What are the key differences between natural and synthetic rubber boots. How do durability, flexibility, and waterproofing compare. Which material offers better chemical and electrical resistance. What factors should you consider for comfort, sustainability, and cost-effectiveness.

The Battle of Materials: Natural Rubber vs Synthetic in Boot Manufacturing

When embarking on the quest for the ideal pair of brown rubber boots, the choice between natural rubber and synthetic materials stands as a crucial crossroads. Both options present unique advantages and potential drawbacks, making it essential to weigh various factors before making a decision. Let’s delve into the key aspects that differentiate these materials and how they impact your boot-wearing experience.

Durability and Longevity: Which Material Stands the Test of Time?

Natural rubber often takes the lead in terms of durability. Derived from the sap of rubber trees, it boasts a robust polymer structure that resists cracking and deterioration from regular wear and tear. This inherent strength allows natural rubber boots to withstand heavy use and abrasion better than many synthetic alternatives.

How long can you expect natural rubber boots to last? With proper care, high-quality natural rubber boots can serve you well for several years, often outlasting their synthetic counterparts. However, it’s important to note that not all synthetic boots are created equal. Some advanced synthetic materials can rival natural rubber in longevity, especially when reinforced with additional protective layers.

Factors Affecting Boot Durability

- Material quality and thickness

- Manufacturing process

- Frequency and intensity of use

- Exposure to harsh environmental conditions

- Proper maintenance and storage

Flexibility and Comfort: Finding the Right Balance for Your Feet

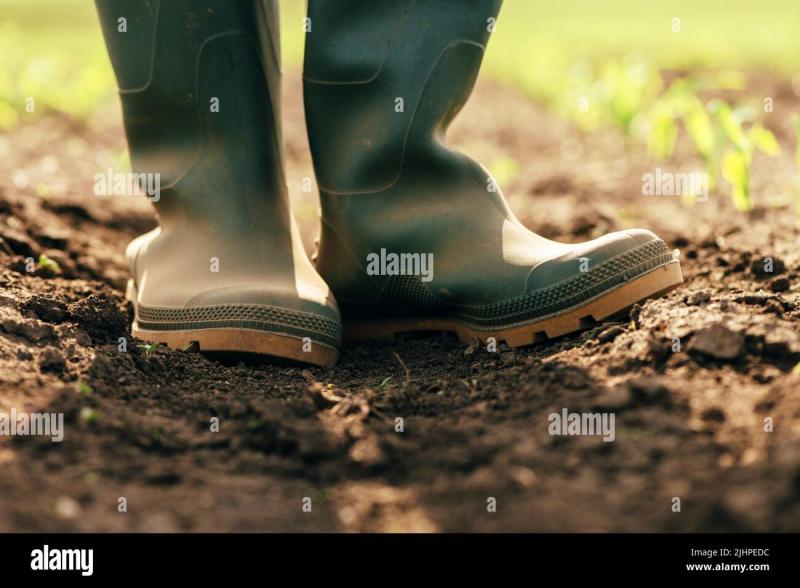

When it comes to flexibility and ease of movement, natural rubber often outperforms synthetic materials. The inherent elasticity of natural rubber allows your feet to bend and flex naturally as you walk, providing a more comfortable and responsive feel. This characteristic makes natural rubber boots particularly well-suited for activities that require a lot of movement, such as farming, gardening, or hiking.

![]()

Are synthetic boots always less flexible? Not necessarily. While many synthetic boots can feel stiffer and more restrictive compared to natural rubber, advancements in material science have led to the development of more flexible synthetic compounds. Some high-end synthetic boots now offer comparable flexibility to their natural rubber counterparts.

Enhancing Boot Comfort

- Choose the right size and fit

- Look for boots with cushioned insoles

- Consider boots with breathable linings

- Opt for models with ergonomic designs

- Break in your boots gradually

Traction and Grip: Staying Steady on Slippery Surfaces

The sticky, grippy nature of natural rubber provides exceptional traction on slippery surfaces. Natural rubber boots cling tenaciously to muddy ground, helping prevent falls and accidents in challenging conditions. This adhesive quality is particularly valuable for those working or spending time in wet, slick environments.

How do synthetic boots compare in terms of traction? While they may not match the innate adhesive properties of natural rubber, many synthetic boots utilize advanced slip-resistant lugs and tread patterns to enhance grip. These engineered solutions can provide excellent traction, especially on specific types of surfaces.

Factors Influencing Boot Traction

- Outsole material composition

- Tread pattern design

- Depth and spacing of lugs

- Softness or hardness of the rubber compound

- Surface characteristics (wet, dry, muddy, icy)

Waterproofing Capabilities: Keeping Your Feet Dry in Wet Conditions

When properly vulcanized, natural rubber is inherently waterproof and water-resistant. Its tight polymer structure effectively seals out moisture, making it an excellent choice for wet environments. Natural rubber boots can maintain their water-repelling abilities for years, even with regular exposure to wet conditions.

Do synthetic boots offer comparable waterproofing? Many synthetic boots utilize specialized coatings and membranes to achieve waterproofing. While these technologies can be highly effective, they may require more maintenance or reapplication over time to maintain their water-resistant properties.

Maximizing Waterproof Performance

- Regularly clean and inspect your boots

- Apply waterproofing treatments as recommended

- Ensure proper fit to prevent water entry at the top

- Use gaiters for additional protection in extreme conditions

- Allow boots to dry thoroughly between uses

Chemical and Electrical Resistance: Safety in Hazardous Environments

Natural rubber offers superior resistance to oils, acids, petroleum, and other caustic chemicals. Its impervious barrier prevents absorption or degradation, making it an ideal choice for those working in environments where exposure to corrosive substances is a concern. Additionally, natural rubber acts as an electrical insulator, providing a high degree of protection against accidental shocks and electrocution hazards.

Can synthetic boots match these protective qualities? The chemical and electrical resistance of synthetic boots can vary greatly depending on the specific materials and manufacturing processes used. Some advanced synthetic compounds offer excellent chemical resistance, while others may be more vulnerable to degradation. Similarly, static-dissipative synthetic blends can provide electrical protection, though they may not reach the same level of insulation as natural rubber.

Key Considerations for Hazardous Environments

- Specific chemical exposures in your work environment

- Required electrical safety ratings

- Frequency and duration of exposure to hazards

- Compatibility with other personal protective equipment

- Regulatory compliance and industry standards

Temperature Tolerance: Performance in Extreme Conditions

Natural rubber excels across a wide temperature range, maintaining its flexibility and performance from frigid winter days to sweltering summer afternoons. It can remain pliable even in temperatures as low as -60째F (-51째C) and withstand heat up to 280째F (138째C) before beginning to melt. This broad thermal stability makes natural rubber boots versatile for various climates and seasons.

How do synthetic boots perform in extreme temperatures? Synthetic materials typically have a narrower window of thermal stability compared to natural rubber. Some synthetic boots may become brittle in very cold conditions or soften excessively in high heat. However, specialized synthetic compounds designed for extreme temperatures can offer comparable or even superior performance in specific conditions.

Adapting to Temperature Extremes

- Choose boots rated for your expected temperature range

- Use appropriate socks or liners for insulation

- Allow boots to acclimate to temperature changes gradually

- Consider using boot warmers in extremely cold conditions

- Store boots properly to prevent temperature-related damage

Environmental Impact and Sustainability: Making an Eco-Friendly Choice

For those prioritizing sustainability, natural rubber often emerges as the more eco-friendly option. Derived from a renewable resource, the production of natural rubber typically has a lower environmental impact compared to oil-based synthetic materials. Natural rubber is also biodegradable, reducing its long-term impact on ecosystems.

Are all synthetic boots environmentally unfriendly? Not necessarily. Advancements in technology are making synthetic materials greener. Some manufacturers now use recycled materials or bio-based synthetics to reduce environmental impact. Additionally, the durability of high-quality synthetic boots can contribute to sustainability by reducing the frequency of replacements.

Factors Influencing Environmental Impact

- Source of raw materials

- Manufacturing processes and energy consumption

- Transportation and distribution methods

- Product lifespan and durability

- End-of-life disposal or recycling options

Cost Considerations: Balancing Quality and Budget

When comparing boots of similar quality, synthetic rubber options tend to be more affordable than their natural rubber counterparts. The large-scale production of synthetic materials often results in lower manufacturing costs, which can be reflected in the final price of the boots.

Does this mean synthetic boots are always the more economical choice? Not necessarily. While natural rubber boots may have a higher upfront cost, their durability and longevity can make them more cost-effective in the long run. By lasting longer and requiring fewer replacements, high-quality natural rubber boots can provide better value over time.

Factors Affecting Boot Costs

- Material quality and sourcing

- Manufacturing complexity

- Brand reputation and marketing

- Additional features and technologies

- Distribution and retail markup

Allergies and Sensitivities: Ensuring Comfort and Safety

One significant consideration when choosing between natural and synthetic rubber boots is the potential for allergic reactions. Natural rubber latex can pose allergy risks for some individuals, with reactions ranging from mild skin irritation to severe anaphylaxis. For those with known latex sensitivities, synthetic rubber boots eliminate this danger.

Are all natural rubber boots equally allergenic? Not all natural rubber products contain the same levels of allergenic proteins. Some manufacturers use processes to reduce these proteins, making their boots less likely to cause reactions. However, individuals with severe latex allergies should exercise caution and consult with healthcare professionals before choosing natural rubber boots.

Managing Boot-Related Allergies

- Check product labels for latex content

- Consider hypoallergenic boot options

- Use barrier creams or liners if necessary

- Monitor for any signs of allergic reactions

- Consult with an allergist for personalized advice

Maintenance and Care: Keeping Your Boots in Top Condition

The ease of cleaning and maintaining your brown rubber boots can significantly impact their longevity and performance. Natural rubber’s smooth finish often makes mud and muck easy to rinse off with water, simplifying the cleaning process. However, the textured surfaces of some synthetic boots may trap debris in grooves and treads, requiring more thorough cleaning.

Does this mean synthetic boots are always harder to maintain? Not necessarily. While the cleaning process may differ, both natural and synthetic rubber boots benefit from regular care and maintenance. Proper cleaning, drying, and storage practices can extend the life of any rubber boot, regardless of its material composition.

Essential Boot Maintenance Tips

- Clean boots after each use

- Remove insoles to dry separately

- Use appropriate cleaning products

- Store boots in a cool, dry place away from direct sunlight

- Regularly inspect for damage and repair as needed

Style and Aesthetics: Finding the Perfect Look

While functionality is crucial, the appearance of your brown rubber boots can also be an important factor in your decision. Natural rubber boots often have a classic, timeless look that appeals to traditionalists and those seeking an authentic outdoor aesthetic. The natural sheen and texture of rubber can develop a unique patina over time, adding character to the boots.

Can synthetic boots match the style of natural rubber? Absolutely. Synthetic materials offer versatility in design and color options, allowing manufacturers to create a wide range of styles from sleek and modern to rugged and traditional. Some synthetic boots are designed to closely mimic the appearance of natural rubber, providing similar aesthetics with different material properties.

Factors Influencing Boot Aesthetics

- Color and finish options

- Boot height and shaft design

- Sole and tread patterns

- Decorative elements and branding

- Aging and wear characteristics

Specialized Features: Addressing Specific Needs

Both natural and synthetic rubber boots can be enhanced with specialized features to meet specific needs or preferences. These additions can significantly impact the functionality and comfort of the boots, making them better suited for particular activities or environments.

What types of specialized features are available? Common enhancements include reinforced toe caps for added protection, quick-drying linings for moisture management, adjustable gussets for a custom fit, and advanced insulation for extreme temperatures. Some boots also incorporate technologies like shock-absorbing midsoles or antimicrobial treatments to prevent odor.

Popular Specialized Boot Features

- Steel or composite toe protection

- Removable and washable insoles

- Reflective elements for visibility

- Side zippers for easy on/off

- Heel kick plates for hands-free removal

Brand Reputation and Quality Assurance

When choosing between natural and synthetic rubber boots, considering the reputation of the brand and its commitment to quality can be crucial. Established brands with a history of producing reliable rubber boots often have refined their manufacturing processes and material selections to deliver consistent performance.

Does a well-known brand always guarantee quality? While reputable brands generally maintain high standards, it’s important to research specific models and read user reviews. Some lesser-known brands may offer excellent quality at competitive prices, while even established brands can have varying levels of quality across different product lines.

Evaluating Brand Quality

- Research company history and values

- Read customer reviews and testimonials

- Check for industry certifications and standards compliance

- Examine warranty and return policies

- Consider the brand’s customer service reputation

In conclusion, the choice between natural and synthetic rubber boots depends on a complex interplay of factors, including durability, comfort, performance in specific conditions, environmental impact, and personal preferences. By carefully considering these aspects and prioritizing the features most important to your needs, you can find the perfect pair of brown rubber boots to keep you comfortable, protected, and stylish in any environment.

Material – Choose between natural rubber or synthetic materials

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

When it comes to selecting the ideal pair of brown rubber boots, one of the most important decisions you’ll make is whether to go with natural rubber or synthetic materials. Both have their advantages and drawbacks, so let’s dive into the key factors to think about.

1. Durability

If longevity is your top priority, natural rubber may be the way to go. Made from the sap of rubber trees, natural rubber stands up to heavy use and abrasion better than synthetic alternatives. The robust polymer structure resists cracking and deterioration from regular wear and tear. Synthetics can be durable too, but may start to show signs of breaking down sooner.

2. Flexibility

For maximum flexibility and ease of movement, natural rubber again excels. The elasticity allows your feet to bend and flex naturally as you walk, while synthetics can feel stiff and restrictive in comparison. This responsiveness and “give” make natural rubber boots more comfortable for activities like farming, gardening and hiking.

3. Traction

The sticky, grippy nature of natural rubber creates unbeatable traction on slippery surfaces. The boots cling tenaciously to muddy ground, helping prevent falls and accidents. Synthetics often utilize slip-resistant lugs and treads instead, which perform well but may not quite match the adhesive quality of natural rubber.

4. Waterproofing

When properly vulcanized, natural rubber is inherently waterproof and water-resistant, sealing out moisture with its tight polymer structure. Synthetics utilize coatings and membranes to achieve waterproofing instead. Both get the job done, but natural rubber may better withstand years of exposure to wet conditions without its water-repelling abilities breaking down over time.

5. Chemical Resistance

Natural rubber offers superior resistance to oils, acids, petroleum and other caustic chemicals. Its impervious barrier prevents absorption or degradation. Synthetics vary greatly in their chemical tolerance, with some faring poorly. If you’ll encounter corrosive substances, natural rubber is the safest bet.

6. Temperature Tolerance

From frigid winter days to sweltering summer afternoons, natural rubber excels across a wide temperature range. It stays flexible even down to -60°F and can withstand heat up to 280°F before melting. Synthetics have a narrower window of thermal stability, potentially becoming brittle in very cold conditions.

7. Tear and Puncture Resistance

A rubber boot’s ability to withstand tears, snags and punctures is vital for protecting your feet. Natural rubber rates well for cut and abrasion resistance, though reinforced synthetics can be equally impervious. Inspect the construction and thickness closely if this attribute is important to you.

8. Electrical Resistance

Natural rubber acts as an electrical insulator, providing a high degree of protection against accidental shocks and electrocution hazards. Static-dissipative synthetic blends offer protection too, though likely not to the same level as natural rubber. This could be a key factor for utility and electrical workers.

9. Odor

Some find the natural scent of rubber unpleasant and bothersome. The telltale odor comes from compounds used to process natural rubber. Synthetics have a lower odor profile. But rinsing with soap and water and airing boots out minimizes smell issues for both types.

10. Eco-Friendliness

If sustainability is important, natural rubber gets the nod. Derived from a renewable resource, its production has lower environmental impact than oil-based synthetics. Natural rubber is also biodegradable. But technology improvements are making synthetics greener.

11. Cost

For comparable quality, synthetic rubber boots tend to be more affordable than natural versions. Large synthetic production volumes keep manufacturing costs down. But natural rubber’s durability can make it the more economical choice in the long run.

12. Sourcing Concerns

Labor practices in the natural rubber industry have come under scrutiny, though reform initiatives are underway. Synthetics sidestep this issue. But check where and how they’re made, as production can carry environmental and human rights impacts too.

13. Allergies

Natural rubber latex poses allergy risks for some wearers. Reactions can range from mild skin irritation to life-threatening anaphylaxis. Synthetic rubber eliminates this danger. Double-check your boot’s latex content if you have sensitivities.

14. Ease of Cleaning

Natural rubber’s smooth finish makes mud and muck easy to rinse off with water. Synthetics’ textures can trap debris in grooves and treads. But this is a minor difference. Thorough cleaning is straightforward for both materials.

15. Style and Color Options

From classic workboot silhouettes to bold fashion statements, you’ll find more variety and choice with synthetics. Natural rubber leans traditional, offering few colors beyond basic black or brown. Synthetics provide a rainbow of possibilities if style matters.

Weighing these factors will guide you to the optimal rubber boot material for your needs. Durability and performance considerations may point toward natural options. But synthetics present pros too. Define your priorities, compare styles and make an informed decision for many seasons of reliable wear.

Sole – Tread depth and style impacts traction and durability

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

When shopping for some sturdy new brown rubber boots, don’t underestimate the importance of the sole. The tread pattern, depth and overall sole design dramatically affect traction, durability and performance. Here are 15 key factors to weigh when evaluating boot soles.

1. Lug Depth

Deep, rugged lugs bite into muddy terrain, snow and loose surfaces, providing grip and preventing slips. Shallower smoother treads quickly lose traction as they wear down. Prioritize deep cleated soles for demanding conditions.

2. Lug Shape and Size

Chunky block or wedge shaped lugs deliver multidirectional traction. Elongated, s-shaped or v-shaped patterns channel water and debris for super slip resistance. Consider the shapes best suited to the surfaces you’ll encounter.

3. Spacing and Siping

Grooves and sipes (narrow slots) between lugs enhance flexibility and grip by providing additional biting edges. Closely spaced lugs shed muck better too. The tradeoff is slightly faster wear, so balance spacing and sipe depth for conditions.

4. Heel and Toe Design

Lug patterns optimized for heel braking and toe-off traction promote surefooted walking and reduce strain. A smooth toe bumper protects against scuffs and abrasion. Prioritize functional traction zones tailored to natural gaits.

5. Multi-Density Rubber

Dual-density soles combine a shock-absorbing cushioned midsole with a durable, grippy outer sole. Triple density adds reinforced lugs for the ultimate in comfort, support and traction. The technology ups cost but pays off in resilience.

6. Oil and Slip Resistance

Oil-resistant rubber compounds provide exceptional non-slip performance on greasy floors. Some soles even meet workplace safety standards for oil and slip resistance. This moderates hazards for industrial and food service workers.

7. Electrical Insulation

Electrically insulated soles certified to ASTMF2413 prevent static discharge and reduce shock risks. A potential lifesaver for electrical and utility work. Verify this safety feature is present if needed.

8. Cushioning

Shock absorbing midsoles soften impacts, easing joint and muscle fatigue. Lacking this cushioning, denser natural rubber soles can feel punishingly hard during prolonged wear. New foams deliver comfort without sacrificing stability.

9. Wear Resistance

Carbon rubber, polyurethane and propriety compounds stand up to heavy abrasion and extended use. Their durability comes at a price premium. Assess whether reinforced materials justify the extra investment.

10. Weather Protection

Cold and chemical resistant soles shield feet from caustic deicer salts, fuels and oils that degrade boot materials. If regularly braving extreme weather, specialized winterized or chem-proof soles are worth considering.

11. Stability and Support

Anatomically contoured, motion-control soles with reinforced arches prevent roll-over accidents on uneven terrain. Features like heel counters add lateral stability too. Seek serious support for challenging environments.

12. Weight

Thick, rugged deep-lugged soles provide unmatched traction but add bulk weight. Lighter soles sacrifice some durability for improved athletic performance and reduced fatigue. Choose accordingly.

13. Flex Point

Forward flex points at the toe encourage natural bending in sync with walking. A standard centered flex can feel stiff in comparison. Test flexibility and ease of movement when worn.

14. Replaceability

Some soles can be replaced when excessively worn, extending boot life at fraction of the cost of new boots. Recraftable construction is an eco-plus too. See if resoling is an option.

15. Cost

Advanced sole technologies demand higher prices. But their rugged performance and durability deliver value over time. Weigh upfront cost vs. longevity when making choices.

Don’t underestimate the importance of boot soles. Evaluating the tradeoffs will lead you to the optimal choice to keep you surefooted in any situation.

Height – Calf-height, knee-high or mid-calf for different coverage

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

Figuring out the ideal boot height is essential to find the perfect pair of brown rubber boots. Calf-height, knee-high or mid-calf options all provide varying levels of coverage and protection. Consider these key factors when deciding:

1. Weather Conditions

Knee-high boots offer maximum coverage from rain, mud and snow. Calf-height may suffice in drier climates. Evaluate typical conditions to choose adequate wetness protection.

2. Worksite Hazards

On jobsites with chemicals, debris or sharp hazards, the extra coverage of knee-high boots helps safeguard legs and feet. Calf-height leaves more skin vulnerable in riskier environments.

3. Insulation Needs

In cold winter temperatures, knee-high boots paired with thick socks provide better insulation and warmth than shorter styles. Calf-height may mean chilly calves and knees.

4. Fit with Pants

Consider pant lengths too – knee-high boots tuck neatly into full length pants. Calf-height pair better with cropped and capri styles. Mid-calf can fit either way.

5. Ease of Entry/Exit

Lower calf-height boots are quicker and easier to take on and off. Knee-highs require more time and effort. Important if you need to remove boots frequently.

6. Weight

Added height equals added weight. Knee-high boots can feel heavy and cumbersome compared to calf-height versions. Consider athletic needs.

7. Circulation and Comfort

If prone to swollen ankles or leg discomfort, avoid very high boots that may constrict circulation. Seek comfortable mid-calf or lower heights instead.

8. Work Requirements

Some workplaces mandate knee-high boots for safety reasons. Others may prohibit tall styles. Know the rules and regulations applicable.

9. Ease of Movement

Calf-height boots allow freer ankle mobility. Knee-high options can limit stride and range of motion. Evaluate required motions.

10. Storage Volume

The taller the boot, the more interior space for insulation, protective toe caps, orthotic insoles etc. Prioritize height for specialized components.

11. Calf Circumference

Wide calves? Seek broad knee-high boots with expandable gussets or laces to customize fit. Calf-height accommodates more calf variability.

12. Riding Use

For horseback riding, narrower knee-high styles prevent saddle rubs and irritation. Wide calf-height can chafe and rub.

13. Cost

More material means higher price tags. Knee-high boots come at a premium over calf-height of similar quality. Budget for added cost.

14. Ease of Cleaning

The shorter the boot, the easier to clean thoroughly after heavy use. Knee-highs require more time and effort.

15. Style Preferences

Calf-height styles exude rugged workwear appeal. Knee-highs carry a dash of equestrian styling. Choose the look you like.

Weigh your needs, conditions and preferences to select the optimal boot height for performance, protection and comfort.

Width – Wide widths accommodate thick socks and wide calves

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

Finding the right width is crucial for maximizing the comfort and performance of brown rubber boots. Wider sizes allow room for thick socks and accommodate larger calves. Consider these key factors when selecting width:

1. Sock Thickness

Do you wear heavyweight socks for insulation? Seek a boot with extra internal room to comfortably fit thick socks without tightness or circulation loss.

2. Athletic Calves

Boots taper toward the top, so those with muscular or fuller calves need wider boots that won’t feel too tight. Measure your calf circumference.

3. Adjustable Closure

Lace-up, buckle or zipper closure? Adjustable systems allow customizing fit. Fixed pull-on styles have less give for variable calf size.

4. Calf Shape

Are your calves widest at the top or bottom half? Choose boots tailored to your calf shape for better coverage without gapping.

5. Expandable Gussets

Some wider boots include stretch gussets or fabric panels to accommodate calves of varying shape/size. These provide wiggle room.

6. Pant Tuck

Will you tuck pants into the boots? Slimmer widths fit neatly inside pants. Wider may bulge and feel baggy when tucked.

7. Orthotics

Do you use custom orthotic inserts? Wider boots leave space to accommodate orthotics without compromising fit and comfort.

8. Toe Box Room

Ample toe box room ensures toes aren’t pinched during flexion. Match width to foot dimensions.

9. Weight

Wider boots require more material and add weight. Narrower boots feel lighter and less clunky by comparison.

10. Traction

Too-wide boots spread weight over more sole area, reducing ground pressure and traction. Moderate width better grips terrain.

11. Lubrication

Narrow boots require lubricant to easily slip feet in and out. Wider boots are easier to enter and exit without lube.

12. Break-In

Snug boots take longer to fully break in. Wider boots mold to feet faster with less blister risk during the break-in period.

13. Balance

Slimmer boots offer more precision and better groundfeel for activities requiring balance and dexterity.

14. Water Entry

Narrow boot shafts prevent water from entering as easily when wading. Wider openings let more water seep in.

15. Price

Due to higher material demands, wider boots usually carry slightly higher price tags than narrower equivalents.

Choosing the optimal width provides wiggle room for toes and calves, preventing discomfort on long days. Size up if between widths.

Lining – Fleece lining provides warmth; mesh lining increases breathability

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The type of lining used in brown rubber boots dramatically impacts warmth, breathability and comfort. Fleece provides plush insulation, while mesh linings enhance air circulation. Consider these key factors when selecting lining:

1. Climate Conditions

In cold winter climates, fleece linings provide critical insulation to keep feet warm and toasty. Mesh is better for warm weather wear.

2. Fit Adjustment

Thick fleece linings take up interior volume, effectively making boots fit snugger. Account for this when sizing boots.

3. Sweat and Odor Control

Breathable mesh linings prevent sweat buildup that causes odors and discomfort. Fleece can hold moisture and smells.

4. Cushioning

Plush fleece linings pad the foot for all-day comfort. Thin mesh provides negligible cushioning against hard surfaces.

5. Skin Irritation

Some may experience skin irritation from fleece. Softer brushed fleece or cotton blends reduce this risk. Mesh is non-irritating.

6. Boot Use

Will boots get wet? Mesh dries quicker than moisture-absorbing fleece lining after exposure.

7. Winter Performance

Fleece lining provides sufficient insulation for cold winter use. Mesh lining requires layering thick socks.

8. Chemical Resistance

Mesh stands up to caustic substances better. Chemicals can degrade fleece over time with repeated exposure.

9. Cleanability

Non-absorbent mesh linings clean up easily. Fleece holds stains, odors and dirt more stubbornly.

10. Cost

Due to higher material costs, fleece-lined boots come at a premium over unlined or mesh-lined options.

11. Weight

Fleece lining adds bulk and weight. Thin mesh has a negligible impact on overall boot weight.

12. Packability

Unlined boots roll and pack tighter. Bulky fleece lining resists compression into tight spaces in luggage.

13. Noise Reduction

Fleece muffles internal foot noises like squeaking and rubbing. Mesh transmits more sound.

14. Bunions and Corns

Mesh can irritate foot bumps and corns. Smooth fleece prevents this irritation during wear.

15. Toe Cap Room

Without lining, boots fit orthotics and toe caps better. Linings tighten interior space.

Evaluate tradeoffs like warmth versus breathability to select the best lining for your brown rubber boots.

Insulation – Insulated boots have added warmth but may get hot indoors

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

When choosing brown rubber boots, deciding between insulated and uninsulated options depends on climate, use conditions and temperature regulation needs. Added insulation provides warmth but can cause overheating issues. Consider these key factors when selecting insulation level:

1. Cold Weather Use

Insulated boots help feet stay warm and prevent dangerous cold exposure. Critical for winter outdoor use in frigid conditions.

2. Indoor/Outdoor Use

Insulated boots get uncomfortably hot when worn indoors. Opt for uninsulated if transitioning between indoor and outdoor areas.

3. Fit Adjustments

Insulation takes up interior volume. Downsize insulated boots or wear thinner socks to compensate for snugger fit.

4. Weight and Bulk

Insulation materials add weight and bulk, making boots heavier and inflexible. Not ideal for athletic needs.

5. Cushioning

In addition to warmth, insulative liners provide padded, shock-absorbent cushioning underfoot for all-day comfort.

6. Breathability

Uninsulated boots allow better airflow, keeping feet drier. Insulated styles can trap sweat, causing dampness.

7. Layering Options

With uninsulated boots, you can control warmth by layering thick socks. Insulated ones have fixed warmth levels.

8. Climate Variability

In temperate climates with fluctuating weather, versatile uninsulated boots accommodate variable conditions and sock thicknesses.

9. Cost

Due to additional material costs, insulated boots are priced higher than equivalent uninsulated versions.

10. Soles

Pair insulated boots with lugged winterized soles for optimal cold weather traction in ice and snow.

11. Waterproofing

Insulated boots keep feet warm even when damp. Rely more on waterproofing membrane to keep uninsulated options dry.

12. Chemical Resistance

Insulation materials degrade faster from chemical exposure than sturdier uninsulated boots.

13. Drying Time

Insulated boots take exponentially longer to fully air dry if interior gets wet. Uninsulated dries quicker.

14. Packability

Bulky insulation resists compression into tight luggage spaces. Uninsulated boots pack down compactly.

15. Odor Resistance

Insulation absorbs odors over time. Uninsulated boots resist odors, especially with breathable mesh linings.

Determine the optimal insulation level based on climate, temperature regulation, and performance needs.

Color – Varying shades of brown to match your style and wardrobe

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

Brown rubber boots now come in a range of rich brown tones from light tan to dark chocolate. The shade you choose impacts style, visibility and how the boots coordinate with your wardrobe. Consider these key factors when selecting color:

1. Visibility

Pale shaded boots increase visibility in dim conditions. Darker earth tones blend into shadows and low light.

2. Dirt Masking

Muddy work sites? Darker brown hides scuffs and dirt better. Lighter shades clearly show smudges and soil.

3. Work Clothes Pairing

Match boot color to pants and overalls shade. Complementary tones give a pulled-together work look.

4. Style Preferences

Do you like bold statement boots or muted classic looks? Choose a color matching your personal taste.

5. Temperature Variations

Lighter tans feel summery and spring-like. Deeper chocolate browns are cozier for winter months.

6. Contrast Level

Monochromatic brown outfits need bold brown statement boots. Lighter shades contrast crisply with dark pants.

7. Complexion Pairing

Light brown complements fair skin nicely. Darker brown pops against darker complexions.

8. Environment

Forest and countryside? Natural woodsy browns blend right in. Urban settings suit sleeker dark chocolate.

9. Denim Pairing

Tan brown boots match light denim wash jeans. Darker washes pair better with deep chocolate hues.

10. Animal Pairing

Horseback riding? Rich chocolate riding boots coordinate with warm horse colors and tones.

11. Gender Neutrality

Unisex work boots come in gender neutral medium brown shades suited to all. Feminine and masculine boots have distinct tones.

12. Weathering

Lighter browns get dingy as they age. Dark brown stays rich even after years of wear.

13. Ease of Replacement

Standard brown allows easy replacing of worn out boots. Custom colors require exact color matching.

14. Accessory Pairing

Coordinate boot color with belts, tool bags and other accessories for a polished look.

15. Brand Options

Some brands only offer limited brown selections. Check color availability for preferred brands.

Choosing that perfect shade of brown comes down to personal preference, wardrobe pairing and performance needs.

Fasteners – Buckles, straps or pull-on for ease of getting boots on/off

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The type of fasteners and closure system used on brown rubber boots affects convenience, adjustability and ease of getting boots on and off. Buckles, straps, laces and pull-on designs all have pros and cons to weigh. Consider these key factors when selecting fasteners:

1. Speed On/Off

Pull-on boots are quickest. Buckles and laces take more time to secure or release when putting on or taking off boots.

2. Fit Adjustability

Laces and multiple buckles allow custom tightening for better fit. Pull-on designs have minimal adjustability.

3. Calf circumference

Wide calves? Laced boots provide adjustable room. Buckled and pull-on styles may feel too snug.

4. Ease of Use

Arthritic hands or dexterity issues? Simple pull-on boots are easiest to get on and off. Complex lacing is challenging.

5. Weather Protection

Pull-on boots form a tight weather-proof seal at the top. Laced and buckled gaps can let water seep in.

6. Durability

Buckles and hardware eventually fail. Pull-on boots have no fasteners to break or corrode.

7. Replacement Parts

Buckles and straps can be replaced if damaged. Entire pull-on boots must be replaced if broken.

8. Weight

Buckles, rings and hooks add a few ounces of weight. Pull-on boots are marginally lighter.

9. Noise

Buckles and hooks can jingle and clank. Pull-on boots have no metal parts to make noise.

10. Cost

Boots with more hardware and moving parts cost more. Simple pull-ons are economical.

11. Aesthetics

Detailed buckled straps provide a decorative touch. Minimalist pull-ons offer a streamlined look.

12. Snugness

Laced boots be tightened for a truly snug fit. Pull-ons depend on elasticity for tightness.

13. Blister Reduction

Adjustable lacing relieves pressure on blister points. Pull-ons can’t be adjusted to accommodate hot spots.

14. Dangling Laces

Avoid tripping on laces. Opt for pull-on or buckles instead in hazard-filled environments.

15. Grip Assistance

Looped straps and pull-tabs provide helpful grip when putting boots on.

Match fastener type to your needs for convenience, customization and performance.

Toe style – Rounded, square or steel toe for protection and comfort

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The shape and construction of the toe box impacts the comfort, protection and style of brown rubber boots. Rounded, square and steel toe options all have unique benefits. Consider these key factors when selecting toe style:

1. Toe Room

Square and rounded toes provide ample room for toe splay and flexion. Steel toes limit space.

2. Impact Protection

Steel toes shield against falling objects. Soft toes offer minimal impact protection.

3. Crush Protection

Steel plates prevent compression injuries. Soft toes carry risk of serious crushing injuries.

4. Stubbing Prevention

Rounded toes better deflect painful stubs. Pointed square toes concentrate force.

5. Abrasion Protection

Leather or rubber square toes resist scuffs. Steel edges dull through abrasion over time.

6. Fit Adjustments

Steel toes tighten fit. Size up or use thin socks with steel styles to compensate.

7. Weight

Steel adds heft. Soft toes are lighter for athletic performance and mobility.

8. Temperature Transference

Steel conducts cold through the toe box. Soft materials provide insulation.

9. Safety Ratings

Steel toes meet workplace safety standards. Soft toes don’t provide equivalent protection.

10. Corrosion Resistance

Steel risks corrosion in wet environments. Soft rubber resists degradation.

11. Style Variety

Steel toe boots lean utilitarian. Soft toes allow both fashionable and functional styles.

12. Casual Wear

Soft square or round work boots suit casual wear. Steel toes look strictly industrial.

13. Toe Bump Comfort

Rigid steel aggravates bunions and corns. Soft rounded toes better accommodate deformities.

14. Electric Shock Risk

Conductive steel risks dangerous static electricity. Non-conductive soft toes are safer.

15. Cost

Steel toe boots demand a price premium. Soft non-safety toes are more budget-friendly.

Determine if protection warrants the cost, weight and reduced comfort of steel toes.

Brand reputation – Established brands known for quality and value

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

When selecting brown rubber boots, the brand’s reputation speaks volumes about expected quality, performance and value. Established workboot companies have proven their reliability over decades. Consider these key factors when selecting brands:

1. Durability Reputation

Choose brands renowned for their extreme durability and longevity, like Red Wing, Carolina and Muck Boots.

2. Materials Used

Top brands rely on premium natural rubber, leathers and components. Check materials used.

3. Fit Consistency

Esteemed brands fine-tune their lasts over time, ensuring consistent and accurate fit.

4. Warranty Coverage

The best companies stand behind their boots with strong warranty programs against defects.

5. Safety Ratings

Reputable industrial brands meet key safety standards for steel toes, electrical resistance, etc.

6. Price for Quality

Reputable brands command higher prices but deliver commensurate quality and value.

7. Selection Variety

Leading companies offer wide selections for all needs: insulated, steel toe, pull-on, etc.

8. Technical Innovation

Top brands invest in R&D to continually improve comfort, durability and performance.

9. Craftsmanship

Attention to detail and premium construction define respected handcrafted boot brands.

10. Work Interface

The best industrial brands Engineer boots collaborating with workers to identify needs.

11. Resoleability

Brands like Red Wing fully supportresolingBOOTS rather than disposal.

12. Heritage

Classic American boot brands have generations of loyal customers.

13. Locally Sourced

When possible, leading brands use regional American materials and factories.

14. Transparency

Reputable companies openly share sourcing information and production practices.

15. Environmentally Responsible

Esteemed boot brands utilize eco-friendly materials and processes.

When in doubt, choose an established brand. It signals quality, performance and sturdiness.

Price – Budget-friendly to high-end based on features and materials

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

Brown rubber boots range widely in price from budget-friendly to high-end premium models. Factors like materials, features, brand reputation and more affect cost. Consider these key factors when evaluating price:

1. Durability

Premium boots made with top-grade natural rubber, leathers and components cost more but last decades.

2. Made in USA

Boots handcrafted domestically with American materials are priced higher than imported boots.

3. Customization

Fully customizable boots with custom colors, logos, sizes etc. come at a premium price.

4. Limited Editions

Small-batch limited edition boots demand higher prices due to exclusivity.

5. Leather Quality

Full-grain leathers are pricier than suede or split-grain leather accents.

6. Height

Added material for knee-high boots increases costs over calf-height boots.

7. Steel Toes

The addition of steel toes adds expense due to material and construction costs.

8. Insulation

Premium thermal liners and insulation jack up costs over uninsulated boots.

9. Waterproofing

Contemporary waterproofing membranes increase expense over basic treated boots.

10. Outsole Toughness

Heavy-duty, rugged traction lugs and high-performing outsole rubber adds cost.

11. Craftsmanship

Handcrafted boots with meticulous construction command premium pricing.

12. Fastener Hardware

Buckles, rings and grommets add up, increasing prices over simple pull-on boots.

13. Brand Prestige

Leading brands justify higher prices based on reputation and consumer trust.

14. Limited Runs

Niche seasonal styles made in small batches add expense.

15. New Styles

The latest styles and technologies debut at full retail before discounts.

Boots delivering decades of performance justify higher prices than disposable products.

Intended use – Everyday, hiking, farm work, etc. impacts ideal features

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The way you plan to use your brown rubber boots should guide your selection. Casual daily wear, hiking, farm work and other uses demand different performance features. Consider these key factors based on use case:

1. Traction Needs

Slippery farm muck requires deep heavy lugs. Light treads suffice for city strolls.

2. Toe Protection

Frequent heavy load work warrants steel toes. Casual uses need only soft toes.

3. Sole Cushioning

All-day work comfort needs well-cushioned soles. Occasional short wear needs less padding.

4. Height Requirements

Deep creek crossing takes knee-high boots. Urban wear can get by with ankle height.

5. Insulation Needs

Winter hiking requires serious insulation. Light liners suffice for transitional months.

6. Waterproofing Levels

Farm work needs waterproofing for deep mud and manure. City strolls can tolerate seepage.

7. Chemical Resistance

Industrial work demands oil- and chemical-resistant soles. Standard soles work for casual use.

8. Zipper Convenience

Frequent on/off favors side zips. Rare removal doesn’t necessitate zippers.

9. Lace Support

All-day wear needs laced adjustability. Light use can get by with pull-on boots.

10. Weight Factors

Heavy boots cause fatigue over miles. Lighter boots suit occasional short stints.

11. Breathability Needs

Hot weather hiking requires mesh lining airflow. Cool days need no breathability.

12. Toe Room

Hiking comfort demands ample toe splay room. Minimal everyday wear needs less space.

13. Cost Considerations

Heavy workwear necessitates quality long-term investment. Light duty can go budget.

14. Style Preferences

Rugged hiker styles differ from sleek city fashion looks.

15. Cleaning Ease

Frequent mucky wear needs quick clean-up. Light use stays cleaner.

Analyze your intended uses and choose the optimal performance features to match.

Flexibility – More flexible uppers are easier to walk in but less sturdy

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The flexibility of the upper portion of brown rubber boots affects mobility, durability and stability. More flexible uppers are easier to walk in but may compromise sturdiness. Consider these key flexibility factors:

1. Bend Point

Optimal flex at ankles, not mid-foot, allows natural gait. Stiff midsections restrict movement.

2. Rubber Firmness

Softer natural rubber upper has give for ankle mobility. Firm rubber limits flexion.

3. Wall Thickness

Thicker upper walls resist bending. Thinner uppers encourage flex.

4. Insulation Bulk

Added insulation makes uppers stiffer. Unlined uppers maximize flexion.

5. Interior Lining

Lining laminates like waterproof membranes reduce flex. Bare rubber upper walls maximize pliability.

6. Polymer Blending

Mixed-polymer uppers combine rigid and elastic polymers for targeted flexibility.

7. Elastic Gore Panels

Flex-points with elastic gores provide articulation without compromising stability.

8. Cushioning Effects

Padded uppers flex comfort, but solid rubber offers greater control and precision.

9. Lace-up Adjustability

Laces fine-tune flex by loosening or tightening fit across flexion points.

10. Break-in Period

Natural rubber uppers relax and soften gradually through repeated wear and bending.

11. Durability

The more flexible the upper, the faster it wears out through repeated creasing and abrasion.

12. Water Entry Risk

Pliancy allows more water seepage. Stiff walls better block liquid entry.

13. Stability

Sturdy stiff uppers provide lateral support. Flexible boots collapse sideways.

14. Shock Absorption

Flexible uppers spread impacts. Rigid walls transmit more shock force.

15. Fit Precision

Snug yet flexible boots enhance precision footing over sloppy loose flexible boots.

Match flexibility to athletic mobility versus stability support needs.

Traction – Deep lugs and tread patterns provide stability on slippery terrain

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

The outsole design greatly impacts the traction and slip resistance of brown rubber boots. Deep lugs and specialized tread patterns help provide stability across loose, wet and uneven terrain. Consider these key traction factors:

1. Lug Depth

Deeper lugs bite into mud and dirt better to prevent slipping. Shallow lugs quickly become smooth.

2. Lug Spacing

Closely spaced lugs shed muck well. Wide lug spacing traps debris, reducing grip.

3. Lug Shape

Angled lugs provide multidirectional traction. Perpendicular lugs only grip forward.

4. Heel Braking Lugs

Defined lugs oriented for heel braking prevent slides and falls on hills or slopes.

5. Toe Spring

A rockered toe profile allows smoother toe-off motion when walking.

6. Slip-Resistant Compounds

Sticky proprietary rubber compounds maximize wet/oily floor traction.

7. Mud Dispersal Grooves

Deep flex grooves and siping help force muck out of soles as you walk.

8. Debris Release Patterns

Strategic lug and groove placement facilitates shedding mud and rocks.

9. Lug Reinforcement

Heavy lugs reinforced at the base withstand prying impacts without tearing.

10. Shock Absorption

Cushioned soles absorb impact, enabling solid footing on hard surfaces.

11. Stability and Support

Firm midsoles provide lateral stability, preventing ankle roll-over on uneven ground.

12. Weather Adaptation

Soles optimized for winter conditions (icy, wet) differ from summer tread designs.

13. Wear Resistance

Carbon rubber lugs last longer through abrasion compared to softer treads.

14. Weight

The deepest lug soles add bulk weight. Light treads enhance athletic performance.

15. Flex Grooves

Flex grooves at toes and ankles articulate to grip terrain through a natural stride.

Aggressive soles engineered for traction reduce fall risks in demanding conditions.

Warranty – Good warranty coverage provides peace of mind on investment

Searching for the Perfect Pair of Brown Rubber Boots? Learn the Top 15 Factors to Consider:

Given the substantial investment quality brown rubber boots represent, a solid product warranty delivers valuable peace of mind should defects arise. Ideal warranties fully cover workmanship and materials. Consider these key warranty factors:

1. Length of Coverage

Top brands offer warranties extending at least 1-2 years. Lifetime coverage is rare but ideal.

2. Defects Covered

Comprehensive warranties cover any product defects, including premature wear, splits, cracking, etc.

3. Waterproofing Coverage

Some warranties specifically cover failure of waterproof membranes and leaking due to materials.

4. Workmanship Flaws

Manufacturing defects like poor assembly, weak seams, unglued soles should be covered.

5. Insulation Failure

If insulation packs down prematurely, quality warranties provide recourse.

6. Hardware Damage

Ring, strap and eyelet breakage or corrosion should be covered under warranty.

7. Sole Delamination

Soles separating from uppers is a defect warranties should address.

8. Wear Life

Better warranties cover boots through a reasonable period of regular wear and tear.

9. Abuse Exclusions

Warranties do not apply to damage from extreme abuse, neglect or unauthorized modifications.

10. Reasonable Wear

Warranties expect boots to show normal signs of wear with age and cannot be “unchanged”.

11. Proof of Purchase

Warranty coverage requires presenting original purchase receipt showing purchase date.

12. Claim Process

Quality companies make submitting warranty claims quick and simple without excessive hoops.

13. Local Dealer Support

Many boot brands offer local dealer assisted returns for easier warranty claims.

14. Remedy Provided

Typically, defective boots are repaired, replaced or refunded at company’s discretion.

15. Country Specifics

Warranty coverage, terms and enforceability vary based on country of purchase.

Thorough warranties deliver confidence in companies standing behind their products.