How does the Brine Clutch Friction ’16 Lacrosse Attack Shaft enhance player performance. What makes this shaft stand out in the competitive lacrosse equipment market. Why should players consider investing in this high-quality piece of gear.

The Evolution of Lacrosse Attack Shafts: Introducing the Brine Clutch Friction ’16

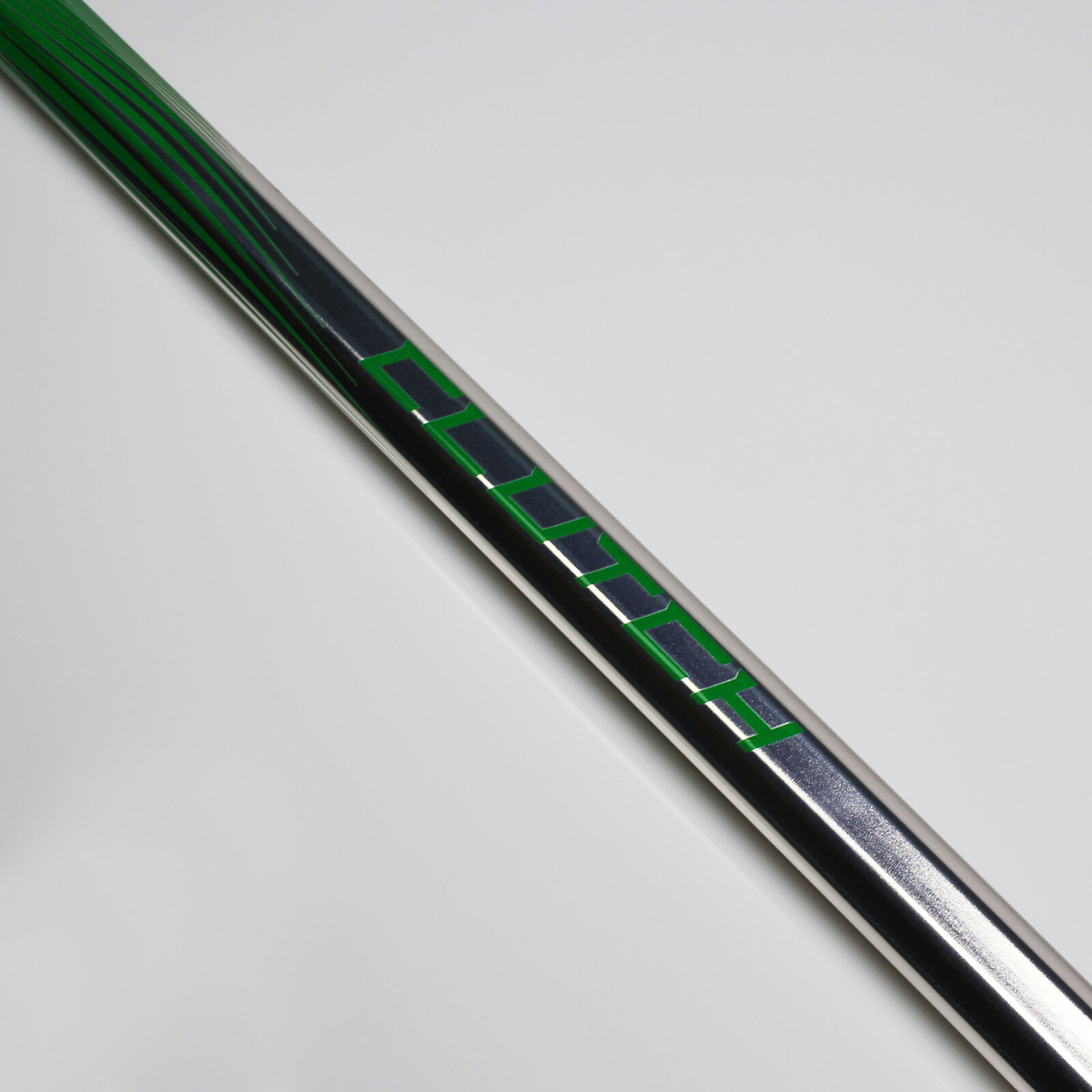

The Brine Clutch Friction ’16 Lacrosse Attack Shaft represents a significant leap forward in lacrosse equipment technology. This 30-inch shaft is designed to give players a competitive edge on the field, combining durability, control, and innovative features that cater to the demands of modern lacrosse.

Key Features of the Brine Clutch Friction ’16

- Lightweight yet durable construction

- Enhanced grip technology

- Optimized balance for improved control

- Sleek green color for style and visibility

- 30-inch length ideal for attack positions

These features work together to create a shaft that not only performs exceptionally but also looks great on the field. The green color adds a touch of style while ensuring visibility during fast-paced gameplay.

Unparalleled Performance: Why the Brine Clutch Friction ’16 Stands Out

The Brine Clutch Friction ’16 is not just another lacrosse shaft. Its design and construction offer several advantages that can significantly impact a player’s performance. Are you wondering how this shaft can elevate your game? The answer lies in its innovative features and thoughtful design.

Superior Grip Technology

One of the standout features of the Brine Clutch Friction ’16 is its advanced grip technology. This ensures players maintain control of their stick even in the most intense gameplay situations. The enhanced grip reduces the chances of the stick slipping during crucial moments, allowing players to focus on their technique and strategy rather than worrying about equipment issues.

Optimal Weight Distribution

The shaft’s weight is carefully distributed to provide the perfect balance between power and maneuverability. This optimal balance allows players to make quick, precise movements while still delivering powerful shots when needed. The result is a shaft that feels like a natural extension of the player’s arm, enhancing overall performance on the field.

Durability Meets Lightweight Design: The Perfect Combination

In the world of lacrosse, equipment durability is crucial. The Brine Clutch Friction ’16 addresses this need without compromising on weight. How does it achieve this delicate balance? Through the use of advanced materials and manufacturing techniques, Brine has created a shaft that can withstand the rigors of high-level play while remaining incredibly light.

Advanced Material Composition

The shaft is constructed using high-grade materials that offer excellent strength-to-weight ratio. This composition ensures that the shaft can absorb impacts and resist wear and tear without adding unnecessary bulk. Players can enjoy the benefits of a durable shaft without feeling weighed down during long games or practice sessions.

Innovative Manufacturing Process

Brine employs cutting-edge manufacturing processes to create the Clutch Friction ’16. These techniques allow for precise control over the shaft’s properties, resulting in a product that meets the exacting standards of professional and amateur players alike. The attention to detail in the manufacturing process contributes to the shaft’s overall quality and performance.

Ergonomics and Comfort: Designed for Extended Play

Comfort is a critical factor in any piece of sports equipment, especially for items that are in constant use like lacrosse shafts. The Brine Clutch Friction ’16 excels in this area, offering ergonomic features that reduce fatigue and enhance player comfort during extended periods of play.

Ergonomic Grip Design

The shaft’s grip is not only about preventing slips; it’s designed to fit comfortably in the player’s hands. The ergonomic design reduces hand fatigue, allowing players to maintain their grip strength and control throughout the game. This attention to comfort can make a significant difference in performance, especially in the later stages of a match when fatigue typically sets in.

Vibration Dampening

Another comfort-enhancing feature of the Brine Clutch Friction ’16 is its ability to dampen vibrations. When catching passes or making contact with other players’ sticks, the shaft absorbs much of the vibration that would typically travel to the player’s hands. This reduction in vibration not only improves comfort but also enhances control and reduces the risk of repetitive strain injuries.

Versatility on the Field: Adapting to Various Playing Styles

While designed primarily as an attack shaft, the Brine Clutch Friction ’16 demonstrates remarkable versatility on the field. Its features make it suitable for a variety of playing styles and positions, offering players flexibility in their game.

Adaptability to Different Positions

Although marketed as an attack shaft, many players find the Brine Clutch Friction ’16 equally effective in midfield positions. Its balance and control allow for smooth transitions between offensive and defensive play, making it a favorite among versatile players who contribute across the field.

Customization Options

The shaft’s design allows for easy customization to suit individual preferences. Players can adjust the grip tape or add personalized elements without compromising the shaft’s performance. This customizability ensures that each player can optimize the shaft to their unique playing style and preferences.

The Economic Advantage: Value for Money in Lacrosse Equipment

Investing in high-quality lacrosse equipment can be costly, but the Brine Clutch Friction ’16 offers excellent value for money. At a sale price of $89.95, down from the regular price of $139.95, this shaft represents a significant saving without compromising on quality.

Long-Term Cost-Effectiveness

The durability of the Brine Clutch Friction ’16 means it will last longer than many cheaper alternatives. This longevity translates to better value over time, as players won’t need to replace their shaft as frequently. The initial investment in a quality product like the Brine Clutch Friction ’16 can lead to substantial savings in the long run.

Performance Benefits Justify the Cost

When considering the cost, it’s important to factor in the performance benefits the shaft provides. The improved control, comfort, and durability can contribute to better play on the field, potentially leading to more enjoyable and successful lacrosse experiences. For many players, these benefits more than justify the investment in a premium shaft like the Brine Clutch Friction ’16.

Comparative Analysis: How the Brine Clutch Friction ’16 Stacks Up Against Competitors

In the competitive world of lacrosse equipment, how does the Brine Clutch Friction ’16 compare to other shafts on the market? A comparative analysis reveals several areas where this shaft stands out from its competitors.

Grip Technology Comparison

Many lacrosse shafts offer some form of grip enhancement, but the Brine Clutch Friction ’16 takes it a step further. Its grip technology provides superior control in various weather conditions, outperforming many competitors in wet or humid environments where maintaining a secure grip is crucial.

Weight and Durability Balance

While some shafts prioritize lightweight design at the expense of durability, and others focus on strength at the cost of added weight, the Brine Clutch Friction ’16 strikes an impressive balance. It manages to be both lightweight and durable, a combination that sets it apart in the market and makes it a versatile choice for players at different levels of the game.

Price Point Competitiveness

When comparing the Brine Clutch Friction ’16 to other high-end lacrosse shafts, its price point is notably competitive, especially considering the current sale price. Many shafts with similar features and quality often come with a higher price tag, making the Brine Clutch Friction ’16 an attractive option for players looking for premium performance without breaking the bank.

Player Testimonials: Real-World Experiences with the Brine Clutch Friction ’16

To truly understand the impact of the Brine Clutch Friction ’16, it’s valuable to consider the experiences of players who have used it in real-game situations. Player testimonials provide insight into how the shaft performs under the pressures of competitive play.

Improved Shot Accuracy

Many players report noticeable improvements in their shot accuracy after switching to the Brine Clutch Friction ’16. The shaft’s balance and grip allow for better control during shooting motions, resulting in more precise shots on goal. One college-level player noted, “My shooting percentage improved significantly within the first few games of using this shaft. The control it offers is game-changing.”

Durability in High-Impact Situations

Defensive players who have used the Brine Clutch Friction ’16 praise its ability to withstand the impacts of checking and ground balls. A high school coach commented, “We’ve seen a significant reduction in broken shafts since introducing the Brine Clutch Friction ’16 to our team. It holds up well even in the most physical games.”

Comfort During Extended Play

Players participating in tournaments or multiple games in a day have highlighted the shaft’s comfort as a key advantage. The ergonomic design and vibration dampening properties help reduce hand fatigue, allowing players to maintain their performance level throughout long playing sessions.

These real-world experiences underscore the practical benefits of the Brine Clutch Friction ’16, demonstrating how its features translate into tangible improvements on the field. The positive feedback from players across different levels of the sport further validates the shaft’s design and performance capabilities.

Maintenance and Care: Ensuring Longevity of Your Brine Clutch Friction ’16

To maximize the lifespan and performance of the Brine Clutch Friction ’16, proper maintenance and care are essential. While the shaft is built for durability, following best practices for lacrosse equipment care can significantly extend its life and maintain its performance characteristics.

Cleaning and Storage Tips

- Regularly wipe down the shaft with a damp cloth to remove dirt and sweat

- Avoid storing in extreme temperatures or humid conditions

- Use a soft brush to clean the grip area, maintaining its tactile properties

- Store the shaft in a dry, room-temperature environment when not in use

Periodic Inspections

Regularly inspect your Brine Clutch Friction ’16 for any signs of wear or damage. Pay particular attention to the following areas:

- Check for any cracks or dents in the shaft

- Examine the grip area for signs of wear

- Ensure all screws and attachments are secure

- Look for any unusual bends or warping in the shaft

By following these maintenance practices, players can ensure their Brine Clutch Friction ’16 remains in top condition, providing consistent performance game after game. Regular care not only prolongs the life of the shaft but also helps maintain its key features, such as grip and balance, which are crucial for optimal play.

The Future of Lacrosse Equipment: Innovations Inspired by the Brine Clutch Friction ’16

The Brine Clutch Friction ’16 represents a significant step forward in lacrosse shaft technology, but it also points towards future innovations in the sport. As manufacturers continue to push the boundaries of equipment design, we can expect to see new developments inspired by the successes of shafts like the Brine Clutch Friction ’16.

Advancements in Material Science

The lightweight yet durable nature of the Brine Clutch Friction ’16 is likely to inspire further research into advanced materials for lacrosse equipment. We may see the development of new composites that offer even better strength-to-weight ratios, potentially revolutionizing not just shafts but other pieces of lacrosse gear as well.

Smart Technology Integration

While the Brine Clutch Friction ’16 doesn’t incorporate smart technology, its success could pave the way for future shafts that do. Imagine lacrosse shafts with built-in sensors that provide data on shot speed, stick handling metrics, or even fatigue indicators. Such innovations could transform how players train and improve their skills.

Customization and Personalization

The trend towards equipment that can be tailored to individual playing styles, as seen in the Brine Clutch Friction ’16’s versatility, is likely to continue. Future lacrosse shafts might offer even more customization options, perhaps including adjustable weight distribution or interchangeable grip sections to suit different game situations or player preferences.

As the sport of lacrosse continues to evolve, equipment like the Brine Clutch Friction ’16 sets a new standard for performance and innovation. It challenges manufacturers to continue pushing the boundaries of what’s possible in lacrosse equipment design, promising an exciting future for players at all levels of the game.

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

– CMD Sports

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

– CMD Sports

Skip to content

Regular price

$139.95

Sale price$89.95

Save 36%

/

Tax included.

Colour

—

GREEN

Colour

GREEN

Size

Size

30″

Quantity

Australian stock ready to ship

Low stock – 2 items left

GREEN / 30″ – $89.95 AUD

[{“id”:42304262406316,”title”:”GREEN \/ 30\””,”option1″:”GREEN”,”option2″:”30\””,”option3″:null,”sku”:”LSh59534 GREEN”,”requires_shipping”:true,”taxable”:true,”featured_image”:{“id”:34584189370540,”product_id”:7549046227116,”position”:1,”created_at”:”2022-12-22T08:35:26+11:00″,”updated_at”:”2023-06-29T17:00:26+10:00″,”alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”width”:2048,”height”:2048,”src”:”\/\/cmdsports. com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}]

com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}]

{“id”:42304262406316,”title”:”GREEN \/ 30\””,”option1″:”GREEN”,”option2″:”30\””,”option3″:null,”sku”:”LSh59534 GREEN”,”requires_shipping”:true,”taxable”:true,”featured_image”:{“id”:34584189370540,”product_id”:7549046227116,”position”:1,”created_at”:”2022-12-22T08:35:26+11:00″,”updated_at”:”2023-06-29T17:00:26+10:00″,”alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”width”:2048,”height”:2048,”src”:”\/\/cmdsports. com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}

com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

{% else %}

{% endif %}

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

+{{ plus_btn_text }}

{% endif %}

{% elsif display_option == “button”%}

{{ option.name }}

- {% assign swatch_i = 1 %}

- +{{ plus_btn_text }}

{% assign plus_btn_text = 0 %}

{% for swatch in option.values %}

{% assign will_hide_swatch = false %}

{% if buttons_to_show > 0 and swatch_i > buttons_to_show %}

{% assign will_hide_swatch = true %}

{% endif %}

{% if will_hide_swatch == true %}

{% assign plus_btn_text = plus_btn_text | plus:1 %}

{% endif %} id}}” data-handle=”{{ product.handle | escape }}”>

{{ swatch }}

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

{% endif %}

{% elsif display_option == “dropdown-list” %}

{{ option.name }}

{% for swatch in option.values %}

{{ swatch }}

{% endfor %}

{% else %}

{{ option. name }}

name }}

- {% assign swatch_i = 1 %}

- +{{ plus_btn_text }}

{% assign plus_btn_text = 0 %}

{% for swatch in option.values %}

{% assign variantImageUrl = ” %}

{% for c_variant in product.variants %}

{% if variantImageUrl == ”%}

{% assign c_option_index = 0 %}

{% for c_option in c_variant.options %}

{% if c_option_index == parentIndex %}

{% if c_option == swatch%}

{% assign variantImageUrl = c_variant.featured_image.src %}

{% break %}

{% endif %}

{% endif %}

{% assign c_option_index = c_option_index | plus: 1 %}

{% endfor %}

{% endif %}

{% endfor %}

{% assign will_hide_swatch = false %}

{% if swatches_to_show > 0 and swatch_i > swatches_to_show %}

{% assign will_hide_swatch = true %}

{% endif %}

{% if will_hide_swatch == true %}

{% assign plus_btn_text = plus_btn_text | plus:1 %}

{% endif %} id}}” data-handle=”{{ product.handle | escape }}”>

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

{% endif %}

{% endif %}

{% assign parentIndex = parentIndex | plus: 1 %}

{% endfor %}

Men’s Lacrosse Defense & Attack Shafts

Men’s Lacrosse Defense & Attack Shafts | Everysportforless.com

Search

Shafts | Handles – Mens

Sort By:

Featured ItemsNewest ItemsBest SellingA to ZZ to ABy ReviewPrice: AscendingPrice: Descending

Products Per Page:

812162040100

Columns:

1

2

3

4

6

On Sale

Choose Options

Quick view

Adidas Dipped FREAK Alloy Lacrosse Attack Shaft 30″ – Various Colors

adidas

MSRP:

$109.

99

99Now:

$44.92

Was:

$58.99

Adidas Dipped FREAK Alloy Lacrosse Attack Shaft 30″ – Various Colors

Model: Dipped FREAK

Model Number: CF320

Size: Attack 30″

Colors: Purple, Pink, Orange, Carolina Blue, Lime, Yellow

Lacrosse Attack Shaft

100% Authentic Adidas Product

We Buy…MSRP:

$109.99

Now:

$44.92

Was:

$58.99

Choose Options

Quick view

Add to Cart

Quick view

Adidas VXR-800 Alloy Lacrosse Attack Shaft 30″ – Silver, Blue

adidas

MSRP:

$44.99

Now:

$24.

92

92Adidas VXR-800 Alloy Lacrosse Attack Shaft 30″ – Silver, Blue

Model: VXR-800 Alloy

Color: Silver, Blue

Size: Attack 30″

Lacrosse Attack Shaft

100% Authentic Adidas Product

We Buy Direct From Adidas to Save You Money!

Features

Rubber End…LSH6659

On Sale

Add to Cart

Quick view

Brine F15 Silver Limited Edition SMU Lacrosse Attack Shaft 30″

Brine

MSRP:

$99.99

Now:

$17.92

Was:

$28.92

Brine F15 Silver Limited Edition SMU Lacrosse Attack Shaft 30″

Model: F15

Model Number: F15FG SL OSZ

Colors: Silver

Weight: 5.3 oz w/o Butt End

Size: 30″ Attack

Lacrosse Attack Shaft

Features

Premium Grade 7000 Alloy Material

Limited Edition -. ..

..LSH55926

MSRP:

$99.99

Now:

$17.92

Was:

$28.92

Add to Cart

Quick view

On Sale

Add to Cart

Quick view

Brine F22 Flip Lacrosse Attack Shaft 30″ – Vegas Gold

Brine

MSRP:

$89.99

Now:

$17.92

Was:

$32.92

Brine F22 Flip Lacrosse Attack Shaft 30″

Model: F22

Model Number: 22S GOV OSZ

Color: Vegas Gold

Size: 30″ Attack

Weight: 6.2 oz w/o Butt End

Lacrosse Attack Shaft

Features

“Vegas” Version – No Graphics

Lightweight, Durable

Ideal for Attack…LSH55996

MSRP:

$89.

99

99Now:

$17.92

Was:

$32.92

Add to Cart

Quick view

Choose Options

Quick view

Brine King Beat Lacrosse Defense Shaft 60″ – Various Colors

Brine

Now:

$45.92 – $48.92Brine King Beat Lacrosse Defense Shaft 60″ – Various Colors

Model: King Beat

Model Number: KNGSWB6D

Colors: Black, Carolina, Royal, Chrome, Navy, Forest, Orange

Size: Defense 60″

Lacrosse Defense Shaft

Features

Ergonomic Grip

Rubber…Add to Cart

Quick view

Maverik Mission Blank Lacrosse Attack Shaft 30″ – White

Maverik

Now:

$114.

99

99Maverik Mission Blank Lacrosse Attack Shaft 30″ – White

Model: Mission Blank

Model Number: 3002526

Color: White

Size: Attack 30″

Lacrosse Attack Shaft

Features

Scandium Alloy

Bead Blasted Finish for grip

Completely Blank of…LSh59067

Add to Cart

Quick view

Maverik Mission Blank Lacrosse Defensive Shaft 60″ – White

Maverik

Now:

$159.99

Maverik Mission Blank Lacrosse Defensive Shaft 60″ – White

Model: Mission Blank

Model Number: 3002592

Color: White

Size: Defense 60″

Lacrosse Defensive Shaft

Features

Scandium Alloy

Bead Blasted Finish for grip

Completely Blank of…LSh59068

Quick view

Maverik Wonder Boy 2020 Lacrosse Attack Shaft 30″ – Various Colors

Maverik

Now:

$84.

99

99Maverik Wonder Boy 2020 Lacrosse Attack Shaft 30″ – Various Colors

Model: Wonder Boy 2020

Model Number: 3002540

Colors: Black, Gray, White

Size: Attack 30″

Lacrosse Attack Shaft

Features

Ideal for an All-Around Midfielder

Matte Finish for an…Now:

$84.99

Quick view

Add to Cart

Quick view

StringKing Metal 3 Pro 30″ Attack Lacrosse Shaft

StringKing

Now:

$109.99

StringKing Metal 3 Pro 30″ Attack Lacrosse Shaft

Model: Metal 3 Pro

Size: Attack 30″

155 grams – Ages 14 to 17

Lacrosse Men’s Attack Shaft

Made with premium alloy and precise manufacturing, Metal 3 Pro lacrosse shafts deliver the performance you…LSH57407

Choose Options

Quick view

StringKing Metal 3 Pro Defense Lacrosse Shaft 60″ – Various Colors

StringKing

Now:

$179.

99

99StringKing Metal 3 Pro Defense Lacrosse Shaft 60″

Model: Metal 3 Pro

Size: Defense 60″

360 grams – Ages 15 and under

Lacrosse Men’s D-Pole

Made with premium alloy and precise manufacturing, Metal 3 Pro lacrosse shafts deliver the performance…Choose Options

Quick view

StringKing Metal 3 Pro Lacrosse Attack Shaft 30″ – Various Colors

StringKing

Now:

$99.99

StringKing Metal 3 Pro Lacrosse Attack Shaft 30″ – Various Colors

Model: Metal 3 Pro

Model Number: ITM-0003770

Colors: Black, Silver

Size: Attack 30″

Lacrosse Attack Shaft

Features

135 Grams

Consistent, Durable Performance

Comes with a Roll…Add to Cart

Quick view

STX Alliance VFT Men’s Lacrosse Attack Shaft – White

STX

Now:

$139.

99

99STX Alliance VFT Men’s Lacrosse Attack Shaft – White

Model: Alliance VFT

Model Number: HE CAX8 76

Color: White

Shaft: 32″ Attack

Position: Attack

Men’s Lacrosse Attack Shaft

Features

Raised Texture

Soft Touch Finish

High Grip Rubber…LSh45694

1,2,3,5 Oil formers. Oil producers.

Repair.

Wear parts

oil formers are gears,

gears, bearings and seals

gearbox gaskets, rubber gaskets

between covers and cylinder bodies.

In addition, there is a collapse of the drum

due to overpressure

product, cracks form in the drum,

into which the product enters wear out

pin, trunnion (half shaft) and drum knives,

bronze bushing in cylinder covers,

shank (fork) of the gearbox shaft, packing

omentum, etc. Causes of premature

wear of fastening parts of drums in

cylinders serve incorrect installation

drum in the cylinder, as well as inaccurate

adjustment of the drum in the axial direction.

When repairing

oil former worn parts

and crumpled drums are replaced. Product,

caught in the drum, removed by heating

drum with steam or hot water, after

what cracks weld. If it is needed

repair gear parts

it is dismantled, oil is drained from the crankcase and,

unscrew the nuts, remove from the studs

electric motor with gear.

In the presence of

oil leaks gasket replace

new. Then remove the gearbox cover

which is enough to replace the gears and

gear wheels. Replacement if necessary

the drum drive shaft is disassembled

gearbox, remove the gear wheel,

disassemble the gland, unscrew the screws

and take out the shaft along with the ball bearings.

Reducer assemble

in reverse order of disassembly. Wherein

after installing the gearbox cover

manually check the ease of rotation

gears and gears when installing

engine gear must enter into

gear engagement. After

assembly, oil is poured into the gearbox.

Corrosion of metal wears out

walls of cylinder jackets, pipes and

fittings for supplying water and brine.

Buttermaker.

Wearable

oil maker parts are

v-belts, ferrodo tape

friction clutch, bronze bushings,

steel drive gear. springs

clutch and band brake,

which are replaced when worn. For replacement

worn parts during repair

the oil manufacturer is removed from it

separate

assembly units in the following order,

For

removal of the leading (in relation to the clutch

clutch) pulley control lever

move to a lower position

– the locking screw in the drive nut

shaft, unscrew this nut, after which

remove the pulley from the shaft.

Withdrawal

clutch and bearing housing

couplings begin by removing the pulley.

Then unscrew the bolts securing the housing

clutch bearing; filmed

two bolts connecting the control lever

with a cam disc for engaging the clutch.

From the clutch bearing bath

drain the oil and disconnect the oil line.

Remove the body by moving towards yourself

clutch bearing together with the clutch and

clutch engagement disc.

At

installation of the clutch bearing

check the correct position

oil ring, which must be

in the groove of the bearing. For removal

brake pulley remove the pulley, clutch

clutch, clutch bearing, guides

clutch keys and brake pulley. For removal

drive shaft remove the drive

pulley, clutch, clutch bearing,

disconnect the stuffing box housing from. beds

and by moving towards themselves they take out the leader

shaft.

Buttermaker

repaired at the place of its installation in

production shop

plant without removal from the foundation.

Repair

oil producers of continuous

actions. On

wear of parts and assembly

units of the oil producer in a significant

degree is affected by increased vibration

machines at work. Wearable

oil maker parts are

bearings, springs, bushings, cuffs,

V-belts of variators, which

when worn, replace. Most details

and assembly units of the machine are

relatively easy to remove.

Installation

oil manufacturer. Oil producers

Oil producers

with cylindrical drums

in wooden packaging. Allowed

supply of oil makers on wooden

skid without packaging. After unpacking

the machine is cleaned and treated

surfaces remove the anti-corrosion

lubricant. Buttermaker set

on the foundation, calibrate according to the level in

longitudinal and transverse directions.

For alignment in the longitudinal direction

level is placed on top

bed and inside the machine along the axial

beams, and in the transverse direction – on

upper part of the bed n pa planed

board resting on ties that fasten

stand with a stand. Align

machine by metal level

pads placed under the paws

beds, and a machine for this

lifted with jacks, which

installed under the flanges of the drum, with

obligatory gasket between the flange

and jacking hardwood block

tree. Installation accuracy in longitudinal

and transverse directions should be

0.1-0.2 mm.

After reconciliation and

fixing the oil maker on

foundation in an oil bath is poured

oil Industrial-45 to the middle

index glass and in accordance

with lubrication map applied

to the passport of the car, lubricate all rubbing

parts.

ROLLERLESS

OIL PRODUCERS OF PERIODIC

ACTION

Oil producers

periodic action are

most dynamic machines

working with high vibrations

and pushes. Therefore, they are mounted on

massive concrete foundation and

attached to it with foundation bolts.

The oil manufacturer is checked by level,

which is installed in the longitudinal

and transverse directions to the top

the edge of the bed (with the guard removed

– bed cover) and, in addition, in

longitudinal direction – along the axis

tank beams (barrels). For example

consider the rules of operation

oil producers of MM brands.

Preparation for

operation and cleaning of the oil maker

produced in accordance with the instructions

for its operation in the presence

production foreman or

site.

The barrel is being filled

40% of its geometric capacity,

which corresponds to the level of cream,

located slightly below the axial

beams, after which they close the hatch cover

and fasten it to the body of the barrel.:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/7747085/nrel_typical_wind_turbine_drivetrain.png)

Before launch

check the presence of oil in the oil lines,

raise the fence, fix it

latch, and the control lever is moved

to the lowest position and fix

latch. Then turn on the motor.

To turn on the drum, the lever is slowly

avoidance of shocks is transferred to the extreme

top position and fix it.

In this case, the barrel should rotate along

clockwise when looking at it

from the drive side. Fixing

control levers in the lower and upper

provisions is necessary in order to

did not spontaneously turn on

or disengagement of the friction clutch

clutch.

Temperature

whipping cream, washing modes and

oil treatment is chosen depending on

from the requirements of technological

oil production process.

To stop

buttermaker control lever

slowly move to the lowest

position so that the barrel stops

hatch to the worker, after which they turn off

electric motor. Oil is unloaded

from the barrel through the hatch. During operation

oil manufacturer must observe

safety regulations.

Electric motor and housing oil-manufacturer

must be reliably grounded. Before

start-up of the oil maker, it is necessary

check cap tightness

hatch and correct position

fencing. Starting and installation of the barrel

only allowed to be done with a lever

control, i.e. you can not let the barrel

direct inclusion

electric motor with the clutch engaged

clutch.During the operation of the oil maker

you can not stop the barrel with your hands,

open the cover of the bed (guard

drive mechanism), remove the guard

belt drive, lower guard

barrels, lubricate the machine. It is forbidden

open the air valve if it

is not in the highest position

rotate the barrel with the hatch and faucet open

for the descent of buttermilk, to work when out of order

brake, move the electric motor

for tensioning belts during operation

machines. Passages near the oil refinery

should not be cluttered, the floor should not

must be slippery.

OIL PRODUCERS

CONTINUOUS OPERATION A1-OLO/1

This oil manufacturer

included in the domestic line

butter production method

continuous churning A1-OLO

with a productivity of 1000 kg/h.

When mounting the frame

oil maker is installed on

floor on four shock absorbers, and free

end of auger texturer (processor)

placed on a removable stand. Pump

for flushing water attached to the foundation

foundation bolts. Vacuum pump

installed on the stove.

ice water

(2-3°C) is supplied from the evaporator of the refrigeration

plant installations or receive

directly in the oil workshop

plate cooler.

At the end

installation is carried out hydraulically

oil maker test: pipelines

product is tested for leaks

at a pressure of 0.3 MPa, installing at the end

test area plug;

pipelines for ice and washing

water – at a pressure of 1.0 MPa.

Launch preparation.

Before the first start-up of the oil maker

after its depreservation and lubrication

check the correct connection

all pipelines, tightening of detachable

compounds, solution according to the instructions

manufacturer, after which

rinse with cold (8-14 ° C) water.

Dosing tank

moisture 6 and the pump is washed with fresh drinking

water temperature 14.-16 ° C and fill

tank of this water.

Surge tank

/ filled with mature cream fat

37-42%, acidity 13-17°T and temperature,

equal to the churning temperature. Temperature

churning cream set in

depending on their fat content, time

year and type of oil produced.

Button.7 (Fig. 21)

include an ice water pump that

turning on the toggle switch 15 is fed into the cylinder

beater, and toggle switch 13 – in a shirt

texturer.

Start. Button 12

turn on the beater drive and install

frequency beat for 100-200 min 1

above the value required for a given

type of oil, with gem to exclude

cream getting into the texturer.

Button 11 turns on the drive of the augers-texturator

and the variator sets the required

their frequency. rotation. Open the faucet at

beater and button 10 turn on

dosing pump for pumping cream into

beater, then open the taps on

buttermilk lines and variator ‘-smoothly reduce

beater speed up to

required value.

With the help of a tumbler

16 supply water for washing the oil

grains. Periodically to the filter mesh

turning on the toggle switch 14 serves pasteurized

chilled (8-14 ° C) water * / or buttermilk for

mesh washing. For this, you can apply

as well as purified compressed air. button

9 include a buttermilk pump. Siphon for

buttermilk outlet is installed in such

position so that in the first screw

chamber, the shafts of the augers were covered with buttermilk.

Performance

dosing pump for cream after it

start is gradually increased to

required value.

First regulation

oil grain size produce

by changing the churning speed: at

speed increase grain size

increases. With the correct first

oil grain size adjustment

buttermilk should flow out of the siphon

light green streaks.

Then adjust

frequency of rotation of texturer screws.

In this case, the oil should come out evenly.

continuous tape.

Include tape

conveyor.

When the oil comes out

from the texturer nozzle .required

turn on the vacuum pump 5 (see Fig. 20).

Pre-check tightness

duct connections, installation

vacuum gauge, open approximately

half vacuum control valve

l button 5 (see Fig. 21) turn on the vacuum pump.

First, with the help of the regulator

valves set a vacuum of about

200 mmHg st., after a few minutes

increase the vacuum to 300 mm Hg. Art., not

allowing moisture to be removed from

oils. The maximum allowable vacuum

in the processing chamber must exceed

500 mmHg Art.

1-2 minutes after

oil coming out of the texturizer nozzle

take a sample for content analysis

moisture in oil. The first portions of oil

removed on a special table and normalized

up to standard moisture content in

packaging process.

When the oil comes out

with low moisture content (15.0—

15.2%) include a donation machine

moisture 6 (Fig. 20), for which they attach

flexible hoses to the injection block

texturer and turn on the electric motor

apparatus.

Butter former.

Butter former and filling table

installed on a clean floor

mounts. Their position is regulated by

level and plumb with adjustable

supports, which are then fixed with locknuts.

Assembling the oil former plate

set according to their ordinal

numbering (beginning of numbering from the reference

plates). After assembling the oil former

using the handle, the drive is scrolled

manually. Rotation should not

jamming and extraneous noise. Pickle

and product systems are tested on

water density.

Exploitation

oil former.

Job

oil former. At the start of work,

3-5 min before feeding into the oil former

high-fat cream, open the valves

and served in the cylinder jackets cold

water and brine.

open the faucet

for air release in the cover of the top

cylinder. At the same time, the valve at the oil outlet

should be closed. Not including

electric motor, oil former

high-fat cream is pumped from

baths. Cylinder filling continues

Cylinder filling continues

few seconds. As soon as through

air faucet will start to flow cream,

it is closed. When air is released under

faucet substitute mug for collection

cream.

After filling

cream cylinders open the faucet on

oil outlet, the regulator is set to the position

minimum output, include

oil-forming motor and

displacement drums start

rotate. When the temperature drops

oil outlet up to 11°С by regulator

increase the oil yield

to keep its temperature at

within 12-15°С. During this time from

oil former, 15-20 kg of oil will flow out,

which is collected in a tub, shifted

into the bath and mixed with hot

high fat cream. When the temperature

oil reaches the required limits,

a box for oil is placed under the outlet valve.

In the established mode of operation in

will be needed only occasionally

control the outlet temperature

oils. outlet oil temperature and

oil-former cooling mode is not

are uniform and permanent. Mode

depends on geographic area, time

year, as well as the composition of the cream. In factories

In factories

should choose the most rational

mode to get high oil

quality with normal consistency.

During work

butter-former high-fat cream

should flow continuously and evenly.

With forced short

a break in the buttermaker is needed

turn off the brine and water supply, do not

turning off the motor. If the break

prolonged, must be stopped

brine and water supply, turn off

electric motor and release the rest

water and brine from cylinders. oil can

harden then into cylinder jackets

let in hot water or steam for

several minutes until the cylinders

the displacement drums will also warm up

can rotate freely. After that

turn on the electric motor, turn off

hot water or steam supply

cold water and brine and install

normal operating mode.

Faults

oil refinery

Fault | Reason | Solution |

Insufficient Insufficient Increased Reduced | Mismatch Insufficient Cream Clogged Too much Mala Siphon | Lead disassemble Increase serve cream Boost Cool water Increase |

Spare parts for feeding lines, manure removal, feeding and others. | Sprut technology

Vacuum conveyor/manipulator suction cup

Universal suction pads for particularly uneven workpieces or when height compensation is required.

They are used in the woodworking, packaging and metalworking industries.

Complete range of vacuum cups here>>>

Pressure roller assembly with bushings of the manure conveyor Farmer Automatic

Plate (washer) of the roller of the pressing conveyor of manure removal Farmer Automatic

Conveyor bushings for the line of manure removal Farmer Automatic

Pressing roller for manure removal conveyor Phaeton

Coupling (square) connecting system nipple drinking Big Dutchman

Repair kit for manure removal line “Techno”, Big Dutchman

Drive gears Z=16 and Z=27 of manure removal belt Big Dutchman

Rubber coupling

Coupling safety feed line ROXELL

Heat-resistant wheels 160*40*20 and 125*38*12 for smoking frames

Springs for scissors

Cleaner Air Motor Housing

Stainless disc knives with a diameter of 100mm to 350mm, a thickness of 2. 0-3.5mm and different sharpening angles.

0-3.5mm and different sharpening angles.

Set of knives and gratings for the top K7-FVP-200

Set of knives and grids for the top LM-82P

Plates and screw incubator HATCHER

Carcass elevator bracket FPP-EPT 2100

99

99 92

92 ..

.. 99

99 99

99 99

99 99

99 99

99 5—0.75 MPa Increase

5—0.75 MPa Increase