Why Ecd Carbon Mtx is a Game Changing TechnologyWhy Ecd Carbon Mtx is a Game Changing Technology

Revolutionary Mechanism Converts CO2 into Fuels

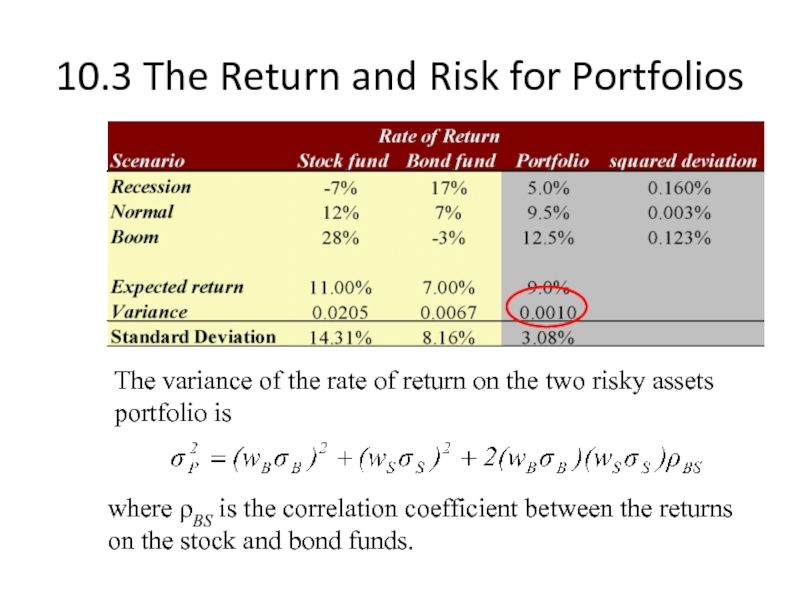

Carbon Mtx represents a major breakthrough in carbon capture and utilization technology. At the heart of this system is a novel catalyst that can efficiently convert waste carbon dioxide into useful liquid fuels and chemicals. This gives Carbon Mtx the unique ability to not just remove CO2, but also repurpose it into valuable products.

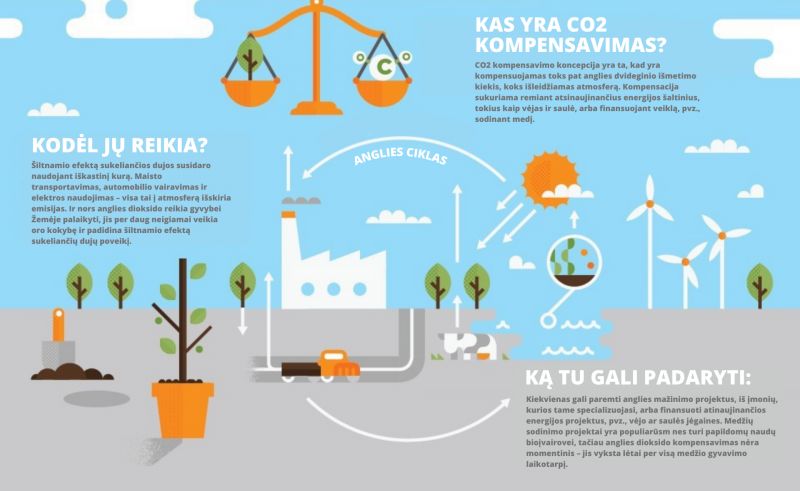

The conversion process works by first capturing CO2 emissions before they enter the atmosphere. This CO2 is then fed into a specialized reactor filled with the proprietary Carbon Mtx catalyst. When heated, this catalyst facilitates a series of chemical reactions that combine the CO2 molecules with hydrogen to form new compounds like methanol, diesel fuel, and olefins.

What makes the Carbon Mtx catalyst so revolutionary is its high selectivity and conversion rates. The catalyst is meticulously engineered at the molecular level to promote the desired chemical transformations with minimal side reactions. Under optimal conditions, the reactor can achieve CO2 conversion rates of over 90% into purified fuel products.

Because of this exceptional performance, Carbon Mtx technology has the potential to significantly reduce the overall carbon footprint across a range of industries. For example, a Carbon Mtx facility integrated with a cement plant could capture the CO2 emissions and convert them into diesel to power the plant’s operations. This would create a closed-loop cycle that takes waste CO2 and turns it into something productive.

The fuels and chemicals created through the Carbon Mtx process can readily displace conventional fossil fuels in the market. This provides a built-in economic incentive by generating revenue from the products. The technology is also modular and scalable, allowing widespread deployment across emissions-heavy sectors like transportation, manufacturing, and power generation.

With Carbon Mtx, we now have a pathway for repurposing carbon waste into valuable commodities. The technology represents a true breakthrough that could help accelerate the global transition to a sustainable, low-carbon economy.

Scalable and Cost-Effective Carbon Removal

One of the major advantages of Carbon Mtx technology is its potential to enable affordable, large-scale carbon removal. This scalability and cost-effectiveness makes Carbon Mtx a practical solution for decarbonizing emissions-heavy industries and reaching global climate goals.

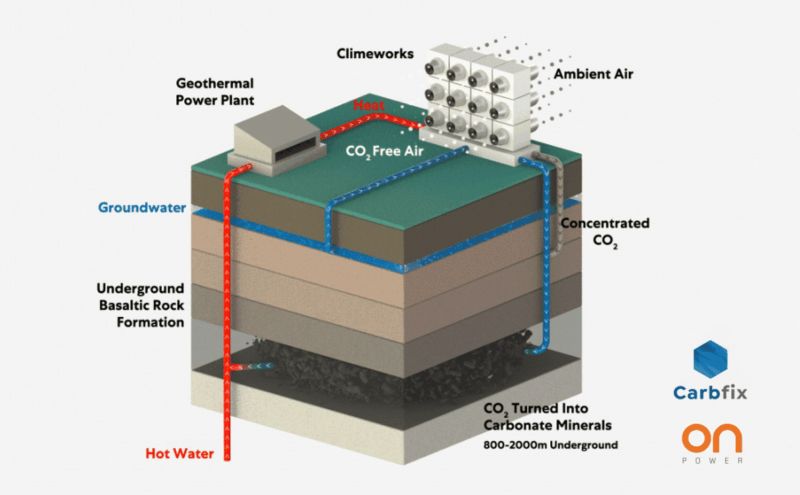

Current carbon removal methods often involve direct air capture, which uses large towers to extract CO2 from ambient air. While technically feasible, these approaches are extremely energy intensive and have prohibitively high operating costs at large scales. In contrast, Carbon Mtx provides a more efficient and economical approach by capturing concentrated CO2 directly at the source, before it enters the atmosphere.

The modular design of Carbon Mtx facilities also allows the technology to be scaled up in a flexible manner. The components like the CO2 capture units, catalytic reactors, and product purification can be built at standardized sizes and replicated as needed. This modular configuration makes it straightforward to right-size a Carbon Mtx plant for any industry or application.

Economic modeling indicates that with sufficient scale, the costs of CO2 captured and utilized via Carbon Mtx could reach as low as $50 per ton. At these prices, Carbon Mtx can realistically compete with conventional fossil fuels and make substantial emissions reductions affordable. What’s more, the value generated from the fuel products offers additional cost offsets.

Widespread deployment of Carbon Mtx could remove gigatons of CO2 annually across the manufacturing, transportation, and energy sectors. When combined with other decarbonization efforts, this technology represents a viable path for limiting global warming to 1.5°C in line with the Paris Agreement.

With both technical and economic viability, Carbon Mtx stands out as a scalable, cost-competitive carbon removal solution. The modular nature of the technology also allows it to grow incrementally to match the needs of different industries and markets. This high scalability makes Carbon Mtx a flexible option for affordable decarbonization.

Creates Clean Fuel from Waste CO2

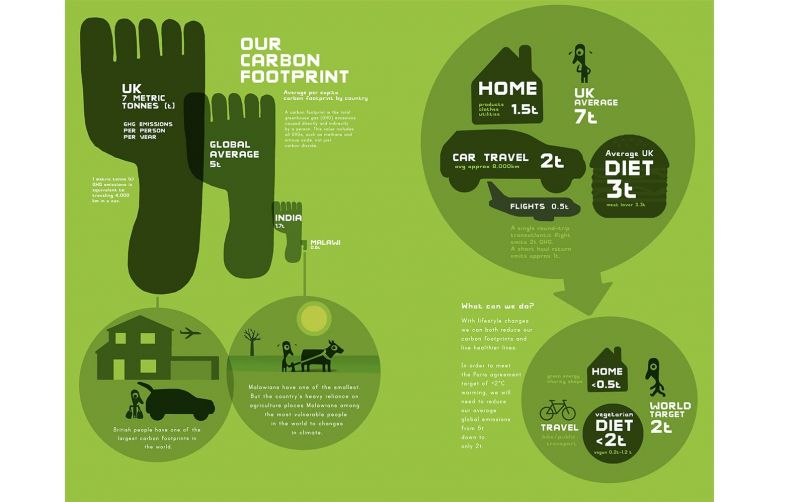

One of the most groundbreaking aspects of Carbon Mtx technology is its ability to convert carbon dioxide emissions into usable, low-carbon fuels. This provides a method of not just capturing CO2, but also transforming it into sustainable liquid fuel products.

The fuels created through the Carbon Mtx process include methanol, diesel, and olefins. These are synthesized by reacting waste CO2 with hydrogen in the presence of the proprietary catalyst. The resulting liquid fuels are ultra-clean burning with virtually no sulfur or particulates when combusted.

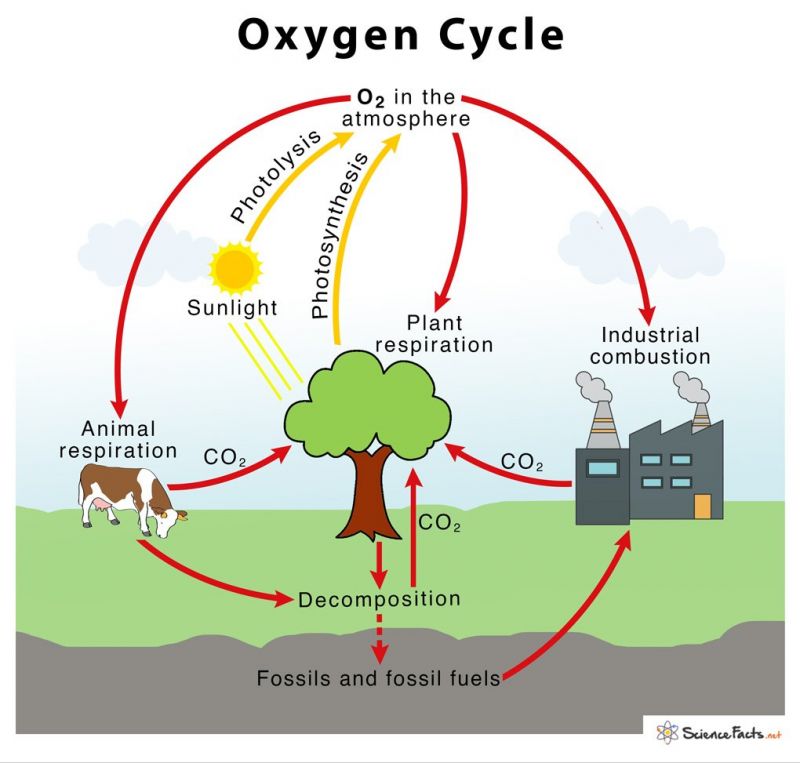

Because these fuels are derived from waste CO2, they have very low lifecycle carbon intensity compared to conventional fossil fuels. In a sense, the fuels are circular – their carbon comes from CO2 that was already in the atmosphere before being recaptured and repurposed. This closed carbon loop greatly reduces the overall greenhouse impact.

The ability to produce clean fuels and chemicals from CO2 emissions provides significant environmental and economic benefits. It enables continued use of liquid fuels in transportation, heating, and industrial processes while lowering net emissions. The fuel products can also generate revenue to help offset the costs of carbon capture.

In many energy-intensive sectors, directly electrifying processes may not always be feasible. Carbon Mtx offers a way to decarbonize these systems through drop-in, CO2-derived fuels. For example, low-carbon diesel and jet fuel could decarbonize heavy transport like shipping, aviation, and haulage.

With Carbon Mtx technology, we have an avenue to develop the next generation of carbon-neutral fuels. Converting CO2 waste into usable liquids helps close the carbon cycle while enabling sustainable energy usage across the global economy.

Mitigates Climate Change While Creating Value

What sets the Carbon MTX catalyst apart?

- High selectivity for desired chemical transformations

- Minimal side reactions

- CO2 conversion rates exceeding 90% under optimal conditions

- Production of purified fuel products

This exceptional performance gives Carbon MTX technology the potential to significantly reduce the overall carbon footprint across various industries. For instance, integrating a Carbon MTX facility with a cement plant could capture CO2 emissions and convert them into diesel to power the plant’s operations, creating a closed-loop cycle that transforms waste CO2 into a productive resource.

The Wide-Ranging Applications of Carbon MTX Technology

The fuels and chemicals produced through the Carbon MTX process can readily replace conventional fossil fuels in the market. This built-in economic incentive generates revenue from the products while simultaneously addressing environmental concerns. The technology’s modular and scalable nature allows for widespread deployment across emissions-heavy sectors such as transportation, manufacturing, and power generation.

With Carbon MTX, we now have a viable pathway for repurposing carbon waste into valuable commodities. This technology represents a true breakthrough that could help accelerate the global transition to a sustainable, low-carbon economy.

Which industries can benefit from Carbon MTX technology?

- Cement production

- Steel manufacturing

- Power generation

- Chemical industry

- Transportation sector

Scalability and Cost-Effectiveness: Key Advantages of Carbon MTX

One of the major advantages of Carbon MTX technology is its potential to enable affordable, large-scale carbon removal. This scalability and cost-effectiveness make Carbon MTX a practical solution for decarbonizing emissions-heavy industries and reaching global climate goals.

Current carbon removal methods often involve direct air capture, which uses large towers to extract CO2 from ambient air. While technically feasible, these approaches are extremely energy-intensive and have prohibitively high operating costs at large scales. In contrast, Carbon MTX provides a more efficient and economical approach by capturing concentrated CO2 directly at the source, before it enters the atmosphere.

How does the modular design of Carbon MTX facilities contribute to its scalability?

The modular design of Carbon MTX facilities allows the technology to be scaled up in a flexible manner. Components such as CO2 capture units, catalytic reactors, and product purification systems can be built at standardized sizes and replicated as needed. This modular configuration makes it straightforward to right-size a Carbon MTX plant for any industry or application.

Economic modeling indicates that with sufficient scale, the costs of CO2 captured and utilized via Carbon MTX could reach as low as $50 per ton. At these prices, Carbon MTX can realistically compete with conventional fossil fuels and make substantial emissions reductions affordable. Moreover, the value generated from the fuel products offers additional cost offsets.

The Potential Impact of Carbon MTX on Global Emissions Reduction

Widespread deployment of Carbon MTX could remove gigatons of CO2 annually across the manufacturing, transportation, and energy sectors. When combined with other decarbonization efforts, this technology represents a viable path for limiting global warming to 1.5°C in line with the Paris Agreement.

With both technical and economic viability, Carbon MTX stands out as a scalable, cost-competitive carbon removal solution. The modular nature of the technology also allows it to grow incrementally to match the needs of different industries and markets. This high scalability makes Carbon MTX a flexible option for affordable decarbonization.

Can Carbon MTX technology significantly contribute to achieving global climate goals?

Yes, Carbon MTX has the potential to play a crucial role in achieving global climate goals. By providing a scalable and cost-effective method for carbon capture and utilization, it can help reduce emissions across multiple industries. Its ability to convert waste CO2 into valuable products also creates economic incentives for adoption, potentially accelerating the transition to a low-carbon economy.

Clean Fuel Production: A Game-Changing Feature of Carbon MTX

One of the most groundbreaking aspects of Carbon MTX technology is its ability to convert carbon dioxide emissions into usable, low-carbon fuels. This provides a method of not just capturing CO2, but also transforming it into sustainable liquid fuel products.

The fuels created through the Carbon MTX process include methanol, diesel, and olefins. These are synthesized by reacting waste CO2 with hydrogen in the presence of the proprietary catalyst. The resulting liquid fuels are ultra-clean burning with virtually no sulfur or particulates when combusted.

What are the environmental benefits of fuels produced by Carbon MTX?

- Lower carbon footprint compared to conventional fossil fuels

- Reduced sulfur and particulate emissions

- Circular economy approach to fuel production

- Potential reduction in dependency on fossil fuel extraction

Because these fuels are derived from waste CO2, they have a significantly lower carbon footprint compared to conventional fossil fuels. When used in vehicles or industrial processes, they can help reduce overall greenhouse gas emissions while still providing the energy density and performance required for various applications.

The Role of Carbon MTX in Promoting a Circular Economy

Carbon MTX technology plays a crucial role in promoting a circular economy approach to carbon management. By capturing waste CO2 and converting it into useful products, it creates a closed-loop system that minimizes waste and maximizes resource efficiency.

This circular approach has several advantages:

- Reduces dependency on virgin fossil fuel resources

- Decreases the amount of CO2 released into the atmosphere

- Creates value from what was previously considered waste

- Encourages industries to view CO2 as a resource rather than a pollutant

The ability to create a circular economy for carbon is particularly important in hard-to-decarbonize sectors such as heavy industry and long-distance transportation. In these areas, Carbon MTX can provide a pathway to significantly reduce emissions while maintaining necessary industrial processes and energy needs.

How does Carbon MTX contribute to industrial symbiosis?

Carbon MTX technology can facilitate industrial symbiosis, where the waste or byproducts from one industry become the raw materials for another. For example, CO2 emissions from a steel plant could be captured and converted into fuels using Carbon MTX. These fuels could then be used to power the plant itself or sold to other industries, creating a mutually beneficial ecosystem of resource efficiency and waste reduction.

Addressing Challenges and Future Developments in Carbon MTX Technology

While Carbon MTX technology shows great promise, there are still challenges to overcome for widespread adoption and maximum effectiveness. Addressing these challenges will be crucial for realizing the full potential of this innovative carbon capture and utilization solution.

What are some key challenges facing Carbon MTX technology?

- Scaling up production to meet global demand

- Optimizing energy efficiency in the conversion process

- Ensuring a sustainable source of hydrogen for fuel production

- Navigating regulatory frameworks and carbon pricing mechanisms

- Integrating with existing industrial infrastructure

Researchers and engineers are actively working on these challenges, with ongoing developments aimed at improving the efficiency and scalability of Carbon MTX technology. Future advancements may include:

- Enhanced catalyst designs for higher conversion rates and selectivity

- Integration with renewable energy sources for more sustainable operation

- Development of novel reactor designs for improved energy efficiency

- Exploration of new product streams beyond current fuel options

- Advancements in CO2 capture technologies to reduce overall costs

As these developments progress, Carbon MTX technology is expected to become an increasingly vital tool in the global effort to combat climate change and transition to a sustainable, low-carbon economy.

The Potential Economic Impact of Carbon MTX Implementation

The widespread adoption of Carbon MTX technology could have significant economic implications across various sectors. By creating value from waste CO2, this technology has the potential to generate new revenue streams, create jobs, and stimulate innovation in the clean energy sector.

How might Carbon MTX technology affect job markets and economic growth?

The implementation of Carbon MTX technology could lead to job creation in several areas:

- Engineering and construction of Carbon MTX facilities

- Operation and maintenance of carbon capture and conversion plants

- Research and development for ongoing technology improvements

- Supply chain management for new fuel distribution networks

- Regulatory and compliance roles related to carbon management

Furthermore, the development of a robust carbon utilization industry could stimulate economic growth by:

- Reducing dependence on imported fossil fuels

- Creating new markets for CO2-derived products

- Improving the competitiveness of industries in regions with stringent carbon regulations

- Attracting investment in clean technology and sustainable infrastructure

The economic benefits of Carbon MTX could extend beyond direct job creation and revenue generation. By helping to mitigate the impacts of climate change, this technology could also contribute to avoiding the potentially enormous economic costs associated with unchecked global warming.

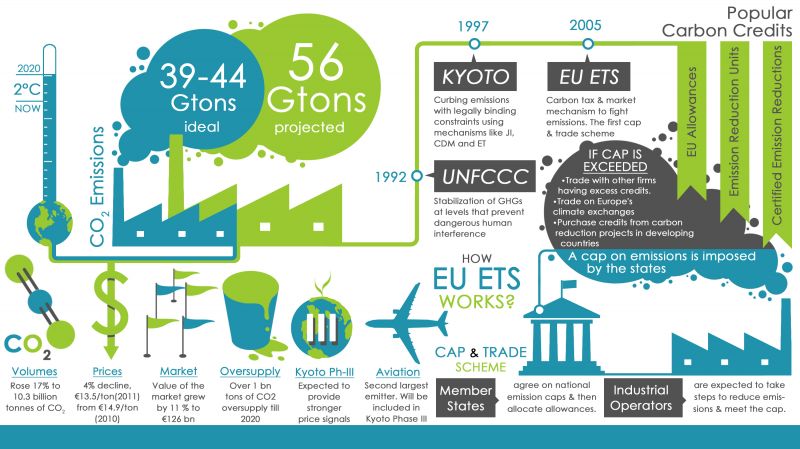

What role might government policies play in promoting Carbon MTX adoption?

Government policies and incentives could play a crucial role in accelerating the adoption of Carbon MTX technology. Potential policy measures might include:

- Carbon pricing mechanisms that make CO2 utilization more economically attractive

- Research and development grants for further technology improvements

- Tax incentives for industries implementing Carbon MTX systems

- Regulatory frameworks that recognize and reward carbon-negative fuel production

- Public-private partnerships to fund large-scale demonstration projects

By creating a supportive policy environment, governments can help overcome initial barriers to adoption and accelerate the deployment of this promising technology.

The Global Perspective: Carbon MTX’s Role in International Climate Efforts

As countries around the world strive to meet their commitments under the Paris Agreement and other international climate accords, technologies like Carbon MTX could play a crucial role in achieving global emissions reduction targets.

How might Carbon MTX contribute to national and international climate strategies?

Carbon MTX technology could contribute to climate strategies in several ways:

- Helping countries meet their Nationally Determined Contributions (NDCs) under the Paris Agreement

- Providing a pathway for hard-to-abate sectors to reduce their carbon footprint

- Facilitating the transition to a low-carbon economy in developing nations

- Supporting the development of negative emissions technologies needed to achieve net-zero targets

- Promoting international cooperation on climate technology transfer and capacity building

The global nature of the climate challenge requires solutions that can be implemented across diverse economic and geographical contexts. Carbon MTX’s scalability and adaptability make it well-suited to address this need, potentially becoming a key component of the global climate technology portfolio.

What role could Carbon MTX play in international carbon markets?

As international carbon markets continue to evolve, Carbon MTX technology could play a significant role in several ways:

- Generating high-quality carbon credits through verifiable emissions reductions

- Providing a mechanism for carbon-intensive industries to offset their emissions

- Creating opportunities for cross-border carbon trading and technology transfer

- Supporting the development of robust methodologies for accounting carbon utilization in emissions inventories

The integration of Carbon MTX into international carbon markets could help drive investment in the technology and accelerate its global deployment, contributing to more rapid progress in emissions reduction efforts worldwide.

Revolutionary Mechanism Converts CO2 into Fuels

Carbon Mtx represents a major breakthrough in carbon capture and utilization technology. At the heart of this system is a novel catalyst that can efficiently convert waste carbon dioxide into useful liquid fuels and chemicals. This gives Carbon Mtx the unique ability to not just remove CO2, but also repurpose it into valuable products.

The conversion process works by first capturing CO2 emissions before they enter the atmosphere. This CO2 is then fed into a specialized reactor filled with the proprietary Carbon Mtx catalyst. When heated, this catalyst facilitates a series of chemical reactions that combine the CO2 molecules with hydrogen to form new compounds like methanol, diesel fuel, and olefins.

What makes the Carbon Mtx catalyst so revolutionary is its high selectivity and conversion rates. The catalyst is meticulously engineered at the molecular level to promote the desired chemical transformations with minimal side reactions. Under optimal conditions, the reactor can achieve CO2 conversion rates of over 90% into purified fuel products.

Because of this exceptional performance, Carbon Mtx technology has the potential to significantly reduce the overall carbon footprint across a range of industries. For example, a Carbon Mtx facility integrated with a cement plant could capture the CO2 emissions and convert them into diesel to power the plant’s operations. This would create a closed-loop cycle that takes waste CO2 and turns it into something productive.

The fuels and chemicals created through the Carbon Mtx process can readily displace conventional fossil fuels in the market. This provides a built-in economic incentive by generating revenue from the products. The technology is also modular and scalable, allowing widespread deployment across emissions-heavy sectors like transportation, manufacturing, and power generation.

With Carbon Mtx, we now have a pathway for repurposing carbon waste into valuable commodities. The technology represents a true breakthrough that could help accelerate the global transition to a sustainable, low-carbon economy.

Scalable and Cost-Effective Carbon Removal

One of the major advantages of Carbon Mtx technology is its potential to enable affordable, large-scale carbon removal. This scalability and cost-effectiveness makes Carbon Mtx a practical solution for decarbonizing emissions-heavy industries and reaching global climate goals.

Current carbon removal methods often involve direct air capture, which uses large towers to extract CO2 from ambient air. While technically feasible, these approaches are extremely energy intensive and have prohibitively high operating costs at large scales. In contrast, Carbon Mtx provides a more efficient and economical approach by capturing concentrated CO2 directly at the source, before it enters the atmosphere.

The modular design of Carbon Mtx facilities also allows the technology to be scaled up in a flexible manner. The components like the CO2 capture units, catalytic reactors, and product purification can be built at standardized sizes and replicated as needed. This modular configuration makes it straightforward to right-size a Carbon Mtx plant for any industry or application.

Economic modeling indicates that with sufficient scale, the costs of CO2 captured and utilized via Carbon Mtx could reach as low as $50 per ton. At these prices, Carbon Mtx can realistically compete with conventional fossil fuels and make substantial emissions reductions affordable. What’s more, the value generated from the fuel products offers additional cost offsets.

Widespread deployment of Carbon Mtx could remove gigatons of CO2 annually across the manufacturing, transportation, and energy sectors. When combined with other decarbonization efforts, this technology represents a viable path for limiting global warming to 1.5°C in line with the Paris Agreement.

With both technical and economic viability, Carbon Mtx stands out as a scalable, cost-competitive carbon removal solution. The modular nature of the technology also allows it to grow incrementally to match the needs of different industries and markets. This high scalability makes Carbon Mtx a flexible option for affordable decarbonization.

Creates Clean Fuel from Waste CO2

One of the most groundbreaking aspects of Carbon Mtx technology is its ability to convert carbon dioxide emissions into usable, low-carbon fuels. This provides a method of not just capturing CO2, but also transforming it into sustainable liquid fuel products.

The fuels created through the Carbon Mtx process include methanol, diesel, and olefins. These are synthesized by reacting waste CO2 with hydrogen in the presence of the proprietary catalyst. The resulting liquid fuels are ultra-clean burning with virtually no sulfur or particulates when combusted.

Because these fuels are derived from waste CO2, they have very low lifecycle carbon intensity compared to conventional fossil fuels. In a sense, the fuels are circular – their carbon comes from CO2 that was already in the atmosphere before being recaptured and repurposed. This closed carbon loop greatly reduces the overall greenhouse impact.

The ability to produce clean fuels and chemicals from CO2 emissions provides significant environmental and economic benefits. It enables continued use of liquid fuels in transportation, heating, and industrial processes while lowering net emissions. The fuel products can also generate revenue to help offset the costs of carbon capture.

In many energy-intensive sectors, directly electrifying processes may not always be feasible. Carbon Mtx offers a way to decarbonize these systems through drop-in, CO2-derived fuels. For example, low-carbon diesel and jet fuel could decarbonize heavy transport like shipping, aviation, and haulage.

With Carbon Mtx technology, we have an avenue to develop the next generation of carbon-neutral fuels. Converting CO2 waste into usable liquids helps close the carbon cycle while enabling sustainable energy usage across the global economy.

Mitigates Climate Change While Creating Value

Carbon Mtx represents a climate solution that goes beyond just reducing emissions – it can actively remove CO2 from the air while also generating economic value. This ability to mitigate climate change and create marketable products makes Carbon Mtx a double-bottom line technology.

Most carbon removal solutions focus solely on capturing and storing CO2, with no additional value creation. In contrast, Carbon Mtx utilizes the carbon it captures as a feedstock to manufacture fuels and chemicals that can be sold. This built-in revenue source improves commercial viability.

Capturing and using CO2 enables Carbon Mtx to reduce emissions from hard-to-abate sectors like heavy industry and transportation. The CO2-derived fuels from Carbon Mtx displace the need for fossil fuels in these markets. This drives down net emissions, mitigating climate change.

At the same time, the demand for sustainable liquid fuels and chemicals is projected to grow considerably in the coming decades. As the market expands, Carbon Mtx allows companies to tap into this demand while benefiting the climate. The CO2-based products offer a revenue opportunity and incentive for adoption.

Carbon Mtx creates a scenario where companies can take meaningful climate action while gaining an additional profit center through CO2 utilization. This value-added component improves the business case for investment in Carbon Mtx facilities.

With both climate and economic benefits, Carbon Mtx represents a holistic approach to emission mitigation. The technology captures carbon while also producing marketable fuels and chemicals – enabling climate progress and business growth at once.

Cuts Emissions Across Industries Like Aviation

One major application where Carbon Mtx can have an outsized climate impact is reducing emissions from the aviation industry. By producing lower-carbon jet fuel, Carbon Mtx provides a pathway for decarbonizing this hard-to-abate but essential sector.

Aviation currently accounts for 2-3% of global carbon emissions and is one of the fastest growing sources. However, fully electrifying air travel is not feasible with current battery densities. An alternative solution is needed to lower emissions without curtailing air transportation.

Here Carbon Mtx presents a viable option – by capturing point-source CO2 from industries like oil refining and steel manufacturing, Carbon Mtx can synthesize clean, low-carbon jet fuel. This CO2-derived jet fuel can directly replace conventional fossil jet fuel, reducing lifecycle carbon intensity by up to 80%.

The lower-carbon jet fuel enables airlines to reduce the emissions associated with their operations and meet sustainability targets. As Carbon Mtx scales up, it could supply a significant share of global aviation fuel demand with ultra-low carbon intensity.

Similarly, Carbon Mtx can cut emissions from marine shipping through low-carbon bunker fuel production. Across transportation sectors, the technology provides a drop-in fuel solution to lower emissions without disrupting operations.

For vital industries like aviation that are difficult to electrify, Carbon Mtx unlocks new options for deep decarbonization. By commercializing CO2-based jet fuel, Carbon Mtx can enable sustainable air travel and help the aviation industry reduce its carbon footprint.

Powers the Transition to Sustainable Energy

Carbon Mtx technology can play an integral role in enabling the global transition to renewable energy systems. By converting CO2 into fuels, Carbon Mtx provides a way to store intermittent renewable electricity in the form of stable, transportable liquid fuels.

The variability of wind and solar poses challenges for grid management as renewables grow. Excess renewable electricity is often curtailed and wasted. Carbon Mtx offers a solution – using renewable power to produce hydrogen through electrolysis, which can then be combined with captured CO2 to synthesize renewable fuels.

These fuels, like diesel and jet fuel made from solar or wind-powered hydrogen and recycled CO2, enable the storage and utilization of renewable energy. Liquid fuels have a much higher energy density compared to batteries, allowing global transport of renewable energy.

Carbon Mtx also creates uses for CO2 as a feedstock, reducing emissions from fossil fuel displacement. As an emissions-to-fuels technology, Carbon Mtx complements electrification and expands options for decarbonization across the entire energy system.

Additionally, the modular and flexible design of Carbon Mtx lends itself well to distributed deployment. Smaller-scale Carbon Mtx units could be set up near renewable energy projects to convert excess power and CO2 into locally usable fuels and chemicals.

With the ability to accommodate large fluctuating supplies of renewable energy and convert CO2 into stable fuels, Carbon Mtx can enable higher renewable energy penetration while advancing the circular carbon economy.

Made in America – Boosts Energy Independence

A key strategic benefit of Carbon Mtx technology is that it can utilize American innovation to boost domestic energy independence and reduce reliance on foreign oil imports. The fuels and chemicals produced by Carbon Mtx facilities on US soil would displace imported fuel needs.

The US currently imports millions of barrels of crude oil and refined products per day. A material portion of this import demand could be displaced by scalable production of lower-carbon fuels derived from CO2 via Carbon Mtx. This improves energy security.

Carbon Mtx technology was pioneered by American researchers and the intellectual property is US-owned. Having this innovative carbon conversion technology developed domestically represents a strategic opportunity for American leadership in climate solutions.

Constructing Carbon Mtx plants in the US would create manufacturing and engineering jobs while catalyzing growth in the carbon tech sector. The economic benefits and technical expertise accrued from deploying this made-in-America technology also serves to strengthen American competitiveness.

In addition to fuel production, Carbon Mtx can enable low-carbon hydrogen at scale – providing a key building block for clean energy. US leadership in CO2 conversion and carbon-neutral fuels production promotes growth across a range of strategic domestic industries.

With its roots in American innovation ecosystem, Carbon Mtx can drive progress towards energy independence by producing cleaner fuels, creating jobs, and fostering new industries right here in the United States.

Carbon Mtx Facilities Create Local Jobs

An often overlooked benefit of deploying Carbon Mtx technology is its potential to create stable, local job opportunities in communities where facilities are built. Constructing and operating a Carbon Mtx plant requires skilled labor across multiple disciplines.

A typical Carbon Mtx facility would employ several hundred full-time staff in roles like engineering, project management, construction, plant operations, maintenance, and more. Many of these roles pay above-average wages and require vocational training or technical certification.

This influx of quality local jobs gives an economic boost to the community where a Carbon Mtx facility is sited. Workers can be hired from the immediate region, reducing unemployment while retaining and attracting talent.

The modular and scalable nature of Carbon Mtx also creates job opportunities across the supply chain. Local manufacturers can be tapped to fabricate key components, further catalyzing job creation. Equipment suppliers and industrial gas companies also benefit from increased demand.

Constructing new Carbon Mtx plants creates temporary construction and contracting jobs during the 2-3 year build phase. Ongoing maintenance and potential expansion of facilities ensures sustained employment over decades.

The job creation potential enables Carbon Mtx projects to gain public support and align with government economic development objectives. This local job impact is a strategic benefit that should be considered hand-in-hand with the climate merits of deploying Carbon Mtx.

Breakthrough Technology Driven by American Innovation

Carbon Mtx represents a true technological breakthrough enabled by the American innovation ecosystem. The catalyst and process design originated from research conducted at leading US national labs and universities before being commercialized into a scalable solution.

Often the most transformative innovations require sustained investment in early stage R&D without clear commercial payoffs. The US has historically been a leader in funding these types of high-risk, high-reward research initiatives that eventually catalyze new industries.

The fundamental chemistry research underpinning Carbon Mtx stretches back over two decades, laying the scientific foundation for CO2 conversion. Iterative prototyping and testing by a US-based startup then unlocked the catalyst design and reactor engineering required to scale up the process.

Close collaboration between academia, national labs and the private sector was essential in transforming the technology from lab concept to industrial-scale viability. Robust knowledge sharing channels and IP access enabled this efficient transfer.

Now as Carbon Mtx moves towards full commercial deployment, American manufacturers and engineering firms are set to benefit from being leaders in this emerging field. Carbon tech leadership can become a net economic positive.

Without sustained R&D support and an enabling innovation ecosystem, the breakthrough science behind Carbon Mtx may have languished. The commercialization journey exemplifies the importance of long-term and patient technology development.

Solution for Hard-to-Decarbonize Sectors Like Concrete

One industrial sector that has proven very difficult to decarbonize is cement and concrete production. The CO2 emissions are inherent to the chemical reactions in cement manufacturing. Here, Carbon Mtx presents a viable solution by converting these unavoidable emissions into usable fuels.

Cement production accounts for around 7-8% of global CO2 emissions annually. The high-temperature kiln calcination process required to make cement from limestone releases large amounts of CO2 as a byproduct.

While some efficiency gains are possible, the majority of these process emissions cannot be eliminated through electrification or fuel switching alone. Instead, Carbon Mtx provides a way to capture these emissions and utilize them.

Capturing the concentrated CO2 from cement plants and converting it into fuels like diesel through Carbon Mtx can effectively reduce net emissions from concrete production by over 60%. The cement plant’s own fleet could be powered by the CO2-derived diesel.

For essential construction materials like concrete that are difficult to decarbonize otherwise, Carbon Mtx represents one of the few technologies that can dramatically reduce emissions through CO2 utilization.

Deploying Carbon Mtx at stationary CO2 sources like cement plants enables deep decarbonization of these hard-to-abate but vital industrial processes. The synergies create a closed-loop system benefitting both the climate and the business bottom line.

Converts CO2 into Lower Carbon Fuels Like Diesel

A key capability of Carbon Mtx technology is its ability to convert carbon dioxide into drop-in liquid fuels like diesel, jet fuel, and methanol. This provides lower carbon fuel options that are compatible with existing engines and infrastructure.

The Carbon Mtx process reacts captured CO2 with hydrogen to produce different types of synthesized hydrocarbons using a specialized catalyst. Adjusting operating parameters like temperature and pressure controls the type of fuel produced.

In the case of diesel production, the technology can output a finished fuel that meets conventional diesel specifications. This synthetic diesel can directly displace traditional diesel derived from crude oil.

Because the CO2 feedstock is recycled from the atmosphere rather than dug up from underground, the lifecycle carbon intensity of the diesel is up to 80% lower compared to fossil diesel. Minimal tailpipe emissions changes are needed.

For large trucks, ships, trains, and other heavy transport that rely on diesel power, Carbon Mtx enables a sustainable drop-in fuel solution. The CO2-based diesel can provide the same energy density and performance while helping decarbonize the transport sector.

Having the ability to produce lower-carbon diesel and jet fuel unlocks new decarbonization pathways for hard-to-electrify sectors. Carbon Mtx’s unique CO2 conversion capacity makes this possible.

Unlocks New Revenue Streams from Carbon Tech

Deploying Carbon Mtx creates potential new revenue streams for companies from the sale of lower-carbon fuels and chemicals produced from recycled CO2. This presents a business opportunity in the growing carbon tech space.

The fuels and chemicals synthesized by Carbon Mtx are expected to attract premium pricing compared to conventional fossil-based equivalents. Market demand for more sustainable materials is rising.

For example, major corporations are looking to procure low-carbon synthetic jet fuel to reduce the carbon footprints of their air travel and transport. Carbon Mtx provides a way to produce such fuels at commercial scale.

Some companies like airlines could even invest directly in Carbon Mtx facilities to secure supplies of lower-carbon fuels and offset their emissions. The CO2-derived products offer new revenue potential.

Additionally, companies that adopt Carbon Mtx can benefit from tax incentives, carbon credits, and access to green financing options by reducing emissions. The carbon tech market is rapidly evolving.

With a facility producing on the order of 10,000 barrels per day of fuel, Carbon Mtx can generate substantial revenues from both product sales and carbon credits. This complements the climate benefits with a compelling business case.

Leading the Way Towards a Zero-Emission Future

Carbon Mtx represents more than just a new technology – it exemplifies the transformative thinking needed to realize a zero-carbon future. By turning emissions into fuels, Carbon Mtx points the way for industries to transition beyond fossil carbon.

Achieving net-zero goals requires both reducing aggregate emissions and actively pulling CO2 out of the atmosphere. Carbon Mtx enables these dual objectives, while also generating economic value.

This solution-oriented mindset that transforms problems into opportunities is crucial. System-level changes will come through technologies like Carbon Mtx that enable circular resource flows.

Early adoption and scaling up Carbon Mtx in key industries will drive down costs along the experience curve, making decarbonization more affordable for all. Wise policy and investment choices are needed to support these technology pioneers.

Technologies themselves do not control destiny – rather, human decisions about how to best deploy technologies like Carbon Mtx shape the future. Sustainability-enabling solutions already exist in many forms.

Carbon Mtx provides a pathway, embodied in steel and catalyst, that models how industries can decarbonize through innovation. This tangible hope empowers ambitious collective action towards emission-free sectors.

Converts CO2 into Lower Carbon Fuels Like Methanol

In addition to diesel and jet fuel, Carbon Mtx technology can also synthesize lower carbon methanol from captured CO2 emissions. Methanol is a widely used industrial chemical and emerging e-fuel.

The Carbon Mtx process follows a similar CO2 hydrogenation reaction to produce methanol. The modularity of the system allows optimization for different fuel and chemical outputs.

Methanol has applications as a blending agent to reduce the lifecycle carbon intensity of automotive fuels. It can also power methanol fuel cells for efficient electricity generation. Methanol’s physical properties also make it viable as a sustainable shipping fuel.

As a widely traded global commodity, methanol made from waste CO2 via Carbon Mtx can help decarbonize the chemical industry. Established distribution infrastructure enables adoption as a drop-in fuel.

Methanol production also represents a relatively easy entry point for companies to take advantage of Carbon Mtx’s CO2 conversion capabilities. Smaller modular systems can produce methanol from CO2 before scaling up to higher volume fuels.

The ability to make lower carbon methanol in addition to other synfuels highlights the versatility of Carbon Mtx technology. Methanol is poised to play a growing role as both a chemical feedstock and an emerging renewable fuel of the future.

Carbon Mtx Enables Carbon Negative Transportation

An especially impactful sustainability benefit of Carbon Mtx technology is its potential to enable carbon negative transportation through CO2 recycling. By converting emissions into ultra-low carbon fuels, Carbon Mtx facilitates removal of CO2 from the air.

CO2 captured from any industrial source is chemically identical regardless of origin. Fuel synthesized via Carbon Mtx has the same lifecycle carbon footprint whether the CO2 comes from a bioethanol plant or a cement kiln.

This means CO2 from a BECCS (bioenergy with carbon capture and storage) biomass process can be converted into negative emission fuels via Carbon Mtx. The biomass absorbs CO2 as it grows before release and permanent removal via fuel synthesis.

Fuels with a negative carbon intensity can help counter ongoing emissions from hard-to-decarbonize transport sectors. Sustainable aviation fuel and methanol are especially viable using BECCS CO2.

Carbon Mtx enables chain production of negative carbon intensity synfuels at scale using CO2 from bioenergy sources. This is a game changer for mitigating emissions from essential transportation.

The potential to remove CO2 from the air while powering vehicles, ships and planes demonstrates Carbon Mtx’s excellence as a versatile climate solution. Carbon negative transport is possible thanks to carbon negative tech.