How does Under Armour’s innovative technology enhance athletic performance. What are the key features of HeatGear, ColdGear, and HOVR technology. How do Under Armour’s fabrics keep athletes cool, dry, and comfortable during intense workouts.

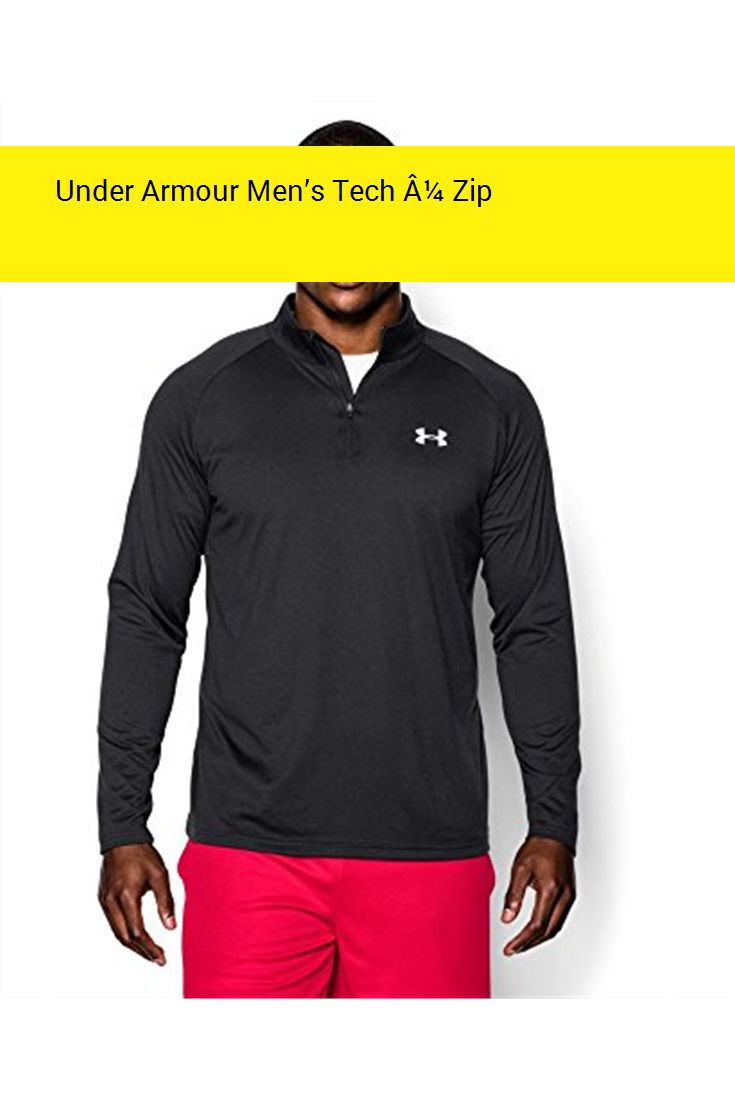

HeatGear: The Foundation of Under Armour’s Cooling Technology

Under Armour’s HeatGear technology is the cornerstone of their cooling fabrics, designed to keep athletes comfortable and performing at their best in hot conditions. This innovative material was the brainchild of Under Armour’s founder, who sought to create a solution for athletes struggling with sweat-soaked clothing during intense workouts.

Key Features of HeatGear Technology:

- Moisture-wicking fabric that draws sweat away from the skin

- Lightweight and breathable construction

- Temperature regulation to prevent overheating

- Soft, comfortable feel against the skin

HeatGear Armour, a variation of this technology, serves as a “second skin” for athletes, providing support without compromising on comfort. The lightweight construction of HeatGear Armour ensures that athletes can move freely while benefiting from its cooling properties.

The Science Behind HeatGear’s Cooling Effect

HeatGear’s effectiveness lies in its unique fabric structure. The material is engineered with special fibers that create micro-channels, allowing air to circulate and heat to escape. This design helps maintain a comfortable body temperature even during high-intensity activities.

Iso-Chill: Advanced Cooling for Extended Performance

Under Armour’s Iso-Chill technology represents the next evolution in cooling fabrics. This innovative material is specifically designed to help athletes maintain lower body temperatures, enabling them to perform at their peak for longer periods.

How Does Iso-Chill Work?

Iso-Chill utilizes ribbon-shaped nylon fibers that lie flat against the skin. This unique structure allows the fabric to disperse heat more effectively than traditional materials. The result is a cooling sensation that can be felt immediately upon contact with the skin.

Does Iso-Chill really make a difference in athletic performance? Studies have shown that athletes wearing Iso-Chill apparel can maintain lower body temperatures during intense workouts, potentially leading to improved endurance and delayed onset of fatigue.

ColdGear: Warmth Without Bulk for Cold Weather Training

While Under Armour is renowned for its cooling technologies, the brand also offers innovative solutions for cold weather training. ColdGear is designed to keep athletes warm and dry without the need for heavy, restrictive layers.

Key Features of ColdGear Technology:

- Dual-layer fabric construction

- Moisture-wicking interior to keep skin dry

- Soft, brushed interior for warmth and comfort

- Lightweight and flexible for unrestricted movement

ColdGear Infrared takes this technology a step further by incorporating a thermo-conductive coating on the interior of the fabric. This coating absorbs and retains body heat, providing long-lasting warmth without added bulk.

HOVR: Revolutionary Cushioning for Enhanced Performance

Under Armour’s HOVR technology represents a significant advancement in athletic footwear. This innovative cushioning system is designed to provide a unique combination of energy return and impact reduction, potentially improving athletic performance across various activities.

The Science Behind HOVR Technology

HOVR technology utilizes a proprietary foam compound that offers both softness and responsiveness. This foam is encased in a mesh Energy Web, which helps maintain the foam’s shape and enhance its energy return properties.

How does HOVR technology benefit athletes? The “zero gravity feel” provided by HOVR cushioning helps reduce the impact of each foot strike while simultaneously returning energy to the athlete. This combination can lead to reduced fatigue and improved performance, particularly in activities like running and jumping.

Storm and Gore-Tex: Keeping Athletes Dry in Any Weather

Under Armour’s commitment to all-weather performance is evident in their Storm and Gore-Tex technologies. These water-resistant and waterproof solutions ensure that athletes can train and compete regardless of the conditions.

Storm Technology: Water-Resistant Performance

Under Armour’s Storm technology provides a water-resistant finish to fabrics without compromising breathability. This treatment causes water to bead up and roll off the surface of the garment, keeping the wearer dry in light rain or snow.

Gore-Tex: Ultimate Waterproof Protection

For more extreme weather conditions, Under Armour partners with Gore-Tex to offer fully waterproof gear. Gore-Tex fabrics feature a microporous structure that blocks water droplets while allowing water vapor to escape, ensuring the wearer stays dry from both external moisture and sweat.

RUSH and Recover: Innovative Fabrics for Performance and Recovery

Under Armour’s commitment to athletic performance extends beyond the workout itself with their RUSH and Recover lines. These innovative fabrics are designed to enhance performance during exercise and speed up recovery afterward.

RUSH: Mineral-Infused Fabric for Enhanced Performance

RUSH technology incorporates minerals into the fabric that are claimed to reflect the body’s energy back to the muscles. This reflected energy may help improve endurance and strength during workouts.

Are the benefits of RUSH technology scientifically proven? While Under Armour states that RUSH has been “scientifically tested and athlete proven,” it’s important to note that independent studies on the effectiveness of mineral-infused fabrics are limited. Athletes should consider their personal experience when evaluating the benefits of RUSH technology.

Recover: Accelerating Post-Workout Recovery

The Recover line uses similar mineral-infused fabrics as RUSH, but is designed for post-workout wear. The goal of Recover apparel is to promote faster muscle recovery and reduce soreness after intense exercise.

Charged Cushioning and Micro G: Innovative Footwear Technologies

Under Armour’s commitment to innovation extends to their footwear line, with technologies like Charged Cushioning and Micro G designed to enhance comfort and performance.

Charged Cushioning: Energy Return for Explosive Performance

Charged Cushioning is a responsive foam that compresses under impact and then quickly returns to its original shape. This energy return can help propel the athlete forward, potentially improving speed and reducing fatigue.

Micro G: Low-Profile Cushioning for Natural Movement

Micro G technology provides a low-to-the-ground cushioning solution that offers both comfort and stability. The lightweight foam is designed to turn cushioned landings into explosive takeoffs, making it particularly beneficial for sports that require quick directional changes.

How does Micro G compare to other cushioning technologies? Micro G’s low profile design allows for greater ground feel and natural foot movement compared to thicker cushioning systems. This can be advantageous in sports that require agility and precise foot placement.

Armour Fleece: Lightweight Warmth for Cold Weather Training

Armour Fleece represents Under Armour’s approach to cold weather gear that doesn’t sacrifice mobility for warmth. This technology provides insulation without the bulk often associated with traditional cold weather apparel.

Key Features of Armour Fleece:

- Brushed interior traps heat for warmth

- Smooth exterior helps repel wind and light precipitation

- Lightweight construction for unrestricted movement

- Moisture-wicking properties to keep the wearer dry

How does Armour Fleece compare to traditional fleece materials? Armour Fleece is engineered to provide warmth with less weight and bulk than conventional fleece. This allows for greater range of motion and layering options, making it ideal for athletes who need to stay warm without sacrificing performance.

Charged Cotton: Performance Enhanced Natural Fibers

Under Armour’s Charged Cotton technology represents an innovative approach to performance apparel that maintains the comfort and feel of natural cotton while incorporating the moisture-wicking properties typically associated with synthetic fabrics.

The Science Behind Charged Cotton

Charged Cotton is a unique blend of cotton and synthetic fibers that combines the best properties of both materials. The natural cotton provides the soft, comfortable feel that many athletes prefer, while the synthetic fibers enhance moisture management and quick-drying capabilities.

How does Charged Cotton perform compared to traditional cotton? Under Armour claims that Charged Cotton dries significantly faster than ordinary cotton, helping to keep athletes cool and comfortable during intense workouts. The addition of synthetic fibers also helps the fabric maintain its shape and resist stretching or sagging over time.

Benefits of Charged Cotton for Athletes

- Soft, natural feel against the skin

- Enhanced moisture-wicking properties

- Quicker drying time compared to traditional cotton

- Improved durability and shape retention

- Versatile for both athletic and casual wear

Is Charged Cotton suitable for all types of athletic activities? While Charged Cotton offers improved performance over traditional cotton, it may not be the optimal choice for high-intensity or extremely sweaty workouts where synthetic fabrics like HeatGear might be more effective. However, for moderate activities or for athletes who prefer the feel of cotton, Charged Cotton provides an excellent balance of comfort and performance.

The Future of Under Armour’s Performance Technology

As Under Armour continues to innovate in the field of performance apparel and footwear, we can expect to see further advancements in their existing technologies as well as entirely new solutions for athletic challenges.

Potential Areas for Future Innovation

- Smart fabrics that adapt to changing body temperatures and activity levels

- Integration of wearable technology for real-time performance tracking

- Sustainable materials that maintain high performance standards

- Customizable gear that can be tailored to individual athlete needs

- Advanced recovery technologies that further speed up post-workout muscle repair

What role will artificial intelligence play in the development of future Under Armour products? As AI continues to advance, we may see it used in the design process to create more effective fabric structures or to analyze athlete data for personalized performance solutions.

Under Armour’s commitment to innovation and performance has established them as a leader in the athletic apparel and footwear industry. Their diverse range of technologies, from cooling fabrics to energy-returning cushioning systems, demonstrates a holistic approach to enhancing athletic performance. As the company continues to evolve and introduce new technologies, athletes can look forward to gear that increasingly adapts to their needs and helps them reach new levels of performance.

Technology & Innovation | Under Armour UK

This is what makes our gear work harder–and smarter–than everything else out there.

STAY COOL

STAY MOVING

STAY WARM

STAY DRY

STAY READY

STAY COOL

HEATGEAR®

WEAR THIS TO FEEL COOL, DRY & LIGHT.

The original innovation our founder dreamed up while sweating under the summer sun. This super-breathable fabric wicks sweat and regulates body temperature so you feel cooler, drier, and lighter than ever.

Shop Now

ISO-CHILL

MAKES YOU COOLER SO YOU CAN WORK LONGER.

Iso-Chill is proven to keep your body cooler, helping you stay out longer and reach your performance peak later. Made with ribbon-shaped nylon fibers that lay flat and disperse heat so it literally feels cool.

Shop Now

HEATGEAR® ARMOUR

ALWAYS START HERE.

Heatgear® Armour Baselayer is the “second skin” that makes all athletes better. Its soft, lightweight construction delivers relentless support without sacrificing comfort.

Shop Now

STAY MOVING

HOVR™

LIFTS YOU UP.

HOVR™ technology provides ‘zero gravity feel’ to maintain energy return that helps eliminate impact on every run.

Shop Now

CHARGED CUSHIONING

ENERGY GIVEN. POWER RETURNED.

As soon as you feel Charged Cushioning under your feet, you want to run. It’s the ultimate advancement in energy, absorbing the impact of your foot strike and converting it into a level of responsive comfort you’ve never felt before.

Shop Now

MICRO G®

TURNS CUSHIONED LANDINGS INTO EXPLOSIVE TAKEOFFS.

Lighter and sleeker than traditional foams, Micro G® cushioning delivers ultra-responsive, low-to-the-ground performance for better, natural stability and comfort.

Shop Now

STAY WARM

COLDGEAR®

WEAR THIS TO FEEL WARM, DRY & LIGHT.

This is the layer athlete’s trust when the mercury drops. ColdGear® eliminates the need to wear heavy, bulky gear in cold weather.

Shop Now

ARMOUR® FLEECE

WARMTH WITHOUT THE WEIGHT.

Armour® Fleece construction has a soft, bushed interior that traps heat and a smooth exterior that helps fight off the elements.

Shop Now

COLDGEAR® INFRARED

STAY WARMER LONGER.

ColdGear® Infrared lining uses a soft, thermo-conductive coating to absorb and retain body heat for lasting warmth.

Shop Now

STAY DRY

STORM

ALWAYS STAY DRY.

A tiered system of water and wind protection that keeps you dry in any wet weather situation.

Shop Now

GORE-TEX

GUARANTEED TO KEEP YOU DRY.

Made of the toughest fabrics & thoroughly tested to guarantee performance even after serious wear and tear.

Shop Now

STAY READY

RUSH

SCIENTIFICALLY TESTED. ATHLETE PROVEN.

RUSH is a new line of workout gear created from innovative fabrics infused with minerals to reflect energy and improve performance.

Shop Now

RECOVER

RECOVER FASTER. RETURN BETTER.

RETURN BETTER.

Recover Is a new line of gear created from innovative fabrics lined with minerals to reflect energy and improve recovery speed.

Shop Now

CHARGED COTTON®

MOTHER NATURE MADE IT. WE MADE IT BETTER.®

Unique cotton-blend performance fabric dries faster than any ordinary cotton out there…but still feels just as soft and comfortable.

Shop Now

Technology | Under Armour

This is what makes our gear work harder–and smarter–than everything else out there.

STAY READY

STAY COOL

STAY DRY

STAY MOVING

STAY WARM

STAY READY

CHARGED COTTON®

MOTHER NATURE MADE IT. WE MADE IT BETTER.®

Unique cotton-blend performance fabric dries faster than any ordinary cotton out there…but still feels just as soft and comfortable.

Shop Now

Rush Infared Athletic Apparel

SCIENTIFICALLY TESTED. ATHLETE PROVEN.

This groundbreaking baselayer has been tested and proven to improve strength and endurance.

Shop Now

ATHLETE RECOVERY

RECOVER FASTER. RETURN BETTER.

RETURN BETTER.

We’ve designed the ultimate post-game, post-train system to help you restore muscle faster & come back better than ever.

Shop Now

STAY COOL

HEATGEAR® ARMOUR

ALWAYS START HERE.

Armour® Baselayer is the “second skin” that makes all athletes better. Its soft, lightweight construction delivers relentless support without sacrificing comfort.

Shop Now

HEATGEAR®

WEAR THIS TO FEEL COOL, DRY & LIGHT.

The original innovation our founder dreamed up while sweating under the summer sun. This super-breathable fabric wicks sweat and regulates body temperature so you feel cooler, drier, and lighter than ever.

Shop Now

ISO-CHILL

ACTUALLY FEELS COOL TO THE TOUCH.

Iso-Chill construction helps dissipate heat from the body creating a cooling effect.

Shop Now

STAY DRY

UA STORM

WATER ROLLS RIGHT OFF.

UA Storm technology repels water without sacrificing breathability

Rain, sleet, snow…the weather doesn’t even matter.

Shop Now

GORE-TEX

GUARANTEED TO KEEP YOU DRY

Made of the toughest fabrics & thoroughly tested to guarantee performance even after serious wear and tear.

Shop Now

STAY MOVING

UA HOVR™

LIFTS YOU UP.

UA HOVR™ technology provides ‘zero gravity feel’ to maintain energy return that helps eliminate impact on every run.

Shop Now

UA MICRO G®

TURNS CUSHIONED LANDINGS INTO EXPLOSIVE TAKEOFFS.

Lighter and sleeker than traditional foams, UA Micro G cushioning delivers ultra-responsive, low-to-the-ground performance for better, natural stability and comfort.

Shop Now

CHARGED CUSHIONING

ENERGY GIVEN. POWER RETURNED.

As soon as you feel Charged Cushioning under your feet, you want to run. It’s the ultimate advancement in energy, absorbing the impact of your foot strike and converting it into a level of responsive comfort you’ve never felt before.

Shop Now

STAY WARM

COLDGEAR® REACTOR

YOUR OWN PERSONAL THERMOSTAT.

Adaptive fabric that maintains a comfortable level of warmth.

Shop Now

ARMOUR® FLEECE

WARMTH WITHOUT THE WEIGHT.

Armour® Fleece construction has a soft, bushed interior that traps heat and a smooth exterior that helps fight off the elements.

Shop Now

COLDGEAR®

WEAR THIS TO FEEL WARM, DRY & LIGHT.

This is the layer athlete’s trust when the mercury drops. ColdGear eliminates the need to wear heavy, bulky gear in cold weather.

Shop Now

Under Armour: The Business of Sweat Goes Digital

Today’s user has evolved: we toggle between physical and virtual worlds effortlessly, made possible by the ubiquity of handheld and accessible technology. Adapting to the user’s connected world is now the industry toll to compete.[1] This have never been more salient than for the fitness industry, with athletes craving more ways to be better, faster, stronger. With this changing tide, Under Armour (UA) is embracing digital transformation to create, capture, and deliver more meaningful value for the connected athlete. [2]

[2]

UA’s Business Model Evolves to “Make Athletes Even Better”

For over 20 years, UA created value for their customers and captured that value by being a shirts-and-shoes company that simply wanted to “make athletes better.” UA saw 23 consecutive quarters of growth under this business model [3], but UA’s CEO Kevin Plank recognizes that the shirts-and-shoes company will not suffice in a world where making athletes better has evolved beyond apparel sales. UA is now focused on a digital innovation strategy that optimizes for the athletes of tomorrow, as showcased by UA’s CES 2016 presentation of Future Girl (Exhibit 1). We see from the video that UA’s digital innovation strategy is predicated on connecting athletes’ devices and daily apparel, deciphering that dataset, and providing actionable insights to produce better and healthier performers.[4]

Exhibit 1: Future Girl Ad [5]

vimeo.com/video/66195683″ frameborder=”0″ title=”Under Armour Future Girl” webkitallowfullscreen=”” mozallowfullscreen=”” allowfullscreen=””/>

Creating Value with Integrated Applications: Gone are the days of an Under Armour that makes only shirts and shoes, selling product through brick and mortar and a standalone website. Over the last several years, UA has invested $710M acquiring and developing three mobile applications to build their connected fitness platform: MapMyFitness, Endomondo, and MyFitnessPal.[6] Fully integrated into UA’s proprietary UA Record application, this collection of personal data tracking apps enables users to optimize activity levels, sync wearables, and analyze aggregated personal metrics. Altogether, these applications create value in excess of UA’s historical business model, giving users access to an action-oriented, comprehensive dashboard of their biometric statistics. As such, users are now armed with personalized tools needed to become better athletes. [7]

[7]

Capturing Value from a Connected User Base: With UA’s latest app acquisitions, the company’s digital community tops 120M unique members worldwide.[8] This user base provides UA two value capture opportunities in excess of their historical business model: 1) accessing new markets, and 2) leveraging their existing customer base. Prior to UA’s connected fitness platform, women accounted for 30% of company sales. UA now sees 60% female users across its apps. This connected fitness platform provides UA with a new captive female audience from which to access previously unrealized dollars. Additionally, the average underarmour.com order that comes in through the connected fitness community is 26% higher than orders from external referral sources.[9] Here, UA’s vast user base enables the company to optimize value capture by leveraging existing customers’ self-reported data to send targeted customer offers.

Operationally, UA Hits a Home Run

UA’s digital transformation has evolved how the company delivers on its promise to “make all athletes better. ” Previously a standalone website with brick-and-mortars, UA did not deliver customer value in a meaningfully differentiated way from competitors. Digital tech has made UA’s value delivery smarter and user-focused. User-reported data within UA apps is spurring product innovation tailored to athlete needs. For example, UA learned from MapMyFitness data that the average run is 3.1 miles. When designing the 2016 Speedform Gemini running shoe — one of UA’s most popular running products — the company added Charged Foam padding to optimize for short-distance runs.[10] From their database of user activity habits, UA can see fitness trends emerge in real-time. This competitive advantage equips UA to design for, and proactively identify, customer needs.

” Previously a standalone website with brick-and-mortars, UA did not deliver customer value in a meaningfully differentiated way from competitors. Digital tech has made UA’s value delivery smarter and user-focused. User-reported data within UA apps is spurring product innovation tailored to athlete needs. For example, UA learned from MapMyFitness data that the average run is 3.1 miles. When designing the 2016 Speedform Gemini running shoe — one of UA’s most popular running products — the company added Charged Foam padding to optimize for short-distance runs.[10] From their database of user activity habits, UA can see fitness trends emerge in real-time. This competitive advantage equips UA to design for, and proactively identify, customer needs.

At Bat: UA’s Next Steps

UA has bigger ambitions than simply selling more workout shirts than Nike, they aspire to be the go-to fitness brand. To be this, UA has room to meaningfully own the market by:

- Disrupting Apparel Wearables: UA introduced HealthBox at CES this year — this kit includes a collection of wearables that sync with UA Record.

[11] To prevent a replay of the Nike FuelBand flop of 2014, UA must supplement its hardware offering with connected clothing. These apparel wearables should have biometric tracking capabilities and seamlessly connect with UA apps.[12] As first-mover in connected clothing, UA will move closer to its vision of a Future Girl world.

[11] To prevent a replay of the Nike FuelBand flop of 2014, UA must supplement its hardware offering with connected clothing. These apparel wearables should have biometric tracking capabilities and seamlessly connect with UA apps.[12] As first-mover in connected clothing, UA will move closer to its vision of a Future Girl world.

- Leveraging Apple’s Fitness Focus: UA is digitally competing with Nike and their Nike+ apps, and also faces the formidable Nike-Apple partnership.[13] But, Nike does not completely own Apple’s fitness mindshare. UA will be the first-mover in connected clothing, and the rapid adoption of Apple’s HealthKit developer platform provides an opportunity for a UA-Apple collaboration. This could materialize as UA developing clothing wearables that connect to Apple devices.[14] A partnership with Apple would expose UA to a new population of users.

Word Count: 798 (excluding citations)

[1] Marco Iansiti and Karim R. Lakhani, “Digital Ubiquity: How Connections, Sensors, and Data are Revolutionizing Business,” Harvard Business Review (November 2014 Issue), pg. 3-5.

Lakhani, “Digital Ubiquity: How Connections, Sensors, and Data are Revolutionizing Business,” Harvard Business Review (November 2014 Issue), pg. 3-5.

[2] David Trites, “How Under Armour’s Digital Transformation Will Improve Your Health,” SAP News Center, February 15, 2016, https://news.sap.com/how-under-armours-digital-transformation-will-improve-your-health/, accessed November 2016.

[3] Thomas Hobbs, “How Under Armour plans to become the world’s biggest sports brand,” Marketing Weekly, May 4, 2015, ABI/INFORM via ProQuest, accessed November 2016.

[4] David Pierce, “How Under Armour Plans to Turn Your Clothes into Gadgets,” Wired, January 5, 2016, https://www.wired.com/2016/01/under-armour-healthbox/, accessed November 2016.

[5] Under Armour MX, “Future Girl,” May 14, 2013, video file, hosted on Vimeo, https://vimeo.com/66195683, accessed November 2016.

[6] David Pierce, “How Under Armour Plans to Turn Your Clothes into Gadgets,” Wired, January 5, 2016, https://www. wired.com/2016/01/under-armour-healthbox/, accessed November 2016.

wired.com/2016/01/under-armour-healthbox/, accessed November 2016.

[7] “Under Armour Launches UA Record, The Latest Addition To The Definitive Digital Health And Fitness Network,” PR Newswire, January 6, 2015, ABI/INFORM via ProQuest, accessed November 2016.

[8] “Under Armour Opens First Digital Headquarters in Austin’s Revitalized Seaholm Power Plant District: Under Armour Connected Fitness Debuts in Iconic Downtown Development,” PR Newswire, March 11, 2015, ABI/INFORM via ProQuest, accessed November 2016.

[9] Tom Foster, “Kevin Plank is Betting Almost $1 Billion That Under Armour Can Beat Nike,” Inc Magazine, February 2016, http://www.inc.com/magazine/201602/tom-foster/kevin-plank-under-armour-spending-1-billion-to-beat-nike.html, accessed November 2016.

[10] Ibid.

[11] Elaine Low, “Tech Will Massive Role in Under Armour: UA’s Robin Thurston,” Investor’s Business Daily, January 26, 2016, ABI/INFORM via ProQuest, accessed November 2016.

[12] Ibid.

[13] CNBC News, “More from Apple and Nike to come: Nike CEO,” May 8, 2015, video file, http://video.cnbc.com/gallery/?video=3000378000, accessed November 2016.

[14] Thomas Hobbs, “How Under Armour plans to become the world’s biggest sports brand,” Marketing Weekly, May 4, 2015, ABI/INFORM via ProQuest, accessed November 2016.

How Under Armour Lost Its Edge

In the summer of 2018, two top Under Armour executives traveled to the West Coast on a critical mission. Kevin Plank, the sports apparel company’s founder and chief executive, and Patrik Frisk, its president and chief operating officer, needed to persuade Stephen Curry, the Golden State Warriors star and the company’s highest-profile endorser, not to leave the brand.

The two sides had grown increasingly frustrated with the relationship, said two former Under Armour executives familiar with the matter, who spoke on condition of anonymity to discuss the previously undisclosed meeting. In 2017, Mr. Curry took public exception to a comment by Mr. Plank calling President Trump “a real asset” to the country, prompting the executive to take out a full-page newspaper ad to explain what he said about Mr. Trump “did not accurately reflect my intent.”

Plank calling President Trump “a real asset” to the country, prompting the executive to take out a full-page newspaper ad to explain what he said about Mr. Trump “did not accurately reflect my intent.”

But the relationship between the two remained tense. Mr. Plank was unhappy that Mr. Curry, whose endorsement deal pays him millions of dollars a year, would rarely wear Under Armour clothing to N.B.A. games. Mr. Curry was upset that sales of the signature Curry 3 shoe had been weak.

At the meeting, participants found a solution that would showcase just how much Mr. Curry meant to the company. Mr. Plank and Mr. Frisk agreed to build a separate business around him, one reminiscent of what Nike had done for Michael Jordan two decades before. The company brought on the former executive who had overseen the creation of the Jordan brand at Nike to run the Curry brand and promised Mr. Curry much more involvement in the development of his shoes. Mr. Curry decided to remain, and a crisis was averted.

Jeff Austin, Mr. Curry’s agent, declined to comment when asked about the meeting. A spokeswoman for Under Armour, when asked about the events, said Mr. Curry had been a “fantastic partner” over the past seven years and that the company was “excited about our future partnership plans.”

In its promise and its turmoil, Under Armour’s relationship with Mr. Curry encapsulates the company’s broader struggles in recent years, and represents a critical piece of its comeback hopes.

Once heralded as the next Nike, Under Armour has faltered, hurt by slumping sales and unflattering revelations about its corporate culture. It is grasping for a hold in the fiercely competitive sports apparel market even as it undergoes the biggest management shift in its history. Investors, analysts, and competitors are wondering if Under Armour can successfully redefine itself and once again win over consumers, or whether the company’s best days are behind it.

Not long ago, Under Armour was a darling of investors. But it has since faced tough scrutiny, resulting in lawsuits from shareholders, who accuse the company of misleading investors, and media coverage around real estate deals involving the company and Mr. Plank’s private holdings. Questions have also arisen about a culture that allowed strip club visits to be expensed on corporate credit cards and, more recently, a disclosure by The Wall Street Journal that federal authorities are conducting investigations into accounting practices.

But it has since faced tough scrutiny, resulting in lawsuits from shareholders, who accuse the company of misleading investors, and media coverage around real estate deals involving the company and Mr. Plank’s private holdings. Questions have also arisen about a culture that allowed strip club visits to be expensed on corporate credit cards and, more recently, a disclosure by The Wall Street Journal that federal authorities are conducting investigations into accounting practices.

It is a far cry from 2015, when Under Armour, founded in 1996 as a maker of high-tech athletic gear, had overtaken Adidas to become the second-largest sports apparel company in the United States by sales, behind only Nike. It posted 26 consecutive quarters of 20 percent or greater year-over-year revenue growth, and its stock more than doubled in two years’ time.

Athletes it sponsored were among the biggest names in the N.B.A. (Mr. Curry), the N.F.L. (Tom Brady), major league baseball (Bryce Harper) and golf (Jordan Spieth). Under Armour signed U.C.L.A. to a sponsorship agreement worth $280 million, the largest ever for a university and a challenge to Adidas and Nike’s dominance of college athletics. The ballerina Misty Copeland gave the company a presence in the fine arts. It spent a total of about $700 million acquiring apps like MapMyFitness and MyFitnessPal, with visions of creating a mobile digital health and fitness community.

Under Armour signed U.C.L.A. to a sponsorship agreement worth $280 million, the largest ever for a university and a challenge to Adidas and Nike’s dominance of college athletics. The ballerina Misty Copeland gave the company a presence in the fine arts. It spent a total of about $700 million acquiring apps like MapMyFitness and MyFitnessPal, with visions of creating a mobile digital health and fitness community.

Now, revenue growth has slumped, increasing less than 1 percent in the first nine months of last year. The company’s stock price has collapsed to around $21 a share from a high of $51 in 2015. Worse, the brand finds itself out of step with consumer taste.

“The fashion cycle moved away from them. They stayed true to their muse, performance footwear and apparel,” said Matt Powell, an analyst with the NPD Group. “But that’s just not where the business is. Right now, it’s all about fashion and athleisure.”

There is no one cause of Under Armour’s struggles. Some factors, like the bankruptcies of the retail giants Sports Authority and Sport Chalet in 2016, were out of the company’s control.

But interviews with several current and former Under Armour employees as well as competitors, advisers to athletes, and financial analysts also point to a company that tried to do too much too fast. It expanded into sports in which it had little expertise and failed to articulate a strategy for its expensive tech acquisitions. It eschewed the athleisure trend, which has buoyed sales at Nike and Adidas, and struggled to translate its brand to an international audience.

Today in Business

April 23, 2021, 1:31 p.m. ET

And when Mr. Plank hired executives from Nike, Adidas and elsewhere to help expand or fix crucial businesses, many said they were viewed by Under Armour employees with a mixture of suspicion and disdain. It was a disconnect that played out in how Mr. Curry’s shoes were made and marketed.

“Loyalty is good, but it can also create blind spots,” said Aaron Miller, who worked as a senior director of footwear at Under Armour from 2013 to 2015, after 18 years at Nike. Mr. Plank “was so loyal to the guys who were there before that when the Nike guys came in, suddenly, they were insiders and we were outsiders.”

Mr. Plank “was so loyal to the guys who were there before that when the Nike guys came in, suddenly, they were insiders and we were outsiders.”

This month, Mr. Plank, 47, officially stepped down as chief executive and was replaced by Mr. Frisk, 57. Mr. Plank now holds the titles of executive chairman and brand chief, and Mr. Frisk reports directly to him.

Under Armour declined to make any executives available to comment for this article. In a statement, a spokeswoman said the company was proud of the global brand that it continued to build, adding, “Like the athletes we serve, we are acutely aware of our strengths and weaknesses and the opportunities that are inherent every time we train, compete and recover.”

From its early days, Under Armour made its mark as a tech-focused sports apparel company. It didn’t just make clothes for athletes; it made clothes that aimed to improve their performance. Beginning with its first product, a T-shirt that wicked away sweat, Under Armour redefined the category, from its HeatGear and ColdGear fabrics in the late 1990s to, more recently, sleepwear intended to help athletes recover from a big game.

With Under Armour’s stock soaring in the fall of 2015, Mr. Plank and his top lieutenants believed nothing could stop the company’s rise. But others were less sanguine, concerned the company’s go-go-growth culture and its lack of discipline around product planning and expenses would result in a reckoning.

One internal debate came that same year, over how many pairs of Curry 2 shoes to manufacture.

The first Curry shoe had sold out immediately, and Mr. Miller wanted to double the number of Curry 2 shoes produced. That quantity, he believed, would also sell out, increasing demand for the next model, the Curry 3. But top executives, he recalled, requested three times the number of shoes he recommended, even as he argued that could cause a glut.

The executives won, and Curry 2 shoes eventually flooded the market, winding up on sale racks. It didn’t help that one all-white low-top version was ruthlessly mocked as a “dad” shoe. The large inventory combined with infighting over and micromanaging of the shoe’s design set the stage for the lackluster sales of the Curry 3 in 2016, Mr. Miller said. On a 2017 earnings call, Mr. Plank blamed a “sluggish signature market” for “softer than expected” sales of the shoe.

Miller said. On a 2017 earnings call, Mr. Plank blamed a “sluggish signature market” for “softer than expected” sales of the shoe.

“It’s crazy. Why recruit talented, proven people and then not listen to them?” said Mr. Miller, who left the company a few months later.

A spokeswoman for Under Armour declined to comment on the debate around the Curry 2.

Three former executives said that decisions around products were often driven by instinct, rather than consumer analysis of the market.

Two pointed to the DJ, a slip-on shoe for women that they said sold poorly. Yet, the former executives said, the DJ could not be killed because it was named for Mr. Plank’s wife, Desiree Jacqueline Guerzon, who goes by D.J., and she really liked the shoe.

Under Armour declined to respond to questions about the shoe.

Under Armour’s rush to compete for college endorsement contracts resulted in other headaches. Under the terms of the contracts, it supplied jerseys, cleats and sneakers for football and basketball teams. But it also quickly had to manufacture apparel and shoes for other sports, like running and volleyball, in which it had much less expertise.

But it also quickly had to manufacture apparel and shoes for other sports, like running and volleyball, in which it had much less expertise.

A former executive said some runners at Under Armour-sponsored colleges refused to train in the company’s shoes because they worried they might get hurt. Instead they took them to sporting goods stores and tried to exchange them for shoes from other companies.

A spokeswoman for Under Armour declined to comment on its college endorsement deals.

Over the last two years, Mr. Frisk, the new chief, has been given credit for introducing more controls around inventory levels as well as increased oversight on expenses and product planning. Those moves have already improved Under Armour’s profit margins.

The challenge now is figuring out how to increase revenue and recapture the magic that propelled Under Armour’s meteoric rise.

Some Wall Street analysts are skeptical of an approach that focuses too much on products marketed as performance-enhancing, especially for a public that wears basketball shoes or track pants to the grocery store or the movies.

Still, Under Armour and Mr. Plank are undaunted in their strategy. This month, the company released its latest advertising campaign, “The Only Way Is Through,” featuring the swimmer Michael Phelps, D.K. Metcalf of the Seattle Seahawks, and other Under Armour-sponsored athletes sweating and gasping through strenuous workouts.

“The world did not need another competent apparel or footwear manufacturer,” Mr. Plank recently told attendees at the National Retail Federation conference in New York. “What the customer needs is a dream.”

Under Armour – The Technology Behind the Clothing

In 1996, Under Armour was founded with one goal in mind; to keep athletes cool, dry and comfortable during activity. Their first product was the original 0039 Compress t-shirt which boosts muscle performance and wicks moisture, courtesy of the unique synthetic material.

What followed was 21 years of success and numerous revolutionary sportswear products, all of which serve a different purpose in perfecting the performance of the athlete. In 1998, Under Armour introduced their ColdGear Mock which kept athletes dry and protected with a brushed inner layer that circulates heat.

In 1998, Under Armour introduced their ColdGear Mock which kept athletes dry and protected with a brushed inner layer that circulates heat.

A decade later, the company re-released their original compression shirt only this time revolutionised with their new technology – Charged Cotton. With all the comfort of cotton and the light, water repellent properties of their original compression shirt, Charged Cotton and Charged Cotton Storm changed the game.

As well as numerous other notable creations from t shirts to trainers, Under Armour now have a huge catalogue of incredible clothing designed to accommodate any athlete, keeping them cool, comfortable and performing at their peak whatever the weather.

Over time, the brand has defined four main technologies for their products; CoolSwitch, HeatGear, HeatGear Armour and Microthread. CoolSwitch is designed for warmer weather, keeping your body and skin cool so you can perform for longer. The technology utilises an exclusive coating on the inside of the fabric which pulls heat away from your skin, allowing you to feel cooler and perform at your best.

HeatGear, as the name suggests, is designed to be worn in the heat. This is the product Under Armour was originally known for – clothing designed to keep you cool, dry and fresh under any heat courtesy of the breathable fabric which wicks sweat and regulates body temperature.

HeatGear technology later evolved into the popular base layer so widely used in sports today. Utilising the same lightweight breathable fabric as the original HeatGear, the base layer acts as your second skin offering cooling, sweat wicking properties as well as undeniable support to the athlete.

Last but by no means least, Under Armour’s MicroThread technology is perhaps one of the most unique sounding, creating a microclimate around your body which draws sweat away from you allowing for quicker cooling. It’s light and flexible so you won’t even notice you’re wearing it, save for the undeniable cooling effect you’ll experience courtesy of the revolutionary technology.

Written by Aaron Thompson

Tecnhology & Innovation | Under Armour SE

This is what makes our gear work harder–and smarter–than everything else out there.

STAY COOL

STAY MOVING

STAY WARM

STAY DRY

STAY READY

STAY COOL

HEATGEAR®

WEAR THIS TO FEEL COOL, DRY & LIGHT.

The original innovation our founder dreamed up while sweating under the summer sun. This super-breathable fabric wicks sweat and regulates body temperature so you feel cooler, drier, and lighter than ever.

Shop Now

ISO-CHILL

MAKES YOU COOLER SO YOU CAN WORK LONGER.

Iso-Chill is proven to keep your body cooler, helping you stay out longer and reach your performance peak later. Made with ribbon-shaped nylon fibers that lay flat and disperse heat so it literally feels cool.

Shop Now

HEATGEAR® ARMOUR

ALWAYS START HERE.

Heatgear® Armour Baselayer is the “second skin” that makes all athletes better. Its soft, lightweight construction delivers relentless support without sacrificing comfort.

Shop Now

STAY MOVING

HOVR™

LIFTS YOU UP.

HOVR™ technology provides ‘zero gravity feel’ to maintain energy return that helps eliminate impact on every run.

Shop Now

CHARGED CUSHIONING

ENERGY GIVEN. POWER RETURNED.

As soon as you feel Charged Cushioning under your feet, you want to run. It’s the ultimate advancement in energy, absorbing the impact of your foot strike and converting it into a level of responsive comfort you’ve never felt before.

Shop Now

MICRO G®

TURNS CUSHIONED LANDINGS INTO EXPLOSIVE TAKEOFFS.

Lighter and sleeker than traditional foams, Micro G® cushioning delivers ultra-responsive, low-to-the-ground performance for better, natural stability and comfort.

Shop Now

STAY WARM

COLDGEAR®

WEAR THIS TO FEEL WARM, DRY & LIGHT.

This is the layer athlete’s trust when the mercury drops. ColdGear® eliminates the need to wear heavy, bulky gear in cold weather.

Shop Now

ARMOUR® FLEECE

WARMTH WITHOUT THE WEIGHT.

Armour® Fleece construction has a soft, bushed interior that traps heat and a smooth exterior that helps fight off the elements.

Shop Now

COLDGEAR® INFRARED

STAY WARMER LONGER.

ColdGear® Infrared lining uses a soft, thermo-conductive coating to absorb and retain body heat for lasting warmth.

Shop Now

STAY DRY

STORM

ALWAYS STAY DRY.

A tiered system of water and wind protection that keeps you dry in any wet weather situation.

Shop Now

GORE-TEX

GUARANTEED TO KEEP YOU DRY.

Made of the toughest fabrics & thoroughly tested to guarantee performance even after serious wear and tear.

Shop Now

STAY READY

RUSH

SCIENTIFICALLY TESTED. ATHLETE PROVEN.

RUSH is a new line of workout gear created from innovative fabrics infused with minerals to reflect energy and improve performance.

Shop Now

RECOVER

RECOVER FASTER. RETURN BETTER.

Recover Is a new line of gear created from innovative fabrics lined with minerals to reflect energy and improve recovery speed.

Shop Now

CHARGED COTTON®

MOTHER NATURE MADE IT. WE MADE IT BETTER.®

WE MADE IT BETTER.®

Unique cotton-blend performance fabric dries faster than any ordinary cotton out there…but still feels just as soft and comfortable.

Shop Now

Kevin Plank Is Betting Almost $1 Billion That Under Armour Can Beat Nike

“Have you seen Kevin’s whiteboards?”

If you spend any time at Under Armour headquarters, you’ll hear that question again and again. Founder and CEO Kevin Plank really likes whiteboards, and his favorite use for them is to write out leadership maxims for his team. Inside and outside his office, whole walls of floor-to-ceiling whiteboards contain dozens of curt principles he’s scrawled over the years: Expedite the inevitable. Perfection is the enemy of innovation. Respect everyone, fear no one.

These commandments are meant not as simple inspiration or hard rules, he says, but together make up a system of “guardrails” that allow everyone under him to operate as entrepreneurs by channeling his thinking. The Plank principles are drilled into new employees during a weeklong orientation, and they’re painted all over the hallways at company headquarters, a former Procter & Gamble factory on the Baltimore waterfront. Think like an entrepreneur. Create like an innovator. Perform like a teammate.

Think like an entrepreneur. Create like an innovator. Perform like a teammate.

Plank has the affect and intensity of a head coach–direct eye contact, military analogies, the air of someone you do not want to disappoint. “Winning is a part of our culture–it’s who we are,” he says in his lofty office overlooking the harbor. (The only artwork behind his desk: a giant UA logo, its letters stacked to evoke arms raised in victory.) “And culture is formed on habits.” Perhaps the most important guardrail, and the company’s official mission, is seeking to “make all athletes better.” It has long equaled thinking about clothes as high-performance gear, but recently it’s taken on a big new meaning.

Over the past two years, Under Armour has spent close to $1 billion buying and investing in three leading makers of activity- and diet-tracking mobile apps. By doing so, the company has amassed the world’s largest digital health-and-fitness community, with 150 million users. Plank envisions all of those users, and their metrics, as a big data engine to drive everything from product development to merchandising to marketing. Many observers, though, balked at the $710 million cost of the acquisitions, questioning whether Under Armour could quickly produce any return on investment–two of the three companies were unprofitable–let alone succeed in a space that shares little with making shirts and shoes. Longtime staffers worried the moves would crimp company performance, affect bonuses, or divert focus from the core business. Plank spent more hours than he cares to count, including a large chunk of his winter vacation last year, in one-on-one conversations to persuade them otherwise. “It was important,” he says, “that this not just be my decision.”

Many observers, though, balked at the $710 million cost of the acquisitions, questioning whether Under Armour could quickly produce any return on investment–two of the three companies were unprofitable–let alone succeed in a space that shares little with making shirts and shoes. Longtime staffers worried the moves would crimp company performance, affect bonuses, or divert focus from the core business. Plank spent more hours than he cares to count, including a large chunk of his winter vacation last year, in one-on-one conversations to persuade them otherwise. “It was important,” he says, “that this not just be my decision.”

Plank likes to say that the key to Under Armour’s success is that he never focused on all the reasons it couldn’t happen. A former Division 1 college football player, Plank famously bootstrapped Under Armour’s launch in 1995 armed with one simple insight: The cotton undershirts football players wore under their pads slowed them down when they became soaked with sweat. After prototyping a moisture-wicking, formfitting alternative–made of fabric for women’s undergarments–and testing it on ex-teammates, Plank set up shop in his grandmother’s basement and, just before he went broke, scored his first big sale, to Georgia Tech. The company went on to create a whole new market for performance apparel, IPO’d in 2005, and now sponsors some of the world’s greatest athletes, including Jordan Spieth, Stephen Curry, and Lindsey Vonn.

After prototyping a moisture-wicking, formfitting alternative–made of fabric for women’s undergarments–and testing it on ex-teammates, Plank set up shop in his grandmother’s basement and, just before he went broke, scored his first big sale, to Georgia Tech. The company went on to create a whole new market for performance apparel, IPO’d in 2005, and now sponsors some of the world’s greatest athletes, including Jordan Spieth, Stephen Curry, and Lindsey Vonn.

Today, Under Armour has 13,500 employees around the world and nearly $4 billion in revenue. But Plank is still every bit the entrepreneur, chasing audacious dreams–chief among them overtaking Nike as the world’s largest sportswear maker. Under Armour leapfrogged the longtime number two, Adidas, in the U.S. sportswear market in 2014, but worldwide it’s still third. And Nike remains far larger, with more than $30 billion in revenue in 2015 Which is part of why Plank wants to move so aggressively. Nike has about a fifth as many users on its Nike+ platform as Under Armour does on its apps, and in 2014 the shoe giant shut down its FuelBand fitness-tracker business.

The real work is only beginning, though, as Plank has adopted the kind of world-changing ambitions more common to a Google or Facebook. He envisions that Under Armour Connected Fitness will “fundamentally affect global health.” This month–doubters be damned–the company will start selling a pair of biometric fitness devices and a smart scale made in partnership with the Taiwanese smartphone company HTC. The move will put Plank in direct competition with Fitbit and Apple in the fast-growing wearables market. It’s a bold, characteristically Plankian bet–and a “very risky” one, says Morningstar retail analyst Paul Swinand. (Morningstar and Inc. are both owned by Joe Mansueto.)

“Under Armour has been a phenomenal success story,” Swinand says. Its stock has risen steadily–almost 2,000 percent in the decade since its IPO. “But when you’re hitting a home run every quarter on the core apparel business, why mess around with a moon shot?”

Plank rarely admits to much uncertainty or doubt, so it’s telling that he echoes Swinand in describing Connected Fitness’s ambitions as a “moon shot. ” But another of his whiteboard sayings comes to mind, this one courtesy of his friend and former U.S. Special Operations commander Admiral Eric Olson: Nobody ever won a horserace by yelling “Whoa!”

” But another of his whiteboard sayings comes to mind, this one courtesy of his friend and former U.S. Special Operations commander Admiral Eric Olson: Nobody ever won a horserace by yelling “Whoa!”

Robin Thurston, co-founder and then CEO of Austin-based app maker MapMyFitness, got his first taste of Plank’s high-speed force-of-will approach when the Under Armour founder cold-called him in July 2013. Plank explained that he loved Thurston’s app MapMyRun. “I run five miles three times a week, I log everything, I look up routes when I travel,” Plank began. “What are you doing with the company?”

Thurston replied that he was about to raise more venture capital to pursue ambitious expansion plans: The company had bought several hundred domains based on every physical activity, and planned to launch new products for each. Thurston and his investors saw MapMyFitness as poised to become the leading digital health-and-fitness network.

“Don’t do that,” Plank shot back. “Come talk to me instead.”

“Come talk to me instead.”

A couple of weeks later, Plank and three key lieutenants showed up early at the New York City offices of Allen & Company, where Thurston and his team were huddling with their bankers. The MapMyFitness team got about 20 minutes into a detailed PowerPoint presentation when Plank interrupted. “This is awesome,” he said, “but I want to stop you and go talk to Robin myself for a few minutes”–without any bankers running interference. Forty minutes later, Plank and Thurston returned, and Plank asked the MapMyFitness team if they’d like to go to Baltimore, right away, to check out the Under Armour campus.

It wasn’t 11 a.m. when the group–along with NFL veteran and sportscaster Boomer Esiason, who’d been waiting at the airport to hitch a ride on Plank’s jet–pulled up at Under Armour headquarters. Former Washington Redskin LaVar Arrington opened Thurston’s door, and offered a tour of the campus, as well as some oatmeal cookies, to the stunned app makers. Within two weeks, the parties had agreed that Under Armour would acquire the startup for $150 million, and Thurston would remain atop MapMyFitness and become Under Armour’s chief digital officer.

Within two weeks, the parties had agreed that Under Armour would acquire the startup for $150 million, and Thurston would remain atop MapMyFitness and become Under Armour’s chief digital officer.

Thurston, a onetime professional cyclist who maintained MapMyFitness’s position as a top fitness app from the iPhone’s earliest days, tells the story in his new office in downtown Austin, in a brand-new building where giant images of Under Armour athletes adorn the walls (amid, of course, motivational mantras) and several hundred new engineers and other tech employees work. At first, Thurston says, Under Armour’s interest was a puzzler. He’d entertained partnering with insurance companies and media companies, but he always worried they’d exploit all the data MapMyFitness gathers about people’s personal habits in ways that would violate the trust he’d built with the community. Under Armour had simply never occurred to him as a home for his company.

But the first thing Plank did in that private meeting in New York was pull up a concept video Under Armour had created earlier that year called “Future Girl. ” It showed a young woman starting a morning workout in clothes that were touch-sensitive and could call up data displays and even change color with the tap of a finger. “I made this for you,” Plank said to Thurston. (In truth, it had run as a TV commercial; Plank told me it was made for someone like Robin even though “I didn’t know who Robin would be.”) He wanted to be sure that Thurston wouldn’t bolt after the sale, but would instead see an exciting opportunity and lead it. Under Armour had always been a tech company, in its way, Plank explained–but it had struggled with digital.

” It showed a young woman starting a morning workout in clothes that were touch-sensitive and could call up data displays and even change color with the tap of a finger. “I made this for you,” Plank said to Thurston. (In truth, it had run as a TV commercial; Plank told me it was made for someone like Robin even though “I didn’t know who Robin would be.”) He wanted to be sure that Thurston wouldn’t bolt after the sale, but would instead see an exciting opportunity and lead it. Under Armour had always been a tech company, in its way, Plank explained–but it had struggled with digital.

None of the products in the “Future Girl” video existed then–and a variation of one is hitting the market now–but merging performance products with performance data and interactive technology was a top Under Armour priority, given Plank’s instinct that that’s where the world was going. Plank had directed a team several years earlier to create an “electric” product, and they’d come up with the E39 compression shirt, which had sensors embedded in the fabric to track an athlete’s heart rate. The shirt launched at the 2011 NFL training combine to much fanfare, but a simplified consumer version–a sensor-equipped chest band–had only niche appeal. That experience made Plank realize Under Armour couldn’t compete with hardware companies that employ thousands of engineers and constantly turn out incremental innovations.

The shirt launched at the 2011 NFL training combine to much fanfare, but a simplified consumer version–a sensor-equipped chest band–had only niche appeal. That experience made Plank realize Under Armour couldn’t compete with hardware companies that employ thousands of engineers and constantly turn out incremental innovations.

“It’s absurd that you know more about your car than you know about your body,” says Plank. He’s betting athletes’ personal data will turbocharge their fitness and Under Armour’s future.

“It’s very normal for a product company–which is really what Under Armour is–to have gone down the path of trying to create hardware,” says Thurston. “They know the distribution channels, they know how to sell products, they know how to market them. But as they started doing their homework on what was happening in the space, they realized that the strength [of digital fitness] was actually in the community.”

Plank also knew it would take years to build a community like Thurston’s. “It wasn’t that I didn’t know the right answers to be seeking from engineers. I didn’t even know the right questions to ask,” Plank admits. “I’m a sporting goods guy.”

“It wasn’t that I didn’t know the right answers to be seeking from engineers. I didn’t even know the right questions to ask,” Plank admits. “I’m a sporting goods guy.”

After the MapMyFitness acquisition closed in late 2013, Plank and Thurston proceeded uncharacteristically slowly, taking time to set priorities for Under Armour’s digital transformation. Thurston identified four key pillars of health–sleep, fitness, activity, and nutrition–that he based on Plank’s “make all athletes better” mission. Once that vision snapped into focus, Plank saw an opportunity not just to be a collector of human activity data but also to be the central processor that turns that data–regardless of whose device or app collected it–into useful insights. “OK. Let’s do it,” he told Thurston one day in late 2014. By the following March, they had spent more than half a billion dollars acquiring two more companies: San Francisco-based MyFitnessPal, a nutrition-tracking system for people to log their meals, and Copenhagen-based Endomondo, a personal-training program whose users are almost entirely outside the U. S. Under Armour suddenly had not only the world’s largest digital fitness community but hundreds of engineers and reams of user data as well.

S. Under Armour suddenly had not only the world’s largest digital fitness community but hundreds of engineers and reams of user data as well.

Just one big question loomed: How would any of that help Under Armour chip away at Nike’s dominance, or at least sell a lot more workout shirts?

Across the railroad tracks from the Under Armour campus, a low redbrick building houses the company’s innovation lab, where president of product and innovation Kevin Haley leads a team of biomechanists, designers, engineers, and a psychologist to develop shoe and apparel concepts. There are weather chambers to re-create different exercise scenarios, devices that stretch and compress materials, gait-analysis systems, washers and dryers, 3-D printers, laser cutters, and countless other machines. The deeper you go into the long, narrow lab space, the more secretive the operations. The prototyping room is locked down from all but a few select employees and executives, who must pass a biometric scanner to enter.

Before taking over the innovation lab, Haley created the Under Armour consumer insights department. Early on, “the secret of our success was that we were the consumer,” Haley says. “Kevin was a football player. He just knew. But slowly, we got older than our consumer.” The company stopped bragging about not using focus groups and started tapping its sponsored athletes for product insights, sending researchers to look in people’s closets, and running online surveys.

What Under Armour didn’t know with much precision, though, was how people used its products after buying them. “You just know if a person swipes a credit card or not,” as Haley puts it–and even that only happens a couple of times a year for any customer. “We call something a basketball shirt, but is the guy wearing it to football practice? Is the boyfriend shirt he gives to his girlfriend something she wears as pajamas?”

But armed with data from Connected Fitness apps, Haley says, he can take design cues from 150 million people who, having downloaded a fitness app, are exactly the target audience: “There’s unbelievable data in there. You know their running pace, how far they go, how often they go. You literally know what brand of Greek yogurt they use.”

You know their running pace, how far they go, how often they go. You literally know what brand of Greek yogurt they use.”

It’s too early to see many new products as a result of all the new data–developing a piece of gear typically takes 18 months–but Haley points to one. The company learned from MapMyFitness data that the average run is 3.1 miles–“not one or two miles, not five miles, but 3.1,” Haley says. So when it came to making the Speedform Gemini running shoe, which was released last January to largely rave reviews, the company added “charged foam” padding tailored to that kind of run.

“The toughest question for us is not, Are there cool technologies out there?” says Haley. “It’s, What do you want me to work on? This gives us unbelievable insight that’s both incredibly broad and deep, with the same group of people we’re marketing toward.” That could be especially helpful in the two huge growth opportunities for Under Armour. More than 60 percent of Connected Fitness’s users are women, who account for just 30 percent of Under Armour’s apparel sales. And while only about 11 percent of its sales are international, 35 percent of the Connected community is outside the U.S.

And while only about 11 percent of its sales are international, 35 percent of the Connected community is outside the U.S.

Still, the high-stakes bet on Connected Fitness will be slow to pay off. Under Armour recently increased its projections for the next two years, estimating that it would nearly double net revenue by 2018, to $7.5 billion (up from a previous estimate of $6.8 billion). Only $200 million–a paltry 2.7 percent–will come from Connected Fitness. But Thurston likens his digital community to “having a Super Bowl-size audience every day,” and one of the most immediately practical moves will be using those apps as a marketing channel. A feature called Gear Tracker, for instance, allows MapMyFitness users to log the shoes they use every time they go running, and get a reminder when their mileage suggests it’s time to buy new ones. A partnership with Zappos makes ordering replacements easy.

“Imagine you’re traveling in Chicago for work,” Plank says. “You went for a run one morning, and you had a cold the day before. It’s 7 degrees in Chicago, so I know your nose was probably running the whole time. Well, we make this great run glove–we call it the snot finger glove, because it’s got basically a microfiber personal Kleenex attached to it so you can rub your nose. Imagine if I could send you an ad that says, ‘Hey, are you going to be in Chicago for another day? Would you like us to send you a pair of gloves?'” Chris Glode, a key digital executive for the company, told a conference last year that the company has learned that consumers are 83 percent more receptive to fitness messages after a workout–so an ad could hit you right as you log your run. The average Underarmour.com order coming via a Connected Fitness app is 26 percent higher than those from other external sources, the company says, so one big priority is to build e-commerce into the apps.

It’s 7 degrees in Chicago, so I know your nose was probably running the whole time. Well, we make this great run glove–we call it the snot finger glove, because it’s got basically a microfiber personal Kleenex attached to it so you can rub your nose. Imagine if I could send you an ad that says, ‘Hey, are you going to be in Chicago for another day? Would you like us to send you a pair of gloves?'” Chris Glode, a key digital executive for the company, told a conference last year that the company has learned that consumers are 83 percent more receptive to fitness messages after a workout–so an ad could hit you right as you log your run. The average Underarmour.com order coming via a Connected Fitness app is 26 percent higher than those from other external sources, the company says, so one big priority is to build e-commerce into the apps.

If it all sounds eerily like those ads that, because of your browsing history, follow you around the internet, that’s exactly the point–except Under Armour is tracking real behavior and the data is more specific. Everyone in the company says personal data mining will give customers better fitness insights and better shirts and shoes–so they become better athletes. Another way to look at it is that making people better athletes makes them need more gear. As Plank told analysts last July: “Ultimately, the more people exercise, the more athletic footwear and apparel they will buy.”

Everyone in the company says personal data mining will give customers better fitness insights and better shirts and shoes–so they become better athletes. Another way to look at it is that making people better athletes makes them need more gear. As Plank told analysts last July: “Ultimately, the more people exercise, the more athletic footwear and apparel they will buy.”

“I love Monopoly,” Plank tells me. “You know why? When I play Monopoly with you, I’m going to buy everything from Baltic Avenue to Marvin Gardens. If you get to my side of the board, you’d better roll boxcars or you’re going to pay rent.”

He’s trying to describe why buying MapMyFitness was never going to be enough; the real opportunities would come only if he controlled every part of the digital health experience, even if nutrition, say, has only tangential relevance to the sportswear business. If you’re trying to truly understand athletes, you need to see what they do 24 hours a day. “It’s absurd that you know more about your car than you know about your body,” says Plank.

Hence an app called UA Record, a kind of overall health dashboard that relaunches this month in conjunction with the co-branded HTC devices–a Fitbit-like wrist strap, a chest-worn heart-rate monitor, and a connected scale, all sleek black and knobby red plastic, with scoreboard-inspired readouts. Record is an open platform for people to process their fitness data from any device, and Record exec Glode calls it “the ultimate digital expression of Under Armour.” Plank gets especially animated talking about the relaunch of Record and the related devices, which will be sold together under the name Health Box. It’ll be the first time users get to experience his full vision, and it’s where he sees the potential to “affect global health.” Roughly one in five Americans has downloaded one of Plank’s apps, Plank has said, so he wants not only to help users keep track of their running times or weight loss but also to compare their data with that of millions of other people like them and offer valuable insights.

Whether the system sounds ingeniously simple or a bit too clever for its own good may depend on your dedication to fitness. To Plank, it’s the former, of course: “It’s like, I wake up in the morning, my wearable device tells me how long I slept, and data point one beams to the cloud. I go to the bathroom and step on the scale, and data point two beams to the cloud. I’m going to exercise, so I put on my heart-rate strap, and data point three beams to the cloud. And as I walk around all day, the fitness tracker beams how many steps I take. Finally, what did I eat for the day? If I want to go deep into MyFitnessPal and track everything, great, but if not, I just answer if I had a light or average or heavy day.”

I am the opposite of a moderate man reads one key Plankism scrawled on a company whiteboard.

“This is where it gets really exciting,” Plank says, and launches into a series of scenarios. If you are ill one day in October, you might learn that you get sick around the same time every year and that it correlates with your sleep or diet patterns or any number of patterns that you share with others your age and of similar height and weight. If you go to the doctor, all that information might be a lot more useful than the hand-scrawled note the physician has from your last visit 24 months ago and a couple of basic measurements the nurse took a few minutes earlier. “Nobody owns this,” says Plank. “And I’m sitting here thinking, who should? Humana? CVS? You’re going to trust them with your data? Why not us?”

If you go to the doctor, all that information might be a lot more useful than the hand-scrawled note the physician has from your last visit 24 months ago and a couple of basic measurements the nurse took a few minutes earlier. “Nobody owns this,” says Plank. “And I’m sitting here thinking, who should? Humana? CVS? You’re going to trust them with your data? Why not us?”

Fair enough, says Morningstar’s Swinand, but he questions whether Under Armour can win that battle when the competition includes Fitbit, Apple, and even Google. “The way tech works is you have four companies, three end up zeros, and the one that wins wins everything.” He raises the possibility that Under Armour could end up the MySpace of fitness tech–and expresses concern about the recent departure of longtime COO and CFO Brad Dickerson. “I think Brad was the voice of reason, and Kevin is the flamboyant entrepreneur,” Swinand says.

Plank likes his chances, in part because the wide appeal of Under Armour’s locker-room aesthetic and barking brand voice could transfer to any number of connected products (think: Future Girl), but also because he now has more fitness data about users than even the leading tech companies. “If I’m right,” he says, Connected Fitness “becomes a force multiplier that takes us from shirts-and-shoes company to true technology company. If I’m wrong, it costs us some money–we have $710 million on the table.” A flicker of doubt from the unflappable Plank? No. “The one thing we know,” he concludes, “is we can always make more money.” He didn’t need to point out another whiteboard commandment–the one that reads Don’t forget to sell shirts and shoes!

“If I’m right,” he says, Connected Fitness “becomes a force multiplier that takes us from shirts-and-shoes company to true technology company. If I’m wrong, it costs us some money–we have $710 million on the table.” A flicker of doubt from the unflappable Plank? No. “The one thing we know,” he concludes, “is we can always make more money.” He didn’t need to point out another whiteboard commandment–the one that reads Don’t forget to sell shirts and shoes!

From the February 2016 issue of Inc. magazine

Production of armor steel abstract on technology

Production of armor steel Along with mobility and firepower, one of the main combat qualities of a tank is reliable armor protection, which provides it with relative invulnerability from enemy fire. The presence of relatively light and sufficiently strong steel armor mastered in production was one of the most important technical prerequisites for creating a tank. The ability to manufacture armored steels depended on the methods of steel production used, the level of development of metallurgy and the metalworking industry. Steelmaking Steelmaking required lowering the carbon content of cast iron to less than 1.5% and minimizing the presence of impurities. For the first time this was achieved by the English watchmaker Benjamin Huntsman in 1742. He melted mild steel in a clay crucible and added the required amount of carbon. However, his method was very expensive and was only suitable for small-scale production. In 1850, it was replaced by a process that was invented independently of each other, first by the American William Kelly, and a little later by the Englishman Henry Bessemer.But he received widespread use under the name Bessemer, since financial difficulties prevented Kelly from completing his research. Around 1864, Frenchman Pierre Martin and German-born naturalized Englishman William Siemens invented the open-hearth process for smelting steel. In the 19th century, Zlatoust high-quality steel, which was used for the manufacture of edged weapons, became world famous. Steel production at the Zlatoust factories is associated with the name of the outstanding Russian metallurgist Pavel Petrovich Anosov (1797 – 1851).

Steelmaking Steelmaking required lowering the carbon content of cast iron to less than 1.5% and minimizing the presence of impurities. For the first time this was achieved by the English watchmaker Benjamin Huntsman in 1742. He melted mild steel in a clay crucible and added the required amount of carbon. However, his method was very expensive and was only suitable for small-scale production. In 1850, it was replaced by a process that was invented independently of each other, first by the American William Kelly, and a little later by the Englishman Henry Bessemer.But he received widespread use under the name Bessemer, since financial difficulties prevented Kelly from completing his research. Around 1864, Frenchman Pierre Martin and German-born naturalized Englishman William Siemens invented the open-hearth process for smelting steel. In the 19th century, Zlatoust high-quality steel, which was used for the manufacture of edged weapons, became world famous. Steel production at the Zlatoust factories is associated with the name of the outstanding Russian metallurgist Pavel Petrovich Anosov (1797 – 1851). ). Before Anosov, the production of high-quality steel both in Russia and abroad was considered an art that was passed down from generation to generation and was available to only a few steelmakers. Anosov was the first to put the production of high-quality steels on a scientific basis. He was the first to investigate the effect of additives – platinum, gold, manganese, chromium and other substances – on the properties of steel and in 1833 made a “blade of real damask steel”. The steels that Anosov created were later called alloyed.Academicians. S. Kurnakov wrote: “Mining engineer P. P. Anosov, head of the Zlatoust factories in the Urals, was the first researcher who used a microscope back in 1831 to study the structure of a steel surface polished and acid-etched, precisely to determine the characteristic structure of damask blades obtained by the way he worked out. ” For such purposes, Anosov used a microscope 30 years earlier than the Englishman Sorby. World fame was brought to Anosov by his work “On Bulat”, which appeared in 1841 and became a classic among metallurgists.

). Before Anosov, the production of high-quality steel both in Russia and abroad was considered an art that was passed down from generation to generation and was available to only a few steelmakers. Anosov was the first to put the production of high-quality steels on a scientific basis. He was the first to investigate the effect of additives – platinum, gold, manganese, chromium and other substances – on the properties of steel and in 1833 made a “blade of real damask steel”. The steels that Anosov created were later called alloyed.Academicians. S. Kurnakov wrote: “Mining engineer P. P. Anosov, head of the Zlatoust factories in the Urals, was the first researcher who used a microscope back in 1831 to study the structure of a steel surface polished and acid-etched, precisely to determine the characteristic structure of damask blades obtained by the way he worked out. ” For such purposes, Anosov used a microscope 30 years earlier than the Englishman Sorby. World fame was brought to Anosov by his work “On Bulat”, which appeared in 1841 and became a classic among metallurgists. Another remarkable Russian metallurgist of the mid-19th century was Pavel Matveyevich Obukhov. He created in St. Petersburg the famous steel cannon factory, which went down in history under the name of Obukhovsky. Following in the footsteps of Anosov, Obukhov studied the effect of additives on the quality of steels. As a result of Obukhov’s work, they began to make cuirasses from his steels, which could not be pierced by a bullet even from a fairly close distance. Of great importance was the method developed by Obukhov for producing large homogeneous steel castings. This method allowed him to successfully master the manufacture of steel cannons, the barrels of which could withstand up to 4000 rounds.In 1866, Dmitry Konstantinovich Chernov came to work at the Obukhov plant, whose name is associated with outstanding discoveries in the field of metallurgy and metallurgy. In 1868 he published his work “A critical review of the articles of Messrs. Lavrov and Kalakutsky on steel and steel tools and DK Chernov’s own research on this subject.