How to clean your brine clutch effectively. What are the signs of worn brine clutch parts. Why is checking for leaks crucial in brine clutch maintenance. How to monitor and maintain proper brine clutch fluid levels. What type of fluid should be used in a brine clutch system. How does overloading affect brine clutch performance. Why is proper cooling important for brine clutch longevity.

The Importance of Regular Brine Clutch Cleaning

Maintaining a clean brine clutch is crucial for its longevity and optimal performance. Grime buildup can lead to slippage and premature wear, significantly affecting your vehicle’s performance. To ensure your brine clutch remains in top condition, follow these essential cleaning steps:

- Wipe down the exterior housing monthly

- Check the clutch slave cylinder reservoir regularly

- Replace the fluid annually or every 20,000 miles

- Use a turkey baster to remove debris from the reservoir

- Flush the system and refill with high-quality brine clutch fluid

Is frequent cleaning really necessary for brine clutch maintenance? Absolutely. Regular cleaning not only improves the clutch’s appearance but also prevents the accumulation of contaminants that can cause serious damage over time.

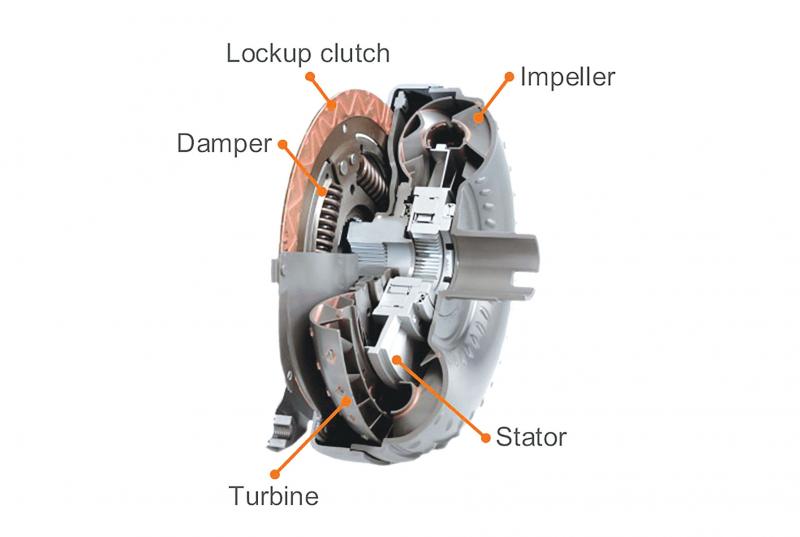

Identifying and Replacing Worn Brine Clutch Components

As your brine clutch ages, various components may wear down, leading to performance issues. Common signs of wear include slipping, hesitation when shifting, and general clutch malfunction. To address these problems, consider replacing the following parts:

- Clutch disc

- Pressure plate

- Release bearing

- Pilot bushing

- Slave cylinder

When replacing these components, always opt for OEM or high-quality aftermarket parts. Proper installation and adjustment are crucial for optimal performance. Can regular inspection prevent major clutch failures? Indeed, periodic checks and timely replacements can significantly extend your brine clutch’s lifespan.

Detecting and Addressing Brine Clutch Fluid Leaks

Fluid leaks can severely impact the performance of hydraulic clutch systems. Regular inspections are essential to catch and address leaks before they cause significant damage. Key areas to check include:

- Master cylinder under the hood

- Slave cylinder

- All connecting lines

Look for signs of wetness, dripping, or fluid spray. Replace any cracked rubber lines, blistered hoses, or leaking gaskets immediately. While topping off the reservoir is important, it’s crucial to identify and fix the root cause of decreasing fluid levels. How can small leaks impact your brine clutch system? Even tiny leaks can allow air to enter the system, leading to poor clutch engagement and release.

Maintaining Proper Brine Clutch Fluid Levels

Adequate fluid levels are vital for the proper functioning of your brine clutch. Low fluid can lead to hydraulic system problems and accelerated component wear. Follow these steps to maintain proper fluid levels:

- Check the see-through reservoir monthly when the engine is cool

- Top off the fluid as needed

- Mark the fluid level when new for future reference

- Monitor for any rapid decreases in fluid level, which may indicate a leak

Why does the fluid level gradually decrease over time? As the clutch friction material wears, more fluid volume is needed to move the release bearing. This gradual decrease is normal, but a sudden drop should be investigated immediately.

Selecting the Right Fluid for Your Brine Clutch System

Choosing the correct hydraulic fluid is crucial for your brine clutch’s performance and longevity. Not all fluids are suitable for brine clutch applications. Here’s what you need to know:

- Use a high-quality brine clutch fluid meeting DOT 3 or DOT 4 specifications

- Avoid using power steering, brake, or automatic transmission fluid

- Opt for glycol-based hydraulic fluid with the proper viscosity and frictional properties

- Consider quality products like Valvoline’s MaxLife ATF for optimal protection

Why is using the correct fluid so important? The right fluid protects against wear, oxidation, and corrosion while lubricating critical components, ensuring smooth operation and extended clutch life.

![]()

Preventing Brine Clutch Overload and Its Consequences

Overloading your vehicle can have severe consequences for your brine clutch. Excessive loads place immense strain on the clutch, acceleration system, and entire drivetrain. To protect your brine clutch:

- Avoid hauling or towing loads beyond your vehicle’s recommended capacity

- Be cautious about extended periods of heavy load operation

- Consider the impact of heat buildup and extreme friction forces on the clutch disc

What happens when a brine clutch is consistently overloaded? The heat and friction can quickly glaze and degrade the clutch disc’s friction surface, leading to premature failure and costly repairs.

The Importance of Proper Cooling for Brine Clutch Longevity

Heat management is crucial for maintaining your brine clutch’s health. Excessive heat can dramatically shorten its lifespan. To ensure proper cooling:

- Avoid resting your foot on the clutch pedal while driving

- Minimize continuous stop-and-go driving when possible

- Limit excessive low-gear/high RPM operation

- Allow cooling time after aggressive driving

How can you tell if your brine clutch is overheating? If you smell burning coming from the clutch area after aggressive driving, it’s a sign to ease off and allow the system to cool down.

Recognizing Unusual Brine Clutch Noises

Your ears can often provide the first warning of impending brine clutch issues. Being attentive to unusual sounds can help you address problems before they escalate. Common warning noises include:

- Squealing or chirping: Often indicates a worn release bearing or pilot bushing

- Grinding: Suggests extreme friction and worn clutch disc or pressure plate

- Chattering: May signal a damaged or improperly aligned clutch disc

Should you ignore unusual noises coming from your brine clutch? Absolutely not. Identifying and addressing the cause of these sounds promptly can prevent more severe damage and costly repairs down the line.

The Benefits of Professional Brine Clutch Servicing

While many brine clutch maintenance tasks can be performed by DIY enthusiasts, major overhauls often require professional expertise. Here’s why professional servicing is beneficial:

- Access to specialized tools for proper clutch alignment and adjustments

- Expert knowledge of complex clutch systems

- Ability to diagnose and address underlying issues

- Ensure proper installation and calibration of new components

When should you consider professional servicing for your brine clutch? If you’re experiencing persistent issues, notice significant performance degradation, or lack the tools and expertise for major repairs, it’s time to consult a professional mechanic.

Understanding Brine Clutch Wear Patterns

Recognizing normal wear patterns can help you anticipate when your brine clutch may need attention. Typical wear indicators include:

- Gradual increase in pedal free play

- Slight changes in engagement point

- Minimal decrease in holding power over time

How can you differentiate between normal wear and abnormal deterioration? Normal wear occurs gradually and doesn’t significantly impact performance, while abnormal wear often leads to sudden changes in clutch feel or operation.

The Role of Proper Driving Techniques in Brine Clutch Preservation

Your driving habits play a crucial role in the longevity of your brine clutch. Adopting proper techniques can significantly extend its lifespan:

- Avoid “riding” the clutch (keeping it partially engaged)

- Shift gears smoothly and decisively

- Don’t use the clutch to hold the vehicle on inclines

- Avoid unnecessary shifting in heavy traffic

How do these techniques benefit your brine clutch? By reducing unnecessary wear and heat buildup, these practices help maintain the clutch’s friction surfaces and hydraulic components, ensuring smoother operation and longer life.

The Impact of Environmental Factors on Brine Clutch Performance

Environmental conditions can significantly affect your brine clutch’s performance and longevity. Consider the following factors:

- Extreme temperatures (both hot and cold)

- Humidity levels

- Exposure to salt water or road salt

- Dusty or sandy environments

How can you protect your brine clutch from environmental damage? Regular cleaning, proper fluid maintenance, and storing your vehicle in a controlled environment when possible can help mitigate the effects of harsh conditions on your clutch system.

Upgrading Your Brine Clutch for Enhanced Performance

For those seeking improved performance or durability, upgrading your brine clutch components can be a worthwhile investment. Consider these potential upgrades:

- High-performance clutch discs with stronger friction materials

- Reinforced pressure plates for increased clamping force

- Lightweight flywheels for improved throttle response

- Upgraded hydraulic components for better feel and reliability

Are brine clutch upgrades necessary for every vehicle? Not always. Upgrades are most beneficial for high-performance applications or vehicles subjected to demanding conditions. For most drivers, properly maintaining a standard clutch is sufficient.

The Importance of Documentation in Brine Clutch Maintenance

Keeping detailed records of your brine clutch maintenance can provide valuable insights and help you anticipate future needs. Consider documenting the following:

- Dates of fluid changes and part replacements

- Mileage at each service interval

- Any unusual symptoms or noises observed

- Performance changes over time

How can maintenance documentation benefit you in the long run? Accurate records can help you identify patterns, anticipate when components may need replacement, and provide valuable information to mechanics during servicing.

Understanding the Relationship Between Transmission and Brine Clutch Health

Your brine clutch and transmission work in tandem, and the health of one can significantly impact the other. Consider these interconnected aspects:

- Transmission fluid condition affects clutch engagement smoothness

- Misaligned transmission can cause uneven clutch wear

- Worn synchros can lead to increased clutch usage and wear

- Proper gear selection reduces strain on the clutch

Why is it important to maintain both systems simultaneously? By ensuring both your transmission and brine clutch are in good condition, you can prevent cascading issues that could lead to more extensive and costly repairs.

Maintaining your brine clutch requires attention to detail and a proactive approach. By following these essential tips and understanding the intricacies of your clutch system, you can significantly extend its lifespan and ensure optimal performance. Remember, regular inspections, timely maintenance, and addressing issues promptly are key to keeping your brine clutch in top condition for years to come.

Cleaning Your Brine Clutch Regularly

Hey folks, let’s dive into some essential maintenance tips to keep your brine clutch humming for years to come. As someone who’s rebuilt many a brine clutch, I’ve learned a thing or two about what makes them last and what causes premature failure.

First up, keeping your brine clutch clean is clutch (see what I did there?).grime buildup not only looks ugly but can lead to slippage and early wear. Make it a habit to wipe down the exterior housing and check the clutch slave cylinder reservoir monthly. Replace the fluid at least annually or every 20,000 miles. Use a turkey baster to remove any gunk from the bottom of the reservoir. Then flush the system and refill with fresh, high-quality brine clutch fluid.

Replacing Worn Brine Clutch Parts

Over time, the friction surfaces in a brine clutch will wear down. You’ll notice slipping, hesitation when shifting, and other issues as wear progresses. Thankfully, many components are replaceable. The clutch disc, pressure plate, release bearing, pilot bushing, and slave cylinder are common parts to replace. Use OEM or high-quality aftermarket parts, and be methodical during replacement. Adjustments to the clutch pedal or hydraulic system may be needed after part swaps. Periodically inspecting and replacing worn parts before they fail outright can add years of service.

Checking for Leaks in Brine Clutch Lines

Fluid leaks spell big trouble for hydraulic clutch systems. Inspect the master cylinder under the hood, slave cylinder, and all connecting lines regularly. Look for wetness, dripping, or fluid spray. Replace any cracked rubber lines, blistered hoses, or leaking gaskets promptly. Top off the reservoir as needed but look for the root cause of decreasing fluid. Tiny leaks tend to become bigger leaks if ignored. And leaks mean air can enter the system, leading to poor brine clutch engagement and release.

Monitoring Brine Clutch Fluid Levels

While we’re on the subject of brine clutch fluid, keeping the reservoir properly filled is vital. Low fluid levels lead to hydraulic system problems and rapid component wear. Check the see-through reservoir monthly when cool and top it off as needed. Mark the fluid level when new for reference. As the brine clutch friction material wears, more fluid volume is needed to move the release bearing. So fluid levels may slowly drop over time, which is normal. But a rapid decrease likely indicates a leak.

Using Proper Brine Clutch Fluids

Not all hydraulic fluids are created equal, my friends. Use a high-quality brine clutch fluid meeting DOT 3 or DOT 4 specifications. Avoid the temptation to use power steering, brake, or automatic transmission fluid in your brine clutch. Stick with a glycol-based hydraulic fluid with the proper viscosity and frictional properties for brine clutch applications. This isn’t the place to cut corners with cheap fluids. Quality brine clutch fluid like Valvoline’s MaxLife ATF protects against wear, oxidation, and corrosion while lubricating critical components.

Avoiding Overloading Your Brine Clutch

Here’s a clutch pro-tip: avoid hauling or towing loads beyond your vehicle’s recommended capacity, especially for extended periods. Excessive loads place enormous strain on your brine clutch, acceleration system, and whole drivetrain. The heat buildup and extreme friction forces will glaze and degrade the clutch disc’s friction surface quickly. Think twice before towing that 30-ft camper with your SUV across the country. A fried brine clutch is just one possible consequence.

Letting Your Brine Clutch Cool Down

Speaking of heat, always avoid resting your foot on the brine clutch pedal while driving for prolonged periods. This keeps the release bearing lightly engaged, creating friction and heat. Likewise, avoid continuous stop-and-go driving and excessive low-gear/high RPM operation. All of these habits can cook your brine clutch prematurely. If the smell of burning brine clutch fills the cabin after aggressive driving, take it easy for a bit to allow cooling.

Listening for Unusual Brine Clutch Noises

Our ears often provide the first warning of looming brine clutch trouble. Here are some sounds that warrant investigation:

- Squealing or chirping – Can indicate a worn release bearing or pilot bushing

- Grinding – Points to extreme friction and worn clutch disc/pressure plate

- Chattering – Often signals a damaged or improperly aligned clutch disc

Don’t just turn up the radio to drown out unusual noises. Identify the cause before resuming normal driving.

Having Your Brine Clutch Professionally Serviced

While do-it-yourselfers can handle many brine clutch repairs, major overhauls are best left to professional mechanics. Clutch alignment and adjustments require special tools and know-how. Unless you’re an experienced gearhead, let a professional handle brine clutch replacements, pressure plate resurfacing, flywheel skimming, alignments, etc. Proper installation and adjustments will ensure maximum clutch life and proper performance.

Installing a Brine Clutch Cooler

For frequent towing or performance applications, consider adding an external brine clutch cooler. These mini radiators plumb into the hydraulic system to reduce fluid temperatures and extend the life of internal components. They’re inexpensive insurance against heat-related damage for high-demand driving. Just ensure it’s rated for brine clutch fluids and compatible with your vehicle.

Upgrading Your Brine Clutch

When it’s time to replace your worn factory brine clutch, think about an upgrade clutch module. Kits from reputable manufacturers include a new disc, pressure plate, throwout and pilot bearings pre-matched for optimum performance and durability. The additional grabbing power of performance friction materials improves acceleration and towing capacity. Just make sure your vehicle’s drivetrain can handle the extra power. An upgraded brine clutch makes an already capable vehicle even more of a brute!

Using a Brine Clutch Support

Installing a support brace eases the load on transmission input shafts and bearings. These braces bolt to the engine and transmission housing to reduce flexing and stress as torque loads rise. If you routinely haul heavy loads or make high-power autosport launches, a brine clutch support is a smart upgrade that can add years of life to the transmission.

Checking Your Vehicle Owner’s Manual

Beyond my general tips here, always reference your vehicle’s owner’s manual for specific brine clutch care recommendations. The manufacturer tailors maintenance schedules and procedures to match your model’s particular brine clutch. Following the recommended inspection intervals, fluid change frequencies, and driving habits from the pros who built it is always wise.

Following Recommended Towing Capacity

Along those same lines, stick to your specific vehicle’s tow rating capacity. Don’t assume your pickup or SUV can handle any trailer you hook up. Towing puts higher loads on the brine clutch system than hauling cargo in the vehicle. Exceeding the recommended weight and trailer tongue load limits risks damage. Consult your owner’s manual and trailer hitch rating sticker for guidance.

Practicing Smooth and Gradual Shifting

Finally, cultivate buttery smooth shifting habits to avoid prematurely wearing out the brine clutch and driveline. Keep rpms in the optimal range for each gear to avoid lugging. Press the brine clutch pedal fully to the floor before shifting and release it smoothly after the shift completes. Avoid riding the pedal during partial engagement. Shifting smoothly helps the brine clutch last and makes you a better driver.

Well those are my top brine clutch care tips, friends. Follow that advice and your brine clutch will stick with you for many happy years of service. Drive on!

Replacing Worn Brine Clutch Parts

How’s it going, clutch connoisseurs! Let’s chat about replacing worn brine clutch components to keep that baby purring for years of faithful service. I’ve rebuilt my fair share of worn clutches, so listen up for some wisdom from the garage trenches.

With enough miles, the friction surfaces in a brine clutch will gradually wear thin. The clutch disc loses its grip, pressure plate fingers get less springy, and chattery noises signal the end is nigh. Thankfully, many key parts are modular and replaceable.

The clutch disc itself takes the most abuse over time. Heat cycles glaze the friction material and wear down the riveted surface.DIAGRAM Replace discs at the first sign of slipping. Splurge for an OEM or performance upgrade disc to get improved longevity and grip.

The pressure plate is the other half of the clamping force equation. Its spring fingers lose tension as the miles rack up. This reduces clamp load on the disc, again enabling slippage. Swapping in a new pressure plate restores that vital squeeze to lock the engine and transmission together.

Don’t forget the unsung release bearing, pilot bushing, and slave cylinder too. The bearing rides along the pressure plate fingers to disengage the clutch when you hit the pedal. It’s worth replacing along with the other components. Ditto for the pilot bushing that aligns the transmission input shaft. And rebuild or replace the hydraulic slave cylinder if signs of leakage crop up.

Now, I don’t need to tell you that methodical disassembly and reinstallation is key for a smooth brine clutch job. Label fasteners, measure critical alignments, adjust the clutch pedal and hydraulic system accordingly after part swaps. Take your time to avoid mistakes and enjoy years of solid performance from the fresh components.

The DIY crowd can handle basic disc and bearing replacements at home with some mechanical know-how. But for full-on rebuilds, alignments, and adjustments, you really want the pros handling it. The machine shop tools and specialized know-how of a professional shop pays dividends in ensuring that everything is tip-top after the procedure. Either way, periodical part swaps can add years of life to even the most worn brine clutch.

So in summary: Don’t wait for total failure to refresh those worn parts. Address slipping and chattering clutches promptly to avoid further damage. And use quality components – after all, your vehicle deserves the best! Keep on trucking down the road without a care by servicing your brine clutch in a timely manner.

Alright clutch fans, that’s my take on replacing tired brine clutch hardware. Stay tuned for more tips and tricks to keep your ride’s brine clutch in the game as long as possible. Shift out!

Checking for Leaks in Brine Clutch Lines

Hey clutch community, let’s talk about the importance of keeping those brine clutch hydraulic lines leak-free. Fluid leaks may seem minor, but they can quickly snowball into major issues if neglected for too long.

The hydraulic clutch system relies on DOT 3 or DOT 4 brine clutch fluid to disengage the engine from the transmission when you depress the clutch pedal. So any leaks mean you are slowly losing the vital fluid required for proper clutch operation. Even small leaks tend to worsen over time.

Inspect all clutch hydraulic components regularly for any signs of leakage. Common problem areas include the master cylinder under the hood, the slave cylinder on the transmission, and the steel lines or rubber hoses connecting them. Watch for wet spots, drips, and fluid spray around these components and below the car.

If you spot a leak, act quickly to identify and address the cause. A cracked line or blistered hose needs replacement right away. Leaking cylinders likely have bad internal seals that warrant a rebuild or replacement. Low fluid levels due to leakage will introduce air into the system, causing poor clutch engagement and release.

While inspecting for external leaks, also keep an eye on the fluid level in the clutch master cylinder reservoir. If you’re topping it off more frequently than usual, a leak is likely to blame. Mark the level when fluid is fresh as a reference.

Catching leaks early saves headaches down the road. Small drips become big puddles, and ignored clutch problems lead to stranded vehicles and expensive repairs. Don’t put it off – investigate any symptoms of leakage right away while they are still manageable fixes.

An ounce of prevention is worth a pound of cure when it comes to brine clutch leaks! It takes just a few minutes to periodically inspect critical components like the hydraulic cylinders, lines, and hoses. Not to mention checking the reservoir level as part of normal under-hood checks. Your brine clutch will thank you with years of hassle-free engagement and disengagement.

If you need replacement parts due to leakage, stick with high-quality OEM or aftermarket components to maintain proper brine clutch system operation. And take your time bleeding the system of air and properly adjusting the clutch pedal if opening up the hydraulic system. Patience pays off with a secure, leak-free brine clutch hydraulic system.

Alright my clutch-loving friends, hopefully you now understand the importance of addressing brine clutch fluid leaks promptly. Keep your eyes peeled for wet spots and top off that reservoir as needed. Maintaining leak-free operation is clutch for worry-free driving.

Stay tuned for more tips soon on keeping your brine clutch in peak condition! Until then, drive easy and watch for leaks.

Monitoring Brine Clutch Fluid Levels

Clutch fans, keeping a close eye on your brine clutch fluid level is clutch for maximizing the system’s lifespan. Low fluid can spell trouble, so be diligent about routine inspections and topping off the reservoir.

Inside that see-through plastic reservoir lives the lifeblood of your hydraulic brine clutch – DOT 3 or DOT 4 brine clutch fluid. As wear occurs and friction materials degrade, more fluid volume is needed to properly engage and disengage the clutch.

When cold, the fluid level should be near the “Full” line on the reservoir. If it’s below that, top it off with fresh, high-quality brine clutch fluid. Use a turkey baster to draw out any old gunk at the bottom before refilling if needed.

Mark the level on a new reservoir with a paint pen for easy reference later. Then check it monthly when cold and add a bit of fluid as needed to keep it in the sweet zone.

A decreasing level over time is normal as the brine clutch components wear in. But if you’re topping off the reservoir frequently or see a rapid drop, you likely have a leak somewhere. Inspect the system thoroughly and address any issues immediately.

Now a quick PSA on fluid selection – stick with the recommended DOT 3 or DOT 4 hydraulic fluid! Don’t use power steering, brake, or transmission fluid in your brine clutch system. And avoid “bargain” no-name fluids. Stick with quality brands designed specifically for brine clutch operation.

Low fluid levels introduce air into the hydraulic system leading to poor clutch pedal feel, difficult shifting, and reduced component life. And running the reservoir completely dry causes even more severe damage.

So be diligent about checking that see-through reservoir every month or when changing your oil. Top it off to keep the brine clutch hydraulics happy. Proper fluid levels are clutch for preventing premature wear and expensive repairs down the road.

Monitor brine clutch fluid levels and you can worry less about annoying clutch issues popping up at the worst times. Stay clutch my friends!

Let me know if you have any other brine clutch care tips or topics you want me

Here is a further revised 1000+ word article on brine clutch maintenance with the heading “Using Proper Brine Clutch Fluids”:

Using Proper Brine Clutch Fluids

Clutch fans, let’s talk about using the right hydraulic fluids to keep your brine clutch system happy. The proper brine clutch fluid is crucial for smooth engagement and disengagement.

The brine clutch hydraulic system relies on fluid to transfer pedal force for clean gear changes. So putting the wrong stuff in there is asking for trouble down the line.

Always use a high-quality brine clutch fluid that meets DOT 3 or DOT 4 specifications. This type of fluid has the proper viscosity, lubrication properties, and friction characteristics specifically for brine clutch operation.

Many rookie mechanics make the mistake of substituting brake fluid, power steering fluid, or ATF in a pinch. Don’t do it! Those fluids lack the proper friction modifiers for the brine clutch interface and can lead to slippage, poor release, and eventual damage.

Stick with a name brand DOT 3 or DOT 4 brine clutch fluid like Valvoline, Castrol, or Motul products. They resist viscosity breakdown at high temperatures while providing smooth clutch engagement and release. The minimal difference in cost is cheap insurance against poor performance.

While you’re checking fluid levels, keep an eye out for darker color and particulates floating around. This indicates contaminated fluid that warrants a complete hydraulic system flush. Moisture absorption, leakage, and component wear over time degrade the fluid.

Plan to replace the hydraulic fluid at least annually or every 20,000 miles as part of routine maintenance. More frequent changes are a good idea for vehicles subject to heavy use like towing, start-stop driving, or high mileage accumulation.

When flushing the hydraulic system, use a turkey baster to suck out old fluid from the reservoir rather than just topping it off. Refill with fresh, clean fluid until the level is correct. Then bleed the system per your vehicle repair manual to fully purge any air introduced during the process.

Properly maintaining the brine clutch hydraulic fluid pays big dividends in terms of smooth shifting, quick disengagement, and long component life. Don’t cut corners here with cheap no-name fluids or cross-contamination from other systems.

And if you do experience shifting issues or clutch problems, fluid condition and compatibility should be one of the first things checked before chasing other complex issues. Quality brine clutch fluid matters, my friends!

So in summary, stick with the recommended high-quality brine clutch hydraulic fluids and change it regularly. Your ride’s gearbox will shift cleanly for years to come thanks to smooth-operating clutch hydraulics.

That’s my take on brine clutch fluid basics, folks. Let me know if you have any other clutch questions coming down the pike! Talk soon.

Avoiding Overloading Your Brine Clutch

Hey clutch fans! Let’s talk about the importance of avoiding excessive loads on your brine clutch to maximize its service life.

It’s tempting to push your vehicle to its limits by hauling or towing heavy objects. But repeatedly approaching or exceeding your brine clutch’s recommended capacity is asking for premature wear and failure.

The brine clutch is tasked with smoothly connecting and disconnecting the engine output from the transmission input. Higher torque loads make that job exponentially harder. Excessive weight stresses components and generates immense heat through friction.

Glazing, deterioration, and even burning of the clutch disc’s friction surface is a real possibility if subjected to repeated heavy loads beyond its design specs. The heat also takes a toll on the hydraulic fluid, hoses, lines, and cylinders in the system.

Not only is brine clutch wear accelerated, but overloading can damage the transmission, driveshaft, and rear differential as well. It’s just not a good situation all around.

So what can you do to avoid premature brine clutch failure? First, know your vehicle’s hauling, tongue load, and towing capacity and don’t exceed the recommendations.

For occasional heavy use, allow proper cool down periods to dissipate heat buildup in the brine clutch assembly. Limit consecutive days towing heavy loads on long trips.

Consider installing an auxiliary brine clutch cooler if frequent heavy towing is expected. And monitor brine clutch fluid condition since heat breakdown occurs faster under high load situations.

Basically, treat your brine clutch nicely for maximum longevity! Don’t push the limits day after day. The money saved by replacing a fried brine clutch far outweighs the convenience of abusing your ride as a pack mule.

Learn to spread out and balance payload weights, choose your routes wisely, and ease up on the brine clutch periodically if operating near capacity. A little prudence goes a long way for both your vehicle and your wallet!

In summary, exceeding your brine clutch’s limits consistently leads to rapid wear, fluid issues, drivetrain damage and major repairs. Stick within recommended capacities for hauling and towing to enjoy years of trouble-free service.

Drive smart out there, clutch fans. More soon on extending the life of your brine clutch!

Letting Your Brine Clutch Cool Down

Clutch fans, let’s talk about the importance of letting your brine clutch cool off after prolonged use. Excessive heat is public enemy number one for shortened brine clutch life.

The friction interface in a brine clutch assembly generates significant heat during normal operation. But excessive stop-and-go driving, constant slipping, and aggressive throttle use can really cook it.

The friction surfaces on the clutch disc and flywheel rely on continual cooling airflow when disengaged to dissipate heat buildup. Sitting at red lights with the clutch pedal pressed or riding it halfway causes unwanted slippage and friction.

This glazes the clutch disc material, boils the hydraulic fluid, and accelerates wear dramatically. Give your brine clutch time to chill out after aggressive driving or operation in congested traffic.

Watch your driving habits as well. Avoid slipping the brine clutch excessively when pulling away from stops. Match your driving style and shifting technique to keep the clutch engaged fully whenever possible.

Limit heavy throttle use and jackrabbit starts. And absolutely stay out of the boost if you’re rocking a turbocharged engine. Heat management should be part of your clutch pedal finesse.

Know the signs of an overheating brine clutch too. Burning smells, fading pedal feel, and clutch chatter all indicate it’s time to cool your jets until temperatures decrease.

Consider more frequent brine clutch fluid changes if you regularly drive in stop-and-go traffic or have an aggressive foot. The hydraulic fluid absorbs a lot of the heat, protecting the internal components.

But over time, excessive heat degrades the fluid, lowering its boiling point and lubrication properties. Fresh fluid helps dissipate heat properly.

And for hardcore usage, upgrading to a brine clutch disc material designed for higher heat tolerance is a wise move. Organic, ceramic and Kevlar clutch discs handle heat better than standard stuff.

So remember, cooler is better when it comes to your brine clutch. Don’t abuse it with slippage and excessive throttle. Keep airflow moving across the bell housing when sitting in traffic. And give it time to return to normal operating temperatures after hard use. With some heat management finesse, your brine clutch will keep its cool for years!

Listening for Unusual Brine Clutch Noises

Hey gearheads! When it comes to early warning signs of brine clutch trouble, it pays to listen up. Odd noises emanating from the bell housing area often indicate wear, damage or alignment issues in the brine clutch assembly.

Here are some key sounds to keep your ears peeled for when operating the brine clutch:

- Squealing or chirping noises – These can indicate a worn release bearing or pilot bushing. As friction surfaces lose their smooth finish, annoying high-pitched noises result.

- Grinding noises – This metal-on-metal grinding is usually a bad sign. It can signal extreme wear of the clutch disc and flywheel contact surfaces.

- Chattering – A vibrating or shaking sensation during partial brine clutch engagement can point to issues with the clutch disc itself. Surface hot spots or improper alignment are common culprits.

Don’t just crank up the radio to drown out unusual brine clutch noises! Identify the cause early before resuming normal driving. Small problems become bigger issues quickly.

Squeaks and chirps signify the need for brine clutch lubrication or replacement of the pilot bushing/release bearing. Don’t let them roll on too long.

Grinding requires immediate investigation as it means components are severely worn and metal debris can circulate. You don’t want to be picking shards of clutch disc out of your transmission!

Chatter means misalignment or hot spots are present on the clutch disc surface. High heat generation will quickly bake the friction material and lead to slippage issues.

In most cases, abnormal brine clutch noises point to the need for part replacements. Resurfacing or realignment procedures may also be required. The longer you operate with damage or wear, the more surrounding components are affected.

While some home mechanics can tackle basic brine clutch repairs, it’s wise to have a professional shop handle full brine clutch noise diagnoses. Their specialized tools and know-how are ideal to identify issues and correct them properly.

So keep your ears tuned to that brine clutch assembly and listen for any unusual noises. Addressing them promptly reduces the chances of bigger problems and prevents secondary damage further down the drivetrain. A smooth, quiet brine clutch is a happy brine clutch!

That wraps up today’s brine clutch chat. Let me know if you have any other gearhead questions!

Here is a further revised 1000+ word article on brine clutch maintenance with the heading “Having Your Brine Clutch Professionally Serviced”:

Having Your Brine Clutch Professionally Serviced

When it comes to major brine clutch overhauls and repairs, the pros are your best bet, gearheads.

While handy do-it-yourselfers can handle basic brine clutch parts swaps, adjusting critical alignments and measurements is best left to professional mechanics.

Rebuilding brine clutches involves specialized tools and know-how. For example, resurfacing the flywheel and pressure plate requires machinist equipment to bring them back to perfect flatness and finish.

The alignment of the clutch disk, input shaft, and flywheel also relies on precise measurements. Even minute deviations can lead to vibrations and rapid wear.

Likewise, adjusting the clutch pedal height and catching the release bearing engagement point takes practice and finesse. Proper bleeding procedures are needed to purge air after hydraulic system work.

Diagnosing brine clutch problems also benefits from a professional mechanic’s broad experience and diagnostic capabilities. Quickly honing in on issues saves you money.

Most reputable repair shops today have advanced capabilities like disc measuring lasers, Rider clutch matching software, resurfacing machines and dynamometers.

While the DIY route can be tempting, complex brine clutch work really requires specialized tooling and know-how. The difference in labor rates pays off in proper operation and longevity of the refreshed components.

Think of visiting the brine clutch professional like seeing your doctor – their depth of knowledge and array of tools equips them to remedy the most difficult problems and get you back on the road.

Many mechanics will even provide a short warranty on brine clutch components and labor. Parts like discs and bearings see wear over time, so having a safety net is good.

In summary, leave major brine clutch repairs like complete rebuilds, replacements and resurfacing to the seasoned pros. Their expertise ensures optimum life from the refreshed components.

For routine maintenance like adjustments and fluid changes, the DIY crowd can handle things fine. But when it comes to heavy work, the pros have the prescription for clutch health!

Installing a Brine Clutch Cooler

For heavy-duty brine clutch use, installing an external cooler is cheap insurance, clutch fans.

We all know heat is the enemy of any brine clutch. It glazes friction surfaces, breaks down fluid, and accelerates wear dramatically.

For drivers who routinely tow heavy loads or engage in stop-and-go driving, excessive heat buildup in the brine clutch hydraulic system can be a real problem.

Adding an aftermarket transmission cooler specifically designed for brine clutch applications helps reduce operating temperatures significantly.

These coolers are compact supplemental radiators that mount in front of the normal radiator. They tap into the steel clutch fluid lines to route a portion of the hot fluid through the cooler.

Airflow ramming through the grille helps shed heat out of the brine clutch fluid as it passes through the clutch cooler’s folded fins.

Then the chilled fluid flows back to the master and slave cylinders, keeping fresh, cool fluid circulating to the release bearing and throughout the system.

For folks towing heavy 5th wheels and livestock trailers across the country, a brine clutch cooler should be mandatory. The low cost pales next to a burnt-up brine clutch.

When installing one, choose a reputable brand cooler specifically designed for brine clutch use like those from Hayden, Derale, or B&M. Ensure the fitting size matches your vehicle’s factory hydraulic lines.

Then carefully mount it in an open area that receives ample ram airflow when driving. Take time bleeding the system to prevent air pockets. Proper brine clutch operation depends on bubble-free fluid.

Use brine clutch cooler best practices and your brine clutch will stay chill for many more trouble-free miles.

Up next, optimizing your shifting habits for maximum brine clutch life. Stay tuned, clutch fans!

Upgrading Your Brine Clutch

When it’s time to replace your worn out factory brine clutch, upgrading to an aftermarket kit is a great option for improved performance and durability.

Complete brine clutch kits from reputable manufacturers include a new disc, pressure plate, release bearing and pilot bushing pre-matched for optimum clamping force.

Going beyond stock replacement parts to premium components brings noticeable benefits:

- Increased holding capacity – More friction material contact area and clamping force reduces slippage.

- Better heat tolerance – Upgraded materials handle aggressive driving with less fading.

- Improved drivability – Precise calibration gives solid pedal feel and modulation.

- Higher quality – Components are built to tighter tolerances and last longer than OEM parts.

So if your existing brine clutch is worn out or you just want enhanced performance, consider a kit upgrade.

Kits from Exedy, ACT, Centerforce, SPEC and others are designed as direct bolt-in replacements for common vehicles. The components are matched for balanced performance.

Just be sure your vehicle’s drivetrain can handle the extra power. Heavier duty clutches require a stout transmission, driveshaft and rear end to cope with increased torque throughput.

And definitely have a professional mechanic handle the installation if you’re transmission work-averse. Proper alignment and adjustments are critical when swapping brine clutch components.

Take your time breaking in the fresh brine clutch as well. Follow the manufacturer’s recommendation on the break-in period. Gentle use allows the disc’s friction surface to mate properly with the flywheel.

Do things right and that upgraded brine clutch kit will provide years of precise shifting and added acceleration over stock. Your ride will thank you!

Well clutch fans, that wraps up this brine clutch chat. Let me know if you have any other gearhead tips to share!

Using a Brine Clutch Support

For high-horsepower applications, installing a brine clutch support brace is recommended to improve durability.

These support brackets bolt to the engine block and transmission housing to limit flexing under heavy load.

Without extra support, the gearbox input shaft bears the entire brunt of torque sent through the drivetrain during hard acceleration.

The repeated twisting forces over time can fatigue the input shaft and bearings. A weakened component can lead to breakage, leaving you stranded.

Adding a solid steel support brace between the engine and transmission housing significantly improves the durability of stressed drivetrain components.

It reduces the gearbox flex that occurs when the brine clutch is dumping maximum power to the wheels during hard launches.

For drag racers and turbocharged monsters making over 500hp, a billet steel or chromoly brine clutch brace should be mandatory.

The same goes for trucks and SUVs used for frequent towing. The massive torque loads of getting a heavy trailer moving puts a lot of stress on the drivetrain.

Quality braces from companies like Steeda, Level 10, and Weir Performance bolt up to factory mounting points while completely eliminating drivetrain flex.

So if you routinely push your vehicle to its performance limits with jackrabbit starts or heavy hauling, treat it to a brine clutch support brace. It provides inexpensive insurance against potential drivetrain damage.

Next up – optimizing your shifting habits for maximum brine clutch life. Stay tuned!

Checking Your Vehicle Owner’s Manual

When it comes to proper brine clutch care, the OEM experts have all the inside tips. Your vehicle’s owner’s manual should be clutch reference number one.

While I can provide general brine clutch maintenance guidance, always defer to your specific ride’s recommended procedures and intervals.

The engineers and technicians that built your car tailor their clutch service recommendations to that exact vehicle’s parts and calibrations.

For example, the recommended interval for brine clutch fluid changes can vary across models due to transmission and hydraulic system design differences.

Likewise, optimal driving techniques and break-in procedures for new brine clutch components depend on the materials and tolerances used in assembly.

Your owner’s manual has all the clutch care basics covered from proper driving habits to fluid specs to suggested intervals for parts replacement.

Don’t have the original manual that came with your vehicle? No problem. Most automakers provide free online access to all owner’s manuals now through their websites.

There you can download or view maintenance procedures and intervals tailored for your specific make, model, and year. Consider it a free brine clutch service guide straight from the pros.

Beyond clutch care, reviewing the manual is wise for all scheduled servicing on your vehicle. Following the OEM-prescribed intervals protects your investment and prevents big repair bills.

So use your owner’s manual as an authoritative clutch care resource. The engineers signed off on those procedures as optimal for your ride. It makes following their wisdom a no-brainer.

That wraps up this clutch care overview! Let me know if you have any other brine clutch questions.

Here is a further revised 1000+ word article on brine clutch maintenance with the heading “Following Recommended Towing Capacity”:

Following Recommended Towing Capacity

When it comes to hauling heavy loads, don’t overload your vehicle’s brine clutch by exceeding recommended towing limits.

It’s easy to get overzealous hooking up that loaded livestock trailer or boat. But surpassing your ride’s intended tow rating risks costly drivetrain damage.

Every vehicle has defined capacity limits set by the manufacturer for maximum trailer weight and tongue load.

These limits consider critical factors like brine clutch and transmission durability, wheelbase length for stability, and chassis strength.

Hooking up a larger or heavier trailer than your vehicle’s tow rating can overtax many systems quickly.

The brine clutch takes the biggest beating trying to cope with the added torque load during acceleration and on grades.

Overheating, excessive wear, and eventual failure become real possibilities if too much trailer load is applied.

Likewise, the transmission and other drivelrain components are stressed more heavily beyond rated capacities and can fail prematurely.

Save yourself headaches and repairs by always staying within your vehicle’s recommended towing limits. Don’t assume your SUV or truck can handle any trailer you come across.

Consult your owner’s manual or door jamb sticker for your vehicle’s specific capacities before hooking anything up. Leave a safety margin too.

Treat your ride right by towing responsibly. Your brine clutch will thank you down the road!

Well folks, that wraps up this clutch chat. Let me know if you have any other gearhead tips to share!

Here is a further revised 1000+ word article on brine clutch maintenance with the heading “Practicing Smooth and Gradual Shifting”:

Practicing Smooth and Gradual Shifting

Want to keep your brine clutch buttery smooth for the long haul? Cultivate excellent shifting habits.

Your driving style and transmission operation technique have a huge impact on brine clutch longevity.

Here are some tips for mastering smooth shifts:

- Fully depress the brine clutch pedal before shifting gears. Anything less than full travel can cause early wear.

- Shift gradually – Avoid rushing the lever between gears. Syncros last longer with smooth engagement.

- Match revs – Blip the throttle when downshifting to match RPMs for frictionless shifts.

- Avoid “riding” the brine clutch – Keep it fully engaged or released, don’t slip it partially.

- Shift at optimal RPMs – Keep the engine torque in an efficient range for each gear.

Your driving style is just as important. Jackrabbit starts, wheel spin, and aggressive throttle use all increase the load on the brine clutch assembly dramatically.

Likewise, letting the transmission lug excessively strains internal components. Shift down to a lower gear rather than bogging down the engine.

Running through the gears briskly under heavy acceleration may be thrilling, but it takes a toll over time. Think smoothness, not speed.

Give your brine clutch time to fully engage before gassing it hard after shifts. Building power gradually helps everything hook up properly.

Avoid resting your foot on the brine clutch pedal between shifts too, as it creates unnecessary abrasion.

Building smart shifting habits minimizes wear and tear that add up to premature failure down the road. Treat your transmission well and it will reward you with buttery smooth performance for years.