Why do treadmill belts slip and cause damage. How can you identify warning signs of a faulty treadmill belt. What are the dangers of ignoring treadmill belt issues. Which affordable DIY tools can fix your treadmill belt. How to choose the right treadmill belt tape for repairs. What is the proper way to prep and clean your treadmill belt before repairs.

Understanding Treadmill Belt Slippage: Causes and Consequences

Treadmill belt slippage is a common issue that many fitness enthusiasts face. It occurs when the belt loses traction and fails to provide consistent friction during use. This problem not only affects your workout experience but can also lead to more serious damage if left unaddressed.

What causes treadmill belts to slip? Several factors contribute to this issue:

- Normal wear and tear over time

- Accumulation of dirt, sweat, and oil on the belt surface

- Reduced friction between shoes and the belt

- Improper tension or alignment of the belt

When a treadmill belt slips, it puts extra strain on the motor as it works harder to move the belt. This can result in squeaking, rubbing, or grinding noises. If not addressed promptly, belt slippage can lead to motor burnout and damage to the deck underneath, potentially necessitating costly repairs or even replacement of the entire machine.

Recognizing the Warning Signs of a Faulty Treadmill Belt

Early detection of belt slippage is crucial for preventing extensive damage to your treadmill. How can you tell if your treadmill belt needs repair? Look out for these warning signs:

- Unusual noises such as squeaking, rubbing, or grinding when the belt moves

- The belt slides or slips during use, especially at higher speeds

- You need to reduce your pace to prevent belt slippage

- The belt feels loose or lacks proper tension

- A burning rubber smell emanates from the treadmill

- Visible wear patterns appear on the edges of the belt

Is belt slippage always immediately noticeable? Not necessarily. Subtle slipping may start slowly and worsen over time if left unaddressed. Regular inspection of your treadmill can help you catch these issues early, making repairs easier and more effective.

The Risks of Neglecting Treadmill Belt Maintenance

Ignoring a faulty treadmill belt can have serious consequences. What happens if you don’t address belt slippage promptly?

- Increased strain on the treadmill motor, potentially leading to burnout

- Erosion and destruction of the walking deck due to friction

- Persistent noisy operation from rubbing and squeaking

- Risk of sudden belt stoppage, which could cause you to trip and fall

- Possible motor seizure, resulting in abrupt belt stoppage

Once significant damage occurs, you may face the need for expensive replacement parts or even a new treadmill. By addressing minor belt issues promptly, you can avoid injuries and costly repairs down the line.

Essential DIY Tools for Treadmill Belt Repair

Repairing a slipping treadmill belt doesn’t require professional expertise. With the right tools, you can restore your belt’s grip quickly and affordably. What supplies do you need for a DIY treadmill belt repair?

- Treadmill lubricant or silicone spray

- Belt cleaner or degreaser

- Lint roller or small brush

- Treadmill repair tape

- Scissors

The key component in this repair kit is the treadmill repair tape, also known as treadmill belt tape. This high-friction adhesive tape is specifically designed to improve traction on treadmill belts and other sports equipment. Popular brands like Treadaid and Trek Tape typically cost less than $10 per roll, making this an incredibly cost-effective repair solution.

Selecting the Ideal Treadmill Belt Tape for Repairs

Choosing the right tape is crucial for effective treadmill belt repair. What should you look for in a treadmill repair tape?

- Specifically designed for treadmill belts

- High-friction adhesive that resists peeling

- Sweat-resistant to prevent degradation

- Easy to cut to desired lengths

- Leaves no sticky residue when removed

Avoid using regular duct tape or packing tape, as they lack the specialized adhesive and grip needed for fitness equipment. Some reliable options include:

- Treadmill belt tape

- Gorilla Tape (for heavy-duty grip)

- Gaffers tape (strong cloth adhesive tape used in sports)

- Anti-slip safety tape

For most DIY repairs, treadmill belt tape applied in short strips aligned with belt movement is the best choice. This special tape creates just the right amount of grip to stop annoying belt slippage without causing other issues.

Preparing Your Treadmill Belt for Repair

Before applying the repair tape, it’s essential to properly clean and prepare your treadmill belt. How should you prep your treadmill for belt repair?

- Unplug the treadmill for safety

- Remove any visible debris with a lint roller or small brush

- Apply a belt cleaner or degreaser to remove oil and dirt buildup

- Wipe the belt clean with a dry cloth

- Allow the belt to dry completely before proceeding

Proper cleaning ensures that the repair tape adheres effectively to the belt surface, maximizing its grip-enhancing properties.

Step-by-Step Guide to Applying Treadmill Repair Tape

Once your treadmill belt is clean and dry, you’re ready to apply the repair tape. Follow these steps for optimal results:

- Cut the treadmill repair tape into strips about 6-8 inches long

- Position the strips perpendicular to the belt’s direction of movement

- Space the strips evenly across the width of the belt, leaving about 1-2 inches between each strip

- Press the tape firmly onto the belt to ensure good adhesion

- Repeat this process along the length of the belt, maintaining consistent spacing

How many strips of tape should you apply? The number of strips depends on the size of your treadmill belt and the severity of the slippage. Start with 5-6 strips and test the belt. If slipping persists, add more strips as needed.

Tips for Optimal Tape Application

- Align the strips carefully to prevent interference with belt movement

- Avoid overlapping tape strips, as this can create bumps in the belt

- For severe slippage, consider applying strips on both the top and bottom of the belt

- Replace worn tape strips as needed to maintain effectiveness

Testing and Adjusting Your Repaired Treadmill Belt

After applying the repair tape, it’s crucial to test your treadmill to ensure the slippage issue has been resolved. How can you properly test your repaired treadmill belt?

- Plug in the treadmill and turn it on at a low speed

- Gradually increase the speed while walking on the belt

- Listen for any unusual noises or feelings of slippage

- Test the belt at various incline settings if applicable

- Run on the treadmill for a few minutes to ensure consistent performance

If you still notice slipping or other issues, you may need to adjust the tape placement or add more strips. Remember, it’s better to start with fewer strips and add more as needed rather than over-applying tape initially.

Maintaining Your Repaired Treadmill Belt

To prolong the effectiveness of your DIY repair and prevent future slippage issues, consider these maintenance tips:

- Clean the belt regularly to prevent dirt and oil buildup

- Lubricate the belt as recommended by the manufacturer

- Check and adjust belt tension periodically

- Inspect the repair tape regularly and replace worn strips

- Address any new slippage issues promptly to prevent further damage

When to Seek Professional Treadmill Repair Services

While DIY repairs can effectively address many treadmill belt issues, some situations may require professional assistance. When should you consider calling a treadmill repair service?

- The belt continues to slip despite proper tape application

- You notice significant wear or damage to the belt or deck

- The motor makes unusual noises or shows signs of strain

- Belt tension adjustments don’t resolve the issue

- You’re uncomfortable performing the repair yourself

Professional technicians have the expertise and tools to diagnose and address more complex treadmill problems. They can also provide guidance on whether repair or replacement is the most cost-effective solution for your specific situation.

Cost Comparison: DIY Repair vs. Professional Service

One of the main advantages of DIY treadmill belt repair is its cost-effectiveness. How does the cost of a DIY repair compare to professional service?

- DIY Repair: Typically under $10 for treadmill repair tape

- Professional Service: Can range from $100 to $300 or more, depending on the issue and location

While professional service may be necessary for complex problems, DIY repair can save you significant money for minor belt slippage issues. Additionally, learning to perform basic maintenance and repairs yourself can help extend the life of your treadmill and reduce long-term costs.

Factors Affecting Professional Repair Costs

If you do need to seek professional help, several factors can influence the cost of treadmill repair:

- The specific issue and required parts

- The age and model of your treadmill

- Your location and service availability

- Whether the repair is covered under warranty

- The reputation and experience of the repair service

Always request detailed quotes from multiple repair services to ensure you’re getting a fair price for the necessary work.

Preventing Future Treadmill Belt Issues

While knowing how to repair a slipping treadmill belt is valuable, preventing issues in the first place is even better. How can you maintain your treadmill to avoid future belt problems?

- Follow the manufacturer’s recommendations for belt lubrication

- Clean the belt and deck regularly to remove dirt and sweat

- Check belt tension and alignment periodically

- Use a treadmill mat to reduce dust and debris accumulation

- Wear clean, appropriate workout shoes when using the treadmill

- Address any unusual noises or performance issues promptly

By implementing these preventive measures, you can significantly reduce the likelihood of belt slippage and other treadmill problems, ensuring a longer lifespan for your fitness equipment.

The Importance of Regular Treadmill Maintenance

Regular maintenance is key to keeping your treadmill in top condition. Establish a routine that includes:

- Weekly cleaning of the belt and surrounding areas

- Monthly checks of belt tension and alignment

- Quarterly lubrication (or as recommended by the manufacturer)

- Annual comprehensive inspection of all components

By staying proactive with maintenance, you can catch potential issues early and prevent them from escalating into more serious problems.

Why Treadmill Belts Slip and Cause Damage

If you’re a treadmill owner, you know how frustrating it can be when the belt starts to slip. That annoying squeaking or rubbing sound is usually a sign that your belt needs some TLC. Ignoring belt slippage can lead to bigger problems down the road, so it’s important to address it right away. In this article, we’ll explore the common causes of treadmill belt slippage and how you can fix it yourself with just a bit of repair tape!

The main job of your treadmill belt is to provide consistent friction as your feet land on it with each step. But over time, normal wear and tear can cause the belt to lose traction. Materials like dirt, sweat, and oil build up on the belt surface, reducing friction between your shoes and the belt. This forces the belt to slide instead of grip. The belt will start to slip, especially when you increase your walking or running speed.

A slippery belt is more than just annoying. It can damage your treadmill over time. The slipping puts extra strain on the treadmill motor as it works harder to move the belt. You may hear squeaking, rubbing, or grinding noises coming from the machine. Left unchecked, belt slippage can eventually burn out the motor. The friction from the slipping belt can also damage the deck underneath, necessitating expensive repairs.

Warning Signs Your Treadmill Belt Needs Repair

Catching and repairing belt slippage early makes fixing it much easier. Here are some common symptoms that your treadmill belt needs help:

- Squeaking, rubbing, or grinding noises when the belt moves

- The belt slides or slips when you run

- You need to slow your pace to keep the belt from slipping

- The belt feels loose or lacks tension

- Burning rubber smell from friction

- Visible wear patterns on edges of belt

Subtle slipping may start slowly, but it will get worse over time without repair. Inspect your treadmill regularly for any signs of belt trouble.

Dangers of Ignoring a Faulty Treadmill Belt

Slipping belt issues only worsen when neglected. Leaving the problem unchecked leads to irreparable damage and safety hazards:

- Increased strain ruins the treadmill motor

- Friction erodes and destroys the walking deck

- Noisy operation from rubbing and squeaking

- Belt may stop suddenly, causing you to trip

- Motor could seize up, abruptly stopping the belt

Once your treadmill starts deteriorating, replacement parts or a whole new machine may be your only option. Avoid injuries and expensive repairs by taking care of minor belt issues now.

Affordable DIY Tools to Fix Your Treadmill

Don’t worry, you don’t have to be a professional repair technician to fix a slipping treadmill belt. With a few simple DIY tools, you can get your belt grip back in just a few minutes. Best of all, the supplies are inexpensive and readily available.

Here are the only tools you need for a DIY treadmill belt repair project:

- Treadmill lubricant or silicon spray

- Belt cleaner or degreaser

- Lint roller or small brush

- Treadmill repair tape

- Scissors

The key item that will get your belt grip back is the treadmill repair tape, also called treadmill belt tape. It’s a high-friction adhesive tape made specifically for improving traction on treadmill belts and other sports equipment. Leading brands like Treadaid and Trek Tape cost less than $10 per roll.

With these handy supplies, you can banish belt slippage and restore safe operation. Read on to learn how!

Types of Tape That Can Repair Treadmill Belts

Look for treadmill repair tape made particularly for fitness equipment use. Avoid regular duct tape or packing tape, which lack the special adhesive and grip needed. Some top options include:

- Treadmill belt tape – Designed for high friction and sweat resistance on belts

- Gorilla Tape – Very thick and heavy duty grip

- Gaffers tape – Strong cloth adhesive tape used in sports

- Anti-slip safety tape – Creates traction for shoes on slippery surfaces

The best DIY choice is treadmill belt tape applied in short strips aligned with belt movement. This special tape won’t peel up, leave residue, or degrade from sweat and friction like regular tapes. Applying it properly creates just the right grip to stop annoying treadmill belt slippage.

How to Choose the Right Treadmill Belt Tape

Look for treadmill repair tape made particularly for fitness equipment use. Here’s what to look for:

- Designed specifically for treadmill belts

- High-friction adhesive that won’t peel up

- Sweat resistant to avoid degradation

- Easy to cut to desired length

- Leaves no sticky residue on belt when removed

Avoid regular duct tape or packing tape, which lack the special adhesive and grip needed for fitness use. With the right treadmill belt tape, you can banish annoying slippage and repair your belt easily.

Prepping Your Treadmill Belt for Repair

Before applying treadmill repair tape, you need to clean and prepare the belt surface:

- Unplug the treadmill before working on it

- Inspect belt for damage needing replacement

- Use treadmill lube or silicone spray under the belt

- Clean belt with degreaser and lint roller

- Let belt dry completely before taping

Proper cleaning removes any oil, dirt, or sweat buildup that is reducing traction. Just be sure the belt surface is completely dry before adding treadmill repair tape. Any moisture under the tape will make it less effective and peel up faster.

Applying Treadmill Repair Tape Correctly

Follow these steps to apply repair tape for maximum results:

- Cut tape into short 1-2 inch strips

- Align strips perpendicular to belt direction

- Apply tape strips evenly across width of belt

- Rub strips firmly to adhere but avoid bubbles

- Test belt tension before full use

Placing the short tape strips across the belt motion prevents peeling. Check after a few uses and reapply tape on any areas still slipping. With this method, one roll of treadmill repair tape can restore most slipping belts.

Securing the Tape for Maximum Hold

Get the best grip from treadmill repair tape by:

- Cleaning belt thoroughly before application

- Letting belt dry fully before taping

- Cutting tape into short strips across belt motion

- Pressing tape strips down firmly without bubbles

- Replacing tape if peeling or wearing off

Proper tape application and maintenance will keep your belt traction restored. No more annoying slippage and grinding sounds!

Re-Aligning the Belt After Repairs

If slipping has shifted your belt off-center, re-align it:

- Run belt at low speed to see alignment

- Power off and adjust belt centering bolts

- Rotate bolts equally on both sides to move belt

- Run again and check alignment

- Repeat until belt tracks centered

Repairing a slipped belt can cause it to track off-center. Carefully realigning the belt prevents unnecessary friction and wear. Refer to your owner’s manual for proper belt alignment procedures.

Testing Belt Tension Before Use

Check these signs of proper belt tension before use:

- Belt stays centered during use

- No hesitation moving feet from belt to sides

- Belt doesn’t slip during running

- No squeaking or rubbing sounds

- Motor runs smoothly without strain

If you notice any issues, adjust belt tension bolts per the owner’s manual. Proper tension prevents slippage and undue strain on the motor.

Safety Checks to Perform After Repairs

Before hopping back on, double check:

- Belt moves smoothly without slipping

- No odd noises from motor or belt

- Belt stays centered during use

- Stopping clip works properly

- No exposed wires or damage under motor hood

Verify full treadmill function and security before use, especially if children or pets are around. Watch for any recurrence of slipping or unusual performance issues.

Preventative Maintenance for Treadmill Belts

Keep your belt grip lasting longer by:

- Cleaning belt regularly with degreaser

- Using treadmill lubricant under belt monthly

- Inspecting belt for signs of wear

- Checking and adjusting belt tension

- Re-taping areas of belt slippage

Well-maintained belts stay drier and cleaner, minimizing slippage. Periodic re-taping extends the repair effectiveness.

When to Call in a Treadmill Repair Professional

See a technician for treadmill issues like:

- Belt won’t move or stops suddenly

- Motor sounds strained even at low speeds

- Smoke or burning smell from motor

- Cracks or rips in walking belt

- Deck is uneven, warped, or damaged

While DIY tape fixes most simple belt slippage, major malfunctions need a treadmill repair pro. Know when to call for help avoiding injury or expensive damage.

Enjoy Smooth and Safe Treadmill Running

Now you know how to get a slipping, squeaking treadmill belt back into shape with just a bit of easy repair tape. No need to dread annoying noises and unsafe operation. Apply treadmill belt tape properly and perform preventative maintenance to avoid recurring issues.

With just a few affordable DIY tools, you can restore a solid, even treadmill belt grip for comfortable and safe workouts. Just be alert for any signs of new problems requiring technician skills. Contact a pro promptly if major issues arise. With vigilance and care, your treadmill can provide miles of slip-free running for years to come.

Warning Signs Your Treadmill Belt Needs Repair

Is your treadmill making unusual noises or not running smoothly lately? Those could be telltale signs that your treadmill belt needs some TLC. Don’t sweat it – with a few inexpensive supplies and a little elbow grease, you can often repair a worn treadmill belt yourself for under $10.

A treadmill belt takes a beating with all the walking, running and shuffling it endures. Over time, the continuous friction can cause the belt to stretch out, slip off track or develop tears. Catching problems early allows you to fix them quickly before further damage occurs. Here are some common indicators that your treadmill belt may require repair:

Loud Thumping, Rubbing or Grinding Noises

If your treadmill starts making odd new sounds, the belt is likely the culprit. Thumping noises can signal that the belt is too loose and is not tracking correctly on the deck. A rubbing or grinding noise could mean the belt is too tight. In both cases, tension needs to be adjusted so the belt runs smoothly and quietly.

Belt Slips Off Center

Does your belt drift to one side while the treadmill is in use? This sliding indicates it needs realignment. If not addressed, the belt can get caught on the edge of the deck, increasing wear and tear.

Burning Smell

A stench of burning rubber is a surefire sign something is amiss with your treadmill belt. This odor is usually the result of friction from a loose belt that is slipping and needs to be tightened. Prolonged slipping can damage both the belt and motor.

Tread Belt Hesitates or Stutters

If you notice the tread belt seems to catch or hesitate occasionally as you run, it likely means the belt is beginning to separate beneath the surface. Separation occurs when the belt’s top and bottom layers start to delaminate due to age and use. This will only get worse if not repaired.

Belt is Cracked, Damaged or Excessively Worn

Inspect your treadmill belt regularly for visible wear and tear. Look for cracks, tears, holes or thinning of the belt surface. Check both the topside and underside of the belt. Damage usually starts small but spreads quickly. Replacing a severely worn belt before it snaps prevents injury and protects the motor.

Ready to Repair Your Treadmill’s Belt for Under $10? Here’s How:

Don’t let a failing treadmill belt derail your workout. With a few basic tools and inexpensive supplies, you can often get your belt running smoothly again in under an hour. Here are three simple DIY treadmill belt repairs to try:

1. Adjust Belt Tension

If your belt is noisy, slipping or running off-center, tensioning is likely the fix. Locate the adjustment bolts on the rear roller. Tighten bolts on the side the belt is drifting towards and loosen bolts on the opposite side. Make small adjustments and check after each turn. Continue adjusting until the belt tracks straight and runs quietly. Lubricating the deck also helps.

2. Patch Small Holes and Tears

For minor belt damage like pinholes or small tears, patching can extend its life. Clean the area thoroughly. Apply treadmill belt repair tape or iron-on patches per instructions. Cover all frayed edges and press down firmly. Let adhesive cure before using. This quick fix prevents further tearing.

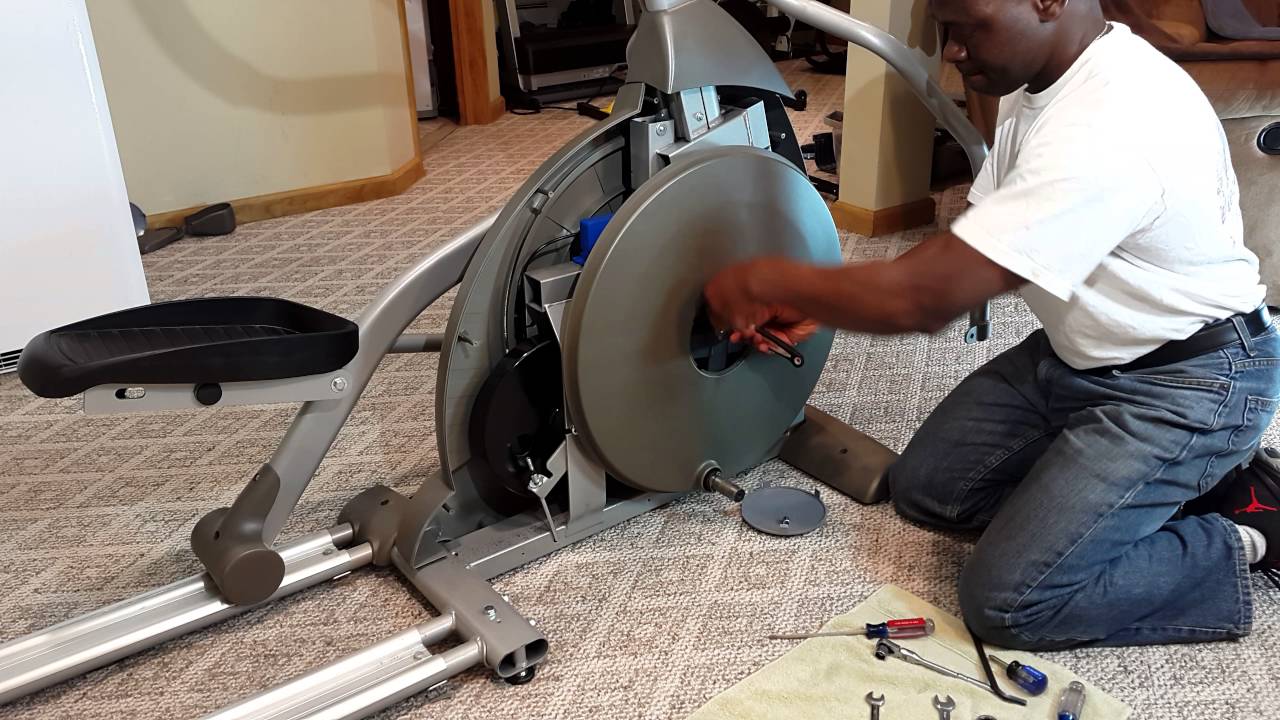

3. Replace Excessively Worn Belts

Heavily damaged, cracked or worn belts should be replaced. Measure belt length and width. Remove old belt. Install new belt, ensuring it aligns correctly with the motor and roller shafts. Applying silicone spray helps the belt grip. Check tracking and tension. Your treadmill will run like new again.

With the right supplies, most DIYers can handle basic treadmill belt repairs:

- Treadmill lubricant or silicone spray – Lubricates deck

- Belt tensioning tool – Adjusts rear roller bolts

- Treadmill belt repair tape – Covers small holes/tears

- Treadmill belt – Replaces worn belts

Follow manufacturer guidelines for proper maintenance. Diagnose noises right away before small issues become big problems. And know when to call in a professional – some repairs like motor work require expert skills. But for many fixes, you can easily revive your treadmill belt yourself for under $10. With a bit of TLC, you’ll be back up and running again in no time!

Dangers of Ignoring a Faulty Treadmill Belt

It’s easy to overlook signs of treadmill belt damage and keep running. But ignoring a failing belt can lead to serious consequences. A malfunctioning belt puts you at risk for slips, trips, falls and even fires. Protect your safety and your treadmill by promptly repairing any belt problems.

With all the pounding treadmill belts endure, it’s no wonder they eventually wear out and require maintenance. But letting belt issues go unchecked allows small problems to become big hazards. Don’t risk injury or equipment damage. Be alert for these dangers if you ignore a faulty treadmill belt:

Tripping and Falling

A loose, damaged or misaligned belt is a tripping risk. If the belt slips or hesitates when your foot strikes, it can easily throw off your gait and cause you to stumble or fall. Tears, holes and thinning also create uneven stepping surfaces. Falling on a fast-moving treadmill can cause sprains, bruises or worse.

Getting Pinched

If belt tension is too loose, the edges can lift off the deck while in use. Stepping on these flipped-up edges traps your shoe underneath, basically “pinching” your foot. This can yank you off balance, twist ankles and wrench knees. Ouch!

Burns and Abrasions

Excessive belt slipping creates friction against the deck, which generates heat. Prolonged slipping can melt and damage the belt. The hot belt surface can also burn skin on contact. In addition, worn, frayed belts expose abrasive underside materials that can scrape and cut skin.

Motor and Belt Damage

Letting a defective belt continue running stresses the motor. The motor has to work harder to move the belt, especially if slipping is involved. This added strain can quickly burn out the motor. Further damage to both the belt and deck occurs as well.

Sparking Fires

In extreme cases, significant slipping between the belt and deck can create enough heat and friction to actually spark and catch fire! Smoke, burning smells, melted parts – don’t let it get to this point. It only takes a small flame to quickly ignite a major fire.

Ready to Repair Your Treadmill’s Belt for Under $10? Here’s How:

Once you notice any belt problems, fix them ASAP before mishaps occur. With a few handyman tools and basic replacement parts, you can often repair a failing treadmill belt yourself for less than $10. Here’s how to breathe new life into a worn-out belt:

1. Tighten a Loose Belt

If slipping is the issue, tightening the belt prevents further skipping. Locate the adjustment bolts on the rear roller. Turn bolts on the loose side a quarter-turn. Retest for slipping and continue tightening gradually. Proper tension will also eliminate noises.

2. Lubricate the Belt and Deck

A small amount of treadmill lubricant or silicone spray helps the belt glide smoothly over the deck, preventing friction and damage. Apply lightly per the manufacturer’s guidelines. Over-lubricating can cause belt slippage.

3. Patch Holes and Tears

Covering damaged spots in the belt helps them from worsening. Thoroughly clean the area then apply treadmill repair tape or patches. Press down firmly over all frayed edges. This prevents further tearing.

4. Align the Belt

If the belt tracks off center, use the adjuster bolts to realign it. Tighten the outside bolt on the side it veers towards. Loosen the opposite outer bolt. Make small adjustments until it runs centered again.

5. Replace Excessively Worn Belts

Heavily damaged belts need complete replacement. Measure the old belt then install an identical new one. Check tracking and tension. It will be like running on a brand new treadmill again.

With these simple repairs, you can fix minor treadmill belt issues in under an hour and prevent bigger problems. Invest in basic DIY maintenance supplies like:

- Treadmill lubricant

- Belt tensioning tool

- Repair tape

- Replacement belts

Catch and repair treadmill belt damage promptly. Ignore it, and you risk fires, falls, injuries and costly repairs. For less than $10 and a little DIY know-how, you can safely revive your worn-out belt again.

Affordable DIY Tools to Fix Your Treadmill

Is your treadmill making weird noises or not running smoothly? Don’t despair – with a few DIY tools and techniques, you can likely fix it yourself for under $10. Repairing your own treadmill is not only cost-effective, but gives you a sense of accomplishment and allows you to understand how your machine works.

One of the most common treadmill problems is a damaged or loose belt. Over time, the belt can become misaligned or start to slip, making an annoying “thump thump” sound as you run. Luckily, there’s an easy DIY belt repair that takes less than 30 minutes and costs next to nothing. All you need is treadmill repair tape, which provides grip and traction to stop the belt from slipping.

Here are the simple steps to fix your treadmill belt using repair tape:

- Unplug your treadmill for safety.

- Locate where the belt is slipping and gently lift the belt to clean underneath it. Use isopropyl alcohol to remove any grease or debris.

- Cut a piece of treadmill repair tape about 6 inches long and apply it to the center of the treadmill belt underneath the slipping area.

- Press the tape down firmly and smooth out any air bubbles or creases.

- Turn on the treadmill and test the belt. The repair tape’s gritty surface should stop the slipping.

- If it still slips, add another layer of tape until the slipping stops.

The repair tape provides just enough friction so the belt stops slipping during use. It’s an easy, fast DIY fix that saves the hassle and expense of replacing the entire belt.

Lubricate a Noisy Belt

Another common treadmill woe is a belt that makes squeaking, grinding or chirping noises while in use. This happens when the belt gets dry and needs lubrication.

You can lubricate your treadmill belt yourself using affordable treadmill maintenance kits. These include lube specially formulated for treadmill belts, as well as applicators to help you spread it evenly.

Here are the simple steps to lube a noisy treadmill belt:

- Unplug the treadmill and lift the belt to access its underside.

- Clean the belt thoroughly using isopropyl alcohol to remove dirt and residue.

- Apply a thin, even layer of treadmill lubricant along the belt’s length using the applicator.

- Lower the belt and wipe away any excess lube.

- Turn the treadmill on and walk on it for a few minutes to spread the lube evenly.

- Listen for noises. Re-apply more lube if any squeaks or grinding persist.

Proper lubrication helps the belt glide smoothly and quietly over the deck. Just a small amount of lube goes a long way to restore peaceful operation. Lubricating your belt every few months extends its life and prevents the need for costly replacements.

Adjust Belt Tracking

If your treadmill belt “drifts” to one side or the other as you run, it likely needs a tracking adjustment. Belt tracking keeps the belt centered as it moves so it doesn’t rub against the sides. But over time the components can shift, causing the belt to move off-center.

Getting tracking back on track (pun intended!) is a quick DIY fix. All you need is a treadmill tracking wrench designed to turn the rear roller bolts and adjust tension.

Here are the steps to adjust belt tracking:

- Identify which way the belt is drifting. If it veers left, you’ll adjust the right rear roller bolt.

- With the treadmill unplugged, use the tracking wrench to turn the rear roller bolt 1/4 turn clockwise.

- Test the treadmill to see if the belt stays centered now.

- If not, turn the bolt another 1/4 turn until the belt stops drifting.

Keeping proper belt tracking prevents unnecessary friction and wear. It also keeps your belt running smoothly without annoying drift. Performing tracking adjustments every few months extends the life of your treadmill.

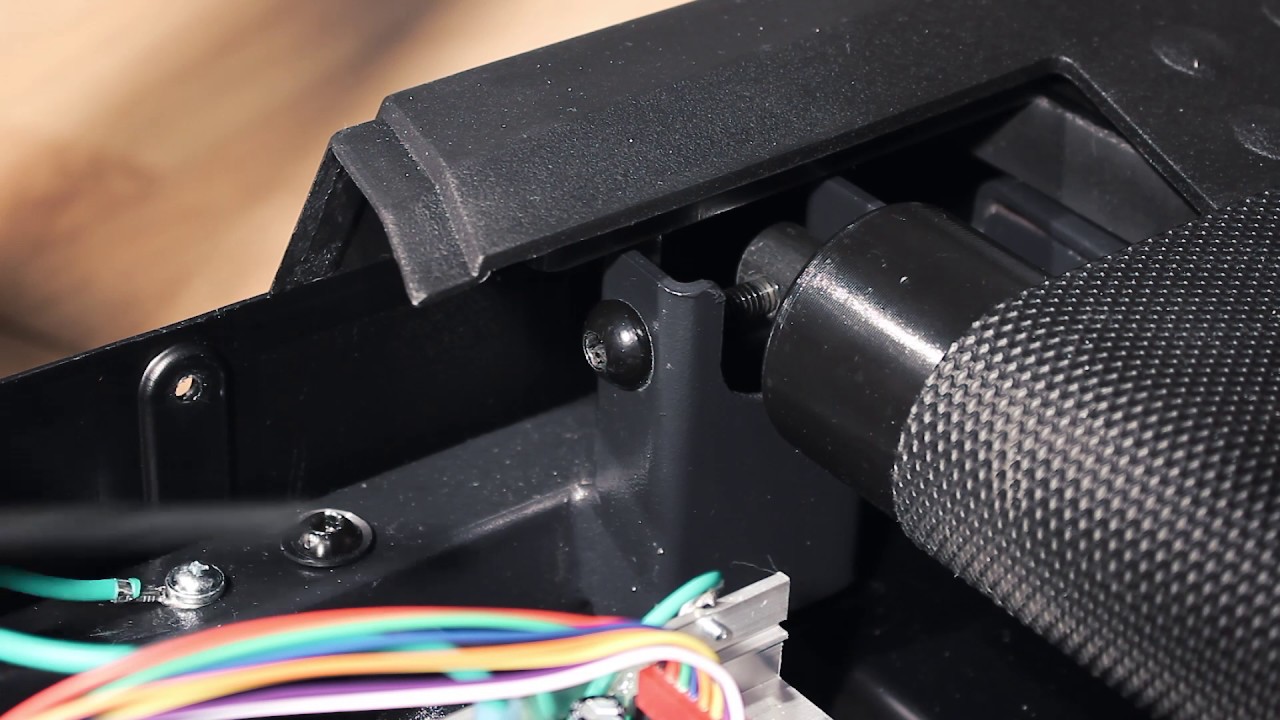

Tighten a Loose Motor Belt

The motor belt is another key treadmill component that can cause problems if it becomes loose. This belt connects the motor to the front roller to power the running belt. If it loses tension, you may notice the belt slowing, hesitating or stopping intermittently.

Tightening a loose motor belt takes a bit more work than other DIY repairs but can still be done at home. You’ll need to partially disassemble the treadmill to access the motor and use wrenches to tighten the motor mount bolts.

Here is the motor belt tightening process:

- Unplug the treadmill and lift the running belt.

- Remove the motor cover and front roller cover to access the motor belt.

- Loosen the bolts on the motor mount just enough to allow adjustment.

- Pull the motor forward to tension the belt, then tighten the mount bolts.

- Rotate the belt by hand and check tension. Loosen the bolts more if needed.

- Once tensioned properly, replace all covers.

It takes some mechanical skill, but tightening a loose motor belt can save hundreds compared to buying a replacement. Keeping the motor belt properly tensioned prevents slowdowns and damage to the motor.

DIY Troubleshooting Saves Time and Money

With a few basic tools and DIY know-how, you can troubleshoot and fix many common treadmill problems yourself. Simple repairs like lubricating the belt, adjusting tracking and tightening components cost little and keep your machine running smoothly for years before major service is required.

Learning basic treadmill maintenance also allows you to diagnose problems right away instead of putting up with subpar performance. Don’t let frustrating technical issues interfere with your workout when Pro tips and affordable supplies can get your treadmill back on track fast.

Types of Tape That Can Repair Treadmill Belts

Is your treadmill belt making annoying thumping or slipping noises when you run? Instead of calling for expensive service, you can often fix minor belt issues yourself with simple DIY repair tape. Certain types of adhesive tape provide the perfect grip and traction to get your treadmill belt working smoothly again.

Repairing a slipping belt is one of the most common DIY treadmill fixes. Here are some of the top tape options to quiet a noisy belt and save you money.

Duct Tape

One of the most versatile household repair tools is ordinary duct tape. The thick, heavy-duty adhesive is perfectly designed to provide traction on a slipping treadmill belt. Duct tape’s natural tackiness grabs the belt to reduce friction and stop the annoying “thump thump” sound of slippage.

To use duct tape for treadmill repair:

- Lift the belt and clean the underside with isopropyl alcohol.

- Apply a 6-8 inch piece of duct tape to the belt’s center under the slipping area.

- Press down firmly to adhere the tape fully to the belt.

- Test the treadmill. If slipping continues, add another layer of duct tape.

Duct tape offers an easy, inexpensive DIY treadmill belt fix. Just be sure to check the tape periodically and reapply fresh layers as needed when the adhesive loses stickiness.

Grip Tape

For a more heavy-duty treadmill belt repair, turn to grip tape. This extra-strong adhesive tape uses grit on the surface to create traction to stop slipping. Grip tape is similar to the sandpaper-like tape used on skateboards and tool handles.

To use grip tape on your treadmill:

- Clean the area under the slipping belt with alcohol.

- Cut a 6 inch piece of grip tape and remove the backing paper.

- Adhere the tape fully to the belt’s center under the slippage area.

- Test the treadmill for improved traction and reduced noise.

The coarse texture of grip tape grabs the deck firmly to prevent slipping. It provides a long-lasting DIY treadmill belt fix that retains stickiness and lasts through plenty of miles.

Double-Sided Tape

For a lighter-duty treadmill belt repair, double-sided tape offers easy stickiness. This thin but sticky tape has adhesive on both sides, so it adheres securely to the underside of the belt and the deck.

Follow these steps to use double-sided tape on your treadmill:

- Lift the belt and wipe the deck with alcohol where slipping occurs.

- Peel off the backing and adhere a 6 inch strip of double-sided tape to the deck.

- Remove the top backing and press the belt down onto the tape.

- Test for reduced slipping and noise. Add more tape if needed.

The strong adhesive provides grip while the thin tape stays flexible to move with the belt. Double-sided tape offers a budget-friendly DIY treadmill repair.

Anti-Slip Tape

For a commercial-grade treadmill belt fix, look for anti-slip tape designed for indoor fitness equipment. These pre-cut treads provide superior traction to instantly stop belt slipping and noise.

To install anti-slip treadmill tape:

- Clean the belt underside and deck where slipping occurs.

- Peel off the backing and stick the pre-cut tape to the belt’s center.

- Use a roller tool to adhere the tape fully and smooth out air bubbles.

- Test for improved function. Add another strip if one doesn’t fully correct slipping.

Anti-slip tape offers industrial strength to repair treadmill belts. Look for gym-grade brands made of very coarse grit on durable adhesive backing.

Gaffer’s Tape

Another strong but temporary treadmill belt fix is gaffer’s tape. This heavy-duty cloth tape is used in theater productions to adhere sets, wiring and more. The fabric backing and natural rubber adhesive provides excellent but non-permanent traction.

Here’s how to use gaffer’s tape on your treadmill:

- Raise the belt and clean the deck underneath.

- Stick down a 6-8 inch piece of gaffer’s tape in the slipping area.

- Rub firmly to maximize adhesion and tread contact.

- Test for noise reduction. Add another strip if one doesn’t eliminate slipping.

Gaffer’s tape repairs treadmill belts long enough to finish your workout. Replace it periodically as the stickiness diminishes. The cloth tape avoids leaving any deck residue.

Treadmill Belt Lube

Finally, don’t forget proper treadmill lubrication in your DIY repair routine. Keeping your belt lubricated helps prevent slipping problems in the first place. Belt lube applied every few months reduces friction so the belt glides smoothly and quietly.

Here are some tips for easy treadmill lubrication:

- Use silicone lube made specifically for treadmill belts.

- Apply a thin, even layer following the product instructions.

- Wipe away any excess lube which could become gummy.

- Walk on the belt for a few minutes to distribute the lube evenly.

Proper lubrication and strategic use of grip tape work hand-in-hand to maximize your treadmill’s performance and longevity between professional servicing.

Affordable, Effective Treadmill Belt Repairs

Don’t spend money replacing an entire treadmill belt when a little DIY repair tape can fix most slipping problems. Keeping these inexpensive supplies on hand allows you to troubleshoot issues immediately and get back to your workout.

Try various tapes to find the perfect solution for your belt. With a bit of trial and error, you can customize an affordable repair that keeps your treadmill quiet and functional for years to come.

How to Choose the Right Treadmill Belt Tape

Is your treadmill making annoying slipping or squeaking noises? Special treadmill repair tape can provide an easy, inexpensive fix to restore smooth and quiet operation. But with so many tape options available, how do you choose the right one?

Consider these key factors when selecting tape to repair your noisy treadmill belt:

Noise Source

First, determine the type of noise and what’s causing it. A “thumping” or slipping noise means the belt lacks traction. Squeaking or grinding usually indicates the belt needs lubrication.

For slipping issues, choose a tape with high grip and traction. Look for tape with a rough, sandpaper-like surface to grab the belt. If lubrication is needed, any tape will work to temporarily restore traction while you lube the belt.

Belt Material

Treadmill belts are typically made of cotton canvas, PVC vinyl, nylon polyester or urethane materials. Match the tape adhesive to the belt surface for the best bond.

For cotton canvas, duct tape adheres well. On vinyl or urethane, stronger adhesives like grip or double-sided tape work better. Test different tapes to see which sticks best without damaging the belt when removed.

Deck Surface

Consider the deck surface that’s underneath the belt. Wood, metal, plastic? The tape must stick to the deck to prevent slipping.

On wood, duct tape and cloth gaffer’s tape adhere better. Metal and plastic decks require sturdier tape like grip, double-sided or anti-slip treadmill tape with durable adhesive.

Belt Width

Measure your belt width and buy tape at least 4-6 inches wide to fully cover the center slipping area. Narrow 1-2 inch tape won’t provide enough coverage.

Wide anti-slip treadmill tape comes pre-cut 6 inches for easy application. Or you can slice wider rolls of grip or duct tape to the needed size.

Temporary vs. Permanent

Some tapes only provide a temporary treadmill belt fix, while others adhere permanently until removed.

For a temporary repair, use cloth gaffer’s tape which is designed not to leave any sticky residue when removed. Or try budget-friendly duct tape, replacing it periodically as the glue loses tackiness.

For a heavy-duty permanent fix, choose commercial anti-slip treadmill tape or extra-powerful grip tape. These maintain traction until you peel them off.

Ease of Use

Basic tapes like duct and gaffer’s tape are simple to apply. Just cut a strip, peel off the backing and stick to the belt.

Double-sided and grip tapes require removing the top backing layer before adhering. Anti-slip tape usually comes with an applicator tool.

Choose a repair tape you’re comfortable installing correctly on the underside of the moving belt.

Cost

Budget-friendly options for DIY treadmill repair include household duct tape and inexpensive double-sided tape. These can provide temporary fixes for under $5.

Invest in premium treadmill repair tapes like grip, gaffer’s or anti-slip for heavy-duty traction. These cost $15-30 but deliver reliable long-term results.

Noise Reduction

The whole point is to make the annoying noises stop! Test different treadmill tapes to see which works best to eliminate the squeaking, grinding or thumping sounds as you run.

Stronger adhesives like grip tape usually outperform basic duct tape, but results vary by treadmill. Apply test strips before committing to a large roll purchase.

Treadmill Age

On very old treadmills with worn belts, even the strongest tapes may provide only temporary noise reduction. Belt replacement may be needed.

But on machines less than 5-7 years old, DIY repair tapes can restore smooth, quiet functioning for long periods before professional service is required.

Get the Right Grip

While trial and error are sometimes needed to find the perfect tape for your treadmill, following these guidelines will narrow the options. Consider noise source, belt material, deck surface, width, and whether you want a temporary or permanent fix.

With the right traction tape for your situation, you can get your treadmill belt working and sounding good as new. No more annoying noises disrupting your workout!

Prepping Your Treadmill Belt for Repair

Before you can fix issues like slipping or squeaking with DIY treadmill repair tape, proper preparation of the belt is key. Taking time to thoroughly clean and inspect the belt first will ensure the tape adheres well and delivers reliable traction.

Follow these steps to prep your treadmill belt for a successful DIY repair:

Unplug the Treadmill

Always unplug the treadmill before working on the belt. This avoids any risk of electric shock while cleaning or handling the underside of the belt.

Lift the Belt

Refer to your owner’s manual for how to safely lift or partially disassemble the treadmill to access both sides of the belt. Often there are clips, latches or screws allowing the motor cover and side rails to detach.

Use care not to damage any parts as you work to expose the belt’s underside.

Inspect Damage

Before cleaning, inspect the belt to identify damaged or worn areas. Look for cracking, cuts, bald spots or uneven texture indicating the belt needs replacement, not just repair tape.

Also note where the belt is making contact with the deck to indicate where to apply the traction tape.

Thorough Cleaning

Use isopropyl alcohol and clean cloths to vigorously scrub the entire underside of the belt, deck surface and belt rollers. Remove all debris, grease, dirt and residues which could impede tape adhesion.

Pay extra attention to cleaning the specific areas where you’ll apply the repair tape for optimal stickiness.

Consider Lubrication

A squeaking belt often needs lubrication in addition to traction tape. Lubricate first following directions, then use the tape to help the lube adhere in slipping areas.

For very dry belts, consider applying lube and letting it soak in overnight before taping.

Determine Tape Placement

Identify the exact area where slipping occurs to position the tape accurately. Measure and cut pieces before lifting the belt to speed up the repair process.

Place tape centrally under slipping zones, or on the edges if belt drift indicates tracking misalignment.

Have Materials Ready

Gather all repair supplies in advance – tape, cloths, lubricant, scissors, applicator. Have everything you need within reach before lifting the belt to make the repair process smoother.

Protect Surrounding Areas

Cover any nearby motor or electronic components with cloth or masking tape to avoid damage. Accidental drips of lube or tape overspray could impact sensitive parts.

Also mask off deck areas not being taped to facilitate tape removal later if needed.

Test Tape Adhesion

Before fully committing to a tape type or brand, do a test patch to ensure it sticks well to the belt and deck surfaces.

Press on the test tape firmly and walk on the belt to see if adhesion holds up to motion and friction.

Take Time for Proper Prep

Rushing into a DIY treadmill belt repair without proper cleaning and inspection can result in tape not adhering well or failing prematurely. Taking time to fully access, clean and evaluate the belt and determine optimal tape placement helps ensure lasting results.

With proper prep work, you can feel confident your repair tape will provide long-term traction and finally stop those annoying slipping or squeaking sounds!

Applying Treadmill Repair Tape Correctly

You’ve chosen the perfect DIY repair tape to stop your treadmill’s slipping or squeaking. Now comes the key step – applying the tape properly so it adheres well and solves the problem.

Follow these tips for flawless treadmill repair tape application:

Review Manufacturer Instructions

Read any guidance provided with your specific tape for proper use on treadmills. Different tapes may require special techniques like using an applicator tool or adding primers.

Cut Tape to Size

Measure the belt width and cut pieces of tape 4-6 inches wide to adequately cover the center slipping areas. Narrow strips won’t provide enough surface contact.

Cut longer pieces than needed so adjusting placement is easy. You can always trim off excess.

Test Fit First

Do a test fit of the tape shape before removing the backing. Ensure proper belt coverage and alignment before adhering the tape permanently.

Mark the deck location with masking tape as a guide for the final tape position.

Remove Backing Slowly

Once position is perfect, peel away the backing paper or plastic slowly to prevent the tape from sticking prematurely. Dispose of the backing immediately.

Avoid Touching Adhesive

When handling the tape, touch only the edges and avoid contact with the adhesive surface. Oils from fingers can interfere with optimal bonding to the belt.

Apply Gradually

Begin adhering the tape at one end and work outwards to avoid air bubbles. Use a plastic smoother to gradually tack down the tape, moving from center outwards.

Rub It Down Firmly

Once placed, firmly smooth over all edges and surfaces of the tape onto the belt. Strong pressure ensures maximum adhesion and traction.

Use an Applicator Tool

For professional results, use a hand roller or treadmill applicator tool to adhere the tape evenly with no gaps or missed areas.

Add Multiple Layers if Needed

One strip of tape may not solve a severe slipping problem. Simply add additional layers on top of the first to increase traction gradually.

Test Treadmill Function

Lower the belt, turn on the machine and walk on the belt to test for reduced slipping or squeaking noises.

Listen closely and check for gaps in the tape repair while the belt is in motion.

Make Adjustments Quickly

If slipping or noise persists, lift the belt again immediately and add more tape while the original tape is still fresh and well-adhered.

Making adjustments quickly prevents having to totally redo the repair later.

Let Tape Cure Properly

It takes most treadmill repair tapes 24-48 hours to fully cure. Avoid heavy use during this period and don’t get the belt wet.

Letting the tape cure properly ensures the strongest long-term traction.

Stick With It!

Applying DIY repair tape is an easy process, but attention to detail ensures optimal results. Follow usage tips carefully and use proper tools and techniques for smooth, quiet treadmill functioning.

With properly applied tape, you can finally stop slipping, stick with your workout plan and save those repair dollars!

Securing the Tape for Maximum Hold

You have your DIY treadmill repair tape cut and ready to stick. But simply slapping it on won’t deliver the long-lasting traction you need. Proper application techniques are key for the tape to securely bond and solve issues like slipping and squeaking.

Use these tips to get the strongest, most durable hold from your repair tape:

Clean Surfaces Thoroughly

Use isopropyl alcohol to vigorously scour the belt underside, deck and rollers where tape will be applied. All grease, dirt and oils must be removed for tape to adhere tightly.

Consider Surface Textures

Rougher belt surfaces provide more grip for tape. If needed, gently sand plastic or urethane belts to create texture so the adhesive bonds better.

Use Primer if Needed

Some slick treadmill belt materials may require a special primer coating before tape application for enhanced traction.

Primers work like glue to help the tape grab the belt tighter.

Apply Firm Pressure

Use your hands, a roller tool, or weighted object to apply very firm pressure across the entire tape surface. This forces maximum contact with the belt.

Don’t be shy – the harder you rub, the better it will stick!

Go Edge-to-Edge

Tape not only the center but also extend completely from edge to edge on the full belt width. No gaps should remain for slipping to persist.

Extra overlap on the edges prevents peeling.

Layer Multiple Strips

For heavy slipping issues, apply 2-3 layers of tape overlapping slightly. Multiple layers increase overall traction and reinforcement.

But let each layer cure fully before adding the next for best results.

Use X-Shapes for Corners

To keep tape from peeling at the edges, apply small X-shaped strips at the corners. This anchors the ends down tightly.

An X pattern also allows flexing without loosening.

Reinforce with String

For extra security, you can also sew the tape edges to the belt using strong upholstery thread. This helps prevent lifting or peeling.

Use a curved upholstery needle to stitch easily under the belt.

Heat It Up

Use a hair dryer on low setting to gently warm the tape as you apply it. Heating helps the adhesive flow into the belt fabric for maximum sticking power.

Just avoid excessive heat which could damage the belt.

Use Two Tapes

Apply double-sided treadmill tape to the deck, then use grip tape on the belt side. The sandwiched adhesive provides an extra-secure bond.

Check Hold Periodically

Inspect the taped areas regularly when using your treadmill. If edges seem loose, press them back down firmly before they peel further.

Catching lift-off early prevents total detachment.

Stick that Repair!

The right techniques ensure your DIY treadmill belt tape sticks for the long run. Adequate surface prep, firm pressure, full coverage, and reinforcement create a powerful bond to finally stop annoying slipping for good!

Re-Aligning the Belt After Repairs

You did it! You successfully repaired your treadmill belt with grip tape or other DIY products to fix slipping and noise issues. But now the belt may be running off-center or misaligned after being lifted. Proper realignment ensures smooth operation.

Follow these key steps to re-align your treadmill belt after repairs:

Inspect Belt Tracking

Turn on the treadmill and observe if the belt now tracks too far left or right. Tracking refers to how centrally the belt runs.

Have someone walk on the belt as you assess since body weight can affect tracking.

Locate Adjustment Bolts

Consult your manual to find the rear roller bolts which control belt alignment. There will be one bolt on each end of the roller.

These bolts tighten and loosen the roller to move the belt side-to-side.

Determine Which Bolt to Turn

If the belt tracks too far left, you’ll tighten the bolt on the right roller end to move it back right.

If it tracks too far right, tighten the left bolt instead. This pivots the roller alignment.

Adjust 1/4 Turn at a Time

Using a wrench or screwdriver, turn the proper bolt only 1/4 clockwise. Excessive tightening can damage the treadmill.

Test run the belt to check if more adjustment is needed.

Repeat Until Centered

Keep making 1/4 turns followed by test runs until the belt tracks centered down the middle of the deck.

Be patient – perfect tracking alignment may take several small adjustments.

Secure Jam Nuts

Once aligned, tighten the jam nuts on the roller bolts to lock them in place. This prevents bolts from turning during use.

If bolts slip, tracking can shift out of alignment again over time.

Try a Tracking Wrench

A specialty treadmill tracking wrench simplifies the alignment process. The double-sided tool fits both adjustment bolts for easy turning.

Tracking wrenches take the frustration out of perfecting belt alignment.

Check Centering Periodically

Inspect belt tracking each time you use the treadmill for the first few weeks after repairs.

Re-adjust immediately if alignment goes off to prevent damage from belt rubbing.

Consider Professional Help

If you can’t get the belt to stay centered despite multiple attempts, contact a repair technician. Severe misalignment risks further treadmill damage.

Professionals have the tools and experience for ideal belt tracking results.

Stay Centered

Re-aligning your treadmill belt properly is the finishing touch after DIY repairs. While it takes patience and care, properly tracking the belt ensures smooth, quiet, long-term operation.

Stick with the small adjustments, and you’ll have that belt running straight down the middle again in no time!

Testing Belt Tension Before Use

You applied DIY treadmill repair tape and realigned the belt. Is your repair job complete? Not quite – it’s crucial to check belt tension and make any needed adjustments for optimal performance.

Follow these steps to test and adjust belt tension:

Inspect Visually

Power the treadmill on without walking. Visually inspect if the belt seems loose or sagging, especially in the center.

Some looseness is normal, but excessive sagging indicates insufficient tension.

Press Down Lightly

With the belt running, gently press straight down in the belt center with your fingertips. More than 1-2 inches of sag means it’s too loose.

Bounce on Belt

Stand straddling the belt and lightly bounce up and down on the balls of your feet. Excessive belt sinkage under body weight reveals inadequate tension.

Listen for Rubbing

Walk on the treadmill and listen closely for any rubbing or contact sounds from the belt scraping the edges.

This usually signals the belt is too tight, not loose.

Feel for Hesitation

Treadmill belts rely on proper tension to move smoothly. Excessively loose belts hesitate or stutter when you step.

This uneven power transfer indicates a need to increase tension.

Check for Slippage

Tightly grip the front handlebars and plant your feet firmly on the belt. If your feet slip backwards when powering up the speed, the belt needs tighter tension.

Compare With Specs

Consult your owner’s manual for the manufacturer’s recommended belt tension range. Use their objective specs to gauge tightness.

Verify you’re within the proper tension parameters.

Err on the Tight Side

When in doubt, tweak tension slightly towards tighter rather than looser. This prevents slipping and stuttering, which are worse than slight rubbing.

You can always loosen later if needed.

Adjust in Small Increments

Use the rear roller bolts to carefully tighten or loosen belt tension in small 1/4 turn increments. Test again after each minor adjustment.

Hit the Sweet Spot

Getting treadmill belt tension just right ensures peak performance and longevity. Take time to check and tweak tension before restarting your regular workout routine after repairs.

Dialing in the perfect tightness keeps your belt gliding smoothly for miles to come!

Safety Checks to Perform After Repairs

You fixed your treadmill belt slipping with some DIY repair tape and elbow grease. But before hopping back on, it’s crucial to do safety checks to ensure proper function and avoid injuries.

Follow this checklist to verify treadmill safety after repairs:

Test the Motor Start

Power on the treadmill and make sure the belt starts smoothly without hesitation or odd sounds.

Erratic startup could indicate motor issues or continued slipping problems.

Listen for Noise

Walk on the belt at different speeds and listen closely for any grinding, squeaking or thumping noises.

Tune your ears to detect even subtle sounds of potential trouble.

Check for Vibration

Place your water bottle on the handlebar and inspect if strong vibrations make it shake at higher speeds.

Excess vibration suggests lingering repair needs.

Confirm Speed Settings

Test all speed buttons to verify correct speeds display on the monitor and adjust properly.

Inaccurate speeds are a safety risk and indicate electronics issues.

Inspect Belt Tracking

Observe the belt for several minutes checking it runs centered without drifting or rubbing edges.

Misaligned tracking creates unsafe uneven deck wear.

Look for Damage

Do full walk-arounds inspecting for any loose parts, cracks, lifting tread, or damage from repairs.

Catching hazards early prevents safety implications down the road.

Confirm Emergency Stop

Check the safety clip is securely installed and test emergency stop function.

This is a critical safety feature to halt the belt if needed.

Use Care When Stepping On/Off

Avoid distractions and hold handles for stability when stepping on and off moving belt.

Carelessness risks dangerous missteps and falls.

Check Belt Lubrication

Inadequate lubrication of the deck and belt can compromise function and safety.

Lubricate after repairs following manufacturer directions.

Safety First!

It’s extremely important to thoroughly test and inspect your treadmill after any repairs to identify potential issues before they cause harm. Prioritizing safety helps ensure your DIY handiwork keeps you and your machine in peak condition.

Preventative Maintenance for Treadmill Belts

Performing regular preventative maintenance helps keep your treadmill belt running smoothly for years before major repairs are needed. Simple DIY care prolongs your machine’s lifespan and avoids disruptive breakdowns.

Follow this proactive treadmill belt maintenance routine:

Weekly Inspections

Give your treadmill a quick visual once-over before each use. Check for loose parts, damaged spots on the belt, or frayed edges. Listen for odd noises when starting.

Early detection of minor issues prevents them worsening over time.

Monthly Lubrication

Apply treadmill lubricant monthly following the manufacturer’s directions. Lubrication prevents the belt and deck from drying out and causing friction, wear, and noise.

Choose quality silicone lubricant made specifically for treadmills.

Clean After Each Workout

Use anti-bacterial wipes to thoroughly clean the belt, display, and handlebars after each use. Sweat and oils can degrade components if left to accumulate.

Keep towels and cleaning supplies handy for a quick post-workout wipe down.

Check Tension and Tracking

Inspect belt tension and tracking monthly or if you hear any slipping or rubbing sounds. Make minor adjustments as needed to prevent bigger issues.

Proper tension and alignment reduce friction and uneven wear.

Inspect Belt Underside

Lift the belt to inspect the underside and deck 2-3 times per year. Look for belt damage or excess deck wear. Use the chance to clean thoroughly.

Belt lifting tools make access easier. Schedule seasons to check under your belt.

Test Incline and Speed

Run through the full range of incline and speed settings every few months. Verify proper adjustment and monitor function.

Catch and correct any electronics issues promptly.

Check Fasteners

Examine all nuts, bolts, clips and fasteners every 6 months. Tighten any loose parts to avoid damage from vibration.

Component shaking takes a toll over time.

An Ounce of Prevention

Don’t wait until major failures happen! Schedule regular treadmill belt inspections and maintenance to maximize performance and safety.

With simple preventative care, your home treadmill will stay fit for miles to come.

When to Call in a Treadmill Repair Professional

DIY repairs with treadmill tape and gumption can fix many minor belt issues. But some problems require experienced technicians to diagnose and service safely. Know when it’s time to hand your treadmill over to the pros.

Seek professional repairs for these treadmill troubles:

Electrical Issues

If the console powers off unexpectedly, buttons malfunction, or you smell burning, unplug the treadmill. Electrical issues pose serious risks.

Only qualified technicians should handle diagnosing and replacing any damaged components.

Motor Problems

A motor making loud grinding noises or losing power needs an expert repair. Don’t attempt motor disassembly yourself.

Professionals have specialized tools to test and rebuild failing treadmill motors.

Belt Replacements

Badly damaged or severely worn belts often can’t be repaired and require full replacement. Let a pro install new heavy-duty belts.

They’ll fit belts perfectly and tension them for optimal performance.

Control Board Failure

If the console displays error codes, resets programs erratically, or won’t respond, the control board likely needs professional service.

Specialized diagnostic tools pinpoint control board issues.

Deck Repair

Excess belt wear that damages the deck surface necessitates professional repair or replacement. It requires partial disassembly.

Don’t run your belt on a damaged deck since it causes rapid deterioration.

Belt Alignment Problems

If the belt continually drifts or tracks off-center despite your best alignment efforts, seek expert help. Severe tracking problems can degrade components.

Experts will accurately align and tension your belt.

Unusual Noises

Grinding, squealing or rattling sounds hint at problems needing professional diagnosis. Unusual treadmill noises mean stop using it.

Technicians pinpoint noise sources and remedy them properly.

Safety Key Issues

A broken safety key clip or malfunctioning emergency stop requires an authorized repair for your safety.

Never bypass or disables safety features.

Trust the Experts

While some repairs are DIY-friendly, others require professional expertise and tools. Don’t hesitate to call a knowledgeable repair company if issues exceed your technical skill or comfort level.

Qualified technicians will get your treadmill running safely again and extend its longevity.

Enjoy Smooth and Safe Treadmill Running

Treadmills provide a convenient way to get your cardio at home. But like any exercise equipment, they require proper maintenance and care for optimal safety and performance.

Follow these tips to keep your treadmill running smoothly for years of enjoyable, injury-free workouts:

Perform Regular Inspections

Make it a habit to visually inspect your treadmill before each use looking for any loose parts, damage or wear. Check belt tracking and tension monthly.

Catching minor issues early prevents bigger problems down the road.

Schedule Professional Service

Have a certified technician perform periodic maintenance to tune up your treadmill’s mechanical function and electronics.

Annual professional service maximizes safety, longevity and performance.

Lubricate the Belt

Apply treadmill lubricant every few months per the manufacturer’s instructions. This prevents the belt and deck from drying out.

Proper lubrication ensures smooth, quiet running.

Keep Children and Pets Away

Never leave children or pets unattended near a running treadmill. Keep small fingers clear of moving parts.

Supervise children at all times when using the machine.

Wear Proper Footwear

Always wear athletic shoes with good traction to avoid slips. Avoid loose clothing that could get caught.

Proper footwear and attire prevent falls.

Start at Low Speeds

When first getting on the treadmill, start walking at just 1-2 mph. Gradually increase speed after warming up.

Sudden high speeds increase risk of missteps or falls.

Use Safety Clip

Always attach the safety clip to your clothing before starting your workout. This will stop the belt if you fall.

Check emergency stop function regularly.

Stay Centered

Walk or run near the middle of the belt surface. Avoid drifting from side to side.

Centered footing minimizes risk of slipping off the edges.

Cool Down Gradually

Finish workouts by gradually decreasing your speed over 5-10 minutes. Don’t abruptly stop from a full run.

Slow, gentle cooldowns prevent dizziness and muscle strain.

Tread Safely

Like any exercise machine, treadmills require care and common sense for optimal safety. But a little preventative maintenance and smart use let you enjoy your own home gym without worries.

Follow these tips to keep your treadmill providing smooth, injury-free miles for years of healthy workouts!