The Key Differences Between Knit and Woven Fabrics ExplainedThe Key Differences Between Knit and Woven Fabrics Explained

The Superior Breathability and Airflow of Knit Fabrics

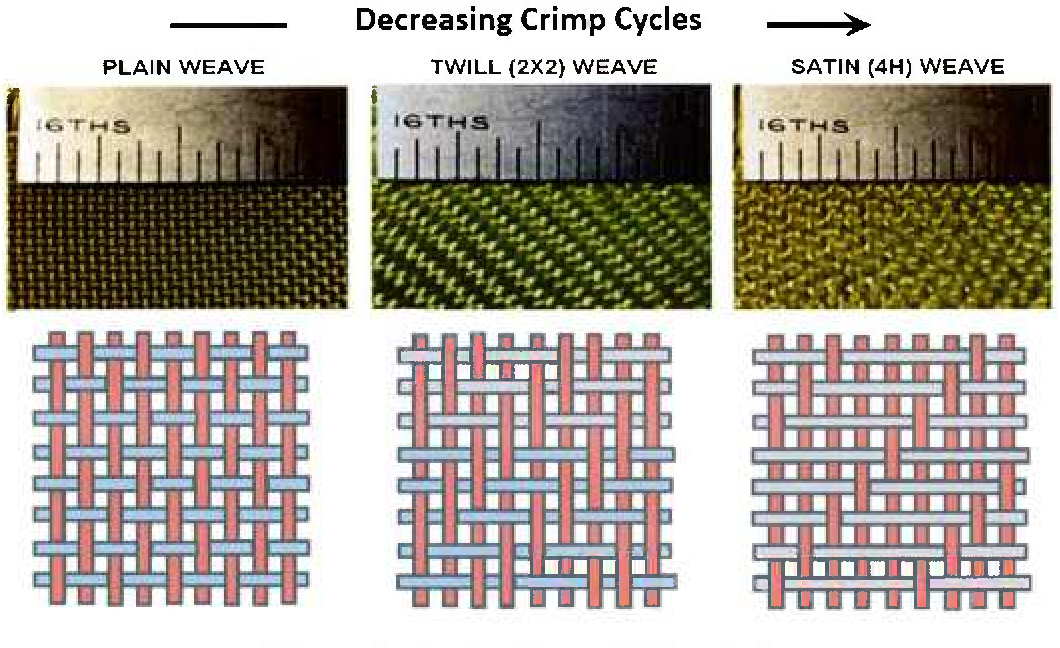

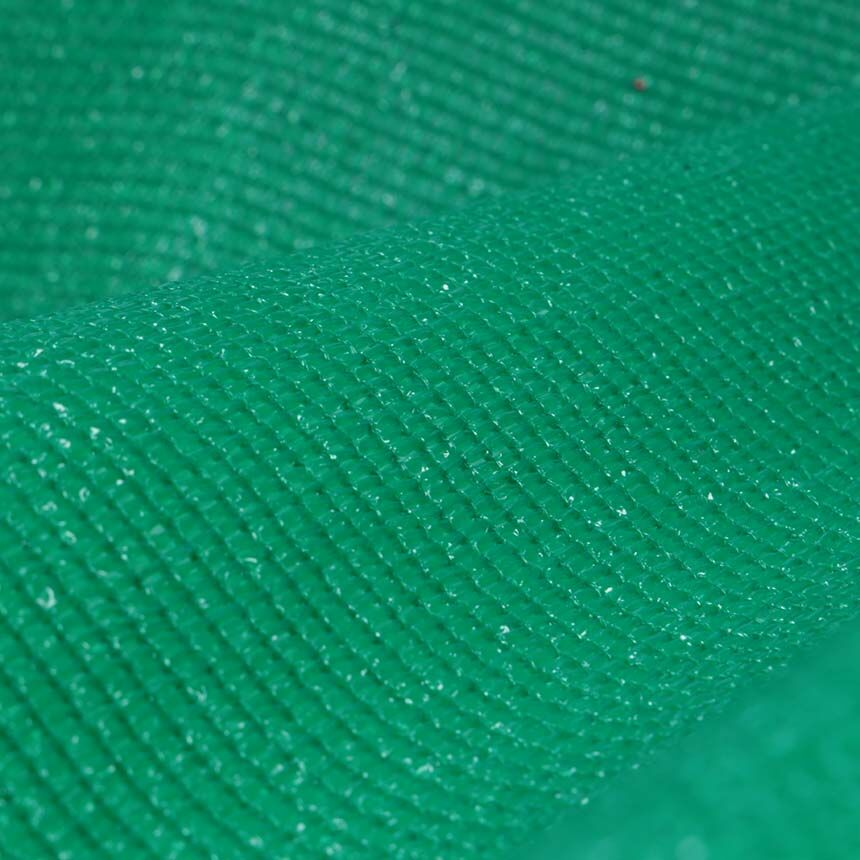

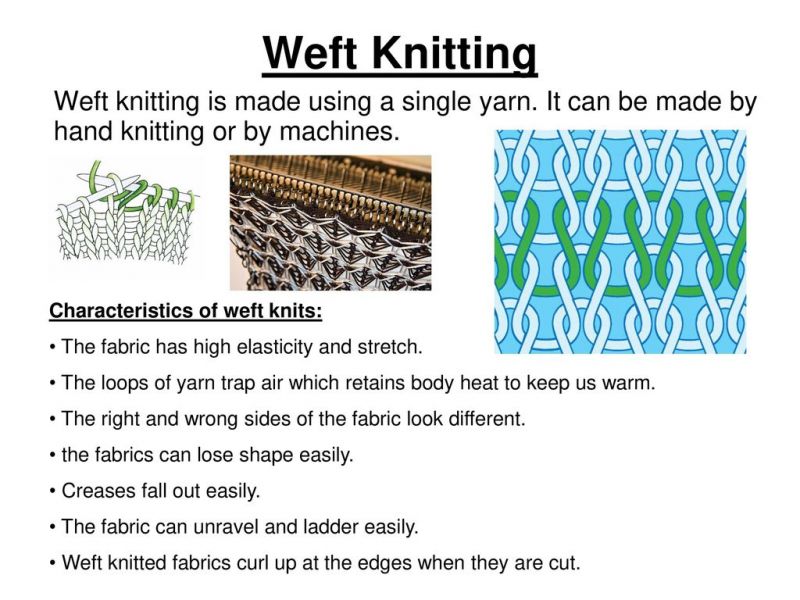

One of the key differences between knits and woven fabrics is the breathability and airflow that each can provide. Knitted fabrics tend to be much more breathable and provide greater airflow than wovens. This is due to the inherent structure and construction of knitted textiles. Because knits are formed by interlocking loops of yarn that have natural openings between the stitches, they allow for significantly more air permeability than woven fabrics. The gaps between the stitches provide channels where heat and moisture can escape. This enables garments made from knitted fabrics to feel cool against skin and prevent overheating. Woven materials, on the other hand, are made by interlacing perpendicular yarns which creates a tight, flat surface with minimal gaps for airflow. The compact structure of woven fabrics restricts breathability and makes wovens feel hotter in warm weather. Knits are ideal for athletic and casual wear where ventilation and moisture wicking are desirable. The unmistakable breathability of a cotton t-shirt or performance sports jersey can be attributed to the use of knitted construction. So if keeping cool is a priority, knits have a clear functional advantage over closely woven fabrics due to their exceptional airflow and breathability. This unique structural characteristic makes knits the perfect choice for warm weather apparel and athletic gear where good ventilation is needed.

The Superior Stretch and Flexibility Provided by Knitted Fabrics

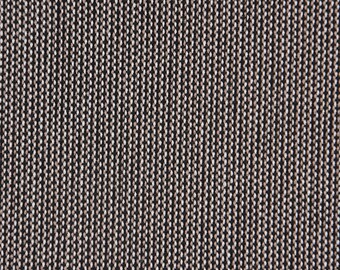

Stretchability and flexibility are key traits that distinguish knitted fabrics from woven materials. Knits inherently have much more give and elasticity versus wovens due to the looped construction that allows the fabric to easily stretch without distortion or damage. The interconnected loops in knitted fabrics are able to slide over one another when pulled, creating stretchiness and a close, body-hugging fit. This flexibility makes knits ideal for form-fitting garments like t-shirts, sweaters, socks, and athletic apparel. The natural stretch in the knit structure also allows the material to flex with body movements, increasing comfort and freedom of motion. Woven fabrics, however, have very limited stretch because the perpendicular weave structure does not permit flexibility or elongation. The tight interlacing of warp and weft yarns creates a fabric with minimal give that resists stretching. Any significant pulling on the material will cause woven fabrics to lose their shape, deform, or potentially tear. The only woven fabrics with some stretch are those incorporating elastomeric fibers like spandex or lycra. But even those do not match the degree of stretch and flexibility inherent to knitted textiles. So if you want clothing that moves with your body and has that “like a glove” fit, knitted fabrics are clearly superior. The unrestricted movement provided by the exceptional stretchability of knits makes them the ideal choice for activewear, underwear, hosiery, and any apparel where flexibility and range of motion are desirable qualities.

The Superior Drape and Soft Structure of Knitted Fabrics

Knitted and woven fabrics have markedly different characteristics when it comes to drape, structure, and handfeel. Knits tend to be soft, flexible, and drape gracefully due to their looped construction which prevents stiffness. The interconnected stitching allows knitted fabrics to conform closely to the body and flow smoothly over curves and contours. This creates a flattering silhouette and reduces bulk. The loops also give knits a discernibly softer, more pliable handfeel and surface texture compared to most wovens. Woven fabrics, on the other hand, have a flatter, firmer surface and outline. Their tight perpendicular weave results in a more structured, sturdy fabric that holds its shape rather than conforming and draping. Unless blended with elastic fibers, woven materials do not readily flex or stretch, so garments made with wovens tend to have a more rigid, angular construction. Certain tailored coats, suits, and dresswear depend on the firmness of woven fabrics to maintain crisp lines and silhouette. But for casualwear, underwear, and athletic apparel where softness and flexibility are priorities, knits are clearly superior. The graceful drape, close fit, and plush handfeel offered by knits makes them preferable for loungewear, sleepwear, and clothing worn close to bare skin. So when evaluating the tactile qualities and visual flow of fabrics, knitted materials stand out as the softer, more supple, and elegantly draping option compared to most woven textiles.

The Resilient Durability of Knit Stitches and Seams

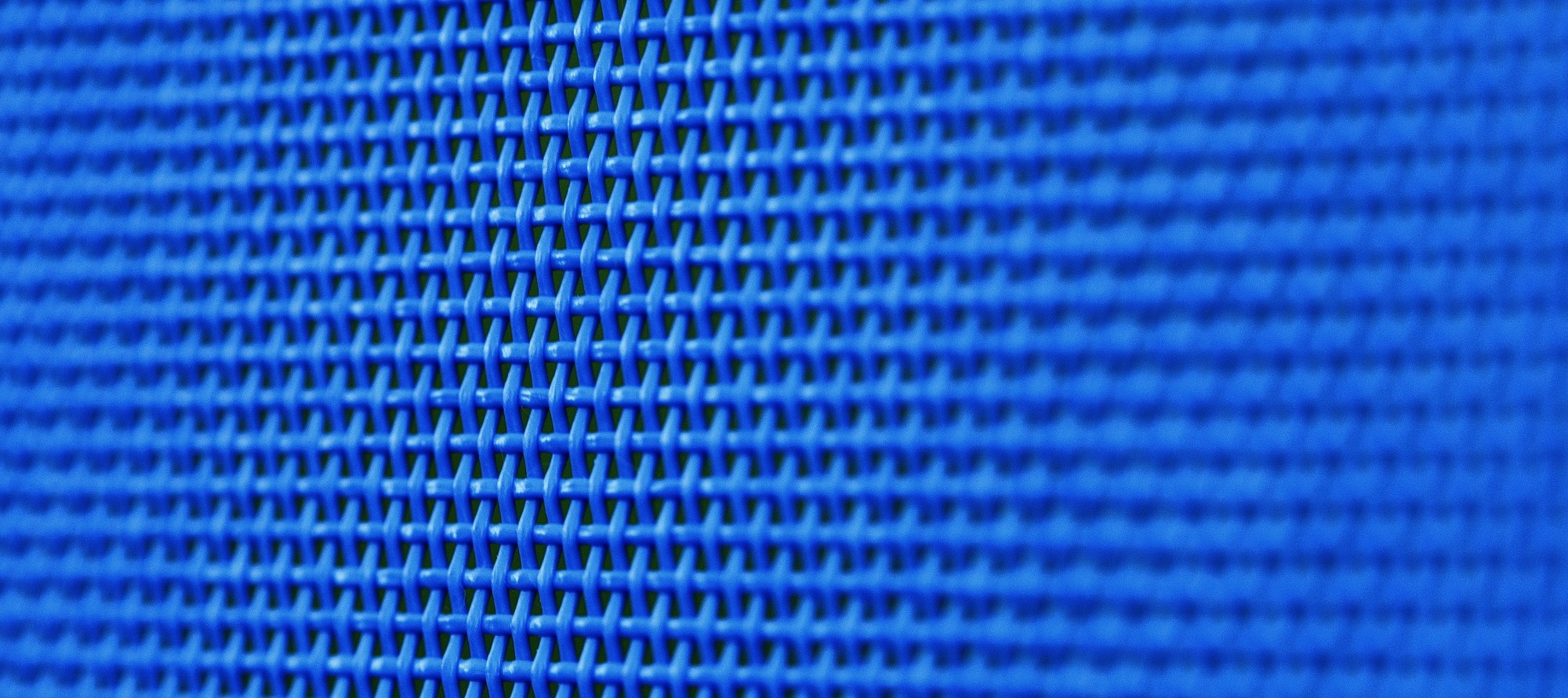

Woven Fabric Construction

In contrast, woven fabrics are produced by interlacing perpendicular yarns, resulting in a tight, flat surface with minimal gaps. This compact structure restricts airflow, making woven fabrics less breathable than their knitted counterparts.

Benefits of Knit Fabric Breathability

- Improved comfort in warm weather

- Enhanced moisture-wicking capabilities

- Reduced risk of overheating during physical activities

- Ideal for athletic and casual wear

Can knit fabrics regulate body temperature more effectively than woven fabrics? Indeed, the superior breathability of knit fabrics allows for better temperature regulation, making them an excellent choice for garments worn in warm conditions or during intense physical activities.

Stretch and Flexibility: The Knit Fabric Advantage

One of the most significant differences between knit and woven fabrics lies in their stretch and flexibility properties. Knitted fabrics possess inherent elasticity and give, setting them apart from their woven counterparts.

The Science Behind Knit Fabric Stretch

The looped construction of knit fabrics allows the individual stitches to slide over one another when pulled. This unique characteristic enables the fabric to stretch without distortion or damage, providing exceptional flexibility and a close, body-hugging fit.

Limitations of Woven Fabric Stretch

Woven fabrics, due to their perpendicular weave structure, have limited stretch capabilities. The tight interlacing of warp and weft yarns creates a fabric with minimal give that resists elongation. Significant pulling on woven materials can lead to loss of shape, deformation, or potential tearing.

Applications Benefiting from Knit Fabric Flexibility

- Form-fitting garments (t-shirts, sweaters, leggings)

- Athletic apparel

- Underwear and hosiery

- Comfortable loungewear

Do knit fabrics provide better freedom of movement than woven fabrics? Absolutely. The natural stretch in knit structures allows the material to flex with body movements, increasing comfort and range of motion, making them ideal for activewear and garments requiring unrestricted movement.

Drape and Softness: The Knit Fabric Advantage

When it comes to drape, structure, and handfeel, knitted and woven fabrics exhibit markedly different characteristics. Knits are renowned for their soft, flexible nature and graceful draping qualities.

The Draping Quality of Knit Fabrics

The looped construction of knit fabrics prevents stiffness, allowing them to conform closely to the body and flow smoothly over curves and contours. This results in a flattering silhouette and reduced bulk, making knits ideal for garments that require a close fit or elegant drape.

Texture and Handfeel of Knit Fabrics

Knitted fabrics typically possess a softer, more pliable handfeel and surface texture compared to most wovens. The interconnected stitching contributes to a plush, comfortable feel against the skin, making knits particularly suitable for garments worn close to the body.

Woven Fabric Structure and Feel

In contrast, woven fabrics generally have a flatter, firmer surface and outline. Their tight perpendicular weave results in a more structured, sturdy fabric that holds its shape rather than conforming and draping. This characteristic makes woven fabrics suitable for tailored garments that require crisp lines and defined silhouettes.

Are knit fabrics more comfortable for everyday wear than woven fabrics? Generally, yes. The soft texture, flexibility, and graceful drape of knit fabrics make them exceptionally comfortable for casual wear, underwear, and garments worn directly against the skin.

Durability and Resilience: Comparing Knit and Woven Fabrics

When evaluating the structural integrity of knits versus wovens, each fabric type has its own strengths and potential weaknesses. Understanding these differences is crucial for selecting the right fabric for specific applications.

Durability of Knit Fabric Stitches

The looping construction of knit fabrics often provides an advantage in stitch durability. The interconnected loops can stretch and recover without breaking, allowing knit fabrics to withstand repeated stress and movement. This resilience makes knits particularly suitable for garments that undergo frequent stretching or flexing.

Seam Strength in Knit Fabrics

Knit fabrics can present challenges when it comes to seam strength. The stretchy nature of knits can lead to seam slippage or distortion if not properly constructed. However, with appropriate stitching techniques and seam finishes, knit garments can achieve excellent seam durability.

Woven Fabric Durability

Woven fabrics are known for their stability and resistance to tearing. The interlaced structure of warp and weft yarns creates a strong, stable fabric that can withstand considerable tension and wear. This makes woven fabrics ideal for applications requiring high durability and minimal stretch.

Which fabric type is more resistant to pilling? Woven fabrics generally have better resistance to pilling compared to knits. The tight, flat surface of woven fabrics makes it more difficult for loose fibers to form pills. However, the pilling resistance of both knit and woven fabrics can vary depending on the fiber content and fabric finish.

Care and Maintenance: Knit vs Woven Fabrics

The care and maintenance requirements for knit and woven fabrics can differ significantly due to their distinct constructions and properties. Understanding these differences is essential for preserving the quality and longevity of garments made from each fabric type.

Washing and Drying Knit Fabrics

Knit fabrics often require gentler care to maintain their shape and elasticity. Here are some key considerations:

- Use cool or lukewarm water to prevent shrinkage

- Choose a gentle cycle or hand wash for delicate knits

- Avoid wringing or twisting to prevent distortion

- Lay flat to dry to maintain shape

Caring for Woven Fabrics

Woven fabrics are generally more resilient to washing and drying processes. However, care instructions can vary based on the specific fiber content and fabric finish:

- Machine wash in warm or cold water, depending on the fabric type

- Tumble dry on low or medium heat, or line dry

- Iron on appropriate heat setting to remove wrinkles

Do knit fabrics require more careful handling than woven fabrics? In many cases, yes. The stretchy nature of knits makes them more susceptible to distortion during washing and drying, necessitating gentler care methods to preserve their shape and elasticity.

Choosing Between Knit and Woven Fabrics: Applications and Considerations

Selecting the appropriate fabric type for a specific application involves weighing the unique properties of knit and woven fabrics against the intended use and desired characteristics of the final product.

Ideal Applications for Knit Fabrics

Knit fabrics excel in applications that require:

- Stretch and flexibility

- Close, body-hugging fit

- Breathability and moisture management

- Soft, comfortable feel against the skin

Common uses for knit fabrics include:

- T-shirts and casual tops

- Athletic and performance wear

- Underwear and lingerie

- Sweaters and knitwear

- Leggings and stretch pants

Optimal Uses for Woven Fabrics

Woven fabrics are best suited for applications that require:

- Stability and structure

- Resistance to stretching and distortion

- Crisp, tailored appearance

- Durability and tear resistance

Common uses for woven fabrics include:

- Dress shirts and blouses

- Suits and tailored garments

- Denim jeans and structured pants

- Outerwear and jackets

- Home furnishings (curtains, upholstery)

Which fabric type is more versatile in clothing design? Both knit and woven fabrics offer versatility in clothing design, but in different ways. Knits provide flexibility in creating form-fitting, comfortable garments with excellent stretch recovery. Wovens offer stability and structure, allowing for crisp, tailored designs and a wide range of surface textures and patterns.

Innovations in Knit and Woven Fabric Technologies

The textile industry continually evolves, with new technologies and innovations enhancing the properties and performance of both knit and woven fabrics. These advancements are blurring the traditional boundaries between fabric types and expanding their potential applications.

Advancements in Knit Fabric Technology

Recent innovations in knit fabrics include:

- Seamless knitting techniques for reduced bulk and improved comfort

- Integration of smart textiles and wearable technology

- Development of high-performance moisture-wicking and quick-drying knits

- 3D knitting for customized fit and reduced waste

Developments in Woven Fabric Technology

Advancements in woven fabric production include:

- Creation of stretch woven fabrics with improved flexibility

- Integration of functional finishes for enhanced performance (e.g., water-repellent, stain-resistant)

- Development of ultra-lightweight and breathable woven materials

- Sustainable weaving processes and eco-friendly fiber blends

Hybrid Fabric Technologies

Emerging technologies are also leading to the development of hybrid fabrics that combine the benefits of both knit and woven constructions:

- Knit-woven composites for enhanced durability and flexibility

- 3D spacer fabrics with unique structural properties

- Multi-layer fabrics incorporating both knit and woven elements

How are these innovations impacting the textile industry? These advancements are expanding the potential applications for both knit and woven fabrics, enabling the creation of high-performance textiles that meet increasingly demanding consumer expectations for comfort, functionality, and sustainability.

As fabric technologies continue to evolve, the distinctions between knit and woven constructions may become less defined. However, understanding the fundamental differences between these two fabric types remains crucial for designers, manufacturers, and consumers alike. By leveraging the unique properties of knit and woven fabrics, along with emerging hybrid technologies, the textile industry can create innovative solutions that cater to a wide range of applications and performance requirements.

The Superior Breathability and Airflow of Knit Fabrics

One of the key differences between knits and woven fabrics is the breathability and airflow that each can provide. Knitted fabrics tend to be much more breathable and provide greater airflow than wovens. This is due to the inherent structure and construction of knitted textiles. Because knits are formed by interlocking loops of yarn that have natural openings between the stitches, they allow for significantly more air permeability than woven fabrics. The gaps between the stitches provide channels where heat and moisture can escape. This enables garments made from knitted fabrics to feel cool against skin and prevent overheating. Woven materials, on the other hand, are made by interlacing perpendicular yarns which creates a tight, flat surface with minimal gaps for airflow. The compact structure of woven fabrics restricts breathability and makes wovens feel hotter in warm weather. Knits are ideal for athletic and casual wear where ventilation and moisture wicking are desirable. The unmistakable breathability of a cotton t-shirt or performance sports jersey can be attributed to the use of knitted construction. So if keeping cool is a priority, knits have a clear functional advantage over closely woven fabrics due to their exceptional airflow and breathability. This unique structural characteristic makes knits the perfect choice for warm weather apparel and athletic gear where good ventilation is needed.

The Superior Stretch and Flexibility Provided by Knitted Fabrics

Stretchability and flexibility are key traits that distinguish knitted fabrics from woven materials. Knits inherently have much more give and elasticity versus wovens due to the looped construction that allows the fabric to easily stretch without distortion or damage. The interconnected loops in knitted fabrics are able to slide over one another when pulled, creating stretchiness and a close, body-hugging fit. This flexibility makes knits ideal for form-fitting garments like t-shirts, sweaters, socks, and athletic apparel. The natural stretch in the knit structure also allows the material to flex with body movements, increasing comfort and freedom of motion. Woven fabrics, however, have very limited stretch because the perpendicular weave structure does not permit flexibility or elongation. The tight interlacing of warp and weft yarns creates a fabric with minimal give that resists stretching. Any significant pulling on the material will cause woven fabrics to lose their shape, deform, or potentially tear. The only woven fabrics with some stretch are those incorporating elastomeric fibers like spandex or lycra. But even those do not match the degree of stretch and flexibility inherent to knitted textiles. So if you want clothing that moves with your body and has that “like a glove” fit, knitted fabrics are clearly superior. The unrestricted movement provided by the exceptional stretchability of knits makes them the ideal choice for activewear, underwear, hosiery, and any apparel where flexibility and range of motion are desirable qualities.

The Superior Drape and Soft Structure of Knitted Fabrics

Knitted and woven fabrics have markedly different characteristics when it comes to drape, structure, and handfeel. Knits tend to be soft, flexible, and drape gracefully due to their looped construction which prevents stiffness. The interconnected stitching allows knitted fabrics to conform closely to the body and flow smoothly over curves and contours. This creates a flattering silhouette and reduces bulk. The loops also give knits a discernibly softer, more pliable handfeel and surface texture compared to most wovens. Woven fabrics, on the other hand, have a flatter, firmer surface and outline. Their tight perpendicular weave results in a more structured, sturdy fabric that holds its shape rather than conforming and draping. Unless blended with elastic fibers, woven materials do not readily flex or stretch, so garments made with wovens tend to have a more rigid, angular construction. Certain tailored coats, suits, and dresswear depend on the firmness of woven fabrics to maintain crisp lines and silhouette. But for casualwear, underwear, and athletic apparel where softness and flexibility are priorities, knits are clearly superior. The graceful drape, close fit, and plush handfeel offered by knits makes them preferable for loungewear, sleepwear, and clothing worn close to bare skin. So when evaluating the tactile qualities and visual flow of fabrics, knitted materials stand out as the softer, more supple, and elegantly draping option compared to most woven textiles.

The Resilient Durability of Knit Stitches and Seams

When comparing the structural integrity of knits versus wovens, knitted fabrics often have the advantage in stitch and seam durability. The looping construction of knits allows the stitches to flex and move without breaking or unraveling. If snagged or pulled, the loops in a knit fabric will stay intact rather than run. Knit fabrics are typically stable enough to not require hemming or finishing of raw edges, unlike most woven materials. The natural elasticity of the interlocked knit loops enables the fabric to repeatedly stretch and recover without deteriorating. And while seams and hems in wovens can rip over time from fabric stiffness or tension, sewn seams in knits retain flexibility and rarely pop or break. The resilient loops are better able to distribute stress and withstand wear-and-tear. Woven fabrics are not as seam-friendly due to the restrictive interlacing of fibers that leaves cut edges prone to fraying. Durability and resilience can vary in knits based on the fiber content, yarn quality, gauge, and stitch type. But overall, the flexible looping construction gives knitted fabrics an advantage in withstanding stress, flexing motions, snags, and long-term use. Knitted garments like t-shirts can remain intact for years if not abused. So when selecting a fabric for durability and resilience against daily wear-and-tear, knits are typically the strongest option due to their flexible, interlocking structure and seamless construction. Their capacity to stretch repeatedly without breaking puts knitted materials ahead of tightly woven fabrics in resilience and longevity.

The Superior Moisture Absorbing and Wicking Abilities of Knitted Fabrics

When it comes to moisture management, knitted fabrics have distinct absorbent and wicking advantages over tightly woven materials. The construction of knits with intersecting yarn loops creates an open, porous structure that readily absorbs moisture. The gaps between stitches provide channels for moisture transport across the fabric surface. This gives knits excellent wicking ability to disperse perspiration, preventing clamminess. The absorbent loops can hold moisture without feeling wet against the skin. Woven fabrics, however, lack openings for moisture to penetrate. Their tight weave causes perspiration to pool on the surface rather than absorbing effectively. Poor wicking ability makes woven fabrics feel damp and clingy during physical activity or in humidity. Exceptional moisture absorption is what makes cotton knits a preference for underwear, t-shirts, and athleticwear where sweat-wicking performance is needed. Blends of wool knits and performance synthetics have even greater ability to insulate while moving moisture away from the body. The unmistakable comfort of a sweat-wicking performance jersey comes from knitted construction. So whether for casual everyday wear or high-exertion activities, knitted textiles excel at absorbing and spreading moisture quickly across the fabric surface before excess wetness can accumulate. This gives knits a functional edge for apparel worn close to the skin where managing perspiration buildup and dampness is essential.

The Pilling Challenges Presented by Knitted Fabrics

One downside of knitted fabrics is their tendency to pill and fray with wear, especially when compared to most tightly woven materials. The construction of knits from intersecting loops of yarn makes them prone to pilling, which is when small tangles of loose fibers bundle together on the fabric surface. These pesky pills create a fuzziness that worsens over time with abrasion and agitation during laundering. The looser structure of knitted fabrics allows fibers to work free from yarns and entanglement each other. Pilling is most common in knits made of shorter staple fibers like cotton. Whereas woven fabrics are less prone to pilling due to their smooth, tight weave and longer twisted yarns that resist unraveling. The interlaced yarns of woven materials stay locked in place and do not allow loose fibers to sprout up. However, pilling on knits can be minimized by selecting high-quality yarns with longer fibers, using tighter knit gauges, and blending with synthetics that resist fraying. But overall, knits are more high-maintenance when it comes to pilling. Proper laundry practices and fabric care are essential. Using a dedicated garment shaver is often needed to remove pills and revitalize old knits. So knits do require extra diligence to prevent excessive fuzziness and maintain a smooth appearance over time. But many consider the soft comfort and performance benefits of knits to be worth the tradeoff. Weighing the advantages that knitted fabrics provide for casual and activewear, pilling tendencies seem a reasonable compromise compared to the restrictive nature of tightly woven constructions.

The Superior Warmth and Insulation Provided by Knitted Fabrics

Knitted fabrics inherently provide more warmth and insulation against cold temperatures compared to woven materials. The construction of knits with intersecting yarn loops creates thickness to trap heat close to the body. The open, porous structure also allows knits to hold insulating air pockets within the stitches. This provides excellent protection against chill and wind. Loose knits with bigger loops and gauges are especially warm due to increased loft and air space. Tightly woven fabrics cannot rival the warmth and insulation of knits because their flat, compact weave lacks thickness and air pockets. Heat passes more easily through the thinner, denser structure of wovens. This makes woven fabrics feel cooler against bare skin. Insulative lining or interfacing must often be added to wovens to increase warmth for outerwear like coats. But knits are naturally warmer even in lighter weights. A wool sweater provides comfort on a cold day thanks to heat-trapping loops. And a thick cotton thermal knit undershirt delivers essential insulation under clothes. So for cold weather apparel or layering, knitted fabrics have clear functional superiority for retaining body heat. Their thicker, loftier construction makes knits the ideal choice whenever warmth and insulation against chill are needed.

The Challenges of Sewing Knitted Fabrics

One key difference between knits and wovens is the level of sewing difficulty each fabric presents. In general, woven fabrics tend to be much easier to work with and yield higher quality results for sewing garments. The stable, non-stretchy structure of wovens makes pattern alignment and construction more straightforward. Seam allowances and garment shaping hold up well in tightly woven materials. But knits are trickier to sew due to their flexible, stretchy nature. Keeping knit fabric stable enough for clean seams and lines requires more effort. Without proper needle, thread, and machine settings, knits can pucker, distort, or create skipped stitches during sewing. The natural elasticity also makes fittings more difficult. Knits must be handled gingerly to avoid damaging the loops when pinning and cutting. And special stitches like zigzag or overlock are needed for optimal seam strength, durability, and flexibility. Handling the variable stretch and drape of knits while ensuring professional results demands advanced skill and practice. Even hemming knits presents challenges due to their tendency to curl and deform when stitched. So sewing high-quality knit garments and home décor from stretchy cotton jerseys, silky lingerie fabrics, or textured sweater knits requires extra care, patience, and expertise compared to sewing wovens. The obstacles of constructing knitwear means fewer sewists are willing to tackle the learning curve. But with the right guidance, tools, and techniques, sewing knitted fabrics can reward you with fluid garments that showcase the beauty and versatility of knits.

The Precise Laundering Needs of Delicate Knitted Fabrics

One of the main drawbacks of knitted fabrics is that they require very specific laundering methods to prevent damage, shrinkage, and distortion. The looped structure of knits makes them prone to felting and losing shape when washed incorrectly. High heat, agitation, and improper drying can ruin the elasticity and appearance of knits. So delicate wash cycles, cold water, and flat drying are essential. Many knits should even be hand washed or dry cleaned to protect their fibers, shape, and size. Woven fabrics are generally less fussy when it comes to laundering. Their durable, locked weave allows them to withstand higher heat drying, machine washing, and tumble drying without adverse effects. Wovens like denim and corduroy retain their structure despite vigorous cleaning methods. But such intense laundering would spell disaster for most knits. The exceptions are commercial-grade performance knits blended with synthetics to withstand heat and repeated washings. But natural fiber knits like wool, silk, bamboo, and cotton demand a gentle touch. Taking time to learn the ideal washing methods for each knit fabric is key to maintaining quality and performance. So knits do require more diligent laundry practices compared to wovens. But carefully following fabric care instructions allows knits to retain their softness, structure, and appearance over many wears. The benefits of luxurious natural fiber knits often make a bit of extra laundering care worthwhile.

The Wrinkle Resistant Nature of Knitted Fabrics

One advantage knitted fabrics offer over wovens is an inherent resistance to wrinkling that makes knits ideal for travel and everyday wear. The stretchy structure and soft drape of knitted materials allows them to bounce back from folding or bunching up. The elastic loops swiftly spring back to regain their shape once tension is released. Unless severely overstretched, knits retain their smooth appearance with minimal creasing. But woven fabrics are prone to developing creases and stubborn wrinkles when folded or compressed. Their non-flexible weave prevents wovens from springing back effortlessly, resulting in lasting lines and rumpling. Traveling with knits reduces the need to meticulously fold, hang, or steam garments to prevent wrinkling. from dresses to shirts to suits, wrinkle-resistant woven fabrics rely on chemical treatments or blended synthetics to try mimicking the natural resistance inherent to knits. A stretchy knit skirt or dress can endure being stuffed in a suitcase and still emerge relatively smooth. And a cotton knit tee retains its polished look wear after wear without ironing. So if hassle-free care and packing are priorities, knits are clearly superior to wovens when it comes to avoiding wrinkles. Their forgiving nature makes knits an unfussy option for busy lifestyles where resisting wrinkles is a must.

The Extreme Versatility Offered by Knitted Fabrics

One of the key advantages of knitted fabrics is their incredible versatility for a vast range of end uses compared to woven materials. The fundamental softness, stretch, and drape of knits makes them suitable for all types of apparel from delicate undergarments to rugged outerwear. Fashion designers rely on the limitless possibilities knits provide through creative use of stitches, textures, gauges, and yarn blends. Knits can mimic luxurious cashmere, create novel geometric patterns, provide UV protection, and wick moisture – all from the same base fabric. The range of possible weights, opacities, and surface interests is endless with knitted constructions. From sheer stockings to bulky sweaters, knits span the spectrum. Even home décor like blankets and pillows benefit from the customizable nature of knits. But tightly woven fabrics do not offer the same breadth of possibilities. Their scope is far more limited except in high-end couture. For mainstream fashion and accessories, knits dominate and outpace wovens in novelty, performance, and application. Blending knits with other fabrics unlocks even more potential. Their unparalleled flexibility makes knits the foundation of modern textile design and garment production. With innovations like 3D printing applying knit technology in agriculture, medicine, and beyond, the future possibilities are limitless. This unmatched versatility solidifies the superiority of knitted fabrics across all areas of textile manufacturing and end use.

The High Production Costs of Quality Knitted Fabrics

One potential downside of knitted fabrics is they can be more expensive to produce compared to mass-produced woven fabrics. Knitting machinery is generally more complex, with finer gauges and more moving parts to manipulate yarns into the interlocking looped stitches. Producing fine gauge knits for apparel requires advanced equipment and skilled technicians. Hand knitting is extremely labor intensive. These factors increase production costs for knit fabrics versus basic weaving machinery that quickly turns out inexpensive woven yardages. Blends with luxury fibers like cashmere or alpaca also drive up the costs of yarns for knitting. However, technological advances are bringing down manufacturing expenses for commercial knitting operations. Computerized machines are optimizing output. And 3D knitting holds promise for reducing labor through automated fabrication. But overall, maximizing profit margins on affordable apparel usually relies on utilizing cheaper woven fabrics as much as possible. Delicate lingerie and figure-hugging fashions demand higher quality knits despite the costs. And niche artisanal knitters can command premium pricing for their craftsmanship. But in the world of commercial textile manufacturing, woven fabrics maintain a stronghold for mass production because their construction keeps expenses lower per yard versus the intricacies of quality knitted constructions.

The Sustainable Appeal of Natural Fiber Knitted Fabrics

When comparing the environmental impacts of knits versus wovens, knitted fabrics tend to be more eco-friendly based on common fiber choices. Knitting lends itself well to plant-based and animal fibers like organic cotton, wool, linen, hemp, and bamboo. These natural materials make knits biodegradable and renewable. And qualities like durability and longevity keep natural fiber knits from quickly ending up in landfills. But woven fabrics more often rely on petroleum-based synthetics like polyester. The plastic-based fibers used in most inexpensive wovens do not decompose, shedding microplastics into waterways when washed. However, both knits and wovens aim to incorporate more recycled polyester and plastic bottle yarns. For sustainable luxury, eco-conscious brands turn to natural yarns and organic farming methods for knitting. So while both knits and wovens continue improving their environmental footprint through innovation, knitting’s roots in natural fibers give it an inherent advantage for elevating sustainability in the fashion and textile industry. With care and repair, a timeless wool sweater or organic cotton tee can provide lasting use and appeal. This makes natural fiber knits a key component of the growing circular economy and eco-conscious future for apparel manufacturing.

The Superior Visual Appeal and Texture of Knits

When evaluating the aesthetic qualities of knitted versus woven fabrics, knits stand out as the more visually interesting and tactile option. The very nature of knitted constructions lends itself to appealing variations in texture and surface design. The loops and stitches provide natural visual interest and a characteristic three-dimensional look compared to the flat face of wovens. Even simple stockinette knits have an engaging ridge pattern along rows. And knitting allows for infinite possibilities to create eye-catching geometric shapes, specialized stitches for unique textures, playful novelty yarns, and jacquards with embedded color patterns. The resulting surface complexity and feel creates compelling visual styles unavailable to wovens. Of course, high-end couture weaving techniques can craft intricate designs. But for accessible and commercial fabrics, knits provide limitless possibilities for novelty and creative aesthetic appeal. The tactile dimension is also part of the allure of knits. The springy loops just beg to be touched, evoking sensory responses crucial to consumer appeal. No wonder knits dominate the worlds of fashion and décor. Their unparalleled ability to attract the eye and please the hand makes knitted fabrics magnetic. This beauty and tactile advantage helps explain the craze for unique handknits and the prominence of knits across the textile and apparel industry.