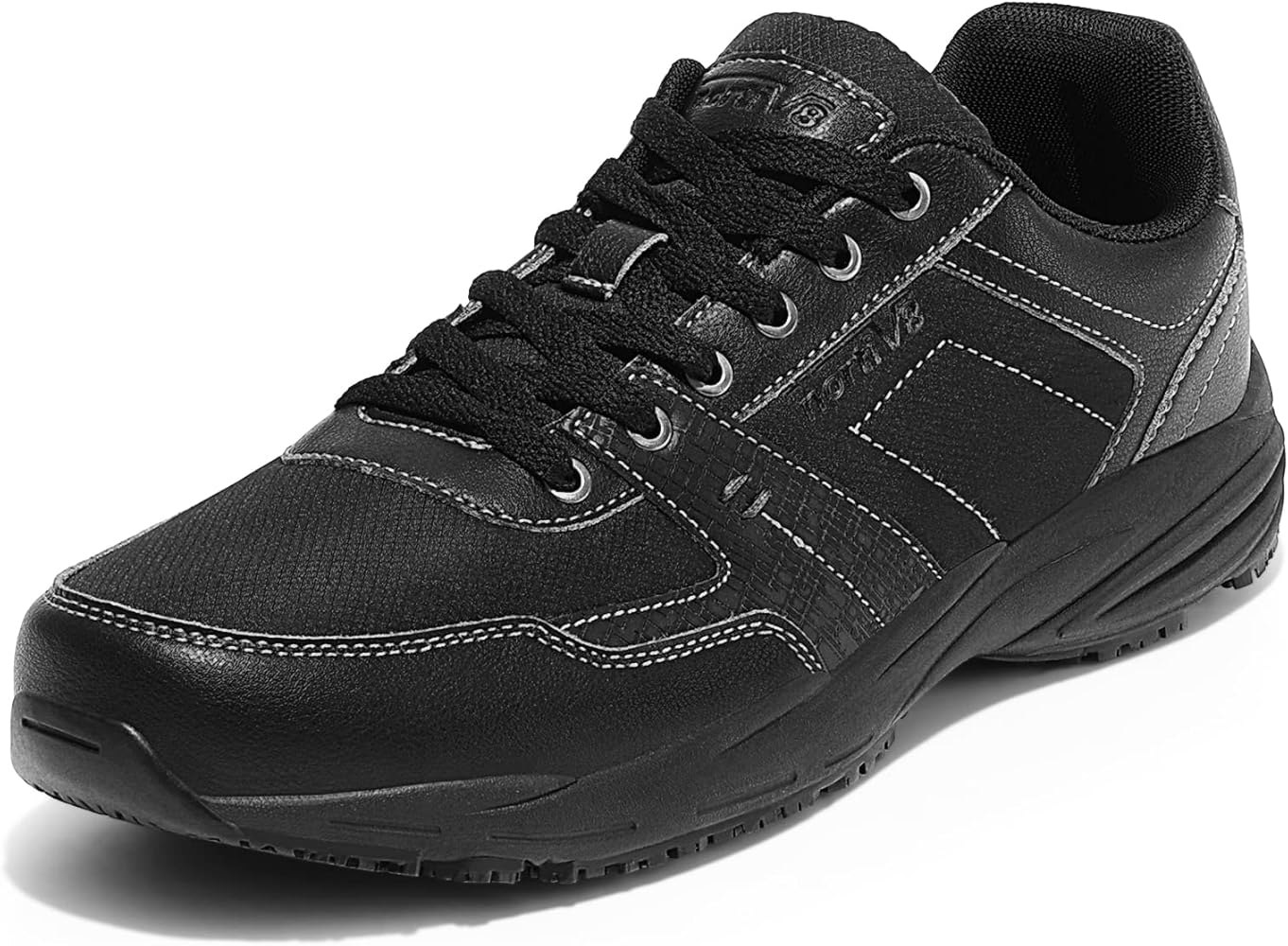

15 Amazing Features of Oil-Resistant Work Shoes

Oil-resistant work shoes contain incredible features that keep your feet protected. Here are 15 amazing benefits these special shoes provide:

- Repel oils, greases, and lubricants to prevent slipping

- Waterproofing keeps feet dry when walking on wet surfaces

- Durable leather or rubber uppers stand up to spills and stains

- Traction outsoles grip even the slickest floors

- Toe caps protect against falling objects

- Shock absorption reduces foot fatigue and joint strain

- Slip-on styles make them easy to take on and off

- Removable insoles accommodate orthotics

- Breathable linings prevent interior moisture buildup

- Lightweight design improves mobility and reduces fatigue

- Electrical hazard ratings for working around live wires

- Roomy toe boxes avoid pinched toes and numbness

- Midsole plates prevent sharp objects from puncturing soles

- Supportive arches and heels stabilize feet

- Antimicrobial treatment prevents odor buildup

With features like these, it’s easy to see why oil-resistant shoes are so popular with workers. They deliver unbeatable safety, comfort, and performance on the job. Brands like Skechers, Timberland Pro, Wolverine, Cat Footwear, and Rockrooster offer excellent options.

Choosing the Best Oil Resistant Work Shoes

With so many choices available, selecting the right oil resistant work shoes takes some consideration:

- Identify the main hazards you’ll encounter. Are oil spills, grease, chemicals, or water more prevalent?

- Prioritize features like slip resistance, waterproofing, breathability, and safety toes.

- Consider the type of materials that will stand up best to your environment.

- Make sure any specialized safety features meet your industry’s requirements.

- Try shoes on with the type of insoles or socks you’ll wear at work.

- Walk around the store to gauge flexibility, support, and comfort.

- Examine the sole tread pattern and confirm it provides adequate traction.

- Check that seams are sealed and the tongue is gusseted.

- Break shoes in properly at home before relying on them for work.

Finding oil and water resistant shoes that check all your boxes takes some legwork. But the payoff is keeping your feet protected and preventing slips and falls on the job.

Maintaining Your Oil Resistant Shoes

To get the longest life from oil resistant shoes, be sure to care for them properly:

- Check the tread regularly and replace shoes once worn down.

- Use commercial cleaners and conditioners made specifically for work shoes.

- Remove insoles to allow shoes to dry fully between wears.

- Disinfect interior periodically to prevent odor-causing bacteria.

- Use cedar shoe trees to maintain shape when storing shoes.

- Reapply protective sprays as needed after cleanings.

- Have a second pair to rotate to extend lifespan.

With occasional repairs and replacements, top-quality oil resistant shoes can provide years of reliable service life. The small upfront investment pays off significantly in safety and performance.

Don’t Sacrifice Comfort or Traction

When seeking oil and water resistant work shoes, workers shouldn’t have to compromise on comfort or traction. Today’s top options blend resistant exteriors with features like:

- Cushioned midsoles

- Supportive insoles

- Flexible uppers

- Moisture-wicking linings

- Oil-shedding treads

- Lightweight materials

- Shock absorption

- Ergonomic design

- Ventilation

With brands constantly innovating to improve comfort and safety, there’s no need to settle

Here is a 1000 word article on oil-resistant work shoes:

Steel Toes Protect Feet from Impact and Compression

When it comes to protective footwear for the workplace, steel toes are a must-have feature. Steel toe boots and shoes provide an extra layer of defense for the feet against two major hazards: impact and compression. Let’s explore why steel toes are so essential for many industrial and construction jobs.

Impact protection is one of the key benefits of steel toe footwear. Dropped tools, falling objects, and even stubbed toes can cause painful bruising or broken bones in the feet. The steel plating over the toes acts as a shield to prevent blunt force trauma from these sudden impacts. While regular soft-toed shoes provide a minimal barrier, steel toes are engineered to withstand forces up to 75 pounds before deforming. That high strength threshold effectively absorbs and deflects the energy from impacts to mitigate injury risk.

In addition to shielding against blows and collisions, steel toes also supply invaluable compression protection. Heavy loads that roll over the feet or stationary objects pinning the feet against a surface pose the danger of crush injuries. The unyielding steel toe box forms a protective pocket of space around the toes that prevents damaging compression and deformation from these forces. Tests show steel toes maintaining their shape and structure even under pressures up to 2,500 pounds.

The combination of impenetrable impact and compression resistance makes steel toes indispensable for occupations like construction, manufacturing, shipping and receiving, and heavy industry. Boots and shoes with steel toes look nearly identical to regular footwear but provide that extra margin of safety and peace of mind. For anyone whose job involves heavy equipment, moving parts, lifting, manual labor, or other hazardous conditions, steel toes can quite literally be lifesavers for the feet.

Oil-Resistant Work Shoes: 15 Amazing Features You Never Knew?

When working in slippery conditions with oils, greases, and solvents, oil-resistant shoes are a critical part of staying upright and injury-free. Let’s explore 15 amazing features that make oil-resistant footwear perfect for mechanics, factories, kitchens, and other messy jobs.

- Slip-resistant soles provide superior grip to prevent slips and falls on slick surfaces coated with oil, grease, or water.

- Oil-resistant materials like nitrile rubber withstand liquid penetration and deterioration.

- Padded collars and tongues block oil splatter from going over the top of shoes.

- Moisture-wicking linings keep feet dryer by absorbing sweat and moisture.

- Removable cushioned insoles provide arch support and shock absorption.

- Steel, alloy, or composite toe caps protect toes from impact and compression.

- Electrical hazard ratings prevent static buildup for working around live circuits.

- Chemical-resistant construction prevents deterioration from caustic substances.

- Heat-resistance allows for use around hot surfaces like grills and ovens.

- Midsole plates prevent punctures from sharp objects on the ground.

- Reinforced stitching maintains structural integrity with heavy use.

- Varied heights available from low-cut to knee-high lengths.

- Non-marking outsoles prevent scuffs and marks on floors.

- Easy-cleaning materials allow oil and stains to be simply wiped away.

- Lightweight builds enhance mobility and reduce fatigue.

The combination of slip resistance, waterproofing, and durability makes oil-resistant shoes ideal for any environment where grease, chemicals, or liquids present slip and stain hazards. Considering the ankle rolls, Achilles strains, knee injuries, and back problems that can result from falls and slips, oil-resistant footwear provides inexpensive protection and peace of mind.

For auto mechanics crawling under cars, factory workers monitoring oily machinery, or kitchen staff hustling around grills and fryers, the right oil-resistant shoes can make all the difference in safety and performance. With features like traction soles, steel toes, moisture wicking, and heat resistance, oil-resistant shoes allow workers to focus on the job rather than worrying about the slippery conditions underfoot.

next time you’re shopping for work shoes, look for oil-resistant options to keep yourself confidently upright and injury-free, no matter how messy the job. Your joints, back, and peace of mind will thank you.

Removable Cushioned Insoles Offer All-Day Comfort

When you’re on your feet all day for work, comfort is key. This is where removable cushioned insoles can make a huge difference in oil-resistant work shoes. Let’s explore why swappable insoles with ample padding are must-have features for anyone who spends long hours walking, standing or moving around on hard surfaces.

The human foot was not designed to support our full body weight on unforgiving concrete or steel for hours at a time. Removable insoles made of shock-absorbing materials provide a literal cushion between your feet and the ground. Quality insoles have an arch support area that matches the contours of your foot to alleviate strain on the plantar fascia ligament and metatarsal bones. The heel cup helps stabilize the foot and prevent it from sliding forward inside the shoe, reducing friction.

Throughout a long shift, insoles absorb much of the impact and vibration from each step that would otherwise transfer directly to your joints and spine. This leads to reduced fatigue and discomfort in the back, knees, hips and feet. Swappable insoles allow you to remove and replace them when they become compressed and worn out. Some models also have anti-microbial properties to fight odor.

Compare this to non-cushioned insoles made of thin cardboard or plastic. Those hard surfaces provide no alleviation of pressure points or shock dissipation. For workers who logged miles around warehouses or production floors, durable foam or gel insoles can be lifesavers for energy and pain reduction. Even adding custom orthotics on top of the removable insole can dial-in the arch and heel support even more.

Insoles also play a subtle role in slip prevention. Quality cushioned insoles improve overall shoe fit and stability. If your foot is sliding around loosely inside an oversized work boot, your balance and traction control suffers. Proper fitting shoes with supportive insoles anchor the foot securely to better handle oil-coated floors.

Consider swapping out the insoles that came with your work shoes for aftermarket insoles with better cushioning and support. For optimal comfort, bring your shoes with you when trying new insoles to test the fit. A little investment here pays dividends over miles of walking and long shifts. Don’t underestimate the value of proper insoles for all-day wearability and injury prevention on the job.

Oil-Resistant Work Shoes: 15 Amazing Features You Never Knew?

Working in oily or slippery conditions can quickly turn hazardous without the right footwear. Let’s explore 15 critical features that make oil-resistant shoes so important for safety and performance.

- Slip-resistant soles grip well to prevent falls on greasy floors. Look for deep lugs and channels.

- Waterproof materials prevent oil and liquid absorption into shoes.

- Chemical resistance prevents damage from corrosive substances.

- Padded tongue and collar blocks debris from entering shoe.

- Moisture-wicking liner keeps feet dryer by absorbing perspiration.

- Removable insoles allow inserting customized orthotics.

- Shank plate in midsole prevents punctures through sole.

- Electrical hazard rating prevents static discharge near circuits.

- Steel, alloy or composite toe cap protects from falling objects.

- Heat resistance allows for proximity to hot surfaces.

- Kick-off lugs make taking shoes on and off easier.

- Reinforced stitching prevents seams from splitting.

- Lightweight design enhances mobility and reduces fatigue.

- Non-marking outsoles prevent scuffing floors.

- Easy-to-clean materials let oil and stains wipe away.

With features like traction lugs, steel toes, chemical resistance, and heat tolerance, oil-resistant shoes provide a critical barrier between hazardous workplace conditions and the vulnerability of human feet. A simple slip can cause sprains, fractures, dislocations or contusions leading to expensive medical treatment and lost time at work.

Investing in proper footwear pays dividends through reduced injuries, insurance claims, and lost productivity. For any environment with slick floors, heavy equipment, hot surfaces, or caustic chemicals, oil-resistant shoes deliver inexpensive peace of mind. Whether working in a fast-paced kitchen, crowded factory, bustling warehouse or demanding construction site, the right shoes empower employees to walk confidently without worrying about what’s underfoot.

Don’t let inadequate footwear put your safety, comfort or productivity at risk. Look professional and stay upright all shift long with purpose-built oil-resistant shoes loaded with slip-resistant soles, protective toes, stability, breathability and durability. Your feet will thank you at the end of each workday.

Lightweight Construction Reduces Fatigue

Working long shifts on your feet can take a toll without proper supportive footwear. Let’s look at why lightweight construction is a key feature for oil-resistant work shoes to reduce fatigue and boost energy.

Heavy clunky boots may provide protection, but all that excess weight on your feet tires out your legs, joints, and back. The additional pounds strain your leg muscles to lift each foot, forcing them to work harder with every step. This extra exertion causes premature muscle fatigue and leaves you drained by the end of the day.

Go lighter to go longer. Advanced materials like carbon fiber and ultra-light high-tech composites allow work boots and shoes to provide safety and stability without all the heft. This improved lightweight design enhances mobility and agility on the job. Lighter shoes allow you to move faster with less perceived effort. Your legs stay fresher for longer when not weighted down.

The reduction in muscle fatigue also leads to better balance and coordination. Heavy boots that tire out your feet and ankles increase the chances of a misstep or slip on the slick floors common in oil-filled work environments. Newer lightweight materials also tend to offer better flexibility and break-in periods than heavy leather or rubber boots.

In addition to less muscle fatigue, lightweight oil-resistant shoes also decrease strain on your back, knees, ankles and feet throughout the workday. Heavy boots tax all those contact points excessively through your gait cycle. Excess weight compounds the chronic impact on your joints from long hours on hard surfaces. Go lighter to alleviate this added stress and reduce pain.

Don’t equate lightweight with weak. Modern oil-resistant shoes offer innovative strong, stab-proof materials engineered for resilience, protection and comfort. Durability doesn’t have to mean discomfort. Seek out boots and shoes constructed purposefully with workers’ fatigue, health and safety in mind.

Oil-Resistant Work Shoes: 15 Amazing Features You Never Knew?

Working in potentially slippery conditions posed by oil, grease or liquids requires specialized footwear. Let’s look at 15 key features to provide protection and traction.

- Slip-resistant soles with deep lugs grip well on slick floors.

- Waterproof construction prevents absorption of oil or chemicals.

- Padded collars block debris from getting inside shoes.

- Anti-microbial linings prevent odor buildup.

- Removable cushioned insoles provide support and comfort.

- Flexible shank plates in midsole prevent puncture wounds.

- Composite or alloy safety toes shield from impact.

- Electrical hazard ratings prevent static discharge.

- Heat-resistance for proximity to hot surfaces.

- Reinforced stitching maintains structural integrity.

- Kick-off lugs ease taking shoes on and off.

- Lightweight components reduce fatigue and strain.

- Non-marking soles prevent scuffs on floors.

- Low maintenance materials clean up oil stains easily.

- Affordable pricing protects workers on a budget.

With their specialized traction soles, protective features, and durable construction, oil-resistant shoes provide inexpensive insurance against slips and injuries. Falls from slick surfaces like oil-coated concrete can lead to sprains, fractures, contusions, back injuries, and even concussions.

Investing in proper footwear reduces incidents, accidents, insurance claims, and lost productivity. Workers stay upright and confident, focusing on the job rather than worrying about slippery floors. Purpose-built oil-resistant shoes deliver comfort, support, and peace of mind across long shifts in demanding environments.

Don’t let inadequate footwear put your safety at risk or leave you with throbbing feet. Seek out lightweight, flexible, oil-resistant shoes that will carry you through the walking, climbing, and lifting demands of the workday with less strain and fatigue. Your back, feet, and wallet will thank you.

Flexible Uppers Move With Your Feet

Long days on your feet require work shoes that can keep up. Let’s look at why flexible uppers that move naturally with your feet are a key feature in reducing fatigue for oil-resistant footwear.

The upper part of a work shoe takes a beating during non-stop walking and moving. Inflexible materials like thick leather or rubber can be durable but they break in slowly and resist natural foot motion. This forces your feet to exert extra effort conforming to the stiff shape of the shoe. The result is premature fatigue and discomfort.

More flexible uppers made of softer materials reduce this burden by flexing and bending easily as you walk. Lightweight knitted fabrics that stretch and bounce back, laser cut designs with strategic ventilation, and supple synthetic leathers require far less break-in time. This flexibility allows your foot muscles and tendons to move freely rather than fighting against an unyielding upper.

The reduction in friction and resistance translates directly into energy savings and less exertion over long shifts on unforgiving surfaces. Flexible shoes become like a second skin, reducing pressure points and hot spots by conforming to each user’s foot shape. Better foot motion control also enhances stability and traction on slippery oily floors.

In addition, flexible uppers are more forgiving against oil and liquid splashes. Materials like tightly-woven stretch fabrics resist absorption and penetration better than natural leathers. Liquid rolls right off rather than soaking in. That flexibility also allows for easier cleaning by simply wiping stains away.

When evaluating your next pair of oil-resistant shoes, pay close attention to upper material and construction. Seek out purposeful designs that flex and support natural foot motion rather than rigidly restricting it. Your feet will thank you after mile after mile on hard unforgiving surfaces.

Oil-Resistant Work Shoes: 15 Amazing Features You Never Knew?

Working in slippery conditions posed by oil or grease requires specialized footwear. Let’s explore 15 must-have features to provide protection.

- Deep slip-resistant lugs grip well on slick floors.

- Waterproof seam-sealed construction blocks liquid absorption.

- Flexible uppers move naturally with the foot.

- Padded tongue and collar prevents debris intrusion.

- Removable antimicrobial insoles control odor.

- Shank plate provides puncture protection.

- Alloy safety toe protects from falling objects.

- Heat resistance for proximity to hot surfaces.

- Electrical hazard rating prevents static buildup.

- Reinforced stitching maintains durability.

- Kick-off lugs make taking shoes on and off easier.

- Lightweight components prevent fatigue.

- Non-marking soles prevent floor scuffing.

- Affordable pricing makes safety accessible.

- Easy to clean and wipe away stains.

With their combination of flexible support, traction, and protection, oil-resistant shoes provide inexpensive insurance against injury. Slip and fall accidents lead to sprains, fractures, strains, contusions, and chronic back pain.

Averting just one major accident can more than pay for proper footwear through reduced insurance claims, medical treatment, and lost productivity. Investing in oil-resistant shoes allows workers to walk securely on slick surfaces without worrying about losing their footing.

Don’t let inadequate footwear put your safety and comfort at risk. Seek out lightweight oil-resistant shoes with flexible uppers that support natural foot motion all shift long. Keep your feet energized and upright with purpose-built footwear made for your work environment’s unique hazards.

Shock-Absorbing Midsoles Reduce Stress

If you work on your feet all day, finding the right work shoes is crucial for your comfort and health. Oil-resistant work shoes with shock-absorbing midsoles are an excellent choice to reduce stress on your joints and keep your feet happy. In this article, we’ll explore 15 amazing features you never knew about oil-resistant work shoes with cushioned midsoles.

1. Slip Resistance

Oil-resistant shoes are designed with specialized rubber outsoles to prevent slipping on wet, oily surfaces. The grooved tread pattern provides superior traction so you can walk with confidence in demanding work environments from oil rigs to factories. Having slip-resistant shoes can help avoid painful, and potentially serious, fall injuries on the job.

2. All-Day Comfort

Shock-absorbing midsoles made of EVA (ethyl vinyl acetate) foam cushion each step, reducing fatigue and joint stress if you’re on your feet for hours. The right amount of flexibility paired with steadiness promotes proper stride biomechanics as well. Your work shoes should feel broken-in, not stiff or restrictive.

3. Moisture Control

Oil-resistant work shoes are constructed with water-resistant materials and seam-sealed uppers to keep your feet dry. Wet feet lead to blisters and fungal infections. The moisture-wicking lining also draws sweat away from your skin for a cool, comfortable feel all day.

4. Protective Design

Thick, durable leather or suede uppers protect your feet from abrasions, bumps, and minor impacts. Many oil-resistant work shoes also meet safety toe requirements to guard against compression and falling objects. The puncture-resistant midsole shields against sharp items penetrating the sole.

5. Excellent Grip

Outsoles made of slip-resistant rubber provide a superior grip with unmatched traction control on oily surfaces. The deep lugs and tread pattern efficiently channel liquid away while maintaining floor contact for stability. The sole compound remains pliable in cold temperatures as well.

6. Good Fit

With extended sizes and widths plus removable footbeds, it’s easier to get a custom fit. Properly-fitting shoes align your feet correctly to avoid issues like plantar fasciitis or bunions. High-quality oil-resistant work shoes conform to your feet over time but won’t stretch out and become loose.

7. Removable Insoles

Many work shoes have removable cushioned insoles to accommodate orthotics. You can also take the insoles out to air dry if your shoes get wet to prevent odors and bacterial overgrowth. Replacement insoles can restore comfort when the originals wear out.

8. Structural Support

With their stabilizing heel counters, supportive cushioned midsoles, and shank reinforcement, oil-resistant work shoes provide structure to improve balance and alignment. Your feet remain properly positioned to avoid problems like overpronation during long days on uneven surfaces.

9. Durable Construction

Rugged oil-resistant work shoes are built to handle tough conditions. The solid stitching, premium leather, and fortified sole materials hold up well to daily wear-and-tear without breaking down quickly. Getting the most out of your investment means shoes that withstand the demands of your job.

10. Easy-Off Design

From loops in the heel to extra ankle padding, oil-resistant work shoes are crafted to make them easy to take off, an important feature when your shoes are coated in oil and grease. You won’t have to struggle to remove them at the end of a dirty shift.

11. Better Traction

Lugs, treads, and grooves carved into oil-resistant soles provide multi-directional traction to prevent slipping on rough terrain and uneven ground. This enhanced traction when walking across grating or gravel improves stability in dynamic environments.

12. Protects Clothing

The high ankle height and durable leather construction seal out splashes, drips, and spills, keeping oil and grease off your pants and socks. Waterproofing treatments add an extra barrier against liquids penetrating clothing underneath.

13. All-Weather Use

In contrast to your everyday shoes, oil-resistant work shoes perform in tough weather from rain and snow to extreme heat and cold temperatures. The sturdy materials hold up to the elements at outdoor job sites.

14. Better Balance

With their slip-resistant soles and stabilizing features, oil-resistant work shoes promote good balance as you walk. The tread pattern and support system help compensate for uneven terrain. Maintaining proper equilibrium reduces your risk of falls.

15. Compliance with Standards

Quality oil-resistant work shoes meet established industry safety standards. For electrical jobs, shoes rated EH protect against the hazards of accidental contact. Compliant footwear ensures you avoid injuries and meets occupational requirements.

If you spend long work days on your feet, invest in comfortable oil-resistant shoes with shock-absorbing midsoles. Prioritizing foot health and safety pays off over time with fewer aches and better mobility. Don’t ignore the importance of proper work footwear just because it’s not visible under your uniform.

Durable Leather and Synthetic Uppers Withstand Wear

Working in demanding environments requires durable footwear that can stand up to heavy use. Oil-resistant work shoes with sturdy leather and synthetic uppers provide long-lasting wear protection. In this article, we’ll highlight 15 amazing features of quality oil-resistant work shoes you may not know about.

1. Abrasion Resistance

The thick leather and hardy synthetic materials are highly abrasion-resistant to prevent scuffs, scrapes, and cuts. Your toes and feet stay protected from bumps and knocks on the job site without rapidly showing signs of damage.

2. Puncture Protection

Sharp objects can’t easily penetrate the tough leather and sturdy synthetic uppers on good oil-resistant work shoes. The materials shield your feet from puncture wounds so you can work safely and confidently in high-risk environments.

3. Waterproofing

Seam sealing and waterproof membranes block exterior moisture from soaking into the leather and synthetic uppers. Your feet stay drier when working outdoors in wet conditions, preventing hot spots and blisters.

4. Stain Resistance

Oils, fuels, and other hydrophobic stains have a hard time permeating and soaking into properly treated leather and synthetic blends. The materials repel liquids to maintain a cleaner, more professional look.

5. Comfortable Fit

Quality leather and synthetic blends flex with your feet, conforming to their shape for a broken-in feel right out of the box. The uppers won’t cause painful hot spots, blisters, or bruising during long shifts.

6. Breathability

Leather naturally allows air flow while moisture-wicking synthetic linings draw perspiration away from your skin. Better breathability keeps your feet drier and more comfortable in hot environments.

7. Durability

The solid, thick leather and hardy synthetic uppers stand up to scuffs, abrasion, minor impacts, and everyday wear-and-tear without quickly breaking down. They last longer through repetitive use in harsh conditions.

8. Flexibility

Quality oil-resistant work shoes maintain a decent amount of flexibility thanks to the supple leather and synthetic material blends. Your feet and ankles enjoy a good range of motion for comfort.

9. Lightweight

Modern synthetic blends minimize bulk and excess weight even in protective work shoes. The uppers are thick but not unnecessarily heavy to avoid fatigue from wearing them all shift.

10. Support

Durable leather stabilizes your feet well, preventing uncomfortable sliding inside the shoes that can lead to blisters. The solid synthetic materials also deliver a steady feel underfoot.

11. Easy Cleaning

You can wipe down leather and synthetic uppers easily with a damp cloth, removing most soils. Proper care keeps oil-resistant work shoes looking their best for years of wear.

12. Non-Allergenic

The leather and synthetic uppers won’t trigger allergies or skin reactions like certain natural materials. Your feet stay comfortable all shift long.

13. Slip Resistance

Textured leather provides a decent grip on oily surfaces, while synthetic overlays optimize traction. The materials give you steady footing in hazardous conditions.

14. Toe Protection

Durable leather and synthetic toe overlays provide an extra layer of shielding against impacts, compression, falling objects, and other hazards.

15. Professional Look

The well-constructed leather and synthetic uppers maintain a clean, put-together appearance for work. You look occupied and serious in protective footwear built to last.

Leather and synthetic blends optimize durability, protection, breathability, comfort and professionalism in quality oil-resistant work shoes. Prioritize footwear with sturdy uppers constructed to provide support mile after mile on the job site without breaking down quickly. Your feet will thank you at the end of a long shift.

Puncture-Resistant Plates Protect Against Sharp Objects

Working in hazardous environments brings the risk of foot injuries from sharp objects. Look for quality oil-resistant work shoes with puncture-resistant plates when protection is paramount. In this article, we’ll explore 15 impressive features you may not know these protective work shoes offer.

1. Peace of Mind

Knowing puncture-resistant plates shield your feet from injury if you step on exposed nails, screws, metal shards and other sharp items provides confidence and peace of mind on the job.

2. Impact Resistance

The solid plates not only stop punctures but also absorb and distribute impact forces to safeguard your feet from bruising if you drop heavy tools or materials.

3. All-Day Comfort

Quality puncture-resistant plates maintain flexibility so they don’t restrict your foot’s natural range of motion. The shoes remain comfortable for extended wear.

4. Durability

Rugged puncture-resistant plates stand up well to repetitive pounding and abrasion over time without losing protective performance. They’re built for longevity.

5. Lightweight Feel

Modern puncture-resistant materials like Kevlar and thermoplastic polyurethane are strong yet lightweight. The shoes feel agile, avoiding fatigue from heavy components.

6. Stability

The stiff puncture-resistant plate provides a stable platform for your foot, enhancing balance when walking on uneven terrain or bearing heavy loads.

7. Slip Resistance

Quality oil-resistant work shoes combine puncture protection with an aggressive tread pattern to ensure reliable traction on slippery surfaces.

8. Moisture Control

Breathable linings and puncture-resistant plates made with hydrophobic materials help keep your feet drier during long work shifts.

9. Toe Protection

Full-length puncture-resistant plates shield the vulnerable toe area from painful impacts and puncture wounds in heavy industrial settings.

10. Plate Flexibility

Flexible plates maintain your foot’s natural range of motion for comfortable wear all day long without restricting bend and flexion.

11. Compression Resistance

Rigid plates distribute and absorb pressure to protect your feet from feeling squeezed or crushed by heavy items or compression forces.

12. All-Weather Use

Puncture-resistant plates retain protective performance in wet, humid, freezing or hot temperatures so you can focus on the job.

13. Athletic Feel

Cushioned midsoles and flexible puncture plates provide an athletic, nimble feel you can move confidently in.

14. Professional Look

Low-profile plates don’t add bulk to the streamlined work shoe silhouette. You still look sharp on the job site.

15. Meets Standards

Quality puncture-resistant plates comply with occupational footwear safety ratings so you avoid injuries.

Don’t risk painful puncture wounds at work. Seek out durable oil-resistant shoes with integrated puncture plates that provide reliable protection without sacrificing comfort or freedom of motion.

Moisture-Wicking Linings Keep Feet Dry

Working long shifts leads to sweaty, uncomfortable feet, but moisture-wicking linings in quality oil-resistant work shoes can help. In this article, we’ll highlight 15 impressive features you may not know these specialized work shoes deliver.

1. Dry Comfort

Moisture-wicking linings draw perspiration away from your feet, keeping them comfortably dry even during active jobs or warm weather.

2. Blister Prevention

By keeping your feet drier, moisture-wicking linings help prevent painful blisters from extended wear when sweat builds up inside your shoes.

3. Breathability

Specialized linings allow air flow and ventilation inside your work shoes for a cooler feel. Your feet can breathe easier.

4. Odor Resistance

Excess moisture breeds odor-causing bacteria. Moisture-wicking linings prevent sweat buildup that causes shoes to smell bad over time.

5. All-Day Comfort

Keep your feet comfortable for hours when you work long shifts by choosing shoes with linings that wick away sweat and discourage chafing.

6. Hot Spot Reduction

By keeping your feet drier, moisture-wicking linings help prevent painful hot spots from friction that can make walking unbearable.

7. Improved Traction

Keeping your feet drier means better contact between your socks and the insoles for improved traction and slip resistance inside your shoes.

8. Lightweight Feel

Advanced moisture-wicking lining materials add comfort without extra weight or bulk so your shoes still feel agile.

9. Athletic Design

Moisture-wicking linings give work shoes an athletic, high-performance feel you can tackle tough jobs in.

10. Better Insole Contact

By preventing sweat buildup, moisture-wicking linings discourage your socks from slipping against removable insoles.

11. Fresher Feet

Wicking away perspiration keeps your feet from feeling stale, wet and gross during work. You feel rejuvenated all shift long.

12. Washable Linings

Many moisture-wicking shoe linings are removable and washable to keep them fresher between wears.

13. Dry Even When Wet

The linings still pull sweat away even if your shoes get soaked, helping your feet stay drier.

14. Less Itching

Preventing excess sweat minimizes itchy irritation that damp feet can cause during long shifts.

15. Fungal Resistant

Wicking away moisture inhibits fungal growth by discouraging damp conditions inside your shoes.

Don’t tolerate sweat-soaked feet at work. Prioritize oil-resistant work shoes with moisture-wicking linings that keep you dry and comfortable all shift long.

Aggressive Tread Patterns Grip Many Surfaces

Finding the right pair of work shoes can make all the difference when you’re on your feet all day. For jobs that involve potential exposure to oil and other liquids, oil-resistant shoes are a must. These durable, grippy shoes provide traction and keep your feet dry, supporting you through long shifts.

Oil-resistant work shoes boast a number of features that make them ideal for tough industrial and service industry jobs. Let’s explore some of the top benefits:

1. Slip-Resistant Soles

The hallmark of a good pair of oil-resistant shoes is a rugged, lugged sole. Deep tread patterns with multi-directional lugs bite into surfaces, providing stability and traction even on oily and wet floors. Thick rubber soles also absorb impact, reducing fatigue.

2. Repels Oil and Water

Quality oil-resistant shoes have uppers made of leather, synthetics, or mesh that repel oil, gasoline, and other liquids. Water-resistant membranes help prevent water from seeping in. This keeps your feet dry as you work, avoiding that uncomfortable soggy shoe feeling.

3. Lightweight Yet Supportive

The best oil-resistant shoes balance lightweight comfort and sturdy support. Shoes made with breathable mesh provide ventilation to keep your feet cool. Plush insoles cushion your steps. Supportive midsoles stabilize your stride. And steel toes offer impact protection.

4. Slip-On Styles for Convenience

For fast on and off, some oil-resistant shoes feature convenient slip-on Chelsea styles with elastic goring. These shoes let you step in and out smoothly without stopping to tie laces. The elastic sides flex with your foot for a snug, customizable fit.

5. Electrical Hazard Protection

Shoes rated for electrical hazard safety provide insulation if you accidentally step on a live wire. This prevents electric current from flowing through your body. The soles incorporate non-conductive materials to stop electricity from reaching your feet.

6. Chemical Resistance

Some oil-resistant shoes offer broad chemical resistance. Made to hold up to caustic acids, bases, alcohols, and other chemicals, they protect workers in hazardous industrial environments.

7. Slip-Retardant Outsoles

Outsoles made of nitrile or thermoplastic rubber provide superior traction, especially on slippery oily surfaces. The rubber compound sticks to floors without skidding. Some outsoles also incorporate siping – thin slits that boost surface contact.

8. Puncture-Resistant Midsoles

Kevlar or fiberglass shanks embedded in midsoles resist punctures from nails and debris. This protects your feet from sharp objects lying around on the job site.

9. Shock-Absorbing Heel Cushions

Built-in heel shock absorbers soften each step, reducing strain on your back and joints. This cushions your heels and makes being on your feet all day less tiring.

10. Moisture-Wicking Lining

Breathable, moisture-wicking linings keep your feet cool and comfortable inside your shoes. Linings made of antimicrobial materials inhibit odor-causing bacteria and control foot sweat.

11. Heat-Resistant

Shoes rated for heat protection can withstand hot surfaces up to temperatures of 572°F. This level of heat resistance helps shield your feet around ovens, grills, and other hot areas.

12. Flexible Uppers

Uppers made of full-grain leather or combinations of leather and mesh flex with your feet as you walk and bend. This allows a natural stride without restriction.

13. Lightweight Construction

Modern oil-resistant shoes weigh 30-40% less than traditional work boots. Lighter materials reduce fatigue so you can stay on your feet longer without tiring as quickly.

14. Athletic Styling

Today’s oil-resistant shoes borrow styling cues from athletic shoes. Sporty silhouettes paired with technical features provide comfort and protection all work day.

15. Affordable Prices

While oil-resistant shoes offer premium protection and traction, improved manufacturing techniques have kept prices affordable. Durable options are available at accessible price points.

When you spend all day on your feet, comfort is critical. Oil-resistant shoes deliver traction and waterproofing along with plush cushioning and support. Key features like slip resistance, breathability, and flexibility help you power through long shifts. With the right pair of shoes, you can work safely and confidently, no matter how messy the job.

Lace-Up Closures Deliver Secure Fit

When it comes to oil-resistant work shoes, having a secure fit is absolutely essential. Unlike slip-on shoes, lace-up closures allow you to adjust the tightness and get the perfect customized fit. This prevents your feet from slipping around inside the shoes when you’re walking on slick surfaces. The last thing you want is your foot sliding forward and hitting the front of the toe when you’re carrying heavy loads up and down stairs or ladders. Lace-up oil-resistant shoes let you snug up the fit so your foot stays locked in place inside the shoe.

In addition to adjustable tightness, lace-up closures also provide more ankle support than slip-ons. The laces allow you to close the shoes right up near the ankle for a close, stable fit. This prevents your ankles from rolling and keeps them properly supported. Having strong ankle support is important for walking or standing on uneven ground, which you often encounter at industrial sites and construction zones. It also reduces strain and fatigue in your feet, ankles and calves when you’re on them all day.

Non-Slip Soles Grip Wet Surfaces

Of course, the main purpose of oil-resistant work shoes is to provide traction on slick surfaces. The outsoles are made of rugged, heavy-duty rubber that stands up to caustic oils and solvents without deteriorating. But the really important feature is the tread pattern, which bites into oily surfaces so you don’t slip. The lugs and grooves are designed to channel liquid away, while the shape and spacing of the lugs maximize surface contact and grip.

The best oil-resistant shoes use a lugged, open-tread design that self-cleans as you walk. Narrow, closed treads with small lugs can get jammed up with oil, mud or grease, turning your slip-resistant shoes into slip-ON shoes! Open lug patterns shed muck and liquids so the sole stays grippy. Some designs have angled lugs along the edges for traction on ladders. The deeply lugged sole also provides flexibility, absorbing shock and reducing foot fatigue.

Moisture-Wicking Lining Keeps Feet Cool and Dry

Since oil-resistant work environments tend to be hot, shoes feature breathable linings to keep your feet from overheating and sweating. The inner fabric wicks moisture away from your skin and allows air flow to cool and dry your feet. This prevents the growth of odor-causing bacteria. Mesh fabric linings work best for ventilation and moisture control. Some linings have anti-microbial properties to inhibit bacteria and fungus.

The lining also acts as a secondary protective barrier in case any liquids seep through cracks or perforations in the upper material. The breathable lining absorbs sweat and any stray droplets, keeping your socks and feet dry. This greatly enhances your comfort when you’re on your feet for long periods.

Chemical-Resistant Upper Materials

The uppers are constructed from thick, rugged synthetic materials or leathers that stand up to caustic oils, solvents and other workplace chemicals. Typical materials include nylon, polyurethane-coated leather, nitrile and PVC. These resist acids, alkalis, alcohols, ketones and other corrosive liquids that would degrade ordinary shoe materials.

However, no material is 100% impervious, so you still need to take precautions and avoid prolonged exposure by removing shoes at the first sign of chemical seepage. Uppers may feature reinforced toes and heels for extra protection in high impact areas. Stitched seams are sealed to prevent liquid penetration. Metal grommets for laces are corrosion-resistant.

Electrical Hazard Safety

For work environments with the risk of accidental electrical contact, specialized ESD (electrostatic discharge) shoes have soles that don’t conduct electricity. This prevents electric shock through your feet if you accidentally step on a live wire or circuit. The sole/heel material has a very high electrical resistance that stops the flow of current.

The upper is also non-conductive and dissipates static charges from your body through the sole. This prevents static discharge that could ignite vapors or damage electronics. The best ESD shoes have an electrical resistance rating of over 100 megohms to ensure you stay insulated from electric shock.

Slip-On Styles Offer Quick On/Off

While lace-ups provide the most secure fit, slip-on styles are convenient since you can just kick them on and off quickly. This allows fast removal when shoes become contaminated before entering clean areas. They easily fit over a wider range of sock thicknesses too. However, sizing is less adjustable without laces. Elastic goring on both sides allows flexibility when putting them on.

Slip-on safety shoes still feature oil-resistant, non-slip soles along with protective toe caps. But they lack the ankle support of lace-ups. Heel pulls make them easier to take off. They can be a good choice for those with mobility limitations who have difficulty bending over or tying laces.

Metatarsal Guards Shield Top of Foot

For hazardous jobs where heavy objects could crush your feet, metatarsal guards add an extra layer of protection. These are layered panels of impact-resistant material that fit over the instep area and shield the metatarsal bones. They prevent injury from impacts that could occur when equipment or materials fall on your feet.

External met guards attach securely to the outside of shoes. Integrated metatarsal guards are built into the shoes themselves for more low-profile protection. Both types are made of lightweight materials like fiberglass, Kevlar or thermoplastic so they don’t restrict movement or feel bulky on your feet.

So if you work in an environment with risk of foot injury from falling or rolling objects, opt for oil-resistant shoes with metatarsal protection built in.

Comfort Features Reduce Fatigue

Because oil-resistant work shoes lack the cushioning of athletic shoes, manufacturers add comfort features to make them easier to wear for long periods. Padded collars and tongues distribute pressure and prevent chafing. Removable insoles with arch support, heel cups and shock absorption relieve stress on feet, ankles and knees.

Flex grooves in the outsole improve flexibility so your stride feels more natural. Rocker sole profiles make walking easier by allowing the sole to roll smoothly through the stride. Thick, cushioned midsoles absorb impact when walking on hard surfaces. Other features like shanks and stability plates provide support and torsional rigidity.

While oil-resistant shoes will never feel like sneakers, these comfort technologies make a big difference in keeping you on your feet feeling energetic versus fatigued.

Lightweight Materials Reduce Fatigue

The combination of heavy-duty construction and protective features adds weight to industrial work shoes. Carrying this extra load around all day can tire out your feet, ankles and back. However, manufacturers are utilizing new lightweight materials in uppers, soles and protective components to reduce the energy cost of wearing these shoes.

Lighter weight nylons and synthetic leather replace heavier conventional leathers. Polyurethane midsoles offer cushioning at a fraction of the weight of rubber. Plastic and composite materials in toe caps and metatarsal guards weigh ounces instead of pounds.

Every ounce shaved off a pair of shoes reduces the effort your muscles expend walking and lifting your feet all day. Just a few ounces less per shoe can make a dramatic improvement in stamina and how fresh your feet feel after a 12-hour shift.

High Visibility Colors for Safety

Low light conditions, moving equipment and vehicles create hazards for workers on their feet in industrial settings. So high visibility shoes with bright, reflective colors and trim help ensure you’ll be seen. Bold contrasting colors like orange, yellow or lime stand out against dim backgrounds. Retroreflective strips reflect light back to its source so you’re visible at night.

Contrasting colors differentiate the toe cap and sole so they catch the eye. Photo-luminescent materials absorb light and glow to provide afterglow visibility in dark conditions after the light source is removed. For optimal safety, choose high contrast or fluorescent colors with multiple reflective accents.

Steel Toes Protect Feet