How to choose the right screws for your ECD LAX head. What are the best practices for installing lacrosse head screws. Why proper screw maintenance is crucial for optimal performance. How to avoid common mistakes when working with lacrosse head screws. What materials and tools are recommended for lacrosse head screw installation.

The Importance of Proper Screw Sizing for ECD LAX Heads

Selecting the correct screw size is paramount for optimal performance of your ECD LAX head. Using ill-fitting screws can lead to a host of issues, including reduced ball control, impaired shooting accuracy, and diminished passing precision. To ensure you’re using the right size, always consult the manufacturer’s guidelines for your specific ECD LAX head model.

To find the perfect fit:

- Measure your current screws accurately

- Compare measurements with manufacturer specifications

- Purchase replacement screws that match these exact dimensions

Remember, screws that are too small or too large won’t secure the head to the shaft properly, resulting in annoying rattles and compromised performance. Taking the time to find the right size will pay off in improved gameplay and longevity of your equipment.

Mastering the Art of Screw Tightening: Finding the Perfect Balance

Achieving the ideal tightness for your lacrosse head screws is a delicate balance. Over-tightening can damage the plastic integrity of the head, while under-tightening may cause screws to vibrate loose during play. To strike the right balance, follow these steps:

- Hand-tighten the screws firmly

- Use a screwdriver to turn an additional quarter to half rotation

- Check for snugness without stripping the screw holes

Is there a way to ensure screws stay in place? Consider using a threadlocker solution like Loctite Blue 242. This medium-strength formula helps secure screws without making them impossible to remove later. Apply a small drop to the screw threads before insertion, and allow about 10 minutes for the adhesive to set.

Proactive Maintenance: Identifying and Replacing Stripped Screws

Stripped screws can quickly derail your lacrosse game, causing frustration and potentially damaging your equipment. To avoid this issue:

- Regularly inspect your screws for signs of wear

- Replace any damaged screws immediately

- Keep spare screws on hand for quick replacements

- Use the proper sized screwdriver to prevent stripping

Can stripped screws be prevented? Absolutely. By avoiding over-tightening and using the correct tools, you can significantly reduce the risk of stripping your screws. Remember, prevention is always easier than dealing with the consequences of damaged equipment during a crucial game or practice session.

The Strategic Approach to Tightening Lacrosse Head Screws

Proper tightening technique can make a significant difference in the performance and longevity of your ECD LAX head. To ensure even distribution of clamping pressure and minimize the risk of warping, follow this strategic approach:

- Start with the bottom screws and work your way up

- Alternate between left and right side screws as you progress

- Tighten gradually, making small adjustments to each screw in turn

This method helps seat the screws deeper into the plastic, resulting in an ultra-secure fit. It also reduces the chance of misalignment issues that can occur when one side is tightened more than the other. By following this technique, you’ll achieve a perfectly straight and balanced stringing setup, optimizing your stick’s performance on the field.

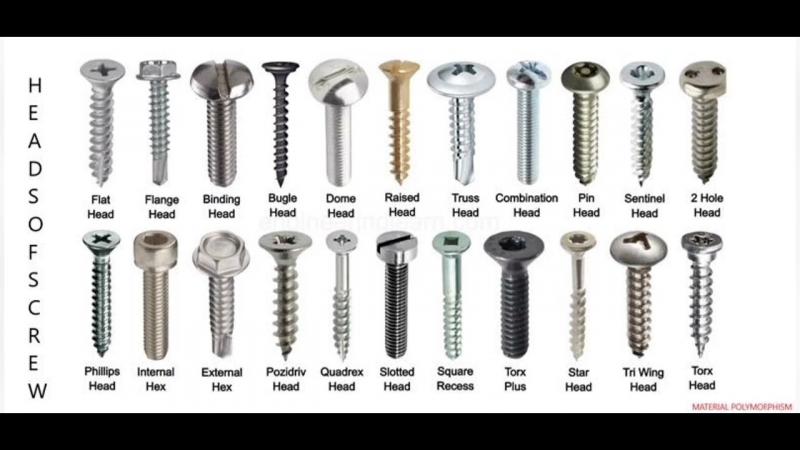

Choosing the Right Material: Why Stainless Steel Screws Reign Supreme

When it comes to selecting the best material for your ECD LAX head screws, stainless steel is the clear winner. Despite the allure of lightweight titanium screws, stainless steel offers several advantages that make it the superior choice for lacrosse players:

- Superior shear and tensile strength to withstand aggressive stick checks

- Excellent rust resistance for durability in various weather conditions

- Maintenance of smooth threading even after extended use

Are there any downsides to using stainless steel screws? While they may be slightly heavier than titanium alternatives, the difference is negligible in the context of overall stick weight. The benefits of increased durability and performance far outweigh this minor drawback.

Vigilance in Maintenance: Checking for Cracks and Wear

Regular inspection of your ECD LAX head is crucial for maintaining peak performance and preventing equipment failure. Pay close attention to the areas surrounding the screw holes, as these are prone to stress and potential damage. Here’s what to look for:

- Small cracks radiating outward from screw holes

- Signs of plastic fatigue or discoloration

- Enlarged or deformed screw holes

If you notice any of these issues, take action immediately. For minor cracks, consider relocating the affected screw to a non-damaged hole if possible. In cases of significant damage, replacing the entire head may be necessary to ensure safety and optimal performance.

What causes these cracks to form? Repeated screw removal and over-tightening are the primary culprits. By following proper installation techniques and avoiding excessive force when tightening, you can significantly extend the life of your ECD LAX head.

Upgrading Your Equipment: The Benefits of High-Quality Screws

While factory-installed screws are generally adequate, upgrading to higher quality options can provide noticeable improvements in performance and durability. Consider these benefits of investing in premium screws:

- Enhanced strength and resistance to stripping

- Improved corrosion resistance for longer lifespan

- Better thread engagement for a more secure fit

When selecting upgrade screws, look for aircraft-grade stainless steel options designed specifically for sporting equipment. These screws are engineered to withstand the rigors of competitive play while maintaining their integrity over time.

Is the cost difference worth it for upgraded screws? For serious players and those looking to maximize their equipment’s performance, the investment in high-quality screws can pay dividends in terms of reliability and peace of mind during crucial games.

The Dos and Don’ts of Screw Installation

To ensure the best results when working with your ECD LAX head screws, keep these important dos and don’ts in mind:

Do:

- Use hand tools for tightening to maintain control and avoid over-tightening

- Clean out dirt and debris from screw holes before installation

- Apply a small amount of threadlocker for added security

Don’t:

- Use power tools, which can easily lead to over-tightening and damage

- Ignore signs of wear or damage on existing screws

- Rush the installation process – take your time for the best results

By following these guidelines, you’ll ensure a proper fit and optimal performance from your ECD LAX head screws.

Preparing for Game Day: A Screw Maintenance Checklist

Before heading to your next game or practice, run through this quick checklist to ensure your ECD LAX head screws are in top condition:

![]()

- Visually inspect all screws for signs of wear or looseness

- Gently test each screw’s tightness with a screwdriver

- Clean any dirt or debris from around the screw heads

- Carry a small kit with spare screws and a suitable screwdriver

- Perform a final check of screw tightness after warming up

This proactive approach will help prevent any unexpected equipment issues during play, allowing you to focus on your performance on the field.

Understanding the Impact of Weather on Lacrosse Head Screws

Weather conditions can significantly affect the performance of your ECD LAX head screws. Different temperatures and humidity levels can cause the plastic of the head to expand or contract, potentially altering screw tightness. Consider these weather-related factors:

- Cold temperatures may cause the plastic to contract, potentially loosening screws

- Hot, humid conditions can lead to expansion, which might increase stress on screws

- Extreme temperature changes can accelerate wear on both screws and screw holes

To mitigate these effects, periodically check and adjust screw tightness, especially when playing in varying weather conditions. This attention to detail can help maintain consistent performance regardless of the environment.

The Role of Proper Storage in Screw Longevity

How you store your lacrosse stick when not in use can impact the longevity of your ECD LAX head screws. Proper storage practices include:

- Keeping your stick in a cool, dry place to prevent moisture damage

- Avoiding leaving the stick in direct sunlight, which can cause plastic warping

- Using a stick bag to protect against accidental impacts that could loosen screws

- Storing the stick horizontally to prevent uneven pressure on the head

By implementing these storage tips, you can help extend the life of your screws and maintain the overall integrity of your ECD LAX head.

Customizing Your Setup: Experimenting with Different Screw Types

While stainless steel screws are generally recommended, some players may benefit from experimenting with different screw types to fine-tune their stick’s performance. Consider these options:

- Nylon screws for a slightly more flexible connection

- Titanium screws for the ultimate in lightweight performance

- Brass screws for enhanced corrosion resistance in humid environments

When trying different screw types, always ensure they meet the size and thread specifications for your ECD LAX head. Keep in mind that any deviation from manufacturer recommendations may affect warranty coverage, so weigh the potential benefits against these considerations.

![]()

The Future of Lacrosse Head Screw Technology

As lacrosse equipment continues to evolve, so too does the technology behind head screws. Some emerging trends and innovations to watch for include:

- Self-locking screw designs that reduce the need for threadlocker

- Composite materials that offer the strength of metal with the weight of plastic

- Smart screws with embedded sensors to monitor tightness and stress levels

While these technologies are still in development, they represent exciting possibilities for the future of lacrosse equipment. Staying informed about these advancements can help you make educated decisions about your gear as new options become available.

By implementing these tips and staying vigilant about the condition of your ECD LAX head screws, you’ll ensure optimal performance and longevity for your lacrosse stick. Remember, attention to these small details can make a big difference in your game, giving you the confidence to focus on what really matters – dominating on the field.

As any lacrosse player knows, a high-performing lacrosse head is only as good as its screws. The right lacrosse head screws are crucial for optimal ball control, shooting accuracy, and passing precision. However, finding and properly installing the best screws for your ECD LAX head can get confusing. Don’t worry – we’ve got you covered with these must-know tips for upgrading your lacrosse head screws.

Proper Screw Sizing Matters

One of the most common mistakes is using screws that are too small or too large for your particular ECD LAX head. Each model has specific sizing requirements, so always double-check the manufacturer guidelines before purchasing replacement screws. Ill-fitting screws won’t properly secure the head to the shaft, leading to annoying rattles and reduced performance. Take the extra time to measure your current screws and buy the right size.

Avoid Over or Under Tightening

It can be tempting to really crank down on those lacrosse head screws, but over-tightening can actually damage the integrity of the plastic. You want a snug fit without stripping the screw holes. On the flip side, screws that are too loose can vibrate out over time. Shoot for firmly hand-tightened and then use a screwdriver to gently turn an extra quarter-to-half rotation.

Use Blue Loctite Threadlocker

Threadlocker solutions like Loctite will help secure screws in place, preventing them from loosening over time. We recommend a medium strength formula like Loctite Blue 242 for lacrosse sticks. Just add a drop to the screw threads before inserting into the head. The adhesive will set up in about 10 minutes, locking the screws in position. This gives you extra insurance against lost screws during games or practice.

Replace Stripped Screws Immediately

Nothing can ruin your lacrosse game faster than dealing with stripped screw heads that spin uselessly in place. Don’t wait to replace damaged screws. They will only further degrade and potentially damage the screw holes in the head. Keep spare screws on hand and swap out any stripped fasteners right away. Preventing stripping in the first place comes down to using the proper sized screwdriver and avoiding over-tightening.

Tighten from the Bottom Up

Here is a pro tip to help evenly distribute clamping pressure across the head: always start tightening from the bottom screws first, then work your way up. This minimizes any twisting or warping of the head as you go. Alternate back and forth between left and right side screws as you move up the head cap. You’ll end up with a perfectly straight and balanced stringing setup.

Alternate Sides When Tightening

Building on the previous tip, be sure to alternate between left and right screws as you tighten the head down. This ensures even tightening on both sides, reducing the chance of misalignment issues. Don’t risk over-tightening one side more than the other. Plus, going side-to-side helps seat the screws deeper into the plastic for an ultra-secure fit.

Only Use Stainless Steel Screws

While titanium screws might seem tempting for their lightweight properties, stainless steel is really the best bet for ECD LAX heads. Stainless provides superior shear and tensile strength to stand up to those brutal stick checks. The rust-resistant steel alloy will also maintain smooth threading through all sorts of gameplay abuse and weather conditions.

Check for Cracks Around Screw Holes

Inspect the plastic surrounding all screw holes prior to installation. Small cracks radiating outward from the holes can be a sign of structural fatigue. Enlarging cracks may require replacing the entire head. At a minimum, move any damaged screw to a different non-cracked hole if possible. Cracks result from repeated screw removal and over-tightening.

Consider Upgrading Screw Quality

Most lacrosse heads come from the factory with relatively inexpensive screws – usually stainless steel or titanium. Upgrading to higher quality screws can make a noticeable difference in your stick’s performance and longevity. We recommend considering aircraft-grade stainless steel screws designed specifically for optimal strength properties.

Don’t Use Power Tools for Tightening

It may seem convenient to break out the power drill for really cranking down lacrosse head screws, but this is a big no-no. High torque power tools make it way too easy to over-tighten and fracture the plastic. Always stick to hand tightening the screws with a proper-fitting screwdriver. Let the screwdriver do the work for a snug, even fit.

Clean Out Dirt and Debris from Holes

Make sure old screw holes are completely free of any compacted dirt, grime, or debris before inserting new screws. Use a toothpick, paperclip, or cotton swab dipped in rubbing alcohol to thoroughly clean out the holes. Any contaminants left in the holes can keep new screws from seating correctly. Take a minute to clear out any gunk.

Lubricate Screw Threads Before Inserting

Here is one extra trick to make screwing in new lacrosse head screws even easier: lubricate the threads with wax or oil prior to installation. This reduces friction as you tighten screws into plastic. Just add a drop of lubricant and rub it into threads. The screws will smoothly glide into place with less chance of stripping.

Ensure Proper Driver Fit to Avoid Stripping

Using the wrong size screwdriver is the fastest way to ruin lacrosse head screws and damage the plastic. The driver tip must precisely match the screw head shape and size. Most LAX stick screws have a #1 Phillips head, but always double check before tightening. Press the driver down firmly in the screw head and ensure the fit feels snug with no wobble or play.

Examine Screw Head and Tip for Wear

Before reinstalling used screws, take a close look at both the head and tip. Screws with excessive rounding, smoothing, or damage to the threads should be discarded and replaced. Worn drive tips are prone to camming out under torque. Rough tips can further degrade the screw holes. Don’t risk reusing questionable screws.

Follow Manufacturer’s Recommended Tightening Torque

Most lacrosse head manufacturers provide a recommended tightening torque range for their screws. This spec helps ensure you tighten screws to the optimal level. Too loose and they’ll rattle and fall out. Too tight and you’ll strip the heads or crack the plastic. Consulting the torque specs takes the guesswork out of tightening.

Upgrading the screws on your ECD LAX head is one of the easiest ways to improve performance and extending the life of your stick. Follow these tips during your next restringing for screws that stay tightened through season after season of play. With the right techniques, you’ll keep all those passes, scoops, and shots on target.

Securing an ECD LAX head to your lacrosse stick is no simple task. With the intricate weaving and tight stringing, you need screws that will hold everything in place through seasons of play. But knowing how much to tighten those lacrosse head screws can be confusing. Under-tighten and vibrations loosen the mounting. Over-crank and you’ll strip the plastic. It’s a delicate balance only experience can teach. Let’s examine the art of tightening LAX head screws for optimized ball control and handling.

Avoid Over or Under Tightening

New players often struggle figuring out the sweet spot for lacrosse head screw tightness. Too loose, and the head develops annoying rattles that throw off passing accuracy. Overly tight screws slowly shear away the plastic mounting holes. The goal is firmly hand-tightened with a quarter-turn extra squeeze from the screwdriver. No need for gorilla grip strength to get things snug.

I learned the hard way during my first stringing project. Excited to test my new head, I really cranked down on the screws. Sure enough, I stripped two holes and had to reposition the screws. Now I stick to gentle tightening by hand before lightly finishing with the screwdriver. No more damaged heads or prematurely enlarged holes.

Start Low and Move Up

Here’s a handy trick I use to evenly tighten lacrosse head screws: always begin with the bottom screws first, slowly working upwards towards the scoop. This minimizes any twisting force on the head as you tighten. Alternate left and right screws for symmetrical tightness on both sides too. You’ll end up with a perfectly straight stringing setup ready for threading.

Do the Turn-Test

Unsure if your LAX head screws are tight enough? Try the turn-test. Simply attempt turning an installed screw with your fingers, not the screwdriver. If the screw rotates at all, tighten it down more. The screw should be fully seated and immobilized in the mounting hole. Just don’t muscle it down too forcefully. Finger-tight is ideal.

Use Threadlocker for Security

Even properly tightened screws can gradually loosen over time, especially after hard checks that rattle the stick. Apply a small drop of removable threadlocker like Loctite Blue to the screws before installing them. The glue will set up after about 10 minutes, helping to secure the screws.

I apply threadlocker to all my lacrosse head screws now for added insurance. No more chasing bounced-out screws around the field! The adhesive keeps everything locked tightly in place but can still be removed if needed.

Inspect Screws and Holes

Before inserting screws, carefully examine the heads and holes for any defects. Cracks radiating from the holes mean the head is fatigued. Try repositioning cracked hole screws to solid areas if possible. Discard any screws with rounded tips or smoothed drive slots – they’ll only cam out.

I also scrub out all debris in old screw holes using a toothpick and rubbing alcohol. Built-up gunk keeps new screws from seating properly. Take time to clean and inspect both screws and plastic before tightening down your handiwork.

Upgrade Your Fasteners

Most manufactuers supply lacrosse heads with cheap stock screws. For a few extra bucks, upgrading to high-strength stainless steel aircraft-grade screws makes a noticeable difference in performance. The quality materials resist shearing from checks and won’t round off.

Avoid Power Tools

It’s convenient to whip out the power drill for quickly driving in LAX head screws. But take it from me, resist the temptation! It’s way too easy to over-torque and crack the plastic. Hand tighten only, even if it takes a few extra minutes. The screws will seat perfectly every time.

Finding that ideal tightness for ECD LAX head screws takes trial-and-error. But follow these tips and soon you’ll be stringing heads like a pro. Take time to inspect, clean, and hand-tighten using the lower-to-upper pattern. Your lacrosse stick will thank you with seasons of dialed-in performance.

Getting those lacrosse sidewall strings pulled tight on an ECD LAX head requires some serious screw strength. The last thing you want is spending hours stringing the perfect pocket only to have it loosen up after a few practices. Fortunately, there’s an easy upgrade that takes the anxiety out of keeping lacrosse head screws tightened – threadlocker.

Use Blue Loctite Threadlocker

Threadlocker solutions like Loctite work wonders to keep lacrosse head screws securely fastened. Simply apply a drop to the screw threads before driving them into the plastic mounting holes. After around 10 minutes, the threadlocker sets up and locks the screws firmly in place.

I used to constantly fret over loosening screws until I discovered Loctite. Now I apply Blue 242 threadlocker to every screw during stringing. It provides cheap insurance against losing screws mid-game or finding loose pockets. The adhesive is strong enough to prevent backing out but can still be removed later if needed.

Go Easy on Application

A little dab of threadlocker goes a long way. I made the mistake of glopping it on too thick early on. The excess adhesive got squeezed out the sides of the holes and made a mess. All it takes is a thin ring around the first few threads before installing the screw.

Allow Proper Curing Time

Patience is key when using lacrosse head screw threadlocker. I couldn’t wait to test out my first threaded head and ended up with loose screws later. Let the adhesive fully cure for at least 10-15 minutes before stressing the head. The threadlocker needs time to work into the threads and set up.

Clean Off Old Threadlocker First

When reapplying threadlocker to existing screws, make sure to thoroughly remove any old residue first. I use a brass wire brush to gently clean screw heads and holes. The new threadlocker won’t adhere correctly over gunked-up old adhesive.

Snug Fit Before Threadlocker

While threadlocker keeps lacrosse head screws from loosening, it can’t make up for improper screw tightness. I always hand-tighten until snug first before using Loctite. The adhesive locks the screws in place but doesn’t add extra tension.

Remember, over-tightening can damage the plastic. Get screws hand-tight in sequence from bottom to top before finishing with a light pass from the screwdriver. Then apply threadlocker as insurance against loosening.

Have Backup Screws Handy

Threadlocker makes lacrosse head screws very difficult to remove and install multiple times. The adhesive partially fills in the threads, causing damage over repeated use. I always keep extra new screws on hand in case I need to swap one out.

Use Medium-Strength Formula

For LAX sticks, I recommend a medium strength threadlocker like Loctite Blue 242. It will resist vibration loosening without requiring too much force to remove later. I save the heavy duty Loctite Red for permanent applications, not my lacrosse heads.

Applying threadlocker like Loctite really takes the stress out of keeping lacrosse sidewalls tightly strung. Just remember, let it cure completely before playing to avoid loosening issues. Follow these tips and you’ll never have to stop mid-game to re-tighten a pesky screw again!

Let’s face it, lacrosse can be rough on equipment. After a tough game getting hammered by checks, you may find the screws on your ECD LAX head are stripped out. The constant vibrations take a toll over time. But continuing to use damaged screws will only make the problem worse. Here’s why you need to stay on top of replacing stripped lacrosse head screws immediately.

Replace Stripped Screws Immediately

Nothing ruins a perfectly strung lacrosse head faster than the frustration of a spinning stripped screw that won’t tighten down. The temptation is to let it slide, but damaged screws must be replaced ASAP. Here’s why:

Avoid Damage to Holes

When lacrosse head screws strip out, their damaged threads chew into the plastic mounting holes as you try tightening. This leads to enlarged, elongated holes that no longer grip screws. Replacing stripped screws right away minimizes further damage.

Prevent Loosening Head

Loose, stripped screws won’t hold your lacrosse sidewalls tightly. The inevitable rattling leads to decreased ball control and erratic throwing. Get those stripped screws swapped out to restore a rigid head for accurate passing again.

Stop Annoying Rattles

Few things are more annoying than an unsecured lacrosse head rattling around on its shaft. The distracting vibration throws off your game. Don’t put up with it – replace any stripped screws to get a noise-free stick again.

Have Spares Ready

To quickly replace damaged lacrosse head screws on the fly, always keep extras handy in your gear bag. The last thing you want is to run out mid-stringing and have a head you can’t secure. Generic replacement screws are cheap online.

Examine Driver Fit

An incorrectly sized screwdriver is often the culprit behind stripped screws. Carefully examine your driver tip before installing replacements. It should fit snugly into the screw head without wobbling around.

Consider Upgrading Quality

Rather than basic factory screws, try upgrading to hardened stainless steel or titanium replacements. The improved hardness helps them resist stripping from vibration and abuse. Just be sure to match the thread sizing.

Use Lubricant

A small dab of oil, wax, or grease on replacement screw threads makes driving them in easier. The reduced friction means less potential for damaging new screw heads or plastic holes.

Caring for your lacrosse gear means addressing issues immediately, like stripped screws. Don’t play with damaged or loose heads that will ruin your game. Stay stocked with spares and swap out stripped screws before they worsen. Your stick will thank you!

Installing lacrosse head screws on an ECD LAX head requires patience and technique. Rushing the job leads to uneven tightening, misalignment issues, and stripped plastic. For optimal control and ball handling, the screws must be gradually tightened in sequence. Let’s examine the proper pattern for evenly securing screws from bottom to top.

Tighten from the Bottom Up

The biggest mistake lacrosse players make is randomly tightening LAX head screws. This puts uneven stress on the plastic and risks warping the head shape. For evenly distributed clamping force, always start by tightening the bottom screws first.

I learned this lesson after my first lopsided stringing job. By working bottom to top, the head stayed perfectly aligned as I tightened. Now I always follow this sequence for uniform tightness and straight sidewalls.

Go Up Incrementally

Don’t try skipping around when tightening your ECD LAX head. Move methodically up from the bottom, one screw at a time. Gradually increase the pressure as you work upwards to avoid stress concentrations.

Alternate Sides

In addition to moving bottom to top, remember to alternate screws left and right. This ensures the head clamps down evenly on both sides. Going side to side also helps seat the screws deeper for maximum holding strength.

Do the Tip Test

Here’s a quick way to check your tightening sequence: when secured properly from bottom up, the head tip should have no flex. Grab the tip and try to wiggle – there should be zero movement if tightened correctly.

Pre-Thread for Easier Insertion

Because lacrosse head screws are going into soft plastic, they can catch and stall if you don’t pre-thread the holes. I always turn the screws through each hole a couple rotations before fully tightening. This lets them bite in easier.

Let Plastic Relax

Don’t power through screwing down your LAX head in one shot. Tighten a few screws partially, then let the plastic relax for 5 minutes before continuing. Going low to high in increments allows the material to acclimate.

Retighten After Stringing

Once stringing is complete, do one final pass tightening the screws from bottom up. The tension from threading can loosen screws slightly over time. Starting low ensures even clamping force.

Be patient when installing ECD LAX head screws. Gradual tightening from the bottom up is the key to keeping those sidewalls straight and rigid for perfect ball control. Take it slow and your pocket will maintain that sweet spot season after season.

Installing screws on an ECD LAX head requires finesse. Simply cranking them down risks uneven tightness that throws off ball control. The key is gradually building clamping force while alternating sides. Let’s examine why it’s crucial to tighten lacrosse head screws in a left-right alternating pattern.

Alternate Sides When Tightening

Working up the lacrosse head tightening one side then the other is tempting for speed. But this puts uneven stress on the plastic and risks warping. Always alternate left and right screws as you tighten for uniformity.

I learned this lesson after my first lopsided stringing job. By alternating sides as I tightened, the head stayed perfectly straight and balanced. Now it’s second nature to go side-to-side when installing screws.

Start Bottom Left, Move Right

Begin by tightening the bottom left screw first, then move to the bottom right. Repeat this up the head, alternating sides after each screw. This builds symmetrical tightness on both sides of the head.

Use Equal Turns on Each Screw

In addition to alternating sides, tighten screws the same amount on both left and right. Don’t risk putting more torque on one side. Matching turns avoids twisting the head off-center.

Check Alignment Frequently

Periodically check lacrosse head alignment as you alternate tightening screws. Look down the length to ensure it remains straight. Catch any twisting early before it gets out of hand.

Hand Tighten First

Before using your screwdriver for the final turns, hand tighten the LAX head screws as much as possible by finger. This gets the screws seated squarely before applying torque.

Use a Threadlocker

A threadlocker like Loctite Blue applied to screws before installation will help keep sidewall tension even over time. The adhesive prevents individual screws from loosening.

Retighten After Stringing

The tension from stringing can loosen lacrosse head screws slightly. Go back and do one final alternating pass after threading to restore even clamping force.

Take the time to alternate sides when tightening ECD LAX heads. The symmetry pays off in balanced stringing and rock-solid ball control. Your crosses and shots will stay on point all season long.

When it comes to lacrosse head screws, stainless steel is really the only way to go. The unmatched durability and corrosion resistance makes stainless the ideal choice for securing ECD LAX heads. Let’s take a look at why you should only use stainless steel screws on your lacrosse stick.

Only Use Stainless Steel Screws

While titanium screws seem tempting for weight savings, stainless steel provides superior properties for LAX head screws:

Great Tensile Strength

Stainless steel has excellent tensile strength, meaning it resists stretching and deforming under load. This allows stainless screws to maintain clamping force over years of vibration and abuse.

Shear Strength

In addition to tensile strength, stainless has high shear strength. This enables the screws to resist shearing forces from all those tough checks on the field without failing.

Corrosion Resistance

Stainless steel contains chromium that forms an impervious oxide layer protecting from rust and corrosion. No need to worry about degraded threads from weather exposure.

Match the Head Material

When selecting stainless steel screws, be sure to choose a grade that pairs well with the plastic lacrosse head material. I prefer 303 or 316 stainless for most LAX heads – strong yet easier on more delicate plastics.

Proper Sizing Matters

Don’t forget to reference manufacturer specs for the proper screw sizing. Stainless steel screws come in a range of thread diameters and lengths. Using undersized or oversized screws can lead to problems.

Pre-Thread the Holes

Because stainless steel is so hard, pre-thread the mounting holes by hand before fully driving the screws. This allows the threads to cut in easier reducing the chance of stripping.

next time you are re-stringing, splurge on quality stainless steel screws. The performance and longevity over basic screws is immediately noticeable. Just be sure to match specifications and pre-thread holes. Your ECD LAX head will maintain that dialed-in feel longer.

Repeatedly installing and removing lacrosse head screws can take a toll over time. The mounting holes in the plastic can slowly become compromised, leading to loosening issues down the road. That’s why it’s critical to periodically check for cracks radiating from screw holes on your ECD LAX head.

Check for Cracks Around Screw Holes

Inspect the plastic surrounding all screw holes carefully before each stringing. Tiny cracks emanating out from the holes are a red flag. Here’s what to look for:

Hairline Fractures

Examine screw holes closely under bright light for any hairline cracks. These small fractures are often hard to see but can expand over time.

Discoloration

In addition to visible cracks, discolored or whitened plastic around holes can indicate material fatigue. This leads to breakdown over repeated screw removal/reinstallation.

Enlarged Holes

If the mounting holes seem significantly larger than your screws, theLAX head may be compromised. Gaps point to loosening issues.

Avoid Overtightening

Frequent overtightening of screws is usually the cause of cracks around holes. Ease up on torque levels and tighten just until snug. Also skip using power tools – the high speed compounds problems.

Limit Screw Removal

Only remove lacrosse head screws when absolutely necessary. The more you take them out and reinstall, the more damage caused to holes. Minimize unscrewing.

Use Threadlocker

Applying threadlocker gel helps secure screws without excessive cranking down. This reduces stress on the fragile plastic mounting points.

Catching cracked screw holes early on your ECD LAX head gives you the chance to relieve stress before complete failure. Be diligent about inspecting for fatigue and avoid over-tightening screws. Your stick will thank you with seasons more of precise pocket performance.

Re-stringing your ECD LAX head presents the perfect opportunity to upgrade those lackluster stock screws. Investing a few extra bucks in higher end screws can make a noticeable improvement in performance and longevity. Let’s look at why you should consider upgrading screw quality on your next lacrosse head project.

Consider Upgrading Screw Quality

Most manufacturers supply basic, low cost titanium or stainless steel screws with lacrosse heads. While these get the job done, upgrading to aircraft-grade screws offers big advantages:

Strength

Higher end screws utilize steel alloys engineered for maximum shear, tensile, and vibration resistance. This equates to a rock-solid head that won’t loosen up.

Precision Fit

Quality lacrosse screw sets are manufactured to tighter tolerances for snug, uniform fit without slop. This enhances stringing accuracy.

Corrosion Resistance

Premium alloys like stainless steel 303/316 offer complete corrosion and rust protection. Your LAX screws will maintain smooth threads season after season.

Match Head Material

When upgrading ECD LAX head screws, be sure to select alloys compatible with the plastic material. For most heads, 316 stainless or hardened steel work well without cracking.

Consider Titanium

If reducing weight is your main goal, look into aircraft-grade titanium screws. Just ensure the titanium grade has adequate shear strength for lacrosse.

Anti-Seize Compound

High-precision screws can gall and seize in plastic holes over time. A small dab of anti-seize lube prevents this issue.

Don’t settle for the cheap factory screws in your new ECD LAX head. For a few dollars more, upgrade to quality hardware engineered for strength and precision. Your shots, passes, and checks will benefit.

Installing lacrosse head screws can be tedious by hand. It’s tempting to speed things up with a power drill for quick tightening. But power tools are a big no-no when securing ECD LAX heads. Avoid these mistakes and stick to hand tightening only for the best results.

Don’t Use Power Tools for Tightening

It seems convenient to break out the cordless drill and power through lacrosse head screws. However, this is risky business:

Over-Torquing

High torque power tools make over-tightening screws way too easy. This can fracture delicate plastic mounting points and damage the head.

Uneven Tightness

A power drill can apply inconsistent tightening force as you move around the head. Hand tightening ensures uniform screw pressure.

Stripped Screws

High speed power drivers greatly increase the chance of damaging screw heads or stripping them out entirely.

Hand Tighten in Sequence

The proper way to install LAX head screws is gradually by hand, tightening in sequence. Start from the bottom and work upwards while alternating sides.

Pre-Thread Holes

Partially threading screws into holes first allows them to bite in better when hand tightening. Just don’t fully power them down.

Use a Threadlocker

A threadlocker like Loctite will help secure screws without excessive manual torque. Just don’t overdo application.

Resist the urge to grab power tools when installing your ECD LAX screws. Hand tightening takes a few extra minutes but is essential for even tightness and reducing damage. Take it slow and let the screwdriver do the work.

Before installing new screws on your ECD LAX head, take a minute to thoroughly clean out the mounting holes. Packed in dirt and debris can prevent screws from seating properly, leading to loose heads and poor ball control. Here’s how to clean holes for ideal screw installation.

Clean Out Dirt and Debris from Holes

Each time you restring, examine the plastic screw holes carefully and clean out any contaminants:

Use Compressed Air

Blast lacrosse head holes with short bursts of compressed air. This will eject dried mud, grass, and most loose debris.

Toothpick Scrub

For more stubborn gunk, use a toothpick to gently scrape out material from the holes. Slowly twist the pick to dislodge buildup.

Rubbing Alcohol

Dip a cotton swab in alcohol and rotate inside each hole. This will dissolve and extract compacted dirt for a squeaky clean screw channel.

Examine Screw Fit

Test fit each screw by hand after cleaning holes. The threads should glide smoothly without binding when properly cleaned. If not, re-clean and inspect for damage.

Rethread Holes

Use screws to carefully rethread any elongated or distorted holes before final installation. This reshapes the channels for optimal screw engagement.

Check Screw Tips

Inspect screw tips for rounding or burrs that might catch on plastic holes. Damaged tips can further scuff clean holes.

Taking just a few minutes to thoroughly clean lacrosse head screw holes pays off in the long run. Debris causes nothing but headaches and loose hardware down the road. Keep those holes pristine!

Lubricate Screw Threads Before Inserting

Got a new lacrosse head and need to string it up? Hold your horses there, bucko. Before you go jamming those sidewall screws into the brand new head, it’s crucial that you lubricate the threads first. Failure to lube those bad boys could lead to disaster down the road – stripped screws, snapped heads, you name it. Read on to discover 15 must-know tips for properly lubricating your ECD LAX head screws and avoiding screw thread tragedy.

1. Choose the Right Lubricant

Not just any old lube will do here, friends. We need something that will stand up to the unique demands of lacrosse head screws. Regular household oils tend to be too thin and will wear off quickly with use. Thick greases can collect debris and get gummy over time. The best bet is a threadlocking fluid or paste designed for metal parts. Brands like Loctite or Vibra-TITE make great options that will keep your screws slipping smoothly for a long time.

2. Clean the Threads

Before lubricating, take a minute to clean out both the screw threads and the matching holes in the head. This removes any dirt or debris that could interfere with the action of the lubricant. A quick swipe with a stiff brush or blast of compressed air does the trick.

3. Read the Instructions

Not all lubes are created equal, so be sure to read the product instructions before getting started. Some threadlockers need to fully cure to reach maximum strength, while others work instantly. Using the lube correctly will ensure a smooth screw installation.

4. Apply a Thin Coat

A little dab will do ya here – we only need a thin layer of lubricant on the threads to do the job. Less is more, as excessive amounts can lead to issues like hydrolocking. Focus the lube on the first few threads that enter the head first.

5. Let it Soak In

Before inserting the screws, let them sit for a few minutes after lubricating so the fluid can soak in. This gives the lube time to penetrate fully into every nook and cranny of the threads for maximum effectiveness.

6. Twist As You Insert

Here’s a pro lacrosse stringing tip: twisting the screw as you insert helps evenly distribute the lubricant throughout. The spinning action spreads the lube around and gets those threads nicely coated as they engage the head.

7. Tighten in Sequence

When dealing with multiple screws (like on an ECD Rebel or Bravo1 LAX head), be sure to tighten them gradually in a sequence. This ensures even pressure across the head and prevents stripping or warping. Work opposite corners back and forth.

8. Stop at Snug

Over-tightening lubed screws can actually cause them to get stuck in the threads. Once the screw feels snug, give it just a touch more turn and you’re good. No need to crank it down hard.

9. Reapply if Needed

If a screw feels sticky or gritty when removing, a fresh coat of lube is in order before reinserting. Regular reapplication helps maintain smooth function over the life of your lacrosse head.

10. Avoid Petroleum Products

Though slippery, oil-based lubricants like WD-40 aren’t recommended for lacrosse screws. They tend to run and drip, attract dirt, and break down plastics over time. Stick to specially formulated threadlocking compounds.

11. Don’t Force It

If a screw just isn’t wanting to start or feels stuck, stop. Forcing it can strip the head, screw, or both. Re-lubricate and gently work it back and forth to loosen before continuing insertion.

12. Check for Debris

A screw that’s becoming increasingly difficult to insert may have debris in the threads. Use compressed air or a thin pick to clean them out before adding more lube and trying again.

13. Avoid Overheating

Friction from screws can generate heat, degrading plastic materials. Lubrication helps prevent this, allowing lower insertion forces. Take care not to aggressively work an unlubricated screw back and forth.

14. Don’t Overtighten

Once a screw starts getting difficult to turn, it’s tightened enough; maybe a quarter-turn more at most. Overtightening can weaken the surrounding plastic. Let the lubricant work to keep things snug.

15. Check Annually

As part of your regular lacrosse gear maintenance, check the condition of your head screws each season. Reapply lubricant if needed to keep things operating smoothly for the long haul.

Lubing lacrosse head screws takes just a minute, but pays off big time in easier stringing, fewer headaches, and longer equipment life. Following these lacrosse stringing tips helps ensure a smooth screw installation. Now get out there and unleash that new pocket!

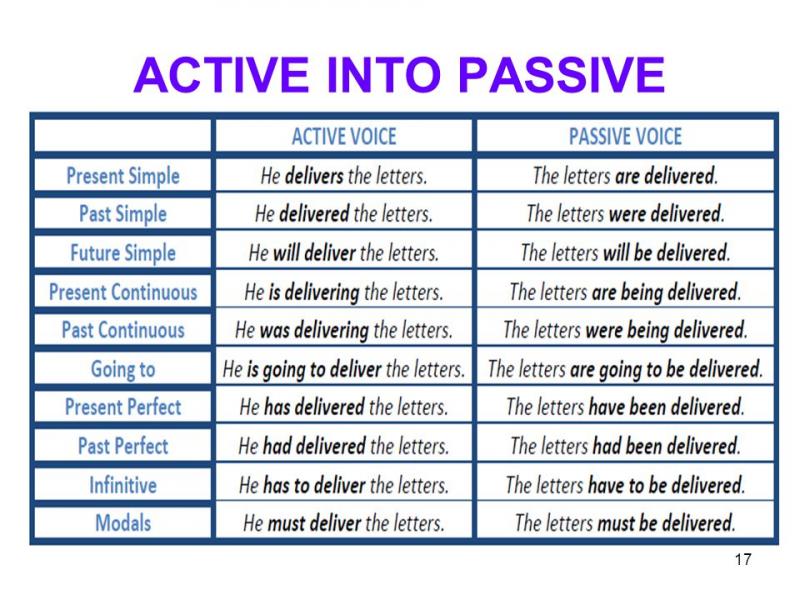

Ensure Proper Driver Fit to Avoid Stripping

Installing screws on your new lacrosse head? Grabbing whatever driver is handy can be a recipe for disaster. Using the wrong size driver can lead to cam-out, stripping, or worse. For smooth sailing, it’s critical to ensure proper driver fit before inserting screws into your ECD LAX head. Read on for 15 must-know tips to avoid screw stripping nightmares.

1. Match Driver to Screw Head

The driver tip should match the shape and size of the screw head exactly. With lacrosse sidewall screws, this is usually a #1 Phillips head. Using a #2 Phillips risks cam-out and damage.

2. Insert Fully into Screw Head

For maximum torque, the driver must be fully inserted into the screw head before turning. Partial engagement can cause the driver to slip and strip the screws.

3. Apply Even Pressure

Applying excessive force to one side of the driver can cause it to slip, damaging the screw. Keep pressure centered to avoid stripping disaster.

4. Use Snug Fit Drivers

A loose driver that wobbles in the screw head is a recipe for stripping. Tight tolerance drivers that fit snugly help apply torque evenly and cleanly.

5. Grease the Grooves

Lightly coat the driver tips and screw heads with grease first. This fills any gaps, improves fit, and reduces friction and driver slippage during insertion.

6. Use New Drivers

Old, worn driver tips tend to cam out more easily. Splurge for fresh drivers with crisp, unworn edges for best screw driving performance.

7. Take It Slow

Rushing leads to stripping! Insert and turn the screws slowly and smoothly. Let the driver do the work without forcing anything.

8. Follow Torque Specs

Heads have recommended torque settings for sidewall screws. Use a calibrated driver that clicks when reaching the correct torque.

9. Use Magnetic Drivers

Magnetized driver tips help keep the driver secured in the screw head, preventing slippage during tightening.

10. Push Down when Turning

Applying downward pressure when turning helps keep the driver seated fully in the screw head for maximum engagement.

11. Stop at First Strip

At the first sign of cam-out or stripping, stop immediately and reassess sizing, fit, and technique before continuing.

12. Use a Screw Holder

Screw holders that grip the threads help guide screws straight into holes without wobbling, reducing stripping risks.

13. Check Driver Condition

Inspect drivers regularly for wear, bending, or damage. Bent, dull, or worn drivers can slip and strip out screws.

14. Avoid Power Drivers

High-torque power drivers make it too easy to overdrive and strip plastic screw holes. Hand drivers allow better feel and control.

15. Let Lubricant Cure

If using a curing threadlocker, allow full cure time before driving screws. Premature tightening risks stripping.

Avoiding lacrosse screw stripping takes proper driver selection, fit, control, and technique. Following these tips when installing your ECD LAX head sidewall screws prevents headaches down the road. Get out there and unleash that fresh stringing job!

Examine Screw Head and Tip for Wear

Having trouble driving those lacrosse head screws? Before you grab a power tool, inspect the screw head and tip closely first. Undetected wear can lead to cam-out, stripping, and other undesirable results. Catching issues early and replacing worn screws can save major headaches when inserting them into your ECD LAX head. Read on for 15 tips to spot and address screw wear.

1. Check for Rounding

Look for a rounded or deformed driver contact area in the screw head. This reduces driver engagement and can cause cam-out.

2. Feel for Smoothness

Run a finger over the screw head and tip. Rough spots or peening indicate wear and potential for driver slippage.

3. Inspect Under Lighting

Use bright lighting and magnification to inspect for microscopic wear like flattened driver contact points, pitting, or cracking.

4. Look for Discoloration

Heavily worn parts tend to take on a different colored patina from work hardening and friction heat.

5. Try a Test Fit

Insert a driver into the screw head and check for looseness. Movement indicates a compromised fit requiring replacement.

6. Compare to New Screw

Place a used screw beside a new one to spot subtle shape abnormalities indicating wear.

7. Shake Side-to-Side

Gently grip inserted driver and screw and try wiggling side-to-side. Any play is a red flag for replacement.

8. Assess Torque Required

If tightening a used screw takes noticeably more torque, its head is likely worn and prone to cam-out.

9. Try Different Drivers

If multiple new drivers can wiggle in the screw head, it’s definitely worn and ready for replacement.

10. Note Deforming Screwdriver

Driver tips that start flattening, spreading, or showing heavy wear may indicate a consumed screw.

11. Examine Thread Area

Check for stripped, crossed, or broken threads which can prevent proper screw engagement.

12. Consider Total Use Cycles

Fasteners have a finite overall life, typically 100-1000 uses before replacement is needed.

13. Know Material Limits

Softer screws like aluminum are more prone to wear issues than hardened steel options.

14. Review Environmental Exposure

Prolonged exposure to elements can accelerate wear and decomposition of screws.

15. When In Doubt, Replace

Small screws are cheap – if a used fastener is questionable, swap in a new one.

Staying on top of lacrosse screw head and tip wear helps avoid aggravation during insertion into your ECD LAX head. Following these inspection tips as part of regular gear maintenance keeps things trouble-free. Now get out there and unleash that wicked stringing job!

Follow Manufacturer’s Recommended Tightening Torque

Installing those essential lacrosse sidewall screws? Cranking them down by “feel” can spell disaster. Stripping, breakage, and poor retention can result from improper torque. For smooth sailing, follow the manufacturer’s recommended tightening specs when inserting screws into your ECD LAX head. Read on for 15 tips to dial in ideal torque.

1. Check Documentation

Consult user manuals, spec sheets, or packaging to find the head maker’s torque recommendations for all screws.

2. Account for Screw Size

Bigger screws need more torque; smaller ones less. Use size-appropriate torque ranges.

3. Consider Screw Material

Harder materials like steel allow higher torques than softer aluminum. Match torque to the screw.

4. Use a Torque-Limiting Driver

These click when reaching preset torque values, eliminating guesswork and over-tightening.

5. Go Slow

Gradually increase torque rather than tightening quickly to prevent overshooting the optimum level.

6. Tighten in Sequence

Following crisscross or star patterns ensures even clamping force without distortion.

7. Check with a Torque Wrench

Confirm final torque with a beam-style or click-type wrench to verify screws are within spec.

8. Mark the Setting

Note the torque driver setting needed to reach proper torque for consistent fastening.

9. Consider Age of Plastics

Brittle, aged plastic requires less torque to avoid damage compared to fresh materials.

10. Lubricate First

Lubricating screw threads reduces friction and clamping force, requiring less torque.

11. Test on Sacrificial Piece First

Dial in torque on a scrap head or plastic piece before working on the real thing.

12. Account for Static Friction

It takes added torque to initially break a screw free from static friction.

13. Stop at First Twinge

If plastic begins to deform before reaching specified torque, stop to avoid damage.

14. Periodically Retorque

Recheck torque after break-in as screws can loosen slightly until fully seated.

15. Trust Torque over Turns

Turning a certain amount is not as accurate as using a torque value. Rely on specs.

Dialing in the manufacturer’s recommended lacrosse head screw torque prevents problems down the road. Follow these tips when installing screws in your ECD LAX head to keep things tight yet trouble-free. Now get out there and unleash that wicked pocket!