What are the common complications associated with hernia mesh. How do patients know if they qualify for a hernia mesh lawsuit. What types of injuries are people suing for in hernia mesh cases. Why are manufacturers being held liable for hernia mesh failures.

What is Hernia Mesh and Why Are Lawsuits Being Filed?

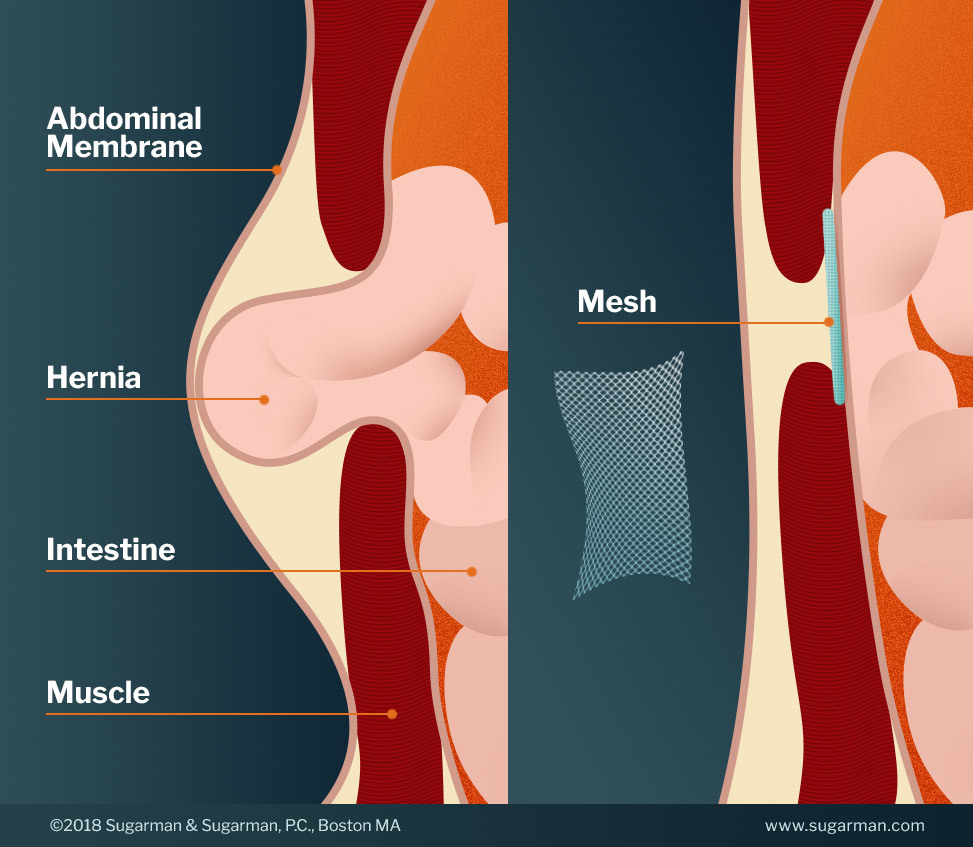

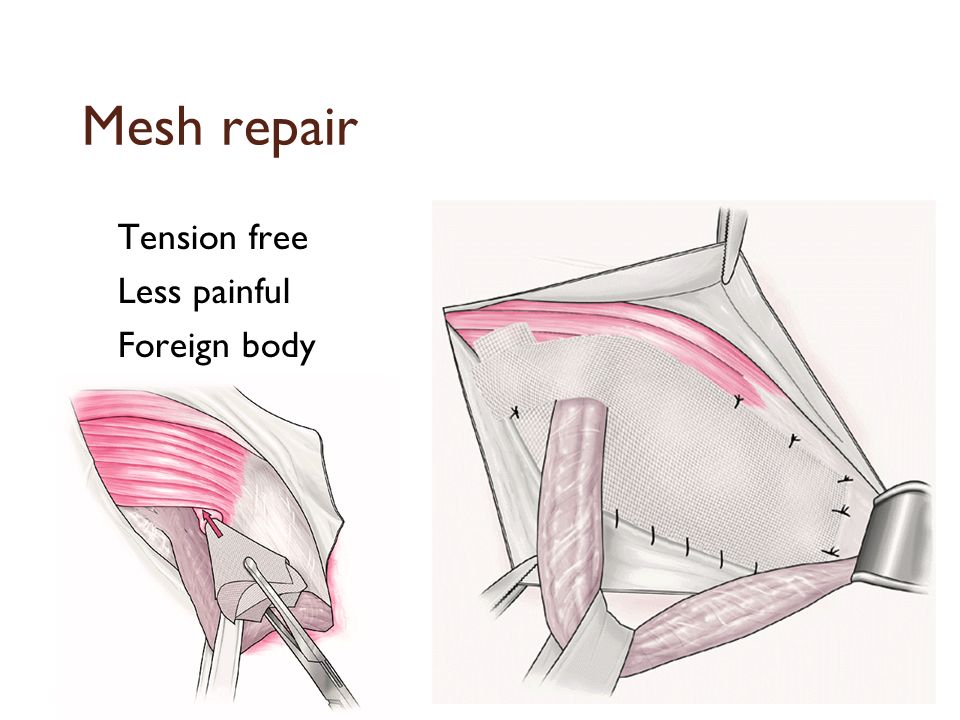

Hernia mesh is a medical device used in hernia repair procedures to provide support to weakened or damaged tissue. While it was developed as an improvement over traditional suture-only repairs, many patients have experienced serious complications, leading to a wave of lawsuits against manufacturers.

Trial attorney Trent B. Miracle, head of the Pharmaceutical Litigation Group at Simmons Hanly Conroy, explains that people are suing hernia mesh manufacturers for two primary reasons:

- Defective design of the hernia mesh

- Failure to warn of the risks associated with using hernia mesh

Hernia mesh was initially advertised as a durable and flexible solution that would provide lasting repairs with minimal side effects. However, the reality has fallen short of these promises for many patients.

Understanding Hernia Mesh Failure and Its Consequences

Hernia mesh failure occurs when the implanted mesh causes complications that necessitate its removal or require secondary surgery to correct mesh-associated injuries. These failures can lead to severe health issues and significant pain for patients.

Are certain types of hernia mesh more prone to failure? According to Miracle, the issue is less about specific manufacturers and more about particular products. Many pharmaceutical companies have both problematic and non-problematic hernia mesh products in their lineups.

Common Hernia Mesh Injuries

Patients who have experienced hernia mesh failure often report a range of serious complications. Some of the most common injuries include:

- Chronic pain

- Infections

- Fistulas

- Abscesses

- Mesh deformity

- Organ perforation

- Adhesions

- Bowel obstruction

- Hernia recurrence

These complications can significantly impact a patient’s quality of life and may require additional surgeries or long-term medical care.

Qualifying for a Hernia Mesh Lawsuit: What Patients Need to Know

Do you suspect that you might be eligible for a hernia mesh lawsuit? Miracle advises that individuals who have had hernia mesh implanted and have suffered painful side effects may qualify for legal action.

To determine if you have a valid claim, consider the following factors:

- You have undergone hernia repair surgery using mesh

- You have experienced complications or side effects related to the mesh

- Your complications have resulted in additional medical treatment or surgeries

If you meet these criteria, it may be worth consulting with a legal professional to explore your options further.

The Importance of Preserving Failed Hernia Mesh as Evidence

While preserving the failed hernia mesh can be beneficial for building a strong case, it is not an absolute requirement for filing a lawsuit. Typically, the operative report detailing the surgeon’s observations and actions during a hernia mesh repair surgery provides sufficient information to indicate mesh failure.

However, if you are considering legal action and are scheduled for mesh removal surgery, there are steps you can take to preserve the evidence:

- Inform your attorney about the upcoming surgery

- If you haven’t retained an attorney, request that the hospital preserve the removed mesh

Taking these precautions can potentially strengthen your case if you decide to pursue legal action in the future.

Current State of Hernia Mesh Litigation: Settlements and Verdicts

Have there been any significant settlements or jury verdicts in hernia mesh cases? While there was previous litigation involving a recalled hernia mesh product that resulted in a resolution, Miracle notes that large-scale settlements regarding the current hernia mesh litigation involving different products are not yet known.

This ongoing litigation highlights the complexity of these cases and the evolving nature of hernia mesh lawsuits. As more cases progress through the legal system, it’s likely that we’ll see further developments in terms of settlements and verdicts.

The Role of Manufacturers in Hernia Mesh Complications

Why are manufacturers being held liable for hernia mesh failures? The key issues revolve around two main points:

- Knowledge of potential risks: Manufacturers are being accused of having prior knowledge about the injuries patients were suffering before marketing the hernia mesh.

- Failure to warn: Some lawsuits allege that manufacturers continued to sell hernia mesh products after becoming aware of the injuries, without adequately warning of the dangers.

These allegations suggest that manufacturers may have prioritized profits over patient safety, leading to the current wave of litigation.

Navigating the Complexities of Hernia Mesh Lawsuits

For patients who have suffered complications from hernia mesh, navigating the legal landscape can be challenging. Here are some key considerations:

- Statute of limitations: There are time limits for filing a lawsuit, which vary by state

- Documentation: Gathering medical records and evidence of complications is crucial

- Legal representation: Choosing an experienced attorney familiar with medical device litigation is important

Understanding these factors can help potential plaintiffs make informed decisions about pursuing legal action.

![]()

The Future of Hernia Repair: Alternatives to Mesh

Given the complications associated with hernia mesh, are there alternative methods for hernia repair? While mesh remains a common solution, some surgeons are exploring other options:

- Suture-only repairs for small hernias

- Biological meshes made from animal tissue

- Laparoscopic techniques that may reduce the need for large mesh implants

As research continues, it’s likely that new, safer methods of hernia repair will emerge, potentially reducing the reliance on synthetic mesh products.

Advancements in Hernia Mesh Design

Despite the ongoing litigation, some manufacturers are working to improve hernia mesh designs. These efforts include:

- Developing new materials that may be less likely to cause complications

- Creating meshes with improved integration properties

- Designing products that are easier for surgeons to place accurately

These advancements aim to address the shortcomings of earlier mesh products and improve patient outcomes.

Patient Advocacy and Awareness in Hernia Mesh Cases

The rise in hernia mesh lawsuits has led to increased patient advocacy and awareness. Support groups and online forums have emerged, providing platforms for patients to share their experiences and information.

These advocacy efforts have several important impacts:

- Raising awareness about potential hernia mesh complications

- Encouraging patients to be proactive in their healthcare decisions

- Pushing for greater transparency from manufacturers and healthcare providers

By sharing their stories, patients are not only supporting each other but also contributing to a broader understanding of the risks associated with hernia mesh.

The Role of Regulatory Bodies

How have regulatory bodies responded to the hernia mesh controversy? The FDA and other international regulatory agencies have taken several steps:

- Issuing safety communications about specific hernia mesh products

- Recalling certain mesh products found to have higher complication rates

- Updating guidelines for the approval of new hernia mesh devices

These actions demonstrate the ongoing efforts to balance the benefits of hernia mesh with the potential risks to patient safety.

Long-Term Health Implications of Hernia Mesh Complications

For patients who have experienced hernia mesh failure, the health implications can be long-lasting. Some of the potential long-term effects include:

- Chronic pain that may impact daily activities

- Reduced mobility due to adhesions or other complications

- Psychological effects, such as anxiety or depression related to ongoing health issues

- Need for continued medical monitoring and potential future surgeries

Understanding these long-term implications is crucial for both patients and healthcare providers in making informed decisions about hernia repair options.

The Importance of Follow-Up Care

For patients who have undergone hernia repair with mesh, regular follow-up care is essential. This should include:

- Regular check-ups with the surgeon or primary care physician

- Prompt reporting of any new symptoms or complications

- Awareness of the signs of potential mesh failure

Proactive monitoring can help identify and address any issues early, potentially improving outcomes for patients.

The Economic Impact of Hernia Mesh Litigation

The wave of hernia mesh lawsuits has significant economic implications, affecting various stakeholders:

- Manufacturers facing potential financial losses from settlements and legal fees

- Healthcare systems dealing with the costs of revision surgeries and extended patient care

- Patients experiencing financial strain due to medical bills and lost wages

These economic factors underscore the far-reaching consequences of the hernia mesh controversy beyond individual health outcomes.

The Role of Insurance in Hernia Mesh Cases

How does insurance factor into hernia mesh complications and litigation? Several aspects come into play:

- Coverage for initial hernia repair surgeries

- Policies regarding coverage for revision surgeries and complication treatments

- The potential impact on future insurance rates for affected patients

Understanding these insurance considerations is crucial for patients navigating the aftermath of hernia mesh complications.

Ethical Considerations in Hernia Mesh Manufacturing and Marketing

The hernia mesh controversy raises important ethical questions about the medical device industry:

- Balancing innovation with patient safety

- Transparency in reporting adverse events and study results

- The responsibility of manufacturers to educate healthcare providers about potential risks

These ethical considerations are likely to shape future practices in the development and marketing of medical devices.

The Importance of Informed Consent

The hernia mesh litigation highlights the critical role of informed consent in medical procedures. Patients should be fully aware of:

- The potential risks and benefits of hernia mesh repair

- Alternative treatment options

- The specific type of mesh being used and its track record

Ensuring thorough informed consent can help patients make better decisions about their healthcare and potentially reduce future complications.

A Q&A with Trial Lawyer Trent Miracle

Hernia surgery is one of the most common surgeries in the United States. Most surgeons perform hernia repairs with surgical mesh. The net-like implant helps fix weak spots in muscle or connective tissue and prevents organs or fat from bulging through the weak spot.

Most people have no problems after hernia repairs with mesh, and they can return to their regular activities. But sometimes hernia mesh fails and causes serious, painful problems that leave some people with debilitating health complications. Surgeons have to remove and replace defective mesh.

Trent B. Miracle

Thousands of people across the country have filed hernia mesh lawsuits seeking compensation for medical bills, lost wages, pain and suffering and lost quality of life.

Trial attorney and pharmaceutical litigation expert Trent B. Miracle is the head of the Pharmaceutical Litigation Group at Simmons Hanly Conroy, an award-winning national firm based in Illinois. Under Miracle’s leadership, the litigation group has won $360 million in settlements for people who say pharmaceuticals and medical devices harmed them.

Under Miracle’s leadership, the litigation group has won $360 million in settlements for people who say pharmaceuticals and medical devices harmed them.

In this Q&A, Miracle explains why people are filing hernia mesh lawsuits, who qualifies to file a claim and the most important thing to know about hernia mesh lawsuits.

Q: What is hernia mesh and why are people suing mesh manufacturers?

A: Hernia mesh is a medical device used in various hernia repair procedures to help provide support to the weakened or damaged tissue that caused the hernia. Prior to hernia mesh, doctors typically used a suture only repair. But the potential for a recurrence of the hernia was possible because the tissue was already weakened and therefore could further weaken causing another hernia. So the pharmaceutical companies came up with hernia mesh.

There are many different types of hernia mesh, but the most prevalent are constructed from animal tissue or synthetic material. The most common synthetic material that is used is called polypropylene. Polypropylene was advertised as a durable and flexible mesh which was supposed to provide a lasting hernia repair with little to no adverse side effects.

The most common synthetic material that is used is called polypropylene. Polypropylene was advertised as a durable and flexible mesh which was supposed to provide a lasting hernia repair with little to no adverse side effects.

Unfortunately, hernia mesh has not lived up to the hype. People are suing hernia mesh manufacturers for defective design of the hernia mesh and failure to warn of the risks of using hernia mesh.

Q: What is hernia mesh failure?

A: Hernia mesh failure occurs when the mesh is causing complications and must be removed or requires a secondary surgery to correct the hernia mesh-associated injuries, such as a bowel obstruction requiring a lysis of adhesions or even a bowel resection.

Did you suffer serious injuries from your hernia mesh?

Get A Free Case Review

Q: Are some brands of mesh more likely to fail than others?

A: The defective hernia mesh is less about specific manufacturers and more about the specific products. It’s also about the knowledge the manufacturers had regarding injuries patients were suffering from prior to marketing the hernia mesh or continuing to sell the hernia mesh after becoming aware of the injuries and failing to adequately warn of the dangers.

It’s also about the knowledge the manufacturers had regarding injuries patients were suffering from prior to marketing the hernia mesh or continuing to sell the hernia mesh after becoming aware of the injuries and failing to adequately warn of the dangers.

Most pharmaceutical companies have hernia mesh products that are not involved in any current litigation. However, most of the major manufacturers of hernia mesh have several products that cause serious injuries which are the subject of current litigation.

Q: What types of hernia mesh injuries are people suing for?

Common hernia mesh injuries are:

- Pain

- Infection

- Fistulas

- Abscesses

- Lack of mesh incorporation

- Mesh deformity once placed

- Organ perforation

- Adhesions to the mesh

- Bowel obstruction

- Bowel resection

- Mesh removal

- Mesh revision

- Hernia recurrence

Q: How do people know if they qualify for a hernia mesh lawsuit?

A: If someone had a hernia mesh product placed and has suffered painful side effects, including those mentioned above, they may qualify for a hernia mesh lawsuit.

Q: How important is preserving failed hernia mesh for evidence at trial, and what tips can you give people for preserving their failed mesh?

A: Preserving the defective mesh is always helpful, but it is not a prerequisite for a hernia mesh lawsuit. Typically, the operative report where the surgeon dictates their notes on what they saw and did during a hernia mesh repair surgery will have sufficient information to indicate a failure of the mesh.

To preserve the mesh that was removed, a patient would need to inform their attorney of the surgery before it takes place. Or if they have not retained an attorney at that time, they should request the hospital preserve the mesh.

Q: Have there been any settlements or jury verdicts?

A: There was litigation several years ago involving one hernia mesh product that was recalled by the FDA which resulted in resolution. However, we are unaware of any large scale settlements regarding the currently hernia mesh litigation involving different products. Additionally, we are unaware of any trials which have proceeded all the way to a jury verdict regarding the current hernia mesh products.

Additionally, we are unaware of any trials which have proceeded all the way to a jury verdict regarding the current hernia mesh products.

Unfortunately, for those suffering hernia mesh injuries, the COVID-19 pandemic slowed the litigation process down. That said, trials are currently being scheduled for later in the year and into 2022.

Q: What is the current status of hernia mesh litigation?

A: Cases are continuing to be filed and scheduled for trials, although at a slower pace given the COVID-19 pandemic.

We believe the public will start to see jury verdicts regarding hernia mesh sometime later this year and into next year. Plaintiffs’ counsel around the country, including our firm, continues to litigate these cases and try to obtain compensation for our injured clients.

Q: What is the most important thing people should know about filing a hernia mesh lawsuit?

The most important thing to know is we feel strongly about the validity of these cases and are working tirelessly to represent people injured by these products.

Additionally, given the sheer number of hernia mesh surgeries in the past, there are a multitude of cases currently pending. That means litigation which has taken several years could possibly last several more.

That said, with the upcoming trials, we strongly believe much more pressure will be brought to bear upon the manufacturers, forcing them to come to the negotiating table.

TELL US WHAT YOU THINK

Did You Find Drugwatch Helpful?

Yes

No

Thank you for your feedback. Do you have any thoughts you’d like to share about Drugwatch.com?

This article changed my life!

This article was informative

I have a question

How can we improve this page?

This article contains incorrect information

This article doesn’t have the information I’m looking for

I have a question

How can we improve this page?

Thank You for Your Feedback

We appreciate your feedback. One of our content team members will be in touch with you soon.

One of our content team members will be in touch with you soon.

We appreciate your feedback. One of our content team members will be in touch with you soon.

Baby Bjorn Miracle – Baby carriers – Carriers & slings

In a nutshell

A top notch carrier that will serve you well beyond your baby’s first year. Fully adjustable, well padded and easy to use but expensive and not without niggles.

What we tested

Overall Rating

A star rating of 4.6 out of 5.

- Can last from birth to 15 months, two carrying positions, new improved weight distribution system, sleek design, adjustable

- Expensive, not suitable for babies weighing under 3.5kg at birth

Skip to view product specifications

Showing item 1 of 3

The Baby Bjorn Miracle is the latest baby carrier from the Swedish company’s stable. The new updated carrier, launched as the company turns 50, combines the practicality and comfort of existing Baby Bjorn carriers with an entirely new, streamlined design. But despite the improvements there are still a few niggles.

But despite the improvements there are still a few niggles.

Baby Bjorn has been making baby carriers and baby products for half a century. Its aim? To make life a little easier for parents. The latest baby carrier, the Miracle, has been two years in the making and can be used from birth to around 15 months (at least 8lb/3.5kg up to 26lb/12kg). Made from 60% cotton and 40% polyester the Miracle is super soft and machine washable at 40 degrees.

The Miracle is fully adjustable and can be used by anyone regardless of how big or small you are (think height and waist size here!). The overall design of the carrier is so tried and trusted that it remains pretty much the same as its siblings – your the baby is carried in a soft, moulded shell that clips to an adjustable harness, it can be used forward or parent facing and has an adjustable head support.

What’s new is the padding around the adjustable waistband and the all-new size adjuster, which is now like a ruler showing each centimetre increment (so rather than guesstimate the fit, you can be totally accurate).

The biggest improvement however, is the system that transfers your baby’s weight from your shoulders to your hips. Your newborn likes to sit up high, chest to chest near the comforting sound of your heartbeat. By loosening the shoulder straps and pulling down on the triangular back support, the waistband is lowered to sit on your hips, a better position for carrying your older child (from around 6 months) who is heavier and may face outwards.

What we love

My other Baby Bjorn carrier has been used by several babies (my two girls, Minnie and Poppy, and my nephews) and it is still going strong. Poppy, its fourth tester, has been on board since she was a few days old and loves it. As a sicky baby being upright suits her and she prefers to look out on the world rather than being stuck down low in the double buggy.

However, getting the fit right on this existing Baby Bjorn of mine isn’t easy. I spend a lot of time pulling and tugging at straps only to feel like I am being cut in half by three inches of (albeit organic) cotton. On the Miracle, the new mechanism of pulling down the back support makes it much easier to transfer your baby’s weight onto your hips and get a bespoke fit. It’s easy to forget that you’re wearing a baby!

On the Miracle, the new mechanism of pulling down the back support makes it much easier to transfer your baby’s weight onto your hips and get a bespoke fit. It’s easy to forget that you’re wearing a baby!

I’m also glad to see that extra padding has been added on the waistband.

The accurate size adjuster is a Godsend, as long as you’ve been to have your baby measured recently!

What to watch out for

Despite being billed as suitable from birth, the Miracle can only be used when your baby is over 3.5kg. Both of mine have weighed in under that, so would’ve needed to wait a few weeks until it could be used.

My major bugbear of the Baby Bjorn system is the way that the chest support flips up into the baby’s face when you’re using it forward facing – many a cake has been baked with poor Poppy shrouded in darkness! This is still a problem on the Miracle.

At £109.99, it’s not the most expensive carrier around, but it still costs more than some buggies!

Who is the Baby Bjorn Miracle baby carrier best for?

Style-conscious parents who want a top-rate carrier that will last beyond the first year.

MadeforMums verdict

An innovative baby carrier that scores highly on comfort and design. Easy to use and fully adjustable, the Miracle is guaranteed to become a family staple but at over £100, you’ll need to make sure there’s room in budget for this one.

Sarah Barker

Product Specifications

| Product | |

|---|---|

| Brand | Baby Bjorn |

| Model | Miracle |

| Price | £109.99 |

| Suitable for | |

|---|---|

| Child age (approx) | Birth to 15 months |

| Child weight | 3.5kg to 12kg |

| Features | |

|---|---|

| Washing instructions | Machine washable |

| Fastening | Click fit |

| Number of carrying positions | 2 |

| Features |

|

| Accessories | |

|---|---|

| Head hugger | Yes |

| Optional extras | Cover, sun cover, bib |

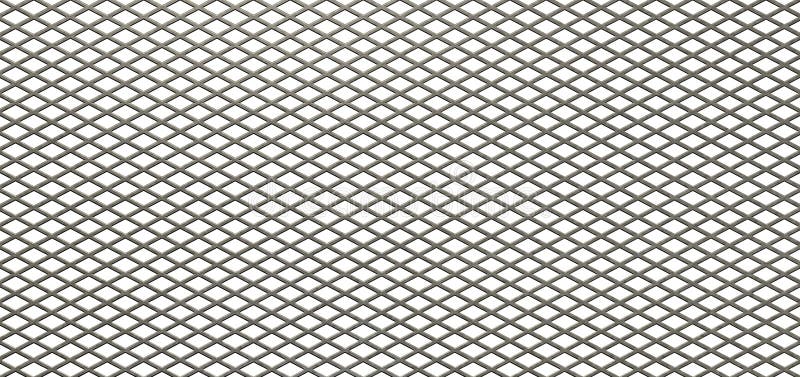

Basalt mesh is a marvel of engineering.

Basalt mesh is an engineering marvel. This material has replaced the metal mesh, which is inferior to it in many respects.

Basalt mesh – a material that has increased strength, can significantly increase the bearing capacity of the structure due to the content of basalt fibers in its composition. Basalt fiber is obtained from various, similar in composition, rocks. Basalt is melted in specialized melting furnaces, and then the contents are poured through a special unit made of platinum or other heat-resistant materials. The result of these manipulations is to obtain the thinnest fiber, a few nanometers thick!

The complexity of the fiber manufacturing process greatly slowed down the appearance of this material on the market, but thanks to modern technologies, the price of it has decreased and production has become massive.

Today, almost no construction site can do without this reinforcing fiber. The scope of masonry mesh is extensive. It is used for reinforcement:

The scope of masonry mesh is extensive. It is used for reinforcement:

Ties

Structures made of gas silicate block, foam concrete, expanded clay

Brickwork

Jumpers

Concrete floors and asphalt pavement in road construction

Runways and dirt roads

The masonry mesh made of basalt fibers is valued for the many advantages that the material should have for such a plan. Namely:

Low thermal conductivity

Resistance to fluctuations in low and high temperatures

Lightness (roll 50*1m weighs no more than 15 kg)

Strength

Not affected by an alkaline environment (e.

g. when using concrete)

g. when using concrete)Affordable price

Easy installation

Compact, which greatly simplifies storage.

What do you prefer?

Usually the choice in the matter of reinforcement is not difficult. In most cases, preference is given to the basalt grid. But in fairness it should be said that there are other materials that have a different composition. This is a metal mesh and fiberglass polymer.

If we talk about metal mesh, then it is worth considering the following features:

The weight of the lightest metal mesh is from 2 kg / m 2 , and this will serve as an additional load on the object under construction

The thermal conductivity of the metal is about 100 times higher than basalt – this is fraught with the formation of cold bridges, which significantly reduces the life of the building

Grids with the same cross section will differ in strength.

Basalt mesh

Basalt meshalso wins here

It’s no secret that metal is prone to corrosion. This property will not play the best role in the durability of the future design

Metal withstands fewer cycles of temperature fluctuations

Paradoxically, the basalt mesh is lower at a price of

Mounting a metal mesh is much more difficult. This is due to the greater mass of the roll, and also, it must be added that, unlike a metal mesh, basalt mesh is easily cut with ordinary scissors

It has been experimentally proven that structures erected with metal reinforcement are less durable

As for the fiberglass polymer, it cannot be used in buildings with a large load; and if you need to change the direction of the rods, then, unfortunately, this will not work.

It turns out that the use of fiberglass in construction is a risky business, because the consequences can be sad.

Dimensions of basalt masonry mesh

When choosing a basalt mesh, you should not save. Ultimately, you are directly interested in the durability of your building. When choosing a masonry mesh, you need to proceed from what basic material you use for construction, and how many floors you plan to build. The range of prices is wide as well as the range of material sizes.

The strength of the mesh depends on the size of the cells, the smaller they are, the stronger the mesh. The size of the grid depends on its type. There are meshes that are used when filling smooth walls (roll width in this case is 1 m), as well as a mesh used in working with corners, seams, areas where windows and doors come into contact with walls, where walls meet the ceiling, drywall joints and other materials (such a mesh is called sickle and it is produced in rolls from 4.5 to 20 cm).

Manufacturers of masonry nets offer a wide range of sizes, but there are three main ones that are most popular.

Indicator name | Basalt masonry mesh | ||

station wagon | masonry | block | |

Surface density (g/m 2 ) | 250 | 250 | 150 |

Mesh size (mm) | 25*25 | 25*8 | 50*50 |

Width (m) | 0. | 0.37-5 | 0.37-5 |

Reinforcement with basalt masonry mesh of various surfaces

Any structure built of brick or gas block requires the creation of an armored belt.

Installation of basalt masonry mesh on aerated concrete block.

When strengthening walls made of aerated concrete, the so-called U -shaped blocks or partition blocks , 5-10 cm thick.

The easiest way to create an armored belt is to use U-shaped blocks. True, this option will require a little more capital investment, but will significantly save labor costs.

If we consider the option using a partition block, then the following actions are performed to create an armored belt. To begin with, the outer wall is pasted over with blocks 10 cm thick (a special aerated concrete adhesive ), then from the inside the wall is laid out in blocks of 5 cm – this will be your formwork. The blocks are insulated with foam boards, the reinforcing material is laid at a distance of 5 cm from the wall and poured with concrete.

To begin with, the outer wall is pasted over with blocks 10 cm thick (a special aerated concrete adhesive ), then from the inside the wall is laid out in blocks of 5 cm – this will be your formwork. The blocks are insulated with foam boards, the reinforcing material is laid at a distance of 5 cm from the wall and poured with concrete.

It should be added that the interfloor ceilings from the gas block are reinforced in two layers. The second layer is laid already on the dried surface of the belt using a special glue.

If necessary, inter-row reinforcement of gas silicate masonry, the following actions are performed. On the upper edge of the lined row, two furrows (strobes) are laid with a depth and width of 2.5 cm (a special tool is used to perform these works – wall chaser ). If the width of the block is 20 cm, then the reinforcing material is placed in the center in one strobe and glued with a cloth. For wider blocks, two furrows are required. The grooves are freed from dust and debris, sprayed with water and lubricated with glue for aerated concrete. It is better to place the adhesive mixture directly into the strobe, which will strengthen the reinforcement. The corners of the building are reinforced with L-shaped reinforcement and two transverse layers of reinforcing fabric. Next, the next layer of the block is mounted.

The grooves are freed from dust and debris, sprayed with water and lubricated with glue for aerated concrete. It is better to place the adhesive mixture directly into the strobe, which will strengthen the reinforcement. The corners of the building are reinforced with L-shaped reinforcement and two transverse layers of reinforcing fabric. Next, the next layer of the block is mounted.

Installation of basalt masonry mesh on bricks.

Immediately, we note that the installation of the grid on a brick base can be carried out in three ways: longitudinal, parallel and perpendicular. The most common option is the transverse method. As a result of using this installation method, the bearing capacity of the walls of the structure becomes 50% stronger, so you should not spare time, effort and money for laying.

What type of basalt mesh to choose for this reinforcement option is decided at the design stage of the future structure, when a preliminary calculation of the expected load on the walls is carried out. Then the following happens: the mesh is attached to the glue on the laid out brick row (the glue reduces the thermal conductivity of the mesh, which is important for the thermal insulation of the future building), then it is completely (“head”) filled with masonry mortar and a new row of bricks is laid on top.

Then the following happens: the mesh is attached to the glue on the laid out brick row (the glue reduces the thermal conductivity of the mesh, which is important for the thermal insulation of the future building), then it is completely (“head”) filled with masonry mortar and a new row of bricks is laid on top.

There is another important point in the installation of the grid on the brick. Since the brick is different, the laying technology for each of them is different.

Silicate brick M 150 – reinforcement of every 5th row

Double brick – every 4th row

Ceramic – in every 3rd row.

Before starting facing work, it is necessary to lay a layer of vapor barrier and insulation between the brickwork and the aerated concrete wall. Remember that structures made of gas silicate blocks shrink after 2-3 months after construction. Therefore, in order to prevent the appearance of cracks on the walls, it is necessary to reinforce the structure.

Therefore, in order to prevent the appearance of cracks on the walls, it is necessary to reinforce the structure.

We draw your attention to the fact that there are always places that require mandatory reinforcement with basalt masonry mesh. This is the laying of the 1st floor, the bottom of window openings, lintels and overlap zones.

So, we have already said that the row in which the grid will be located is selected based on the brand of brick. In addition, the following factors must be considered:

Walls that are subjected to mechanical stress or aggressive environmental influences are reinforced with greater frequency unquestioningly.

For continuous masonry, the reinforcing fabric is located in the center.

If the distance between the blocks is 30 cm, then the grid is used at least in 3 places. If less than 30 cm, then such an arrangement of the grid is necessary for window openings and the space under them.

g. when using concrete)

g. when using concrete) Basalt mesh

Basalt mesh 37-5

37-5