How to choose the right wax for lacrosse mesh. What is the ideal consistency for lacrosse mesh wax. How to apply wax to new and broken-in lacrosse mesh. Why is proper heating of lacrosse mesh wax crucial. How to effectively wax shooting strings on a lacrosse head.

The Importance of Proper Lacrosse Mesh Waxing

Waxing your lacrosse mesh is a crucial step in maintaining your equipment and enhancing your performance on the field. A well-waxed pocket can significantly improve ball control, hold, and release. But what exactly does waxing do for your lacrosse mesh?

- Weatherproofs the mesh, maintaining pocket shape in wet conditions

- Reduces friction on the ball for quicker releases and better hold

- Strengthens the nylon mesh, preventing premature breakdown

Understanding these benefits is key to appreciating the importance of proper waxing technique. Now, let’s dive into the pro tips that will elevate your waxing game.

Selecting the Ideal Wax for Your Lacrosse Mesh

Choosing the right wax is crucial for achieving optimal results. Which types of wax work best for lacrosse mesh?

Opt for waxes specifically formulated for synthetic nylon mesh. Trusted brands like StringKing, Throne of String, and East Coast Dyes offer excellent options. While beeswax can work in a pinch, it tends to be overly tacky. The ideal lacrosse mesh wax should:

- Apply smoothly

- Soak into the mesh effectively

- Leave a tacky finish without being gummy or sticky

A small 4-8 oz tin of high-quality wax should last you a full season or two, even with regular reapplications.

Achieving the Perfect Wax Consistency

Getting the right consistency is crucial for effective waxing. How can you ensure your wax is neither too thin nor too thick?

Use a double boiler or crock pot to melt your wax slowly and evenly. This method prevents scorching or burning, which can alter the wax’s chemical composition. To test the consistency:

- Drip a small amount of melted wax into cold water

- The wax should solidify into a soft, pliable ball

- It should slowly flatten out when pressed

If the wax is too thin, it won’t provide enough tackiness or durability. If it’s too thick, it won’t penetrate the mesh properly. Adjust by reheating and adding a bit of water or oil if needed.

Waxing Techniques for Brand New Lacrosse Mesh

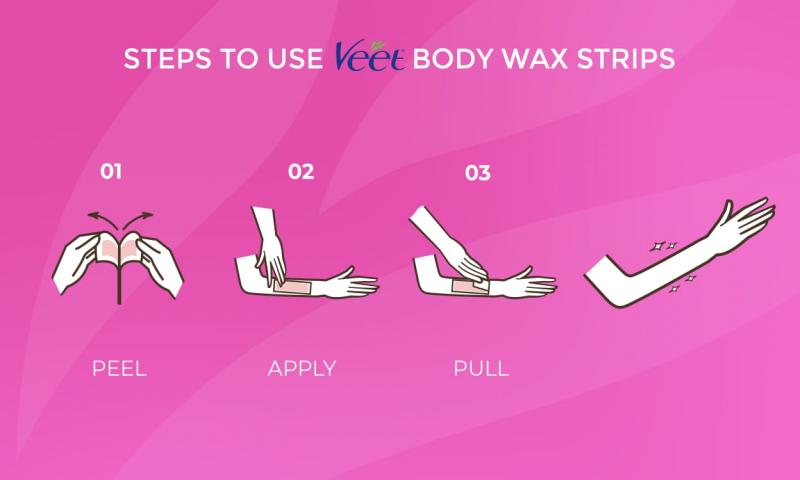

Applying wax to a new lacrosse head requires a specific approach. How should you prepare and wax fresh mesh?

Start by preparing both the wax and the head:

- Heat the wax to the proper consistency

- Use a stiff nylon brush to gently rough up the mesh surface

- Pay extra attention to fray-prone areas along the sidewalls

For application, use a wax brush, foam brush, or old rag. Apply the wax liberally along the diamonds, sidewalls, and shooting strings. Alternate between dipping the brush in wax and stroking across the mesh. For best results, apply 2-3 coats, allowing each layer to dry fully before adding the next.

Waxing Strategies for Broken-In Lacrosse Pockets

Waxing an already broken-in pocket requires a more delicate touch. How can you maintain your preferred ball feel while still benefiting from waxing?

Follow these steps for waxing a used lacrosse head:

- Clean the pocket with a damp paper towel to remove dirt and debris

- Apply thinner, single coats of wax

- Focus on the middle and lower parts of the pocket that need it most

- Use alternating vertical and horizontal brush strokes to work the wax into the diamond pattern

Remember, too much wax buildup in an older, bagged-out pocket can negatively affect your ball control and release. Be conservative with your application and focus on the areas that truly need it.

Proper Heating Techniques for Lacrosse Mesh Wax

Heating your wax correctly is crucial for achieving the right consistency and preserving its properties. What’s the best method for melting lacrosse mesh wax?

Always use indirect heat, such as a double boiler or slow cooker, to melt your wax. Direct stovetop heat can burn the wax and evaporate its lighter fluid components, resulting in a thick, sticky substance that’s difficult to work with. Follow these guidelines:

- Keep the wax temperature around 200°F (93°C)

- Stir frequently to ensure even heating

- Remove from heat as soon as it’s fully melted

Properly melted wax should pour easily and appear transparent. This consistency allows for smooth application and optimal penetration into the mesh fibers.

Dip Method vs. Brush Application: Which is Best?

When it comes to applying wax to your lacrosse mesh, you have two main options: the dip method or brush application. Which technique should you choose?

The dip method involves repeatedly submerging your lacrosse head into the melted wax. While this can saturate the mesh well, it may lead to thick buildup if not done carefully. On the other hand, using a wax brush to apply the melted wax often results in more even coats with better precision.

For most players, the brush method is recommended. Here’s how to do it effectively:

- Use a wax brush to liberally apply the melted wax

- Alternate between vertical and horizontal strokes across each diamond

- Pay extra attention to fragile areas around the top and sidewalls

- Allow the wax to fully dry and harden before applying additional coats

Whichever method you choose, remember that consistency and patience are key to achieving a well-waxed lacrosse head.

The Importance of Waxing Shooting Strings

While focusing on the mesh, it’s easy to overlook the shooting strings. Why is waxing these horizontal nylon strings crucial?

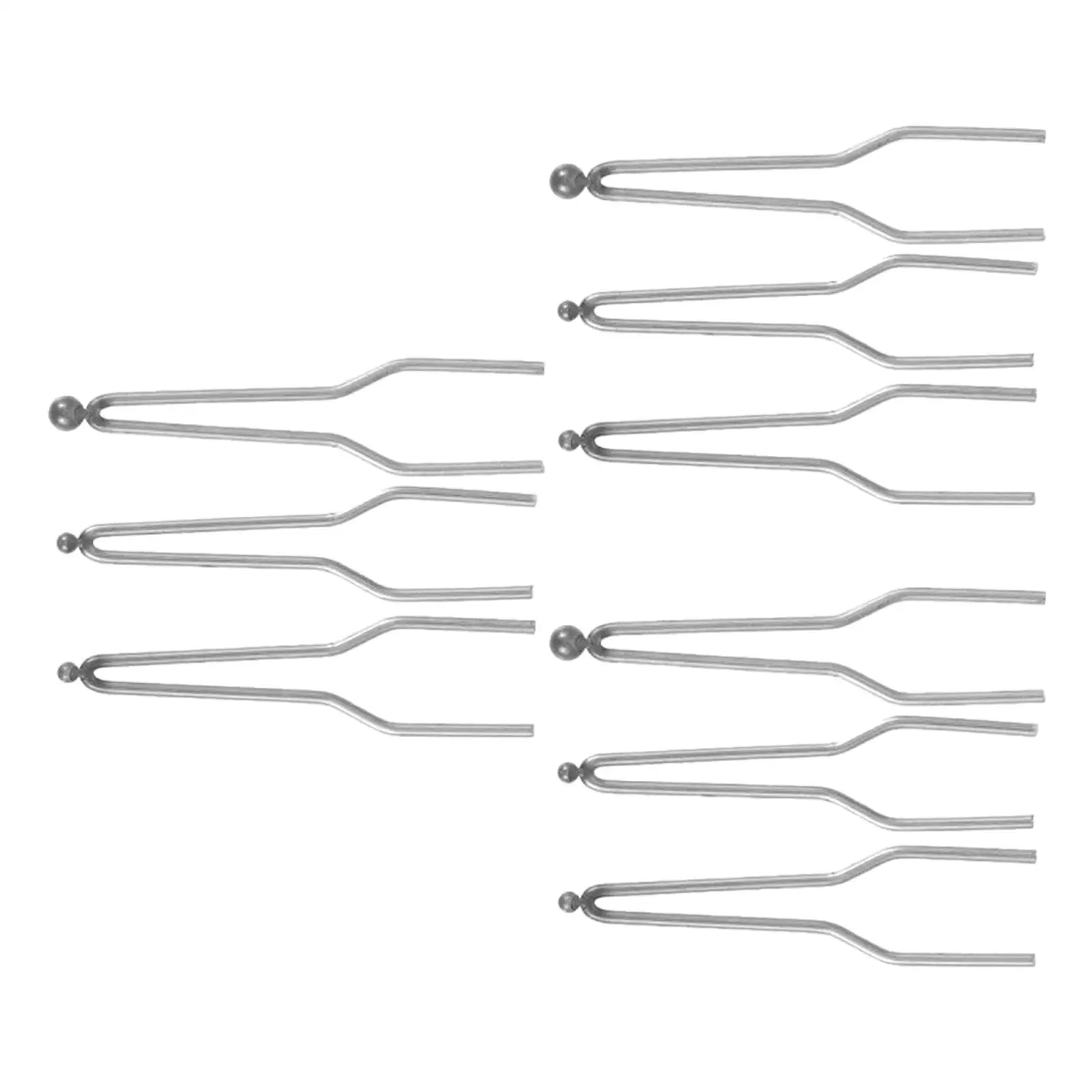

Shooting strings, also known as “V” strings, play a vital role in your lacrosse head’s performance. They endure significant stress during shots, passes, and face-offs. Applying wax to these strings offers several benefits:

- Weatherproofs the strings, protecting them from moisture

- Reduces stretching, maintaining consistent pocket shape

- Prevents early breakdown, extending the life of your strings

To wax your shooting strings effectively, use an old rag to thoroughly rub melted wax up and down the strings between each main wax application on the head. This extra step ensures that all components of your lacrosse head are protected and performing at their best.

Optimizing Wax Application for Different Weather Conditions

Weather can significantly impact your lacrosse mesh’s performance. How should you adjust your waxing technique for various weather conditions?

In hot weather, your wax may become softer and stickier. To combat this:

- Apply thinner coats of wax

- Allow more time for each coat to dry and harden

- Consider using a harder wax formulation

For cold weather play, your mesh may become stiff and less responsive. To address this:

- Apply slightly thicker coats of wax

- Focus on areas that receive the most ball contact

- Reapply wax more frequently to maintain flexibility

In wet conditions, proper waxing becomes even more crucial. Ensure thorough coverage of all mesh areas, including the sidewalls and shooting strings, to prevent water absorption and maintain consistent pocket shape.

Maintaining Your Waxed Lacrosse Mesh

Once you’ve waxed your lacrosse mesh, how can you maintain its performance over time?

Regular maintenance is key to preserving the benefits of a well-waxed lacrosse head. Follow these tips:

- Clean your mesh regularly with a soft brush to remove dirt and debris

- Reapply a thin coat of wax every few games or practices

- Pay attention to high-wear areas and reapply wax as needed

- Store your lacrosse head in a cool, dry place to prevent wax melting or degradation

By consistently maintaining your waxed mesh, you’ll ensure optimal performance and extend the life of your lacrosse head.

Common Waxing Mistakes to Avoid

Even experienced players can make mistakes when waxing their lacrosse mesh. What are some common pitfalls to watch out for?

Avoid these frequent waxing errors:

- Over-applying wax, which can lead to a gummy, unresponsive pocket

- Using the wrong type of wax, such as candle wax or pure beeswax

- Neglecting to wax the sidewalls and shooting strings

- Applying wax to a dirty or wet mesh

- Rushing the process and not allowing each coat to dry properly

By being aware of these common mistakes, you can ensure a more effective waxing process and better overall performance from your lacrosse head.

Advanced Waxing Techniques for Competitive Players

For competitive players looking to gain an edge, are there advanced waxing techniques to consider?

Indeed, some advanced players employ sophisticated waxing strategies to fine-tune their pocket’s performance:

- Selective waxing: Apply different amounts of wax to specific areas of the pocket to customize ball control and release

- Layering: Use multiple types of wax in layers to achieve a unique combination of hold and release

- Heat shaping: Carefully heat the waxed mesh to mold it into a specific shape for personalized pocket feel

- Wax blending: Mix different wax formulations to create a custom blend tailored to your playing style and conditions

These advanced techniques require practice and experimentation to master. Always start with small adjustments and test thoroughly before using in competitive play.

The Impact of Waxing on Different Mesh Types

Not all lacrosse mesh is created equal. How does waxing affect different types of mesh materials?

The impact of waxing can vary depending on the mesh type:

- Traditional nylon mesh: Absorbs wax well, becoming more water-resistant and durable

- Wax-coated mesh: Requires less frequent waxing but may benefit from occasional touch-ups

- Performance mesh: Often pre-treated, but can still benefit from light waxing for enhanced weatherproofing

- Synthetic leather mesh: May require special wax formulations designed for this material

Understanding your mesh type and its specific waxing needs can help you achieve optimal performance and longevity from your lacrosse head.

Environmentally Friendly Waxing Options

For environmentally conscious players, are there eco-friendly waxing alternatives available?

Yes, several environmentally friendly options exist for waxing lacrosse mesh:

- Natural beeswax blends: Offer good performance with minimal environmental impact

- Plant-based waxes: Made from renewable resources like soy or carnauba

- Biodegradable formulations: Break down naturally over time, reducing long-term environmental impact

- Recycled packaging: Look for waxes sold in recyclable or reusable containers

While these options may require some experimentation to find the right performance balance, they offer a way to maintain your lacrosse gear while minimizing your ecological footprint.

Waxing and Its Effect on Stick Checks

In competitive play, stick checks are a crucial part of the game. How does waxing impact the legality and performance of your stick during these checks?

Proper waxing shouldn’t negatively affect stick checks, but it’s important to be aware of the following:

- Excessive wax buildup can potentially cause your stick to fail a stick check

- Well-applied wax can actually help your stick pass checks by maintaining consistent pocket depth

- Some leagues have specific rules about wax application, so always check your league’s regulations

- Waxing can help your stick maintain its legal status by preventing stretching and bagging out

To ensure your stick remains legal and performs well during checks, maintain a consistent waxing routine and avoid over-application. Regular cleaning and proper wax distribution will help keep your stick in top condition for both performance and legality.

If you’ve ever played lacrosse, you know the importance of having a properly waxed mesh. A good coat of wax on your pocket can make all the difference when it comes to ball control, hold, and release. But waxing mesh can be tricky if you don’t know what you’re doing. After years of trial and error, I’ve learned a few pro tips that can help you avoid frustration and get the most out of waxing your lacrosse head.

Why Waxing Your Mesh Matters

Waxing the mesh on your lacrosse head serves a few key purposes. First, it helps to weatherproof the mesh so it doesn’t get saturated with moisture. This allows you to maintain the original pocket shape and performance even in wet conditions. Second, wax applied to the mesh and sidewalls helps reduce friction on the ball. This gives you quicker releases and more hold through your pass or shot. Finally, waxing helps strengthen the nylon mesh and prevent premature breakdown. With heavy use, un-waxed mesh can become brittle and fray. A good coat of wax protects those vulnerable areas.

Choosing the Right Type of Wax

Not all waxes are created equal when it comes to lacrosse mesh. You want to look for options specifically formulated for use on synthetic nylon mesh – from trusted brands like StringKing, Throne of String, and East Coast Dyes. Waxes likeBeeswax can work in a pinch but tend to be a bit tacky. The right lacrosse mesh wax will go on smooth, soak into the mesh well, and leave a nice tacky finish without being gummy or sticky on your hands. A small 4-8 oz tin should last you a full season or two even with regular re-applications.

Getting the Perfect Consistency

To get the wax consistency just right, it’s best to melt your wax in a double boiler or crock pot so you don’t scorch or burn it. Heating the wax too quickly can change the chemical composition. Once melted, test the consistency by dribbling a drop or two into a bowl of cold water. The ideal wax will solidify into a soft, pliable ball that slowly flattens out. Too thin and the wax won’t have enough tackiness or durability. Too thick and it won’t penetrate the mesh properly. Reheat and add a bit of water or oil if your lacrosse mesh wax comes out too thick.

Applying Wax to Brand New Mesh

When waxing a brand new lacrosse head, start by heating up your melted wax and prepping the head. Use a stiff nylon brush to gently rough up the surface of the mesh so the wax can penetrate better. Pay extra attention to the fray-prone areas along the sidewalls. Once ready, use a wax brush, foam brush, or old rag to liberally apply the wax along the diamonds, sidewalls, and shooting strings. Alternate dipping the brush into the wax and stroking across the mesh. For best results, apply 2-3 coats letting the wax fully dry in between.

Waxing an Already Broken-In Pocket

If your mesh is already broken in, you’ll need to be a bit more careful when applying wax. Too much buildup of wax in an older, bagged out pocket can be detrimental to your preferred ball feel and release. Use a damp paper towel to gently remove any built up dirt or debris from the pocket first. Next, apply thinner single coats of wax targeting the areas that need it most – typically the middle and lower parts of the pocket. Alternate vertical and horizontal brush strokes to work the wax into the diamond pattern.

Heating the Wax Properly

One of the biggest mistakes I see players make when waxing their mesh is overheating the wax. As I mentioned earlier, you always want to use indirect heat like a double boiler or slow cooker to melt your lacrosse mesh wax down. Direct stovetop heat can burn the wax and evaporate the lighter fluid components – leaving you with a thick, sticky goop. Keep your wax around 200F degrees, stir frequently, and remove from heat as soon as it’s fully melted. The wax should pour easily and appear transparent.

Using the Dip Method vs Brush

When applying wax, you can either repeatedly dip your head into the melted wax or use a brush to stroke it on. Dipping saturates the mesh well but can also create thick build up if you’re not careful. For most players, using a wax brush to liberally apply the melted wax results in more even coats with better precision. Alternate vertical and horizontal strokes across each diamond and pay extra attention to the fragile areas around the top and sidewalls. Let the wax fully dry and harden before re-dipping.

Waxing the Shooting Strings

Don’t forget to wax the shooting or “V” strings in your lacrosse head! These horizontal nylon strings take a beating on shots, passes, and during face-offs. Applying a coat of lacrosse mesh wax keeps them weatherproof, reduces stretching, and prevents early breakdown. Use an old rag to thoroughly rub melted wax up and down the shooting strings between each main wax application on the head. Rotate the head to access and wax the back side shooting strings as well.

Avoiding Common Mistakes

From burning the wax to over-saturating your pocket, it’s easy to mess up waxing lacrosse mesh if you aren’t careful. Don’t overheat the wax, don’t dip a heavily used head too much, and don’t apply thick layers without letting the wax dry in between coats. Thick, tacky build up will change how the ball feels in your stick. Take your time and apply thin even layers focusing on the diamonds, sidewalls, and shooting strings.

Removing Excess Wax

If you do end up with excess wax build up, don’t panic. Simply heat up some water in a pot on the stove and dip just the wax-heavy areas of the head in the hot water. The wax will soften for easy removal with a towel. You can also use a metal pick to gently scrape off any chunky build up. Re-apply thinner coats of wax after cleaning up any heavy spots.

Ensuring Proper Stringing After Wax

Once your lacrosse head is waxed, be sure to double check your pocket set up and stringing. In some cases, wax can cause the nylon strings to loosen up slightly or shift out of place. Make any tension adjustments needed after waxing to dial your pocket back in before hitting the field. Also check sidewall stringing holes for any open gaps where wax buildup may have occurred.

Maintaining Your Pocket

To keep your lacrosse head in top playing condition, aim to strip out and re-wax your mesh every 4-8 weeks during peak season. Use a plastic pick to lightly scrape built up layers before applying fresh wax. Spot treat high-wear areas as needed between full wax jobs. And don’t forget to re-wax your stick after any rainy games to restore tackiness and waterproofing.

When to Re-Wax Your Mesh

You’ll know it’s time to re-apply wax when your mesh loses its tacky grip, feels dry or brittle, or looks faded and weathered. Performance will start to suffer as ground balls slip through, passes miss high or low, and your rocket shot starts floating. Regripping your stick and fiddling with string tension can only do so much at that point. Whip out your mesh wax and breathe new life into that pocket.

Waxing Various Lacrosse Heads

While the waxing concept remains the same across all heads, slight technique adjustments may be needed depending on the brand and model of your lacrosse head. For example, heads with more intricate sidewall stringing may need extra attention around each hole and woven stitching. Wider heads may require more wax to fully saturate the mesh from side to side. Get to know the nuances of your head and optimize your waxing process accordingly.

Finding the Best Lacrosse Mesh and Wax

Using quality lacrosse products goes hand in hand with proper maintenance. Invest in reputable mesh brands like StringKing, Throne, and EastCoastMesh crafted from durable nylon blends. Match that with mesh wax from the same trusted brands, or wax specialists like Mesh Junkie. With the right gear and some helpful pro tips, you’ll be waxing your mesh like a pro in no time!

When it comes to getting the most out of your lacrosse stick, a properly waxed mesh is clutch. But not all waxes are created equal. The type of wax you choose can make or break your lacrosse game. After testing countless mesh waxes over my career, I’ve learned how to discern the good from the bad. Let’s dive into the nuances of picking the best lacrosse mesh wax for optimal performance.

Choosing the Right Type of Wax

Walk into any lacrosse retailer and you’ll likely find a whole wall of mesh wax options from various brands. It can be downright overwhelming trying to select the right one. Here are a few tips to simplify the process:

Look for Lacrosse-Specific Formulas

Not all waxes are made for synthetic nylon mesh. Avoid household waxes like beeswax or paraffin that are meant for wood and candles. Seek out waxes engineered specifically for lacrosse mesh and sidewalls. Brands like StringKing, Throne, and Mesh Junkie design their waxes to penetrate, condition, and weatherproof modern composite materials.

Consider Tackiness and Grip

The ideal lacrosse mesh wax leaves a tacky, grippy finish on the diamonds and sidewalls without feeling sticky on your hands. Less viscous “dipping” waxes make for quick application but often lack the tackiness you want. Heavier paste waxes can be too gummy. Look for wax with a smooth, moderately thick texture and nice grippy residue.

Factor in Durability

Durability goes hand in hand with longevity. A quality lacrosse mesh wax should maintain its performance through tons of catches, whip after whip, and wet conditions. Cheap waxes wear off quickly. Spend a little more for a reputable brand known to go the distance.

Read Reviews and Ask Around

Before buying any new lacrosse mesh wax, read up on product reviews and ask fellow players for recommendations. What works wonders for your buddy’s pocket may totally stiffen up yours. Take notes on which waxes get suggested most for your type of head and mesh.

Consider Weather Conditions

Think about when and where you primarily play lacrosse. In wet climates or during rainy seasons, prioritize waxes with maximum waterproofing. In dry heat, look for waxes that won’t get gummy as temperatures climb. Getting the right wax for your environment makes a big difference.

Test Wax Consistency

Once melted, test wax consistency by dripping a bit into cold water. It should solidify into a soft, flexible ball about the size of a marble. If it remains tacky or spreads out thin, the wax may be too viscous for mesh application. Adjust the ratio of wax to oil if needed.

Buy Sample Sizes

Unless you’re stocking a team, start out with 2-4oz sample or travel sized wax tins before committing to bulk supply. Dabble with a few formulations to find your favorite. You can always upsize once you’ve settled on “the one.”

Consider Value

While some elite waxes carry premium pricing, decent mesh wax can be found for less than $10. Calculate cost per ounce to assess relative value between products. Pay for quality but don’t overpay just for branding.

Ask Your Stringer

Professional lacrosse stringers work with all kinds of heads and waxes daily. Describe your stick specs and playing style and get their input on which wax might pair best. Tap into their expertise.

With so many wax options on the market, choosing the right one for your particular stick and game can be daunting. Keep these tips in mind, do your homework, and you’ll dial in a high performing mesh wax in no time. Just remember – when in doubt, ask around!

Now that you’ve got the perfect wax picked out, proper application is key. Let’s get into the nitty gritty of waxing your lacrosse stick like a pro…

You’ve got your lacrosse stick, your mesh wax, and you’re ready to optimize that pocket. But before globbing on the wax, it’s crucial to melt and temper it properly for ideal consistency. The right wax viscosity leads to smoother application, better absorption, and consistent performance. Let’s go over some pro tips for dialing in perfection.

Getting the Perfect Consistency

To achieve next-level consistency with your melted lacrosse mesh wax, focus on these key areas:

Use Low Indirect Heat

Always melt wax gently using a double boiler or slow cooker, NOT direct stovetop heat. High temperatures can burn the wax, altering the chemical composition. Keep your double boiler under 200°F, stirring periodically as the wax liquefies.

Consider Texture and Flow

Observe how the melted wax flows and its texture. It should pour smoothly like warm syrup. If overly thick like ketchup or thin like water, the consistency is off. Note if any residue clings to your stirring utensil.

Look for Transparency

Properly melted mesh wax takes on a clear, translucent look when heated, like honey. If it remains opaque or has dark specks, the wax may be overcooked. Caution is key with heat.

Test the Droplet

Drizzle a drop of melted wax into chilled water. It should hold its shape on the surface briefly before slowly sinking. If it disperses instantly or remains a bead, adjust the consistency.

Tweak the Formula

Add small amounts of oil to thin wax that comes out too thick. For wax that’s too thin, carefully reheat on low to evaporate excess moisture. Never boil or overheat.

Check Temperature Frequently

Monitor wax temperature often, especially if direct-heating. As soon as the melting point is reached, remove from heat. Overcooking alters the lacrosse wax’s molecular structure.

Consider Humidity & Climate

Environmental factors like humidity can impact wax viscosity. You may need to adjust the ratio of wax to oil to account for sticky or runny wax.

Use a Thermometer

Guessing the wax temperature by eye is risky. Invest in a candy/deep fry thermometer to accurately gauge temperature during melting.

Take Notes

Record details like melting time, max temp reached, consistency observations, and any formula tweaks made. Refer back to your notes for future melting sessions.

Cool and Remelt As Needed

If your melted wax consistency goes awry, let it cool and then remelt it carefully while making adjustments. Don’t continue using wax that’s overheated.

Dialing in the perfect lacrosse mesh wax consistency takes some trial and error. But once you’ve nailed down the ideal texture and viscosity for application, you’ll be reaping the benefits game after game. Keep these tips in mind and you’ll be waxing pro pockets like a pro.

Now that your mesh wax is prepped and ready, let’s get into the fun part – applying it to your head…

You just strung up a sweet new pocket in your fresh lacrosse head. Now it’s time to waterproof and optimize that mesh with some high quality wax. When waxing a brand new head, there are some techniques you’ll want to follow to prep the mesh and ensure maximum performance.

Applying Wax to Brand New Mesh

Follow these tips when waxing a new lacrosse head for the first time:

Rough Up the Diamonds

Use a stiff nylon brush to gently abrade the surface of the mesh. This helps the wax adhere better and penetrate deeper into the material. Focus on the diamonds first.

Prep the Sidewalls

Use the brush or a towel to rough up the sidewalls too. This is where fraying happens most over time. Prepping allows the wax to reinforce this vulnerable area.

Keep Wax Warm

Maintain your melted wax at around 170°F when waxing. Cooler wax won’t spread as easily. Use a thermometer to monitor the temperature.

Apply Thin, Even Coats

Use a foam brush or rag to apply the wax in smooth, thin layers. One thick globby coat can lead to stiffness. Build up 3-4 thin coats for best results.

Overlap Your Strokes

As you brush on the wax, slightly overlap each stroke rather than doing single passes. This helps ensure full coverage across the diamonds.

Go With the Diamond Pattern

Apply your wax strokes in alternating vertical and horizontal directions following the mesh diamond orientation. This packs wax neatly into each junction.

Work from Mid to Top

Start wax application in the center diamonds first, then move up towards the scoop area. Saving the fragile scoop area for last helps prevent excess buildup.

Let Dry Completely

Allow each coat to fully dry and harden before applying the next. Dabbing on too much wet wax leads to dripping and pooling.

Check for Gaps

Inspect for any bare spots you may have missed after each application. Touch up gaps before moving onto the next coat.

Remember the Shooting Strings

Don’t neglect your shooting strings! Apply a wax coating along the full length of the sidewall strings once the mesh waxing is complete.

With brand new mesh, taking your time is key. Rushing through the process can lead to an uneven wax job. Be patient and meticulous when prepping and waxing your new pocket for the first time. Your sticks skills will thank you!

Once you’ve broken that mesh in, wax maintenance becomes a whole different game. Let’s get into best practices for re-waxing older pockets…

So you’ve logged some serious hours on your lacrosse stick and that pocket is nice and broken in. Your precious mesh likely needs some TLC to keep it in top playing form. When it comes to re-waxing an already worn pocket, a delicate touch is required. Let’s go over some best practices.

Waxing an Already Broken-In Pocket

Follow these pro tips when re-applying wax to an older, broken-in lacrosse mesh pocket:

Clean Out Debris

Use a damp cloth to gently wipe away built-up dirt, ball wax, and debris from the diamonds and sidewalls. You want to start with a clean foundation.

Assess Wear Patterns

Note where the pocket shows the most wear like the midsection, scoop, and sidewalls. Focus extra wax attention on those high-friction spots.

Spot Treat Heavily

Rather than fully re-waxing, spot treat the most worn areas. This prevents altering your primed pocket’s sweet spot.

Apply Lighter Coats

With an older head, build up just 1-2 thin wax layers. Too much can overload the pocket, impacting ball feel and release.

Scrape Off Excess Built Up Wax

Use a mesh pick to gently scrape and peel off any thick wax buildup before applying fresh coats. You want a smooth, even surface.

Reinforce Sidewalls

Pay extra attention to re-waxing sidewall strings to restore waterproofing, reduce friction, and prevent premature fraying.

Check Shooting Strings

Examine shooting strings for wear and re-wax along the entire length to maintain tackiness and suppleness.

Work Wax into Diamond Pattern

As you apply new wax, vigorously work it into the diamond shaped stitching pattern to fill gaps and permeate the mesh.

Let Fully Dry and Set

Allow fresh wax applications to dry before playing to prevent transfer and wiping off onto balls. Patience pays off.

Maintain Original Pocket Shape

Re-wax with care to avoid impacting your primed pocket’s hold, release and overall mojo. Less is more on worn mesh.

With some finesse and thoughtful technique, you can keep that buttery broken-in pocket playing like new. Remember – gently does it when re-waxing well-loved mesh.

Next let’s get into best practices for heating and prepping your mesh wax…

You’ve got your mesh wax ready to go – now comes the key step of melting it down properly for ideal viscosity and application. Heating mesh wax requires finesse and caution to get it just right. Follow these pro tips when prepping your lacrosse wax for melting.

Heating the Wax Properly

Proper heating is crucial when preparing mesh wax. Here are some key best practices:

Use a Double Boiler

Always melt wax gently using a double boiler, NOT direct stovetop heat. The indirect steam heat prevents burning or scorching the wax.

Low and Slow

Heating the wax over medium-high direct heat can alter the delicate chemical composition. Keep temperatures under 180°F and stir slowly.

Maintain the Molten State

Once melted, keep the wax warm enough to stay liquefied for application but not so hot it starts evaporating. The goal is a thick, even viscosity.

Monitor Temperature Diligently

Use a candy/fry thermometer and watch wax temperature closely as it melts. As soon as it reaches around 170°F, remove from heat.

Don’t Let it Boil

If you see bubbling or boiling during melting, the wax is way too hot. Turn down the temperature to prevent burning.

Stir Slowly and Thoroughly

Gently stir the melting wax often to evenly distribute heat. But avoid vigorous stirring that introduces air bubbles.

Maintain a Low Flame

Keep the heat source low even after melting is complete. This keeps the wax fluid without continuing to cook.

Watch for Specks and Residue

Overheated wax can take on dark flecks. If the wax leaves gunky residue on your spoon, it’s likely overcooked.

Add Oil If Too Viscous

If your melted wax is too thick for dipping or brush work, stir in small amounts of mesh wax oil to thin it.

Avoid Reheating Multiple Times

For ideal consistency, try not to remelt a batch of wax more than once or twice. Frequent remelting alters the structure.

With care, patience and the right technique, you can melt mesh wax flawlessly every time. Nail down the wax heating process, and application success will surely follow.

Speaking of application methods, let’s explore the dip versus brush techniques next…

You’ve perfectly prepped your mesh wax and now it’s go time. But should you repeatedly dip the head in the wax or use a brush to stroke it on? Both techniques have their pros and cons. Let’s dive into the nuances of the dip versus brush wax application methods.

Using the Dip Method vs Brush

When it comes to getting mesh wax onto your lacrosse head, you’ve got two primary options – dipping or brushing. Here’s how they compare:

Dip Method

Dipping involves repeatedly submerging your lacrosse stick into the melted wax for a few seconds per dip. This allows the wax to fully saturate the diamonds, sidewalls and shooting strings.

Dip Pros

Dipping is quick and delivers wax efficiently into all crevices of the head. It provides excellent waterproofing and protection when done correctly.

Dip Cons

Too much dipping can lead to excessive buildup, restricting pocket movement. Newer heads with thicker sidewall stringing are prone to developing “wax bumps.”

Brush Method

Using a wax brush, foam brush or cloth, this technique involves scooping up wax and gently applying it to the head section by section.

Brush Pros

Brushing allows more precision and control over wax application. You can target high-friction areas while going lighter on other spots.

Brush Cons

Brushing takes more time and effort than dipping. It can be tough fully penetrating intricate sidewall lace areas. The bristles can pull and distort older mesh.

The Verdict?

For brand new mesh on strung heads without a pocket, repeated dipping tends to work best. For re-waxing an older broken-in pocket, a delicate brush application approach is ideal.

Best of Both Worlds

You can use a hybrid approach for the best of dipping and brushing. Try 2-3 dips across the head then use a brush for precision touch ups and smoothing out.

Test out both techniques on scrap mesh to see what works for your style. Finding your waxing groove takes some trial and error. Master dipping first, then incorporate brush work as you advance your lacrosse head waxing game!

Speaking of mastering techniques, avoiding common mistakes is critical for waxing success…

You’ve got your diamonds dialed in, but don’t forget about those shooting strings! Properly waxing the sidewall nylon strings on your lacrosse head is just as important as the mesh itself. Let’s get into best practices for keeping your shooting strings optimized.

Waxing the Shooting Strings

Follow these pro tips when waxing your lacrosse head’s shooting strings:

Assess Condition

Inspect the sidewall strings for any fraying, weathering, or areas that need reinforcement. This will guide where to focus wax application.

De-Gunk First

Use a damp rag to remove built-up dirt, debris, and ball wax from shooting strings before applying new wax. Start with a clean slate.

Warm That Wax

Heating the wax slightly before shooting string application allows better absorption and coating. Ideal temp is around 150°F.

Apply Along Entire Length

Run wax thoroughly along the full length of sidewall strings – top to bottom. Don’t just spot treat the middle.

Get Between Strings

Push wax down into the grooves between woven shooting strings using a pick. Flossing boosts penetration.

Overlap Strokes

When applying wax to shooting strings, slightly overlap each stroke rather than doing single passes for full coverage.

Reinforce Anchor Points

Pay extra attention waxing where sidewall strings anchor to the head. These junction points see lots of friction.

Consider Cross-Strings Too

Don’t forget to wax horizontal cross-strings in specialty heads like the CEO and Clutch Crux. They need love too!

Alternate Sides

Work back and forth waxing both top and bottom sidewall strings to spread coverage evenly.

Let it Dry

Allow wax on shooting strings to fully dry and set before playing to prevent gumming up balls.

Buff it Out

Use a microfiber cloth to gently buff out any wax residue for smooth strings post-application.

Don’t neglect those working-class shooting strings! Keep them primed, protected and slick with proper periodic re-waxing alongside your mesh. Take care of your sidewalls and they’ll take care of you!

Now let’s get into some common newbie mistakes to avoid when waxing your pocket…

Waxing your lacrosse stick doesn’t have to be frustrating and full of trial and error. Learn from those who have made every mesh waxing mistake in the book so you don’t have to! Let’s review some common pitfalls to avoid when prepping and waxing your pocket.

Avoiding Common Mistakes

Steer clear of these frequent errors when waxing your lacrosse mesh and shooting strings:

Overheating the Wax

High direct heat alters wax’s chemical makeup. Use a double boiler and keep temperatures under 180°F. Burnt wax can’t penetrate mesh properly.

Rushing the Process

Proper prep and multiple thin coats make a difference. Don’t fly through waxing in 5 minutes and expect superb results. Take your time.

Applying Gobs of Wax

Avoid slapping on a single thick layer. Build up 3-5 THIN coats, allowing drying in between. Too much wax overload stiffens pocket movement.

Forgetting to Prep Diamonds

Lightly roughing up new mesh first allows better wax adhesion. Don’t skip this key step for brand new pockets.

Skipping the Sidewalls

Failing to wax sidewalls leaves these areas vulnerable to premature fraying and wear. Hot wax helps reinforce.

Waxing an Overused Head

Excessive waxing on a super bagged out and worn pocket alters the feel. Use restraint on vintage sticks.

Waxing in Humid Conditions

Waxing outdoors in high humidity can impact drying and consistency. Hot garage waxing is risky.

Not Letting it Fully Dry

Wet wax transfers onto balls ruining the grip. Allow at least 30 mins drying time before throwing.

Using Petroleum-Based Wax

Automotive and other waxes contain chemicals that can degrade mesh fibers. Use only lacrosse formulated wax.

Overlooking Shooting Strings

Skipping wax on sidewall strings misses a key friction zone. Shooters need love too!

We all mess up mesh waxing sometimes. Learn from those mistakes, laugh them off, and get back out there with confidence. Follow these tips and avoid the pitfalls as you master pocket waxing.

Next let’s get into cleaning up any accidental waxing mishaps or overload…

Uh oh, you got a little overzealous with the wax and now have some thick clumpy buildup. Don’t panic! Excess wax is common but can be removed with care. Let’s go over some techniques for cleaning away globby mesh wax overload.

Removing Excess Wax

Try these methods to remove wax buildup from your lacrosse head and restore pocket performance:

Heat it Up

Dip just the wax-heavy areas into hot water to soften the buildup. Hot water makes excess wax pliable for easy removal.

Gently Scrape

Use a plastic lacrosse mesh pick to gently scrape and lift away any chunky dried wax clumps after softening with heat.

Blur the Lines

For soft remnants after scraping, use your thumb to gently rub the wax remnants into the surrounding diamonds to blend.

Clean With Rubbing Alcohol

Use 90% isopropyl alcohol on a rag to wipe away any last traces of stubborn excess wax buildup.

Rinse Thoroughly

After using solvents, rinse the head well with clean water to remove any residual chemical smell or taste.

Re-Prep the Surface

Once excess wax is removed, do some light surface scuffing again before reapplying. This aids adhesion.

Reapply Thin Layers

Moving forward, build up just 1-2 super thin lacrosse mesh wax layers to avoid heavy buildup.

Focus on Key Areas

When reapplying after removal, just spot treat key friction zones rather than the entire head.

Brush Between Coats

Use a nylon brush to gently remove any wax globs before adding additional thin coats.

Check Your Technique

Analyze what went wrong to cause excess wax. Were coats too thick? Did you dip too long? Adjust accordingly.

With some heat, elbow grease, and a delicate touch you can rectify any mesh wax mishaps. Just remember – less is often more when it comes to wax for optimized lacrosse pocket performance.

Speaking of dialing in your pocket, proper stringing tension after waxing is essential…

You’ve dialed in the perfect wax job and pocket. But before hitting the field, it’s crucial to check stringing tension and adjustments post-waxing. The waxing process can subtly impact pocket setup. Let’s go over some best practices for dialing your strings back in.

Ensuring Proper Stringing After Wax

Follow these steps for optimizing stringing after waxing your lacrosse head:

Give it Time

Allow wax at least 24 hours of cure time before making any stringing adjustments. The wax needs to fully dry and stabilize.

Re-Tighten Sidewalls

Heat and wax can loosen sidewall strings. Carefully tighten back up to restore tautness without over-tightening.

Work the Pocket

After re-tightening, work the pocket by flexing the head and rolling balls around. This helps set the wax.

Check Shooting Strings

Ensure shooting strings are still evenly spaced and taut. Re-adjust knots if needed to realign symmetry.

Re-Set Mid-Pocket

Loosen or tighten mid-diamond strings as needed to re-calibrate your ideal mid-pocket depth and hold after waxing.

Keep It Balanced

Ensure even horizontal pocket symmetry by comparing the angle of the right and left mid-diamonds.

Test Ball Feel

Roll balls around the re-waxed pocket and make micro-adjustments until you restore the exact hold and release sweet spot.

Maintain Contour Shape

Be cautious not to over-tighten after waxing to the point of deforming your ideal pocket shape.

Check Scoop Angles

Ensure upper diamonds near the scoop have the same angles on each side for proper ball guiding.

Examine Sidewall Hole Gaps

Look for any open gaps around sidewall stringing holes that may need re-treatment with wax.

Take your time dialing your pocket and shooting strings back in after waxing. Small adjustments make a big difference in performance. Don’t rush – a properly tuned pocket is worth the effort.

To maintain that dialed-in feel over time, proper wax maintenance is crucial…

You put in the work getting that pocket waxed and tuned just right. Now it’s time to keep it primed for max performance. Proper maintenance is key for preserving your dialed-in pocket setup long-term. Let’s explore best practices for keeping your mesh and strings in top playing condition.

Maintaining Your Pocket

Follow these tips for keeping a lacrosse pocket in peak form over time:

Store Properly

Keep sticks stored in a climate-controlled environment. Avoid excess heat, cold, or humidity which can impact wax condition.

Remove Debris

Use a stiff brush or damp cloth to regularly remove built-up dirt, ball wax, and debris from the pocket and sidewalls.

Frequently Spot Wax

Spot apply mesh wax to high-friction areas as needed between full wax jobs. This touch-up helps a ton.

Check for Fraying

Inspect for any loose fibers, fraying, holes forming, or damage needing repair. Fix issues promptly.

Feel for Stiff Spots

Run your hand over the pocket feeling for any stiff or rigid spots indicating diminishing wax. Re-wax as needed.

Maintain Shooting Strings

Watch for loose, sagging, or worn shooting strings. Tighten knots or re-wax promptly when detected.

Monitor Pocket Depth

Ensure consistent pocket depth and mid-channel shape by checking ruler measurements periodically.

Keep Pocket Hydrated

Apply light lacrosse mesh oil between waxings to nourish and restore suppleness as needed.

Replace Mesh Proactively

At first signs of irreparable damage or deterioration, swap out older mesh for fresh pockets.

Re-Wax Every 4-8 Weeks

During peak season, maintain wax integrity by fully re-waxing pockets at least once a month.

With consistent inspection, prompt tune-ups, and proper storage your primed lacrosse pocket will maintain its peak playability for seasons to come.

Knowing when to re-wax is also key. Let’s get into indicators it’s time for a refresh…

A perfectly waxed lacrosse pocket doesn’t last forever. As wear and tear take their toll, you’ll eventually need to re-wax and restore that like-new performance. But when exactly is it time to break out the mesh wax and re-treat your head? Let’s go over the signs indicating a re-wax is in order.

When to Re-Wax Your Mesh

Watch for these cues that your lacrosse head needs fresh wax:

Visible Fraying

Fraying and loose thread fibers around the scoop, sidewalls, or shooting strings means the protective wax barrier has worn off.

Weathered Appearance

Faded, dull-looking mesh color and strings indicate UV damage and material breakdown. Time to re-protect.

Pocket Bag Out

Over-use can cause pocket bags to sag. Re-waxing supports shape and hold.

Stiffness

Rigid diamonds or “crunchiness” when squeezing the head mean the wax has dried out and new application is needed.

Loss of Tackiness

Mesh lacks grip when you rub it between your fingers. That’s the wax wearing off.

Poor Ball Control

Frequent dropped balls, inaccurate passing, and lack of hold signal a refresher is overdue.

4-8 Weeks of Use

Regardless of look and feel, re-wax every 1-2 months during peak playing seasons for protection.

After Rain Games

Re-apply wax after significant rain exposure to restore waterproofing and suppleness.

Off-Season Storage

Before storing sticks for the off-season, give them a fresh wax coating for protection.

Re-waxing more often than necessary risks buildup and over-saturation. But letting wax wear too thin leaves pockets unprotected. Evaluate above signs to know when the time is right.

The re-waxing technique depends on the type of head. Let’s get into best practices for various lacrosse heads…

While waxing concept are generally universal across lacrosse sticks, you may need to tailor your technique based on the specific head model. Certain heads require additional care and finesse to get an ideal wax job. Let’s go over some head-specific factors to consider.

Waxing Various Lacrosse Heads

Follow these tips when waxing popular lacrosse head types:

Open Sidewall Heads

Heads with open sidewall stringing like Mark 2s require extra wax attention on those exposed areas. Work wax thoroughly into the sidewall lace.

Deep Pocket Heads

Decker and other deep pocket heads often have more exaggerated mid-channels. Use thin coats focusing on mid-diamonds to avoid over-saturation.

Pinched Head Designs

In pinched heads like Saber, be extra diligent waxing around the narrower bottom sidewalls prone to early fraying.

Wider Heads

With wider heads, don’t forget to wax across the entire width of the scoop and sidewalls for full coverage.

Offset Heads

On offset heads, match the angle of your wax strokes to the diamonds to ensure uniform penetration into the mesh pattern.

Specialized Pockets

For unique pockets like V and U shapes, apply thinner coats focused only where needed to avoid altering pocket geometry.

Composite Materials

New age composite heads require mesh wax designed for modern fibers. Traditional wax won’t penetrate or adhere as well.

Wooden Heads

Vintage wooden heads need greater care around moisture. Take time fully drying the wax before use to prevent warping.

While the basic waxing procedure remains the same, each head has its nuances. Get to know the intricacies of your particular setup and optimize technique accordingly. The right touch makes a big difference.

Of course, stellar equipment also plays a role. Let’s discuss considerations around finding the best mesh and wax products…

Waxing a lacrosse head right requires having the right gear. Quality mesh and wax make a huge difference in performance and durability. Let’s go over factors to consider when selecting the best lacrosse mesh and wax for your game.

Finding the Best Lacrosse Mesh and Wax

Keep these key criteria in mind when choosing mesh and wax:

Reputable Brands

Trust known lacrosse companies like StringKing, ECD, and Throne for engineered mesh and formulated wax that maximize playability.

Weatherproofing

Ensure waxes provide UV protection, water resistance, and restore suppleness to maintain pocket integrity.

Compatible Materials

Match wax to modern mesh materials like Dyneema, Dynalax, and nylon composites for ideal synergy.

Premium Fibers

Invest in elite mesh crafted from durable high-grade woven fibers that wax protects rather than stiffens.

Flexible Diamonds

Quality mesh should have supple diamonds that move naturally. Stiff, rigid mesh won’t soften well with wax.

Hybrid Wax Mixes

Look for hybrid wax blends like beeswax, pine tar, and synthetic polymers for balanced grip and glide.

Tacky Finish

The right lacrosse mesh wax leaves a grippy but not sticky residue for excellent ball control.

Smoothing Agents

Waxes with oils, butters, or emulsifiers spread evenly and absorb fully into mesh diamonds.

Melt Point

Ensure wax melts at appropriate temperatures – around 170°F is ideal for proper liquefying and application.

Value

Consider price per ounce between waxes, but don’t sacrifice quality just to save a buck.

Take the time to find mesh and wax well-suited to your particular game for a winning combo. Quality gear optimizes the waxing process and performance.