How can businesses effectively recruit and retain employees in today’s competitive job market. What strategies are successful franchisees using to find and keep top talent. How are companies adapting their hiring and training practices to meet current workforce challenges.

The Challenges of Hiring in a Low Unemployment Economy

In the current economic climate, with unemployment rates at historic lows not seen since 1969, businesses face unprecedented challenges in recruiting and retaining quality employees. This tight labor market has forced companies, particularly franchisees, to rethink their hiring strategies and employee retention tactics.

PuroClean franchisee Keegan Trudgen aptly summarizes the situation: “We’re at full employment and everyone is looking for qualified workers.” This scarcity of available talent, coupled with high turnover rates in certain industries like food service, has made effective hiring, training, and retention practices more crucial than ever.

Why is employee recruitment so challenging in today’s market?

- Record low unemployment rates

- Increased competition for qualified workers

- High turnover in certain industries

- Changing expectations of job seekers

Innovative Recruitment Strategies for Today’s Job Market

To address these challenges, businesses are adopting a variety of innovative recruitment strategies. Many are finding success by looking beyond traditional hiring methods and leveraging personal networks, community connections, and technology.

Tapping into Personal Networks

Trudgen emphasizes the effectiveness of a “friends and family approach, combined with word of mouth.” This strategy capitalizes on existing relationships and personal recommendations, often resulting in higher-quality candidates who are more likely to fit well within the company culture.

Community Outreach and Education

Proactive engagement with local educational institutions is another effective tactic. Trudgen has begun reaching out to high schools, community colleges, and career centers to showcase professional opportunities. This approach not only helps attract young talent but also positions the company as a viable career path rather than just a temporary job.

Leveraging Technology for Recruitment

Many franchisees are turning to technology to cast a wider net in their recruitment efforts. Lance Vaught, vice president of operations for Penn Station East Coast Subs, notes that their franchisees “use various online recruiting platforms, in-person restaurant recruiters, and traditional employee referrals from their crew.” This multi-pronged approach helps ensure a steady stream of potential candidates.

Creative Advertising and Social Media Presence

TJ Schier, founder and president of SMART Restaurant Group, advocates for a broad-spectrum approach to attracting prospects. He likens it to fishing, emphasizing the need to have “many hooks in the water–job boards, ads, in-store, social media–with the right bait, like catchy ads.” This strategy increases visibility and appeals to job seekers across various platforms.

The Importance of Offering Career Growth Opportunities

In today’s competitive hiring environment, offering more than just a paycheck is crucial. Many successful businesses are focusing on providing clear career advancement opportunities to attract and retain employees.

Articulating Career Paths

Penn Station East Coast Subs developed the “My Penn Path” development aid to help franchisees clearly articulate potential career paths to job candidates. This tool engages candidates from the start and allows franchisees to compete on opportunity as much as wage.

Why is offering career growth important?

- Attracts candidates looking for long-term opportunities

- Increases employee engagement and loyalty

- Helps businesses compete beyond just offering higher wages

- Creates a pipeline of internal talent for future leadership roles

Adapting Communication Strategies for Modern Job Seekers

As the job market evolves, so too must the ways businesses communicate with potential employees. Recognizing and adapting to the preferences of today’s job seekers is crucial for successful recruitment.

Embracing Text-Based Communication

Susan Rather, a BrightStar Care multi-unit franchisee, has adjusted her approach to accommodate modern communication preferences. “I’ve changed my stance on communicating with applicants by text,” she says. “Previously, I thought it wouldn’t help us make a connection, but I see now that we have to communicate in the way they’re accustomed to.”

Balancing Modern and Traditional Communication

While adapting to text-based communication for initial outreach, Rather emphasizes the importance of transitioning to more personal forms of interaction once candidates are onboarded. “After we get them onboarded, we do stress the importance of having face-to-face and voice-to-voice conversations.” This approach allows businesses to meet candidates where they are while still fostering the interpersonal skills necessary for many roles.

Innovative Approaches to Employee Screening and Selection

In addition to creative recruitment strategies, businesses are also refining their screening and selection processes to identify the best candidates for their organizations.

Personality Profiling

Penn Station East Coast Subs uses personality profiles as part of their hiring process. Vaught explains, “These profiles help ensure that the candidate is a good fit culturally and emotionally. They also help assess which candidates stand out–those we want to quickly move on to a fast-pace promotional track.”

Focusing on Intangible Qualities

Jeff Meyer, president of Meyer Foods and a Culver’s franchisee, emphasizes the importance of looking beyond teachable skills. “We believe we can teach any skills within the restaurant, but we cannot teach drive, passion, and motivation for success,” he says. “Those are key skills that we keep top of mind during our interview process.”

What qualities are employers prioritizing in candidates?

- Cultural fit

- Emotional intelligence

- Drive and motivation

- Passion for the work

- Potential for growth within the organization

Creating an Attractive Work Environment for Retention

Finding qualified employees is only half the battle; retaining them is equally crucial. Successful businesses are implementing strategies to create work environments that encourage long-term commitment, even for part-time employees.

Offering Competitive Benefits

Jeremiah Bowe, a Culver’s franchisee, has taken an innovative approach to retain his largely part-time workforce. He offers comeback bonuses and, remarkably for part-time positions, paid time off and affordable health insurance. These benefits help set his business apart and encourage employee loyalty.

Fostering a Positive Workplace Culture

Creating an environment where employees feel valued and enjoy their work can be a powerful retention tool. Jeff Meyer notes that many of his team members were originally customers who “liked the environment so much that they inquired about job opportunities.” This organic recruitment demonstrates the power of a positive workplace culture in attracting and retaining employees.

How can businesses create an attractive work environment?

- Offer competitive benefits, even for part-time employees

- Create opportunities for career growth and development

- Foster a positive and inclusive workplace culture

- Recognize and reward employee contributions

- Provide flexible scheduling options when possible

Leveraging Technology and Media in the Hiring Process

As technology continues to evolve, businesses are finding new ways to incorporate digital tools and media into their hiring processes. These innovations can help attract candidates, provide insight into job roles, and streamline the application process.

Virtual Job Previews

TJ Schier’s Which Wich sandwich locations use a “Day in the Life” web page to give prospective employees a realistic preview of the workplace. This visual representation helps set accurate expectations and can increase the likelihood of finding candidates who are well-suited to the role.

Video Demonstrations

BrightStar Care has taken a similar approach, with corporate-produced videos showing caregivers working with simulated clients. These videos provide valuable insight into the day-to-day responsibilities of the job, helping potential applicants better understand what the role entails.

How can technology enhance the hiring process?

- Provide realistic job previews through videos or virtual tours

- Streamline application processes with online platforms

- Use social media for targeted job advertising

- Implement video interviews for initial screenings

- Utilize applicant tracking systems to manage candidates efficiently

As the job market continues to evolve, businesses must remain adaptable and innovative in their approaches to recruiting and retaining employees. By implementing a combination of personal outreach, technology-driven solutions, and employee-focused benefits and culture, companies can position themselves to attract and retain the talent they need to thrive in today’s competitive landscape.

The strategies outlined here represent just a fraction of the creative solutions businesses are employing to address the challenges of hiring and retention in a low unemployment economy. As the job market continues to change, successful organizations will be those that remain flexible, attentive to employee needs, and committed to creating workplaces where people want to build their careers.

Tips for Finding and Keeping Employees

Not since 1969 have so few people been unemployed in the United States. Evidence of a strong economy, but that doesn’t mean franchisees can relax. On the contrary, today’s record low unemployment rate means they must work harder than ever to hire and keep the kind of employees whose work sustains a successful business.

“It’s the hot topic of the day,” says PuroClean franchisee Keegan Trudgen. “We’re at full employment and everyone is looking for qualified workers.” Add in the high turnover typical of certain industries (think restaurants), and that makes good solutions for effective hiring, training, and retention essential.

Some of those solutions are right at hand. “It’s not in the least bit sexy,” says Trudgen, “but we’ve had success with a friends and family approach, combined with word of mouth.” He has also begun reaching out to local high school and community colleges and counselors at career centers to showcase the professional options PuroClean offers. “We’re giving people a path,” he says.

Offering a future that’s more than short-term is an effective strategy, says Lance Vaught, vice president of operations for Penn Station East Coast Subs. “Competing for employees on starting wage alone is not effective in today’s ultra-competitive hiring environment. We have always felt the type of employee our franchisees are looking to recruit is someone who wants to work their way up the ladder from day one.”

With that in mind, Vaught says, “We developed the My Penn Path development aid, which allows franchisees who are recruiting job candidates to more clearly articulate a candidate’s career path. It engages them in the process from the start and allows franchisees to compete on opportunity as much as wage.”

Technology is a popular solution for initial outreach. “Our franchisees use various online recruiting platforms, in-person restaurant recruiters, and traditional employee referrals from their crew,” says Vaught. Candidates are also asked to complete personality profiles. “These profiles help ensure that the candidate is a good fit culturally and emotionally. They also help assess which candidates stand out–those we want to quickly move on to a fast-pace promotional track.”

Candidates are also asked to complete personality profiles. “These profiles help ensure that the candidate is a good fit culturally and emotionally. They also help assess which candidates stand out–those we want to quickly move on to a fast-pace promotional track.”

TJ Schier, founder and president of SMART Restaurant Group and owner of 14 franchised Which Wich sandwich locations, likes a broad spread to attract prospects. “It’s like fishing. You need to have a presence, many hooks in the water–job boards, ads, in-store, social media–with the right bait, like catchy ads.” If prospective employees nibble, they are directed to a “Day in the Life” web page where they can see what the actual workplace looks like.

Wisconsin-based BrightStar Care multi-unit franchisee Susan Rather respects in-house recommendations for recruits, but she’s doing more than just putting up posters or distributing flyers. “We are also doing mock interviews at job centers, and we’re on the boards of organizations such as Centro Hispano, which supports the Hispanic population in Madison with job coaching and resource navigation,” she says. Also helpful, she says, is that BrightStar corporate has recorded videos of its caregivers working with simulated clients.

When it comes to finding potential employees, Rather has adapted to today’s job seekers. “I’ve changed my stance on communicating with applicants by text. Previously, I thought it wouldn’t help us make a connection, but I see now that we have to communicate in the way they’re accustomed to. After we get them onboarded, we do stress the importance of having face-to-face and voice-to-voice conversations.”

Jeff Meyer, president of Meyer Foods, a franchisee of eight Culver’s restaurants in Indiana, looks for something that can be hard to find. “We believe we can teach any skills within the restaurant, but we cannot teach drive, passion, and motivation for success,” he says. “Those are key skills that we keep top of mind during our interview process. ” He also keeps a close eye on his customers. “We view everyone as a potential team member. Many of our current team members were guests in our restaurants and liked the environment so much that they inquired about job opportunities.”

” He also keeps a close eye on his customers. “We view everyone as a potential team member. Many of our current team members were guests in our restaurants and liked the environment so much that they inquired about job opportunities.”

Jeremiah Bowe, another Culver’s franchisee, also looks close to home. “I would say greater than 50 percent of all the people employed in our restaurants are there through word of mouth from our employees–brothers and sisters and friends,” he says. And with a workforce that’s 70 percent part-time, he works extra hard to keep those employees coming back, despite the temptation of other seasonal jobs. He offers comeback bonuses and, something quite remarkable for part-timers, paid time off and affordable health insurance.

Train ’em

With each successful hire, training begins–or should. “We’ve all worked in jobs where we were hired, then been thrown in to sink or swim,” says Todd Jackson, a longtime Newk’s Eatery franchisee. “A proper orientation that puts your culture at the forefront sets the standard for every new hire,” he says. “Having someone in charge of training who does not have the mindset, or who does not exhibit the restaurant’s desired culture hurts you in the long run. Commit the dollars to training. You will benefit in the end with lower turnover and lower training wages.”

Jackson is using whatever technology supports the communication of that training. “In our organization we are relying more and more on technology- and video-based training. This allows us to give consistent messages to each new hire, whether it is about culture, how to properly make a dressing, or how to set up our restaurants,” he says. “Our hourly partner demographic is shifting to a group that embraces technology. We must do the same. The key is to blend that technology with motivated and qualified trainers and with tracking that reduces the odds that someone will fall through the cracks.”

To accomplish that, Jackson and his team use HotSchedules for communication and scheduling, and Schoox for online digital training. “We’re using Schoox more and more with all of our training now being done on tablets, pads, or phones,” Jackson says. “Interactive versions of register training, line builds, and other items are made in a way that the new generation enjoys interacting with, and in a way they are familiar with. We are also able to continue culture building by using this vehicle to have employees watch videos of their peers explaining what the culture means to them and how the new hire can live our values.” Schoox also can be used to monitor whether training is taking place and to ensure new hires are being cared for properly.

“We’re using Schoox more and more with all of our training now being done on tablets, pads, or phones,” Jackson says. “Interactive versions of register training, line builds, and other items are made in a way that the new generation enjoys interacting with, and in a way they are familiar with. We are also able to continue culture building by using this vehicle to have employees watch videos of their peers explaining what the culture means to them and how the new hire can live our values.” Schoox also can be used to monitor whether training is taking place and to ensure new hires are being cared for properly.

At Penn Station East Coast Subs, training starts right away, with a tool called “My Penn Path,” says Don Robinson. His 18 locations make him the brand’s largest multi-unit franchisee. “We have incorporated My Penn Path into a local training program that we have had in place for many years. This has allowed us the opportunity to have a clear and precise outline of expectations for both the employee and our management team. We let them know on day one how the training process will go and exactly how they can earn raises as fast as they can master each station. Some may earn 50 cent increases as fast as two weeks and some may take six months.”

Before any employee is allowed to work a shift, they must attend an orientation from one of Penn Station’s operations directors–supervisors who oversee multiple locations. “This orientation allows us the opportunity to have a high-level supervisor be the voice of the company and outline the training process, our culture, and how the employee can move up or earn raises,” he says. “These are performed a few times every week in our regional office or at the store level on occasion. It is another huge commitment of time, but worth every minute.”

For the past 3 years, says Vaught, Penn Station’s training program has made Training magazine’s Top 125 list for organizations with the most successful learning and development programs in the world.

For his Which Wich stores, Schier has found employee development can be guided with an assessment that finds what he calls right-fit talent. “We lay out the development ladder on their first day of employment and have a philosophy of ‘Train until they can’t get it wrong.’ We help guide the employee up the ladder.” The materials are a mix of e-learning modules, books on management, on-the-job training, and interactive exercises.

Meyer likes employee training for his Culver’s employees to be available on a consistent basis. “We feel that we must continue to invest in our team members, and a large part of that is providing them with a best-in-class training team. We provide monthly workshops that allow team members from different locations to come to our central office and participate in a learning environment while sharing best practices,” he says. “We actively coach and train to emotional intelligence and leadership-style coaching.”

Keep ’em

A few years ago, Robinson changed up his hiring process. “I decided to do a final interview for every single hourly manager before they are promoted,” he says. “With 20 locations this was a huge commitment of time, but worth every moment.” His goal then, as now, is “to show them we care about their development and their time here with the company.” It also allows him to identify future leaders he can start training to become assistant managers and eventually GMs or higher. “This also allows me to develop relationships with our newly promoted team leaders and give them a comfort level of reaching out if they feel something isn’t right within the store.”

For Keegan and his PuroClean team, one new change has had tremendous effect. “Just about a year ago we really started stressing culture, the idea that we want to be the best, pushing the culture of who we are and what we do–our mission, our values, our anchors,” he says. “When we did that, all of a sudden people’s mindsets started to change. We started holding each other accountable. When we did that, our turnover dramatically decreased–by at least half. I really think it’s about people feeling as though they belong to a team where everyone is holding everyone accountable, that they have a purpose, and that gives them some satisfaction.”

We started holding each other accountable. When we did that, our turnover dramatically decreased–by at least half. I really think it’s about people feeling as though they belong to a team where everyone is holding everyone accountable, that they have a purpose, and that gives them some satisfaction.”

As others have learned, Meyer knows that flexible scheduling is a useful perk, but so are other incentives. “Our teams really like our ongoing monthly team contests where they can win different prizes and recognition across our group of restaurants,” he says. More than that, he adds, the monthly meetings create a platform for team members to bring up ideas for discussion on how to improve operations and the working environment. He says this gives team members an opportunity to have a larger impact on their jobs and feel a greater part of the company.

Robinson says he discovered that once a person was promoted to general manager, training and development diminished. To remedy this, he added several continuing education classes that assistant managers and GMs must attend throughout the year. He and his operations directors teach these classes, which cover hiring, interviewing, coaching, profitability, inventory, point-of-sale features, and more. “This has been a great addition for our company that I believe will be a big step in increasing profits and reducing turnover,” he says.

Schier’s tactics for Which Wich include considering some unusual approaches to retain employees. “We are looking into gig economy sites that have popped up as a way to keep a solid, well-paid core, instead of having a merry-go-round of turnover. We are also looking at supplementing when needed with people hired on gig sites–Qwick.com is an example. We are also going to start testing a pay-as-you-go option that an employee can select to get paid the next day, similar to how Uber works. If that is well-received, it’s another message we can recruit with–getting paid quickly. “

“

Tom Baber, an IHOP and Money Mailer franchisee, is also thinking creatively with meaningful rewards for work well done. “We keep the environment positive with small extra bonuses, for example. We recently raised all pay $1 per hour. Sales and customer satisfaction were strong so it was earned,” he says. “We have a mandated dollar increase in the minimum wage coming soon, and our goal is to be a certain amount above that to start, as we are today, and to keep that space at all levels in the organization. This will mean another pay rise coming soon, but this last one was proactive and very much appreciated. Again, it was earned. Our managers and team have done a very good job.”

He also offers other benefits, including partially paid Aflac insurance. “We also offer a telephone and online medical service for every employee and their families. It is not very pricey and does not replace health insurance, but is very handy and has been very well-received. Both of these have led to higher satisfaction and retention.”

Baber understands that kindness and respect for employees is not always about money. “Whether it be a normal greeting when we meet, a more difficult conversation like a discipline issue, or the aforementioned pay raises and other benefits, we treat it all like the employee is our customer and we will do all that we can within reason to make them feel welcomed, appreciated, valuable, and needed,” he says. “While there is no doubt we and the brand create high expectations, we also treat our employees just as we would like our customers to be treated.”

He does one more thing that he sees as a way to communicate his dedication to his employees. “I work personally at a store on Mother’s Day and Father’s Day. I am not part of any regular schedule at any location, but on those days I work up front and as hard as I am able. I know how rough those days are. It never goes unnoticed, plus it is a teaching opportunity for how to handle the toughest days, both from an attitude and a customer service perspective. “

“

At Newk’s Eatery, Jackson has figured out that retention is all about treating people right. “All of this is in the culture or environment. If an hourly partner or manager feels valued, they will stay. Everyone talks about this, and it is true. You make someone feel valued by doing the little things–saying hello, good-bye, and thank-you every shift,” he says.

“You also do this by providing an environment that is disciplined where everyone knows what is expected. Good people want to stay working with good people. If the environment starts to change because people are slacking off, the good people are the first to go.`” says Jackson. “If turnover is too high, culture is most likely to be the culprit, and it starts with the leadership.” That leadership, he says, can be the GM, the area director, or the franchisee.

Jackson agrees that employees need to know that they have longer-term career options. “It is important for people to feel like they are working toward a goal. If advancement is possible and demonstrated, they work harder. For us, the most effective tool has been promotion from within. We’ve had great success taking hourly partners from starting in a position, moving to a certified trainer, then to an hourly shift leader, and finally into management. When others see this progression is possible, it inspires them to strive for the next position as well. When everyone is trying to get to the next level, it is great for quality of operations as well as morale.”

That helps with recruitment, too, he says. “In our organization, we have approximately a 1-to-1 ratio of internal promotions to external hires–and that’s attractive to people coming from the outside.”

At Culver’s, keeping things simple is working for Bowe. “We ask people to show up when scheduled, to respect others, and to show up with a good attitude for work. If people do those three things, I tell them they can work for us forever.”

How to recruit, train, and retain talent for Supply Chain 4.

0

0

The integration of digital technologies into the supply-chain function has made it more critical than ever to recruit, train, and retain the best supply-chain talent. The challenge becomes even greater as more and more tasks are automated, requiring a shift not only in skillsets but also mind-sets. In a fast-moving and competitive talent marketplace, how can supply-chain organizations best position themselves for this next stage?

Companies are still struggling to solve this issue. With a few notable exceptions among the most visible technology leaders, supply-chain companies may not appear to be the most exciting career options at first glance. But as the adoption of digital technologies passes the tipping point to become widespread, these roles will offer opportunities for candidates to develop and hone their digital skills in a function that touches every area of an organization, from planning to distribution.

We therefore believe that an organization’s employee value proposition provides a useful starting point. By considering—and increasing if necessary—the weight placed on the supply-chain function as a critical enabler of an organization’s success, there is an opportunity to reposition the supply chain as an attractive career option for digital professionals.

Developing a talent pipeline to sustain the transformation into Supply Chain 4.0 requires the recruitment of early-career people with the right capabilities (exhibit). To ensure access to graduates with the digital and business-planning skills needed to thrive in supply-chain roles, organizations can partner with education institutions in designing tailored curricula. For example, successful graduates of a supply-chain program developed by a group of pharmaceutical companies in the same business park and a nearby technical college get preferential placement opportunities at the companies. And as these individuals progress throughout their tenure, they should be encouraged to continue their development through an independent professional body, several of which provide qualifications in a range of supply-chain disciplines.

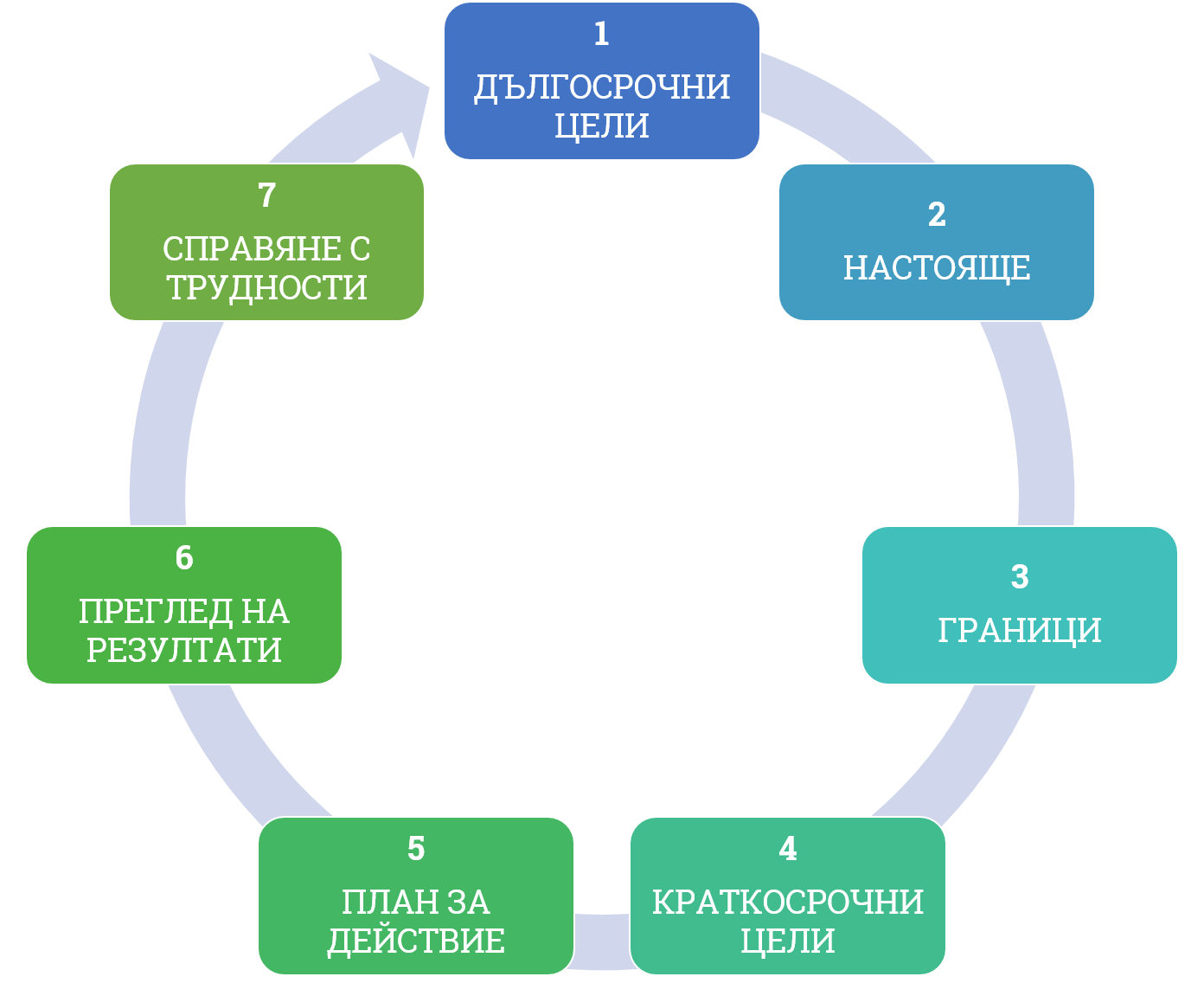

Exhibit

We strive to provide individuals with disabilities equal access to our website. If you would like information about this content we will be happy to work with you. Please email us at: [email protected]

As well as creating a set of graduates with the skills needed to thrive in the supply-chain function, organizations should seek to capitalize on the digital talent pool already available, such as the Asia-Pacific bank that moved IT staff into new digitization roles. Their expert input can create advanced-analytics tools, apply design thinking to challenges within the discipline, create apps to be used across an organization, and design and develop algorithms that combine to create a faster, more flexible, more granular, and more efficient business function. These digital experts, and the tools and skills that they bring, help break through silos in an organization’s supply-chain, creating a connected ecosystem that allows organizations to react quickly, improving both performance and customer satisfaction.

Beyond these roles is the need to recruit—or reskill—from within an organization “digital translators,” who will monitor and interpret the masses of data produced by these digital inputs, and champion the translation of analytics insights into business actions to sustain the impact of a solution. Recruiting to this type of role from within an organization, as a large telco did for its retail operation, offers the opportunity to fill these specialist positions with people who already know and understand a business, making their translation skills more valuable than those of a pure digital expert. Conversely, making an external hire can bring in a more objective viewpoint to the table when decisions on how and where new technologies should be applied, are being taken.

Other challenges in retaining supply-chain talent echo broader employment trends in a wide range of industries and disciplines, particularly amongst professionals with a digital skill base. These specialized employees know their value and have high expectations that their career and workplace will offer the right conditions and opportunities for progression, including roles that allow for extensive pilot programs to test and learn from new technologies. Freelance, contract, and remote working prevail in many areas, and organizations must decide which professionals should be brought into an organization and which roles can be outsourced to experts.

These specialized employees know their value and have high expectations that their career and workplace will offer the right conditions and opportunities for progression, including roles that allow for extensive pilot programs to test and learn from new technologies. Freelance, contract, and remote working prevail in many areas, and organizations must decide which professionals should be brought into an organization and which roles can be outsourced to experts.

A role within a contemporary organization’s supply-chain function is more than the logistics and warehousing management of old. In the latest iteration of Supply Chain 4.0, it offers professionals the opportunity to work with the very latest DnA technologies, in a function that is a key strategic pillar supporting an organization’s growth, touching every area from R&D and planning, through to distribution. An investment in your current talent—and careful development of the pipeline of future talent with the skills needed in Supply Chain 4.0—will create a function within your organization ready to meet rapidly evolving consumer demands.

How to Successfully Recruit, Retain, and Train Your Employees | by Terry Mansfield

Here are some effective ways to successfully recruit, retain, and train employees.

Photo by Perry Grone on Unsplash

As a part of your company’s recruiting and staffing process, you should continuously and proactively seek out the very best talent available who have the needed skills and experience to support your customers’ requirements. Once a new hire comes on board, ensure that he or she gets off to a great start through a comprehensive onboarding counseling process.

To speed up the process, once a new hire accepts a position, to the greatest extent possible, gather essential information on the new employee to use for creating an access badge, etc., so they are as ready to go from Day 1 of their employment. This applies to work they are going to do on a customer site as well; being very proactive is the key.

Make sure a new employee fully understands what to expect in terms of job duties and performance, as well as the customers they will be supporting and expectations. Also, inform them of the training they will receive at various stages that will help with not only their job performance but also with their career enhancement and advancement opportunities. Onboarding counseling should include other vital matters of particular interest to them, such as benefits, etc.

Traditionally your company’s human resources person is the primary point of contact (POC) for onboarding new employees into the company itself. However, for employees earmarked to work directly for a customer as support staff, the primary POC is usually your company’s contracts manager or a designated representative. This person will work closely with the customer’s contract representative on badging and integrating your contract support personnel onto the customer’s site based on access security and other relevant policies.

When you know the date that your employee starts work at a customer site, be very proactive in gathering all the required information from the employee. Especially important is to begin the process to obtain a physical access badge and apply for an identification card, if one is needed, for computer system access. Your contracts manager (or a designated representative) coordinates with the customer about the location where your contract support staff person will work, customer-provided equipment (e.g., computer, desk, etc.), and other matters.

The key to increasing the speed of badging and integration of personnel is to be very proactive on your company front-end, by having a focal point for tracking and ensuring actions get carried out through working in close coordination with the customer. These practices and processes work well for quickly and smoothly doing badging and integration of your company personnel on a customer site.

Your employees are vital in the running of your business, of course; they are the key to your success. Thus, you must strive to not only recruit the most talented and qualified employees you can find but then to do your level best to retain these excellent employees. One fundamental way to do this is by providing a stimulating workplace environment, which fosters happy, motivated, and empowered individuals, and lowers employee turnover and absentee rates. When you create and maintain a work environment that fosters personal and professional growth promotes harmony and encouragement on all levels, and thus the effects are felt company-wide.

Thus, you must strive to not only recruit the most talented and qualified employees you can find but then to do your level best to retain these excellent employees. One fundamental way to do this is by providing a stimulating workplace environment, which fosters happy, motivated, and empowered individuals, and lowers employee turnover and absentee rates. When you create and maintain a work environment that fosters personal and professional growth promotes harmony and encouragement on all levels, and thus the effects are felt company-wide.

Training is another critical component of retaining your employees. Continual training and reinforcement develop your workforce — one that is competent, consistent, competitive, effective, and efficient. Beginning on the first day of work, you must provide your new employees with the necessary information to perform their jobs successfully.

It is best if you also stress to them how important it is to satisfy your customers. Even before your new employee starts their first day on the job, during the interview and hiring process, you should give them a thorough explanation of your company. This way, they will know whether the job is their best choice and the best fit for both them and the company.

Once hired and onboard, networking and strategizing within the company provides ongoing performance management and helps your employees build relationships among co-workers. It is also important to motivate your employees to focus on customer success, profitable growth, and your company’s overall well-being.

A key, successful practice is to keep your employees informed and involved by including them in planning, policy changes, etc., as well as introducing new hires in meetings to the employees who have gone above and beyond performance-wise. This practice provides positive role models they can emulate. Early engagement and continual involvement along the way, a full “lifecycle approach,” shows your employees they are valuable through information or recognition rewards, making them feel included.

In terms of recruitment and retention, when you hire the best people, the new talent you bring on board, along with longer-tenured employees, are enabled to reach company goals, maximizing the investment of each employee. This approach also allows them to advance their own personal, professional, and career goals and objectives.

Listen to your employees. Make them feel involved. In doing so, you will create loyalty, which, in turn, will dramatically reduce turnover and enhance the retention of good employees. By doing this, you will enable further company growth as well as greater satisfaction on the part of the customers you serve because you are providing them with highly capable, stable, reliable support personnel with the requisite skills and experience to achieve success.

Robust and effective human resources-related efforts on your company’s part are essential in not only recruiting but in retaining valuable employees. As mentioned before, your company should take a “full lifecycle” approach. What this means is that from the beginning and throughout their employment, your employees know you are interested in and committed to doing whatever you can to work in partnership with them to foster and promote their continuous personal, professional, and career growth and success.

Your company’s overall Employee Training Plan must ensure that your employees receive training that is necessary to enable them to stay current with internal and external requirements on different topics (e.g., safety, job-related qualifications, and certifications, etc.). A crucial part of this training is enhancing your ability to monitor and maximize quality for your customers — something you obviously must take extremely seriously.

You should ensure quality-related efforts receive the proper senior leadership emphasis and attention throughout your company in support of your customers. Thus, someone on your executive staff with the requisite qualifications and experience should be assigned the overall responsibility of overseeing quality control and quality assurance throughout your company. This person ensures that the company’s Quality Assurance/Quality Control Plan (QA/QC Plan), a vital part of the overall Employee Training Plan, is in force and implemented effectively.

This person ensures that the company’s Quality Assurance/Quality Control Plan (QA/QC Plan), a vital part of the overall Employee Training Plan, is in force and implemented effectively.

One proven way to go about this is to follow the principles of Plan, Do, Check, Act, and Improve (PDCAI), a quality management system in ISO 9001.

• Plan: Establish the objectives and processes that will allow us to deliver specific results and outputs.

• Do: Implement the process developed. Perform tasks as designed and provide training and guidance along the way.

• Check: Measure, monitor, and evaluate the process by testing it and comparing results against the planned objectives.

• Act: Analyze the differences to determine their cause. Make improvements to the process where necessary.

• Improve: Track individual processes with statistics on performance compared to stated objectives. Use this information to work with stakeholders, customers, and suppliers to improve interconnected processes and enhance overall performance.

Your company should ensure that all your employees have the necessary qualifications and receive the training required to carry out basic QA/QC Plan requirements. Employees must adhere to all processes and procedures, and all personnel should fully understand the Plan, including specified tasks, such as:

• Who is responsible for checking any work done.

• Materials and supplies used for projects meet Industry or Government specifications, standards, and criteria.

• That customer feedback is received and acted upon, as necessary, as part of a corrective action process that involves the timely investigation of customer complaints and correction of non-compliance issues, to include identification of a viable solution on how to deal with a quality problem.

Bottom line: If your company employs a viable, comprehensive QA/QC Plan, especially one based on the PDCAI principles as outlined above, your chances of having happy, satisfied customers increase significantly. And that translates into business success.

And that translates into business success.

__________________

Thanks for reading. (Copyright Terry Mansfield. All rights reserved.)

- Check out my online daily newspaper, “The Social Media Daily” (it’s free), and stay up-to-date on all the happenings in the fascinating world of Social Media, Marketing, and related topics.

These are my most popular pieces:

Gain Access to Expert View — Subscribe to DDI Intel

The Keys to Quality Revenue Cycle Staffing

Revenue cycle management is only as good as the people working toward it. A highly trained, diverse team is necessary to fill the roles required to maintain a healthy cash flow for an ambulatory surgery center. This includes certified coders, billers, payment posters, and collectors.

It also takes a continual investment — of time and money — to find (and keep) professionals for those positions and ensure they know how to fulfill their responsibilities. How should you recruit, train, and, as importantly, retain, qualified revenue cycle staff?

Keep reading as we break down each step.

Recruit

Recruiting a qualified revenue cycle staff — one with the motivation, experience, and competences necessary to keep your business running at its best — isn’t easy. You should make sure to have detailed job descriptions, outlining the qualifications and skills you seek for each position and choose candidates to interview that meet the designated criteria.

But it’s not just about what you see on paper. When sitting down to interview candidates, you need to determine if they have the personality that fits the intended role by paying attention to the behavioral aspects of their persona. Do they have energetic optimism (perfect for a payment poster) or a take-charge, aggressive attitude (ideal for a collector)?

Also make sure you are trying to recruit people who are creative and not necessarily “task-oriented. ” Revenue cycle roles have long been considered assignment-guided positions. In truth, there are many different scenarios that can force someone to work outside of the regular processes, and they need to be able to think creatively to do so. This is especially true in ASCs where limited resources often force employees to wear many different hats. Similarly, the type of person for these roles should be motivated by a results-only work environment.

” Revenue cycle roles have long been considered assignment-guided positions. In truth, there are many different scenarios that can force someone to work outside of the regular processes, and they need to be able to think creatively to do so. This is especially true in ASCs where limited resources often force employees to wear many different hats. Similarly, the type of person for these roles should be motivated by a results-only work environment.

Train

In my experience, the number one problem when it comes to training is a lack of training. Even if you find a qualified individual with the right personality who meets your standards for the role, this individual will still need to be well trained. Many facilities tend to bring new employees in, sit them at the elbow of someone else, and expect them to just watch and do. The problem is, after that we don’t even look back at their work for six months, and then wonder why they haven’t been doing what they’re supposed to be doing.

You must put an organized training program in place. It needs to be structured and required — and it needs ongoing monitoring. This all goes back to that whole process of auditing — what isn’t monitored and measured isn’t done. Train someone to do something, communicate the importance of their role, test their competency, then watch them regularly to make sure they’re doing what is required.

You can even consider external education resources to help get this accomplished. Many facilities require new employees to attain certifications (i.e. – the AAPC Medical Billing and Coding Certification) or complete certain training programs.

Retain

While revenue cycle staff are typically hourly employees, you should still offer competitive compensation to avoid high turnover, which is common in the industry. Consider incentive plans that reward strong performance to support employee satisfaction. This also provides an affirmation of good work. One of the biggest employee stressors is ambiguity, i. e., “What means I’m doing a good job versus a bad one?” Since business office roles have always been so task-oriented, workers are often judged by what work looks like instead of what work accomplishes. But the best way to retain great revenue cycle management employees is through empowerment, trust, encouraging creativity, and allowing thinking outside of the box. This creates an environment that encourages options for creativity and flexibility that makes workers want to stay.

e., “What means I’m doing a good job versus a bad one?” Since business office roles have always been so task-oriented, workers are often judged by what work looks like instead of what work accomplishes. But the best way to retain great revenue cycle management employees is through empowerment, trust, encouraging creativity, and allowing thinking outside of the box. This creates an environment that encourages options for creativity and flexibility that makes workers want to stay.

Achieve Success Through Support

The people who manage your revenue cycle have a great deal of responsibility. After all, the financial security of your business is in their hands. Make sure throughout the recruiting, training, and retaining processes that you’re not only communicating the roles they must fill, but the importance of those roles. Then let their treatment, and your appreciation of them, reflect that value.

2018 Recruit, Train, Retain | Wise

|

Recruit, Train, and Retain the Best: The Implementation of a Competency-Based Clinical Research Workforce Initiative

Clinical Researcher—December 2017 (Volume 31, Issue 6)

PEER REVIEWED

Rebecca Namenek Brouwer, MS; Deborah Hannah, BS; Christine Deeter, BS; Betsy Hames, JM; Denise Clutter Snyder, MS, LDN, RD

[DOI: 10.14524/CR-17-0040]

Bringing scientific discoveries to bear as safely and efficiently as possible is the goal of those involved in clinical research. To accomplish this, a skilled and stable workforce is critical—this means retaining staff who understand best practices, regulations, and how best to get things done. With today’s tight labor market, however, attracting the best and brightest to the profession of clinical research may be as challenging as retaining skilled employees.

With today’s tight labor market, however, attracting the best and brightest to the profession of clinical research may be as challenging as retaining skilled employees.

Academic medical centers (AMCs) may experience particular challenges in recruiting high-quality staff, given the general decline of clinical research activities in this venue.1 Therefore, it’s important to create a clinical research workforce system within AMCs that appeals to potential job candidates as well as valuable incumbents, and that serves an ever-changing industry by emphasizing and rewarding development of specific competencies.

This paper describes an initiative that created a competency-based staffing structure at an AMC to provide, or at least encourage, the following:

- Standardized research roles

- A consistent approach to hiring and evaluating employees

- Advancement opportunities that rely on demonstrated competencies

- A transparent pathway for career growth and skill development

This workforce initiative was funded in part by an institutional Clinical and Translational Science Award (CTSA) grant from the National Institutes of Health (NIH) (UL1TR001117) to Duke University Medical Center. As such, it is the authors’ desire to share their experiences with others who may benefit from the work.

Background

Most adults need to work to earn a living; however, each individual has his or her own reasons for being attracted to, and remaining at, a particular job. This likely comes down to what motivates them, and many theories provide explanations for how this affects employee behavior.2

Champagne and McAfee3 offered an employee motivational theory that listed five important aspects of satisfying employee needs: physiological, security (economic, psychological, etc.), affiliation (encouraging social interaction), esteem (job challenge), and self-actualization. These needs are based on the well-known hierarchy of needs, articulated by Abraham Maslow. 4

4

Meanwhile, the equity theory of motivation, determined by John Stacey Adams,5 invites additional factors that motivate employees. Here, staff motivation is dictated by whether they think what they are putting into a job relates to what they get out of it. Similarly, it is important that what a staff member gets out of the job is the same as his or her colleague—fair, consistent treatment is key to the equity theory.

To build and maintain a clinical research workforce within an AMC setting, Duke employed strategies to affect motivation at several levels. In this article, the authors explain the various components of the workforce initiative, which aimed to recruit, train, and retain valuable staff and bolster professionalism in clinical research support.

Setting Up a Successful System

Since July 2014, Duke has been working on professionalizing its clinical research workforce via a comprehensive initiative that involves many elements (see Figure 1 for a timeline of related activities).6,7 At its core, the initiative utilizes core competencies, developed by the Joint Task Force for Clinical Trials Competency (JTFCTC).8 The eight competency domains are: (1) Scientific Concepts and Research Design, (2) Ethical and Participant Safety Considerations, (3) Medicines Development and Regulation, (4) Clinical Trial Operations (GCPs), (5) Study and Site Management, (6) Data Management and Informatics, (7) Leadership and Professionalism, and (8) Communication and Teamwork. The work was undertaken by the Clinical Research Professionals Working Group (CRPWG), comprised of staff from Duke’s School of Medicine, the Duke Office of Clinical Research,9 and the university’s Human Resources and Rewards and Recognition units.

Importantly, this initiative was heavily supported by leadership within the School of Medicine and the Human Resources unit, and it has had implications throughout the institution.

Standardizing Research Roles

The standardizing of research roles was made possible by the development of competency-based job descriptions and incumbent alignment with those job descriptions. The number of job classifications held by clinical research staff at Duke had become difficult to manage and impossible to track. In order to create consistency and standardization across the institution, the CRPWG aimed to consolidate and simplify the number of clinical research job classifications. As result of this project, the number of classifications was reduced from approximately 80 to 12.6

A tool was created to assess the current job duties and competencies of clinical research staff at Duke. The competencies were founded in the work done by the aforementioned JTFCTC, and were tracked in alignment with an initiative undertaken by the 61 institutions participating in the NIH CTSA program at the time.

Each staff member was asked to complete a survey tool, designed for collection in REDCap™ (Research Electronic Data Capture; https://www.project-redcap.org),10 based on the job duties and level of identified competencies. The staff member’s manager reviewed the tool, then validated and altered as needed the responses based upon his or her assessment of the employee’s job duties and level of competency.

The answers provided by the staff member and manager were assessed by committee, in conjunction with review of the staff member’s CV and job description. The job classification that was deemed the “best fit” was provided to the leadership of the staff member’s research unit to ensure there were no major concerns regarding the position identified. More than 700 research professionals were mapped into these new classifications in two distinct waves.

Consistent Hiring Practices

The competencies that were utilized to map each of the incumbents into their new job classifications were modified for use in a REDCap™ tool for new hires. The survey requires hiring managers to answer a series of questions based on the competencies needed to meet the requirements of the open position. Outcomes of the survey are then analyzed by a group of subject matter experts to provide the job classification that most closely aligns with the position being discussed.

The survey requires hiring managers to answer a series of questions based on the competencies needed to meet the requirements of the open position. Outcomes of the survey are then analyzed by a group of subject matter experts to provide the job classification that most closely aligns with the position being discussed.

Once the best fit has been identified, the results are recorded in a database and a position-specific job description is sent to the hiring manager. Communication and collaboration with the Human Resources unit ensures all positions that may fit into one of the 12 clinical research job classifications are routed through the survey tool. By utilizing this systematic method, the time to classify and post a position has been reduced significantly.

Tier Advancement

More than 40 competencies for staff in these tiered positions were leveled into four categories—”fundamental,” “skilled,” “advanced,” and “expert.” Multimodal, standardized assessments were developed for each competency, to determine the candidate’s level of skill/knowledge. Core, required competencies were identified for each role. Points were assigned for each level, and the accumulated point total determines advancement to the next tier. (It is important to note that competencies in the domain of Leadership and Professionalism play a key role.)

Through the tier advancement process, staff are able to clearly see opportunities for growth and development. This relies on the staff being able to exhibit competency in the skills required to perform their job. Staff are evaluated on these competencies by completing the previously mentioned assessments.

While an employee and his or her manager can select from several competencies, the Leadership and Professionalism competencies are required in order to progress. This fosters a sense of collaboration, professional growth, and innovation throughout the clinical research community.

The tools developed for the tier advancement process can be modified and used for training and onboarding purposes. The utilization of these tools for new hires creates consistency and efficiency across a variety of therapeutic areas of research and enhances a culture of professionalism.

The utilization of these tools for new hires creates consistency and efficiency across a variety of therapeutic areas of research and enhances a culture of professionalism.

While Duke has done much to professionalize its workforce, additional initiatives are in the planning stages, which will allow the institution to continue to build upon the competency model created. An example of this is that each employee who completes a competency assessment will have access to an individualized profile that reflects areas of strength within each domain. This can serve as part of an employee’s portfolio, and can be shared within the institution, as the assessments are consistent across units.

Portfolios may provide other AMCs information about research capability for staff who need to relocate and wish to continue their work at the same level. In addition, the hope is to take the competencies for each job classification and weave them into Duke’s clinical research training program and performance management system. By continuing to harmonize the expectations of managers across units, the institution aims to ensure consistent professional standards.

Discussion

This project was a significant undertaking, with regard to both time and money. Numerous staff and stakeholders were involved across the institution over several years. A core group of individuals were paid for the effort they devoted to operationally administer this initiative, but countless others volunteered their time to make it possible.

Many champions across the institution socialized the idea that the provision of career development opportunities to research professionals aims to positively affect not only individual staff, but also the institution and clinical research at large. There was some resistance to change, and concern about the financial impact shouldered by individual departments and research investigators. However, the strong commitment from the School of Medicine, Duke University Human Resources, and the research community in general made this project possible.

Stakeholder engagement in a project of this magnitude is absolutely necessary for success. The faculty were involved through their participation in an assembled Faculty Advisory Committee representing a number of clinical department disciplines, and are actively conducting their own research supported by diverse clinical research professional support teams. Their input and willingness to involve their staff in the “pilot” phase was critical.

The managers of the staff involved were also deeply engaged in this process. Manager involvement was important because managers recognized the work being done by staff, understood the expectations of each job classification, and were familiar with the specific competencies involved in each job classification. They were also called on as subject matter experts throughout the process. There were several training opportunities for these managers as the project moved along, which was key to its success and to staff understanding of the advancement opportunities.

The job classifications that were developed for clinical research staff rely on the idea of competencies being “building blocks.” The staff at a higher tier are expected to have attained their current tier’s expectations as well as the competencies of those at a lower tier. As an example of this for data entry and collection, a “fundamental” employee would be able to collect data according to a predefined plan; an “advanced” employee would not only be able to collect data according to a predefined plan, but is likely to be leading the development of standard operating procedures utilized to collect data.

The tier advancement process is point-based, and is consistent across all tiered job classifications. The institution requires the employee to meet a standardized threshold at each tier; “fundamental” requiring at least nine points, “skilled” requiring at least 36 points, and “advanced” requiring at least 84 points. Employees can achieve this threshold in many different ways. This allows for growth in areas that will fit staff who have specialties and those who may be a “jack of all trades.” Utilizing the same threshold for all clinical research staff ensures consistency and fairness.

This allows for growth in areas that will fit staff who have specialties and those who may be a “jack of all trades.” Utilizing the same threshold for all clinical research staff ensures consistency and fairness.

Referring back to Adams’s equity theory of motivation, the tier advancement process provides staff with direct means to see what they are getting out of the job equals what they put in. It also creates a sense of consistency that what they are putting into their job and what they get out is equivalent to that of their peers.

The competency-based tier advancement workforce initiative also meets many of Champagne and McAfee’s aspects of employee needs. It addresses “security,” both in the psychological and economic sense, by providing clear job descriptions and by employing a regular market analysis to ensure fair wages. It speaks to “affiliation” by promoting leadership; in order to advance in tiers, candidates must meet the leadership competencies appropriate for the tier toward which they are working. Leadership and professionalism inherently encourages participation in things outside “the job” that will further the clinical research community. “Esteem” and “self-actualization” are met through the development of challenging job advancement criteria with a definite outcome of achieving the next tier.

Duke will continue to focus on advancing its clinical research workforce. The framework described here is expected to be woven into the institution’s performance review process in the coming years, with the possibility that competency-based assessments will be applied to senior and management positions. By tying these expectations to existing performance and merit review processes, Duke will enhance an already established workflow rather than “reinvent the wheel.”

Conclusion

Shifting the research culture takes time. Standardizing job classifications and introducing new processes for advancement can be of great benefit to staff involved in clinical research.

The role of the clinical research professional needs to be valued, and should be more widely recognized as requiring high-level skills. Advancing the language and expectations in clinical research job classifications allows for a standardized pathway for building a career in an AMC. However, it does not guarantee this by way of tenure, but rather through demonstration of competencies.

By shifting the workforce’s expectations at Duke to competency-based advancement, the institution expects to have less attrition and more job satisfaction among staff choosing to work in clinical research. The tier advancement model has multiple advantages that are anticipated to result in a cultural shift that focuses on advancing clinical research and that leads to improved patient care and health outcomes.

References

- Meador KJ. 2015. Decline of clinical research in academic medical centers. Neurology 85(13):1171–6.

- Ramlall S. 2004. A review of employee motivation theories and their implications for employee retention within organizations. J Am Acad Bus 5(no.1/2):52–63.

- Champagne PJ, McAfee RB. 1989. Motivating Strategies for Performance and Productivity: A Guide to Human Resource Development. Quorum Books.

- Maslow AH. 1943. A theory of human motivation. Psych Rev 50(4):370.

- Adams JS. 1963. Towards an understanding of inequity. J Abnormal Soc Psych 67(5):422–36. http://psycnet.apa.org/record/1964-04111-001

- Brouwer RN, Deeter C, Hannah D, Ainsworth T, Mullen C, Hames B, Gaudaur H, McKellar T, Snyder D. 2017. Using competencies to transform clinical research job classifications. J Res Admin. In press.

- Causey M. 2017. Professional pathways boost staff retention in clinical research settings. ACRP Blog. www.acrpnet.org/2017/04/24/professional-pathways-boost-staff-retention-clinical-research-settings/

- Sonstein SA, et al.

2014. Moving from compliance to competency: a harmonized core competency framework for the clinical research professional. Clin Res 28(3:17–23. www.coapcr.org/wp-content/uploads/2014/10/Clinical-Research-Competencies.pdf

2014. Moving from compliance to competency: a harmonized core competency framework for the clinical research professional. Clin Res 28(3:17–23. www.coapcr.org/wp-content/uploads/2014/10/Clinical-Research-Competencies.pdf - Snyder DC, et al. 2016. Retooling institutional support infrastructure for clinical research. Contemp Clin Trials 48:139–45.

- Harris PA, Taylor R, Thielke R, Payne J, Gonzalez N, Conde JG. 2009. Research electronic data capture (REDCap)—a metadata-driven methodology and workflow process for providing translational research informatics support. J Biomed Informatics 42(2):377–81.

Rebecca Namenek Brouwer, MS, ([email protected]) is director of research initiatives at Duke University in Durham, N.C.

Deborah Hannah, BS, ([email protected]) is research practice manager at Duke University Medical Center.

Christine Deeter, BS, ([email protected]) is operations coordinator at Duke University School of Medicine.

Betsy Hames, JM, ([email protected]) is senior human resources executive at Duke University School of Medicine.

Denise Clutter Snyder, MS, LDN, RD, ([email protected]) is associate dean for clinical research at Duke University School of Medicine.

3 Key Strategies to Recruit and Retain Your Best Employees

Your ideas and vision will drive your company from its infancy, but it’s your employees who will have the most impact on the long-term performance of your business, especially as you move into a growth period.

In fact, our business has thrived because we’ve been able to recruit and retain talent who quickly adopt leadership roles. With their help, we’ve seen our sales multiply year-over-year. By developing a company culture our employees enjoy, empowering them to accomplish more at their jobs and incorporating social good into our business processes, we’ve established a brand our team members are proud to work for.

Below are three strategies you can use to make your company a place your top performers will never want to leave.

Build a dynamic company culture.

Strong company cultures that attract passionate and talented employees don’t arise out of thin air. They have to be strategically created, built from the top down and nurtured over time. Otherwise, your organization’s culture will be a disorganized combination of competing ideas with no guiding philosophy behind them. When you know in detail what your company culture is, then you can hire people who will be a good fit for it. This is vital since studies show culture fit is a crucial component of employee retention.

When you focus on building a value-added culture from the very beginning of the organization’s existence, then the benefits of that culture make waves throughout the entire business. This includes being better positioned to retain high-impact employees for years to come.

Set clear expectations and empower employees to exceed them.

The first big responsibility you have to your employees is to establish ambitious, yet feasible expectations for them. Hardworking, talented employees want to work with their colleagues to achieve great things, but they’re also wary of any company that doesn’t have defined milestones. If, in an interview, and entrepreneur claims, “We’re in a rapid growth phase, and things are changing too fast to have specific goals for your position,” the applicant interprets this as, “I have no idea what they’ll hold me accountable for.”

Once you let your employees know exactly what will be expected of them, your second major task is to empower them to achieve those goals. Give them the tools they need to thrive in their role, whether it is technology, training or intra-office communication.

Highlight your company’s social impact.

The impactful workers of today are looking for much more than just a paycheck when they agree to take a job. They want to work for an organization that has defined values and routinely makes a difference in society. In fact, 58 percent of millennials say they would take a lower salary in order to work for a company that has similar values to their own, according to Net Impact’s 2012 Talent Report in partnership with the Heldrich Center for Workforce Development at Rutgers University.

They want to work for an organization that has defined values and routinely makes a difference in society. In fact, 58 percent of millennials say they would take a lower salary in order to work for a company that has similar values to their own, according to Net Impact’s 2012 Talent Report in partnership with the Heldrich Center for Workforce Development at Rutgers University.

These days, many companies still rely on a business model in which they produce quick, disposable products that are convenient for customers but are bad for the environment. I believe product-based brands have a responsibility to consumers, their staff and the world to reduce the waste they create. In the UK, low-quality and older mattresses are overwhelming recycling centers, according to reports by the British newspaper The Sun. Many are likely to be burnt or dumped in a landfill.

At Amerisleep, we view this as a problem created mainly by opportunistic manufacturers who produce cheap and replaceable products that aren’t made-to-last. That’s why we build our beds to last decades and take an eco-friendly approach to making our mattresses with plant-based materials, a zero-emissions manufacturing process and optimized shipping methods to minimize our carbon footprint. Businesses like ours increase their likelihood of retaining top talent when they support social causes their team members care about.

The opinions expressed here by Inc.com columnists are their own, not those of Inc.com.

90,000 Magnetic Levitation Trains – Transport That Can Change the World

Maglev trains are the fastest form of ground public transport. And although only three small tracks have been put into operation so far, research and testing of prototypes of magnetic trains are taking place in different countries. How the technology of magnetic levitation has developed and what awaits it in the near future, you will learn from this article.

Formation history

The first pages of Maglev history were filled with a series of patents obtained in the early 20th century in different countries. Back in 1902, the German inventor Alfred Seiden was awarded a patent for the design of a train equipped with a linear engine. And four years later, Franklin Scott Smith developed another early prototype of an electromagnetically suspended train. A little later, in the period from 1937 to 1941, several more patents related to trains equipped with linear electric motors were received by the German engineer Hermann Kemper. By the way, the rolling stock of the Moscow monorail transport system, built in 2004., use asynchronous linear motors for movement – this is the world’s first monorail with a linear motor.

Back in 1902, the German inventor Alfred Seiden was awarded a patent for the design of a train equipped with a linear engine. And four years later, Franklin Scott Smith developed another early prototype of an electromagnetically suspended train. A little later, in the period from 1937 to 1941, several more patents related to trains equipped with linear electric motors were received by the German engineer Hermann Kemper. By the way, the rolling stock of the Moscow monorail transport system, built in 2004., use asynchronous linear motors for movement – this is the world’s first monorail with a linear motor.

Train of the Moscow monorail system near Telecentr

station In the late 1940s, researchers moved from word to deed. British engineer Eric Layswaite, who many call “the father of the Maglev”, managed to develop the first working full-size prototype of a linear induction motor. Later, in the 1960s, he joined the development of the Tracked Hovercraft high speed train.Unfortunately, in 1973 the project was closed due to lack of funds.

RTV 31 linear engine prototype (Tracked Hovercraft project)

In 1979, the world’s first magnetic levitation train prototype licensed to provide passenger transport services, the Transrapid 05, appeared. A 908 m long test track was built in Hamburg and presented during exhibition IVA 79. The interest in the project was so great that Transrapid 05 managed to work successfully for another three months after the end of the exhibition and transport a total of about 50 thousand items.passengers. The maximum speed of this train was 75 km / h.

Transrapid 05 system at IVA 79

And the first commercial magnetoplane appeared in 1984 in Birmingham, England. A magnetic suspension rail line connected the terminal of Birmingham International Airport to the nearby train station. She successfully worked from 1984 to 1995. The length of the line was only 600 m, and the height to which the train with a linear induction motor rose above the road bed was 15 millimeters. In 2003, the AirRail Link passenger transportation system based on Cable Liner technology was built in its place.

In 2003, the AirRail Link passenger transportation system based on Cable Liner technology was built in its place.

In the 1980s, the development and implementation of projects for the creation of high-speed magnetic levitation trains began not only in England and Germany, but also in Japan, Korea, China and the United States.

How it works

We know about the basic properties of magnets from the physics lessons for the 6th grade. If you bring the north pole of a permanent magnet to the north pole of another magnet, they will repel.If one of the magnets is turned over, connecting different poles, it is attracted. This is a simple principle found in maglev trains, which slide through the air over a rail for a short distance.

The magnetic suspension technology is based on three main subsystems: levitation, stabilization and acceleration. At the same time, at the moment there are two main technologies of magnetic suspension and one experimental, proven only on paper.

Electromagnetic Suspension Technology (EMS) trains use an electromagnetic field to levitate, the strength of which varies over time.At the same time, the practical implementation of this system is very similar to the operation of conventional railway transport. Here, a T-shaped rail track is used, made of a conductor (mainly metal), but the train, instead of wheelsets, uses a system of electromagnets – support and guides. The support and guide magnets are parallel to the ferromagnetic stators located at the edges of the T-track. The main disadvantage of EMS technology is the distance between the reference magnet and the stator, which is 15 millimeters and must be monitored and adjusted by special automated systems depending on many factors, including the inconsistent nature of the electromagnetic interaction.By the way, the levitation system works thanks to batteries installed on board the train, which are recharged by linear generators built into the reference magnets. Thus, in the event of a stop, the train will be able to levitate long enough on batteries. Transrapid trains and, in particular, the Shanghai Maglev were built on the basis of EMS technology.

Thus, in the event of a stop, the train will be able to levitate long enough on batteries. Transrapid trains and, in particular, the Shanghai Maglev were built on the basis of EMS technology.

Trains based on EMS technology are propelled and braked by a low-acceleration synchronous linear motor represented by support magnets and a belt over which the magnetoplane hovers.By and large, the motor system built into the web is a conventional stator (the stationary part of a linear electric motor) deployed along the bottom of the web, and the supporting electromagnets, in turn, act as an anchor for the electric motor. Thus, instead of generating torque, the alternating current in the coils generates a magnetic field of excited waves, which moves the composition contactlessly. Changing the strength and frequency of the alternating current allows you to adjust the traction and speed of the train.In this case, to slow down, you just need to change the direction of the magnetic field.