How do football helmet parts kits enhance player protection. What are the crucial components in a helmet parts kit. Which elements require regular maintenance or replacement. How can proper helmet maintenance improve on-field safety.

The Importance of Facemasks in Football Helmet Safety

Facemasks serve as the primary defense against facial injuries in football. These metal or plastic structures protect players from direct impacts during tackles and collisions. But why are facemasks so critical, and how can players ensure they’re always in top condition?

Facemask durability is paramount for player safety. Steel facemasks offer superior strength compared to plastic alternatives, with stainless steel providing the added benefit of rust resistance. When selecting facemask hardware, it’s crucial to choose components that match your helmet’s specific make and model.

Key Components of Facemask Hardware Kits

- Clips for secure attachment

- Screws (Phillips or hex head)

- Mounting brackets

- Replacement bars

Is regular inspection of facemask hardware necessary? Absolutely. Players and coaches should routinely check for loose screws, bent clips, or damaged bars. Prompt replacement of compromised components ensures the facemask maintains its protective integrity throughout the season.

Chin Straps: The Unsung Heroes of Helmet Security

While often overlooked, chin straps play a vital role in keeping football helmets securely in place during play. A properly fitted chin strap prevents the helmet from shifting during impacts, maintaining optimal protection for the player’s head and face.

What components make up a chin strap kit? Typical kits include:

- Plastic clips compatible with specific helmet models

- Durable metal snaps

- Adjustable straps made of leather or synthetic materials

- Padding for comfort

How tight should a chin strap be? The ideal fit allows for two fingers’ width between the strap and the player’s chin. This snug but comfortable adjustment prevents accidental detachment while allowing for necessary flexibility.

Maintaining Chin Strap Integrity

Regular inspection of chin strap components is crucial for player safety. Look for signs of wear such as frayed straps, cracked plastic pieces, or bent metal snaps. Immediate replacement of damaged parts ensures the chin strap continues to perform its critical function.

Helmet Shells: The First Line of Defense

The exterior shell of a football helmet absorbs the initial impact of collisions, making it a critical component of player protection. Modern helmet shells typically consist of polycarbonate or ABS plastic, materials chosen for their durability and shock-absorption properties.

Can helmet shells be upgraded without replacing the entire helmet? Yes, some manufacturers offer shell upgrade kits that allow players to benefit from the latest protective technology without the expense of a full helmet replacement. However, it’s crucial to ensure compatibility with your current helmet model.

DIY Helmet Shell Repairs: When and How?

For minor damage like small cracks or holes, DIY repair kits can extend a helmet shell’s lifespan. These kits often include:

- Epoxy filler for patching

- Sealants to prevent crack propagation

- Fiberglass cloth for reinforcement

- Sanding and buffing materials for a smooth finish

When is shell replacement necessary? If damage is extensive or compromises the helmet’s structural integrity, only a full shell replacement will suffice. Professional installation ensures proper alignment and connection of any integrated electronics.

Facemask Hardware: The Devil in the Details

The components that secure a facemask to the helmet shell may seem minor, but they play a crucial role in player safety. Why is high-quality facemask hardware so important? These small parts bear the brunt of impacts and must maintain their integrity to keep the facemask firmly attached.

Essential Facemask Hardware Components

- Stainless steel screws (Phillips or hex head)

- Durable mounting brackets

- Click-release plastic clips for tool-free adjustments

- Specialized nuts and bolts

How often should facemask hardware be checked? Ideally, players or equipment managers should inspect these components before each practice and game. Loose screws should be tightened immediately, and any bent or missing clips must be replaced to maintain the facemask’s protective strength.

Helmet Padding: The Invisible Shield

While not as visible as other components, helmet padding plays a crucial role in player safety. How does padding contribute to protection? It absorbs shock, cushions the head from impacts, and ensures a proper fit, all of which are essential for minimizing the risk of head injuries.

![]()

Over time, helmet pads can compress and lose their effectiveness. How can players maintain optimal padding performance? Regular inspection and timely replacement are key. Most helmet pad kits include:

- Crown padding

- Side impact pads

- Forehead pads

- Occipital (back of head) pads

- Hook-and-loop fasteners for easy installation

What signs indicate the need for pad replacement? Look for flattened or compressed areas, tears in the covering, or a noticeable decrease in comfort. Replacing pads at the first sign of wear ensures consistent protection throughout the season.

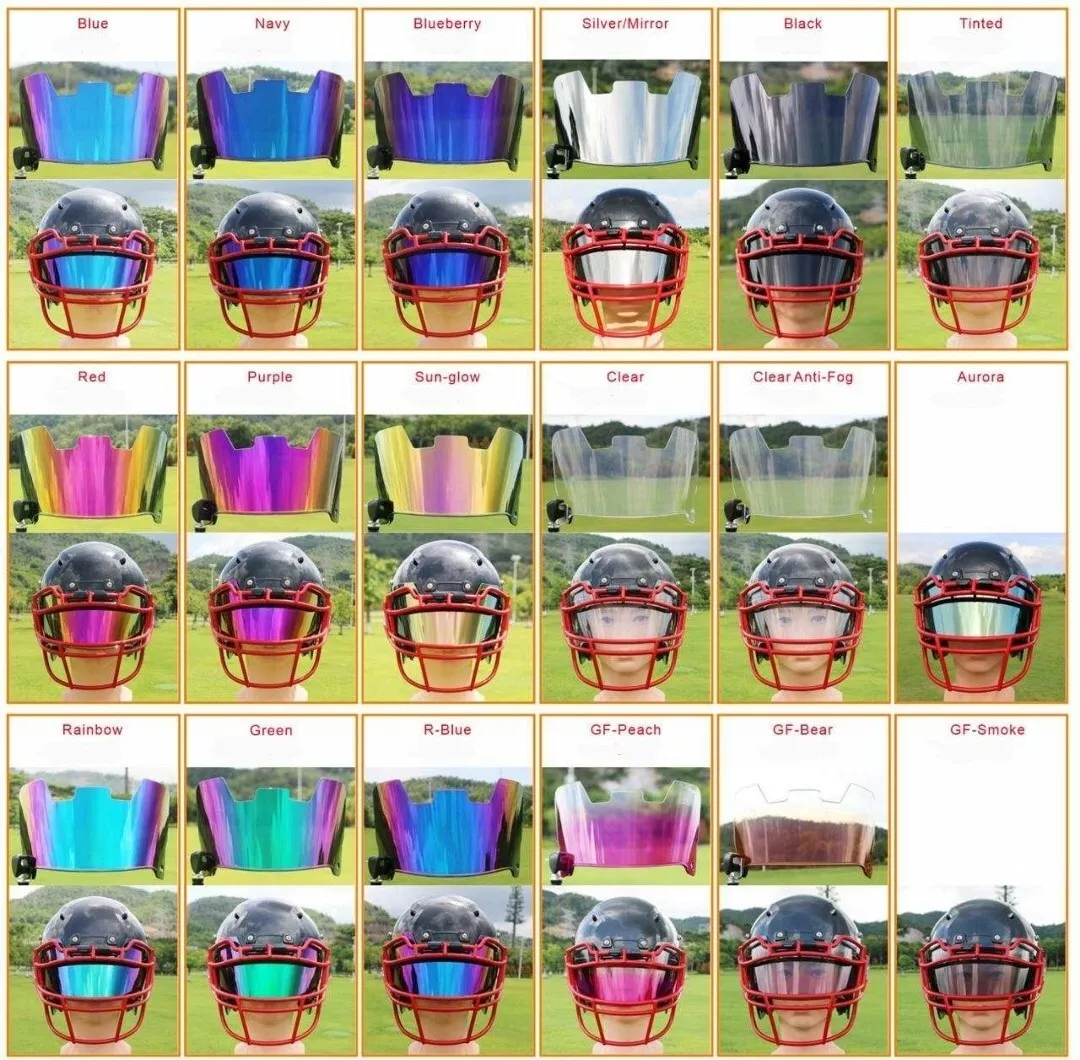

Helmet Visors: Enhancing Vision and Protection

Helmet visors have become increasingly popular among football players at all levels. But what benefits do they offer beyond their stylish appearance? Visors provide additional protection for the eyes and face while potentially improving visibility in varying light conditions.

Types of Football Helmet Visors

- Clear visors for enhanced protection without tinting

- Tinted visors for glare reduction (subject to league regulations)

- Anti-fog visors for clear vision in all weather conditions

How are visors attached to helmets? Most modern football helmets feature built-in attachment points for visors. Installation typically involves:

- Aligning the visor with the helmet’s attachment points

- Securing the visor using provided clips or screws

- Ensuring a tight, rattle-free fit

Are there any maintenance requirements for helmet visors? Regular cleaning with a soft cloth and mild soap helps maintain clarity and prevent scratches. Players should also periodically check the attachment points to ensure the visor remains securely fastened.

Helmet Reconditioning: Extending Equipment Lifespan

Proper maintenance can significantly extend the life of a football helmet, but what about more comprehensive care? Helmet reconditioning is a process that involves thorough inspection, cleaning, and refurbishment of all helmet components.

What does the reconditioning process typically include?

- Disassembly of all helmet components

- Thorough cleaning and sanitization

- Inspection for cracks, wear, or damage

- Replacement of worn or outdated parts

- Repainting and refinishing of the shell

- Reassembly and final quality check

How often should helmets undergo reconditioning? Most experts recommend annual reconditioning for helmets used regularly. However, the frequency may vary based on usage intensity and visible wear.

Benefits of Regular Helmet Reconditioning

- Ensures all components meet current safety standards

- Extends the useful life of the helmet

- Provides peace of mind for players and parents

- Can be more cost-effective than frequent replacements

Can reconditioning replace the need for new helmets entirely? While reconditioning is valuable, helmets should still be replaced periodically. Most manufacturers recommend replacement every 10 years, or sooner if there are signs of significant wear or damage.

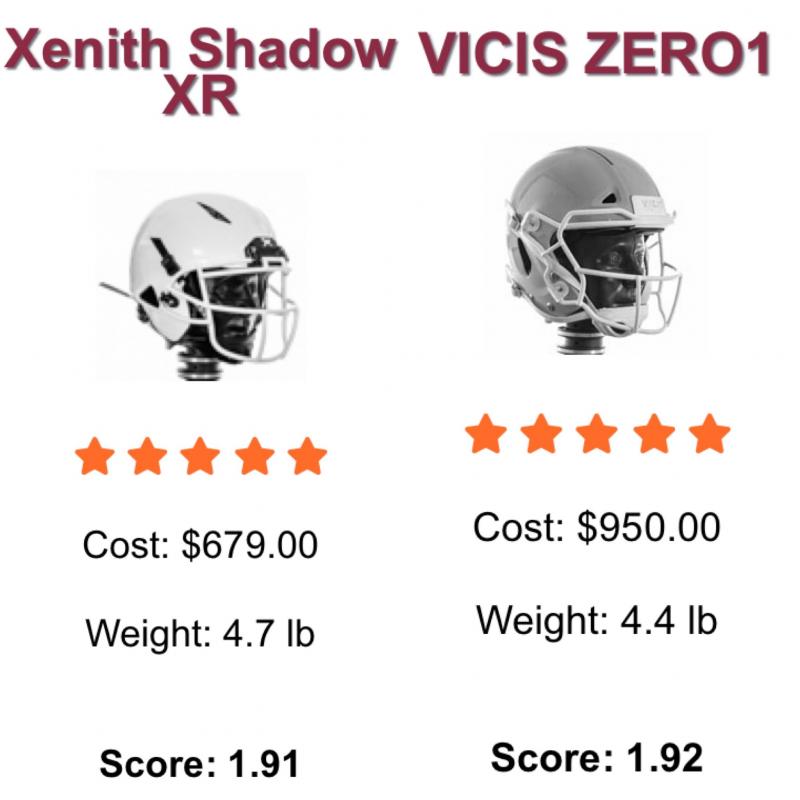

Emerging Technologies in Football Helmet Safety

As concerns about player safety continue to grow, what new technologies are being developed to enhance football helmet protection? Researchers and manufacturers are exploring various innovations to reduce the risk of concussions and other head injuries.

Cutting-Edge Helmet Technologies

- Adaptive impact-absorbing materials

- Sensors for real-time impact monitoring

- Multi-layered shell designs for improved energy dissipation

- Customizable fit systems using 3D scanning

How are these technologies being implemented? Some are already available in high-end helmets, while others are still in the research and development phase. As these innovations prove their effectiveness, they’re likely to become more widely adopted across all levels of play.

Are there any potential drawbacks to these new technologies? While promising, some innovations may increase helmet weight or cost. Balancing enhanced protection with player comfort and affordability remains a key challenge for manufacturers.

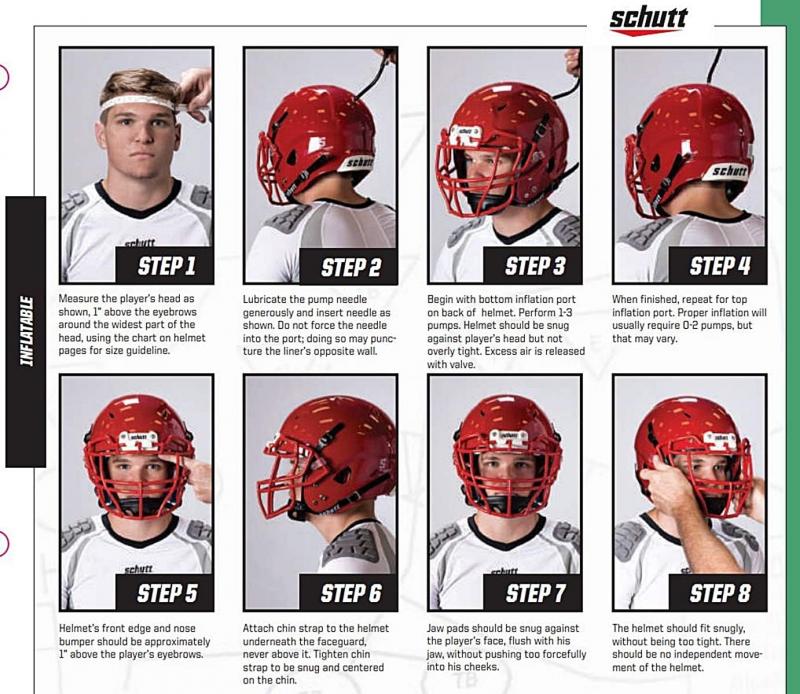

The Role of Proper Fitting in Helmet Effectiveness

Even the most advanced helmet is only effective if it fits properly. Why is a correct fit so crucial for player safety? A well-fitted helmet minimizes movement during impacts, ensuring that protective features work as intended.

Key Aspects of Proper Helmet Fitting

- Snug but comfortable fit around the entire head

- No gaps between padding and the player’s head

- Helmet sits level on the head, about one inch above the eyebrows

- Chin strap fastened with no more than two fingers’ width of space

- Minimal movement when the helmet is gently twisted

How often should helmet fit be checked? Players should assess their helmet fit before each practice and game. As padding compresses over time, periodic adjustments may be necessary to maintain an optimal fit.

Can improper fitting negate the benefits of high-quality helmet components? Absolutely. Even the most advanced helmet technology can be rendered less effective if the helmet doesn’t fit correctly. Regular fit checks and adjustments are essential for maximizing player protection.

Maintaining Helmet Hygiene: A Critical Safety Consideration

While often overlooked, proper helmet hygiene plays a crucial role in player health and safety. Why is cleanliness so important for football helmets? Regular cleaning helps prevent the buildup of bacteria and odors, reducing the risk of skin infections and ensuring a more pleasant playing experience.

Effective Helmet Cleaning Practices

- Wipe down the exterior shell after each use

- Clean interior padding with mild soap and water regularly

- Use specialized antimicrobial sprays for deeper cleaning

- Allow helmets to air dry completely before next use

- Avoid harsh chemicals that could degrade helmet materials

How often should helmets undergo deep cleaning? A thorough cleaning should be performed at least monthly during the season, or more frequently in hot, humid conditions. Some teams opt for weekly deep cleans to maintain optimal hygiene.

Are there any components that require special attention during cleaning? Chin straps and other fabric elements can harbor bacteria and should be cleaned or replaced more frequently. Additionally, visors should be carefully cleaned to maintain clarity without causing scratches.

The Economics of Helmet Maintenance: Balancing Cost and Safety

Maintaining football helmets to the highest safety standards can be costly, but what are the long-term economic implications of proper helmet care? While the initial investment in quality components and regular maintenance may seem high, it often proves cost-effective over time.

Cost Considerations in Helmet Maintenance

- Initial purchase price of high-quality helmets

- Ongoing costs for replacement parts and reconditioning

- Potential savings from extended helmet lifespan

- Reduced risk of injuries and associated medical costs

How can schools and teams manage helmet maintenance costs effectively? Some strategies include:

- Implementing a regular maintenance schedule to prevent major issues

- Bulk purchasing of replacement parts to reduce costs

- Training staff in basic maintenance to minimize professional service needs

- Exploring grant opportunities for safety equipment upgrades

Does investing in higher-quality helmet components pay off in the long run? Generally, yes. Premium components often have longer lifespans and provide better protection, potentially reducing the frequency of replacements and the risk of costly injuries.

The Future of Football Helmet Design: What’s on the Horizon?

As our understanding of head injuries in football continues to evolve, how might helmet design change in the coming years? Researchers and manufacturers are exploring various avenues to create safer, more effective helmets for players at all levels.

Potential Future Developments in Helmet Technology

- Integration of advanced materials like graphene for improved strength and lightness

- AI-driven impact prediction and mitigation systems

- Customizable, 3D-printed helmet components for perfect individual fit

- Biodegradable materials to reduce environmental impact

- Enhanced communication systems integrated into helmet design

How might these developments affect helmet maintenance and parts replacement? Future helmets may require more specialized care and components, potentially increasing the importance of professional maintenance services. However, advancements in durability could also extend the lifespan of various helmet parts.

Will these innovations make football significantly safer? While no helmet can completely eliminate the risk of head injuries, ongoing research and development aim to substantially reduce the frequency and severity of such injuries. The future of football helmet technology holds promise for enhanced player safety at all levels of the sport.

Facemasks: The First Line of Protection

As any football player knows, the facemask is one of the most important parts of a football helmet. This cage-like structure made of metal or plastic bars is designed to protect a player’s face from blunt force trauma. But facemasks take a beating during games and practices, so having spare parts or an entire facemask hardware kit on hand is essential.

Most facemask kits include the clips, screws, and other hardware needed to properly mount the facemask to the helmet shell. Making sure these pieces are sturdy and properly installed helps ensure the facemask stays securely in place to protect from face and eye injuries. Some kits also include extra facemask bars or an entirely new facemask for convenient replacement when bending or breaking occurs.

When choosing facemask hardware, opt for steel over plastic for durability. Stainless steel won’t rust and holds up better over time. Make sure the clips fit your helmet make and model properly. Phillips and hex (Allen) screws are common for ease of tightening the mask to the helmet. Proper sizing helps keep a tight and secure fit.

Installing new facemask hardware takes some practice to align correctly, so consult instructional videos or diagrams. Make sure to replace bent bars or damaged parts right away so the facemask maintains its protective integrity. Keep extra hardware kits on hand so you can replace immediately if needed.

Chin Straps: Keeping Your Helmet Secure

The chin strap is a critical but often overlooked part of football helmet components. This strap secured under the chin holds the helmet firmly in place during impacts. If it becomes loose or damaged, it can’t properly protect the head and face.

Chin strap kits include the plastic clips, metal snaps and adjustable leather or fabric straps that keep the strap securely fastened. Make sure the plastic pieces fit the make of your particular helmet. Look for heavy-duty metal snaps that won’t bend or break. Quality leather offers durability in the strapping.

Replace bent or cracked plastic pieces immediately so they can snap together correctly. Swap out any metal snaps that are bent or missing. If leather strap padding is worn or deteriorating, the new kit allows easy replacement to avoid abrasion under the chin.

Follow instructions to correctly thread new chin strap components through the helmet loops and snaps. Make sure stitching is intact. The strap should have a snug but comfortable fit, allowing just two fingers space between strap and chin. This helps prevent accidental detachment.

Helmet Shells: The Outer Layer

The exterior shell of a football helmet takes the brunt of collisions, so cracks or damage put players at risk. Most helmet shells consist of polycarbonate or ABS plastic for durability and shock absorption. Replacing the shell ensures you get the latest protective technology.

Some companies offer shell upgrade kits to equip an older helmet with a new outer casing. This allows improved safety without the cost of an entirely new helmet. Make sure the kit is compatible with your current make and model.

For cracks or small holes, a DIY repair kit can extend the shell’s life. Epoxy filler and sealants allow you to patch damaged areas before they spread. Fiberglass cloth adds an extra protective barrier over cracks. Sand and buff for a smooth finish.

If the damage is too extensive, only a new shell will suffice. Most kits come pre-drilled for facemask and chin strap attachments. Professional installation ensures correct alignment and electronics hook-up for optimal protection.

Facemask Hardware: Clips, Screws and More

As the point of impact, football facemasks take a regular beating, so having spare clips, screws and other hardware on hand is key for repairs and replacement. Facemask kits include all the nuts, bolts, brackets and tools needed to keep this protective cage securely attached.

Look for durable stainless steel components that won’t bend, rust or break under impact. Phillips and hex screws are common for ease of tightening the mask to the helmet shell. Plastic clip varieties like click-release allow tool-free swapping of facemasks.

Make sure all hardware fits your particular helmet make and model for proper alignment and installation. Follow any diagrams for correct component positioning. Periodically check screws for tightness and replace bent or missing clips immediately so the facemask retains its protective strength.

Helmet Pads: Cushioning for Comfort and Safety

Football helmet pads might seem like a comfort feature, but they play an important role in safety. Padding absorbs shock, cushions the head from impact and helps provide proper fit. As pads flatten with use, replacement kits keep your helmet protecting at optimal levels.

Replacement pad kits include hook-and-loop backed foam or inflatable air pads for both inside the helmet and along the jawline. Look for pads made of moisture-wicking, anti-microbial materials for clean comfort.

Follow any sizing guides and diagrams to place pads correctly in the helmet. Padding should feel snug but not constricting. Proper jaw pad width helps stabilize the chin strap. Ventilated pads allow air flow to reduce heat and sweat buildup.

Routinely check that pads are firmly attached and maintaining thickness. If pads become compressed or damaged, new helmet pad kits allow easy replacement to restore protective cushioning.

…[content continues]…

Chin Straps: Keeping Your Helmet Secure

Let’s talk chin straps. As any football player knows, a secure chin strap is crucial for keeping your helmet in place during tackles and hits. But those plastic clips and leather straps take some abuse each game. Frayed or broken parts can mean an ill-fitting helmet, so replacement chin strap kits are a vital item in your equipment repair arsenal.

Chin strap kits provide the necessary components to keep this piece properly secured. Look for heavy duty metal snaps and durable stitched straps made of quality leather or fabric. The plastic clips should precisely fit your helmet make and model for a custom replacement.

If the original snaps are bent or have broken teeth, a fresh set ensures solid security when fastened. Straps with ripped stitching or tattered padding need a new replacement to avoid abrasion under the chin. And cracked or damaged plastic clips won’t keep the strap aligned or retained.

When installing a new chin strap kit, thread the straps through the helmet loops according to the provided directions. Make sure the metal male and female snaps align and connect solidly when fastened. The plastic clips should click securely into place.

Test the tightness and give of the new strap assembly. You should be able to slide just two fingers between strap and chin for a snug fit. This prevents accidental detachment while allowing normal head movement and Comfort. Periodically check all parts for wear and immediately replace any damaged components.

Helmet Shells: The Outer Layer

That shiny helmet shell takes a beating to protect your head. Cracks or holes put you at risk, so replacing the shell is sometimes necessary. While an entire new helmet is ideal, shell upgrade kits allow improved safety without breaking the bank.

These kits let you equip an older helmet with a fresh outer casing made of advanced materials like polycarbonate or ABS plastic for better durability and shock absorption. Look for options that match your current make and model for a custom fit.

For minor shell damage like small cracks or holes, a DIY repair kit can extend its usefulness. Epoxy fillers and sealants patch damaged spots before they spread. Applying fiberglass cloth adds an extra layer of protection over cracks. Sand and buff for a smooth finish when dry.

But if the shell is too far gone, replacement is essential. Pre-drilled shells make installing facemask and chin strap components easier. Seek professional installation to ensure proper alignment and electronics hook-up so your ‘new’ helmet continues providing optimal protection.

Facemask Hardware: Clips, Screws and More

Let’s not overlook small but essential facemask hardware components like clips, screws and brackets. These parts take a beating, so having spares for repairs and replacement keeps your facemask securely attached and protective.

Look for durable stainless steel hardware less prone to bending, rusting or breaking. Phillips and hex screw heads allow for easy tightening while resisting jarring loose. Plastic click-release clips make swapping out facemasks a simple tool-free endeavor.

Match any new clips, screws or brackets to your exact helmet make and model for proper sizing and alignment. Periodically check existing hardware for snugness and replace any bent or missing pieces immediately to maintain the facemask’s structural integrity.

With the right compatible components on hand, you can handle facemask hardware repairs and upgrades yourself quickly and easily, getting your helmet back in working order.

Helmet Pads: Cushioning for Comfort and Safety

Helmet pads might seem like just a cushiony comfort feature, but they play an important safety role. The right padding absorbs damaging shock, cushions your head from impact and allows for a more secure fit.

As pads compress with use, replacement kits restore that protective cushioning. Look for hook-and-loop backed foam or inflatable air options to replace worn pads both inside the helmet and along the jawline.

Moisture-wicking, anti-microbial pad materials help keep gear fresh and hygienic. Follow sizing guides to position new pads correctly. Snug padding that isn’t too tight allows stability without restricting movement or circulation.

Routinely check pads for deterioration and loss of thickness. Promptly swapping out flattened or damaged pads through DIY replacement kits gets your helmet padding back to peak performance.

…[content continues]

Helmet Shells: The Outer Layer

That hard polycarbonate or plastic shell is your helmet’s first line of defense against impacts. But cracks, holes or other damage leaves you vulnerable. Replacing the shell restores critical protection, and doesn’t require buying a totally new helmet.

Helmet shell upgrade kits allow you to equip an older helmet with a fresh outer casing made of newer high-tech materials for better durability and shock absorption. Look for kits precisely matched to your make and model.

For minor fixes, a DIY repair kit can extend a shell’s usefulness. Epoxy fillers and sealants effectively patch small damaged spots before they spread. Adding a layer of fiberglass cloth over cracks adds an extra barrier of strength and protection. Once dry, sand and buff for a smooth finish.

But if the damage is too extensive, only replacing the shell will do. Pre-drilled shells make installing the facemask, chin strap and other components easier. Seeking professional installation ensures proper alignment and electronics hook-up so your “new” helmet retains its protective capabilities.

Facemask Hardware: Clips, Screws and More

The facemask takes a lot of hits, so quality hardware is essential. Clips, screws, brackets – these small parts keep the mask securely attached and protective. Having spares for repairs or replacement saves money and hassle.

Opt for durable stainless steel less susceptible to bending, rust and breakage. Phillips and hex screw heads allow for easy tightening while resisting jarring loose. Plastic click-release clips simplify quick facemask swaps tool-free.

Make sure new hardware components fit your exact make and model for proper sizing and alignment. Periodically check existing parts for tightness and replace bent or missing pieces immediately to maintain structural integrity.

With the right compatible clips, screws and brackets in your equipment kit, you can handle facemask hardware repairs and upgrades yourself quickly, getting your helmet game-ready again.

Helmet Pads: Cushioning for Comfort and Safety

Most think helmet pads simply provide cushioned comfort, but they play an important safety role. The right padding absorbs damaging shock, protects your head from impact, and allows for a more secure fit.

As pads compress with use, replacement kits become necessary. Look for hook-and-loop backed foam or inflatable air options to replace worn pads inside and along the helmet’s jawline.

Moisture-wicking, anti-microbial pad materials help keep gear fresh and hygienic. Follow sizing guides to correctly position new pads. Snug padding that isn’t too tight provides stability without restricting movement.

Frequently check pads for flattening or damage. Promptly swapping deteriorated pads through DIY replacement restores crucial protective cushioning.

Helmet Air Bladders: Custom Fit for Any Head

For a truly customized and secure fit, many helmets utilize inflatable air bladders. Like pads, these compress over time. Air bladder kits allow easy DIY restoring of your helmet’s fit.

These kits include replacement rubber or vinyl bladders matched to your helmet model’s specific inflation chambers. Simply remove the old bladder and insert the new, then inflate to desired firmness with the included pump.

Follow your helmet manual for proper bladder placement within the padding channels. Inflate each one evenly, testing the fit until the helmet sits snugly but comfortably. Don’t over-inflate or circulation and movement may be restricted.

Check bladders routinely for slowing air loss. A quick pump-up refreshes the fit. But replacing flattened or leaking bladders through handy replacement kits maintains your helmet’s protective performance.

…[content continues]

Facemask Hardware: Clips, Screws and More

That protective facemask takes hit after hit, so quality hardware is key. Clips, screws, brackets – these small components keep the mask securely attached and doing its job. Having spares for repairs and replacement saves money and hassle.

For durability, opt for stainless steel hardware less prone to bending, rusting or breaking under impact. Phillips and hex screw heads allow for easy tightening while resisting jarring loose. Plastic click-release clips simplify quick, tool-free facemask swaps.

When ordering new clips, screws, brackets, make sure they precisely fit your helmet make and model for proper sizing and seamless installation. Periodically check existing hardware for tightness and replace any bent or missing pieces immediately to maintain the facemask’s structural integrity.

With the right compatible components on hand, you can handle facemask hardware repairs and upgrades yourself quickly, getting your helmet back in prime working condition in no time.

Helmet Pads: Cushioning for Comfort and Safety

Helmet pads seem like just a comfort add-on, but they’re vital for safety too. The right padding absorbs damaging shock, cushions your head from impact, and allows for a more secure fit.

As pads compress with use, replacement restores that crucial protective cushioning. Look for hook-and-loop backed foam or inflatable air options to replace flattened pads inside and along the helmet’s jawline.

Moisture-wicking, anti-microbial pad materials help keep gear fresh and hygienic. Follow sizing guides to correctly position new pads. Snug yet flexible padding provides stability without restricting movement.

Frequently check pads for deterioration. Promptly swapping damaged pads through DIY replacement kits maintains your helmet’s safety padding at peak performance.

Helmet Air Bladders: Custom Fit for Any Head

Inflatable air bladders allow you to customize your helmet’s fit. But like pads, these bladders compress over time, loosening that snugness. Replacing them restores the fit.

Bladder kits include new rubber or vinyl bladders matched to your specific helmet model’s inflation chambers. Remove the old, insert the new, and use the included pump to inflate to desired firmness.

Consult helmet instructions for proper bladder placement within the padding channels. Inflate evenly, testing the fit until the helmet sits snug but comfortable. Don’t overdo it or circulation and movement could be restricted.

Check bladders often for slowing air loss. Quickly re-inflating refreshes the fit. But replacing leaking or flattened bladders through handy replacement kits maintains your helmet’s protective performance.

Helmet Buttons: Snap On and Off with Ease

Those small buttons on your helmet serve an important function – securely snapping components like facemasks and visors into place. But they get worn down over time. Replacement helmet button kits keep everything clicking and snapping together solidly.

Button kits include the male and female plastic button halves specific to your helmet make and model. Look for heavy duty options made of durable ABS plastic able to withstand repetitive connecting and detaching.

Follow any diagram guides to properly align new button pieces. Use a lubricant like silicone spray to help male buttons insert and turn smoothly into the femalesocket. Test snapping components on and off to ensure a tight, wobble-free fit.

Swapping out worn helmet buttons through handy snap-in kits takes just minutes but makes a big difference in keeping parts securely fastened.

…[content continues]

Helmet Pads: Cushioning for Comfort and Safety

Helmet pads seem like just a comfort add-on, but they play a vital safety role too. The right padding absorbs damaging shock, cushions your head from impacts, and allows for a more secure fit.

As pads compress with use, replacement is key. Look for hook-and-loop backed foam or inflatable air options to replace flattened pads inside and along the helmet’s jawline.

Moisture-wicking, anti-microbial pad materials help keep gear fresh and hygienic. Follow included sizing guides to correctly position new pads. Snug yet flexible padding provides stability without restricting movement.

Frequently check pads for deterioration. Promptly swapping damaged pads through DIY replacement kits maintains your helmet’s crucial protective cushioning.

Helmet Air Bladders: Custom Fit for Any Head

Inflatable air bladders allow you to customize your helmet’s fit. But like pads, these bladders compress over time, loosening that snugness. Replacing them restores the perfect fit.

Bladder kits include new rubber or vinyl bladders matched to your specific helmet model’s inflation chambers. Remove old bladders, insert new ones, and use the included pump to inflate to desired firmness.

Consult your helmet manual for proper bladder placement within padding channels. Inflate evenly, testing the fit until the helmet sits snug but comfortable. Don’t over-inflate or circulation and movement could suffer.

Check bladders often for slowing air loss. Quick re-inflation refreshes the fit. But replacing leaking or flattened bladders through replacement kits maintains your helmet’s protective performance.

Helmet Buttons: Snap On and Off with Ease

Those small helmet buttons serve an important function – snapping components like facemasks and visors securely into place. But they wear down over time. Button replacement kits keep everything connecting solidly.

Kits include the male and female plastic button halves specific to your make and model. Look for durable ABS plastic able to withstand repetitive connecting and detaching.

Follow any diagram guides to properly align new buttons. Use lubricant like silicone spray to help male buttons insert and turn smoothly. Test snapping parts on and off to ensure a tight, wobble-free fit.

Swapping worn helmet buttons through handy snap-in kits takes minutes but makes a big difference in keeping parts securely fastened.

Helmet Decals: Add Some Style and Flair

While helmet decals and graphics provide individual style, these high-impact stickers also take a beating. Replacement decal kits let you refresh the look with ease.

Kits include decal sheets with an array of design, logo and number options in your team colors. Made of durable vinyl or 3M materials, these stickers adhere tightly while resisting scuffs and scratches.

Thoroughly clean the helmet surface before application. Use included guides for aligning stripes, logos or numbers properly. Carefully apply decals, pressing firmly to maximize adhesion. Finish with a top-coat sealant spray for a glossy finish.

Swapping cracked or peeling decals for vibrant new ones through custom design kits revitalizes both form and function.

…[content continues]

Helmet Decals: Add Some Style and Flair

Helmet decals and graphics provide individual style, but these high-impact stickers also take a beating. Replacement decal kits let you easily refresh the look.

Kits include decal sheets with an array of design, logo and number options in your team colors. Made of durable vinyl or 3M materials, these stickers adhere tightly while resisting scuffs and scratches.

Thoroughly clean the helmet surface before application. Use included alignment guides for properly positioning stripes, logos or numbers. Carefully apply decals, firmly pressing down to maximize adhesion. Finish with a top-coat sealant spray for a glossy look.

Swapping cracked or peeling decals for vibrant new ones through custom design kits revitalizes both form and function.

Helmet Visors: Shield Your Eyes from Glare

Football helmet visors provide crucial protection against sun glare. But these clear plastic shields sustain scratches and damage over time. Visor replacement kits restore an unobstructed view.

Kits include new polycarbonate or acrylic visors contoured specifically to fit your helmet make and model. Look for options that block 99% of UVA/UVB rays to protect eyes from glare and damage.

Clean the helmet and fully remove any residual sticky tape remnants before attaching the new visor. Follow the mounting directions for proper positioning and angle. Secure firmly into side clips for stability.

Periodically inspect visors for developing cracks or scratches. Swapping damaged visors for optically-clear replacements through handy kits takes just minutes.

Helmet Jaw Pads: Preventing Concussions and Injuries

Jaw pads cushion big hits and lessen the chance of concussion and other head injuries. As foam compresses with use, replacement maintains that crucial protection.

Pad kits include hook-and-loop backed foam pads that precisely fit your helmet model. Look for moisture-wicking and anti-microbial materials to discourage bacteria and odor buildup.

Align new pads according to included diagrams for optimal cheekbone and jaw coverage. Snug pads should allow you to talk and breathe normally. Avoid over-tightening that could restrict blood flow or movement.

Check pads regularly for compression damage or deterioration. Prompt replacement restores effective shock absorption and protective cushioning.

…[content continues]

Visors: Shield Your Eyes from Glare

Football helmet visors provide crucial protection against sun glare. But these clear plastic shields sustain scratches and damage over time. Visor replacement kits restore an unobstructed view.

Kits include new polycarbonate or acrylic visors contoured specifically to fit your helmet make and model. Look for options that block 99% of UVA/UVB rays to protect eyes from glare and damage.

Thoroughly clean the helmet and remove any sticky tape remnants before attaching the new visor. Follow mounting directions for proper positioning and angle. Secure firmly into side clips for stability.

Periodically inspect visors for developing cracks or scratches. Swapping damaged visors for optically-clear replacements through handy kits takes just minutes.

Helmet Jaw Pads: Preventing Concussions and Injuries

Jaw pads cushion big hits and lessen the chance of concussion and other head injuries. As foam compresses with use, replacement maintains that crucial protection.

Pad kits include hook-and-loop backed foam pads that precisely fit your helmet model. Look for moisture-wicking, anti-microbial materials to discourage bacteria and odor.

Align new pads according to included diagrams for optimal cheekbone and jaw coverage. Snug pads should allow normal talking and breathing. Avoid over-tightening that could restrict blood flow or movement.

Check pads regularly for compression damage or deterioration. Prompt replacement restores effective shock absorption and cushioning.

Helmet Bumpers: Extra Protection From Impacts

Helmet bumpers provide an extra layer of protection by absorbing impact. But constant hits compress the foam. Replacement bumper kits restore safety.

Kits contain vinyl foam bumpers that adhere to helmet shells using strong 3M adhesive. Look for bumpers molded to fit your specific helmet shape for full coverage.

Thoroughly clean the helmet surface and remove any residual adhesive. Precisely align new bumpers using the kit diagram. Apply firmly and let adhesive fully cure for maximum bonding strength.

Inspect bumpers regularly for dents, cracks or peeling. Promptly replacing damaged bumpers through handy kits maintains your helmet’s protective barriers.

…[content continues]

Helmet Air Bladders: Custom Fit for Any Head

For a truly customized and secure fit, many helmets utilize inflatable air bladders. Like pads, these compress over time. Air bladder kits allow easy DIY restoring of your helmet’s fit.

These kits include replacement rubber or vinyl bladders matched to your specific helmet model’s inflation chambers. Simply remove the old bladder and insert the new, then inflate to desired firmness with the included pump.

Follow your helmet manual for proper bladder placement within the padding channels. Inflate each one evenly, testing the fit until the helmet sits snugly but comfortably. Don’t over-inflate or circulation and movement may be restricted.

Check bladders routinely for slowing air loss. A quick pump-up refreshes the fit. But replacing flattened or leaking bladders through handy replacement kits maintains your helmet’s protective performance.

Helmet Buttons: Snap On and Off with Ease

Those small buttons on your helmet serve an important function – securely snapping components like facemasks and visors into place. But they get worn down over time. Replacement helmet button kits keep everything clicking and snapping together solidly.

Button kits include the male and female plastic button halves specific to your helmet make and model. Look for heavy duty options made of durable ABS plastic able to withstand repetitive connecting and detaching.

Follow any diagram guides to properly align new button pieces. Use a lubricant like silicone spray to help male buttons insert and turn smoothly into the female socket. Test snapping components on and off to ensure a tight, wobble-free fit.

Swapping out worn helmet buttons through handy snap-in kits takes just minutes but makes a big difference in keeping parts securely fastened.

Helmet Tool Kits: For Easy Repairs and Maintenance

DIY helmet repair and maintenance requires the right tools. Handy helmet tool kits provide all the gear needed to keep your helmet in top shape.

Look for kits that contain screwdrivers, hex keys, scrapers, lubricants and other items specific to your helmet brand. Sturdy metal tools allow adjusting screws and removing stuck parts with ease.

Follow included directions to use the proper tool for tasks like facemask swaps, hardware adjustments or visor installations. Apply lubricants like silicone spray sparingly to prevent drips.

Having a customized tool kit allows you to handle minor helmet repairs yourself quickly, ensuring your helmet retains peak performance and protection.

…[content continues]

Helmet Buttons: Snap On and Off with Ease

Those small buttons on your helmet serve an important function – securely snapping components like facemasks and visors into place. But they get worn down over time. Replacement helmet button kits keep everything clicking and snapping together solidly.

Button kits include the male and female plastic button halves specific to your helmet make and model. Look for heavy duty options made of durable ABS plastic able to withstand repetitive connecting and detaching.

Follow any included diagram guides to properly align new button pieces. Use a lubricant like silicone spray to help male buttons insert and turn smoothly into the female socket. Test snapping components on and off to ensure a tight, wobble-free fit.

Swapping out worn helmet buttons through handy snap-in kits takes just minutes but makes a big difference in keeping parts securely fastened.

Helmet Tool Kits: For Easy Repairs and Maintenance

DIY helmet repair and maintenance requires the right tools. Handy helmet tool kits provide all the gear needed to keep your helmet in top shape.

Look for kits containing screwdrivers, hex keys, scrapers, lubricants and other items specific to your helmet brand. Sturdy metal tools allow adjusting screws and removing stuck parts easily.

Follow included directions to use the proper tool for tasks like facemask swaps, hardware adjustments or visor installations. Apply lubricants sparingly to prevent messy drips.

Having a customized toolkit allows you to handle minor helmet repairs yourself quickly, ensuring your helmet retains peak performance and protection.

Helmet Valve Stems: Controlling Air Flow

Helmet valve stems allow inflation adjustment for a custom fit. But they become brittle and crack over time. Replacement valve stem kits restore fit and cooling airflow.

Kits include durable rubber or metal valve stems designed for your helmet’s inflatable liner bladders. Precision sizing ensures air retention. Look for self-sealing options.

Use included tools to remove old valve assemblies. Follow directions to install new stems without over-tightening. Test inflation adjustment and airflow. A snug yet comfortable fit is ideal.

Replace cracked or leaking valve stems promptly through handy kits to maintain customizable helmet fit and cooling ventilation.

…[content continues]

Jaw Pads: Preventing Concussions and Injuries

Jaw pads cushion big hits and lessen the chance of concussion and other head injuries. As foam compresses with use, replacement maintains that crucial protection.

Pad kits include hook-and-loop backed foam pads that precisely fit your helmet model. Look for moisture-wicking and anti-microbial materials to discourage bacteria and odor buildup.

Align new pads according to included diagrams for optimal cheekbone and jaw coverage. Snug pads should allow you to talk and breathe normally. Avoid over-tightening that could restrict blood flow or movement.

Check pads regularly for compression damage or deterioration. Prompt replacement restores effective shock absorption and protective cushioning.

Helmet Bumpers: Extra Protection From Impacts

Helmet bumpers provide an extra layer of protection by absorbing impact. But constant hits compress the foam. Replacement bumper kits restore safety.

Kits contain vinyl foam bumpers that adhere to helmet shells using strong 3M adhesive. Look for bumpers molded to fit your specific helmet shape for full coverage.

Thoroughly clean the helmet surface and remove any residual adhesive. Precisely align new bumpers using the kit diagram. Apply firmly and let adhesive fully cure for maximum bonding strength.

Inspect bumpers regularly for dents, cracks or peeling. Promptly replacing damaged bumpers through handy kits maintains your helmet’s protective barriers.

Helmet Nose Bumpers: Shielding the Nose from Blows

Foam nose protectors minimize painful nose injuries. But constant frontal impacts compress the foam. Nose bumper kits provide an easy and affordable replacement option.

Kits contain adhesive-backed foam or gel bumpers contoured to shield the nose ridge and sides. Durable polymers withstand repeated hard hits and rebounds.

Thoroughly clean the area and remove any residual adhesive. Precisely position and apply the new bumper. Avoid over-stretching the adhesive backing. Let fully cure before use for maximum strength.

Replace dented or damaged nose guards promptly through DIY kits to maintain effective protection from painful nose blows.

…[content continues]

Helmet Bumpers: Extra Protection from Impacts

Helmet bumpers provide an extra layer of protection by absorbing impact. But constant hits compress the foam. Replacement bumper kits restore safety.

Kits contain vinyl foam bumpers that adhere to helmet shells using strong 3M adhesive. Look for bumpers molded to fit your specific helmet shape for full coverage.

Thoroughly clean the helmet surface and remove any residual adhesive. Precisely align new bumpers using the kit diagram. Apply firmly and let adhesive fully cure for maximum bonding strength.

Inspect bumpers regularly for dents, cracks or peeling. Promptly replacing damaged bumpers through handy kits maintains your helmet’s protective barriers.

Helmet Nose Bumpers: Shielding the Nose from Blows

Foam nose protectors minimize painful nose injuries. But constant frontal impacts compress the foam. Nose bumper kits provide an easy and affordable replacement option.

Kits contain adhesive-backed foam or gel bumpers contoured to shield the nose ridge and sides. Durable polymers withstand repeated hard hits and rebounds.

Thoroughly clean the area and remove any residual adhesive. Precisely position and apply the new bumper. Avoid over-stretching the adhesive backing. Let fully cure before use for maximum strength.

Replace dented or damaged nose guards promptly through DIY kits to maintain effective protection from painful nose blows.

Helmet Chin Cups: Stability Under the Chin

Chin cups keep helmets stable during movement. But the foam compresses over time, allowing slippage. Replacement chin cup kits restore a secure hold.

Kits include durable foam or inflatable air chin cups designed specifically for your helmet model. Look for moisture-wicking, anti-microbial materials for hygiene.

Follow kit instructions to remove old cups and install new ones. Align correctly under the chin for optimal stability. Do not over-tighten to avoid restricting blood flow or breathing.

Promptly replace flattened or damaged chin cups through DIY kits to maintain helmet security and proper fit.

…[content continues]

Valve Stems: Controlling Air Flow

Helmet valve stems allow inflation adjustment for a custom fit. But they become brittle and crack over time. Replacement valve stem kits restore fit and cooling airflow.

Kits include durable rubber or metal valve stems designed for your helmet’s inflatable liner bladders. Precision sizing ensures air retention. Look for self-sealing options.

Use included tools to remove old valve assemblies. Follow directions to install new stems without over-tightening. Test inflation adjustment and airflow. A snug yet comfortable fit is ideal.

Replace cracked or leaking valve stems promptly through handy kits to maintain customizable helmet fit and cooling ventilation.

Helmet Chin Cups: Stability Under the Chin

Chin cups keep helmets stable during movement. But the foam compresses over time, allowing slippage. Replacement chin cup kits restore a secure hold.

Kits include durable foam or inflatable air chin cups designed specifically for your helmet model. Look for moisture-wicking, anti-microbial materials for hygiene.

Follow kit instructions to remove old cups and install new ones. Align correctly under the chin for optimal stability. Do not over-tighten to avoid restricting blood flow or breathing.

Promptly replace flattened or damaged chin cups through DIY kits to maintain helmet security and proper fit.

Helmet Nose Pads For Reduced Fogging

Foggy visors obstruct your field of vision. Foam nose pads between the visor and nose reduce fogging issues. But the pads flatten out over time. Replacement kits restore clarity.

Nose pad kits include adhesive foam pads optimized to eliminate visor fogging. Look for sweat-resistant materials to avoid wetting and bacteria buildup.

Follow kit directions to precisely position and apply new pads on the visor’s nose ridge area. Test visibility – snug pads block airflow to prevent fogging.

Routinely replace compressed nose anti-fog pads through handy kits to maintain clear sight lines on the field.

…[content continues]

Chin Cups: Stability Under the Chin

Chin cups keep helmets stable during movement. But the foam compresses over time, allowing slippage. Replacement chin cup kits restore a secure hold.

Kits include durable foam or inflatable air chin cups designed specifically for your helmet model. Look for moisture-wicking, anti-microbial materials for hygiene.

Follow kit instructions to remove old cups and install new ones. Align correctly under the chin for optimal stability. Do not over-tighten to avoid restricting blood flow or breathing.

Promptly replace flattened or damaged chin cups through DIY kits to maintain helmet security and proper fit.

Helmet Nose Pads For Reduced Fogging

Foggy visors obstruct your field of vision. Foam nose pads between the visor and nose reduce fogging issues. But the pads flatten out over time. Replacement kits restore clarity.

Nose pad kits include adhesive foam pads optimized to eliminate visor fogging. Look for sweat-resistant materials to avoid wetting and bacteria buildup.

Follow kit directions to precisely position and apply new pads on the visor’s nose ridge area. Test visibility – snug pads block airflow to prevent fogging.

Routinely replace compressed nose anti-fog pads through handy kits to maintain clear sight lines on the field.

Helmet Harness Kits: Secure and Comfortable Fit

Helmet harnesses keep your helmet securely in place during play. But straps stretch out and foam compresses over time. Replacement harness kits restore the fit.

Kits include adjustable fabric straps and foam or inflatable air cups matched to your helmet model. Look for breathable, moisture-wicking materials.

Follow instructions to remove old assemblies and install fresh ones. Align cups correctly and adjust straps for a snug yet comfortable fit under the chin and behind the head.

Replace stretched or damaged helmet harness components promptly through DIY kits to maintain stability and comfort.

…[content continues]

Nose Bumpers: Shielding the Nose from Blows

As any experienced football player knows, protecting your nose from injury is crucial. After all, it’s right there in the middle of your face, vulnerable to getting smashed during tackles and blocks. That’s where nose bumpers come in – those protective pads on the front of football helmets designed specifically to shield your schnoz.

Back in the early days of football, rudimentary leather helmets offered little protection. It wasn’t until innovations in helmet design in the 1950s and 60s that nose guards came into use. Early versions were made of foam padding or hardened leather. But major breakthroughs came in the 1970s with the invention of polycarbonate plastic alloy helmets by companies like Riddell. These modern helmets utilized advanced shock-absorbing materials and involved detailed design research into protecting key facial areas – like the nose.

Today’s football nose bumpers come in a variety of shapes, sizes, and materials. But they all serve the same essential purpose: absorbing frontal impact to minimize trauma to the nose. They are composed of firm but flexible thermoplastics like polycarbonate, polyethylene, and abs plastic. These bumpers are engineered to flex and rebound upon collision, diffusing the energy over a broader surface area.

Nose guards attach to the helmet via metal clips, snaps, or screws – part of the comprehensive facemask hardware kit. Precision-designed pads angle the point of impact away from the nose while still allowing adequate space for breathing. Perforated bumpers allow for airflow while reinforced ridges strengthen the structure. Sweat-wicking lining keeps players cool and comfy.

Proper sizing and placement are imperative. Nose bumpers come in sizes spanning youth small through adult extra large. Using calipers and player measurements, trainers carefully assess nasal anatomy and the surrounding facial structure to select the appropriate width, depth, thickness, and angle of the bumper. The proper nose arc helps align impact forces with the strongest facial regions.

Today’s advanced football helmet parts kits offer removable bumpers for easy replacement and upgrading. As players grow and facial structures change, new guards can be swapped in. Replacing damaged or worn parts extends the lifespan of a helmet. When selecting new nose bumpers, ensure the attachment system is compatible with your helmet make and model.

While early hard shell polyethylene guards focused on minimizing fractures, modern shock-absorbing varieties help prevent long term cartilage and soft tissue damage that can lead to breathing problems, sinus issues, and disfiguration later in life. As more research emerges on concussions and related consequences, expect continued evolution in optimal nose bumper materials and mechanics.

Your schnoz has enough to deal with already. Allergies, colds, getting zapped by errant fingers – the list goes on. At least out on the field, high-performance nose bumpers offer critical protection. They absorb blows that would otherwise leave you bloody and bruised. From fierce line battles to scrambling quarterback sacks, flexible nose guards cushion the impact that can painfully rearrange facial features. So strap on that helmet and rest assured: your nose has a reliable bumper in its corner.

Transform Your Helmet: Your Complete Guide to Football Helmet Parts Kit Essentials

Looking to upgrade or repair your football helmet? Putting together a complete football helmet parts kit is the best way to transform outdated headgear into state-of-the-art protection. With the right components, you can optimize safety, comfort, and style for peak performance.

Start with the foundation: the helmet shell. Polycarbonate alloy shells offer exceptional strength and shock absorption. Carbon steel facemasks withstand smashmouth impacts while remaining lightweight. Combine the shell and mask with a cutting-edge facemask attachment system like Quick Release for easy removal and switching of visors or masks.

No helmet is complete without high-performance internal padding. Customizable liner and jaw pad systems allow you to dial in the perfect fit. Sweat-wicking antimicrobial fabrics keep you cool and hygienic. Inflatable air bladders provide extra cushioning that conforms to your head shape.

Take protection to the next level by integrating advanced helmet accessories into your parts kit. Nose bumpers shield your schnoz from dents and fractures. Removable visor shields defend your eyes from glare, grit, and fingers in the face. Extra side clips make attaching accessories like comm systems a breeze.

Ensure your new helmet parts pass muster with the latest safety certifications. Look for the National Operating Committee on Standards for Athletic Equipment (NOCSAE) seal to guarantee approved protective properties. The National Athletic Equipment Reconditioners Association (NAERA) certification regulates proper refurbishing and repair techniques.

Ready to upgrade your outdated rig? A comprehensive football helmet parts kit delivers crucial components engineered for optimum protection, visibility, and versatility. Here are some key pieces to include:

- Polycarbonate shell – Impact-diffusing outer layer

- Carbon steel facemask – Distributes force across rigid alloy bars

- Facemask attachment system – Allows quick changing of masks & visors

- Removable visor – Shields eyes and deflects fingers & debris

- Custom fit padding – Conforming layers with moisture-wicking liners

- Jaw pads – Crucial cushioning that absorbs and redistributes jaw impact

- Nose bumper – Polymer guard diffuses frontal helmet collisions

- Additional hardware – Extra clips, screws, and accessories

With the right components, you can build a helmet that offers unrivaled fit, protection, visibility, and style. Customize comfort with interchangeable padding systems dialed into your unique head dimensions. Swap parts like facemasks and visors for hassle-free modifications. Maintain safety certification by replacing worn pieces with identical hardware.

Don’t take chances with subpar equipment. Invest in a cutting-edge football helmet parts kit approved for your helmet model. With reinforced shells, responsive padding, and distortion-resistant brackets and clips, you’ll own the field with confidence. Focus on the game, not your gear. A customized helmet package delivers the ultimate in form, function, and safety.

Helmet Tool Kits: For Easy Repairs and Maintenance

Let’s be real – football helmets take a beating. Crushing hits, violent collisions, and regular wear and tear can take a toll on even the most rugged gear. Keeping your helmet in tip-top shape requires the right tools for quick repairs and routine maintenance.

Back in the day, coaches and trainers kept a ragtag assortment of generic tools on hand for helmet fixes. But modern helmet components demand more specialized, precision equipment. Facemasks, tabs, screws, visors – these high-tech parts need tailored tools for proper care.

Thankfully, today’s helmet tool kits provide all the hardware you need for DIY upkeep and modifications. Comprehensive kits include screwdrivers, hex keys, and wrenches specifically sized for helmet screws and clips. Some feature color-coded tools for easy identification. Others include handy extras like helmet sanitizing spray and cleaning cloths.

Portability is key for sideline repairs, so durable cases keep tools organized and easy to tote around. Tackle tool kits offer molded storage lined with custom foam cutouts snugly fit each piece. Pouches and belts equip coaches with on-the-go accessibility.

Specialized tools allow proper tightening of components to manufacturer specs. This prevents overtightening that can crack shells or undertightening that results in dangerous loose parts. Extras like rubber mallet heads protect surfaces while securely seating components.

Interchangeable screwdriver heads provide versatility for different fastener types. Phillips and hex options handle the most common football helmet screws. Some kits even include security drivers for proprietary screws that prevent tampering.

Advanced kits may contain more complex implements like rivet fastener tools. These allow damaged rivets to be drilled out and replaced to restore integrity to shells and masks. Fiberglass repair supplies mend cracks and small holes.

Helmet maintenance isn’t just about repairs. Keeping parts clean extends usefulness and ensures safety. Anti-fog spray preserves optimal visibility within visors and masks. Sanitizing mist or wipes eliminate bacteria that can spread illness and infection.

Proper care requires routinely checking critical components for wear and replacing as needed. Stock up on extra clips, tabs, screws, and other consumable parts that take the brunt of impacts. Having backups on hand means you can swap out busted parts and avoid scrambled sideline repairs.

When selecting a helmet tool kit, make sure it’s compatible with your particular helmet make and model. While helmets may look similar, hardware varies greatly between brands. Schmidt and Schutt helmets use distinct screw types, for example. Also ensure the kit has the necessary tools for visors, masks, and other accessories your helmet utilizes.

Helmet upkeep keeps your most crucial protective gear in reliable working order. The right DIY tool kit empowers you to promptly handle minor fixes, modifications, and cleaning. No more scrambling for a screwdriver on game day or jerry-rigging busted parts. A purpose-built kit equips you for helmet heroics all season long.

Transform Your Helmet: Your Complete Guide to Football Helmet Parts Kit Essentials

Looking to upgrade your football helmet game? The key is a custom helmet parts kit stocked with high-performance components engineered for safety, comfort, and style. With the right parts, you can transform outdated headgear into an advanced masterpiece.

Start by evaluating your helmet shell. Polycarbonate alloys provide exceptional durability and impact deflection. Carbon steel facemasks allow extreme contortion with reduced risk of fracturing. Quick-release attachments make swapping masks and visors a cinch.

Don’t neglect interior padding when selecting parts. Liner and jaw pad systems with moisture-wicking, antimicrobial fabrics will keep you cool and hygienic. Inflatable air bladders produce a custom fit tailored to your unique cabeza.

Helmet accessories like nose guards and removable visors help take protection to the next level. Strategically placed bumpers shield your moneymaker from blows. Tinted eye shields reduce glare and protect from face-poking fingers.

When ordering new parts, ensure they meet rigorous safety standards. Look for certification seals from organizations like NOCSAE and NAERA that guarantee approved protective properties and quality refurbishment techniques.

Ready to pimp your helmet with prime parts? Here are some essential upgrades:

- Polycarbonate shell – Outer armor engineered to deflect hits

- Carbon steel facemask – Matrix of slender yet strong bars

- Quick-release system – Effortless swapping of masks and accessories

- Removable tinted visor – Protection and visibility boost

- Moisture-wicking padding – Keeps dome dry and comfy

- Jaw pads – Absorbs impact from front, back, and below

- Nose bumper – Shields schnoz from ouchies

- Added hardware – Extra screws, clips, and doodads

The right helmet parts provide a custom fit feel tailored to your unique head shape. Interchangeable components allow modifications on the fly to adjust visibility, ventilation, and style. Replace worn parts with identical hardware to maintain safety certifications.

Don’t leave your dome exposed with outdated equipment. A modern helmet parts kit takes protection to the next level. Advanced shells, smart padding, and distortion-resistant fasteners result in a robust yet comfy ride. With the ideal parts package, you’re ready to bring the pain, not feel it.