How does carbon fiber technology enhance lacrosse equipment performance. What are the key benefits of carbon fiber lacrosse shafts. Which top carbon fiber defense shafts dominate the market. How to choose the right shaft flex for optimal play.

Carbon Fiber Lacrosse Shafts: A Game-Changing Innovation

Carbon fiber technology has revolutionized the world of lacrosse equipment, offering players unprecedented advantages in performance and durability. These cutting-edge shafts have quickly gained popularity among athletes seeking to elevate their game to new heights.

Carbon fiber composite materials form the backbone of these advanced lacrosse shafts, resulting in a product that boasts exceptional strength while maintaining an incredibly light weight. This unique combination translates into superior playability and longevity on the field.

Unparalleled Strength-to-Weight Ratio

The most striking feature of carbon fiber lacrosse shafts is their remarkable strength-to-weight ratio. This property allows for shafts that exhibit extraordinary stiffness and rigidity without the burden of excess weight. As a result, players can enjoy enhanced resistance to checks and slashes during intense gameplay, all while avoiding the fatigue associated with swinging heavier metal shafts.

Enhanced Flex and “Whip”

Carbon fiber lacrosse shafts typically offer a greater degree of flex and “whip” compared to traditional aluminum options. This increased flexibility contributes to improved ball control, allowing players to execute quicker releases on shots and deliver more powerful checks. The minimal weight of these shafts further enhances handling speed and maneuverability, giving players a significant edge when navigating around defenders.

Superior Vibration Dampening

Another notable advantage of carbon fiber construction is its exceptional vibration dampening properties. Unlike aluminum shafts, which can transmit uncomfortable vibrations to a player’s hands, carbon fiber effectively absorbs and dissipates these vibrations. This reduction in impact shock and fatigue allows players to maintain peak performance throughout extended periods of play.

Unmatched Durability

Carbon fiber lacrosse shafts exhibit superior durability compared to their metal counterparts. While aluminum shafts are prone to dents, chips, and breaks with prolonged use, carbon fiber maintains its structural integrity over time. Although carbon can crack under extreme force, it generally withstands the rigors of an entire season better than traditional materials, resulting in a longer-lasting piece of equipment.

Top Carbon Fiber Defense Shafts: Elevating Defensive Play

For defensive players, selecting the right carbon fiber lacrosse shaft can make a significant impact on performance. These advanced shafts enable defenders to execute precise checks, efficiently scoop ground balls, and swiftly move the ball upfield. Let’s explore some of the top carbon fiber defense shaft options available in the market:

Maverik Hyper Carbon Pro

The Maverik Hyper Carbon Pro utilizes multi-modulus carbon fiber placement to optimize stiffness and enhance handling. Its textured grip ensures secure cradling under pressure, while the angular handle shape effectively channels force to the lower end for powerful checks. Weighing in at a mere 140 grams, this shaft provides defenders with exceptional mobility on the field.

Epoch Dragonfly Integra

Designed for superior ball control, the Epoch Dragonfly Integra employs Minimus Carbon fiber to create an ultra-smooth flex profile. This innovative design results in excellent touch on ground balls, precise passing, and deadly accurate shots. With comfortable node grips and a thoughtfully engineered shaft shape, the Integra excels in transition play. At just 145 grams, it offers effortless maneuverability for defensive players.

STX Surgeon 700

The STX Surgeon 700 leverages multi-resin carbon fiber to deliver a rigid yet lightweight shaft that thrives in physical defensive play. Its octagonal shape ensures comfort, while the EndoKross texture optimizes grip. Defensive players will appreciate the pinpoint accuracy and excellent ball control from any angle, making it a top choice for shutdown defenders.

Warrior Regulator Max

Ideal for aggressive defensive styles, the Warrior Regulator Max provides extreme stiffness for delivering powerful checks. The Max technology enables superior energy transfer and ball control, complemented by an Armortex grip that prevents slippage. Weighing 160 grams, this shaft strikes an excellent balance between low weight and exceptional sturdiness.

Nike Vandal

Constructed with a blend of high and low-modulus carbon fibers, the Nike Vandal optimizes flex and feel. Its unique HyperWhip technology enhances handling and ball control, while the textured Nike Grip ensures a secure hold even in wet conditions. This shaft stands out as an exceptionally lightweight yet durable option for defensive players.

Selecting the Optimal Carbon Fiber Lacrosse Shaft Flex

One of the most significant advantages of carbon fiber lacrosse shafts is the ability to customize the flex profile. Shaft flex plays a crucial role in handling, passing, shooting, and even durability. With numerous flex options available, it’s essential to understand how different flex profiles can impact your game.

Understanding Flex Ratings

Flex ratings typically range from 0 to 100, with lower numbers indicating greater flexibility and higher numbers representing increased stiffness. For example, a shaft with a flex rating of 25 will have more bend than one rated at 75.

Position-Specific Flex Considerations

- Attackmen often prefer more flexible shafts (20-40 flex) for quicker release and enhanced feel.

- Midfielders generally opt for medium flex (40-60) to balance shooting power with control.

- Defenders typically choose stiffer shafts (60-80 flex) for improved checking and groundball scooping.

- Goalies usually prefer the stiffest options (80-100 flex) for maximum control during clears and outlet passes.

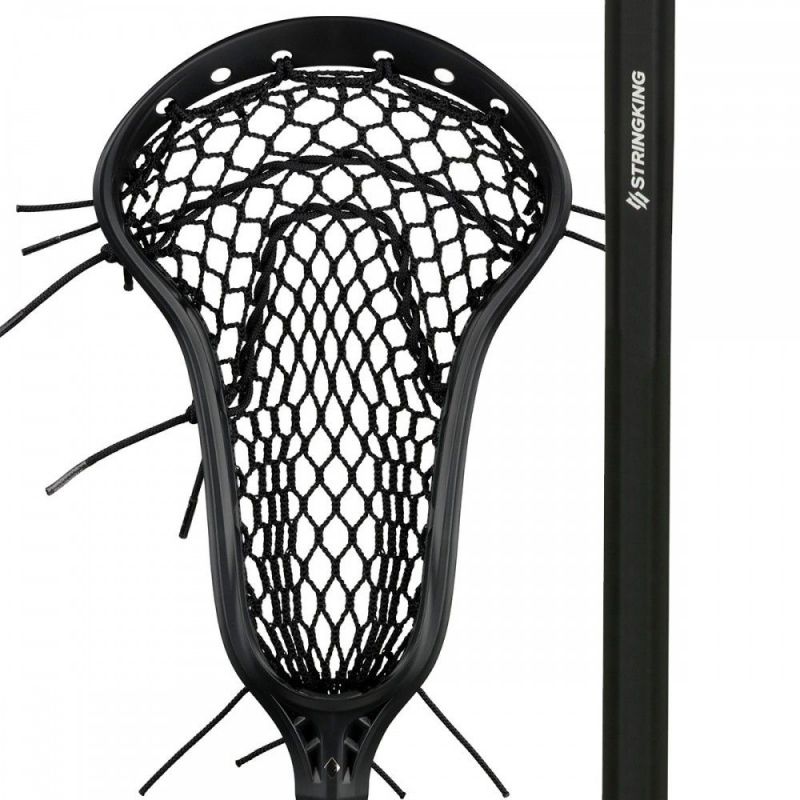

Carbon Fiber Heads: Revolutionizing Lacrosse Stick Design

While carbon fiber shafts have gained significant popularity, the technology is now being applied to lacrosse heads as well. Carbon fiber heads offer unique advantages that are reshaping the way players approach the game.

Unmatched Stiffness and Stability

Carbon fiber heads provide exceptional stiffness, resulting in more consistent pocket shape and improved ball control. This stability allows for more accurate passes and shots, especially in challenging weather conditions.

Lightweight Performance

The lightweight nature of carbon fiber heads contributes to faster stick movement and improved maneuverability. Players can execute quicker checks, make faster shot releases, and change directions more swiftly with these innovative heads.

Enhanced Durability

Carbon fiber heads are highly resistant to warping and maintain their shape even in extreme temperatures. This durability ensures consistent performance throughout the season and reduces the need for frequent replacements.

Maintenance and Care for Carbon Fiber Lacrosse Equipment

To maximize the lifespan and performance of carbon fiber lacrosse equipment, proper maintenance and care are essential. Follow these guidelines to keep your carbon fiber gear in top condition:

Regular Inspection

Routinely examine your carbon fiber shaft and head for any signs of damage, such as cracks, chips, or delamination. Early detection of issues can prevent more severe damage and extend the life of your equipment.

Cleaning and Storage

Clean your carbon fiber equipment after each use with mild soap and water. Avoid using harsh chemicals or abrasive materials that could damage the carbon fibers. Store your equipment in a cool, dry place away from direct sunlight to prevent degradation of the material.

Proper Transportation

When transporting your carbon fiber lacrosse gear, use protective cases or bags to prevent accidental damage. Avoid placing heavy objects on top of your equipment, as this could lead to cracks or deformation.

The Future of Carbon Fiber in Lacrosse

As carbon fiber technology continues to advance, we can expect to see even more innovative applications in lacrosse equipment. Some potential developments on the horizon include:

Advanced Composite Blends

Manufacturers are exploring new composite materials that combine carbon fiber with other high-performance fibers to create shafts and heads with even more specialized characteristics.

Customizable Flex Zones

Future carbon fiber shafts may feature multiple flex zones, allowing players to fine-tune the performance characteristics of different sections of the shaft for optimal play.

Smart Technology Integration

The integration of sensors and smart technology into carbon fiber lacrosse equipment could provide players with real-time performance data, helping them analyze and improve their game.

Making the Switch to Carbon Fiber: Is It Right for You?

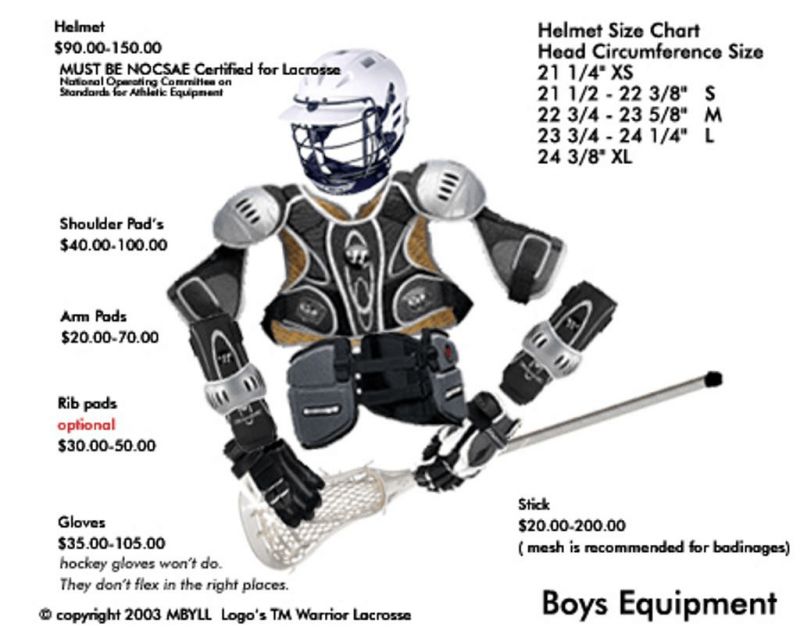

Transitioning to carbon fiber lacrosse equipment is a significant decision that can have a substantial impact on your game. Consider the following factors when deciding if carbon fiber is the right choice for you:

Playing Style and Position

Evaluate how carbon fiber’s unique properties align with your playing style and position requirements. Attackmen may benefit from the enhanced flex and feel, while defenders might appreciate the increased durability and checking power.

Skill Level and Experience

Consider your current skill level and experience. Advanced players may be better equipped to take full advantage of carbon fiber’s performance benefits, while beginners might focus on developing fundamental skills before investing in high-end equipment.

Budget Considerations

Carbon fiber lacrosse equipment typically comes with a higher price tag than traditional materials. Weigh the potential performance benefits against your budget to determine if the investment is worthwhile for your situation.

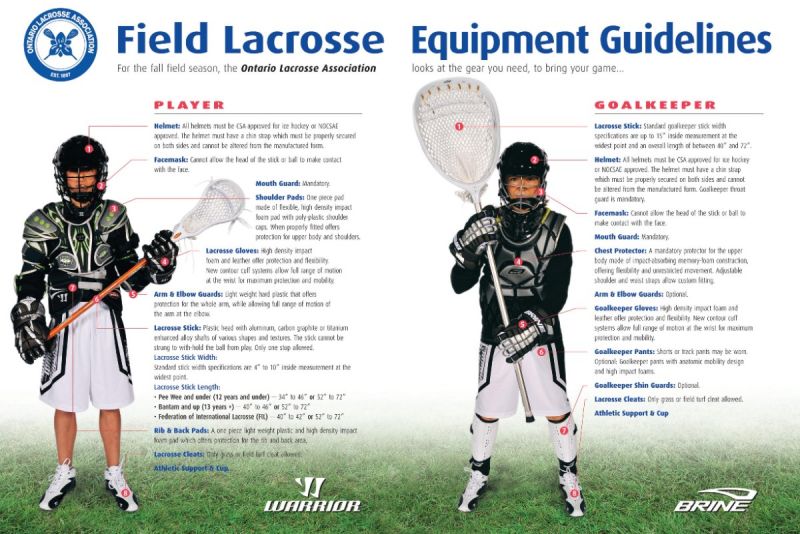

League and Tournament Regulations

Before making the switch, ensure that carbon fiber equipment is permitted in your league or tournament. Some organizations may have specific rules regarding the use of advanced materials in lacrosse gear.

By carefully considering these factors and understanding the unique advantages of carbon fiber lacrosse equipment, players can make informed decisions about incorporating this cutting-edge technology into their game. As the sport continues to evolve, carbon fiber is poised to play an increasingly significant role in shaping the future of lacrosse performance and equipment design.

Introducing Carbon Fiber Lacrosse Shafts and Their Benefits

Carbon fiber lacrosse shafts have become increasingly popular in recent years due to the unique benefits they offer players. Made from carbon fiber composite materials, these shafts are exceptionally strong yet incredibly lightweight. For lacrosse players, this combination translates into shafts with superior durability and playability.

One of the main advantages of carbon fiber lacrosse shafts is their strength-to-weight ratio. Carbon fiber has an exceptionally high strength-to-weight ratio, which means it has incredible stiffness and rigidity while still being very lightweight. This makes carbon lacrosse shafts extremely resistant to checks and slashes during gameplay, while avoiding the fatigue that comes with swinging around heavy metal shafts.

In addition, carbon fiber lacrosse shafts tend to have more flex and “whip” than traditional aluminum options. The flex profile enhances ball control, allows for quicker release on shots, and makes it easier to unleash powerful checks. At the same time, the minimal weight enables faster handling and improved maneuverability around defenders.

Moreover, carbon fiber construction provides superior vibration dampening. This means fewer vibrations are transferred to the player’s hands, reducing impact shock and fatigue. Aluminum shafts resonant vibrations can lead to “stingers” in the hands, whereas carbon dampens these unpleasant sensations.

Durability is another key advantage, as carbon fiber lacks the dents, chips and breaks associated with overuse of metal shafts. While carbon can crack under extreme force, it maintains its integrity better over time. Less damage means a longer-lasting shaft that can stand up to the rigors of an entire season.

For lacrosse players looking for the pinnacle of performance, carbon fiber lacrosse shafts deliver an unparalleled experience. Their elite strength-to-weight ratios lend them unmatched maneuverability, while flex profiles allow for excellent ball control. At the same time, vibration dampening provides a comfortable feel even after repeated use. Simply put, carbon lacrosse shafts represent the future of the sport.

Top Carbon Fiber Defense Shafts on the Market

For defensive players, having the right carbon fiber lacrosse shaft can make all the difference. Carbon fiber defense shafts allow defenders to throw accurate checks, scoop up ground balls, and quickly move the ball upfield. With so many options on the market, it can be tough to determine which carbon d-shaft is the best fit. Here’s an overview of some of the top carbon fiber defense shaft options available:

Maverik Hyper Carbon Pro – This lightweight shaft uses multi-modulus carbon fiber placement to optimize stiffness and improve handling. The Hyper Carbon Pro has a textured grip, making it easy to cradle under pressure. Its angular handle shape helps channel force to the lower end for great checks. At just 140 grams, the Hyper Carbon Pro gives defenders excellent mobility.

Epoch Dragonfly Integra – For superior ball control, the Integra uses Minimus Carbon fiber to create an ultra-smooth flex profile. This results in great touch on ground balls, accurate passing, and deadly accurate shots. With comfortable node grips and shaft shape, the Integra excels at transition play. It weighs only 145 grams for effortless maneuverability.

STX Surgeon 700 – Utilizing multi-resin carbon fiber, this rigid yet lightweight shaft excels in physical defense play. The Surgeon 700 has an octagonal shape for comfort, while its EndoKross texture optimizes grip. With pinpoint accuracy and excellent ball control from any angle, it’s a top choice for shutdown defenders.

Warrior Regulator Max – Great for aggressive defensive styles, this carbon handle provides extreme stiffness for booming checks. The Max technology enables superior energy transfer and ball control, while Armortex grip prevents slippage. At 160 grams, the Regulator Max combines low weight with excellent sturdiness.

Nike Vandal – Built with a mix of high and low-modulus carbon fibers, the Vandal optimizes flex and feel. The unique HyperWhip technology boosts handling and ball control. Meanwhile, the textured Nike Grip provides control even in wet conditions. It’s an exceptionally lightweight yet durable option.

When selecting a carbon fiber defense shaft, players should consider their position, playing style, and personal preferences. However, these options represent some of the best carbon d-shafts available today. With the right carbon fiber handle, defenders can play smarter, faster, and control the game.

Choosing the Right Carbon Fiber Lacrosse Shaft Flex

One of the biggest benefits of carbon fiber lacrosse shafts is the ability to customize flex profile. Shaft flex influences handling, passing, shooting, and even durability. With so many flex options for carbon shafts, selecting the right one for your game is crucial.

For attackmen who rely on quick stunts and fakes, more flexible shafts in the 30F to 70F range are ideal. The whip these shafts generate on shots creates tremendous velocity. Their smooth, graduated flex also makes it easier to sink tight feeds into the tightest spaces. A more flexible carbon handle essentially acts like a slingshot to amplify the attackman’s moves.

Midfielders who need equal parts finesse and power should look at medium flex shafts in the 50F to 110F range. This blend of stiffness and flex provides excellent control over balls on the run. A medium flex carbon shaft also supplies enough stiffness to rip off hard checks and create leverage when jostling for ground balls. The medium flex range offers the best of both worlds.

For defensemen and faceoff specialists who need maximum stiffness, shafts above 100F up to 180F+ are preferable. The limited flex of a stiff carbon handle allows d-middies to deliver bone-crushing slashes and maintain position against dodging attackmen. FOGOs also rely on stiff shafts when grinding out possessions and absorbing constant abuse at the ‘X’.

Goalies have very specific flex needs as well. Because goalies don’t take regular swings or make firm passes, more flex in the 70F-100F range helps produce better ball control when outletting clears. The flex aids in “cradling” difficult passes into the pocket.

Even player height and weight impacts ideal carbon shaft flex. Smaller, lighter players generally benefit more from extra flex, while bigger, stronger athletes can utilize stiffer shafts without losing feel. Testing different flex levels is the only way to determine what works best.

While carbon fiber lacrosse shafts provide almost endless tuning possibilities, choosing the right flex is critical. Attackmen need whip, midfielders seek balance, defensemen require stiffness, and goalies want feel. With the proper flex, any player’s game can reach new heights.

Are Carbon Fiber Lacrosse Heads Worth It?

As carbon fiber lacrosse shafts have grown in popularity, some lacrosse head manufacturers have started producing heads using the same materials. But are carbon fiber lacrosse heads truly worth the investment? There are several factors to consider.

The main benefit of carbon fiber heads is their exceptionally light weight. With carbon’s unmatched strength-to-weight ratio, heads can be made incredibly lightweight while maintaining stiffness and durability. This reduces overall stick weight, making cuts faster, shots quicker off the release, and handles easier to swing repeatedly.

In addition, carbon heads provide superior ball control and handling. Carbon fiber naturally dampens vibrations better than most metals. This translates into smoother catches, cleaner releases, and more accurate passing. The absence of hand-numbing vibrations also reduces fatigue over the course of a game.

Moreover, carbon fiber lacrosse heads are highly resistant to warping or deforming over time. Constant use can bend or misshape metal heads, but carbon’s rigidity and impact resistance minimizes these effects. Well-made carbon heads maintain their precise geometry even after seasons of play.

However, carbon fiber heads do have some downsides. The main drawback is the high cost – pricing easily exceeds $150 per head, whereas aluminum heads cost $80-$100 typically. Repairing carbon heads is also more difficult, usually requiring total replacement if damaged. And extremely stiff carbon heads may not provide enough “give” on faceoff moves.

For most players, the benefits of carbon fiber lacrosse heads likely outweigh any negatives. The elite-level performance, precise consistency, and feather-light feel are major advantages. While the price tag is steep, hardcore lacrosse athletes who play at the highest levels will appreciate what carbon fiber heads bring to their game.

In the end, players need to assess if the hefty investment is justified by their skill level and how often they play. But there’s no denying that carbon lacrosse heads represent the future thanks to game-changing technologies borrowed from other sports.

How Carbon Fiber Helps Reduce Helmet Weight

One of the most important recent innovations in lacrosse equipment has been the development of carbon fiber lacrosse helmets. Carbon fiber construction enables helmets to be supremely protective while shedding unnecessary weight. For lacrosse players, this combination translates into cooler, drier, and less fatiguing play.

Carbon fiber is an extremely lightweight yet robust material made from thin strands of carbon bonded together. The criss-crossed pattern of the carbon fiber strands makes it incredibly rigid and impact absorbent. Carbon fiber disperses energy much more efficiently than most plastic or metals.

By constructing key components like the shell and facemask from carbon fiber, manufacturers can use less material while maintainingintegrity. Strategic carbon fiber placement helps redirect impact forces across the helmet, reducing the risk of concentrated point loads leading to catastrophic failures.

Reduced helmet mass also lowers the rotational forces incurred during impacts. Greater mass at the end of the lever (the head/neck) increases rotational acceleration. Lighter carbon fiber helmets lessen these forces, reducing the likelihood of concussions or neck injuries after big collisions.

The minimal mass makes accelerating and changing direction easier as well, enhancing agility. Since less muscle force is needed to move and stop the head, reaction times improve and players feel quicker on their feet.

Moreover, lighter helmets translate into less neck strain and fatigue over the course of a game. The forces from repeated head deceleration accumulate much faster with heavy helmets. Shedding even a few ounces with carbon fiber construction significantly reduces this fatigue factor.

For lacrosse players, a carbon fiber helmet’s blend of decreased weight and uncompromising protection provides a huge on-field advantage. The reduced mass directly enhances performance and safety. As the technology improves, carbon fiber will likely become standard in all lacrosse helmets.

Improving Comfort with Carbon Fiber Lacrosse Gear

One of the main benefits of carbon fiber lacrosse equipment is enhanced comfort during play. Carbon fiber construction provides several advantages that reduce fatigue and discomfort over the course of a game or practice.

Firstly, carbon fiber gear like shafts and helmets is significantly lighter than traditional metal equivalents. The reduced mass takes strain off the muscles, especially in the shoulders, neck, and back. Lugging around heavy gear leads to progressive fatigue and soreness, which carbon fiber lacrosse equipment minimizes.

Secondly, carbon fiber naturally dampens vibrations extremely well. Metal lacrosse shafts and helmets often transfer unpleasant vibrations into the player’s hands and head. This can cause “stingers” and ringing sensations resulting from checks, shots, and hits. Carbon fiber construction helps isolate these vibrations before they reach the player.

Moreover, carbon fiber gear like shafts and pads tend to contour to the player’s body better. The highly modifiable nature of carbon fiber composites allows gear to match players’ hands and limbs more closely. This reduces chafing, rubbing, and discomfort during play.

Carbon fiber also does not absorb moisture or retain odors like many other lacrosse gear materials. Sweat and bacteria buildup in helmets and pads creates discomfort and skin irritation. Carbon fiber surfaces stay drier and resist these issues.

Lastly, carbon fiber equipment retains its structural integrity better over time. Metal shafts and helmets are prone to dents, cracks, and deformation as they age and incur damage. This can introduce discomfort-causing pressure points and snagging. Carbon fiber construction remains smooth and consistent.

For lacrosse players who experience nagging issues like stingers, heaviness, chafing, and fatigue, switching to carbon fiber gear can provide a real comfort advantage. The unique properties of carbon make it ideal for eliminating discomfort during play.

The Importance of Stiffness in Carbon Fiber Shafts

One of the key traits of carbon fiber lacrosse shafts is their exceptional stiffness and rigidity. But why is stiffness so important for performance, and how does carbon fiber achieve optimal levels?

In lacrosse, shaft stiffness heavily influences a player’s ability to cradle, pass, catch, and shoot with control and accuracy. Greater stiffness means less flex and instability when maneuvering the stick at high speeds. It also allows better energy transfer into checks, passes, and shots.

Carbon fiber composites can be highly tuned to achieve incredible stiffness thanks to their long, aligned carbon fiber molecules. The parallel molecular structure transmits forces efficiently down the length of the shaft. Manufacturers also use sheets of carbon fiber cloth layered at optimized angles to reinforce the shaft.

Moreover, the epoxy resins that bind the carbon fibers together can be formulated for maximum rigidity. Thermoplastic resins like polyether ether ketone (PEEK) create carbon shafts with the highest stiffness and compression strength for elite performance.

However, not all carbon fiber lacrosse shafts are equally stiff. Factors like the quality of the carbon fabric, the precise resin type, and structural engineering affect overall rigidity. High-end shafts utilize top-grade aerospace or military-grade carbon fiber materials to achieve the greatest stiffness.

Ultimately, optimizing carbon fiber stiffness comes down to advanced computer modeling and testing. Manufacturers simulate stresses and fine-tune the angled layering to produce precision stiffness levels unmatched by metal shafts. The result is carbon fiber lacrosse shafts with superior rigidity for pinpoint accuracy.

For lacrosse players, a properly stiff carbon fiber shaft acts like an extension of their arms, providing unmatched control. Only space-age carbon composites allow tailoring shaft stiffness to exacting levels for each player’s needs and preferences.

Lacrosse Shaft Materials Compared – Aluminum vs Carbon Fiber

When selecting a new lacrosse shaft, one of the biggest decisions is whether to choose traditional aluminum or modern carbon fiber construction. How do these two materials compare in terms of performance, durability, and value?

Aluminum shafts have been popular for decades thanks to their affordability and decent durability. However, aluminum’s main downside is its weight. The greater mass makes accelerating the stick more difficult and fatiguing over a full game. Aluminum also transfers significant vibrations into the hands.

In contrast, carbon fiber shafts are exceptionally light while still retaining stiffness and strength. The lightweight build enhances maneuverability and slashes fatigue. Carbon fiber also damps vibrations better, providing a more comfortable feel during play.

Durability favors carbon fiber lacrosse shafts as well. Aluminum is prone to dents, cracks, and bend deformation, whereas carbon fiber retains its shape and strength after impacts. Only catastrophic breaks can damage a carbon shaft.

Customization potential goes to carbon fiber too, thanks to the ability to carefully engineer the precise flex profile and balance based on a player’s position, size, and preferences. Aluminum offers no such customization.

The main knock against carbon fiber lacrosse shafts is the high price, usually $150 and up. Aluminum can be found for under $50 in most cases. However, the carbon fiber performance enhancements and long-term durability offset the initial investment over years of use.

In the end, elite lacrosse players gain a definite edge by using the latest carbon fiber shaft technologies. The strength, feather-light feel, vibration reduction, and customization create a clear performance advantage. While aluminum gets the job done, nothing compares to carbon fiber’s lacrosse shaft superiority.

Maintaining and Caring for Carbon Fiber Lacrosse Equipment

Carbon fiber lacrosse gear represents a major investment for most players. Properly maintaining carbon fiber shafts, heads, and helmets is crucial to preserving performance and extending durability over time. Here are some tips for caring for carbon fiber lacrosse equipment:

Store gear properly – Keep carbon fiber equipment in a cool, dry place away from direct sunlight when not in use. The fibers can degrade under intense UV exposure. Avoid excessive heat as well. Also store shafts vertically or hung up to prevent bending.

Clean regularly – Use mild soap and water to keep carbon fiber gear fresh. Salt, dirt, and grime can abrade the resins if left to build up. Gently scrub to remove any debris. Disinfect gear occasionally with non-abrasive anti-bacterial cleaners to prevent staph and MRSA.

Inspect for damage – Check carbon fiber equipment before and after each use for any cracks, chips or major scratches. Even small cracks in the resin can spread over time and compromise integrity. Address any damage right away.

Avoid harsh chemicals – Never use solvents like acetone, gasoline or lacquer thinner on carbon gear. These can break down the resin binds and corrode the carbon fibers. Stick to mild, pH-neutral cleaners only.

Protect from direct impacts – Try not to drop carbon fiber equipment or bang shafts together. Direct collisions in unprotected areas can crack the resin even if the surface seems undamaged.

Keep dry – Dry carbon fiber thoroughly with a microfiber cloth after use to prevent moisture buildup. Allow at least 24 hours of drying time if gear gets significantly wet before using again.

With proper care and maintenance habits, carbon fiber lacrosse gear can deliver elite performance and outlast aluminum equipment. Taking steps to maintain, clean and inspect carbon components ensures maximum return on investment.

Carbon Fiber Lacrosse Gear for Faceoffs and FOGOs

For faceoff specialists, having the right gear is critical to gaining any small edge at the ‘X’. Carbon fiber lacrosse equipment offers several advantages for FOGOs competing in the trenches.

Ultralight carbon fiber shafts improve quickness on clamp moves and make it easier to sharply change direction. The minimal mass also reduces fatigue over long tournaments when taking draw after draw. Stiff carbon handles provide great leverage when jostling for possession off the whistle.

Meanwhile, carbon fiber heads optimize scooping. Their stiffness springs the ball out of the back of the head, while the lightweight feel makes it easier to corral ground balls. The ball just seems to stick better in a carbon head.

Helmets and gloves round out the carbon gear ensemble for FOGOs. Lightweight carbon helmets allow faster head movement and decrease strain on the neck when absorbing checks. Low-profile carbon gloves provide dexterity and touch for grip fights at the line.

For gloves, carbon fiber increases protection across the back of the hand while retaining flexibility. This helps withstand slashes during draws without restricting motion. Thin carbon fiber is also utilized for palm padding to absorb clamping impact.

Arm pads and elbow caps with carbon fiber shielding add impact protection without bulky weight. And carbon fiber soles in cleats make pushes and pivots off the whistle lightning quick.

While the price tag of carbon lacrosse gear is steep, for committed faceoff men the advantages are substantial. The mix of decreased weight, optimized stiffness, vibration dampening, and protection conferred by carbon fiber pays dividends at the X. FOGOs wielding carbon give themselves an edge right from the start.

Ultimately, carbon fiber allows faceoff specialists to perform at their highest level. The gear gets out of the way and lets a FOGO’s skills and technique shine through. Nothing accentuates excellent fundamentals like lacrosse equipment engineered from carbon fiber.

Durable Carbon Composite Lacrosse Shafts for Middies

For midfield players constantly involved in the physical grind of transition play, durability is a top priority in a lacrosse shaft. Carbon composite shafts offer the ruggedness needed for midfielders while providing high-performance.

The carbon fiber materials utilized in elite lacrosse shafts are exceptionally impact-resistant, preserving their structural integrity after checks. Midfielders can fearlessly deliver slashes without worrying about their shaft taking damage.

Advanced resin systems like PEEK thermoplastics create strong inter-laminar bonds between the carbon fiber sheets. This prevents delamination or fracturing when forces are applied from multiple directions during play.

Manufacturers also strategically layer the carbon fiber sheets at calculated angles. The multidirectional orientation reinforces the shaft’s strength along all axes, not just vertically. So the construction withstands tortional forces as well.

Moreover, additional fibers like Kevlar are sometimes blended into the composite matrix alongside the carbon. Kevlar has very high tensile strength and abrasion resistance. This augments protection of the carbon shaft from chips and cracks.

For middies constantly grinding through traffic, these durable carbon fiber construction techniques prevent damage while retaining responsive feel. Stiffness and lightweight properties still enhance play, but robustness takes priority in midfield shafts.

New epoxy resin formulas also provide improved weathering resistance, ensuring the composite bonds retain integrity over years of exposure to UV and the elements. This prevents sudden failures or fractures.

In the end, carbon fiber allows engineers to tailor shafts to a middie’s run-and-gun style of play. The materials science behind carbon lacrosse shafts makes them the ideal robust yet responsive shaft for workhorse midfielders.

Attackmen Benefits of Lightweight Carbon Fiber Handles

For lacrosse attackmen who rely on speed, quickness, and constant motion, lightweight carbon fiber shafts provide a clear competitive edge.

The minimal mass of elite carbon lacrosse handles allows attackmen to change direction sharply and accelerate out of cuts faster. Lightweight shafts mean less inertia to overcome when starting and stopping movements. Attackmen feel more agile dodging defenders.

Whippy carbon shafts also make it easier to sink tight feeds into traffic around the crease. Excellent flex and response translate quick stick moves into goals. Shooting also benefits from effortless shot acceleration.

Moreover, the reduced weight decreases fatigue over the course of a game. Attackmen wave their sticks through countless passing, shooting, and dodging motions each game. Heavy metal shafts take a toll, whereas carbon fiber stabilizes energy levels.

Durability is also key, as attackmen constantly absorb checks during interior play. Carbon fiber constructions retain their integrity better, while metal shafts accumulate dents and bends until failing.

For elite attackmen, the difference between a split-second goal or a missed opportunity comes down to equipment. The speeds of the modern game demand lightweight carbon handles that accentuate attack skills rather than hinder them.

While carbon lacrosse shafts carry a premium price, their performance enhancements justify the investment for serious attack players. Scoring goals is about exploiting every fractional advantage in quickness, feel, vision, and instincts – traits that carbon fiber shafts amplify.

Goalie Specific Carbon Fiber Lacrosse Gear Explained

While all lacrosse players can benefit from carbon fiber equipment, goalies have very specialized needs that carbon fiber gear can address.

For goalie heads, carbon’s stiffness prevents warp or deformation over time. A head that loses its precise geometry handicaps a goalie’s ability to track shots and make saves. Carbon heads retain their shape season after season.

Shafts focused on excellent feel and ball control help goalies outlet passes smoothly after saves. More flexible carbon shafts absorb some vibration for a “softer” cradle. Textured grips also create handling confidence.

Chest protectors and shin guards take advantage of carbon fiber’s strength to redirect impact forces. Strategic carbon fiber reinforcement disperses and deflects ball impacts without heavy bulk. Range of motion remains uncompromised.

Carbon fiber cleats provide goalies with sure footing and quickness when moving laterally across the crease. The thin, stiff carbon plates optimize push off power and traction on sudden moves.

For goalie gloves, partial carbon fiber backs improve protection from stingers. Thin carbon shielding absorbs shots without sacrificing dexterity for stick saves and throws. Inner carbon fingers maintain feel.

Lastly, carbon fiber additions to goalie pants improve slide protection without restricting mobility. Small shields over thigh and shin areas augment coverage during leg kick saves.

Ultimately, carbon fiber allows engineers to enhance goalie-specific gear with protection and durability while minimizing weight. The materials science behind carbon fiber meshes perfectly with a goalie’s desire for lightweight, low-profile equipment that performs consistently under fire.

Is Carbon Fiber Lacrosse Equipment Worth the Investment?

There’s no doubt that carbon fiber lacrosse shafts, heads, and protective gear carries a premium price tag. For players, coaches, and parents debating an investment in carbon lacrosse equipment, determining whether the expense is justified involves weighing several factors.

First and foremost is the player’s skill level. Top high school and elite college players have the fundamentals to benefit most from carbon gear performance enhancements. Youth and new players will see less advantage until skills develop.

Intended use frequency also plays a role. Athletes playing club ball year-round and high school spring seasons will maximize carbon fiber’s durability. Occasional recreational leaguers may not use equipment enough to warrant the cost.

Player position affects considerations too. Middies and faceoff specialists subject gear to constant physical abuse, amplifying carbon fiber’s ruggedness and stiffness edge. Goalies also rely heavily on equipment performance.

It’s smart to try out carbon gear first rather than buying it untested. Demoing lacrosse shafts and pads provides a feel for the performance difference compared to metal or plastic gear. Only hands-on experience reveals if the upgrade truly elevates play.

For dedicated lacrosse athletes aiming to play at the next level, lightweight carbon gear can provide a distinct physical edge. And serious players logging major field time will get the most value from carbon’s durability.

In the end, carbon fiber lacrosse equipment delivers significant performance and safety advantages. While the investment required gives budget-minded players pause, carbon gear helps elite competitors reach the pinnacle of their potential.