How do polycarbonate lacrosse shafts compare to metal and composite alternatives. What makes polycarbonate shafts ideal for all weather conditions. Why is flexibility crucial for improved ball control and shooting accuracy.

The Advantages of Polycarbonate Lacrosse Shafts

Polycarbonate lacrosse shafts have emerged as a game-changing option for players seeking the perfect balance between flexibility and durability. These shafts offer a unique combination of benefits that set them apart from traditional metal and composite alternatives.

Polycarbonate is an engineered thermoplastic material that combines the lightweight properties of plastic with exceptional impact resistance. This innovative material provides players with the flex they need for precise passing, accurate shooting, and superior ball control, all while maintaining exceptional resilience and longevity.

Key Benefits of Polycarbonate Shafts:

- Optimal flexibility for improved ball handling

- Exceptional durability and impact resistance

- Consistent performance in all weather conditions

- Lightweight design for enhanced maneuverability

- Improved energy transfer for powerful shots

Are polycarbonate shafts suitable for players of all skill levels? Absolutely. The unique properties of polycarbonate make these shafts an excellent choice for both developing players and experienced athletes. Beginners can benefit from the forgiving nature of the material, which helps build key techniques like cradling, scooping, and shooting form. Advanced players can leverage the whip and precision of polycarbonate to elevate their passing and shooting accuracy to new heights.

Polycarbonate vs. Metal and Composite Shafts

To truly appreciate the advantages of polycarbonate lacrosse shafts, it’s essential to compare them to their metal and composite counterparts. Each material has its own set of strengths and weaknesses, but polycarbonate offers a unique combination of benefits that addresses many of the shortcomings of other options.

Metal Shafts:

- Pros: Unmatched strength and rigidity

- Cons: Stiffness reduces ball control, prone to corrosion, can become brittle in cold temperatures

Composite Shafts:

- Pros: Offer more bend than metal shafts

- Cons: Less durable than metal, can break more easily, may absorb moisture

Polycarbonate Shafts:

- Pros: Ideal balance of flexibility and durability, weather-resistant, consistent performance in all conditions

- Cons: May not be as rigid as metal shafts for players who prefer maximum stiffness

How does the molecular structure of polycarbonate contribute to its performance? The unique molecular composition of polycarbonate allows it to be far more flexible than aluminum or titanium shafts while maintaining higher rigidity than most composites. This balance results in excellent energy transfer for powerful shots and enables players to load energy during dodges before unleashing breakaway speed.

Weather Resistance: A Major Advantage of Polycarbonate

One of the standout features of polycarbonate lacrosse shafts is their exceptional performance in all weather conditions. Unlike metal shafts that can rust or corrode, and composite shafts that may absorb moisture, polycarbonate maintains its integrity regardless of the elements.

Performance in Various Weather Conditions:

- Rain and humidity: Polycarbonate resists moisture absorption, maintaining consistent performance

- Cold temperatures: Unlike metal shafts that can become brittle, polycarbonate retains its flexibility

- Hot weather: Polycarbonate maintains its structural integrity even in high temperatures

- Varying conditions: Consistent performance throughout the unpredictable spring lacrosse season

Why is weather resistance crucial for lacrosse players? The ability to perform consistently in all conditions is vital for players who compete in various environments throughout the season. Polycarbonate shafts provide the reliability needed to excel in any weather, from scorching summer days to frigid winter practices.

Flexibility and Ball Control: The Polycarbonate Advantage

The flexibility of polycarbonate lacrosse shafts offers significant advantages in terms of ball control and overall performance. This characteristic sets polycarbonate apart from stiffer materials like metal, providing players with enhanced feel and precision.

How Flexibility Improves Performance:

- Enhanced cradling: The slight give in the shaft allows for smoother ball retention

- Improved shooting accuracy: Flex helps players fine-tune their release point

- Better passing precision: The whip of the shaft can be used to add finesse to passes

- Increased ball security: Flexibility aids in maintaining possession during checks

Can the flexibility of polycarbonate shafts benefit players of different positions? Indeed, players across all positions can leverage the flexibility of polycarbonate shafts to their advantage. Attackmen can utilize the whip for quick, accurate shots. Midfielders can benefit from improved ball control during transitions. Defenders can maintain better possession when clearing the ball under pressure.

Durability and Longevity: Why Polycarbonate Shafts Last

The exceptional durability of polycarbonate lacrosse shafts is a key factor in their growing popularity. These shafts are built to withstand the intense physical demands of the sport, outlasting many of their metal and composite counterparts.

Factors Contributing to Polycarbonate Durability:

- Impact resistance: Polycarbonate can absorb and disperse energy from hits and checks

- Crack resistance: Unlike some composites, polycarbonate is less prone to cracking or splitting

- Weather resilience: Consistent performance in various temperatures and conditions

- Corrosion resistance: No risk of rusting or oxidation like metal shafts

How does the durability of polycarbonate shafts translate to cost-effectiveness? While the initial cost of a polycarbonate shaft may be comparable to other materials, its longevity often results in better value over time. Players may find themselves replacing polycarbonate shafts less frequently than other types, leading to potential long-term savings.

Optimizing Performance: Pairing Polycarbonate Shafts with the Right Equipment

To fully harness the benefits of polycarbonate lacrosse shafts, it’s crucial to pair them with complementary equipment. The right combination can enhance overall performance and bring out the best in a player’s game.

Considerations for Equipment Pairing:

- Head selection: Choose a head that complements the flex of the polycarbonate shaft

- Pocket design: Experiment with different pocket styles to optimize ball control

- String tension: Adjust stringing to work in harmony with the shaft’s flexibility

- Grip options: Select a grip that enhances control without compromising the shaft’s feel

How can players determine the best equipment combination for their playing style? Experimentation is key. Players should try different head and pocket combinations with their polycarbonate shaft to find the setup that feels most natural and effective for their individual playing style. Consulting with coaches or experienced players can also provide valuable insights into optimizing equipment choices.

The Future of Lacrosse Shaft Technology: Polycarbonate Innovations

As lacrosse equipment continues to evolve, polycarbonate shafts are at the forefront of innovation. Manufacturers are constantly exploring ways to enhance the performance and durability of these versatile shafts.

Emerging Trends in Polycarbonate Shaft Technology:

- Advanced polymer blends: Combining polycarbonate with other materials for optimized performance

- Texture innovations: Developing new surface treatments for improved grip and feel

- Weight reduction: Exploring methods to further lighten polycarbonate shafts without sacrificing strength

- Customization options: Offering more personalized flex and response characteristics

What can players expect from future generations of polycarbonate lacrosse shafts? As research and development in materials science progress, we can anticipate even more refined polycarbonate shafts that offer an ideal balance of flexibility, durability, and performance. These advancements may lead to shafts that can be fine-tuned to meet the specific needs of individual players and playing styles.

In conclusion, polycarbonate lacrosse shafts represent a significant leap forward in equipment technology. Their unique combination of flexibility, durability, and all-weather performance makes them an excellent choice for players of all skill levels. As the sport continues to evolve, polycarbonate shafts are poised to play an increasingly important role in shaping the future of lacrosse equipment.

Polycarbonate Lacrosse Shafts Provide Needed Flexibility Without Sacrificing Durability

When it comes to lacrosse shaft construction, finding the ideal balance between flexibility and durability can be a challenge. Metal shafts provide unmatched strength, but their stiffness reduces ball control. Composite shafts offer more bend, but they lack the ruggedness of metal and can break more easily. This is where polycarbonate lacrosse shafts really shine – they give players the flex they need for crisp passing, accurate shooting, and ball security, while still being extremely resilient and long-lasting.

Polycarbonate is an engineered thermoplastic material that combines the lightness of plastic with exceptional impact resistance. The molecular structure of polycarbonate makes it far more flexible than aluminum or titanium shafts, giving it a nice whip when shooting or dodging checks. At the same time, polycarbonate has higher rigidity than most composites, so it doesn’t fold under pressure. This unique blend of flex and stiffness provides excellent energy transfer for powerful shots, while also allowing players to load energy during the dodge before uncoiling into breakaway speed.

While carbon fiber or composite shafts may dent or crack over time, polycarbonate holds strong season after season. Its solid construction withstands all the checks, slashes, and bruising impacts of elite play. Even in cold winter temperatures that can make aluminum shafts brittle, polycarbonate retains its balanced responsiveness and toughness. Rain, snow, or shine, polycarbonate outperforms in flexibility and durability.

For developing lacrosse players, the bend and pop of polycarbonate shafts helps build key techniques like cradling, scooping, shooting form, and stick protection. Experienced players can leverage the whip and precision of polycarbonate to reach new levels of passing and shooting accuracy. With the right pocket and head combo, polycarbonate shafts bring out the best in any player’s game through optimized ball control, handling, and power transfer.

So when choosing your next lacrosse shaft, look for polycarbonate construction to get the ideal blend of flex for feel and durability for longevity. Polycarbonate gives players the responsive bend they need to develop skills and outmaneuver opponents, while standing up to hardcore wear and tear over many seasons. Once you try it, you may never go back to another shaft material again.

Polycarbonate Withstands All Weather Conditions: Won’t Rust or Corrode

One of the biggest advantages of polycarbonate lacrosse shafts is their unmatched durability in all weather conditions. While metal shafts can rust and composite shafts can absorb moisture, polycarbonate holds up rain or shine.

Aluminum shafts are known for their stiffness and strength, but they have a major downside – they corrode and oxidize when exposed to moisture. Sweaty hands, damp grass, and rainy weather will cause aluminum shafts to gradually rust over time, leading to unsightly corrosion and pits in the surface. The oxidation process actually makes the aluminum shaft more brittle and prone to breaking. Once an aluminum shaft starts rusting, the corrosion quickly spreads and ruins the shaft.

Titanium shafts solve the corrosion issue, but they lack the responsiveness of aluminum. Plus, titanium comes with a premium price tag far above polycarbonate shafts. Composite shafts with carbon fiber or polymer construction avoid rusting, but they have a tendency to absorb moisture. This can cause soft spots, dents, and decreased stiffness in composite shafts over time.

Polycarbonate lacrosse shafts skirt these drawbacks of metal and composite materials. The smooth exterior surface of polycarbonate completely resists corrosion and will never rust. Polycarbonate also does not absorb water like some composites, maintaining its consistency in damp conditions. That means polycarbonate performs the same on a dry summer day as a cold rainy spring game – no oxidation, no moisture absorption issues.

Polycarbonate shafts stand up to heavy usage in all weather extremes. The summer sun won’t cause issues, nor will winter cold make polycarbonate shafts more brittle like metal ones. From the highest heat and humidity to icy sleet and snow, polycarbonate handles it all while retaining the same precise flex and response. No need to worry about pitting, corrosion, soft spots or dents over time.

Considering the typical lacrosse season spans spring months with wildly fluctuating conditions, polycarbonate is the obvious choice for durability. The last thing any player wants is to attack the cage on a fast break, only to have their shaft snap in the cold weather. With rugged polycarbonate, players have the reliability they need to perform in any environment while wielding a consistent, high-performing stick.

Polycarbonate Shafts Offer Superior Vibration Dampening for Better Control

When a lacrosse ball makes contact with the head, vibrations travel down the shaft into the player’s hands. Too much vibration can cause sting, pain, and even loss of control. This is where polycarbonate lacrosse shafts stand out, providing excellent vibration dampening for optimal performance.

Aluminum lacrosse shafts transmit significant vibration, as their ultra-stiff construction provides minimal dampening. Every checked shot, scooped ground ball, or blocked pass reverberates intensely through an aluminum shaft into the hands. This can make even routine plays quite jarring and painful over time, leading to fatigue, loss of feel, and drops.

Composite shafts like carbon fiber dampen vibration better than aluminum, but they lack the lively responsiveness of metal shafts. Composites can also transmit uneven vibrations if their wall thickness and layering is not consistent throughout the shaft’s construction.

Polycarbonate provides the ideal solution through superior vibration dampening that doesn’t sacrifice responsiveness. The molecular structure of polycarbonate naturally isolates and diffuses vibrations extremely well. Polycarbonate shafts maintain lively feel for precision play, but without the painful sting and discomfort of aluminum. Think of the difference in catching a lacrosse ball with a padded glove versus your bare hand – polycarbonate delivers that absorbed, cushioned feel on every play.

With polycarbonate’s smooth vibration damping, players can scoop, pass, catch, and shoot comfortably all game long. Less vibration translates to better ball control, as the stick won’t rattle in the hands on contact. Superior dampening also reduces arm and hand fatigue, enabling polycarbonate shaft users to maintain consistency from the first whistle to the final horn. Players can retain a soft yet responsive hold on the stick, allowing them to cradle cleanly, protect the rock through traffic, and place accurate touches on passes or shots.

Polycarbonate construction allows designers to engineer shafts for optimal flex and vibration profiles for different player positions and preferences. For example, some polycarbonate shafts feature strategically placed harmonic dampers to further quell sting and harmonics. With polycarbonate, it’s possible to build a lacrosse shaft that feels like an extension of the player’s body.

Polycarbonate Construction Reduces Overall Weight of Stick

One of the main benefits of polycarbonate lacrosse shafts is that they are significantly lighter than metal shafts without compromising durability. The lightweight feel helps boost play speed, ball control, and handling.

Aluminum lacrosse shafts have ruled the sport for decades due to their stiffness, strength, and cost-effectiveness. But aluminum comes with a hefty weight penalty – the dense metal construction results in noticeably heavy sticks that weigh a player’s arms down over time. As players fatigue, their shooting, passing, and dodging skills decline.

Carbon fiber composite shafts trimmed weight compared to aluminum, while providing more flex and vibration dampening. But durability issues plague some composite designs, while the premium price limits widespread adoption. So a lightweight yet rugged design has remained elusive – until polycarbonate.

Polycarbonate lacrosse shafts strike the ideal balance with remarkably light weight coupled with outstanding durability. At around 140 grams or less, polycarbonate shafts are approximately 40% lighter than aluminum and right in line with professional-grade composite shafts. The lightweight polycarbonate construction boosts stick speed, quickness on draws, and finesse in cradling through heavy traffic.

With less weight pulling down the hands, players can execute precise feeds and shoot rockets all game long without tiring. Polycarbonate shaft users gain an edge in endurance as their sticks feel like extensions of their arms even into the late stages of games. Plus the lively feel and response generated by polycarbonate improves a player’s overall ball control and command of their stick.

The lightweight advantage extends to younger players as well. Heavy aluminum sticks can be difficult for children and smaller athletes to wield efficiently. With polycarbonate’s featherlight feel, developing players can focus on proper form and skill-building instead of just trying to swing bulky metal sticks around. Lighter sticks build confidence.

Polycarbonate marries the low weight players want with the high durability coaches and parents demand – the best of both worlds. Every lacrosse player wants a stick that feels like part of their body, and polycarbonate delivers.

Polycarbonate Lacrosse Shafts Enable Faster Shot Speeds and Releases

Every lacrosse player strives to improve their shooting velocity and release time, giving goalies less reaction time to make saves. Polycarbonate shaft technology helps players achieve lightning-quick shot releases along with maximum ball speed.

Aluminum shafts can produce hard shots, but their rigidity makes it difficult for players to fully load energy up and unleash it through the stick. Composites like carbon fiber have more “whip” yet lower durability. Polycarbonate provides the best traits of both materials for optimizing shooting performance.

The flexible yet strong construction of polycarbonate shafts allows for an amplified “flex and shoot” effect. As players prepare to shoot, they can bend the shaft to load potential power. When swinging through the shooting motion, the shaft releases this stored energy and actually catapults the ball out of the stick head at high velocity. Polycarbonate flexes deeply on wind-up then rebounds extremely fast to impart speed.

This flex and recoil happens in a split second, far faster than human reaction times. When players shoot with polycarbonate shafts, goalies simply cannot react in time to make the save even from point blank range. The ball appears almost a blur coming out of a polycarbonate shaft.

In addition to improving shot power, polycarbonate shafts allow players to release their shooting motion faster than stiff aluminum. The quick-release benefit becomes pronounced during rapid inside rolls on goal or quick sticks from tight quarters. Every millisecond counts in getting a shot off before defenders can react and challenge.

Between the flex-generated ball speed and quick release, polycarbonate shafts give shooters a profound advantage. Goals that would be saved with other materials suddenly find the back of the net with polycarbonate. Even from long range, polycarbonate helps maintain higher ball velocities for more potent shooting. Accuracy also improves as players learn to leverage the exceptional energy transfer.

For midfield and attack players focused on putting up goals, a polycarbonate shaft becomes an indispensable asset. Their shots simply overpower goalies before they can react. Defenders also must respect the shooter more with polycarbonate shafts, opening up the cutters and crease men with gravity. The extra room allows the entire offense to click at a higher level.

Polycarbonate Shafts Offer Excellent Balance and Feel During Play

Great lacrosse shafts become an extension of the player’s hands, offering intuitive feel and weighting that builds confidence. Polycarbonate construction allows engineers to optimize balance and ergonomics for superior performance.

Aluminum shafts can feel “tip heavy” as denser aluminum adds weight down low on the shaft. This forces players to choke up high on the stick for better balance. Composite shafts marked an ergonomic improvement but lack the lively feel of metal designs.

With polycarbonate, shaft designers gain tremendous flexibility in tuning weight distribution, flex points, and balance. By precision engineering the thickness, geometry, and reinforcements along the shaft, polycarbonate can provide true low-kickpoint response and evenly distributed balance.

Balanced polycarbonate shafts allow players to choke down lower on the shaft without sacrificing feel and control. Lower hand positions boost leverage for harder passes, better stick protection, and more overpowering checks. Yet the shaft still maintains perfect weighting so it never feels “butt heavy” like aluminum.

Advanced polycarbonate lacrosse shafts incorporate ergonomic features like textured grip zones and tapered handle ends to seamlessly mesh with players’ hands. The contours guide proper hand placement while providing cushioned comfort, even when wearing gloves.

With dialed-in flex points and balance, polycarbonate shafts reward players’ technique with immediate feedback. The shafts respond smoothly and predictably, inspiring confidence to cradle harder, shoot faster, and pass crisper. Intuition takes over, allowing players’ skills to shine.

Young players benefit from polycarbonate’s balance and ergonomics as well. Properly weighted shafts help newcomers develop proper fundamentals and stick skills from the start. With lightweight polycarbonate construction, younger kids can more easily control the shaft while building handle technique.

When balance, feel, and control all come together in one package, the result is a lacrosse shaft that plays like an extension of a player’s hands. Polycarbonate construction makes this optimized user experience a reality.

How Polycarbonate Lacrosse Shafts Are Molded for Precision and Consistency

Consistent flex and feel are crucial for lacrosse shaft performance. Polycarbonate construction enables optimized precision molding and quality control for unmatched consistency shaft-to-shaft.

Aluminum shafts involve extruding and machining solid aluminum, then tempering it for strength. Small variations in alloy grades and machining can impact the final feel and flex, even in the same model line. Carbon fiber composites depend heavily on hand layup and curing techniques, both of which introduce inconsistencies.

With polycarbonate, shaft manufacturers leverage precision molding processes to eliminate variances. Polycarbonate resin is injection molded into shaft molds under extreme heat and pressure. Computer-controlled processes ensure exact fill levels, temperature curves, and curing times. The molded shafts emerge with perfect consistency in wall thickness, strength, and flexibility.

Molded polycarbonate offers tremendous design freedom as well. Engineers can program the molds to produce any conceivable shape, tapering, or texturing along the shaft’s length. Internal lattice structures molded into the polycarbonate boost strength and rigidity at key flex points without adding exterior weight.

The precision molding even allows finishing steps like decorative graphics to be incorporated into the production. Logos, pinstriping, or other branding fuse seamlessly with the shaft during molding for a sharp integrated look.

With tight quality control testing, polycarbonate shafts exceed aluminum and composite models in uniformity. Every shaft off the production line provides the exact same quick release, responsiveness, and feel the engineers designed. This consistency inspires confidence for all players and goalies, who know exactly what to expect from the shaft.

When you use a polycarbonate lacrosse shaft, you can trust you are getting the intended performance every time. Unlike metal or composite shafts with variances, polycarbonate offers reliable excellence shaft after shaft. Precision molding technology ensures polycarbonate lacrosse shafts perform consistently through years of play.

Polycarbonate Lacrosse Shafts Offer More Styles and Design Options

Lacrosse players love to express their style by customizing their sticks. Polycarbonate construction opens up nearly endless possibilities for colors, designs, and graphic finishes.

With aluminum lacrosse shafts, options are limited to basic anodized colors or factory painted graphics. Custom paint jobs can chip and wear off over time. Carbon fiber composites depend on the underlying weave’s color, limiting personalization.

Polycarbonate shafts blow the doors open for self-expression. The polymer readily accepts dyes and colorants during production, allowing manufacturers to produce shafts in a rainbow of colors. Preventing colors from mixing yields eye-catching fades and ombres. Metallic flake or pearlescent additives produce dazzling effects.

Instead of plain glossy or matte finishes, polycarbonate allows for cool textures like pearskin grips. Factors like grip patterns, logos, pinstripes and more get molded right into the shaft for sharp, resilient aesthetics. Durable hydrographic 3D graphic printing options bring custom designs to life.

Polycarbonate also shines for transparent and translucent designs no other material can match. Clear coated polycarbonate maintains see-through visibility to the underlying structure for an almost supernatural vibe. Or opaque tints yield stunning translucent hues that shift in sunlight.

For true customization, some polycarbonate shaft brands offer online design studios. Players can create their dream shafts with colors, fades, patterns and logos tailored specifically to them. Bring your imagination, and it becomes reality thanks to polycarbonate.

On the field, these eye-catching polycarbonate designs crank up players’ swagger and intimidate foes. Trick shafts GA gamers crave become simple to produce. The broad color palette and effects allow teams to coordinate uniform looks as well. When it comes to lacrosse style, polycarbonate offers possibilities aluminum and composites cannot match.

Customizing Your Lacrosse Stick With Polycarbonate Shaft Technology

To play their best, lacrosse players need sticks tailored to their exact preferences. Polycarbonate shafts enable full customization for the perfect personalized fit.

With aluminum or composite shafts, players are limited to factory specs and off-the-shelf offerings. You get what you get. The limited flex, weight, and balance options may not align with every athlete’s needs and play style.

Polycarbonate unlocks a new level of lacrosse stick personalization through advanced manufacturing techniques. The injection molding process allows engineers to fully control the shaft’s flex profile, shape, weight distribution, and features.

By adjusting the polycarbonate resin formula, they create shafts with different rigidity, vibration dampening, and shooting responsiveness. Strategic structural reinforcing via internal lattice molds or external surface geometries boosts strength and stiffness right where players need it most.

Grip texture patterns and contours get optimized for specific hand sizes and comfort preferences. Personalized weight balancing caters to players’ exact choking style for ideal leveraging of the shaft’s kickpoint and shooting motion.

Players can even work with designers to develop dream graphics or color schemes reflecting their identities. Add your number, inspirational phrase, or name right into the molded polymer. With online customizers, craft your vision from millions of possible color and design combinations.

Polycarbonate shafts ultimately allow manufacturers to deliver prosthetic-grade personalization in a sports equipment context. Whereas aluminum and composites have set limitations, polycarbonate enables shafts engineered to move and feel like natural extensions of players’ bodies.

When you wield a customized polycarbonate lacrosse shaft, any weaknesses or limitations of generic factory models disappear. The shaft maximizes your abilities through optimized performance and ergonomics. Why settle for “one size fits most” when you can engineer lacrosse stick perfection?

Polycarbonate Lacrosse Shafts Meet NCAA and High School Rules

New lacrosse stick technologies often get banned from organized play until they can prove compliance with rules. Polycarbonate shafts have quickly gained acceptance into scholastic and collegiate leagues thanks to their durability and performance within regulations.

Cutting-edge lacrosse stick designs sometimes exploit loopholes in an attempt to gain a competitive advantage. While exciting, many of these sticks stretch past the sport’s intent and get prohibited. It takes years of real-world testing before new materials and features get approved.

Polycarbonate shaft manufacturers worked closely with sporting governing bodies throughout the development process. Extensive testing validated polycarbonate’s strength, flexibility, and vibration properties align with longstanding equipment guidelines.

This upfront work cleared polycarbonate for NCAA men’s and women’s play right from its launch. There is no waiting period or controversy – players can use polycarbonate shafts right away. The same applies for National Federation of State High School Associations boys and girls lacrosse rules.

Since certification, polycarbonate shafts have built a strong reputation through elite play at all levels. Coaches and officials acknowledge polycarbonate provides no unfair edge compared to permitted aluminum and composite shafts. In fact, polycarbonate’s blend of control and durability benefits players of all skill levels.

Knowing your new shaft qualifies for high school and college competition brings peace of mind. Polycarbonate shafts carry the same permitted stamp of approval as traditional designs, just with greatly advanced performance and customization.

NCAA and NFHS endorsement proves polycarbonate lacrosse shafts uphold the spirit of the sport and ethics of fair play. The governing bodies’ rigorous testing validates polycarbonate as an exciting innovation that expands possibilities within established regulations. All lacrosse players can reap the benefits in their quest for excellence.

Top Polycarbonate Shaft Manufacturers: Maverik, STX, Warrior, Brine

While a relatively new category, polycarbonate lacrosse shafts come from leading gear brands known for quality and innovation. Maverik, STX, Warrior, and Brine lead the charge with excellent polycarbonate shaft options.

As pioneers of advanced lacrosse sticks, these big names bring tremendous engineering resources to polycarbonate shafts. By leveraging computational design, lab testing, and player feedback, they fast-track development of high-performance shafts.

Maverik stands out with its HEX shaft line maximizing ball control through optimized flexure design. STX offers the versatile Stallion 700 handle with two flex point models. Warrior takes lightweight feel to the extreme with its ultra-light Blaze shafts.

Brine leads in women’s lacrosse sticks with the transformational Triloy shafts. They tap into polycarbonate’s vibration-dampening traits for a smooth responsive feel that builds fundamentals.

While offering different flex profiles and features, all these brands’ polycarbonate shafts provide excellent durability, lightweight handling, and weather resistance. Backed by powerhouse companies, they deliver the same standards of quality and construction players expect.

Maverik, STX, Warrior and Brine also leverage polycarbonate for greater customization and design expression. Across the board, these next-gen shafts outshine old-school models thanks to advanced materials and engineering.

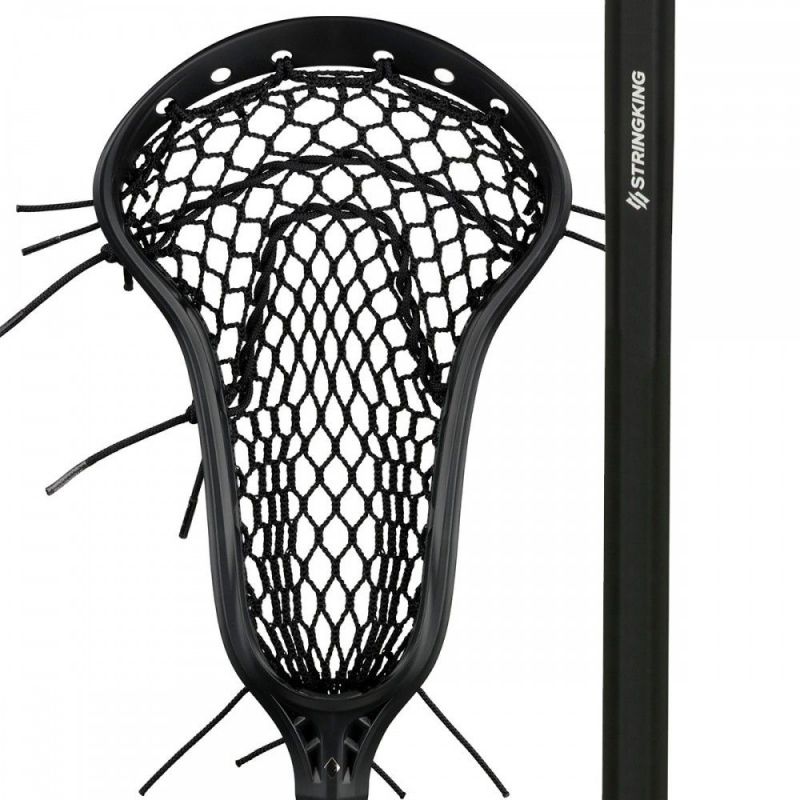

Newer brands like Epoch and StringKing now offer polycarbonate options as well. But the category leaders have a proven track record you can count on to back up their innovative sticks. When transitioning to polycarbonate, stick with shafts from the most trusted names in the game.

Comparing Polycarbonate Lacrosse Shafts by Weight, Flexibility, and Price

With different brands now making polycarbonate shafts, it helps to compare models across key specs like weight, flex profiles, and cost. This makes it easier to select the right shaft for your game.

Weight ranges from ultra-light models around 100 grams for speedy handling to 140+ gram shafts providing rugged durability. Average polycarbonate shaft weights sit around 130 grams, significantly below aluminum.

Flex profiles vary from flexible whippy shooting shafts to stiffer options for checking defensemen. Look for kickpoints and stiffness ratings to match your position and style.

Prices largely correlate to weight and materials used. Entry-level polycarbonate shafts run $80-$100, while super lightweight 100-gram models go up to $150+. High-end alloy/composite hybrids cost over $200 but provide the best of all worlds.

It’s wise to demo different polycarbonate shafts to feel how the weight, balance, and flexwork for you. While generally light and whippy compared to aluminum, subtle differences matter, especially concerning your most frequent stick actions.

Don’t overlook aesthetics either. Graphics, colors, and customization vary model to model. Select designs expressing your personal style to intimidate foes. But also consider budget – flashy pro custom shafts get pricey.

Read lacrosse gear forums and reviews to shortlist 4-5 shafts with preferred traits. Demo these selections on the field to determine your ideal flex, grip, balance, and swing weight. The right stick becomes an extension of your hands.

While polycarbonate universally provides benefits over old-tech shafts, take time to research and trial different options. Dialing in the best weight, flex, and feel for your game maximizes the performance advantages of these next-gen lacrosse shafts.

Caring for Your Polycarbonate Shaft: Proper Maintenance and Use

Polycarbonate lacrosse shafts are extremely durable, but proper care optimizes longevity while preventing damage. Following a few shaft maintenance best practices ensures peak performance.

Avoid leaning on your stick like a cane, which can cause splintering or cracks over time. Don’t use it as a hammer or crowbar prying and wedging objects – the focused stresses damage the shaft.

When taping your stick, don’t wrap overly tight. Tape compresses the shaft gradually, weakening the structure. Apply tape in moderation with careful attention to wrinkles.

Inspect your shaft frequently for cracks, especially around the head and butt ends where stresses concentrate. At first sign of a crack, stop use immediately and re-shaft.

Clean grime buildup with mild soap and water versus harsh chemicals that could weaken the polymer. Wipe down after each use once the shaft is dry.

Avoid storing sticks in excessively hot places like car trunks on hot days, as heat accelerates polymer degradation. Don’t leave shafts outside in winter freeze-thaw cycles either.

When transporting sticks, secure them well to avoid clanging together which causes scratches and dents over time. Use stick bags or tubes instead of jamming loose in a crowded trunk.

Replace or re-tighten any loose screw collars immediately to prevent damage from play impacts. Inspect for missing or sheared screws regularly.

Never step or stand on your stick. The focused compressive load can damage the shaft without visible exterior signs at first. Treat it with care, not as a doormat.

Following these simple polycarbonate shaft care tips helps your stick last many seasons at peak playability. Proper maintenance comes with a little diligence and lacrosse sense. Take good care of your shaft, and it will take good care of you!

Polycarbonate Lacrosse Shafts: The Future of Lacrosse Stick Technology

Polycarbonate shafts represent an evolution in lacrosse stick engineering. The material provides the quick release, lively feel, and resilience players demand along with unlimited possibilities for customization.

Aluminum defined lacrosse sticks for decades, but its limitations are clear – heavy weight, corrosion issues, and rigid feel. Composite shafts improved things but lack metal’s ruggedness and consistency.

Polycarbonate combines positive traits of both material categories without major downsides. The engineered thermoplastic transfers energy responsively while remaining featherlight and durable. It finally optimizes what players seek in a shaft.

Already polycarbonate dominates elite fields from the high school ranks up through the pros. Expect even greater adoption as costs come down over time. Its performance and customization advantages prove irresistible.

R&D teams continue pushing polycarbonate lacrosse technology further. Advances in nano-additives, lattice structures, and hybrid materials will enable unprecedented balance, feel, and energy manipulation in shafts.

Future “tunable shafts” may leverage polycarbonate to adjust performance characteristics on the fly. Games evolve – sticks should too.

While titans like aluminum are tough to unseat, polycarbonate represents the first real leap in lacrosse shaft materials since the sport’s origins. It brings Creators together with players to engineer the ideal extension of athletes’ bodies and abilities.

Sticks of wood and metal ruled history. But polycarbonate now ushers in the future of lacrosse. The material empowers innovators to take player equipment into realms once unimaginable.