What are the key features of the Brine Clutch Friction ’16 Lacrosse Attack Shaft. How does it enhance player performance on the field. Is this shaft worth the investment for serious lacrosse players.

The Evolution of Lacrosse Attack Shafts: Introducing the Brine Clutch Friction ’16

The lacrosse equipment industry has seen significant advancements in recent years, with manufacturers constantly striving to create gear that enhances player performance. Among these innovations, the Brine Clutch Friction ’16 Lacrosse Attack Shaft stands out as a game-changer for offensive players. This 30-inch shaft has garnered attention for its unique design and performance-enhancing features.

A Brief History of Brine in Lacrosse

Brine has been a prominent name in the lacrosse world for decades. Founded in 1922, the company has consistently pushed the boundaries of equipment design and technology. Their commitment to innovation has resulted in products that cater to players of all skill levels, from beginners to professionals.

Design and Construction: Breaking Down the Brine Clutch Friction ’16

The Brine Clutch Friction ’16 Attack Shaft is a marvel of engineering, combining cutting-edge materials with thoughtful design elements. Here’s a closer look at its construction:

- Material: High-grade aluminum alloy

- Length: 30 inches (76.2 cm)

- Weight: Approximately 190 grams

- Finish: Proprietary friction texture

- Color: Green (as per the product description)

The shaft’s lightweight nature is a crucial factor in its performance. How does the weight of a lacrosse shaft affect a player’s game? A lighter shaft allows for quicker stick movements, faster shots, and more precise ball control. The Brine Clutch Friction ’16, weighing just 190 grams, provides players with the agility needed for high-level offensive play.

The Friction Advantage: Enhancing Grip and Control

One of the standout features of the Brine Clutch Friction ’16 is its proprietary friction texture. This innovative finish addresses a common challenge faced by lacrosse players: maintaining a secure grip on the shaft during intense gameplay.

The friction texture serves multiple purposes:

- Improved handling in all weather conditions

- Reduced need for excessive tape usage

- Enhanced feel and connection between player and stick

- Increased confidence during cradling and shooting

Does the friction texture really make a difference in gameplay? Many players report a noticeable improvement in their ability to maintain control of the stick, especially during quick directional changes and in wet conditions. This enhanced grip can translate to more accurate passes and shots, potentially giving players a competitive edge on the field.

Performance on the Field: Real-World Application

While the technical specifications of the Brine Clutch Friction ’16 are impressive, the true test of any lacrosse equipment lies in its on-field performance. Players who have used this shaft consistently praise its balance of strength and lightweight design.

Key performance benefits include:

- Increased shot velocity due to reduced weight

- Improved accuracy in passing and shooting

- Enhanced maneuverability during dodges and fakes

- Reduced fatigue during extended play

How does the Brine Clutch Friction ’16 compare to other attack shafts on the market? While individual preferences vary, many players find that the combination of lightweight construction and innovative grip technology gives the Clutch Friction ’16 an edge over traditional shafts.

Durability and Longevity: Investing in Quality

For serious lacrosse players, the durability of equipment is a significant concern. The Brine Clutch Friction ’16 is designed to withstand the rigors of high-level play, including aggressive checks and ground ball battles.

Factors contributing to the shaft’s durability include:

- High-grade aluminum alloy construction

- Reinforced stress points

- Corrosion-resistant finish

Is the Brine Clutch Friction ’16 worth the investment? While the initial cost may be higher than some entry-level shafts, many players find that the performance benefits and durability make it a worthwhile long-term investment. The shaft’s ability to maintain its performance characteristics over time can potentially save money in the long run by reducing the need for frequent replacements.

Customization and Personalization: Making It Your Own

While the Brine Clutch Friction ’16 comes in a striking green color, many players enjoy further customizing their equipment to reflect their personal style or team colors. The shaft’s surface is compatible with various customization techniques, allowing players to create a unique look.

Popular customization options include:

- Custom vinyl wraps

- Personalized engravings

- Team decals and stickers

- Colored tape accents

Can customizing your lacrosse shaft impact performance? While aesthetic modifications generally don’t affect the shaft’s performance, some players find that personalization increases their confidence and connection to their equipment, potentially leading to improved play on the field.

The Brine Clutch Friction ’16 in Competitive Play

The adoption of equipment at higher levels of play often serves as a testament to its quality and performance. The Brine Clutch Friction ’16 has been embraced by players at various competitive levels, from high school to college and even professional leagues.

Notable aspects of its use in competitive play include:

- Popularity among leading scorers in college lacrosse

- Adoption by professional players known for their shooting accuracy

- Positive feedback from coaches regarding player performance improvement

How has the Brine Clutch Friction ’16 influenced playing styles at competitive levels? Some coaches report that players using this shaft demonstrate increased confidence in their stick skills, leading to more aggressive and dynamic offensive play. The shaft’s lightweight nature and enhanced grip have allowed players to execute complex maneuvers with greater ease and precision.

Maintenance and Care: Preserving Your Investment

To ensure the longevity and optimal performance of the Brine Clutch Friction ’16, proper maintenance is essential. While the shaft is designed for durability, regular care can significantly extend its lifespan and maintain its performance characteristics.

Key maintenance tips include:

- Regular cleaning with mild soap and water to remove dirt and sweat

- Inspecting for any signs of damage or wear after each game or practice

- Storing in a cool, dry place away from direct sunlight

- Avoiding exposure to extreme temperatures

- Periodically checking and tightening the head attachment

How often should you replace your lacrosse shaft? With proper care, the Brine Clutch Friction ’16 can last for several seasons of regular play. However, it’s important to monitor for any signs of significant wear or damage that could affect performance or safety. Many players choose to replace their shaft every 1-2 years, depending on the intensity and frequency of use.

The Environmental Aspect: Sustainability in Lacrosse Equipment

As environmental concerns become increasingly important across all industries, it’s worth considering the sustainability aspects of lacrosse equipment. While the Brine Clutch Friction ’16 is not marketed specifically as an eco-friendly product, its durability contributes to sustainability by reducing the frequency of replacements.

Considerations for environmentally conscious players:

- The aluminum used in the shaft is recyclable

- Longer lifespan means less frequent disposal of equipment

- Potential for repurposing or donating used shafts

Can lacrosse equipment manufacturers do more to promote sustainability? As awareness grows, there may be opportunities for companies like Brine to explore more eco-friendly materials and production processes without compromising on performance.

The Future of Lacrosse Attack Shafts: What’s Next?

The Brine Clutch Friction ’16 represents a significant step forward in lacrosse shaft technology, but innovation in the sport never stops. As players continue to push the boundaries of performance, equipment manufacturers are likely to respond with even more advanced designs.

Potential future developments in attack shaft technology may include:

- Integration of smart technology for performance tracking

- Development of new, even lighter materials

- Advanced ergonomic designs for improved handling

- Customizable flex points for personalized performance

How might these advancements change the game of lacrosse? As equipment becomes more sophisticated, it could lead to changes in playing styles, training methods, and even rule adaptations to ensure fair play.

The Role of Player Feedback in Product Development

The success of products like the Brine Clutch Friction ’16 often stems from manufacturers’ willingness to incorporate player feedback into their design process. This collaborative approach between players and equipment makers has driven much of the innovation in lacrosse gear.

Ways player feedback influences product development:

- Identifying pain points in existing equipment

- Suggesting new features or improvements

- Providing real-world performance data

- Testing prototypes in game situations

How can players contribute to the evolution of lacrosse equipment? Many manufacturers actively seek feedback through surveys, sponsored athletes, and direct engagement with the lacrosse community. Players at all levels can potentially influence future designs by sharing their experiences and ideas with equipment makers.

Comparing the Brine Clutch Friction ’16 to Competitors

While the Brine Clutch Friction ’16 has made a significant impact in the lacrosse equipment market, it’s important to consider how it stacks up against other popular attack shafts. This comparison can help players make informed decisions based on their specific needs and playing style.

Key factors to consider when comparing attack shafts:

- Weight and balance

- Durability and strength

- Grip technology

- Price point

- Brand reputation and warranty

How does the Brine Clutch Friction ’16 compare to other top attack shafts? While specific comparisons would require in-depth testing, many players report that the Clutch Friction ’16 offers a unique combination of lightweight design and enhanced grip that sets it apart from competitors. However, personal preference plays a significant role in equipment choice, and what works best for one player may not be ideal for another.

The Importance of Trying Before Buying

Given the personal nature of equipment preferences, it’s advisable for players to test different shafts before making a purchase. Many retailers and team suppliers offer demo programs or trial periods that allow players to experience the Brine Clutch Friction ’16 and other shafts in real game situations.

Benefits of trying before buying:

- Assessing the shaft’s feel and balance

- Evaluating the effectiveness of the friction texture

- Comparing performance to your current equipment

- Determining if the shaft complements your playing style

Where can players test out the Brine Clutch Friction ’16? In addition to specialty lacrosse retailers, many teams and clubs have relationships with equipment suppliers that may provide access to demo products. Lacrosse camps and clinics are also excellent opportunities to try out new equipment.

Making the Investment: Is the Brine Clutch Friction ’16 Right for You?

Deciding whether to invest in the Brine Clutch Friction ’16 Lacrosse Attack Shaft ultimately comes down to a combination of factors, including your skill level, playing style, budget, and personal preferences. While the shaft offers numerous advantages, it’s important to consider your individual needs and goals as a player.

Factors to consider when making your decision:

- Your current skill level and areas for improvement

- The level of competition you typically face

- Your budget for lacrosse equipment

- The importance of cutting-edge technology in your game

- Your long-term goals in the sport

Is the Brine Clutch Friction ’16 suitable for all players? While the shaft’s features can benefit players at various skill levels, it may be particularly valuable for more experienced players who can fully utilize its advanced design. Beginners may find that more budget-friendly options suffice as they develop their skills.

The Long-Term Value Proposition

When considering the cost of the Brine Clutch Friction ’16, it’s important to look beyond the initial price tag and evaluate the long-term value it provides. High-quality equipment that enhances performance and lasts longer can be a wise investment for dedicated players.

Potential long-term benefits of investing in quality equipment:

- Improved performance leading to greater enjoyment of the sport

- Reduced need for frequent replacements

- Potential for better results in competitive play

- Increased confidence in your gear during crucial moments

How can players maximize the value of their investment in the Brine Clutch Friction ’16? Proper care and maintenance, as discussed earlier, are crucial. Additionally, fully committing to learning and utilizing the shaft’s features in your training and gameplay will help you realize its full potential.

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

– CMD Sports

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

– CMD Sports

Skip to content

Regular price

$139.95

Sale price$89.95

Save 36%

/

Tax included.

Colour

—

GREEN

Colour

GREEN

Size

Size

30″

Quantity

Australian stock ready to ship

Low stock – 2 items left

GREEN / 30″ – $89.95 AUD

[{“id”:42304262406316,”title”:”GREEN \/ 30\””,”option1″:”GREEN”,”option2″:”30\””,”option3″:null,”sku”:”LSh59534 GREEN”,”requires_shipping”:true,”taxable”:true,”featured_image”:{“id”:34584189370540,”product_id”:7549046227116,”position”:1,”created_at”:”2022-12-22T08:35:26+11:00″,”updated_at”:”2023-06-29T17:00:26+10:00″,”alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”width”:2048,”height”:2048,”src”:”\/\/cmdsports. com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}]

com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}]

{“id”:42304262406316,”title”:”GREEN \/ 30\””,”option1″:”GREEN”,”option2″:”30\””,”option3″:null,”sku”:”LSh59534 GREEN”,”requires_shipping”:true,”taxable”:true,”featured_image”:{“id”:34584189370540,”product_id”:7549046227116,”position”:1,”created_at”:”2022-12-22T08:35:26+11:00″,”updated_at”:”2023-06-29T17:00:26+10:00″,”alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”width”:2048,”height”:2048,”src”:”\/\/cmdsports. com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}

com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″,”variant_ids”:[42304262406316]},”available”:true,”name”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\” – GREEN \/ 30\””,”public_title”:”GREEN \/ 30\””,”options”:[“GREEN”,”30\””],”price”:8995,”weight”:190,”compare_at_price”:13995,”inventory_management”:”shopify”,”barcode”:”026585426400″,”featured_media”:{“alt”:”Brine Clutch Friction ’16 Lacrosse Attack Shaft 30\””,”id”:27074256732332,”position”:1,”preview_image”:{“aspect_ratio”:1.0,”height”:2048,”width”:2048,”src”:”\/\/cmdsports.com.au\/cdn\/shop\/products\/2299486_source_1576767174.jpg?v=1688022026″}},”requires_selling_plan”:false,”selling_plan_allocations”:[]}

Brine Clutch Friction ’16 Lacrosse Attack Shaft 30″

{% else %}

{% endif %}

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

+{{ plus_btn_text }}

{% endif %}

{% elsif display_option == “button”%}

{{ option.name }}

- {% assign swatch_i = 1 %}

- +{{ plus_btn_text }}

{% assign plus_btn_text = 0 %}

{% for swatch in option.values %}

{% assign will_hide_swatch = false %}

{% if buttons_to_show > 0 and swatch_i > buttons_to_show %}

{% assign will_hide_swatch = true %}

{% endif %}

{% if will_hide_swatch == true %}

{% assign plus_btn_text = plus_btn_text | plus:1 %}

{% endif %} id}}” data-handle=”{{ product.handle | escape }}”>

{{ swatch }}

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

{% endif %}

{% elsif display_option == “dropdown-list” %}

{{ option.name }}

{% for swatch in option.values %}

{{ swatch }}

{% endfor %}

{% else %}

{{ option. name }}

name }}

- {% assign swatch_i = 1 %}

- +{{ plus_btn_text }}

{% assign plus_btn_text = 0 %}

{% for swatch in option.values %}

{% assign variantImageUrl = ” %}

{% for c_variant in product.variants %}

{% if variantImageUrl == ”%}

{% assign c_option_index = 0 %}

{% for c_option in c_variant.options %}

{% if c_option_index == parentIndex %}

{% if c_option == swatch%}

{% assign variantImageUrl = c_variant.featured_image.src %}

{% break %}

{% endif %}

{% endif %}

{% assign c_option_index = c_option_index | plus: 1 %}

{% endfor %}

{% endif %}

{% endfor %}

{% assign will_hide_swatch = false %}

{% if swatches_to_show > 0 and swatch_i > swatches_to_show %}

{% assign will_hide_swatch = true %}

{% endif %}

{% if will_hide_swatch == true %}

{% assign plus_btn_text = plus_btn_text | plus:1 %}

{% endif %} id}}” data-handle=”{{ product.handle | escape }}”>

{% assign swatch_i = swatch_i | plus: 1 %}

{% endfor %}

{% if plus_btn_text > 0 and page_type_collection == true and show_sold_out_variants == true %}

{% endif %}

{% endif %}

{% assign parentIndex = parentIndex | plus: 1 %}

{% endfor %}

Men’s Lacrosse Defense & Attack Shafts

Men’s Lacrosse Defense & Attack Shafts | Everysportforless.com

Search

Shafts | Handles – Mens

Sort By:

Featured ItemsNewest ItemsBest SellingA to ZZ to ABy ReviewPrice: AscendingPrice: Descending

Products Per Page:

812162040100

Columns:

1

2

3

4

6

On Sale

Choose Options

Quick view

Adidas Dipped FREAK Alloy Lacrosse Attack Shaft 30″ – Various Colors

adidas

MSRP:

$109.

99

99Now:

$44.92

Was:

$58.99

Adidas Dipped FREAK Alloy Lacrosse Attack Shaft 30″ – Various Colors

Model: Dipped FREAK

Model Number: CF320

Size: Attack 30″

Colors: Purple, Pink, Orange, Carolina Blue, Lime, Yellow

Lacrosse Attack Shaft

100% Authentic Adidas Product

We Buy…MSRP:

$109.99

Now:

$44.92

Was:

$58.99

Choose Options

Quick view

Add to Cart

Quick view

Adidas VXR-800 Alloy Lacrosse Attack Shaft 30″ – Silver, Blue

adidas

MSRP:

$44.99

Now:

$24.

92

92Adidas VXR-800 Alloy Lacrosse Attack Shaft 30″ – Silver, Blue

Model: VXR-800 Alloy

Color: Silver, Blue

Size: Attack 30″

Lacrosse Attack Shaft

100% Authentic Adidas Product

We Buy Direct From Adidas to Save You Money!

Features

Rubber End…LSH6659

On Sale

Add to Cart

Quick view

Brine F15 Silver Limited Edition SMU Lacrosse Attack Shaft 30″

Brine

MSRP:

$99.99

Now:

$17.92

Was:

$28.92

Brine F15 Silver Limited Edition SMU Lacrosse Attack Shaft 30″

Model: F15

Model Number: F15FG SL OSZ

Colors: Silver

Weight: 5.3 oz w/o Butt End

Size: 30″ Attack

Lacrosse Attack Shaft

Features

Premium Grade 7000 Alloy Material

Limited Edition -. ..

..LSH55926

MSRP:

$99.99

Now:

$17.92

Was:

$28.92

Add to Cart

Quick view

On Sale

Add to Cart

Quick view

Brine F22 Flip Lacrosse Attack Shaft 30″ – Vegas Gold

Brine

MSRP:

$89.99

Now:

$17.92

Was:

$32.92

Brine F22 Flip Lacrosse Attack Shaft 30″

Model: F22

Model Number: 22S GOV OSZ

Color: Vegas Gold

Size: 30″ Attack

Weight: 6.2 oz w/o Butt End

Lacrosse Attack Shaft

Features

“Vegas” Version – No Graphics

Lightweight, Durable

Ideal for Attack…LSH55996

MSRP:

$89.

99

99Now:

$17.92

Was:

$32.92

Add to Cart

Quick view

Choose Options

Quick view

Brine King Beat Lacrosse Defense Shaft 60″ – Various Colors

Brine

Now:

$45.92 – $48.92Brine King Beat Lacrosse Defense Shaft 60″ – Various Colors

Model: King Beat

Model Number: KNGSWB6D

Colors: Black, Carolina, Royal, Chrome, Navy, Forest, Orange

Size: Defense 60″

Lacrosse Defense Shaft

Features

Ergonomic Grip

Rubber…Add to Cart

Quick view

Maverik Mission Blank Lacrosse Attack Shaft 30″ – White

Maverik

Now:

$114.

99

99Maverik Mission Blank Lacrosse Attack Shaft 30″ – White

Model: Mission Blank

Model Number: 3002526

Color: White

Size: Attack 30″

Lacrosse Attack Shaft

Features

Scandium Alloy

Bead Blasted Finish for grip

Completely Blank of…LSh59067

Add to Cart

Quick view

Maverik Mission Blank Lacrosse Defensive Shaft 60″ – White

Maverik

Now:

$159.99

Maverik Mission Blank Lacrosse Defensive Shaft 60″ – White

Model: Mission Blank

Model Number: 3002592

Color: White

Size: Defense 60″

Lacrosse Defensive Shaft

Features

Scandium Alloy

Bead Blasted Finish for grip

Completely Blank of…LSh59068

Quick view

Maverik Wonder Boy 2020 Lacrosse Attack Shaft 30″ – Various Colors

Maverik

Now:

$84.

99

99Maverik Wonder Boy 2020 Lacrosse Attack Shaft 30″ – Various Colors

Model: Wonder Boy 2020

Model Number: 3002540

Colors: Black, Gray, White

Size: Attack 30″

Lacrosse Attack Shaft

Features

Ideal for an All-Around Midfielder

Matte Finish for an…Now:

$84.99

Quick view

Add to Cart

Quick view

StringKing Metal 3 Pro 30″ Attack Lacrosse Shaft

StringKing

Now:

$109.99

StringKing Metal 3 Pro 30″ Attack Lacrosse Shaft

Model: Metal 3 Pro

Size: Attack 30″

155 grams – Ages 14 to 17

Lacrosse Men’s Attack Shaft

Made with premium alloy and precise manufacturing, Metal 3 Pro lacrosse shafts deliver the performance you…LSH57407

Choose Options

Quick view

StringKing Metal 3 Pro Defense Lacrosse Shaft 60″ – Various Colors

StringKing

Now:

$179.

99

99StringKing Metal 3 Pro Defense Lacrosse Shaft 60″

Model: Metal 3 Pro

Size: Defense 60″

360 grams – Ages 15 and under

Lacrosse Men’s D-Pole

Made with premium alloy and precise manufacturing, Metal 3 Pro lacrosse shafts deliver the performance…Choose Options

Quick view

StringKing Metal 3 Pro Lacrosse Attack Shaft 30″ – Various Colors

StringKing

Now:

$99.99

StringKing Metal 3 Pro Lacrosse Attack Shaft 30″ – Various Colors

Model: Metal 3 Pro

Model Number: ITM-0003770

Colors: Black, Silver

Size: Attack 30″

Lacrosse Attack Shaft

Features

135 Grams

Consistent, Durable Performance

Comes with a Roll…Add to Cart

Quick view

STX Alliance VFT Men’s Lacrosse Attack Shaft – White

STX

Now:

$139.

99

99STX Alliance VFT Men’s Lacrosse Attack Shaft – White

Model: Alliance VFT

Model Number: HE CAX8 76

Color: White

Shaft: 32″ Attack

Position: Attack

Men’s Lacrosse Attack Shaft

Features

Raised Texture

Soft Touch Finish

High Grip Rubber…LSh45694

1,2,3,5 Oil formers. Oil producers.

Repair.

Wear parts

oil formers are gears,

gears, bearings and seals

gearbox gaskets, rubber gaskets

between covers and cylinder bodies.

In addition, there is a collapse of the drum

due to overpressure

product, cracks form in the drum,

into which the product enters wear out

pin, trunnion (half shaft) and drum knives,

bronze bushing in cylinder covers,

shank (fork) of the gearbox shaft, packing

omentum, etc. Causes of premature

wear of fastening parts of drums in

cylinders serve incorrect installation

drum in the cylinder, as well as inaccurate

adjustment of the drum in the axial direction.

When repairing

oil former worn parts

and crumpled drums are replaced. Product,

caught in the drum, removed by heating

drum with steam or hot water, after

what cracks weld. If it is needed

repair gear parts

it is dismantled, oil is drained from the crankcase and,

unscrew the nuts, remove from the studs

electric motor with gear.

In the presence of

oil leaks gasket replace

new. Then remove the gearbox cover

which is enough to replace the gears and

gear wheels. Replacement if necessary

the drum drive shaft is disassembled

gearbox, remove the gear wheel,

disassemble the gland, unscrew the screws

and take out the shaft along with the ball bearings.

Reducer assemble

in reverse order of disassembly. Wherein

after installing the gearbox cover

manually check the ease of rotation

gears and gears when installing

engine gear must enter into

gear engagement. After

assembly, oil is poured into the gearbox.

Corrosion of metal wears out

walls of cylinder jackets, pipes and

fittings for supplying water and brine.

Buttermaker.

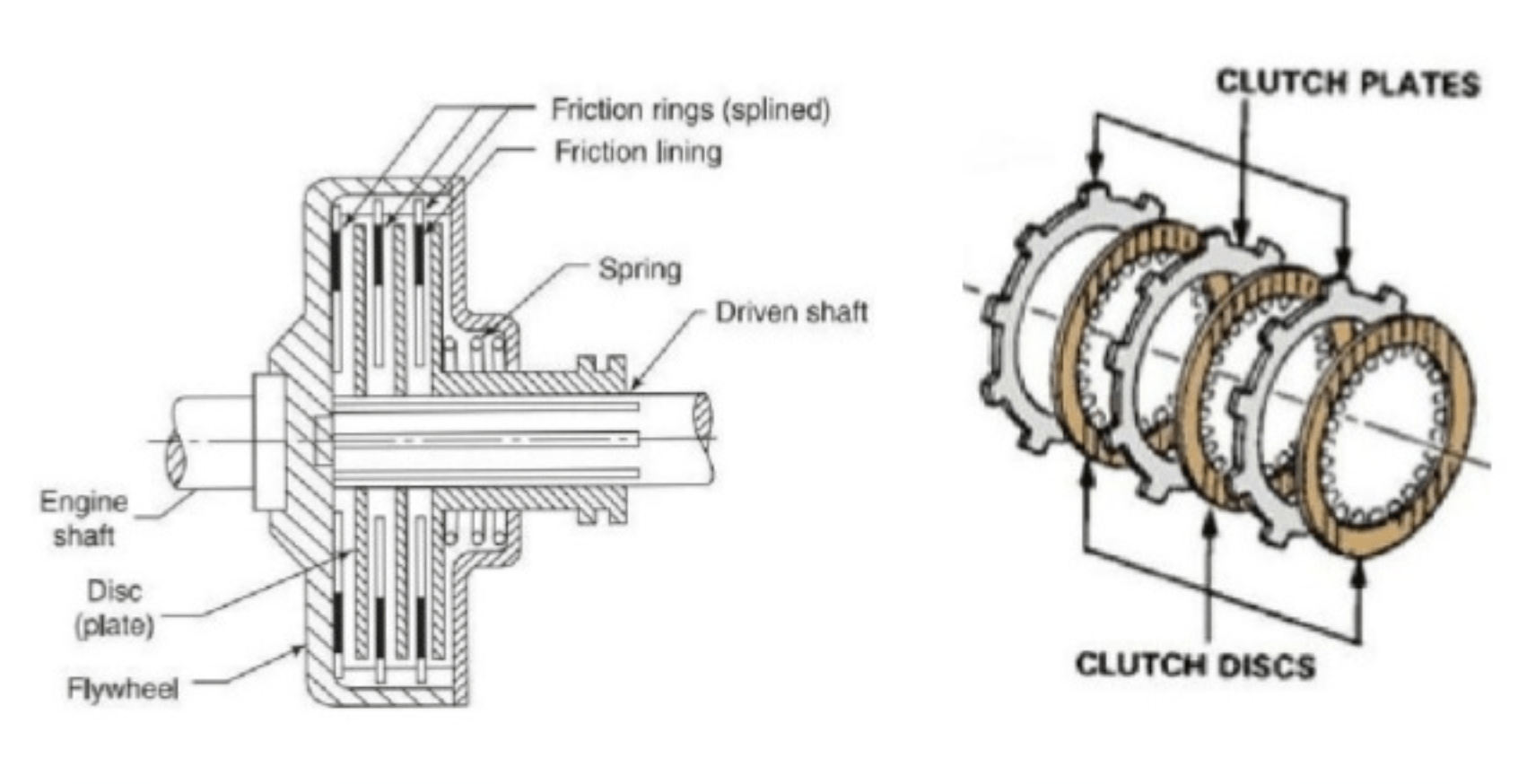

Wearable

oil maker parts are

v-belts, ferrodo tape

friction clutch, bronze bushings,

steel drive gear. springs

clutch and band brake,

which are replaced when worn. For replacement

worn parts during repair

the oil manufacturer is removed from it

separate

assembly units in the following order,

For

removal of the leading (in relation to the clutch

clutch) pulley control lever

move to a lower position

– the locking screw in the drive nut

shaft, unscrew this nut, after which

remove the pulley from the shaft.

Withdrawal

clutch and bearing housing

couplings begin by removing the pulley.

Then unscrew the bolts securing the housing

clutch bearing; filmed

two bolts connecting the control lever

with a cam disc for engaging the clutch.

From the clutch bearing bath

drain the oil and disconnect the oil line.

Remove the body by moving towards yourself

clutch bearing together with the clutch and

clutch engagement disc.

At

installation of the clutch bearing

check the correct position

oil ring, which must be

in the groove of the bearing. For removal

brake pulley remove the pulley, clutch

clutch, clutch bearing, guides

clutch keys and brake pulley. For removal

drive shaft remove the drive

pulley, clutch, clutch bearing,

disconnect the stuffing box housing from. beds

and by moving towards themselves they take out the leader

shaft.

Buttermaker

repaired at the place of its installation in

production shop

plant without removal from the foundation.

Repair

oil producers of continuous

actions. On

wear of parts and assembly

units of the oil producer in a significant

degree is affected by increased vibration

machines at work. Wearable

oil maker parts are

bearings, springs, bushings, cuffs,

V-belts of variators, which

when worn, replace. Most details

and assembly units of the machine are

relatively easy to remove.

Installation

oil manufacturer. Oil producers

Oil producers

with cylindrical drums

in wooden packaging. Allowed

supply of oil makers on wooden

skid without packaging. After unpacking

the machine is cleaned and treated

surfaces remove the anti-corrosion

lubricant. Buttermaker set

on the foundation, calibrate according to the level in

longitudinal and transverse directions.

For alignment in the longitudinal direction

level is placed on top

bed and inside the machine along the axial

beams, and in the transverse direction – on

upper part of the bed n pa planed

board resting on ties that fasten

stand with a stand. Align

machine by metal level

pads placed under the paws

beds, and a machine for this

lifted with jacks, which

installed under the flanges of the drum, with

obligatory gasket between the flange

and jacking hardwood block

tree. Installation accuracy in longitudinal

and transverse directions should be

0.1-0.2 mm.

After reconciliation and

fixing the oil maker on

foundation in an oil bath is poured

oil Industrial-45 to the middle

index glass and in accordance

with lubrication map applied

to the passport of the car, lubricate all rubbing

parts.

ROLLERLESS

OIL PRODUCERS OF PERIODIC

ACTION

Oil producers

periodic action are

most dynamic machines

working with high vibrations

and pushes. Therefore, they are mounted on

massive concrete foundation and

attached to it with foundation bolts.

The oil manufacturer is checked by level,

which is installed in the longitudinal

and transverse directions to the top

the edge of the bed (with the guard removed

– bed cover) and, in addition, in

longitudinal direction – along the axis

tank beams (barrels). For example

consider the rules of operation

oil producers of MM brands.

Preparation for

operation and cleaning of the oil maker

produced in accordance with the instructions

for its operation in the presence

production foreman or

site.

The barrel is being filled

40% of its geometric capacity,

which corresponds to the level of cream,

located slightly below the axial

beams, after which they close the hatch cover

and fasten it to the body of the barrel.

Before launch

check the presence of oil in the oil lines,

raise the fence, fix it

latch, and the control lever is moved

to the lowest position and fix

latch. Then turn on the motor.

To turn on the drum, the lever is slowly

avoidance of shocks is transferred to the extreme

top position and fix it.

In this case, the barrel should rotate along

clockwise when looking at it

from the drive side. Fixing

control levers in the lower and upper

provisions is necessary in order to

did not spontaneously turn on

or disengagement of the friction clutch

clutch.

Temperature

whipping cream, washing modes and

oil treatment is chosen depending on

from the requirements of technological

oil production process.

To stop

buttermaker control lever

slowly move to the lowest

position so that the barrel stops

hatch to the worker, after which they turn off

electric motor. Oil is unloaded

from the barrel through the hatch. During operation

oil manufacturer must observe

safety regulations.

Electric motor and housing oil-manufacturer

must be reliably grounded. Before

start-up of the oil maker, it is necessary

check cap tightness

hatch and correct position

fencing. Starting and installation of the barrel

only allowed to be done with a lever

control, i.e. you can not let the barrel

direct inclusion

electric motor with the clutch engaged

clutch.During the operation of the oil maker

you can not stop the barrel with your hands,

open the cover of the bed (guard

drive mechanism), remove the guard

belt drive, lower guard

barrels, lubricate the machine. It is forbidden

open the air valve if it

is not in the highest position

rotate the barrel with the hatch and faucet open

for the descent of buttermilk, to work when out of order

brake, move the electric motor

for tensioning belts during operation

machines. Passages near the oil refinery

should not be cluttered, the floor should not

must be slippery.

OIL PRODUCERS

CONTINUOUS OPERATION A1-OLO/1

This oil manufacturer

included in the domestic line

butter production method

continuous churning A1-OLO

with a productivity of 1000 kg/h.

When mounting the frame

oil maker is installed on

floor on four shock absorbers, and free

end of auger texturer (processor)

placed on a removable stand. Pump

for flushing water attached to the foundation

foundation bolts. Vacuum pump

installed on the stove.

ice water

(2-3°C) is supplied from the evaporator of the refrigeration

plant installations or receive

directly in the oil workshop

plate cooler.

At the end

installation is carried out hydraulically

oil maker test: pipelines

product is tested for leaks

at a pressure of 0.3 MPa, installing at the end

test area plug;

pipelines for ice and washing

water – at a pressure of 1.0 MPa.

Launch preparation.

Before the first start-up of the oil maker

after its depreservation and lubrication

check the correct connection

all pipelines, tightening of detachable

compounds, solution according to the instructions

manufacturer, after which

rinse with cold (8-14 ° C) water.

Dosing tank

moisture 6 and the pump is washed with fresh drinking

water temperature 14.-16 ° C and fill

tank of this water.

Surge tank

/ filled with mature cream fat

37-42%, acidity 13-17°T and temperature,

equal to the churning temperature. Temperature

churning cream set in

depending on their fat content, time

year and type of oil produced.

Button.7 (Fig. 21)

include an ice water pump that

turning on the toggle switch 15 is fed into the cylinder

beater, and toggle switch 13 – in a shirt

texturer.

Start. Button 12

turn on the beater drive and install

frequency beat for 100-200 min 1

above the value required for a given

type of oil, with gem to exclude

cream getting into the texturer.

Button 11 turns on the drive of the augers-texturator

and the variator sets the required

their frequency. rotation. Open the faucet at

beater and button 10 turn on

dosing pump for pumping cream into

beater, then open the taps on

buttermilk lines and variator ‘-smoothly reduce

beater speed up to

required value.

With the help of a tumbler

16 supply water for washing the oil

grains. Periodically to the filter mesh

turning on the toggle switch 14 serves pasteurized

chilled (8-14 ° C) water * / or buttermilk for

mesh washing. For this, you can apply

as well as purified compressed air. button

9 include a buttermilk pump. Siphon for

buttermilk outlet is installed in such

position so that in the first screw

chamber, the shafts of the augers were covered with buttermilk.

Performance

dosing pump for cream after it

start is gradually increased to

required value.

First regulation

oil grain size produce

by changing the churning speed: at

speed increase grain size

increases. With the correct first

oil grain size adjustment

buttermilk should flow out of the siphon

light green streaks.

Then adjust

frequency of rotation of texturer screws.

In this case, the oil should come out evenly.

continuous tape.

Include tape

conveyor.

When the oil comes out

from the texturer nozzle .required

turn on the vacuum pump 5 (see Fig. 20).

Pre-check tightness

duct connections, installation

vacuum gauge, open approximately

half vacuum control valve

l button 5 (see Fig. 21) turn on the vacuum pump.

First, with the help of the regulator

valves set a vacuum of about

200 mmHg st., after a few minutes

increase the vacuum to 300 mm Hg. Art., not

allowing moisture to be removed from

oils. The maximum allowable vacuum

in the processing chamber must exceed

500 mmHg Art.

1-2 minutes after

oil coming out of the texturizer nozzle

take a sample for content analysis

moisture in oil. The first portions of oil

removed on a special table and normalized

up to standard moisture content in

packaging process.

When the oil comes out

with low moisture content (15.0—

15.2%) include a donation machine

moisture 6 (Fig. 20), for which they attach

flexible hoses to the injection block

texturer and turn on the electric motor

apparatus.

Butter former.

Butter former and filling table

installed on a clean floor

mounts. Their position is regulated by

level and plumb with adjustable

supports, which are then fixed with locknuts.

Assembling the oil former plate

set according to their ordinal

numbering (beginning of numbering from the reference

plates). After assembling the oil former

using the handle, the drive is scrolled

manually. Rotation should not

jamming and extraneous noise. Pickle

and product systems are tested on

water density.

Exploitation

oil former.

Job

oil former. At the start of work,

3-5 min before feeding into the oil former

high-fat cream, open the valves

and served in the cylinder jackets cold

water and brine.

open the faucet

for air release in the cover of the top

cylinder. At the same time, the valve at the oil outlet

should be closed. Not including

electric motor, oil former

high-fat cream is pumped from

baths. Cylinder filling continues

Cylinder filling continues

few seconds. As soon as through

air faucet will start to flow cream,

it is closed. When air is released under

faucet substitute mug for collection

cream.

After filling

cream cylinders open the faucet on

oil outlet, the regulator is set to the position

minimum output, include

oil-forming motor and

displacement drums start

rotate. When the temperature drops

oil outlet up to 11°С by regulator

increase the oil yield

to keep its temperature at

within 12-15°С. During this time from

oil former, 15-20 kg of oil will flow out,

which is collected in a tub, shifted

into the bath and mixed with hot

high fat cream. When the temperature

oil reaches the required limits,

a box for oil is placed under the outlet valve.

In the established mode of operation in

will be needed only occasionally

control the outlet temperature

oils. outlet oil temperature and

oil-former cooling mode is not

are uniform and permanent. Mode

depends on geographic area, time

year, as well as the composition of the cream. In factories

In factories

should choose the most rational

mode to get high oil

quality with normal consistency.

During work

butter-former high-fat cream

should flow continuously and evenly.

With forced short

a break in the buttermaker is needed

turn off the brine and water supply, do not

turning off the motor. If the break

prolonged, must be stopped

brine and water supply, turn off

electric motor and release the rest

water and brine from cylinders. oil can

harden then into cylinder jackets

let in hot water or steam for

several minutes until the cylinders

the displacement drums will also warm up

can rotate freely. After that

turn on the electric motor, turn off

hot water or steam supply

cold water and brine and install

normal operating mode.

Faults

oil refinery

Fault | Reason | Solution |

Insufficient Insufficient Increased Reduced | Mismatch Insufficient Cream Clogged Too much Mala Siphon | Lead disassemble Increase serve cream Boost Cool water Increase |

Spare parts for feeding lines, manure removal, feeding and others. | Sprut technology

Vacuum conveyor/manipulator suction cup

Universal suction pads for particularly uneven workpieces or when height compensation is required.

They are used in the woodworking, packaging and metalworking industries.

Complete range of vacuum cups here>>>

Pressure roller assembly with bushings of the manure conveyor Farmer Automatic

Plate (washer) of the roller of the pressing conveyor of manure removal Farmer Automatic

Conveyor bushings for the line of manure removal Farmer Automatic

Pressing roller for manure removal conveyor Phaeton

Coupling (square) connecting system nipple drinking Big Dutchman

Repair kit for manure removal line “Techno”, Big Dutchman

Drive gears Z=16 and Z=27 of manure removal belt Big Dutchman

Rubber coupling

Coupling safety feed line ROXELL

Heat-resistant wheels 160*40*20 and 125*38*12 for smoking frames

Springs for scissors

Cleaner Air Motor Housing

Stainless disc knives with a diameter of 100mm to 350mm, a thickness of 2. 0-3.5mm and different sharpening angles.

0-3.5mm and different sharpening angles.

Set of knives and gratings for the top K7-FVP-200

Set of knives and grids for the top LM-82P

Plates and screw incubator HATCHER

Carcass elevator bracket FPP-EPT 2100

99

99 92

92 ..

.. 99

99 99

99 99

99 99

99 99

99 5—0.75 MPa Increase

5—0.75 MPa Increase