How do you find the right size shin guards for soccer. What factors should you consider when selecting shin guards. How can you ensure proper fit and protection for your position on the field.

Types of Soccer Shin Guards: Choosing the Best Protection for Your Play Style

Soccer shin guards are an essential piece of protective equipment for players at all levels. Understanding the different types available can help you select the best option for your needs. Let’s explore the three main categories:

Slip-In Shin Guards

Slip-in shin guards are lightweight shields that fit directly under your socks. They offer maximum freedom of movement, making them a popular choice among advanced players. However, they may require additional accessories to keep them in place during intense gameplay.

- Lightweight and flexible

- Preferred by experienced players

- May need tape, stays, or compression sleeves for secure fit

Ankle Shin Guards

Ankle shin guards provide additional protection for both the shin and ankle areas. They are often recommended for youth and intermediate players due to their comprehensive coverage.

- Extra padding on both sides of the ankle

- Secured with stirrups and straps

- Some models feature removable ankle guards for versatility

Shin Socks

Shin socks combine protective guards with the sock itself, offering a convenient all-in-one solution. This hassle-free design makes them particularly popular among young players.

- Built-in protection

- Easy to use

- Great for youth players

Position-Specific Shin Guard Features: Enhancing Your Performance on the Field

Your position on the soccer field can significantly influence the type of shin guard that will best suit your needs. Let’s break down the key considerations for each role:

Defenders: Maximum Protection

As a defender, you’re likely to face more physical challenges and tackles. Your shin guards should prioritize robust protection.

- Heavier, more durable construction

- Ample coverage area

- Consider options with ankle protection

Midfielders: Balanced Protection and Flexibility

Midfielders require shin guards that offer a good balance between protection and freedom of movement.

- Medium-weight options

- Moderate coverage area

- Focus on flexibility for quick direction changes

Forwards: Lightweight and Agile

Forwards need shin guards that allow for explosive speed and agility without compromising on safety.

- Lightest available options

- Minimal design for unrestricted movement

- Emphasis on speed and maneuverability

Goalkeepers: Minimal Protection

Goalkeepers typically require the least amount of shin protection due to the nature of their position.

- Lightweight options

- Minimal padding

- Focus on comfort and flexibility

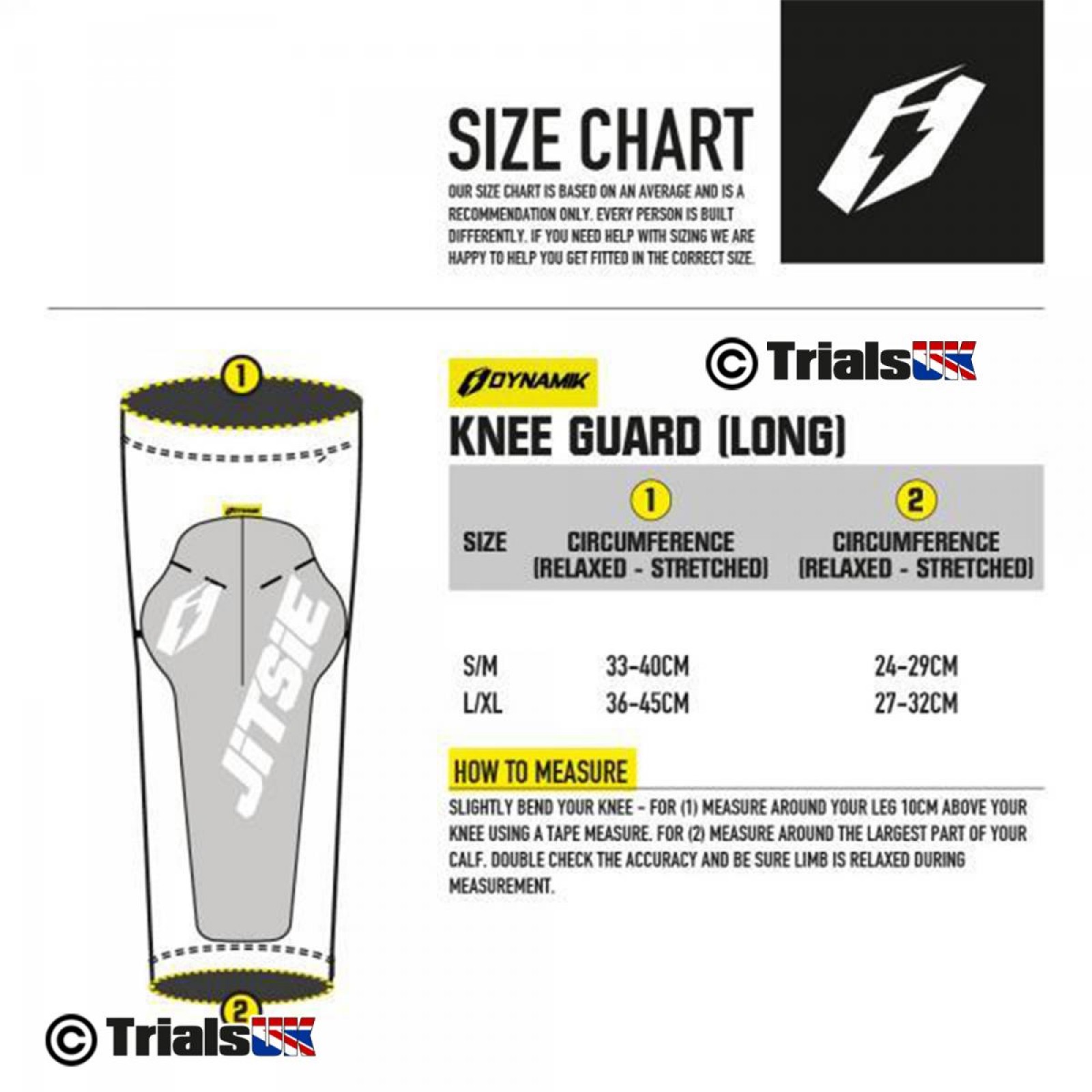

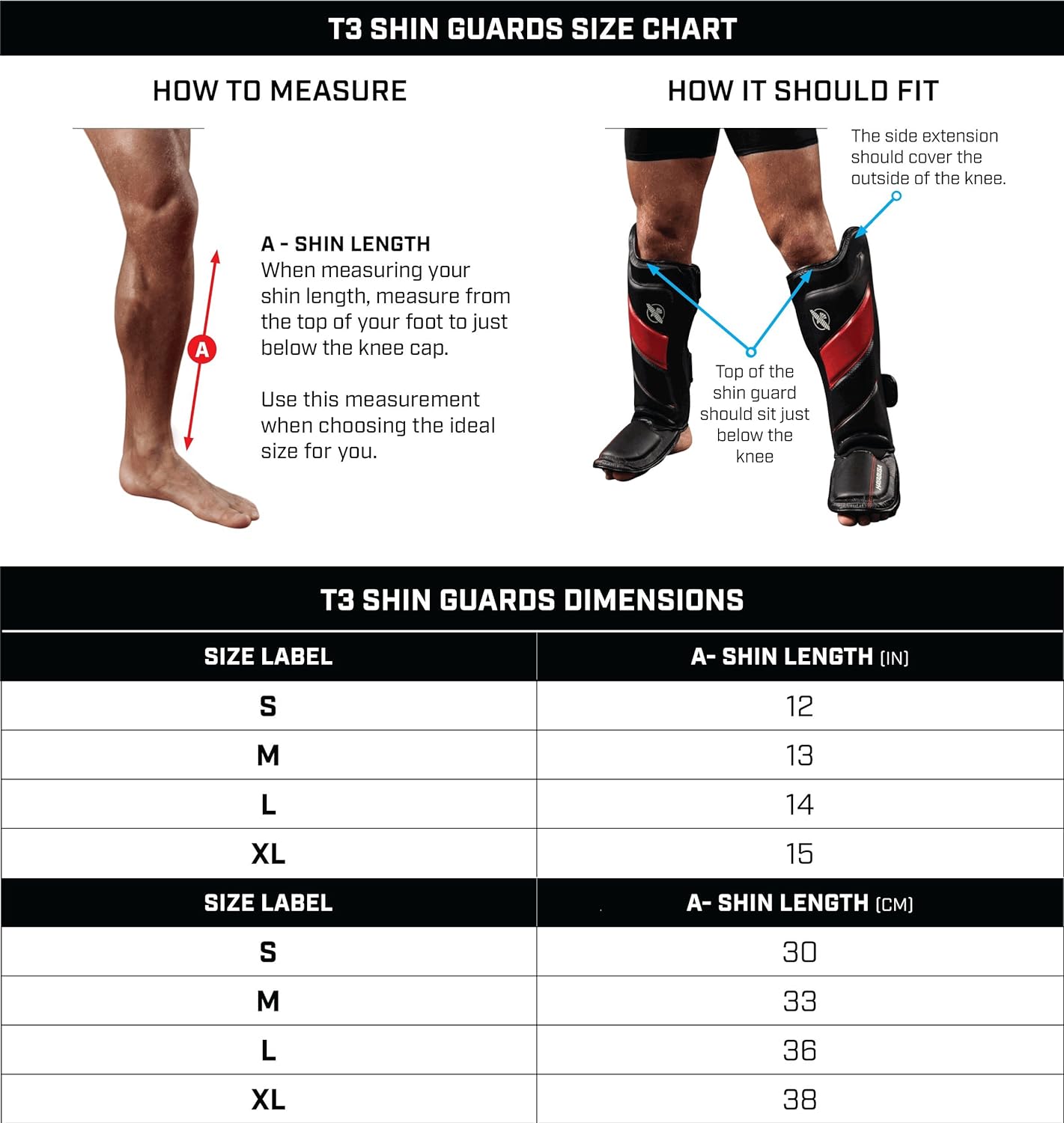

Sizing Your Shin Guards: Ensuring Proper Fit for Optimal Protection

Proper sizing is crucial for shin guards to provide effective protection without hindering your performance. Here are some key guidelines to follow:

- Shin guard size is primarily determined by player height

- They should cover most of the area between your ankle and knee

- Aim for shin guards to end at least 2 inches below the knee

- Ensure a snug fit to prevent shifting during play

To help you find the right size, here’s a general sizing chart based on player height:

| Player Height | Recommended Shin Guard Size |

|---|---|

| 3’4″ – 3’8″ | XXS |

| 3’9″ – 4’5″ | XS |

| 4’6″ – 5’2″ | S |

| 5’3″ – 5’7″ | M |

| 5’8″ – 5’11” | L |

| 6’0″ and above | XL |

Remember that sizing may vary slightly between manufacturers, so always check the specific size chart for the brand you’re considering.

Essential Shin Guard Accessories: Enhancing Comfort and Security

To maximize the effectiveness of your shin guards, consider these useful accessories:

Shin Guard Sleeves

Shin guard sleeves help keep slip-in guards securely in place during intense gameplay.

- Provide compression for a snug fit

- Often made of moisture-wicking material

- Can offer additional protection against minor impacts

Shin Guard Tape

Athletic tape can be used to further secure shin guards and prevent them from shifting.

- Allows for customizable tightness

- Can be applied over socks

- Easy to remove and replace as needed

Shin Guard Stays

Shin guard stays are an alternative to tape, offering a reusable solution for keeping guards in place.

- Often feature hook-and-loop closures

- Easy to adjust during play

- More environmentally friendly than disposable tape

Ankle Guards

For players using slip-in shin guards who want additional ankle protection, separate ankle guards can be a valuable addition.

- Provide extra cushioning around the ankle bones

- Can be worn with or without shin guards

- Ideal for players transitioning from full ankle shin guards

Regulatory Compliance: Ensuring Your Shin Guards Meet Safety Standards

When selecting shin guards, it’s important to consider any applicable safety regulations, especially for competitive play.

For high school level soccer in many regions, shin guards must be approved by the National Operating Committee on Standards for Athletic Equipment (NOCSAE). Look for the NOCSAE stamp on the front of the shin guard to ensure compliance.

Other leagues and organizations may have their own specific requirements, so it’s always a good idea to check with your coach or league officials about any regulations regarding shin guard use.

Maintenance and Care: Prolonging the Life of Your Shin Guards

Proper care and maintenance of your shin guards can help extend their lifespan and ensure they continue to provide optimal protection. Here are some tips to keep your shin guards in top condition:

- Air out your shin guards after each use to prevent odor buildup

- Clean them regularly with mild soap and water

- Avoid exposing shin guards to extreme heat or direct sunlight for prolonged periods

- Check for signs of wear and tear, such as cracks or significant compression of padding

- Replace your shin guards when they no longer provide adequate protection or fit properly

Advanced Features in Modern Shin Guards: Innovations in Protection Technology

As soccer equipment technology continues to evolve, shin guards are benefiting from innovative features designed to enhance protection, comfort, and performance. Let’s explore some of the advanced features you might encounter in modern shin guards:

Impact-Dispersing Materials

Many high-end shin guards now incorporate advanced materials that help distribute impact forces across a wider area, reducing the risk of injury.

- Foam compounds that harden upon impact

- Gel inserts for improved shock absorption

- Carbon fiber or similar lightweight, high-strength materials

Breathable Designs

To combat heat buildup and improve comfort during play, manufacturers are developing shin guards with enhanced ventilation features.

- Perforated shells for increased airflow

- Moisture-wicking liners

- Channeled designs to promote air circulation

Anatomical Shaping

Advanced shin guards often feature contoured designs that better conform to the natural shape of the leg, providing improved fit and protection.

- Pre-curved construction

- Left/right specific models

- Flexible materials that adapt to individual leg shapes

Antimicrobial Treatments

To combat odor-causing bacteria and extend the freshness of shin guards, some manufacturers apply antimicrobial treatments to their products.

- Silver-based compounds

- Zinc pyrithione or similar antimicrobial agents

- Odor-resistant materials

When shopping for shin guards, consider these advanced features alongside traditional factors like size, protection level, and position-specific requirements to find the best option for your needs.

Customization Options: Personalizing Your Shin Guards

For players looking to add a personal touch to their equipment, many manufacturers now offer customization options for shin guards. These can range from simple aesthetic choices to functional modifications:

Color and Design Options

Express your personal style or match your team colors with customizable shin guard exteriors.

- Choose from a range of colors and patterns

- Add team logos or personal insignia

- Select from various finishes (matte, glossy, etc.)

Personalized Fit

Some high-end shin guard options allow for a more tailored fit to your leg shape.

- Heat-moldable materials that conform to your leg

- Adjustable padding placement

- Interchangeable components for versatility

Custom Protection Levels

Certain brands offer modular shin guard systems that allow you to adjust the level of protection based on your needs.

- Add or remove padding layers

- Interchange different guard plates

- Combine with additional protective accessories

While customization options can add to the cost of shin guards, they may be worth considering for players who prioritize comfort, style, or specific performance features.

Environmental Considerations: Sustainable Shin Guard Options

As environmental awareness grows in the sports industry, some manufacturers are developing more sustainable shin guard options. If eco-friendliness is a priority for you, consider looking for shin guards with the following features:

Recycled Materials

Many brands now incorporate recycled plastics and other materials into their shin guard construction.

- Shells made from recycled ocean plastics

- Padding derived from recycled foam products

- Packaging made from post-consumer recycled materials

Biodegradable Components

Some innovative shin guard designs incorporate biodegradable materials to reduce long-term environmental impact.

- Plant-based plastics for non-critical components

- Biodegradable foam padding options

- Compostable packaging materials

Durability for Longevity

While not explicitly marketed as an eco-friendly feature, shin guards designed for long-term durability can help reduce waste by lasting longer.

- High-quality materials resistant to wear and tear

- Replaceable components to extend overall lifespan

- Timeless designs that won’t quickly become outdated

By considering these environmentally conscious options, you can make a choice that aligns with your values while still ensuring proper protection on the field.

Frequently Asked Questions: Addressing Common Shin Guard Concerns

To help address some of the most common questions and concerns about soccer shin guards, here’s a quick FAQ section:

How often should I replace my shin guards?

The lifespan of shin guards can vary depending on usage and quality, but as a general rule, you should replace them when you notice significant wear, reduced protection, or if they no longer fit properly. For most players, this typically means every 1-2 seasons.

Can I wear my shin guards over my socks?

While it’s possible to wear shin guards over socks, it’s generally recommended to wear them under your socks for better fit and to comply with most league regulations.

Are more expensive shin guards always better?

Not necessarily. While higher-priced shin guards often offer advanced features or materials, the best shin guard for you depends on your specific needs, playing style, and comfort preferences. Sometimes, a mid-range option may provide the perfect balance of protection and value.

Can I use the same shin guards for other sports?

While some shin guards may be suitable for multiple sports, it’s generally best to use sport-specific protection. Soccer shin guards are designed with the unique demands of the sport in mind and may not provide adequate protection for other activities.

How tight should shin guards be?

Shin guards should fit snugly against your leg without being uncomfortable or restricting movement. They should stay in place during active play but not cause any pinching or chafing.

By considering these common questions and the detailed information provided throughout this guide, you’ll be well-equipped to choose the perfect shin guards for your soccer needs, ensuring both protection and performance on the field.

How to Choose Soccer Shin Guards

Shin guards are likely the most important piece of equipment a soccer player will buy. Why? Because EVERYONE on the field — no matter the level of play — must wear them. How can you make sure you get the right fit?

First, let’s look at the three main types of shin guards.

SLIP-IN SHIN GUARDS

Slip-in shin guards are lightweight shields that can be worn right under your socks. Some socks are snug enough to keep the shin guards from moving, but many players prefer to use tape, stays or compression sleeves to keep the shields in place throughout the game. More advanced players typically prefer slip-in shin guards for the freedom of movement they offer.

ANKLE SHIN GUARDS

Because of the additional protection they provide, ankle shin guards are typically recommended for youth and intermediate players. This style offers additional padding on both sides of the ankle to shield it from kicks. Most ankle shin guards feature stirrups that slide under the feet, along with a hook-and-loop strap or elastic band that wraps around the calf to ensure a secure fit. Some brands offer styles with removable ankle guards, allowing players to wear only the shin shield as they get older and progress.

Most ankle shin guards feature stirrups that slide under the feet, along with a hook-and-loop strap or elastic band that wraps around the calf to ensure a secure fit. Some brands offer styles with removable ankle guards, allowing players to wear only the shin shield as they get older and progress.

SHIN SOCKS

As the name implies, shin socks are built into the socks for convenience. Because of the hassle-free design, shin socks are a popular choice for youth players.

Keep in mind: Shin guards worn at the high school level must be approved by the National Operating Committee on Standards for Athletic Equipment (NOCSAE). Look for the NOCSAE stamp on the front of the shin guard.

CONSIDER YOUR POSITION

If you primarily play one position, you’ll want to look for specific features in your shin guards to enhance your game.

- Defenders: Defenders can take a lot of punishment, so they should look for a heavier shin guard with ample protection, perhaps including ankle coverage.

- Midfielders: If you’re a midfielder, you’ll need a balance of protection and flexibility that won’t restrict your movement.

- Forwards: Forwards need shin guards that allow for explosive bursts of speed and quick changes in direction as they elude defenders on their way to the net. Forwards will want to find the lightest, smallest shin guards available for optimum mobility.

- Goalkeepers: Goalkeepers require the least protection of all positions. Look for a lightweight option with minimal padding.

SIZING

Finally, you need to make sure your shin guards fit properly. Shin guard sizing is determined by the height of the player. When choosing a pair of shin guards from DICKS.com, you will see sizing guidelines in the product description. Make sure to read the size chart carefully to ensure a great fit.

You’ll want your shin guards to cover most of the area between your ankle and knee. Shin guards should fit snugly and be at least 2″ below the knee.

Shin guards should fit snugly and be at least 2″ below the knee.

SHIN GUARD ACCESSORIES

There are a few shin guard accessories you may want to consider in order to have the best possible experience on the pitch.

- Shin Guard Sleeves: As mentioned earlier, if you wear slip-in shin guards, you may want to wear shin guard sleeves to ensure a snug fit. The last thing you want is your shin guards sliding down your leg when the game is on the line.

- Shin Guard Tape: Typically, players who use shin guard tape will wrap it over their socks at both the top and bottom of the shin guard to hold it in place. The one clear advantage of shin guard tape is that it allows the player to decide how firm of a hold they want on the shin guard.

- Shin Guard Stays: If you find tape to be a hassle or simply uncomfortable, shin guard stays are a great alternative. Most shin guard stays wrap around your leg with a hook-and-loop closure to hold your shin guards in place.

- Ankle Guards: If you opt for a pair of shin guards that does not come with ankle guards, you can always add them later if you decide you need them. They are sold separately, typically with the same stirrup design found in ankle shin guards.

Shin Guard Size Chart – SoccerPro

Shin Guard Size Chart

The sizes listed below are considered common size conversions. SoccerPro accepts no responsibility for shoes that do not fit properly. Specific sizes may vary by manufacturer and/or style. Please contact SoccerPro with any questions regarding soccer shinguard sizing.

| Size (in inches) | Manufacturer | |||

adidas | Puma | Nike | Nike Shin Sock | |

| XXS | 2′ 11″ | 3′ 7″ |

|

|

| XS | 3′ 11″ | 3′ 9″ | 5′ 5″ or shorter |

|

| S | 4′ 7″ | 4′ 5″ | 5′ 5″ – 5′ 7 1/2″ | S/M: 3’4″ – 3′ 8″ |

| M | 5″ 3″ | 5′ 1″ | 5′ 7 1/2″ – 5′ 10″ | S/M: 3’4″ – 3′ 8″ |

| L | 5′ 11″ | 5′ 9″ | 5′ 10″ or taller | M/L: 3′ 8″ – 4′ 2″ |

| XL | 6′ 3″ | 6′ 5″ |

| L/XL: 4′ 2″ – 4′ 7″ |

| XXL | 6′ 6″ |

|

| |

Full90 Headgear Sizing

Use the sizing chart below in order to get the best fit. Use a flexible tape measure around the widest part of the head, just above the ears and eyebrows, to the nearest half inch.

Use a flexible tape measure around the widest part of the head, just above the ears and eyebrows, to the nearest half inch.

| SIZE | INCHES | CM |

|---|---|---|

| S/M | 19 – 22 | 49 – 56 |

| L | 21 7/8 – 24 | 55 – 62 |

Post navigation

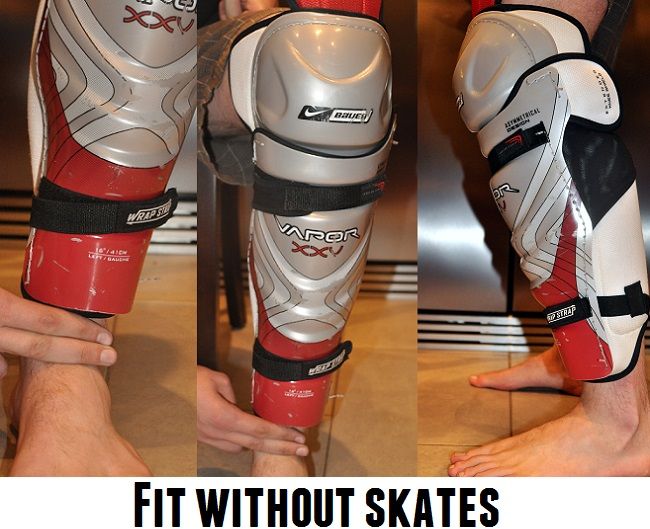

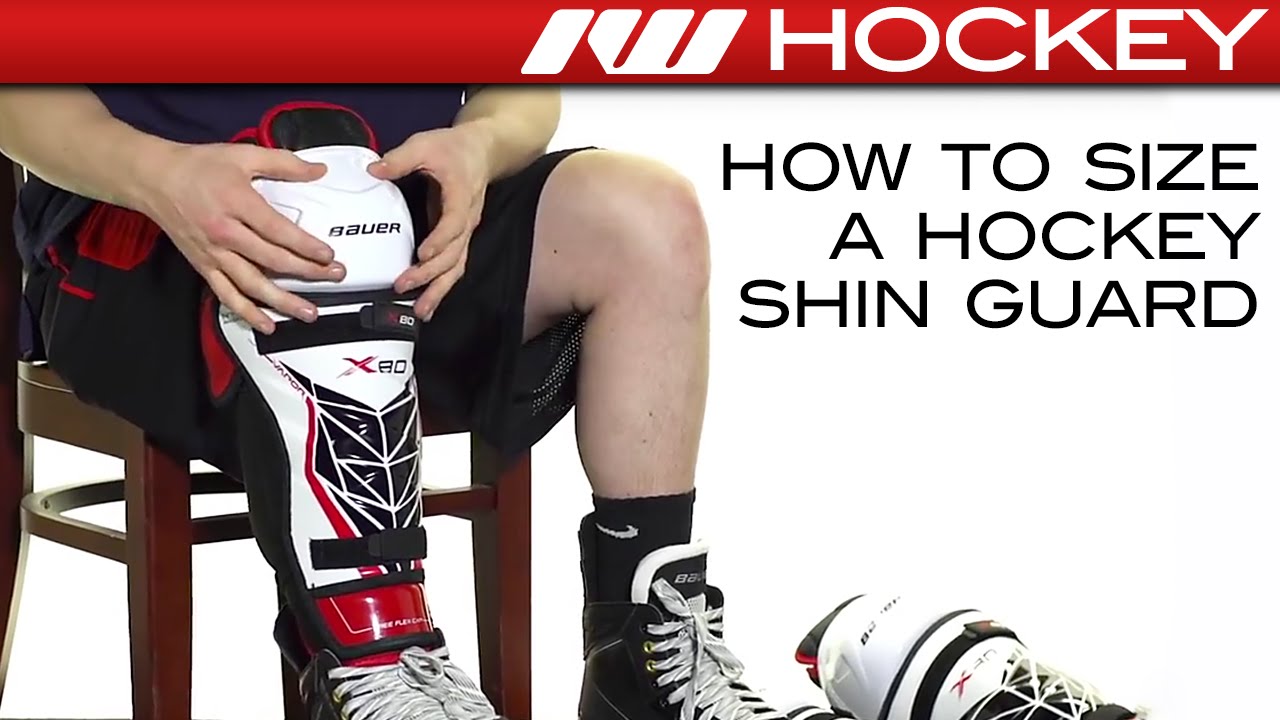

How to Size a Hockey Shin Guard

Shin Guards can either be worn above or below the skate tongue. One isn’t better than the other and the choice is a completely personal preference. However, each one requires a different measurement to ensure a proper fit for complete coverage and the necessary range of motion.

Over the Skate Tongue – Shin Guard Sizing

Sitting at a 90 angle with skates on your feet, measure from the center of your kneecap to 1” below the top of the skate’s tongue. Correspond this measurement with the sizing chart below or on the description page.

Correspond this measurement with the sizing chart below or on the description page.

Under the Skate Tongue – Shin Guard Sizing

Sitting at a 90 angle with skates on your feet, measure from the center of your kneecap to the top of the skate’s tongue. Correspond this measurement with the sizing chart below or on the description page.

Strap the shin guard to your leg and make sure to have it over or under the skate tongue depending on the measurement you previously took.

All gaps are sealed between the skate and the shin guard, thus ensuring complete coverage and protection. The knee should rest at the center of the knee doughnut, providing full leg mobility.

If the shin guards are too small, there will be visible gaps in protection between the skates and the shin guards, which increases the risk of injury. If the knee is above or below the center of the knee doughnut, it will inhibit the range of motion needed for the skating stride.

The information below is a general sizing guideline and DOES NOT guarantee fit. The chart is not specific to any item or brand so if a product does have specific sizing guidelines on the product page, DO NOT reference the general sizing guidelines below.

| Pad Size | Shin | Height |

|---|---|---|

| 8″ | 7″ – 8″ | 3’4″ – 3’9″ |

| 9″ | 8″ – 9″ | 3’8″ – 4’1″ |

| 10″ | 9″ – 10″ | 4′ – 4’6″ |

| 11″ | 10″ – 11″ | 4’4″ – 4’8″ |

| 12″ | 11″ – 12″ | 4’8″ – 5’2″ |

| 13″ | 12″ – 13″ | 5’1″ – 5’6″ |

| 14″ | 13″ – 14″ | 5’5″ – 5’8″ |

| 15″ | 14″ – 15″ | 5’7″ – 5’11” |

| 16″ | 15″ – 16″ | 5’10” – 6’2″ |

| 17″ | 16″ – 17″ | 6’1″+ |

Now that you have found out what size you should wear, check out our quick buying guide below that will help you figure out what level of play and what shin guard fit profile best suits your needs!

Shin Guard Size Chart – Soccer Master

Shin Guard Size Chart

The sizes listed below are considered common size conversions. Soccer Master accepts no responsibility for shoes that do not fit properly. Specific sizes may vary by manufacturer and/or style. Please contact Soccer Master with any questions regarding shinguard sizing.

Soccer Master accepts no responsibility for shoes that do not fit properly. Specific sizes may vary by manufacturer and/or style. Please contact Soccer Master with any questions regarding shinguard sizing.

| Size (in inches) | Manufacturer | |||

adidas | Puma | Nike | Nike Shin Sock | |

| XXS | 2′ 11″ | 3′ 7″ |

|

|

| XS | 3′ 11″ | 3′ 9″ | 5′ 5″ or shorter |

|

| S | 4′ 7″ | 4′ 5″ | 5′ 5″ – 5′ 7 1/2″ | S/M: 3’4″ – 3′ 8″ |

| M | 5″ 3″ | 5′ 1″ | 5′ 7 1/2″ – 5′ 10″ | S/M: 3’4″ – 3′ 8″ |

| L | 5′ 11″ | 5′ 9″ | 5′ 10″ or taller | M/L: 3′ 8″ – 4′ 2″ |

| XL | 6′ 3″ | 6′ 5″ |

| L/XL: 4′ 2″ – 4′ 7″ |

| XXL | 6′ 6″ |

|

| |

Full90 Headgear Sizing

Use the sizing chart below in order to get the best fit. Use a flexible tape measure around the widest part of the head, just above the ears and eyebrows, to the nearest half inch.

Use a flexible tape measure around the widest part of the head, just above the ears and eyebrows, to the nearest half inch.

| SIZE | INCHES | CM |

|---|---|---|

| S/M | 19 – 22 | 49 – 56 |

| L | 21 7/8 – 24 | 55 – 62 |

How to Measure Shin Guards

As their name suggests, ice hockey shin guards are meant to guard a player’s shins and lower leg from fast-flying pucks and sticks. In order to achieve the ultimate protection and comfort, it’s important to know how to size shin guards properly.

Here, we’ll give you everything you need to know about shin guards – sizes, comfort and finding the right fit. We’ll take a look at:

Hockey Shin Guard Sizing Chart

Shin guards are a vital piece of equipment for any serious hockey player. With pucks flying up to 100 mph, there’s no arguing: ice hockey is a fast game. Pucks are shot hard, sticks are in constant motion and sometimes the only thing to save a player from serious injury is properly fitted gear…shin guards included. But with so many hockey shin guard sizes, it can be hard to know which one is best. Using this shin guard size chart, you can find proper sizing guidelines, from youth shin guard sizing all the way through adult hockey shin pad sizes, just by using height and leg measurements.

With pucks flying up to 100 mph, there’s no arguing: ice hockey is a fast game. Pucks are shot hard, sticks are in constant motion and sometimes the only thing to save a player from serious injury is properly fitted gear…shin guards included. But with so many hockey shin guard sizes, it can be hard to know which one is best. Using this shin guard size chart, you can find proper sizing guidelines, from youth shin guard sizing all the way through adult hockey shin pad sizes, just by using height and leg measurements.

| Hockey Shin Guard Sizing Chart | |||

|---|---|---|---|

| Shin Guard Size | Knee Cap to Ankle (in.) | Height (ft.) | |

| Youth | 7″ | 6 – 7″ | 3’3″ – 4’5″ |

| 8″ | 7 – 8″ | 3’9″ – 4’7″ | |

| 9″ | 8 – 9″ | 4’3″ – 4’9″ | |

| Junior | 10″ | 9 – 11″ | 4’5″ – 4’11” |

| 11″ | 10 – 11″ | 4’7″ – 5’1″ | |

| 12″ | 10 – 12″ | 4’9″ – 5’4″ | |

| Senior | 13″ | 12 – 13″ | 5’5″ – 5’9″ |

| 14″ | 13 – 14″ | 5’7″ – 5’11” | |

| 15″ | 14 – 15″ | 5’9″ – 6’1″ | |

| 16″ | 15 – 16″ | 5’11” – 6’3″ | |

| 17″ | 16 – 17″ | 6’1″ – 6’3″ | |

| 18″ | 17 – 18″ | 6’3″ + | |

How to Measure Hockey Shin Guard Sizes

Follow these steps:

- Put on your hockey skates and tie them as if you were ready to play.

- Sit down on a chair or bench with your feet flat on the floor and legs bent at the knee at a 90-degree angle.

- Measure the distance from the top of your skate boot to the center of your knee cap.

- The distance you measure, rounded up to the nearest inch, is a good starting point for knowing what size shin guard you need.

Keep in mind, not every hockey player of the same height has the same sized legs, so going strictly by our shin guard size chart may not give you the perfect fit, but it really is a great place to start if you’re not sure what size to go with.

There is room to go up or down a size based on personal preference. Some players prefer to wear the shin guard over the tongue of the skate, in which case they may go with a larger size. Other players might like them to fit under the tongue of the skate, and they can generally go with a smaller size.

The important thing to remember is to make sure that neither the knee cap, nor the ankle, is exposed. If your shin guards are too small, you may end up with parts of your leg exposed to slashing sticks and 100-mph pucks. And if your shin guards are too big, you risk restricting your movement and an uncomfortable fit.

If your shin guards are too small, you may end up with parts of your leg exposed to slashing sticks and 100-mph pucks. And if your shin guards are too big, you risk restricting your movement and an uncomfortable fit.

Parts of a Hockey Shin Guard

Hockey shin guards can be broken down into six main parts.

- Upper Knee Flap: The upper knee flap protects the top of the knee. It’s flexibly-attached to allow it to move when the leg flexes.

- Knee Cap: The knee cap is composed of hard material to protect the knee from pucks, sticks and falls.

- Inner Lining: The inner lining is padded and made from soft material to provide a comfortable fit.

- Knee Flap: The knee flap is flexible enough to move as a player skates while protecting the sides of the knee.

- Shell: The shell covers the shin and can protect against a flying puck or a slashing stick.

- Calf Protector: The calf protector provides protection for the back of a player’s leg.

Hockey Shin Guard Brands

As with all equipment, there are many brands of shin guards to choose from. Often, what it generally comes down to is personal preference based on comfort and brand loyalty. But, there are a few brands well-known in the world of hockey that players love and gravitate to most for a variety of reasons.

- Bauer – variety of styles and fits to choose from, maximized protection, comfort and fit.

- CCM – lightweight without compromising any protection, great movement.

- Warrior – multiple styles available, known for their Polygiene odor-fighting technology.

Common Hockey Shin Guard Questions

How to Clean Hockey Shin Guards

Hockey shin guards can be washed in your washing machine. Use a bleach-free detergent and wash on a gentle cycle. To help remove odors, you can add white vinegar at the same time as detergent. Make sure you air dry your shin guards, rather than using your clothes dryer.

How to Tape Hockey Shin Guards

In order to ensure a snug fit and prevent shin guards from moving during play, most players use sock tape to keep their shin guards in place. There are a few different ways to tape for a tight fit. Follow these steps:

- Make sure you tape over your hockey socks. This will hold both your socks and shin guards in place.

- Start just below the knee and tape around the leg multiple times.

- Repeat this process just above the ankle or mid-calf.

- Some players will add an extra diagonal wrap of tape between the two

Taping your shin guards is a personalized process, so it’s ok to experiment to find what’s most comfortable for you.

What are hockey shin guards made out of?

Modern hockey shin guards are made from numerous types of materials. Some shin guards are constructed from composite plastics, fiberglass and polyurethane.

Looking for new shin guards? HockeyMonkey has all the gear you need, and with dozens of brands and styles to choose from, you’re sure to find the right pair of shin guards that are both comfortable and protective.

How To Fit Hockey Shinguards

by Source For Sports Tips for Parents

Hockey shin guards are designed to protect a player’s legs from pucks, slashes, impacts and skate blades, and are an important part of the complete protection series.

Hockey shin guards are designed to protect a player’s legs from pucks, slashes, impacts and skate blades, and are an important part of the complete protection series. Choosing a size and model will vary based on your personal preferences, playing style and position, but will also need to integrate with your hockey skates and pants.

Shin guards are designed with a knee cap that is padded on the inside, and a hard shell exterior that covers the front and sides of the leg from the knee to the ankle. They are ergonomically designed to be wider at the top under the knee cap, and tapering down to a narrower profile at the ankle. Above the knee cap will be a flap that fits under your hockey pant

Above the knee cap will be a flap that fits under your hockey pant

Other shin guard design details that will vary between manufacturers include:

- Velcro fastening straps that offer a custom fit may either attach laterally or cross diagonally behind the calf for a more secure fit, and can vary from a 2-strap system or a 3-strap system.

- Some designs offer a cap at the bottom of the shin guard that flexes with your ankle for greater forward flex in your skate.

- There are some models with removable padding so you may wash them in your home machine.

- The front molded piece can vary in width, which will have a significance if you are on defence and require more coverage, or a forward who is relying on speed to move the puck down the ice.

To determine the correct size shin guards, it is best to have your skates and hockey pants on first so that you can see and feel how they incorporate with the rest of your equipment. The first thing you have to decide is whether you prefer to have the tongue of your skate in front of the shin guard (over) or behind the shin guard (under). Generally if you play with your shin over the tongue, you will need a bit of extra length to compensate for the bulk of the skate tongue.

Generally if you play with your shin over the tongue, you will need a bit of extra length to compensate for the bulk of the skate tongue.

Shin guards are sized in inches. With a measuring tape, measure the distance from the centre of your kneecap, straight down the front of your shin to the point where your shin meets the inside of your skate – this correlates to approximately 1 inch above the center of the outside ankle bone. This measurement will indicate the size of your shin guards, which are generally sized as follows:

- YOUTH 8” – 10”

- JUNIOR 11” – 13”

- SENIOR 14” – 18”

Using this measurement as a starting point, try on the corresponding size of shin guards, checking that you have the Left and Right pads on the proper legs, and that your knee fits in the cap and is cradled snugly. Fasten the straps of the calf wraps, ensuring that they enclose your lower leg with no gaps. The lower bottom edges of the shin guards curve upward to fit the tendon guards of your skates like a puzzle piece; when properly fitted, there will be no gap between the ankle pad of the skates and the lower edges of the shin guards. If it is too long, you will have difficulty flexing your ankle; if too short, your ankle will be exposed and the calf wraps may not go all the way around your leg. You should be able to bend your knee and have ankle flex with no restriction of movement. When you put your hockey pants on, the top flaps of the shin guards should fit under the pant legs, giving a seamless covering from waist to ankle.

If it is too long, you will have difficulty flexing your ankle; if too short, your ankle will be exposed and the calf wraps may not go all the way around your leg. You should be able to bend your knee and have ankle flex with no restriction of movement. When you put your hockey pants on, the top flaps of the shin guards should fit under the pant legs, giving a seamless covering from waist to ankle.

Having the right size of equipment will not only protect you on the ice, but will be comfortable and allow you to perform your best.

Check out our shin guards, and come to Source For Sports to experience the Pro-Formance Advantage Custom Fitting System that guarantees you get the right gear for your game.

Source For Sports. We know our stuff.

5 Best Youth Shin Guards – Oct. 2021

One reason soccer is a popular sport worldwide is because it doesn’t actually cost much to play. All you really need is a ball, and you can improvise the rest for a fun pickup game.

But if your child is on a team, one of the must-have pieces of safety gear is a pair of shin guards. Youth shin guards allow players to reduce their injury risk, and they’re often mandatory for some leagues and teams. If this is your first time shopping for a pair, you’ll soon learn there are many styles to choose from and, depending on which position your child plays, some may provide better protection than others.

To learn more, read our shopping guide with helpful tips for choosing the best pair of youth shin guards. If you’re ready to buy, check out our top picks.

Key considerations

Design

When shopping for the right shin guards for your youth player, it’s helpful to understand the three different styles of shin guards. Some will be more comfortable to wear; others will provide a higher level of protection. [If your child is also in need of footwear, take a look at our recommended soccer cleats for kids.]

- Ankle shin guards: While chasing the soccer ball, younger players will receive a high level of protection with these.

This style has extra padding for the ankle area, as it wraps around the shin, protecting against collisions from the sides. It also has a hard plastic shield to protect the shins. Some of these guards have stirrups that stretch under the foot, holding them in place. An additional strap fits around the calf for more support.

This style has extra padding for the ankle area, as it wraps around the shin, protecting against collisions from the sides. It also has a hard plastic shield to protect the shins. Some of these guards have stirrups that stretch under the foot, holding them in place. An additional strap fits around the calf for more support. - Slip-in shin guards: The slip-in style of shin guard is the easiest to wear for kids. It slips inside the long socks that the soccer player wears. It allows for the highest level of freedom of movement for players, making it a comfortable choice. However, some socks may not be tight enough to the leg to hold the slip-in guard in place. In this case, you’ll want shin guard tape, a compression sleeve, or a tighter sock to keep the shin guard from slipping.

- Socks with shin guards: Another good choice for young players who may balk at wearing shin guards is a pair of socks with guards built into them. This type of sock has the shin guard sewn into it or has a pocket for a separate shin guard, which makes these more comfortable for players.

Parents never have to worry about the kids forgetting the shin guards at home when the guards are sewn into the sock.

Parents never have to worry about the kids forgetting the shin guards at home when the guards are sewn into the sock.

Did you know?

Some youth leagues require that players use shin guard tape that’s the same color as the player’s socks.

STAFF

BestReviews

Features

Outer materials

The exterior of the shin guard needs to consist of a hard material. This protects the shin bone from blows from other players. This front plate often will consist of a hard plastic or carbon-fiber material. Outer plates typically are one piece, but some may consist of two or three interconnected pieces for flexibility.

Inner materials

The material on the backside of the shin guard will be softer to provide cushion when another player strikes the front of the shin guard. It also absorbs the impact of the strike, protecting the shin. Foam is a common inner material for the shin guard. Some players will wear a thin sock under the shin guard to protect against abrasions.

Accessories

Most youth shin guards are able to accommodate accessories for additional protective features. To make a slip-in shin guard fit tighter, you may want to place it inside a compression sleeve that’s made specifically for a guard. Shin guard tape is another common option to hold a shin guard in place. It wraps over the top of the sock.

“Soccer rules for nearly all leagues require that a player’s shin guard is completely covered by an exterior sock or stocking.”

STAFF

BestReviews

Youth shin guard prices

As a general rule, youth shin guards aren’t expensive pieces of athletic equipment. When purchasing shin guards, they ship in pairs, which ensures you’ll receive a good value.

The least expensive shin guards will cost $10 to $20 for the pair. Typically, these are made for really young children. (Larger shin guards have more material in them and tend to cost more.) Shin guards for preteens may cost $15 to $30. For teenagers, you can expect to pay $15 to $40 for the pair.

Always pay attention to what’s included in your purchase. For example, some basic shin guards may require a purchase of straps, shin guard tape, or compression sleeves separately, which may add $5 to $15 to your purchase.

Tips

We’ve put together some tips that can help you determine the best type of shin guard for your child to wear, based on the soccer position he or she plays.

- Defenders need a heavy shin guard. Defenders, who are the primary defensive players, occasionally will collide with strikers during normal game play. To receive extra protection, they will want to use a thicker shin guard. Some may even want an ankle shin guard for wrap-around protection.

- Midfielders need an all-around shin guard. Because midfielders can be playing offense or defense at any point in the game, they need both a flexible and protective shin guard. You don’t want an overly thick shin guard that restricts movement too severely.

- Forwards and goalkeepers need a flexible shin guard. Forwards, the primary offensive players, need the least protection from a shin guard. They need to change direction quickly, so a lightweight shin guard is the smartest choice. Goalkeepers also need to be able to move quickly, so they’ll want a similar lightweight shin guard.

- Kids without a specific position need an all-around shin guard. If your youth player plays multiple positions, consider a shin guard with both flexibility and protection. This would be similar to the shin guard a midfielder would wear.

FAQ

Q. Does my child need shin guards every time he or she plays soccer?

A. If your child is just practicing in the backyard, shin guards aren’t really required. Practices where there’s no chance of your child colliding with another player probably don’t require shin guards either. Shin guards are a necessity during competitive games or practices. Some youth leagues will have specific rules on when and how shin guards must be used.

Q. Beyond soccer, in which youth sports are shin guards commonly worn?A. Some youth sports leagues require shin guards, such as ice hockey, field hockey, lacrosse, and football. Soccer is the most common youth sport for using shin guards. But if your child plays more than one sport, you may be able to use the same shin guards to give you a nice value. Baseball and softball catchers also wear shin guards, but these are larger and designed differently than other sports’ shin guards.

Q. How much of the lower leg should the shin guard protect?

A. It’s important to select the proper size of shin guard for a youth player. An ill-fitting shin guard will be uncomfortable and restrict movement, and it won’t protect the player properly. The shin guard should stretch from the top of the ankle to just a couple of inches below where the knee bends. Many manufacturers use the child’s overall height to help you find the right size.

Q. What’s the proper way to wear shin guards?

A. Players often will want to put on long, thin socks and then attach the shin guards over these. They’ll then wear additional socks (or stockings) over the top of the shin guards. The inner layer of socks prevents the shin guards from rubbing directly on the skin.

How to choose hockey pads | Hockey Without Borders

Hockey pads are necessary for reliable protection and fixation of the knee joint, as well as the athlete’s lower leg, from various mechanical injuries, including blows with a stick or hit with a puck. Their design consists of two main elements. This is an additional part made of special fabric with a shock-absorbing effect and equipped with comfortable adjustment straps. And also the main one, which is made of high-strength plastic and protects the cup and lower leg.

If you are not sure how to choose your hockey shin guards and not make a mistake, then you should pay attention to the following points:

- Be sure to measure the shin length. It is measured from the middle of the kneecap to the top of the ridge. You can determine the size of a suitable model from a special table that is available on the websites of online stores with hockey products.

- Defenders should pay attention to shields with an increased level of protection, which will allow you to painlessly block shots.

- Forwards will be interested in lightweight models that provide agility on the playing field.

Today, there are a huge number of options available from different manufacturers, which can have several layers on the lining of the shin guards, most often removable, as well as an adjustable ankle protector.

Additional Features

It is important to remember that all shin guards, both for amateurs and professionals, are divided into models for goalkeepers, defenders and strikers.The options for defenders are slightly wider than others, they have special overlays, but they restrict movement. Striker models are streamlined and lightweight.

If you have any questions about how to choose your hockey pads, you can take advantage of the professional help of our experienced managers. They will be happy to provide you with additional information regarding the available models and answer all your questions.

How to choose Muay Thai leg guards?

Shingards are one of the most important accessories for a successful Muay Thai training.These are special shields on the legs, which are considered strictly mandatory everywhere: without them, a fighter will not be allowed even to the very first training session, because it is the shingards that create reliable protection. It is also impossible to fight without protection. But in order to achieve the desired effect both in simple exercises and in competitions, it is important to choose these elements correctly.

What shields are needed?

This defense is extremely relevant, because in Thai boxing, the lion’s share of blows falls on the legs (or rather, on the shins).As a result, even one workout is enough to get serious injury. Moreover, fighters who know that the enemy has no defense are forced to constantly control the force of the blow, fearing to injure the opponent, and this seriously impairs the quality of the training itself.

For wrestling to bring the desired effect without injury and damage, it is important to choose the optimal shin guards for Muay Thai. There are three types of such protection on sale:

- Shingracks protecting only shin,

- Shin and foot pads,

- Special devices that protect both the lower leg, the foot and the toes.

The third option is the best choice for a beginner. It constrains movement a little, but it completely protects against injury. An experienced fighter can stop at the first or second type of defense.

Secrets of the “correct” shingards

Having chosen the structure itself, it is important to pay attention to the material from which it is made. Optimal – genuine leather, which has durability, good air permeability, plasticity. Of course, such material is quite expensive, but its price is justified: genuine leather wears out much longer than leatherette.Moreover, it prevents the leg from sweating, which only increases the intensity of the workout.

Another important aspect is the size of the shingards. It is measured by length, and finding the optimal performance is just as important as when you want to buy Muay Thai shorts. The better the protection adheres to the body, the less it constrains the movements, the more successful the training will be, and the more significant the progress in the fighter’s technique will be. The rules in this case are simple:

- Small shingards will not protect well, so it is better to pay attention to larger accessories,

- At the same time, excessively large shields can jump off or slide on their side, so it is worth choosing the strictly optimal option, taking into account the individual characteristics of the athlete.

When selecting, it is easiest to focus on your own height and size. As a rule, different manufacturers have their own dimensional grids, and all of them are “adjusted” to the growth indicators of fighters, based on traditional values:

- up to 157 cm – size S,

- height within 157-175 cm – size M,

- height 175-185 cm – size L,

- height over 187 cm – the largest size XL.

In the overwhelming majority, these indicators will necessarily be indicated on the protection, and therefore it will not be difficult to choose it.At the same time, over time, an athlete can change his shingards, choosing the most suitable option for the most successful trainings and competitions.

Melee leg protection

In a sport like hand-to-hand combat, defense is key. The equipment includes special shin and foot shields that reliably protect the fighter and his sparring partner during training or competition from injuries, sprains and bruises. Equipment for the legs is selected depending on the personal preferences of the fighter or coach.Our online store offers products that protect the legs during training. They are of high quality, made of wear-resistant material and are sold at a favorable cost.

What makes our products different?

Leg protection allows you to fully practice blows with the lower extremities, hone your technique to perfection. It is convenient to work with them both with a sports equipment and in sparring with another fighter. Our shin guards provide maximum protection for the leg from injury, even with a very strong impact.The main advantages of our products:

· Possibility of choosing a suitable size;

· High strength of the material;

· Effective protection of the foot and lower leg;

· Convenient elastic bands for secure fixation;

· Simplicity of fastening due to two velcro strips;

· Durability;

· Favorable price.

Shin-toe protectors are made of durable modern raw materials, so they can easily endure even intense workouts, do not deform in the process and do not tear.At the same time, the presented products are distinguished by their lightness, which allows them to be used with particular comfort.

How to choose the right size?

In such an occupation as hand-to-hand combat, equipment plays an important role. Without it, a fighter risks his health and remains unprotected, so it is worth making sure that appropriate uniforms are included in the kit for training or competitions. The product for the legs (shin-foot) is selected by size. Usually, the initial indicator is the growth of the athlete, and they are repelled from him when choosing.Our assortment includes:

· S. Designed for people up to 170 cm tall;

M. Suitable for athletes with a height of 170-180 cm;

· L. Designed for height 180-190 cm;

XL. Used by athletes taller than 190 cm.

Correctly selected size is the key to reliable fixation of equipment and ease of use during training. Therefore, if in the process of choosing a suitable product or size, questions arise, you can get a full consultation by contacting our specialists.To do this, you can use the chat or dial the phone number indicated on the website.

90,000 How to choose soccer shin guards? – Formas

Have you started playing football regularly? Then you should think about choosing football shields. The accessory is essential for amateurs and professionals. You can always get injured during a match and during training. It is often difficult for novice footballers to understand the variety that manufacturers of sports equipment offer today.

Rules for the selection of football shields

According to the rules, the player must wear this accessory on the field.There is no regulation only about the type of construction. There are two types of attributes, depending on the length in relation to the leg:

- Light version;

- With additional protection for the Achilles tendon and ankle.

The player himself must choose the protection according to his individual needs: “large” or “small”. Usually, the second option is bought, then gradually switches to the first.

There is no single definition of what should be the size of large and small scutes.All manufacturers produce their own models and determine this characteristic on their own.

It should be understood that products with additional panels are more reliable and durable. But they can interfere with the player’s fast movements. Such models consist of shields, material and fasteners (strip), which allow you to fix the accessory on the leg.

Lightweight ones are sometimes called “built-in” because they consist only of a plate and straps (compression sleeves) to fix them.Such options allow you to feel the ball well and do not hinder the movement of the athlete.

Choosing the material and dimensions of the shields

The material must be strong and lightweight. These parameters should be considered at the time of purchase. The most common are:

- Fiberglass – light, with good strength, but too stiff;

- Polyurethane – reliable, durable, but heavy;

- Microporous rubber – notable for its lightness and flexibility, elastic, unfortunately, not strong;

- Plastic is an inexpensive option, although not very reliable.

All shields are also equipped with a special soft cushioning layer, which is made of foam material. To wick away sweat and excess moisture in the heat, it is covered with a special fabric.

It is very important to choose the correct size, otherwise the product will interfere with the match and negatively affect its result. To do this, you should measure your leg from the middle of the kneecap to the beginning of the foot. The resulting figure should be multiplied by 0.75. This will give you the size you want.Also focus on your height. Manufacturers offer special tables in which you can find the option that suits you quickly and without any problems.

If you are buying shin guards for a teenager who may have a non-standard figure (for example, too long legs), it is better to choose the first option.

What is the correct way to wear soccer shin guards?

It all depends on the design of the product itself. If you have only the front panel, you must put on the sock of the gaiter.The protective part should be placed on the front of the lower leg and securely fastened with fasteners (straps, Velcro, etc.). Pulls over the rest of the gaiters. There are models without fasteners, the shields are then simply inserted inside.

Better fixation is possible with tape. It is wrapped around the fabric of the leggings so that the flap does not move up and down. So this sports attribute holds up better.

Do you have an option that consists of a panel and a compression sleeve? The process will look different.A stocking is put on, then a sock of a gaiter. The panel fits neatly into the stocking or underneath (with or without a special pocket). Next, you need to pull on the gaiters. Stretchable Velcro cuffs or tape will keep the flaps securely in place.

Some famous football players use not only leggings or stockings, but also socks. This design is believed to better secure protective bezels that might slip during play. First they put on stockings, then socks. Insert the flap inside and pull the sock so that its elastic supports the lower part of the panel, preventing the latter from moving.Then pull on the gaiter.

Can football shin guards be washed?

In order for these football attributes to serve you as long as possible, you need to know how to properly care for them. Before use, be sure to check for any signs of wear – scratches, dents, cracks. If there are any, it is better to replace the protection. Remember that contact with harsh chemicals, hot or cold temperatures will result in loss of strength.

Remember that such items can only be washed by hand.The water temperature should not be higher than 30 degrees. It is strictly forbidden to use the washing machine, as well as dry cleaning with bleach. After cleaning, they should dry at room temperature, away from any sources of heat. It is recommended to store it in a cool and dry place.

90,000 Location of distribution boards behind the video wall. Where is the best place to install the switchboard, and how many should there be

HomeWallPosition of distribution boards behind the video wall

Installation of a switchboard: assembly, installation, connection

The internal power supply network of an apartment or house is a complex system that includes various elements.It is made up of more than just electrical wires, cables, sockets and switches.

The most important part of the entire wiring complex is the electrical distribution board, inside which there are protective devices, automatic circuit breakers, metering devices and other necessary equipment. It is in the electrical panel that all the nodes for controlling the internal power supply of a private house, apartment or summer cottage are concentrated.

Long gone are the days when one electricity meter, fuse plugs and no additional equipment were installed on a house or apartment.At present, the consumption of electricity has increased several times, compared with what it was 30 years ago.

The saturation of private properties with powerful electrical equipment is very high. Some microwave ovens and electric kettles have a capacity of up to 2 kW. How much electricity do modern washing machines, air conditioners and computers consume?

Along with the manifold increase in electricity consumption, the requirements for internal electrical wiring and equipment have completely changed.Modern electrical panels have firmly taken their place in private houses and apartments. Their housings can be made of both metal and polymer materials, built-in or mounted.

It is possible to independently assemble and install these main elements of the power supply network only if you have basic knowledge of electrical work. Otherwise, you should contact a specialist.

Preparation for the installation of the switchboard

Installation and assembly of the electrical panel is the final stage in creating the entire internal power supply system of a private house, apartment or other real estate object.After completing the work on connecting the building to the general electrical networks and installing the internal wiring, you can start installing the switchboard housing and assembling its internal equipment.

This procedure should be started by drawing up a schematic diagram of the electrical panel, while taking into account the following factors.

- Type of internal wiring: “star” or “loop”, in junction boxes or in a mixed version. The type of internal electrical wiring determines the number of wires that fit into the switchboard.There can be up to several dozen of them. Which electrical equipment needs to be placed in the dashboard, its quantity and technical characteristics depends on this indicator.

- Total power of all electrical appliances: determined by the sum of the ratings for each appliance. Also, this general indicator must be broken down by consumption zones from each line of internal wiring inserted into the dashboard. This is necessary for the selection of machines and other components for the maximum load current.

- Taking into account all possible load options: connecting additional electrical appliances, simultaneously turning on all equipment, and so on.Most likely, such a calculation has already been performed when installing the internal wiring, but it is advisable to duplicate it. All machines and other electrical equipment must be purchased with a power reserve.

- Determination of types of electrical appliances on site: many electrical appliances require the installation of additional equipment. For example, the operation of a washing machine must be secured by installing an RCD (residual current device). This will provide reliable protection of a person from electric shock in the event of a phase short to the body of the electrical appliance.

After developing the circuit diagram of the electrical panel, purchasing all the necessary components and materials, we proceed to the selection of the device case and its installation.

Selection and installation of the switchboard housing

It should be said right away that the switchboard can be assembled in two ways: bench or mounted. The first method involves the installation of the dashboard case with modular devices pre-installed and connected according to the scheme, but the second is vice versa.

There is no fundamental difference between these two methods – only the sequence of assembly and installation operations changes. We will look at the second method, which first mounts the switchboard housing, and then installs the modular devices, and connects to internal wiring and external cable.

By the type of housing, the shields are divided into built-in and hinged. We will not describe the advantages and benefits of these two types, just say that in each specific case it is necessary to choose the best option.The hinged enclosure is easy to install and the flush mount is compact but more difficult to install. So, the choice is yours! The size of the chassis depends on the number of modular devices and other equipment that needs to be installed in it.

That’s it! The choice is made, the switchboard housing is installed in the required place, the supply cable and internal wiring wires are inserted into it – it’s time to start assembling!

Laying external cables and wires

This operation is one of the most important! It is not permissible to damage the insulating layer of the cable outlets.It is recommended to purchase a special tool for stripping the belt insulation. The requirements for stripping the insulation from the conductors are also high. This operation is performed using a stripper, in a different way a skinner. It is forbidden to melt the insulation, remove it with a knife or pliers. All these conditions must be strictly observed in order to exclude negative consequences in the form of short circuits and other emergency situations.

Important! Stripped metal conductors must not be damaged.Otherwise, during the installation process, they will simply break or receive internal damage, which will lead to further unpredictable consequences.

The technique of laying the external cable and internal wiring wires in the switchboard is quite simple. The belt insulation is almost completely removed. It should be present only at the place where the cable is laid through the shield body, plus a few more centimeters. The cores are passed under the rails for mounting modular devices and are brought to their destination.Zero and protection to common blocks, and phase to certain groups of modular devices.

Attention! The length of the cores of the cables and wires included in the switchboard must be selected with a margin in case of re-arrangement of modular devices or other unforeseen work.

After laying the cables and wires of the internal wiring, you can proceed to the installation of modular devices and other equipment, if provided by the schematic diagram.

Installation of electrical equipment in a switchboard

There are no standards governing the place of installation of modular devices in electrical panels.There is only one installation rule: the layout of the equipment should be clear to both other masters and users. It is advisable to place an input circuit breaker, a block of general protection and measuring instruments in the upper row. Place frequently used modules below.

This arrangement of the panel elements allows the input unit to be connected to the upper terminals, and the voltage distribution along the lines is made from the lower terminals.

Attention! Modular devices and other equipment in the electrical panel can be installed in any sequence, the main thing is that they are correctly connected to each other.However, it is much more convenient if the arrangement of the equipment corresponds to the sequence indicated in the circuit diagram.

All internal equipment of the electrical panel is installed on special DIN rails, which are most often already installed in the housing. Most panel equipment manufacturers complete their products with various useful add-ons. In addition to DIN rails, this list includes various clamps for wires and cables, gland seals, false panels, as well as special roll-out frames to facilitate equipment installation.We can say that any switchboard case is initially equipped with everything necessary for installing modules and other devices.

But closer to the subject! We have already decided where to install the main groups of modular devices. The upper part is occupied by the entrance group, followed by frequently used modules. These include group type RCDs. As a rule, one RCD is installed on each outlet line and additionally for the bathroom and kitchen. Such overcurrent protection, together with automatic devices, allows you to refuse the installation of differential automatic devices.

If we talk about circuit breakers, the first to be installed are modules to protect lighting lines, then outlet and specially allocated ones: for a boiler, a washing machine, and so on.

It is very easy to install circuit breakers, RCDs and other equipment on DIN rails. The modular device is inserted on the rail until it clicks, no other operations are required, as it will be securely fixed.

To dismantle or displace the equipment, simply squeeze the module tab with a screwdriver – the device can be easily removed from the mounting plate.If it is necessary to install an electricity meter in the switchboard, it is also installed on a DIN rail. Well, that’s all about the installation of equipment in the electrical panel! It’s time to move on to connecting the elements according to the schematic diagram.

Connection of the internal equipment of the electrical panel

The equipment inside the switchboard is installed, it remains only to connect all the modules and other devices according to the schematic diagram, correctly and without creating a tangled web.It should be said right away that one core can be connected to one terminal. If it is necessary to combine several conductors, they should be crimped in a sleeve lug and the ends should be closed with a heat-shrinkable nozzle. The second rule: for all modular devices, most often, it is indifferent to which terminals the voltage is supplied and from which ones it is removed. This allows for easier wiring.

If the installation is carried out in a panel previously installed in place, then the outgoing lines of wires are connected first.They must be passed under the DIN rails and brought to the connection point. Surplus wires should be hidden between the back panel and modular devices. The veins are bound together into loops with polymer ties. Zero and grounding wires are packed separately in a bundle, since they have different routing. The phases are combined in rows and vertically brought to the rail, where they bloom on the sides.

It is more convenient to connect one row of modular devices using a special connecting comb.They are available in two versions: single-row and three-row. If the module needs to be connected to another source, it is enough to remove the comb contact with nippers. The use of such simple parts makes it possible to simplify the installation of the switchboard. After connecting all the elements of the electrical panel, check that they are connected correctly. Everything! All work has been completed, the electrical switchboard can be put into operation.

Conclusion

In conclusion, I would like to give some general recommendations for the assembly and installation of a switchboard in a private house, apartment or in the country.They will help to avoid common mistakes made during self-assembly of switchboard equipment.

- The enclosure for the switchboard needs to be purchased slightly larger than is required for the installation of the equipment. This will allow the installation of additional devices and modular devices, if the need arises with an increase in the number of serviced electrical appliances. Extra space inside the shield never hurts.

- Do not protect a group of electrical devices with different purposes with a single RCD or differential switch.Such a connection scheme, for example, will turn off the computer when a hair dryer breaks down in the bathroom, which will create certain inconveniences for the consumer. It is better to provide zonal current protection – separately for the bathroom, kitchen, and so on.

- Energy supervision rules state that an RCD cannot be installed in front of the machine, it must be placed after it. A mechanical RCD is better than an electronic one, it does not cause false alarms and is more reliable. It is best to install this device in each zone after the machine.

- When assembling electrical panels, you should use additional consumables, such as blocks with holes (in another way, tires) to combine neutral and grounding conductors. Place them around the edges so as not to obscure the working bezel.

Installation and assembly of a switchboard in a private house, apartment or country house does not require any permits, but the general rules for electrical work should be observed.

Regardless of who does this work, you personally or an experienced electrician hired, you must be guided by the relevant PES (electrical installation rules) standards.if the installation of the electrical panel is carried out as part of the initial connection of the house, apartment or summer cottage to the power supply networks, then verification of the correct installation by the power supply organization is guaranteed!

In addition, it should be borne in mind that the Ministry of Emergency Situations, represented by fire inspectors, may issue an order to eliminate deficiencies in the event that the electrical panel does not comply with fire safety standards.

Therefore, if you are not confident in your abilities, refuse to assemble the switchboard yourself and invite a professional electrician! This will avoid not only a conflict with the controlling structures, but also more serious consequences: electric shock or fire!

Related videos

profazu.ru

Where is it better to install the switchboard, and how many should there be

Published on 19.08.2015

Where and in what places is it optimal to install the switchboard? Why is the importance of installing a switchgear paramount? The article provides detailed information regarding the installation of power shields in specific buildings: in houses, in summer cottages, in cottages.

The switchboard is a box inside which electricity meters and network protectors are installed.

The importance of installing switchgear

The circuit breaker can often not cope with its tasks. This usually happens in cases when the broken device is located at a great distance (about one hundred meters) from the network protective device, or in case of malfunctions of the residual current device itself [hereinafter referred to as the RCD]. The insulation of the wires can ignite at any second, and therefore it is important to get to the switchboard as quickly as possible.

While you are clearing the way to the switchboard, the house can simply burn down! – And this is not a joke.

There are a number of requirements and recommendations regarding where the electrical cabinet should be installed and how it should be equipped.

Where can the distribution box be installed?

– Outdoors.

The shield should be in a well-ventilated area.Natural ventilation is preferable to forced ventilation. The latter, in the event of a power outage in the house, stops working, which can create certain problems.

– Away from combustible materials.

The switchboard must not be installed in fire hazardous areas. Namely: in boiler rooms, in the immediate vicinity of gas tanks and in other places where there are flammable substances.

– In easy access.

The panel room should in no case be a warehouse of unnecessary things. Try to provide easy access to the flap. Otherwise, you will not be able to quickly de-energize the network in the event of an emergency.

– In the light.

If possible, provide access to natural light in the room where the shield is installed so that the master can troubleshoot the switchgear without resorting to the use of flashlights.

In a house, the number of shields depends on its area, as well as on the complexity of the power supply wiring.

Let’s analyze specific situations

At the dacha – 1 power shield

For small summer cottages, as well as for houses with a total area of no more than two hundred square meters, one switchboard installed at the power input is sufficient.The components of the electrical panel are a powerful input automaton that controls the entire circuit of the house power supply, as well as the meter. There are also several smaller circuit breakers. Usually, one of the switches controls the outlet network, and another one controls the lighting network. The rest of the switches have a narrow specialization, protecting specific devices: washing machines, electric heaters in saunas, electric stoves … There is also an RCD: one common and several additional ones.

In a large house – there should be several

For large houses and cottages, one input panel will not be enough.Therefore, there should be several of them. In such houses, there is a long length of electrical wiring, so the circuit breaker can be triggered with a significant delay. There are times when it doesn’t work at all.

Good to know: electrical panels do not have to be installed in remote areas, in the “underground”. Modern materials will allow you to concisely fit the switchgear into the interior of the apartment.

In the house, the following scheme is desirable: 1 common switch cabinet at the input of electricity to the house, plus several additional switchgears on each floor.A meter, a general RCD, an introductory machine are mounted inside the first switch cabinet. The other distribution boards contain circuit breakers for the outlet network and the lighting network for this floor. There is also an RCD group that controls the same areas. Such a scheme allows you to reduce the distance from electrical appliances to protective devices. In the event of a malfunction, not the entire house is de-energized, but only a separate floor or only a room. This simplifies the search for the cause of the operation of the protective device.

Results and conclusions:

Summing up the above, we note that the owner certainly needs to know where the shield should be installed in the apartment / house / cottage. And in what quantity – too. This is valuable and useful information for fire safety.

Other articles in the section “Electrical work”: Installation of lighting: features, materials and cost Electrical work: how to choose a service and a craftsman Installation of a switchboard and other slippery moments: why introduce a designer to an electrician Washing machine is electrocuted: reasons and solutions Saving energy: 5 legal ways for electrical work

domodel.by

Assembling a convenient and correct switchboard with your own hands

The current regulations impose minimum requirements on switchboards. It is enough to close the contacts so that you cannot reach them with your fingers, install one machine and one RCD – and this will be considered safe and sufficient. But using such a system is extremely inconvenient, so every house and apartment must be equipped with a modern switchboard.

Where to place

The power shield should be located in an accessible place, where it can be reached without opening additional doors and without making your way through the pile of things.The standard and most convenient location for the switchboard is in the hallway area, near the front door. Usually, it is in this place that the input power cable passes, to which the switchboard will subsequently be connected.

The height of the flap on the wall should provide convenience for turning on / off while standing, at the same time high enough to exclude children from accessing it. The bottom edge of the switchboard must be at least 140 cm above the floor.

If it is necessary to install outdoor switchboards, they should be fixed only under a canopy to avoid direct rainwater jets, and at a height of at least 100 cm from the ground to prevent splashing water.

Types of switchboards

The switchboard is not a high-tech device and is designed for convenient installation and then the use of various equipment. There are no special requirements for characteristics either, the main thing is that it fits in size and contains the required number of devices. You should not buy the biggest one, “to fit everything” or the smallest “but beautiful”. It is necessary to accurately calculate the number of switches / RCDs / circuit breakers and only then make a decision.

Built-in or hinged

SCHRN – mounted SCHRV – built-in

If possible – use only built-in boards. The protruding hinged distribution board can be hooked on when carrying furniture or repairing it. The built-in shield recessed into the wall does not have this drawback. Therefore, if there is an opportunity to place the shield in an existing niche or make it yourself – do it.

Metal or plastic

There is no definite answer here.Both plastic and metal distribution boards last equally long when used correctly. But in the case of metal shields, you will always be able to repair the case, cut threads or secure something (such as a flashlight) with a magnet on the shield cover.

Outdoor or indoor

In many cases, the presence of a street panel is a prerequisite for the supply of electricity. Inside such a shield, a counter and an introductory machine are usually located.When choosing a street shield, you should choose only metal with a bottom cable entry, in order to avoid water ingress into the system. Take care also of permanent tightness and access to meter readings without opening the lid. So the shield will last much longer. The degree of protection of the outdoor switchboard must be at least IP 44.

The switchboard provides protection against moisture and view the meter readings without opening

How to assemble

The main task of the switchboard is to provide access to various electrical circuits, the ability to turn them on / off.This access should be convenient and understandable. There are several ways to organize a convenient location of circuit breakers and RCDs in the panel. Here are some examples of the competent organization of switches in the panel.

Before assembling the switchboard, a power supply plan for the facility should be worked out, taking into account all consumers. Distribution by groups of electrical consumers is made. In all cases, single-phase current is considered as the most common one. A two-pole automatic switch must be installed at the input.The rating of this switch must be less than or equal to the input switch (at the entrance, street).

Scheme 1

The simplest organization of the switchboard

The first version of the switchboard assembly. Here, after the introductory machine, the switches are connected. They can be grouped according to the following principle (from left to right):

- Single high-power consumers

- Distribution of the socket / light among the rooms

The distribution logic can be changed by placing the machines responsible for lighting in the dashboard first, then the sockets and end with single consumers.

To protect against electric shocks and electrical leaks, the shields must be equipped with an RCD (residual current device). If one RCD is used, then it should be located immediately after the introductory machine.

Circuit board with RCD

it is easier for the consumer to understand. In it, each room (group) is connected to its own RCD and is separated from the others.

Dashboard diagram for rooms

With this arrangement, it becomes clear to which circuit the circuit breakers belong. The disadvantage of this switchboard assembly is that additional space is required on the DIN rail.

Scheme 3

Optimal panel connection scheme