What are the main characteristics of woven fabrics. How do woven fabrics differ from knit fabrics. Which types of woven fabrics are best suited for different sewing projects. What factors should be considered when selecting woven fabrics for garments.

Distinguishing Features of Woven Fabrics: Appearance, Stretch, and Care

Woven fabrics are an essential component of the textile industry, characterized by their unique construction and properties. These fabrics are created by interlacing two or more threads or yarns at right angles, resulting in a distinctive crisscross pattern. Understanding the key features of woven fabrics is crucial for both sewing enthusiasts and fashion-conscious consumers.

Visual Identification of Woven Fabrics

One of the primary ways to identify a woven fabric is through visual inspection. Under close examination, woven fabrics display a basket-like weave structure. For those with less experience or when dealing with fabrics featuring small stitches, using a magnifying glass can be helpful in observing this characteristic pattern.

Stretch Properties of Woven Fabrics

Woven fabrics are known for their limited stretch capabilities. When pulled, they may exhibit slight elongation along their length but minimal stretch along their width. This property makes woven fabrics generally easier to work with in sewing projects compared to their knit counterparts.

Wrinkle Behavior of Woven Fabrics

To determine if a fabric is woven, a simple wrinkle test can be performed. Take a small piece of the fabric, ball it up in your fist, and press firmly. If the fabric creases easily, it is likely woven. This tendency to wrinkle is a characteristic feature of many woven fabrics, although some modern treatments can reduce this effect.

Shrinkage and Care Considerations

Compared to knit fabrics, woven materials are generally less prone to shrinking. However, exposure to very hot water during washing can cause some shrinkage, particularly in fabrics with a high percentage of natural fibers like cotton. To maintain the shape and size of garments made from woven fabrics, it’s advisable to use pre-shrunk materials or follow proper care instructions.

Fraying Tendencies and Finishing Techniques

One notable characteristic of woven fabrics is their tendency to fray at the edges. To prevent unraveling, it’s essential to finish the fabric edges using techniques such as serging or zigzag stitching. This step is crucial for ensuring the longevity and neat appearance of woven fabric projects.

Popular Types of Woven Fabrics and Their Applications

The world of woven fabrics is diverse, with each type offering unique properties and suited for specific applications. Let’s explore some of the most popular woven fabric types and their common uses in the fashion and textile industries.

Buckram: The Supportive Fabric

Buckram is a stiff, coarse woven fabric primarily used as a supportive material in garment construction. It finds application in reinforcing necklines, collars, waistbands, and other areas requiring additional structure. Typically white in color, buckram is also used in linings and bag making due to its strength and durability.

Cambric: Lightweight and Crisp

Cambric is a lightweight woven fabric known for its crisp finish, making it an excellent choice for women’s and children’s clothing that requires a structured appearance. It is one of the finest and most densely woven materials available, primarily made from cotton fibers.

Chiffon: Luxurious and Sheer

Chiffon is renowned for its lightweight, smooth texture and luminous finish. Traditionally made from silk yarn, modern versions often incorporate polyester to reduce costs while maintaining the fabric’s luxurious feel. Chiffon is popular in evening wear, scarves, and delicate blouses.

Poplin: Durable and Versatile

Poplin is a sturdy woven fabric that excels in creating fitted shirts and other garments requiring a crisp appearance. Its durability and resistance to wrinkling make it ideal for formal wear and business attire. Modern poplin often includes polyester blends to enhance its performance and ease of care.

Dobby: Textured and Distinctive

Dobby fabric is characterized by its textured surface, created using a special loom that produces small geometric patterns. This fabric type is often used in men’s dress shirts, adding visual interest and a touch of sophistication to the garment.

Choosing the Right Woven Fabric for Your Project

Selecting the appropriate woven fabric for a sewing project is crucial for achieving the desired outcome. Several factors should be considered when making this choice:

- Intended use of the garment or item

- Desired drape and texture

- Care requirements and durability expectations

- Seasonal appropriateness

- Comfort and breathability needs

By carefully evaluating these aspects, you can ensure that your chosen woven fabric aligns with your project goals and produces a satisfactory result.

Techniques for Working with Woven Fabrics

Working with woven fabrics requires specific techniques to achieve professional-looking results. Here are some key considerations:

Cutting and Preparing Woven Fabrics

When cutting woven fabrics, it’s essential to pay attention to the grain line and ensure that pattern pieces are aligned correctly. Using sharp scissors or a rotary cutter can help achieve clean, precise cuts.

Seam Finishes for Woven Fabrics

To prevent fraying and ensure durability, proper seam finishes are crucial when working with woven fabrics. Common techniques include:

- French seams

- Flat-felled seams

- Serged edges

- Hong Kong finish

- Bias binding

Choosing the appropriate seam finish depends on the fabric type, garment style, and desired aesthetic.

Care and Maintenance of Woven Fabric Garments

Proper care and maintenance are essential for preserving the quality and appearance of woven fabric garments. Here are some general guidelines:

Washing and Drying Recommendations

Always check the care label for specific instructions. In general, woven fabrics benefit from gentle washing cycles and lower temperatures to minimize shrinkage and wear. Some delicate woven fabrics may require hand washing or dry cleaning.

Ironing and Pressing Techniques

Many woven fabrics respond well to ironing or pressing to remove wrinkles and maintain a crisp appearance. Use the appropriate heat setting for the fabric type, and consider using a pressing cloth to protect delicate materials.

Innovations in Woven Fabric Technology

The textile industry continues to innovate, developing new technologies and treatments for woven fabrics. Some recent advancements include:

Performance Finishes

Modern woven fabrics often feature performance finishes that enhance their properties. These may include:

- Wrinkle-resistant treatments

- Moisture-wicking capabilities

- Stain-repellent coatings

- UV protection

Sustainable Woven Fabrics

With increasing focus on environmental sustainability, many manufacturers are developing eco-friendly woven fabrics. These may incorporate recycled fibers, organic materials, or innovative production processes that reduce water and energy consumption.

Comparing Woven and Knit Fabrics: When to Choose Each

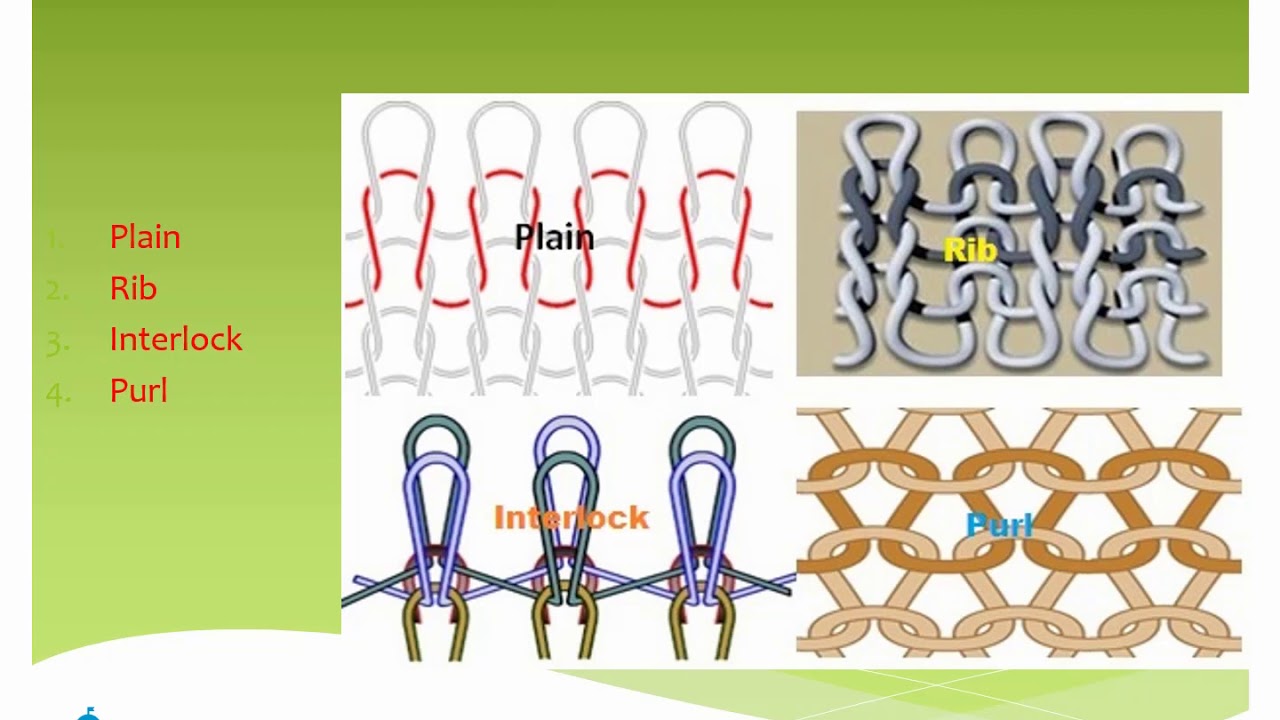

Understanding the differences between woven and knit fabrics is crucial for selecting the right material for your project. Here’s a comparison of key characteristics:

Structure and Appearance

Woven fabrics feature interlaced threads in a crisscross pattern, while knit fabrics are created by interlocking loops of yarn. This structural difference affects the fabric’s appearance, stretch, and behavior.

Stretch and Recovery

Knit fabrics generally offer more stretch and recovery than woven fabrics. This makes knits ideal for form-fitting garments and activewear, while wovens excel in structured pieces and tailored clothing.

Durability and Care

Woven fabrics often have superior durability and resistance to pilling compared to knits. However, they may require more careful handling to prevent fraying and may be more prone to wrinkling.

Choosing between woven and knit fabrics depends on the specific requirements of your project, including desired fit, comfort, and maintenance needs.

Exploring Specialty Woven Fabrics

Beyond the common types of woven fabrics, there are numerous specialty varieties that offer unique properties and aesthetics. Let’s examine some of these intriguing options:

Jacquard Fabrics

Jacquard fabrics feature intricate woven patterns created using a specialized loom. These fabrics can display complex designs and are often used in high-end upholstery, formal wear, and decorative textiles.

Brocade

Brocade is a luxurious woven fabric characterized by raised patterns, often incorporating metallic threads. It is commonly used in formal wear, home decor, and ceremonial garments.

Seersucker

Seersucker is a lightweight cotton fabric with a distinctive puckered surface. This unique texture is achieved through a special weaving process that creates alternating smooth and gathered strips. Seersucker is popular for summer clothing due to its breathability and low maintenance requirements.

Tweed

Tweed is a rugged woven fabric typically made from wool. It features a textured surface and is often associated with traditional British country clothing. Modern tweeds can incorporate various fibers and are used in both fashion and home decor.

These specialty woven fabrics offer designers and craftspeople a wealth of options for creating unique and visually striking projects.

The Role of Woven Fabrics in Fashion History

Woven fabrics have played a significant role in shaping fashion trends and cultural expressions throughout history. Understanding this historical context can provide valuable insights for modern designers and fashion enthusiasts.

Ancient Weaving Techniques

The art of weaving dates back thousands of years, with evidence of woven textiles found in ancient civilizations worldwide. Early weavers used natural fibers such as flax, wool, and cotton to create fabrics for clothing and other purposes.

Industrial Revolution and Textile Production

The Industrial Revolution brought significant changes to textile manufacturing, with the invention of power looms dramatically increasing the production of woven fabrics. This advancement made textiles more accessible and affordable, leading to new fashion possibilities.

Iconic Woven Fabrics in Fashion

Throughout fashion history, certain woven fabrics have become iconic and associated with specific styles or eras. Examples include:

- Denim: Originally developed for workwear, now a staple in casual fashion

- Tartan: Traditional Scottish fabric that has influenced global fashion trends

- Silk brocades: Luxurious fabrics associated with royalty and high fashion

- Muslin: Fine cotton fabric that played a crucial role in the development of dressmaking techniques

By understanding the historical significance of woven fabrics, modern designers can draw inspiration and create innovative interpretations of classic styles.

Sustainability and Ethical Considerations in Woven Fabric Production

As consumers become increasingly aware of environmental and ethical issues, the textile industry is responding with more sustainable approaches to woven fabric production. Here are some key considerations:

Sustainable Fiber Sources

Many manufacturers are exploring eco-friendly alternatives to traditional fiber sources. These include:

- Organic cotton grown without harmful pesticides

- Recycled polyester made from post-consumer plastic bottles

- Lyocell and other cellulose-based fibers produced using closed-loop systems

- Hemp and other fast-growing, low-impact crops

Water and Energy Conservation

Textile production can be resource-intensive. Innovative technologies and processes are being developed to reduce water and energy consumption in weaving and fabric finishing.

Ethical Labor Practices

Ensuring fair labor practices throughout the supply chain is a growing concern in the textile industry. Many brands are now prioritizing transparency and ethical manufacturing processes.

Circular Economy Initiatives

The concept of a circular economy, where materials are reused and recycled rather than discarded, is gaining traction in the textile industry. This includes developing fabrics that are easier to recycle and implementing take-back programs for used garments.

By considering these sustainability factors when choosing woven fabrics, consumers and designers can contribute to a more environmentally responsible fashion industry.

What is Woven Fabric? – Fabrics by the Yard

Every sewing enthusiast should get a little informed about the types of

fabric before choosing one for a sewing project. Choosing the right color and

pattern aren’t enough to help you wear a piece that you actually like. Other

factors, like the type of fabric, will affect the quality of the final result.

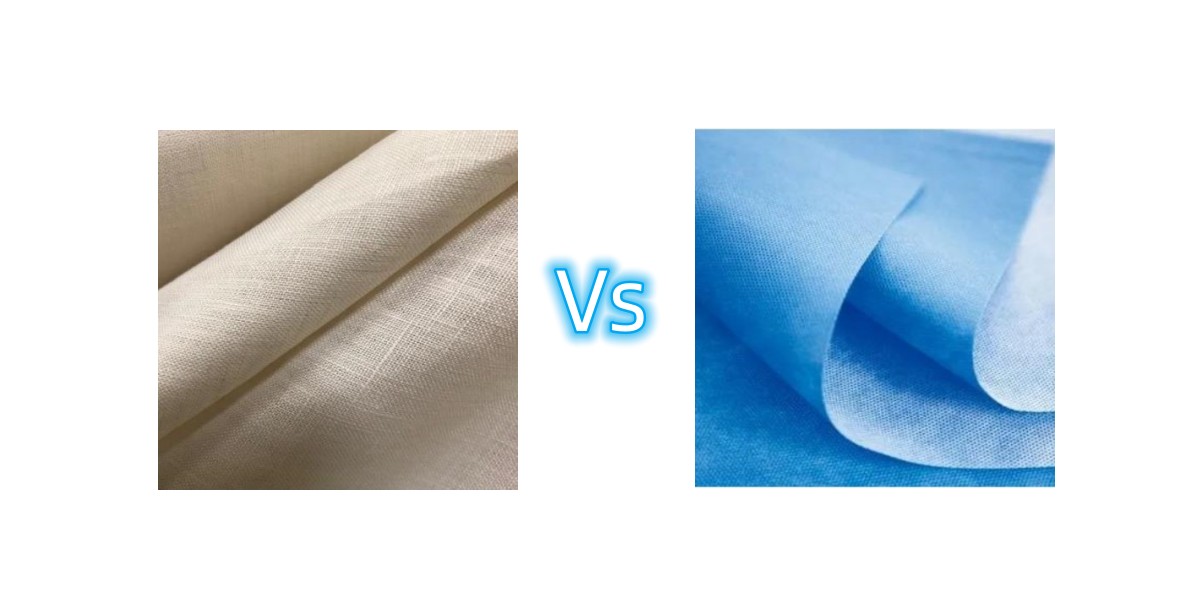

Fabrics are either knit or woven. These two types

differ in almost everything; how they’re made, whether they wrinkle, how much

they’re likely to stretch, and whether they shrink or fray.

Knowing the type of your fabric allows you to care for it properly

before and after you’ve executed an elegant custom-made piece. In this article,

you’ll know everything about woven fabrics.

Everything You Need to Know About Woven Fabrics

Even if you’re shopping for clothes, it’s still important to know the

type of fabric you’re choosing. Some experienced users can tell the type of

fabric by looking at. Sometimes, it’s not that easy, especially if you’re not

Sometimes, it’s not that easy, especially if you’re not

that trained and the stitches are too small.

Look

If you feel that the stitches aren’t clear enough, you can use a

magnifying glass to take a look at the fabric. The fibers, pieces of thread or

yarn, are weaved in a crisscross form. The basket-like weave is a distinctive

feature of the woven fabric.

Stretch

Woven fabrics don’t stretch much. If you pull the fabric really hard, it

will stretch a little along its length, but it will hardly stretch along its

width. This is one of the features that make woven fabrics quite easy to work

with.

Wrinkle

Doing a wrinkle test will help you determine whether your fabric is

woven or knit. Take a small piece and ball it up in your fist and press hard.

If it creases, then this is probably a woven fabric.

Shrink

Unlike knit fabrics, woven fabric isn’t prone to shrinking. However, if

However, if

you use very hot water, you might experience some shrinking. The only way you

can maintain a piece made of woven fabric is to use a material that has already

been shrunk in the manufacturing process. The higher the percentage of natural

fibers like cotton in your fabric, the more prone to shrinking it will be.

Fray

Woven fabrics unravel easily so they’ll fray. As a result, you should

finish the fabric with a serger or a zigzag stitch to prevent fraying. This

will guarantee that working with your woven fabric will be a lot easier.

Types of Woven Fabrics

Woven fabrics are made of two or more threads or yarn interlaced at

right angles on top of each other. They type of fibers used gives the fabric

its distinctive name and features.

Woven fabrics are quite easy to work with because they don’t stretch

much. Having a high count fabric, with more threads, means that the fabric will

be more durable. Low count fabrics are less durable and will snag easily. Here

Low count fabrics are less durable and will snag easily. Here

are some types of woven fabrics that you might want to try for your upcoming

sewing project.

This fabric is used as supportive material in necklines, collars,

waistbands, and other parts where you need to reinforce the fabric you’re

working with. It’s made of woven weave that’s supported by fillers and adhesive

materials that will give it more strength and durability.

Buckram fabric is very useful to amateur and experienced sewing enthusiasts

because it overcomes the problems associated with other softer fabrics like

satin and silk. This fabric is usually white and has a coarse texture. It’s

widely used in linings and can also be used in bags.

A great choice for women’s and kids’ clothes that need to be crisp,

Cambric fabric is a lightweight material which has a stiff finish. It’s one of

the finest and most dense types of materials that can be used for different

clothing apparel. Most cambric fabrics are made of cotton.

Most cambric fabrics are made of cotton.

Chiffon is probably one of the most popular types of woven fabrics and

also the most luxurious. This lightweight smooth fabric has a luminous finish

and is usually made of silk yarn. However, silk chiffon is very expensive and

this prompted manufacturers to make new versions that contain polyester yarn.

If you wish to make a fitted shirt, then you should think about using

poplin. This rather durable fabric is similar to cotton but is stiffer so it’s

an excellent choice for tight-fitting shirts that fit beautifully under a

formal suit. Now you can find poplin fabrics that are made of polyester blends

to overcome the problems associated with using pure cotton. Poplin fabric is

treated so it doesn’t wrinkle easily so you can safely wear it all day long. If

it creases, you can easily iron it.

The dobby

fabric is made of woven yarn produced on the dobby loom. The

fibers might be the same color or different. Wool dobby fabric can be used for

Wool dobby fabric can be used for

dresses because it drapes beautifully. When fine yarn is used, the fabric is

lightweight and looks slightly patterned.

Corduroy fabric is usually made of cotton but most of the time cotton is

combined with polyester and other synthetic fibers. Corduroy has a visible and

distinctive pattern that runs throughout the length of the fabric. Some

lightweight fabric has a short pile. Ironing this fabric can damage it, so you

should do it on the wrong side. At the same time, you shouldn’t press the iron

too hard as this might crush the pile.

Crepe is either made of silk fibers or silk combined with synthetic fibers.

Crepe is a popular choice for blouses and dresses. It’s one of the most popular

choices for summer and formal occasions because the fabric feels luxurious.

It’s suitable for daily wear as well because it’s comfortable. Some crepe

fabrics are made of wool fibers.

Woven fabrics shouldn’t be washed in hot water. Lukewarm water is enough

Lukewarm water is enough

to prevent the fabric from shrinking and to maintain its status. Use a mild

detergent and no bleach to make sure that the fabric stays in shape.

Types of Woven Fabrics – universally used fabric names

Woven fabric is any textile formed by weaving. Woven fabrics are often created on a loom, and made of many threads woven on a warp and a weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another. Woven fabrics are generally more durable.

The woven fabric only stretches diagonally on the bias directions (between the warp and weft directions), unless the threads used are elastic. The woven cloth usually frays at the edges, unless techniques are used to counter it, such as the use of pinking shears or hemming.

Fabrics that are woven do not stretch as easily as knitted fabrics, which can make them advantageous for many uses.

Much variety is produced by weaving. They can be easily cut into different shapes and are excellent for producing styles in garments. Fabrics having more fabric count (number of wrap and weft yearns present) keep the shape well. Low count fabrics are less durable and may snag or stretch.

They can be easily cut into different shapes and are excellent for producing styles in garments. Fabrics having more fabric count (number of wrap and weft yearns present) keep the shape well. Low count fabrics are less durable and may snag or stretch.

Woven fabrics are manufactured in different widths depending on the end use.

Types of Woven Fabrics – universally used fabric names

1. Buckram Fabric

A stiff coated fabric made from a lightweight loosely woven fabric, impregnated with adhesives and fillers, this fabric is used as interfacing so as to provide support and shape retention to necklines, collars, belts, cuffs, waistbands, button closures etc in garments. They are also used as reinforcements for handbags and other articles.

Buckram is a stiff cotton (occasionally linen or horse hair) cloth with a loose weave, often muslin. The fabric is soaked in wheat starch paste, glue (such as PVA glue), or pyroxylin (gelatinized nitrocellulose, developed around 1910), as sizing and then dried. When rewetted or warmed, it can be shaped to create durable firm fabric for book covers, hats, and elements of clothing. In bookbinding, pyroxylin impregnated fabrics are considered superior to starch-filled fabrics because their surfaces are more water resistant, they are more resistant to insects and fungi, and are generally stronger. They wear well and are particularly suitable for use in library binding where many people will be repeatedly handling the same books. Pyroxylin also allows for unique decorative effects on book covers. They, too, are water repellant and immune to insect attack and fungi, but they do not wear as well as starch impregnated cloths because of cracking at the joints and occasional peeling of the coating.

When rewetted or warmed, it can be shaped to create durable firm fabric for book covers, hats, and elements of clothing. In bookbinding, pyroxylin impregnated fabrics are considered superior to starch-filled fabrics because their surfaces are more water resistant, they are more resistant to insects and fungi, and are generally stronger. They wear well and are particularly suitable for use in library binding where many people will be repeatedly handling the same books. Pyroxylin also allows for unique decorative effects on book covers. They, too, are water repellant and immune to insect attack and fungi, but they do not wear as well as starch impregnated cloths because of cracking at the joints and occasional peeling of the coating.

2. Cambric Fabric

Cambric a lightweight fabric woven in plain weave and produced with a stiff finish. It is suitable for women’s dresses and children’s dresses that require crispness.

Cambric or batiste, one of the finest and most dense kinds of cloth, is a lightweight plain-weave cloth, originally from the French commune of Cambrai, woven in greige, then bleached, piece-dyed and often glazed or calendered. Initially it was made of linen; later, the term came to be applied to cotton fabrics as well. Cambric is used as fabric for linens, shirts, hand kerchieves, ruffs, lace and needlework. The term “cambric cloth” also applies to a stiff, usually black, open-weave cloth typically used for a dust cover on the bottom of upholstered furniture.

Initially it was made of linen; later, the term came to be applied to cotton fabrics as well. Cambric is used as fabric for linens, shirts, hand kerchieves, ruffs, lace and needlework. The term “cambric cloth” also applies to a stiff, usually black, open-weave cloth typically used for a dust cover on the bottom of upholstered furniture.

Chambray, though the same type of fabric, had a coloured warp and a white weft, though it could be “made from any colour as you may wish, in the warp, and also in the filling; only have them differ from each other. “Chambray differs from denim in that “chambray’s warp and weft threads will alternate one over the other, while denim’s warp thread will go over two threads in the weft before going under one.” As a result, the color of chambray cloth is similar front and back, while the reverse side of denim is lighter in color.

3. Casement Fabric

Casement is a medium weight cotton fabric made of closely packed thick warp yarns. Generally, it is used for curtains, table linen, upholstery and rarely used for dresses.

Generally, it is used for curtains, table linen, upholstery and rarely used for dresses.

4. Cheese Cloth

It is a popular lightweight sheer fabric having an open weave. It has a low count fabric consisting of carded yarns. Originally it was used for wrapping cheese or meat and hence the name. It is neither strong nor durable. It is finished in a variety of ways that attract the consumer. It is used not only for women’s and children’s dresses but also for drapery fabrics. Due to its open structure, it does not require much ironing.

5. Chiffon Fabric

Chiffon fabrics are sheer, lightweight fabrics made of hard twisted yarns. Originally these are made in silk fabrics but today they are made from rayon or polyester. They are used for sarees and women’s evening wear. The fabrics encounter the problem of shrinkage.

Types of Woven Fabrics – universally used fabric names

Woven fabrics are made by using two or more sets of yarn interlaced at right angles to each other. Much variety is produced by weaving. Woven fabrics are generally more durable. They can be easily cut into different shapes and are excellent for producing styles in garments. However, the raw edges ravel or fray easily and need to be protected. Fabrics having more fabric count (number of wrap and weft yearns present) keep the shape well. Low count fabrics are less durable and may snag or stretch.

Much variety is produced by weaving. Woven fabrics are generally more durable. They can be easily cut into different shapes and are excellent for producing styles in garments. However, the raw edges ravel or fray easily and need to be protected. Fabrics having more fabric count (number of wrap and weft yearns present) keep the shape well. Low count fabrics are less durable and may snag or stretch.

Woven fabrics are manufactured in different widths depending on the end use. The fabrics used for apparels usually contain 90 cms width. The Sheeting materials are generally made having a width of 160 cm/140cms and 150cms/180 cms.

Buckram Fabric

It is a stiff coated fabric made from a lightweight loosely woven fabric, impregnated with adhesives and fillers. This fabric is used as interfacing so as to provide support and shape retention to necklines, collars, belts, cuffs, waistbands, button closures etc in garments. They are also used as reinforcements for handbags and other articles.

Cambric Fabric

Cambric a lightweight fabric woven in plain weave and produced with a stiff finish. It is suitable for women’s dresses and children’s dresses that require crispness.

Casement Fabric

Casement is a medium weight cotton fabric made of closely packed thick warp yarns. Generally, it is used for curtains, table linen, upholstery and rarely used for dresses.

Cheese Cloth

It is a popular lightweight sheer fabric having an open weave. It has a low count fabric consisting of carded yarns. Originally it was used for wrapping cheese or meat and hence the name. It is neither strong nor durable. It is finished in a variety of ways that attract the consumer. It is used not only for women’s and children’s dresses but also for drapery fabrics. Due to its open structure, it does not require much ironing.

Chiffon Fabric

Chiffon fabrics are sheer, lightweight fabrics made of hard twisted yarns. Originally these are made in silk fabrics but today they are made from rayon or polyester. They are used for sarees and women’s evening wear. The fabrics encounter the problem of shrinkage.

Originally these are made in silk fabrics but today they are made from rayon or polyester. They are used for sarees and women’s evening wear. The fabrics encounter the problem of shrinkage.

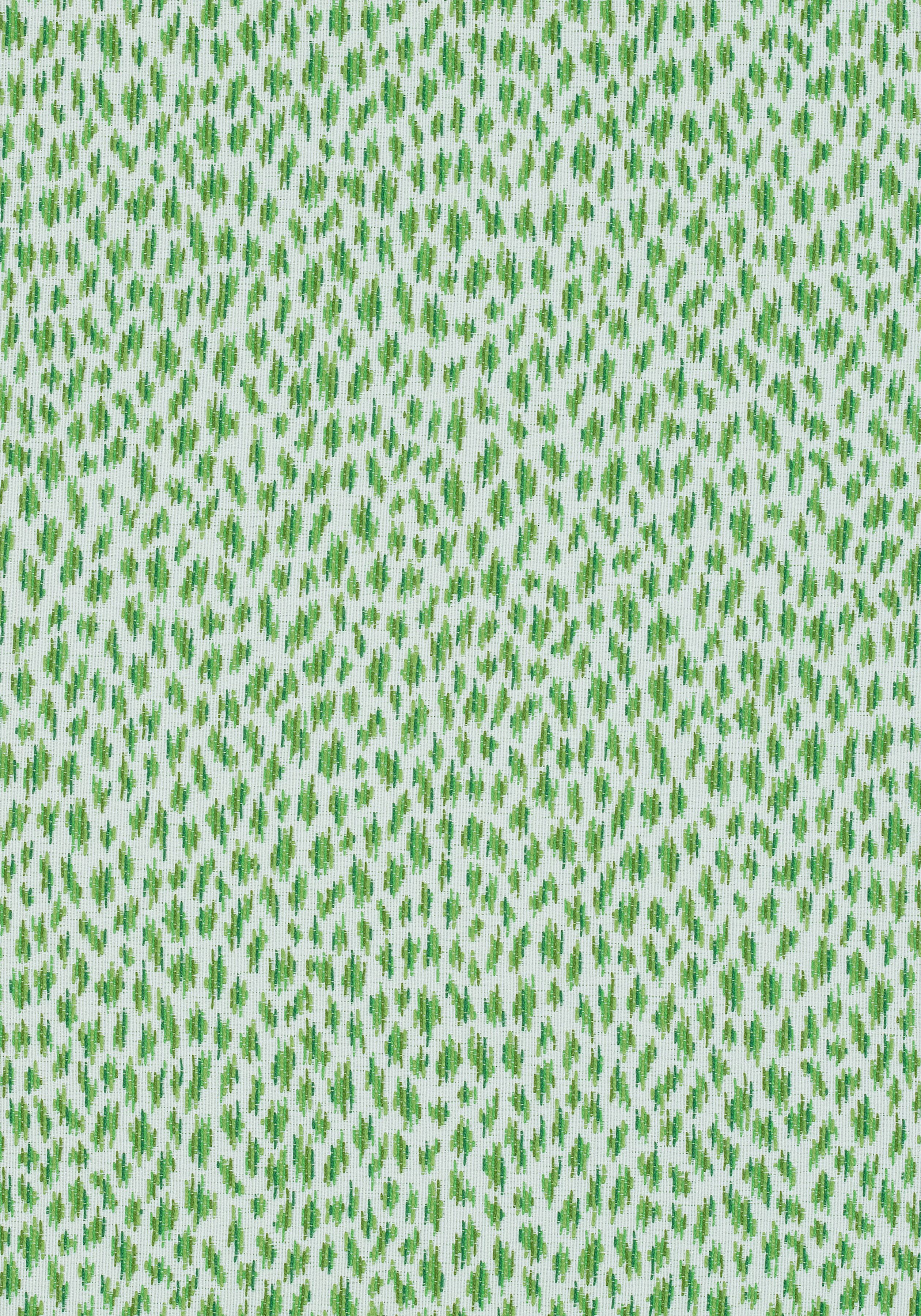

Chintz Fabric

Chintz is a medium weight, plain woven cotton yarn. It is often given a glazed finish which may be temporary or semi-permanent glazed chintz are available in solid colour as well as printed with floral prints. These are often made from blends of cotton and polyester or rayon. They are used for skits, dresses, blouses, pyjamas, aprons, and draperies.

Corduroy Fabric

It is a cut pile fabric available in solid colours. The cut pile fibres are seen in the form of ribs on the surface. It is mainly used for pants, jeans, and shirts.

Crepe Fabric

A silk fabric is originally characterized by a crinkle, puckered surface formed by highly twisted yarns in the warp or weft or both. By using ordinary yarns similar crepe effects can also be produced. Synthetic fabrics also impart crepe effect finish. It is used for sarees, shirts, women and children’s dresses.

Synthetic fabrics also impart crepe effect finish. It is used for sarees, shirts, women and children’s dresses.

Denim Fabric

It was traditionally a yarn dyed, warp-faced cotton twill fabric. Warp is usually coloured (mostly blue, maroon, green and brown) and weft is white. This fabric is made of two weights for sportswear and overalls. Its use as jeans has made it very popular and so the nature of denim is also changed to suit the trend. It is often napped, printed and made with stretch yarn.

Drill Fabric

It is a warp-faced twill woven fabric. It has a stiff finish. Originally it was produced in white and now it is available in solid colours. It is mainly used for pants, knickers, and uniforms.

Flannel Fabric

Flannel is a woollen fabric woven in plain or twill weave having the characteristic soft handle. It looks like a bulky fabric due to the milling that is usually done to this fabric. Flannel fabric is used for suits and pants and infant’s clothing.

This fabric is popular as cleaning fabric due to its extreme softness. This is also used to protect children from the cold atmosphere.

Gabardine Fabric

Gabardine is a closely woven, clear finished warp-faced twill fabric. It contains a number of warp yarns than weft yearns and also more durable. It is usually woven in 2/1 or 2/2 twill and has a raised diagonal twill effect on the right side. It largely used for raincoats, suitings, and sportswear.

Georgette Fabric

Georgette is a sheer lightweight fabric, woven in plain weave. It has a characteristic rough texture produced by hard twisted ply, yarns both in warp and weft. Originally it was made in silk, but today it is produced in rayon and polyester too. It’s mainly suitable for women’s evening wear.

Kashmir Silk Fabric

Kashmir silk is a silk fabric produced in plain weave and is either embroidered or printed. The motifs used are characteristic of Kashmir. It is used for shirts, women’s wear and sarees. Kashmir shawls are woven in twill weave and are usually embroidered with traditional Kashmiri embroidery.

It is used for shirts, women’s wear and sarees. Kashmir shawls are woven in twill weave and are usually embroidered with traditional Kashmiri embroidery.

Khadi Fabric

Khadi is a term used for a wide variety of fabrics that are hand spun and hand woven. They are produced in mainly one cotton fibre, blends of two or more fibres. They are known for durability and simplicity. The fabrics can be suitings dhoties overalls and household textiles.

Lawn Fabric

The lawn is a fine sheet, lightweight, crisp fabric either made of cotton or linen. Various finishes are given to this fabric, in which the fabric is called by the name of the finish. It is mainly used as lining in a dress.

Mulmul Fabric

It is an Indian term generally applied to fine cotton fabric slightly heavier, than muslin. These are often printed fabrics. They find use as sarees.

Muslin Fabric

Muslin is a lightweight open cloth of plain weave. It may be used as grey or bleached and dyed. It is used as household textiles and dress materials. The name is derived from the city of Mosul where the fabric was first made.

It may be used as grey or bleached and dyed. It is used as household textiles and dress materials. The name is derived from the city of Mosul where the fabric was first made.

It is a very light and open tabby (plain) weave fabric used for summer dresses and utility use. At first, the cloth was not always plain but could also have silk and gold thread woven into it. As the ability to spin yarns of greater fineness developed cotton was used more readily than silk. In this muslin, the motif weaves in and out of the cloth, as if it has been embroidered. In the Madras net, the motif is predominately woven on the surface.

Poplin Fabric

Poplin is a medium weight, the cotton fabric having a fine weft rib. it is generally used for shirting, dresses, and upholstery.

Sheeting Fabric

These are primarily used for bed coverings. They are medium weight, closely woven fabrics woven either in plain or twin weave. Sheeting fabrics are made in different widths. High-quality cotton sheetings are made in plain weave with a width of 64″ x 58″ and in a twill weave with a width of 60″x72″.

High-quality cotton sheetings are made in plain weave with a width of 64″ x 58″ and in a twill weave with a width of 60″x72″.

Taffeta Fabric

Taffeta is a smooth, crisp, transparent fabric having a fine rib. Originally it is made with silk fibres but now it is also made of rayon. It has a characteristic finish which produces crispness. It is used as women’s evening wear.

Tissue Fabric

It is a fine fabric either made of silk or man-made fibre. They are characteristically interwoven with gold or silver threads. It is produced in rich colours and they are used as women’s dress material, sarees etc.

Velvet Fabric

It is a warp cut pile fabric, originally made from silk. It is also produced in Rayon. The dense cut pile makes it very soft and lustrous. It is used as dress materials for women and children. It is also produced with special high twisted yarns which are single or ply yarns. Based on the yarns used and twist given, they are named as semi violes (single yarns1x1) full voiles. (ply yarns 2×2) or half voile (double in warp and single in weft 2×1).

(ply yarns 2×2) or half voile (double in warp and single in weft 2×1).

Mousseline Fabric

A term used to denote very fine clear fabrics, finer than muslins. Made of silk, wool or cotton, the weave structure is either (plain) tabby or two and one twill. In the 18th century, the British term referred to a fine cloth with a cotton warp and a worsted weft. In France, from the late 18th century onwards mousseline-delaines were made of very fine wool which was printed in beautiful designs. This fabric

proved very popular for fashionable as dress and shawl fabrics. The mousseline cloth is so fine and transparent it is often found backed with another cloth of either a satin or taffeta silk.

Organdie / Organza Fabric

Originally it is a lawn fabric which is given a stiff finish. Acid is used for this finish to make the fabric transparent and stiff. It is mainly used for women’s wear.

A thin light fabric in a (plain) tabby weave which, if organza, has a very stiff crisp finish; and for organdie, the finish is lighter or there is no finish, and thus the cloth is more pliable. The structure of the cloth always has more warps than wefts per inch, and the weft threads are finer than the warp threads. Illustrated is a colourful group of organza fabrics.

The structure of the cloth always has more warps than wefts per inch, and the weft threads are finer than the warp threads. Illustrated is a colourful group of organza fabrics.

Leno Fabric

A fabric in which an open effect is created by causing certain thread ends or doup threads to cross over. Two threads or ends act as one thread; when a weft thread passes between them, the doup ends twist catching the weft and holding it tightly in place. Very fancy and beautiful clothes can be produced by combining the cross weaving, with other weave structures.

Aertex Fabric

A trade name for a cloth patented in Britain in 1886, which was first manufactured in 1888. The cloth traps air in between its structure, keeping the body cool in summer, and warm in winter. Two threads or ends act as one thread; when a weft thread passes between them, the doup ends twist catching the weft and holding it tightly in place. Very fancy and beautiful clothes can be produced by combining the cross weaving with other weave structures.

Madras Muslin Net Fabric

Madras net is used mainly for furnishing such as curtaining. The cloth is an open gauze ground cloth where an extra weft is inserted to produce a motif, this is then woven into the ground cloth. Where there is a surplus floating weft yarn this is then cut away after weaving revealing the motif, the edge of the sheared motif shows shorn ends of a weft yarn.

Aida cloth Fabric

Aida cloth is a cotton fabric with a natural mesh pattern generally used for cross-stitch embroidery. The open, even-weave Aida fabrics’ natural stiffness enables the fabric the embroiders choice.

20 types of FABRIC WEAVES {An overview}

Dealing with different types of fabric day in and day out, I cannot but notice the fascinating weaving patterns of the fabric. And every time I am entranced by the movement of the yarns that make up the fabric. Studying this is part of my fabric love.

Other than this, it is important to know more about fabric weaves, because when you choose fabric for your project, you should know that the types of weave of the fabric can determine the smoothness, comfort, thickness, durability, tear strength and even drape of the fabric. In effect, the whole success of your hard work and dreams about a sewing project hinges on the weave of your fabric -how’s that!

In effect, the whole success of your hard work and dreams about a sewing project hinges on the weave of your fabric -how’s that!

A fabric weave refers to the way the warp and weft yarns are interlaced in a fabric. In the most basic of fabric weaving, the threads (lengthwise warps and crosswise wefts) go criss-cross in the simplest of pattern, at right angles to each other. But in others, they are woven in so many interesting patterns – artistically, decoratively. Do you know that the fabric factories can come up with a mind-boggling number of weave structures?

But the basic weave types that mix and match to form all the others are – plain, twill and satin weaves. They are given interesting variations or they are combined with each other to form different woven patterns

Different Types of fabric weaves

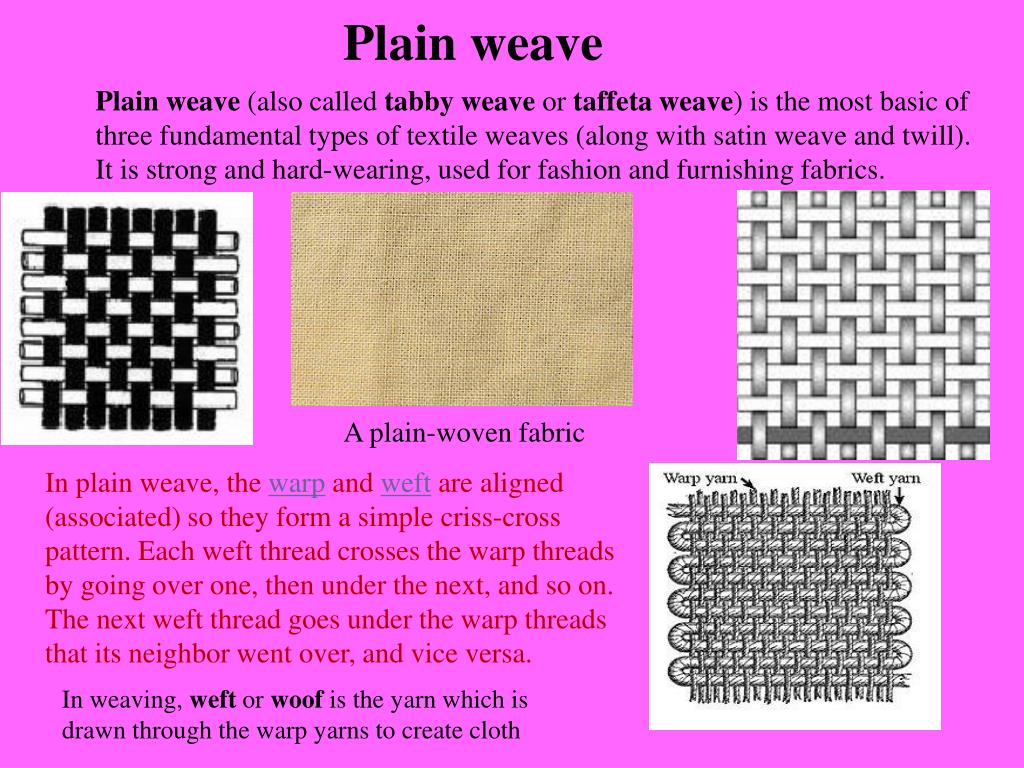

1. Plain weave

This is a weave with the most simple interlacing but it makes for a very strong and firm fabric because these interlacings are more frequent than for any other weave.

In this weave, the warp thread is interlaced over the weft thread by alternately lifting and lowering of the yarns. ie each and every weft thread goes under and over the warp threads across the width of the fabric.

The advantage of this weave is that it is quite strong and durable and produces very fine good quality fabrics.

It is also called tabby weave or taffeta weave or linen weave. Also called Panama weave.

Hopsack is a plain weave with two or more threads in weft and warp interlaced instead of one. Also called Celtic weave. It is popular as a weave for suit fabric.

Percale is a type of plain weave which produces a very smooth high thread count fabric by the same name.

Poplin weave is an unbalanced plain weave in which two weft-threads and one warp-thread of the same colour cross each other. As weft threads are more than the warp thread there is a ridge on the weft thread creating a ribbed weave. In this weave cotton polyester and nylon fibers are used.

In this weave cotton polyester and nylon fibers are used.

In most of the plain weave fabrics the weft thread and the warp thread are of the same colour resulting in an even coloured fabric but for some fabrics like end-on-end poplin and cambric the weft thread will be white or some other colour while the warp thread will be coloured – this results in a subtle shade of the colour.

Ripstop weave

This is a plain weave in which extra thread is incorporated as reinforcement at regular intervals.The extra thread along the weft and warp gives the look of a chequered pattern on the fabric. This extra thread gives extra strength to the fabric and resistance from tearing. Ripstop Nylon

Fabrics with a plain weave: About half of the woven fabrics are in this weave. It includes most of the different types of cotton like muslin, organdy, canvas; linen, rayon, silk, Chiffon, organza, voile, wool, crepe and a whole lot of other fabrics

2. Rib weave

A variation of the plain weave. Here, either weft yarn or warp yarn is woven raised because it is a thicker yarn ie the warp and weft yarns are of different weights. Usually, it is the weft yarn which is thicker in which case there is an appearance of prominent ribs in the horizontal direction.

Fabrics with a rib weave : Broadcloth, Faille, Poplin, grosgrain

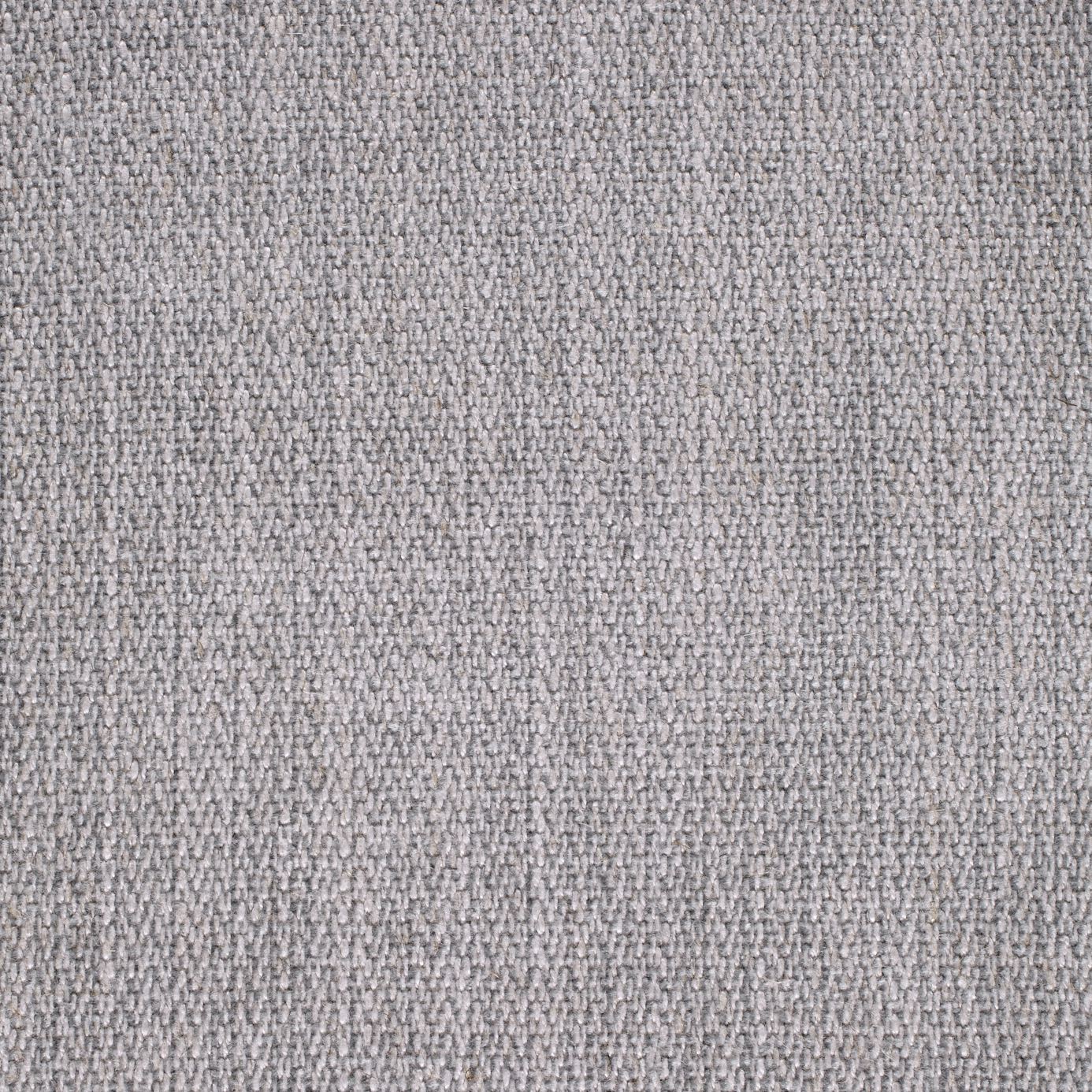

3. Basket weave

This is a variation of the plain weave but with more than one thread. Two or more warp fibers alternately interlace with two or more weft fibers. Instead of the over-under pattern in a plain weave we have a over-over under-under pattern.

The resultant fabric has a matt weave and flexibility and a looser construction. It is not as durable as plain weave, though and may shrink in the wash. It is difficult to sew. Another name is a hopsack weave

Fabrics with this weave: Canvas, Duck cloth, Monk’s cloth.

4. Twill Weave

In this weave, one or more warp fibers alternately weave over and under two or more weft fibers repeatedly (Weft-faced)or one or more weft fibers alternately weave over and under two or more warp fibers repeatedly (warp-faced). This results in a strong and soft fabric which has more drape than all other weaves with a self-design effect, with parallel diagonal ribs formed left-to-right or right-to-left but the fabric has a smooth surface.

There are clear diagonal lines on the surface of the fabric. The back side of this weave is rough and will show the opposite pattern of the front. Fabrics with twill weave are more durable, heavy and wrinkle resistant than ones with plain weave

In denim, inarguably the most famous twill fabric, the weft-thread is white or off-white and the warp-thread is indigo-dyed.

Fabrics with Twill weave: Denim, flannel, Velvet, Drill, Jersey, Gabardine etc has this weave.

Twills have a wale. Wales can be S or Z. If the wales run from upper right to lower left the weave is called right-hand twill / z twill;

If the wales run from upper left to lower right the weave is called left hand twill / s twill. When there is a combination of right-hand and left hand twill it is called a broken twill

Variations : One and one (Pick & Pick) has light and dark warp and weft. 3 by 1 twill has three threads crossing over one weft thread. This is a common denim weave. 2 by 1 twill has two warp thread crossing over one weft thread.

Gabardine is a fine steeply set twill weave. Cavalry twill is a slightly broader steeply set twill; Whipcord is another bold and steep twill. Diagonal twill has a pronounced diagonal twill weave. Double diagonal twill weave has two or three differently wide and bold twill lines.

Twilled hopsack weave looks as if twill is running both left and right. Pinhead has one light and one dark warp and a solid dark weft. Barleycorn is a twill way arranged to look like barley corn. Pepper and salt is a variation of the one and one with a highly contrasted twist in the warp and weft.

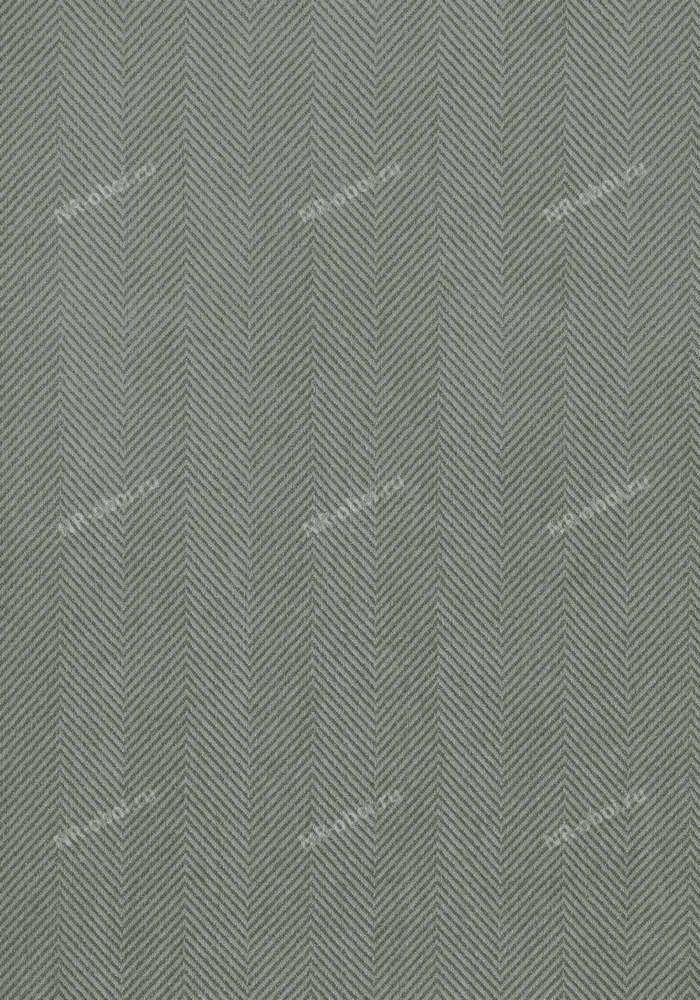

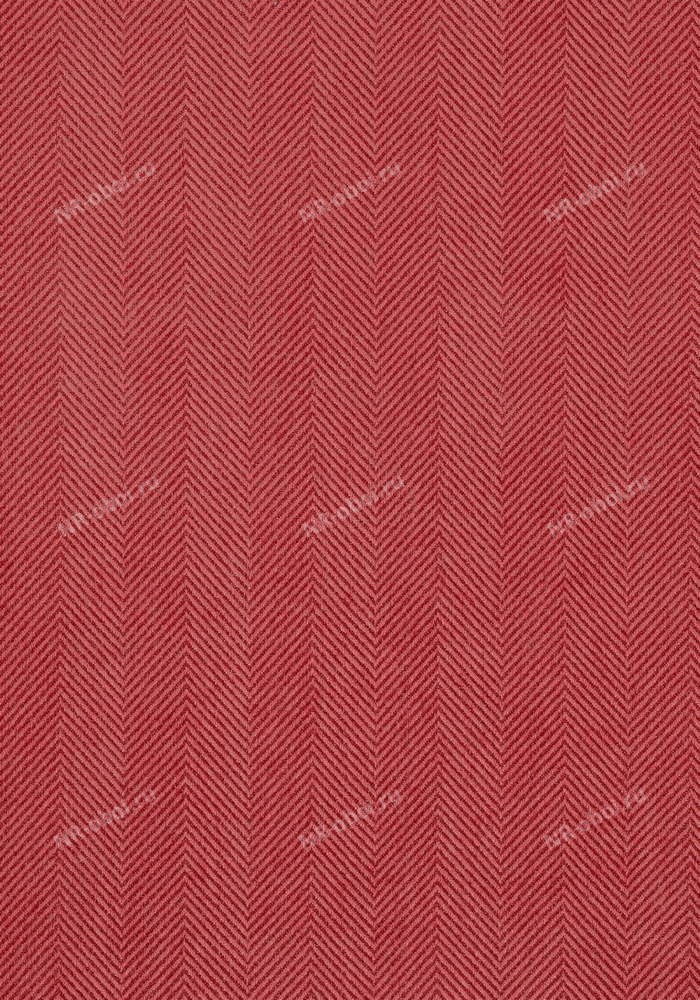

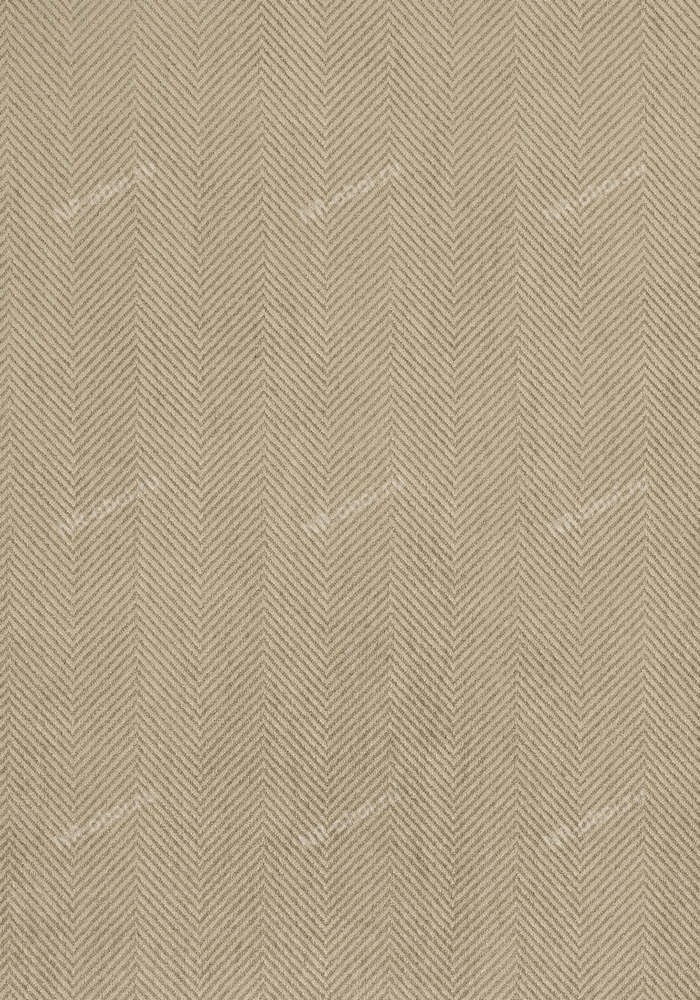

5. Herringbone weave

This refers to a broken twill weave which gives a herringbone (zig zag) pattern with right and left twills appearing alternatively side by side , both having the same width.

The herringbone weave is also called feather twill or arrowhead twill. Other than the attractiveness of its design it has all the qualities of a twill weave. This is similar to other broken twill designs like the chevron pattern

Shell weave has a combination of right and left-hand twills – looks like a shell

Corkscrew weave has the herringbone pattern but at a very low angle.

Fabric with the herringbone weave: Tweed

6. Satin weave

This is a variation of the twill weave but with continuous warp yarn, with as few interruptions of weft as possible ie it has fewer intersections of warp and weft threads – weft yarns are floated over warp yarns, which results in a smooth and shiny surface.

The fibers used are filament fibers like silk or nylon. The fabric in this woven pattern will be very smooth and lustrous and has a flexible structure, because of the long floats. The greatest luster will be in the lengthwise direction.

The disadvantage is that the fabric fibers will easily snag so this weave is not considered as strong as the other weaves.The advantage of this weave is its own disadvantage – it is the long floating yarns that snag.

Fabrics with this weave: Many types of satin fabric like peau de soi, charmeuse.

7. Sateen weave

This is a satin weave with short staple yarns like cotton. The floats will be in the weft direction ie continuous weft yarn, with as few interruptions of warp as possible. The fabric is not as lustrous as the satin weave fabric but they are more durable.

8. Leno weave

In this weave, warp yarns do not lie parallel to each other as in other weaves; the adjacent warp fibers (two or more) are twisted around consecutive weft fibers (one or more)to form a spiral pair (figure 8). It results in a sheer open weave fabric which is at the same time strong. It is also called gauze weave

Fabrics with Leno weave : Gauze, net, tulle.

9. Oxford Weave

In this two, thin warp yarns are woven to each very soft, thicker yarn in the weft direction. This results in the thin warp yarns to break leaving holes. The resultant fabric is very fine and soft. In a similar Pinpoint weave weft-thread alternatively pass over and under two warp-threads

Fabrics with oxford weave : Oxford cloth, shirting.

10. Bedford cord weave

This is a characteristic weave found in the fabric Bedford cord with lengthwise ridges. The weave has prominent lengthwise ribs with sunken lines in between. This is a combination of a plain weave and whipcord twill weave. Wadding threads are introduced in this weaving to bring more prominence to the cords.

11. Waffle Weave

This is also called honeycomb weave because of the pattern it creates on the face of the fabric. The warp and weft threads are interlaced and floated in a manner that produces a regular pattern of small square ridges and hollows in the fabric. This weave has a 3D effect but makes for a rough surface because of the raised areas on the face of the fabric. The shapes formed on the fabric surface maybe square or diamond.

12. Pile weave

This is a weave that is used to make a soft pile fabric which is very absorbent and insulating . You will find cut/uncut piles on one side or either side of the fabric as a result of this weaving. The uncut or loop piles have loops

on the face and back of the fabric. Ground yarns and additional yarns for the pile are used in the fabric construction

Fabrics with a pile weave: Velvet (Cut pile), terrycloth , Corduroy, Velveteen (Uncut/loop pile).

13. Jacquard weave

This is a beautiful weave with intricate and colourful designs woven into the fabric. This weave is produced on a jacquard loom.

The weave results in a fabric which is strong and lustrous and has a luxurious look and feel. Jacquards can be made one color or a mix of colors and can be used to create simple as well as complex patterns.

Often the back side of a jacquard is the mirror image of the pattern on the front. The weave is named after the Frenchman Joseph Marie Jacquard who invented the jacquard loom.

Fabrics with this fabric weave : Brocade, Damask, Brocatelle, Matelasse are fabrics with this weave and these fabrics are typically used for bedding, upholstery, draperies etc.

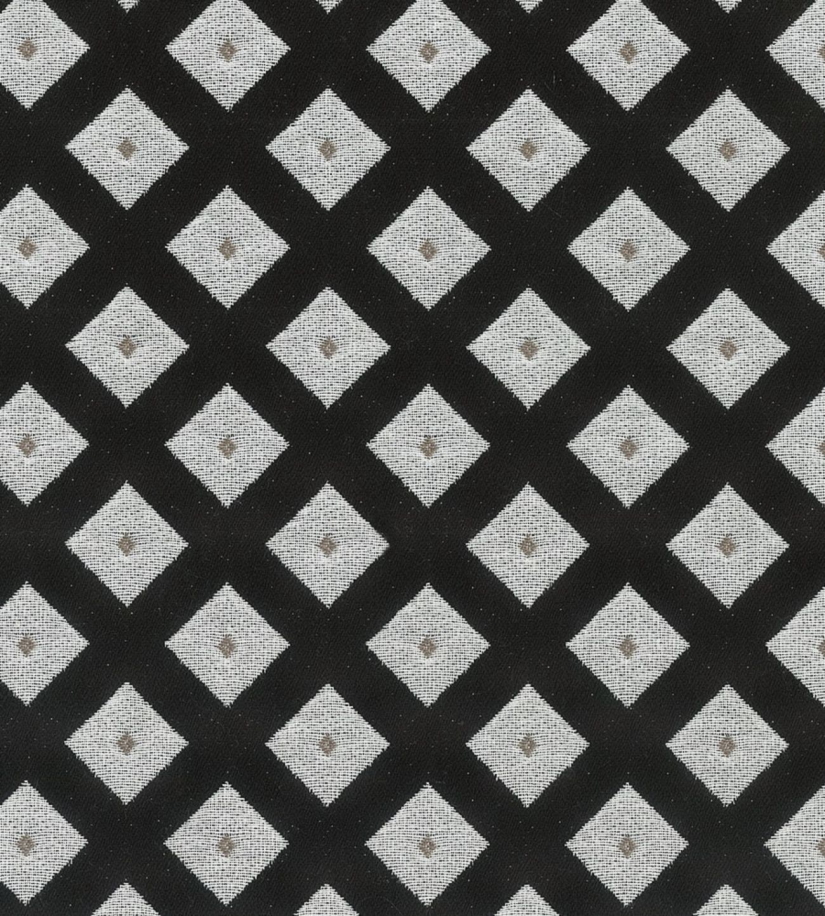

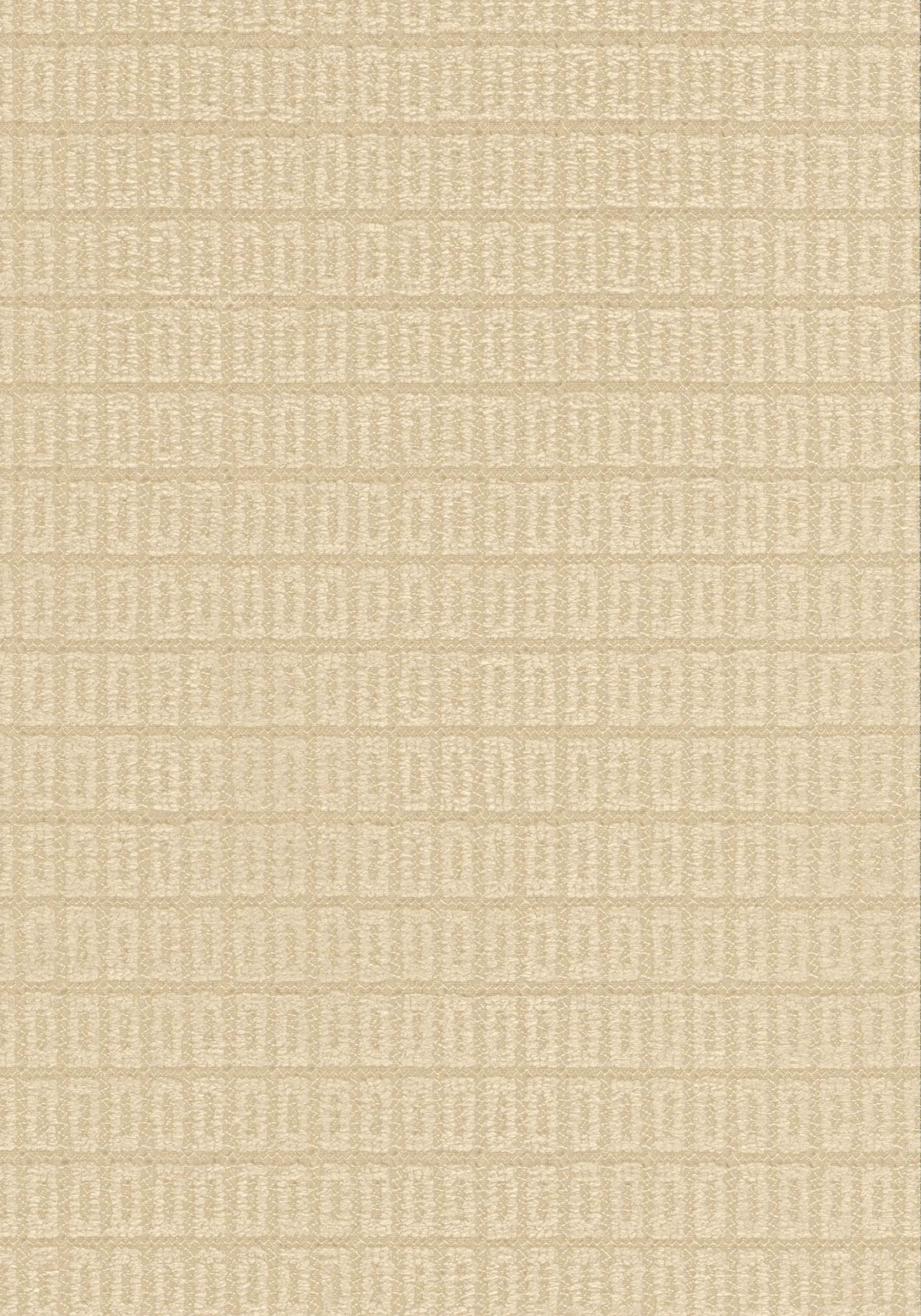

14. Dobby weave

This is a patterned plain weave with small designs/geometric patterns. You need special dobby machines to create this weave. The machine selectively raises some warp threads and selectively depresses others with the help of a dobby card. The fabric which is woven this way is comparatively flat and fine.

Fabric with Dobby weave : Moss crepe.

15. Crepe weave

A type of weave that results in a broken irregular pebbled appearance by the use of high twist yarns and a special method of weaving.

Fabric with this weave : Crepe fabric

16. Lappet weave

Lappet weave is a method of creating machine-made embroidery-like figures on a fabric ground, by introducing warp threads. Swivel weave a similar weave in which weft threads are introduced. It is very similar to how embroidery is done.

17. Tapestry Weave

This is also done by the jacquard loom but it is mostly based on handlooming techniques and has very elaborate designs made usually of a single repeat. The complex designs characterized by numerous colour changes are formed by weft yarns and warp yarns. It is used interchangeably with jacquard weave. You will find wall hangings and flatweave rugs made in this technique

18. Striped weaves

A pinstripe patterned weave has a single fine striped thread that looks like a line made up of pinhead shots

Eton stripe is a Plain weave variation with light and dark warp and weft – resulting in a straight vertical line of light and dark alternatively. Also called Hairline.

Chalk stripe weave results in light lines like the one made by a tailor’s chalk.

You can check out the names of more striped patterns on fabric here.

19. Checquered weaves

This weave makes beautiful checks on the fabric. Think tartans and plaids

Block check weave has blocks of check patterns in light and dark yarns

A diamond weave is a twill weave with right and left twills looking like a diamond pattern

Two and two glen stripe with overcheck has one and one base with a two and two stripe

Three and Three has a twill base with three light three dark weft and warp

Shepherds check has a twill weave with five or more light, five or more dark warp and weft

Glenurquhart check has a twill weave with dark and light warp and weft coloured yarns to give a chequered effect.

Dog’s tooth has a twill weave with four or more light, four or more dark warp and weft

Gun club check has four or more light, four or more mid, four or more light, four or more dark, warp and weft.

You can check out the names of more chequered patterns on fabric here.; Difference between plaid, tartan and checks

20. Double cloth weave

In this weaving technique, two fabrics are held together with another set of yarns. Sometimes, they are separated, as in case with velvet

Fabric with this weave : Velvet.

Choosing Fabric according to weaves

If you want a durable strong fabric you will choose a twill weave fabric or a plain weave fabric than a basket weave or jacquard weave. If you want a drapeable and lustrous fabric you will go for a satin weave than a twill weave. If you want a see through fabric you will now know a leno weave fabric serves you better than any other weaves. For a kitchen towel you would want one with a waffle weave with better absorbency.

Don’t you agree that the patterns that the woven yarns make is a subject in itself and very important for you to know in buying fabrics?

To know more about the surface fabric patterns check out the post 80+ fabric patterns and their names

Related posts :What is Fabric? 20 FAQ answered on checking fabric quality ; Fabric glossary ; How is fiber turned into fabric; More about textiles ; Best fabrics for Upholstery ; Best fabrics for curtains

More interesting reading on fabric weaves :

- Classic and Modern Fabrics by JANET WILSON

- Woven Textile Design by JAN SHENTON

Different Types of Weaves in Woven Fabrics

Textile fabrics are essential material for making clothes, home made-up and other apparel products. Fabrics can be classified into four types according to the fabric weave structure – woven fabric, non-woven fabric, knit fabric and braid. In this post, we will discuss various types of woven fabrics according to the fabric weaves.

| Basket weave |

What are woven fabrics

Any textiles which are made from the process of weaving are called woven fabrics. Weaving is a method of textile production wherein two distinct set of yarns or threads are interlaced at a right angle to one another to form a fabric or cloth. The longitudinal yarns are called warp and the lateral threads are called weft or filling. Woven fabrics are woven in a loom whose basic function is to hold the warp threads under tension to facilitate the interweaving of the weft threads.

The characteristics of the woven fabric depend a lot on the method in which the yarns are interwoven in. The characteristics of the weave also change depending on the type of the fibre used along with the thickness of the yarn it is woven with. Woven fabrics only stretch diagonally (in bias direction) and usually fray at the edges. Depending on the end use, the fabric weave design is selected for weaving the fabric.

Majority of the woven products are created with one of the three basic weaves: Plain weave, Satin weave, or Twill weave. Some of the most common weave made with the alterations of the above are shown here.

Similar reading: Difference between Knits and Woven Fabrics

1. Plan weaves

Plain weave, also known as calico, tabby, taffeta as the name suggests is the simplest type of weave where the threads are woven together one after another meaning threads interlaced over one another. It is one of the strongest weaves as the threads are constantly crossing over each other. Its application can be found ranging from heavy and coarse fabric like the canvas to the lightest and finest fabrics like muslins.

| Plain weave |

2. Matt weave

Matt weave is a variation of plain weave with two warp thread passing over two warp thread instead of a single yarn giving a unique checkerboard-like appearance. Matt weave is also known as basket weave. This provides more structure to the fabric. It has great insulating properties and its structure makes the fabric more breathable. It is also naturally resistant to wrinkles.

Example of Matt weave: Oxford fabrics or oxford weave. The Pinpoint weave, Royal Weave are some variations of matt weave. It is mostly used for making casual or sporty cotton shirts, pants and other casual-to-formal garments. Oxford weave is for shirting fabric.

| Oxford Weave |

More variations are made from the above with examples like basket weave and monk’s cloth, which are made by group of yarns in place of a single yarn in plain weave or by alterations of fine and coarse yarn to make ribbed and corded fabrics with Bedford cord, pique, dimity as warp-ribbed and poplin, rep, grosgrain as weft-ribbed.

3. Twill fabrics

Twill weave is responsible for the diagonal pattern in the fabric. Depending on the technique used in the weave, the diagonal pattern will get different patches. It has lesser binding points compared to plain weave with a higher cloth thickness and mass per unit area. This type of weave is most commonly used for denim fabric and is responsible for two different colours of the fabric in two faces. Some of the alterations of twill weave include gabardine, serge, drill.

| Twill weave |

4. Herringbone fabric

Herringbone is a variation of the twill weave. The pattern is called herringbone as it resembles that of the skeleton of herringbone fish. The threads are woven in a way that a herringbone pattern appears on the fabric. Like the twill weave, it also has countless variations, which give different appearances to the fabric. It is most commonly used for suits and outerwear. Woven fabric tapes are commonly used as garment trims.

| Herringbone fabric weave |

5. Dobby Weave

Dobby is usually an advanced design which is used to create a texture in the fabric with a slightly raised design. Dobby weave is the combination of several different thicknesses of yarn and weave technique. The warp and weft may or may not be the same colour. Unlike plain weave, it is less susceptible to wrinkles. Pique fabric of polo shirt is a common example of dobby weave.

| Dobby fabric |

6. Satin Fabric

There are many types of satin from cotton satin and polyester satin to silk satin. The satin weave has floating or overshot warp threads on the surface which gives the fabric a shiny surface, which is often associated with exclusive fabrics.

| Satin Fabric |

Satin is a type of weave and not a kind of fibre. When the uncrossed threads are in the weft, the weave is called Sateen. It is mostly used for apparel in evening gowns, shirts, wedding dresses, ties etc. along with upholstery and bedding.

7. Pile fabric (Velvet fabric)

In pile fabric, extra sets of warps or fillings are woven over ground yarns of plain or twill weave to form loops. Pile fabrics have been defined as fabrics(s) with a cut or uncut loops which stand up densely on the surface.

Velvet fabric in an example of cut pile. Velvet is known for its soft and smooth surface. It consists of soft threads called pile sticking up out of the fabric. The pile is formed by supplemental yarns that can run both along warp and weft direction. The fabric is woven and then cut apart for the soft pile to emerge. There are many variations of velvet which provide the different look to the surface. Its characteristics depend on the type of yarn used in its manufacturing. Cotton velvet (velveteen) is the strongest and most durable type of velvet.

| Velvet fabric |

There are even variations for pile fabric with warp-pile fabric like terry, plush and weft-pile like velveteen, corduroy.

| Terry weave |

8. Jacquard fabrics

The Jacquard loom is a weaving mechanism done in special looms which can control individual warp threads producing fabrics having complicated woven patterns such as brocade, damask, tapestry etc.

| Brocade Weave |

weaving: Types of Woven Fabrics

Woven fabrics are classified as to weave or structure according to the manner in which warp and weft cross each other. The three fundamental weaves, of which others are variations, are the plain, twill, and satin. In plain weave, also known as calico, tabby, taffeta, or homespun weaves, the weft passes over alternate warp threads, requiring two harnesses only. The relatively simple construction suits it to cheap fabrics, heavy yarns, and printed designs. Variations are produced by the use of groups of yarns, as in basket weave and monk’s cloth, or by alternating fine and coarse yarns to make ribbed and corded fabrics, as the warp-ribbed Bedford cord, piqué, and dimity and the weft-ribbed poplin, rep, and grosgrain. The second primary weave, twill, shows a diagonal design made by causing weft threads to interlace two to four warp threads, moving a step to right or left on each pick and capable of variations, such as herringbone and corkscrew designs. Noted for their firm, close weave, twill fabrics include gabardine, serge, drill, and denim. Satin weave has floating or overshot warp threads on the surface which reflect light, giving a characteristic luster. When the uncrossed threads are in the weft, the weave is called sateen.

Pile fabrics have an additional set of yarns drawn over wires to form loops, and may be cut or uncut. Warp-pile fabrics include terry and plush; weft-pile, velveteen and corduroy. In double-cloth weave two cloths are woven at once, each with its warp and filling threads, and combined by interlacing some yarns or by adding a fifth set. The cloth may be made for extra warmth or strength, to permit use of a cheaper back, or to produce a different pattern or weave on each surface, e.g., steamer rugs, heavy overcoating, and machine belting. Velvet is commonly woven as a double cloth. In swivel weaving, extra shuttles with a circular motion insert filling yarns to form simple decorations, such as the dots on swiss muslin. Figure weaves are made by causing warp and weft to intersect in varied groups. Simple geometric designs may be woven on machine looms by using a cam or a dobby attachment to operate the harnesses. For curves and large figures each heddle must be separately governed. The Jacquard loom attachment permits machine weaving of the most complicated designs.

The Columbia Electronic Encyclopedia, 6th ed. Copyright © 2012, Columbia University Press. All rights reserved.

See more Encyclopedia articles on: Textiles and Weaving

What is Woven Fabric? Types of Woven Fabric? Used of Woven Fabric?

Answer:

Woven fabric:

Woven fabric only stretches diagonally on the bias directions (between the warp and weft directions), unless the threads used are elastic. Woven fabric cloth typically frays at the perimeters, unless techniques are used to counter it, like the utilization of pinking shears or hemming.

The fabrics that are created by interlacing 2 sets of yarn i.e. War yarn and weft yarn by in is termed as woven fabric. It is the intersection or interlacement of 2 sets of straight threads, warp (ends), and weft (picks or filling), that cross and interweaves at the correct angles to every different. Weaving is far and away the oldest and most typical technique of manufacturing continuous lengths of straight-edged fabric.

Woven Fabric Consider:

Woven fabrics determined by considering the following points.

1. Woven fabric is produced by interlacing two sets of yarns, the warp and the wet, which are at the right angle to each other in the plane of the fabric.

2. The warp is oriented in the direction of the length of the fabric and the weft in that of its width.

3. Individual warp and weft yarns are known as Ends and pick severally.

4. The interlacing of the ends and picks with one another produces a coherent structure.

5. The repetition pattern of interlacing is termed the Weave.

Types of Woven Fabric:

There are various types of woven fabrics produced in textile weaving sector which are mentioned in the following:

1. Birdseye design of fabric

2. Broadcloth,

3. Brocade Fabric

4. Buckram

5. Cambric

6. Casement

7. Cashmere Fabric

8. Chambray Fabric

9. Cheese Cloth

10.Chenille Fabric

11.Chiffon

12.Chintz

13.Corduroy Fabric

14.Crepe Fabric

15. Cut Velvet

16. Denim

17.Dobby fabric,

18.Dogtooth

19. Drill

20. Embossed Fabric

21.Flannel Fabric

22.Gabardine Fabric

23.Georgette

24.Herringbone Fabric (Twill weave)

25.JEANS

26.Khadi

27. Lawn

28.Matt weave

29.Mélange fabric,

30.Mesh fabric,

31. Mulmul

32. Muslin

33.Organdy fabric,

34.Oxford Fabric

35.Pinpoint oxford fabric,

36. Poplin

37. Printed Fabric

38.Sandblast shade of Denim

39. Seer Sucker Fabric

40.Sheeting fabric,

41. Silk

42. Solid

43. Taffeta Fabric

44. Terry Fabric

45. Tissue

46. Velour Fabric

47. Velvet

48. Yarn Dyed Fabric (Etc.)

Uses of Woven Fabric:

Woven fabric is used for the below purposes:

1. Jackets,

2. Dress or blouses,

3. Bridal satins,

4. Lining fabrics,

5. Stretch fabrics,

6. Blanket binders,

7. Shower curtain,

8. Umbrellas.

Woven Fabric |

Woven fabrics: main types, features, differences

Fabrics are made using two or more sets of yarn intersecting at right angles to each other. Most of the species are produced by weaving. Woven fabrics are the basis of most textiles.

Woven fabrics are made using two or more sets of yarns intersecting at right angles to each other. Most of the species are produced by weaving. Fabrics are usually more durable.They can be easily cut into different shapes and are great for making a variety of garments. However, raw edges unravel easily and need protection. Fabrics with more threads retain their shape well. Fabrics with fewer threads are less durable and may snag or stretch.

Fabrics are produced in various widths depending on the end use. The fabrics used for garments usually contain a width of 90 cm.Lining materials are usually made in widths of 160 cm / 140 cm and 150 cm / 180 cm.

This is a rigid coated fabric made from a lightweight woven fabric impregnated with adhesives and fillers. This fabric is used as a cushioning material to provide support and shape for necklines, collars, belts, cuffs, waistbands, button closures and other garments. It is also used as additional protection for bags and other items.

Batiste is a lightweight fabric woven in a regular weave and made with a stiff finish.It is suitable for dresses for women and children that require elasticity.

- Curtain fabric

This type of fabric is a medium weight cotton fabric made from closed thick warp threads. As a rule, it is used for curtains, tablecloths, upholstery and rarely for dresses.

- Sieve cloth

This is a popular lightweight open weave fabric. It has a low density and consists of a carded thread.It was originally used to pack cheese or meat. It is neither strong nor durable. It is processed in a variety of ways that appeal to the consumer. The fabric is used not only for women’s and children’s dresses, but also for drapery fabrics. Thanks to its open structure, it does not require ironing.

Chiffon fabrics are clean, lightweight fabrics made from a tough, twisted yarn. They were originally made from silk fabrics, but today they are made from artificial glass or polyester.They are used for sarees and women’s evening wear. These fabrics face the problem of shrinkage.

Chintz – Medium, plain woven cotton yarn. She is often given a glossy finish that can be temporary or semi-permanent. Chintz can be available in solid color and also printed with color prints. It is often made from blends of cotton and polyester or viscose. It is used for suits, dresses, blouses, pajamas, aprons and draperies.

This is a cut pile fabric in even colors.The cut pile fibers are visible as ribs on the surface. It is mainly used for trousers, jeans and shirts.

Originally silk fabric characterized by a wrinkled surface formed by highly twisted threads at the warp or weft. By using regular yarns, you can also get similar crepe effects. Synthetic fabrics are also given a crepe effect with trims. It is used for sarees, shirts, women’s and children’s dresses.

Traditionally, this was a dyed yarn woven with cotton.The main thread is usually dyed (mostly blue, burgundy, green and brown), while the weft remains white. This fabric is made in two thicknesses for sportswear and workwear. Its use for jeans has made it very popular and therefore the nature of denim has also changed in line with the trend. It is often made with pile, printed and made using elastic yarns.

This is a double weave twill fabric. It has a tough finish. Teak was originally produced in white but is now available in plain colors.Usually used for trousers, swimming trunks and uniforms.

Flannel is a woolen fabric woven in a regular or twill weave that is soft to the touch. It looks like a bulky fabric due to the felting process that is usually done with this fabric. Flannel fabric is used for suits, trousers and baby clothes.

This fabric is popular as a cleaning fabric due to its extreme softness. It is also used to protect children from the cold.

Gabardine is a tightly woven, sheer treated twill fabric.It contains more warp than weft and is also more durable. Gabardine is usually woven in 2/1 or 2/2 twill and has a heightened diagonal effect on the right side. It is mainly used for raincoats, suits and sportswear.

Georgette is a simple, lightweight fabric woven in a regular weave. It has a characteristic coarse texture, obtained by rigidly twisting both warp and weft yarns. It was originally made from silk, but today it is also made from rayon and polyester.

It is mainly suitable for ladies’ evening wear.

Cashmere is a silk fabric made from simple weaving, embroidered or dyed. It is characterized by repetitive motives. Cashmere is used for shirts, women’s clothing, and saris. Kashmiri shawls are created in twill weave and are usually embroidered with traditional Kashmiri embroidery.

Khadi is a term used for a wide variety of fabrics that are rolled and woven by hand. They are made primarily from a single cotton fiber, a blend of two or more fibers.They are known for their durability and simplicity. The fabrics can be used for overalls and home textiles.

Linon is a thin, light, crisp fabric made from cotton or linen. It has various finishes and is named accordingly. It is mainly used as a lining for dresses.

This is an Indian term commonly applied to thin cotton fabrics that are slightly heavier than muslin. It is often printed fabric. They find use in saree.

Muslin is a light open fabric of a simple weave.It can be used gray or bleached and dyed. It is used for household textiles and clothing materials.

It was originally a linon, which was given a hard finish. It uses acid to make the fabric transparent and tough. It is mainly used for women’s clothing.

Poplin is a medium weight cotton fabric with a fine weft. It is commonly used for shirts, dresses and upholstery.

It is mainly used for bed linen.Calico is a medium, tightly woven fabric with a regular or double weave. Coarse calico fabrics are made in various widths. High-quality cotton coarse calico fabrics are made in a smooth canvas with a width of 1.6 by 1.4 m and in a twill weave with a width of 1.5 by 1.8.

Taffeta is a smooth transparent fabric with a fine edge. It was originally made from silk fibers, but is now also made from rayon. It has a distinctive finish that creates clarity.Used for women’s evening wear.

This is a fine fabric made of silk or artificial fiber. It is characteristically intertwined with gold or silver threads. It is produced in rich colors and is used as a material for women’s clothing.

This is a fabric made from silk. It is also made from rayon. The dense cut pile makes it very soft and shiny. Velvet is used as a material for clothing for women and children. It is also made using special highly twisted warp and weft yarns.

Page not found – Fabrics

Fabrics

The development of textile technologies is carried out in many directions, which makes it possible to create fabrics with unusual properties.

Fabrics

In fact, the non-woven formband is not a fabric at all, but an auxiliary material used by

Fashion

When choosing clothes, a woman most often relies on taste preferences and does not hesitate,

is suitable

Fabrics

Spandex fabric has high elasticity, fits well and therefore is widely used in the sewing of many

Fabrics

Among the whole variety of knitted fabrics, riban jersey stands out, which combines both high

Fabrics

According to the international classification, polyamide is marked with the Latin letters PA, followed by the numbers corresponding to its

Page not found – Fabrics

Fabrics

The development of textile technologies is carried out in many directions, which makes it possible to create fabrics with unusual properties.

Fabrics

In fact, the non-woven formband is not a fabric at all, but an auxiliary material used by

Fashion

When choosing clothes, a woman most often relies on taste preferences and does not hesitate,

is suitable

Fabrics

Spandex fabric has high elasticity, fits well and therefore is widely used in the sewing of many

Fabrics

Among the whole variety of knitted fabrics, riban jersey stands out, which combines both high

Fabrics

According to the international classification, polyamide is marked with the Latin letters PA, followed by the numbers corresponding to its

Types of fabrics

Satin – made from cotton, the fibers of which are twisted and weaved in a double weave.Such manufacturing makes the material as smooth as silk, in combination with all the properties of cotton: non-allergenic, strong and durable, perfectly breathable, does not wrinkle, and is easy to iron. It is impossible not to note such a dignity of satin – products from it are demi-season. Bed linen will be comfortable to use both in winter and summer.

Satin-jacquard is a double-sided satin fabric, it has no front and back sides, the pattern is formed in the process of making the fabric.A distinctive feature of jacquard is the woven, regularly repeated pattern. The woven elements are shiny and the background is matte. Jacquard is not the composition of the fabric, not the material of the fibers, but the method of their weaving. The embossed pattern gives the products a noble and sophisticated look. Such products shimmer beautifully in the light.

Poplin – double-sided fabric, which is made by traditional plain weaving, threads are used in different calibers. The basis of the fabric consists of thin, smooth fibers, the second fibers are much thicker and coarser, as a result of which the fabric is obtained with a barely noticeable ribbed relief.Today it is the most demanded material used for making bed linen. Poplin is a dense, wear-resistant, crease-resistant, hygroscopic, unpretentious fabric.

Coarse calico – cotton fabric made by interweaving linen threads crosswise. The surface of the canvas is very smooth and matte in appearance, double-sided. Calico products are safe because this fabric is environmentally friendly, hypoallergenic. It washes well, retains the color and pattern, it lends itself to ironing without difficulty, it is pleasant to the touch and does not accumulate static electricity.

Percale – the thinnest, but strongest fabric, produced from combed, untwisted cotton (sometimes mixed with polyester). All threads are processed with a special compound, during which a very dense fabric is formed. Percale has a cruciform weave, which makes it look more aesthetically pleasing. Percale fabric is thin but durable, very soft and delicate, keeps you warm. Percale is very hygroscopic (absorbs moisture well), as it consists mainly of natural raw materials.

Polyester – synthetic fabric.Available at a price to various categories of consumers. Low maintenance, high wear resistance. It can be made from threads of various thicknesses, due to which it is distinguished by a variety of textures and areas of application. Has a silky appearance or matte surface, very delicate and pleasant to the touch.

Microfiber is a modern material based on polyamide fibers, which is not inferior in quality to natural materials. Products made from this material have a number of undoubted advantages: affordable price, practically do not wrinkle and do not require ironing, do not fade, retain their shape well, and are also breathable and hygroscopic, non-allergenic, therefore microfiber occupies a special place in the home textile market and already has regular customers.

Holofiber is a synthetic fiber, unique in its properties, based on padding polyester. Currently, it successfully replaces down and feathers, thus preventing allergic reactions, easy to clean, easy to wash, retains its shape for a long time, does not become electrified. Excellent thermal insulation properties, combined with breathability, make this material indispensable in the manufacture of bedding.

Sintepon is an artificial batting, as this synthetic material is called.This nonwoven fabric is composed of polyester fibers. The fibers in the fabric are thermally glued, due to which the synthetic winterizer has excellent characteristics: wear resistance, does not deform. The undoubted advantages also include the softness and airiness of synthetic winterizer products. The synthetic winterizer is very elastic, keeps its shape perfectly and can be easily washed even in the washing machine.

Teak is a very dense woven fabric, with different types of weaving of threads, which creates different textures of the fabric.Teak is made of natural fibers – cotton, linen, hemp. The characteristic impregnation of teak with a special strengthening solution makes it dustproof and fluffy, which is why this fabric is used when sewing covers for pillows, mattresses and blankets. Density, softness, wear resistance and durability make this fabric indispensable as household textiles.

Velsoft is a modern synthetic fabric, knitted fabric with a low thick pile, created for home comfort and coziness.It differs mainly in softness and silkiness, which is achieved using a special technology for the production of microfibers from polyester. Velsoft has excellent thermoregulation, resistance to mechanical stress, does not deform or shed, has antibacterial properties.

Atlas is a durable fabric with the so-called satin weave of threads, silk or semi-silk. The special weave makes the satin very smooth and shiny on one side and matte on the other.Satin is made from natural silk, and sometimes cotton or synthetic thread is used for the weft thread. The main characteristics of the atlas include strength, durability, good hygroscopicity, hypoallergenicity, breathability, drape and, of course, an unsurpassed appearance.