Need A Baseball Glove Lace Repair. Find Out Why This DIY Kit Is EssentialNeed A Baseball Glove Lace Repair. Find Out Why This DIY Kit Is Essential

Introduction To Rawlings Glove Lace Repair Pack

As a lifelong baseball player, I’ve gone through my fair share of gloves over the years. From little league to high school varsity, those leather mitts have been by my side, forming the pocket and breaking in to fit my hand perfectly. But time and wear eventually take their toll, and one of the first things to go on a well-loved glove are the laces.

When those rawhide laces finally give out and snap, it can seem like the end of the road for your trusty companion. But with the right materials and a little DIY spirit, you can breathe new life into that glove and get back out on the field. That’s where the Rawlings Glove Lace Repair Pack comes in clutch.

Like a firefighter arriving to put out a blaze, this lace repair kit contains everything you need to re-lace your prized glove and save it from retirement. I stumbled upon it after one too many popped laces made my old high school mitt almost unwearable. Figuring it was likely cheaper than buying a new high-end glove, I ordered the Rawlings kit and got to work.

When To Consider Re-Lacing Your Glove

If you’ve played baseball or softball for any length of time, you’ll eventually encounter popped or frayed laces. Your fingers push and pull on them every time you catch a ball, so it’s no surprise they’ll eventually break. If you notice more than a couple busted laces, it’s probably time to replace them all.

Re-lacing does require some time and elbow grease, so I recommend it once your glove has already formed to your hand instead of repeatedly on newer mitts. But it can add years of life and save you from spending big on a replacement. The nostalgia factor of restoring my high school glove rather than retiring it also played a role in my decision.

Removing Old Laces From Glove

Before you can thread the new laces, you’ve got to remove the old, broken ones. I suggest having a seam ripper tool on hand to easily pull the knots through the holes without damaging the leather. Take care not to tear any of the holes open more than they already are.

If you don’t have a seam ripper, small scissors or snips will also do the trick. Just be cautious and patient so you don’t end up with bigger problems than some busted laces. With the proper tools, this step is straightforward, just time consuming.

Preparing Glove For New Laces

Once all the old laces are out, inspect each lace hole carefully. Use a leather conditioner to soften and prep the glove for re-lacing. Look for any holes that are cracked or stretched from wear and tear. For minor cracks, a dab of glue or silicone sealant can prevent further ripping.

If any holes are torn wide open, unfortunately your glove may be too far gone to repair. But if the holes are all reasonably intact, rub conditioner into the leather and you’re ready for new laces.

How Many Feet Of Lace Do You Need?

The Rawlings kit comes stacked with 132 feet of lace, which may seem like overkill. But it’s better to have too much than not enough. You can always trim off the excess once you’ve finished lacing. An average adult glove uses around 20-30 feet, while smaller youth gloves may only need 10-15 feet.

Since every glove is different, it’s impossible to give an exact amount. The key is not skimping yourself, as you’ll need extra for tying knots and overlapping laces. It also doesn’t hurt to have reserves on hand in case you mess up and need to re-do a section.

Lace Selection Types In Repair Kit

Benefits of DIY Glove Repair

- Cost-effective alternative to buying a new glove

- Extends the life of a well-broken-in mitt

- Allows for customization of lace tightness and pattern

- Preserves the sentimental value of cherished gloves

The Rawlings Glove Lace Repair Pack: A Game-Changing Solution

Enter the Rawlings Glove Lace Repair Pack, a comprehensive kit designed to simplify the glove repair process. This DIY solution provides everything needed to restore your glove to its former glory. But what makes this kit stand out from other repair options?

Key Components of the Rawlings Repair Pack

- 132 feet of assorted lacing material

- Multiple lace types for various glove styles

- Detailed instructions for proper re-lacing techniques

- Durable materials for long-lasting repairs

Is the Rawlings kit suitable for all skill levels? Absolutely. Whether you’re a seasoned player or a novice, the included instructions make the repair process accessible to everyone. The abundant lacing material ensures you have more than enough to complete the job, even if you make a few mistakes along the way.

Identifying When Your Glove Needs Re-Lacing

Recognizing the signs that your glove requires re-lacing is crucial for maintaining its performance and longevity. But how can you tell when it’s time to break out the repair kit?

Common Indicators of Lace Deterioration

- Visible fraying or thinning of laces

- Loose or slack areas in the glove’s webbing

- Difficulty closing the glove properly

- Laces that snap or break during play

- Inconsistent ball retention in the pocket

Should you wait until laces completely break before repairing? It’s generally better to address lace issues proactively. By replacing laces at the first signs of wear, you prevent sudden failures during crucial moments in a game and maintain consistent glove performance.

Preparing Your Glove for Re-Lacing

Before diving into the re-lacing process, proper preparation is key to ensuring a successful repair. How should you approach this initial stage?

Steps for Glove Preparation

- Remove all old laces carefully using a seam ripper or small scissors

- Clean the glove thoroughly, removing dirt and debris

- Inspect lace holes for damage or stretching

- Apply leather conditioner to soften the glove material

- Repair any minor cracks or tears in the leather

Can you repair severely damaged lace holes? For minor stretching or small cracks, a dab of leather glue or silicone sealant can reinforce the holes. However, if the damage is extensive, it may be best to consult a professional or consider glove replacement.

Mastering the Art of Glove Lacing Techniques

Re-lacing a baseball glove is a skill that combines precision, patience, and a touch of creativity. But what are the key techniques you need to know?

Essential Lacing Methods

- Traditional crisscross pattern for finger stalls

- Web lacing for various pocket styles

- Heel pad reinforcement techniques

- Wrist strap adjustment lacing

How do you choose the right lacing pattern for your glove? Consider the original lacing style of your glove as a starting point. Different positions and player preferences may call for variations in lacing patterns. Experiment with tension and crossing points to find the perfect balance of flexibility and structure.

Selecting the Right Lace Type for Your Glove

The Rawlings Glove Lace Repair Pack offers a variety of lace types, each with unique properties. Understanding these differences is crucial for achieving the best results in your glove repair.

Comparing Lace Materials

| Lace Type | Characteristics | Best For |

|---|---|---|

| Waxed Rawhide | Durable, slides easily, holds knots well | Most modern gloves |

| Leather | Softer feel, more pliable | Vintage gloves, players preferring a softer touch |

| Hybrid | Combines flexibility and durability | All-around use, balancing performance and feel |

Which lace type should you choose for optimal performance? Consider your playing style, position, and personal preferences. Infielders might prefer the quick-sliding properties of waxed laces, while outfielders could benefit from the durability of hybrid laces.

.jpg)

Step-by-Step Guide to Re-Lacing Your Baseball Glove

Now that you’re equipped with the knowledge of lace types and preparation techniques, it’s time to dive into the actual re-lacing process. Follow these steps to restore your glove to its former glory:

- Measure and cut laces to appropriate lengths for each section

- Begin with the web, following the original pattern or choosing a new style

- Lace finger stalls, starting from the pinky side and working towards the thumb

- Secure the heel pad, ensuring proper tension for optimal ball impact absorption

- Finish with the wrist strap, adjusting for comfort and secure fit

- Trim excess lace and singe ends to prevent fraying

- Break in newly laced areas by flexing and manipulating the glove

How tight should you lace your glove? Aim for a balance between security and flexibility. Laces should be snug enough to maintain the glove’s shape but not so tight that they restrict movement or create pressure points.

Tips for Smooth Lacing

- Use a lacing needle or awl to guide laces through tight holes

- Apply leather conditioner to new laces for easier threading

- Maintain consistent tension throughout the lacing process

- Double-check your work after each major section

Extending Your Glove’s Lifespan: Maintenance After Re-Lacing

After successfully re-lacing your glove, proper maintenance is key to ensuring your hard work pays off in the long run. How can you protect your newly repaired mitt?

Post-Repair Glove Care Routine

- Allow the glove to air dry completely after each use

- Store the glove in a cool, dry place when not in use

- Regularly clean the glove with a soft brush or cloth

- Apply leather conditioner every few months to prevent drying and cracking

- Inspect laces periodically for signs of wear and replace as needed

How often should you re-condition your glove? The frequency depends on usage and environmental conditions, but a general rule of thumb is to condition your glove every 2-3 months during the playing season.

By following these maintenance steps, you’ll significantly extend the life of your repaired glove, ensuring it remains a reliable companion on the field for seasons to come.

Customizing Your Glove: Advanced Lacing Techniques

Once you’ve mastered basic re-lacing, you might want to explore advanced techniques to customize your glove further. These methods can enhance performance and tailor the glove to your specific playing style.

Advanced Lacing Methods

- Double-lacing for reinforced durability in high-stress areas

- Modified web patterns for improved ball visibility or quicker transfers

- Adjustable finger pad lacing for personalized fit and feel

- Specialized pocket designs for different positions (e.g., pitcher’s deep pocket)

Can advanced lacing techniques really improve your game? While proper technique is paramount, customized lacing can indeed provide subtle advantages. For instance, a catcher might benefit from a reinforced pocket lacing to withstand repeated high-speed impacts.

Experimenting with Lace Tensions

Fine-tuning lace tension in different areas of the glove can significantly affect its performance. Consider these variations:

- Looser web lacing for a quicker, softer pocket

- Tighter finger stalls for enhanced control

- Variable tension across the palm for optimal flex points

Remember, finding the perfect balance may require some trial and error. Don’t be afraid to make adjustments as you break in your newly laced glove.

Troubleshooting Common Re-Lacing Issues

Even with careful preparation and execution, you might encounter some challenges during the re-lacing process. Here’s how to address common issues:

Problem-Solving Guide

| Issue | Possible Cause | Solution |

|---|---|---|

| Laces slipping or loosening | Insufficient knot security | Use double knots or apply a drop of clear nail polish to secure |

| Difficulty threading laces | Tight or misaligned holes | Use a lacing needle or awl to guide laces; realign holes if necessary |

| Uneven tension across the glove | Inconsistent lacing technique | Unlace problem areas and re-do with more consistent tension |

| Laces breaking during re-lacing | Excessive force or sharp edges | Use gentler technique; smooth any rough leather edges |

How can you prevent these issues in future re-lacing projects? Practice and patience are key. Each glove you repair will improve your technique and understanding of the intricate lacing process.

The Environmental Impact of Glove Repair

In an age of increasing environmental awareness, the practice of repairing and extending the life of sports equipment takes on added significance. How does glove repair contribute to sustainability in sports?

Benefits of Glove Repair for the Environment

- Reduces waste by keeping gloves out of landfills

- Decreases demand for new glove production, conserving resources

- Encourages a mindset of repair and reuse in other aspects of life

- Supports local repair services and DIY culture

By choosing to repair rather than replace your baseball glove, you’re not only saving money but also making a small yet meaningful contribution to environmental conservation.

Sustainable Lacing Options

For those particularly concerned about environmental impact, consider exploring eco-friendly lacing alternatives:

- Organic cotton laces

- Recycled leather laces

- Plant-based synthetic laces

While these options may not be included in standard repair kits, they represent an area of growing interest in the sports equipment industry.

The Future of Baseball Glove Technology and Repair

As materials science and manufacturing techniques evolve, so too does the world of baseball gloves. What innovations might we see in glove design and repair in the coming years?

Emerging Trends in Glove Technology

- Smart gloves with embedded sensors for performance tracking

- 3D-printed custom glove components for perfect fit

- Self-healing materials that reduce the need for frequent repairs

- Biodegradable glove materials for reduced environmental impact

How might these advancements affect the practice of glove repair? While new technologies may reduce the frequency of needed repairs, they’re likely to create new opportunities for specialized maintenance and customization.

The Role of DIY in Future Glove Care

Despite technological advancements, the art of glove repair is likely to remain an essential skill for serious players. As gloves become more complex, the ability to understand and maintain your equipment will become even more valuable.

Future repair kits might include digital guides, augmented reality instructions, or even small 3D printers for creating custom parts. The core principles of glove care and repair, however, are likely to remain largely unchanged.

Building a Community Around Glove Repair

The practice of glove repair extends beyond individual players; it’s a skill that can bring baseball and softball communities together. How can you share your knowledge and experience with others?

Ways to Spread Glove Repair Knowledge

- Organize repair workshops at local leagues or schools

- Create online tutorials or video guides

- Mentor younger players in equipment care and maintenance

- Participate in or start glove repair forums and discussion groups

By sharing your skills, you not only help others save money and extend the life of their equipment but also contribute to the rich tradition of baseball craftsmanship.

The Social Aspect of Glove Repair

Glove repair can be a social activity, bringing players together to share tips, stories, and a common passion for the game. Consider organizing glove repair gatherings where players can work on their equipment together, fostering a sense of community and shared knowledge.

Introduction To Rawlings Glove Lace Repair Pack

As a lifelong baseball player, I’ve gone through my fair share of gloves over the years. From little league to high school varsity, those leather mitts have been by my side, forming the pocket and breaking in to fit my hand perfectly. But time and wear eventually take their toll, and one of the first things to go on a well-loved glove are the laces.

When those rawhide laces finally give out and snap, it can seem like the end of the road for your trusty companion. But with the right materials and a little DIY spirit, you can breathe new life into that glove and get back out on the field. That’s where the Rawlings Glove Lace Repair Pack comes in clutch.

Like a firefighter arriving to put out a blaze, this lace repair kit contains everything you need to re-lace your prized glove and save it from retirement. I stumbled upon it after one too many popped laces made my old high school mitt almost unwearable. Figuring it was likely cheaper than buying a new high-end glove, I ordered the Rawlings kit and got to work.

When To Consider Re-Lacing Your Glove

If you’ve played baseball or softball for any length of time, you’ll eventually encounter popped or frayed laces. Your fingers push and pull on them every time you catch a ball, so it’s no surprise they’ll eventually break. If you notice more than a couple busted laces, it’s probably time to replace them all.

Re-lacing does require some time and elbow grease, so I recommend it once your glove has already formed to your hand instead of repeatedly on newer mitts. But it can add years of life and save you from spending big on a replacement. The nostalgia factor of restoring my high school glove rather than retiring it also played a role in my decision.

Removing Old Laces From Glove

Before you can thread the new laces, you’ve got to remove the old, broken ones. I suggest having a seam ripper tool on hand to easily pull the knots through the holes without damaging the leather. Take care not to tear any of the holes open more than they already are.

If you don’t have a seam ripper, small scissors or snips will also do the trick. Just be cautious and patient so you don’t end up with bigger problems than some busted laces. With the proper tools, this step is straightforward, just time consuming.

Preparing Glove For New Laces

Once all the old laces are out, inspect each lace hole carefully. Use a leather conditioner to soften and prep the glove for re-lacing. Look for any holes that are cracked or stretched from wear and tear. For minor cracks, a dab of glue or silicone sealant can prevent further ripping.

If any holes are torn wide open, unfortunately your glove may be too far gone to repair. But if the holes are all reasonably intact, rub conditioner into the leather and you’re ready for new laces.

How Many Feet Of Lace Do You Need?

The Rawlings kit comes stacked with 132 feet of lace, which may seem like overkill. But it’s better to have too much than not enough. You can always trim off the excess once you’ve finished lacing. An average adult glove uses around 20-30 feet, while smaller youth gloves may only need 10-15 feet.

Since every glove is different, it’s impossible to give an exact amount. The key is not skimping yourself, as you’ll need extra for tying knots and overlapping laces. It also doesn’t hurt to have reserves on hand in case you mess up and need to re-do a section.

Lace Selection Types In Repair Kit

Not all laces are created equal when it comes to the right one for your glove. The Rawlings kit takes the guesswork out by providing three different lace types:

- Waxed laces – The traditional rawhide laces you’ll find on most modern gloves. They slide through smoothly and hold knots securely.

- Leather laces – Often used for vintage gloves. Softer feel but can be more prone to slipping.

- Hybrid laces – Combination of leather and rawhide. Provides flexibility without being too slippery.

The variety in the kit allows you to match the lace to your specific glove material and re-create the original lacing pattern.

Properly Measuring And Cutting New Laces

To figure out how long each lace strand should be, lay the glove flat and loosely measure the distance between holes where that strand will pass through. Add a few extra inches to allow for knot tying and errors. Repeat this process for each finger and web section you’ll be lacing.

Use sharp scissors to carefully cut the new laces to their measured lengths. Singeing the cut lace ends with a lighter will prevent fraying. Don’t be alarmed if the new laces seem ridiculously long at first compared to the old ones. They’ll shorten up as you tie knots and tension the laces threading them through the glove.

Lacing Methods For Different Glove Types

Whether you string traditional crisscross lacing, go for a quicker straight lacing, or imitation unwelted lacing, the Rawlings kit has you covered. The included instructions provide lace patterns for relacing most baseball and softball glove designs.

I prefer crisscross lacing for a classic look and tighter pocket. But straight lacing is quicker if you’re in a time crunch. Just be sure to crisscross the main glove fingers for optimal strength.

Troubleshooting Common Lacing Issues

Don’t be surprised if you run into a few snags along the way. Knots slipping, laces fraying, or holes tearing more are common hurdles. Patience and the right techniques will help overcome them.

Using tight double knots at the hole exits secures the laces from slipping. Fraying can be minimized by singeing lace ends and handling them gently. For torn holes, gluing small patches over the problem spots can provide reinforcement.

Ensuring Proper Web Formation

One key area to focus on is lacing the web tightly. This helps maintain the glove’s natural pocket and desired shape. Crisscrossing the web laces diagonally pulls the sides in and creates a nice pocketing form.

Don’t be afraid to really cinch and tension those web laces more than the rest. Proper web formation makes the difference between a re-laced glove that feels broken-in versus one that seems stiff.

Breaking In New Laces Correctly

Once the lacing is complete, you’ll want to break in the new rawhide or leather laces to shape them to your glove. This helps soften the materials while forming the ideal pocket.

To break in the laces, repeatedly squeeze a ball into the pocket while flexing your wrist and fingers. Massage conditioner into the leather as you work the pocket. Knock the mitt with your fist to further soften and loosen the new laces.

Maintaining Gloves After A Lace Repair

Now that you’ve restored your glove, be sure to keep it properly maintained. Continue applying conditioner to the leather every few months or any time the glove gets wet. Moisturizing the leather ensures maximum pliability and pocket formation.

Inspect the laces periodically for signs of wear and replace any that appear frayed. Avoid exposing the glove to excessive moisture or heat to prevent the leather and laces from drying out.

Extending Glove Life With Proper Storage

When you’re not playing ball, store your glove with care to get the most years out of it. Keep it away from direct heat or sunlight, which can dry out and crack the leather.

I stuff my glove with a softball when storing it to help the pocket maintain its shape. But you don’t want to over-stuff it to the point of stretching the leather.

Comparing DIY vs Professional Relacing

If you lack the time or confidence to DIY a lace repair, sending your glove to a pro is another option. They’ll typically do a quality job re-lacing, but at a much higher cost.

Expect to pay at least $40-60 for professional re-lacing services. That cost motivated me to take a DIY approach. And with the detailed instructions in Rawlings’ kit, I had the satisfaction of restoring my cherished glove myself.

In the end, the 72 feet of lace left over after repairing my glove was confirmation I chose the right DIY kit. Having extra materials for future repairs or lace replacements provides peace of mind this classic mitt will throw, catch and form a pocket for many seasons to come.

When To Consider Re-Lacing Your Glove

As an avid softballer for over two decades now, my glove and I have been through countless games together. We’ve shared thousands of catches, hauled in endless fly balls, and gotten each other incredibly dirty season after season.

But that kind of heavy-duty use takes its toll. Despite meticulous care and maintenance, my beloved glove has faced its share of wear and tear over the years. Frayed laces, stretched leather, and a constantly loosening web have me looking for ways to squeeze a few more seasons out of this well-worn companion.

When the first few laces began to pop, I initially tried simply replacing them one at a time. But after the sixth or seventh broken lace, it became obvious this piecemeal approach was just a stopgap. It was time for a complete re-lace if I wanted to keep this glove in the game.

popped and broken laces = re-lace time

The most obvious sign your glove needs fresh laces is popped or broken rawhide showing up across multiple fingers. No glove lace will last forever with constant use. The friction of catching and squeezing a ball gradually frays and strains the laces over time.

If you’ve got more than a couple laces that are either partially split or fully snapped, a full re-lace is in order. Trying to spot replace them never achieves the same tight and uniform lace pattern. And the other existing laces are likely close to failure anyway after seasons of play.

Floppy, stretched out leather

Another giveaway that your glove needs re-lacing is when the leather, particularly in the pocket and web areas, becomes excessively soft, floppy, or stretched out. The structural integrity of the laces helps provide shape and support to the leather.

Once those laces have loosened and worn down from use, the leather has nothing left to keep it taught and formed. Re-lacing restores that needed stability and desired pocket depth.

Webbing comes loose too easily

On most gloves, it’s the webbing laces between the thumb and fingers that bear the brunt of the force when catching balls. These horizontal laces absorb a lot of shock and strain with repeated impacts.

Over time, even with proper care, the webbing laces will stretch and loosen. Having to constantly tighten and retie your glove’s webbing is a neon sign that new laces are due.

Seeing frayed spots near lace holes

Take a close look at each lace hole along the edges of the fingers and web when inspecting an older glove. If you notice the leather becoming frayed or stressed right next to the holes, that’s a red flag.

It means the existing laces have worn and allowed the surrounding leather to become damaged from use. Fresh laces will reinforce those vulnerable areas and reduce further fraying issues.

What if it’s a new glove needing a re-lace?

While most re-lacing happens on older, well-used mitts, occasionally a new glove will need it. Maybe the factory lacing job wasn’t done tightly or uniformly. Perhaps a defect caused early lacing failures. Or the leathers just stretches more than expected during break-in.

Whatever the reason, if you notice any of the issues above occurring on a newer glove, don’t hesitate to re-lace it. DIY kits make glove lace repairs easy and affordable.

Check manufacturers’ lace hole warranties

Many glove makers stand behind the construction quality of their products by offering warranties on lace holes tearing or failing prematurely. For higher end gloves, this coverage may extend for multiple seasons of play.

If you notice lace hole failures on a fairly new mitt, check if the manufacturer provides any warranty coverage. You may be able to get free repairs or a discount on re-lacing costs.

Re-lace for an emotional rescue

Finally, for those really special vintage mitts, re-lacing can be like an emotional rescue. The chance to breathe new life into an old favorite that’s been with you for years can feel priceless.

Rather than retiring your trusty ‘gamer’ glove prematurely, consider re-lacing it for a nostalgic project that provides the satisfaction of repairing and preserving a beloved ball glove.

With the right DIY kit, bringing those aging laces up to speed can extend the life of your glove for multiple seasons to come. Keep that pocket popping for another round of plays in the field!

Removing Old Laces From Glove

So you’ve made the call – that beloved old glove needs some new laces after seasons of trusty use. Now comes the messy but necessary step of stripping out those busted old laces before the new ones can go in.

Having re-laced my gamer glove a couple times now, I’ve learned a few tricks that make removing the old laces easier. Taking your time and having the right tools makes all the difference.

Locate your seam ripper

The ideal tool for old lace removal is a seam ripper. This affordable little tool allows you to easily slice through the thread at the lace holes without damaging the surrounding leather.

Insert the sharp tip into the lace knot, give it a turn, and the threads separate without risk of tearing open the holes. Forget about knives or scissors for this delicate task.

Snip laces at the knots first

Before pulling long laces completely out, first snip them as close to the knot as possible at each hole. This leaves minimal loose thread to deal with and avoids excess pulling on the holes.

Use sharp snips or scissors to carefully cut the knotted end of each lace right where it exits the leather. This prep work simplifies the full removal process.

Pull out the old laces gently

With the laces severed at each knot, begin gently pulling the short remains through each hole using your seam ripper tip. Take care not to yank too hard and tear open the holes further.

The laces will likely be brittle, dried out and delicate after seasons of use. Pull slowly and smoothly to avoid breakage during removal.

Watch for hidden anchor knots

On many gloves, the main web laces running horizontally across the top often have hidden anchor knots tied on the inside of the web near the palm. These help keep the web tight but can be tricky to remove.

Carefully feel along the inside webbing to check for any interior anchor knots tied in the laces. Cut and pull these out from the inside using your seam ripper so they don’t go unnoticed.

Deal with frayed lace ends

Old laces removed from a well-used glove will invariably have frayed ends where they exited the holes. Some careful trimming of these frays will make pulling the remains out cleaner.

Use sharp snips to trim off any worst frayed areas after cutting the knotted ends. This leaves less fray potential as you remove the main lace lengths.

Take your time

With many gloves having 20 or more lace holes per finger and web, the removal process takes patience and diligence. Avoid rushing through or you may damage lace holes or leave hidden remnants behind.

Removing frayed and dried laces that have been anchored for years is a slow process. Set aside adequate time to fully clear out the old before putting in the new.

Condition the leather

Once all old laces are fully removed, take the opportunity to condition the now exposed leather inside the glove. This softens and preps it for the new laces while nourishing the areas under the old laces.

Pick a leather conditioner you know works well with the specific glove leather. Massage it thoroughly into all fingers, seams and the web where new laces will go.

Inspect for damaged holes or tears

With the old laces stripped out, closely inspect each lace hole for damage or tears. Especially look for fraying right at the hole edges where laces could further tear the leather.

Small tears may need patching or glue reinforcement before lacing. Badly damaged holes will compromise re-lacing, so inspect closely during removal.

Clean out any debris inside glove

Finally, be sure to clear out any dirt, debris or detached liner pieces that may have accumulated inside the glove over time. A clean interior makes lacing much easier.

Removing old brittle laces takes patience, but it’s a necessary step before those new laces can breathe new life into your glove. Handle the vintage laces gently as you prep for fresh ones.

Preparing Glove For New Laces

With the worn out old laces removed, now is the perfect time to get your glove ready for its new threading. Taking a little time to properly prep the leather, holes, and pockets will make re-lacing much smoother and more effective.

Based on my experience re-lacing my gamer glove several times, here are some key steps I’ve learned for prepping a glove before putting in fresh laces.

Clean and condition the leather

Start by gently cleaning dirt, grime or any stuck-on debris from the glove leather. A soft rag dampened with leather cleaner works well to refresh the surface.

Once cleaned, use your preferred leather conditioner liberally on both interior and exterior surfaces. Get the conditioner worked into all fingers, seams, edges and interior surfaces where laces will contact the leather.

Proper conditioning softens the leather for easier lacing and helps the knots seat tightly into holes without tearing.

Inspect each hole carefully

Examine each individual lace hole closely under good lighting. Look for any excessive cracking, tearing, or deformation around the holes after removing old laces.

Minor cracking can often be treated with leather conditioner. But tears or holes widened from prior lacing may need reinforcement with adhesive patches prior to re-lacing.

Reinforce damaged holes

For any lace holes with concerning cracks or tears, use a small patch of performance fabric like Dyneema glued over the problem area for stabilization.

Cut tiny patches just larger than each distressed hole, roughen the edges, apply glove glue or shoe goo, and press firmly in place until set.

Check for loose liner issues

Examine inside the glove for any areas of detached or frayed liner material. Loose liner pieces can interfere with smooth lacing. Re-adhere any problem spots.

Also look for protruding liner stitching or seam allowance inside fingers that may get in the way of the new laces. Trim any nagging seam edges.

Shape the pocket

With no laces present, you have an opportunity to pre-shape the pocket depth before lacing. Use a ball or other round object to gently shape the desired pocket form.

Don’t over-stretch the leather, just work it enough to dictate the pocket shape. This allows lacing the glove “pre-curved” to your preference.

Stretch the openings

Before lacing closed the glove fingers and web spaces, gently stretch those openings to the desired end shape and circumference.

This avoids trying to over-stretch the laced leather later. Lace the glove to the already ideal stretched size and shape.

Prep tools and workspace

Set up your lacing workspace with proper lighting and all necessary tools at the ready – laces, scissors, pliers, lighter, magnifying glass, etc.

Have your lace patterns or templates on hand along with the instructions. Preparation makes lacing go much smoother.

Mark lace holes if needed

If re-creating a complex lace pattern, use a fine point marker to lightly number or notate holes to avoid errors. Erase later once laces are in place.

Loosely thread new laces through first to visualize lace order and tension before knotting and tightening.

Taking the time to properly clean, condition, and set up the glove in advance allows for efficient, quality re-lacing you’ll be proud of for seasons to come.

How Many Feet Of Lace Do You Need?

One key question facing anyone about to re-lace their baseball or softball glove is trying to estimate how much new lace to get. You want enough to do the job well, but excess would just be wasted money.

The amount needed varies depending on glove size, design, lace pattern, and other factors. But here are some tips to help determine about how many feet of new lace you’ll need for a quality DIY re-lacing project.

Account for practice runs

It’s smart to add extra footage to account for test runs, mistakes, and potentially needing to redo sections during your first re-lace. Having to stop mid-project for more lace would be frustrating.

Plan on an extra 10-20% more lace than you think the glove needs to allow for learning curves and errors the first time through.

Measure total hole circumference

For a good ballpark estimate, use a soft measuring tape to measure around the full circumference of all lace holes combined.

This gives you the total lacing distance needed. Multiply it by 2-3 for crisscross patterns or 1-2 for straight lacing to arrive at a minimum footage.

Allow for knot tying

The lace footage measurements account for the portions threaded through holes. But remember to budget more length for all the knots you’ll need to tie at each hole.

As a general rule, allow for using up about 6 inches of lace for each knot location.

Consider your lace pattern

Some glove lace patterns require substantially more lace than others to complete. A complex crisscross pattern needs more footing than a simple straight-line lace.

Examine the exact lacing technique you plan to use on that specific glove and add length accordingly over the bare minimum.

Bigger gloves need more

Larger adult gloves generally require around 20-30 feet of new lace for adequate re-lacing. Youth gloves may only use 10-15 feet due to smaller size and simpler lace patterns.

Measure your specific glove and add extra for waste factor, knots, and lace pattern rather than guessing yardage.

Type of lace matters

Stiffer rawhide laces don’t thread through holes as easily as softer leather laces, requiring a little more length.

Account for the lace type called for on your particular glove. Rawhide needs more footage cushion than leather laces.

Only buy what you need

Resist overbuying an excessive amount of new lace. Those 100+ foot spools may seem like a great value but quickly become waste.

Better to start with the 30-40 feet you likely need and buy more only if necessary. Leftover scraps can be used for repairs down the road.

Reuse any good old laces

If any of the old laces being replaced are still intact, save those to reuse on the re-lace job where possible. This extends your new lace supply.

Mixing in some reusable old laces reduces the footage of new lace you’ll have to purchase for the project.

While it’s hard to provide a one-size-fits-all lace length recommendation, following these tips helps estimate your unique glove’s ideal re-lacing lace requirements.

Lace Selection Types In Repair Kit

One of the handy features of a quality DIY glove re-lacing kit is that it provides you with different lace types for the job. This allows matching the lace to the specific glove material and design.

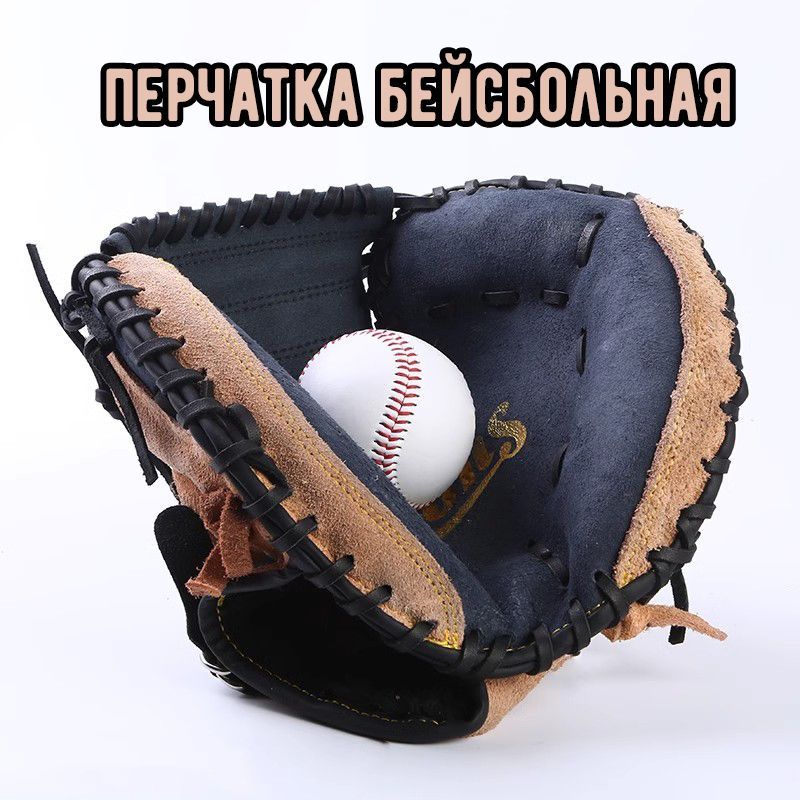

For example, the Rawlings glove lace repair kit includes three common lace varieties – waxed rawhide, leather, and a rawhide/leather hybrid. Let’s examine the best uses for each.

Waxed rawhide laces

These traditional rawhide laces have been coated with wax for smooth threading through holes. The wax coating also provides a level of water resistance while retaining rawhide’s signature stiffness.

Waxed rawhide laces are ideal for most modern leather baseball gloves due to matching textures and feel. The wax coating allows the laces to slide through holes with less friction or tearing.

Leather laces

Some gloves, especially vintage mitts, may have originally been laced with softer leather rather than rawhide. Leather laces provide more flexibility and a lower profile.

For classic gloves made of very supple leathers, matching leather laces help maintain the vintage look and feel while providing increased pliability.

Hybrid rawhide/leather laces

These specialty laces combine rawhide cores wrapped in softer leather exteriors. This offers some stiffness from the rawhide interior while retaining leather’s smoothness.

Hybrid laces provide a balance of strength and flexibility. They work well on gloves made from firmer or heavier types of leather.

Match lace to glove material

In most cases, your best bet is matching new lace material as close as possible to the original lace type and glove leather material.

However, blending different lace varieties can be used for customizing feel. Just be sure to choose lace textures that won’t damage the holes.

Consider lace rigidity needed

Stiffer rawhide laces provide more lasting structure and pocket depth. They resist stretching better under impact stress.

For a deeper pocket or firmer glove, choose waxed rawhide or hybrid laces. Prioritize flexibility? Go with leather laces.

Factor in lace visibility

If your glove has open lace holes visible on the back, lace color and texture becomes part of the look.

Matching the original lace variety preserves the classic glove aesthetic. But custom lacing can provide creative options.

Test different lace sections

One neat trick is mixing up lace types in different sections. Use stiff rawhide laces for the fingers and web, but soft leather on the wrist openings for comfort.

Get creative testing combinations on practice gloves before custom lacing your gamer mitt.

Follow manufacturer guidance

Check your glove company’s website for any specific guidance on best replacement lace types for that model.

The maker understands the gear materials best. Follow their recommendations whenever possible.

Having a variety of quality leather and rawhide lace types on hand gives you the flexibility to match new laces to each glove’s unique needs.

Properly Measuring And Cutting New Laces

To execute a smooth glove re-lacing, getting clean, accurate lace length measurements is crucial. Taking time to properly measure and cut the new laces makes the actual threading move far easier.

Based on my experience re-lacing gloves multiple times, here are some tips for measuring new laces like a pro so they are ready to install.

Account for knot lengths

When measuring laces, be sure to add extra length to account for the knots you’ll tie at each hole. About 3-4 inches of extra lace allows for knot tying at each end.

Without accounting for knot space, your laces will come up painfully short as you start securing them to holes.

Mark hole spacing

Use a marker to lightly mark both entry and exit points for each lace’s threading path through the holes. This lets you measure the exact span length needed between holes.

Knowing the linear distance for each lace segment results in precision cutting rather than guessing lengths.

Leave room for tightening

When in doubt, cut laces a little long to begin. You can always trim excess later, but too short leaves you stuck.

Allow some extra length for pulling laces snug when finishing. Trim only after fully tightening and knotting.

Cut in logical segments

Rather than cutting one giant lace for each finger, measure and cut smaller sections between holes. This allows customizing tension easier.

Cutting each span between holes as its own lengthed lace simplifies adjustments.

Label your laces

To avoid confusion, lightly mark cut lace sections with hole numbers or locations identify where each piece goes.

Labeled laces make the actual installation much smoother. You don’t want blending or crisscrossing errors.

Check lengths as you go

As you progress lacing the glove and tightening sections, double check remaining tail lengths of unlaced laces. Adjust your ongoing cuts accordingly.

Dialing in proper lengths by hole section prevents coming up short halfway through install.

Mind the fraying

New rawhide or leather laces can fray fast when cut. Take care to singe cut ends lightly with a lighter to seal the wrappings.

This tiny step reduces frustrations from frayed laces snagging during install. It really helps.

Have extra lace ready

Even with careful measuring, have backup lace available in case you need to recut any pieces that come up short or get damaged.

Avoid work stoppages by having ample extra lace to make adjustments on the fly as needed.

Investing the time up front to measure and cut new laces with care makes the actual re-lacing process go much smoother and achieve a professional Result.

Lacing Methods For Different Glove Types

Baseball and softball gloves come in a variety of styles, materials, and designs. The optimal lacing method can vary depending on factors like glove patterns, pocket depth, materials, and more.

Understanding the most effective lacing techniques for different glove types helps ensure proper structure and ideal pocket formation after re-lacing.

Size Matters

Larger adult gloves typically utilize more intricate lacing versus smaller youth gloves. More complex crisscross and web lacing better supports fuller-sized gloves.

For kids’ gloves, often a simple straight line lacing across the fingers offers enough structure without sacrificing flexibility.

Material Considerations

Soft vintage leather gloves usually need wider spaced lacing with less tension than stiff modern gloves. Limit over-cinching softer materials to prevent tearing.

Dense rawhide laces can handle tighter crisscross patterns on firmer new leather gloves without issues.

Pocket Depth

Gloves designed for a deeper pocket benefit from dense crisscross lacing to support the pocket shape. This prevents too much stretching from repeated impact.

Shallower pockets require less restrictive lacing to maintain the flatter profile. Too tight of a web risks collapsing a shallow pocket.

Following the Lines

Some gloves feature decorative perforated lines between lace holes on the fingers. Follow this guide path for an authentic look.

However, the perforations are not mandatory. Stick with optimal lacing for performance regardless of decorative lines.

Matching Web Style

Does the glove have an open web, closed web, single post, dual post or no web at all? Lacing techniques vary for each web type for ideal functionality.

Study how the web was originally laced and replicate that pattern even if using different lace materials.

Crisscross Fingers for Strength

While straight lines are quicker, crisscross lacing better supports fingers against impact stress and reinforcement.

Consider straight lacing only less used fingers like pinky and index while crisscrossing the most impacted middle and ring fingers.

Custom Lacing Options

Get creative with mixing lace patterns in different areas like rawhide crisscross on fingers and softer leather straights on outer wrist areas.

You can customize options while still providing structure where needed. Experiment on practice gloves first.

Ask the Manufacturer

Contact the glove maker directly for guidance on optimal replacement lacing techniques for that specific model.

Engineers who designed the glove know best how to maintain structure and performance after re-lacing.

Understanding the ideal lacing methods for each glove style allows matching the lace pattern to the glove design for maximum results.

Troubleshooting Common Lacing Issues

Even with proper preparation, some frustrations are bound to pop up during the process of re-lacing a well-loved baseball or softball glove. Knowing proven troubleshooting techniques for common lacing problems will save your sanity.

Whether it’s lace knots slipping, holes tearing further, or other headaches, here are some troubleshooting tips to overcome obstacles and get your glove re-laced right.

Knots Keep Slipping

Few things are more aggravating than pulling laces tight only to have the knots slip and loosen. Use these tricks to secure knots that grip better:

- Double knot laces at each hole exit when starting

- Wrap knots clockwise initially before finishing with counter-clockwise loops

- Snip lace ends after knotting to reduce pulling through holes

- Consider small dabs of glue inside knots as added insurance

New Holes Tearing

It’s disheartening to cut new laces only to have them tear open fragile holes wider. Reinforce holes prone to tearing using these methods:

- Glue small patches of athletic tape over stressed holes

- Work leather conditioner into problem areas to soften leather

- Avoid pulling laces at sharp angles when threading holes

- Use waxed laces to reduce friction tearing

Webbing Laces Won’t Stay Tight

Proper web tightness is crucial for maintaining a glove’s structure and shape. Try these tips for keeping webs snug:

- Really crank down on initial web lace tension

- Tie tiny knots halfway on web laces to take up slack

- Crisscross side web laces for inward pull strength

- Check for unseen inner knots loosening from wear

Pocket Losing Shape

If the glove pocket gets too baggy or floppy, tighten up lacing in key areas:

- Re-pull finger laces to eliminate slack

- Add extra crisscross laces across deepest pocket

- Work conditioner into pocket while reshaping by hand

- Use rawhide or waxed laces for stiffness

When In Doubt, Reach Out

For any other persistent issues not resolving, don’t hesitate to call the manufacturer’s customer service line for guidance from glove experts on how to troubleshoot problems with that specific model.

With some patience and crafty problem solving, almost any common lacing frustrations can be overcome to deliver a like-new glove.

Ensuring Proper Web Formation

One of the most important aspects of baseball and softball glove re-lacing is ensuring the web area is laced tightly and formed correctly. A weak web leads to loose pockets, floppy leather, and reduced ball control.

Based on my experience replacing glove laces multiple times, here are some proven techniques for achieving ideal web tightness and shape.

Tension Those Laces

Don’t be shy about really cranking down on the web lace tension when first lacing. The web needs to be cinched much tighter initially than the finger laces.

Pull aggressively on the knotted laces to deeply pocket the web shape before tightening off knots. The web will loosen over time through use anyway.

Crisscross Lacing Helps

Rather than straight horizontal lacing across the web, use an X-shaped crisscross pattern. This pulls the leather closed from alternating angles for better pocket formation.

Crisscross the side web lacings first, then fill in the perpendicular center laces last to close the box shape.

Work The Leather

As you tighten the new web laces, manually massage and shape the pocket with a ball or your hands. This helps set the ideal curved shape as laces tighten.

Bend the leather to the desired contour while continuing to tension laces for best results.

Anchor The Ends

Tie tiny knots close to each web lace hole along the outer edges of the pocket. This takes up lace slack and prevents the edges from stretching.

Anchoring the web perimeter keeps the pocket snug. I also run a dab of glue over the knots as backup.

Check For Interior Knots

Many gloves hide interior anchor knots that cinch the bottom edges of the web from inside the palm. Ensure these are still tight, retie as needed.

Excess interior slack you can’t see from outside lets the pocket bulge. Cinch it down.

Reinforce Thin Spots

Over time, the leather along the web edges can wear thin from impact stresses. I use small fabric patches glued behind these thin spots to prevent tearing.

Reinforced thin edges help the tightened laces maintain proper shape.

Watch For Over-Stretching

While you want the web laces extremely tight initially, be careful not to over-stretch or deform the leather pocket area.

Snug is great, but don’t overdo it to where the pocket shape warps. Find the balance.

Taking extra care on the web lacing results in the ideal pocket tightness, curvature, and ball control for seasons to come.

Breaking In New Laces Correctly

Freshly installed rawhide or leather laces will be stiff and need breaking-in just like a new glove. Using proper techniques to break in new laces helps soften and shape them while forming the desired pocket.

Based on re-lacing my gamer glove several times, here are some proven tips for breaking in new glove laces the right way.

Work The Pocket

After lacing, place a ball firmly into the pocket and squeeze repetitively. Flex your glove hand fingers and wrist as you compress the pocket over and over.

This forces the new laces to conform to curved pocket shape while softening the rawhide or leather.

Apply Conditioner

As you work in the pocket, frequently apply leather conditioner to both outer and inner glove surfaces. This lubricates laces and leather for faster break-in.

Pick a conditioner compatible with your specific glove leather material for best results.

Bend And Twist

In addition to squeezing a ball into the pocket, manually bend and twist the glove repeatedly as you break in the laces.

Flexing the fingers, rotating the wrist, and bending the whole glove accelerates lacing break-in across all surfaces.

Use Your Body

To really increase flexibility, slide the glove onto your off-hand and knead your palm over the pocket while closing your fingers.

Your palm’s warmth and pressure speeds up the lace shaping process.

Pound The Pocket

While holding a softball inside, pound your closed fist firmly but not excessively into the pocket from outside the glove.

This forces the ball against the laces while softening the rawhide or leather.

Loosen The Laces

If laces feel overly stiff, carefully loosen knots in sections and re-tighten to reduce lace tension as needed.

Find the sweet spot between tight lacing and necessary break-in flexibility.

Give It Time

Be patient during the break-in process. Rushing can damage laces or over-stretch leather.

Allow days or weeks for full break-in of laces depending on frequency of use.

Taking a careful approach to breaking in new glove lacing maximizes pliability while optimizing the re-formed pocket to your exact preferences.

Maintaining Gloves After A Lace Repair

Just because you’ve restored your glove with fresh laces doesn’t mean the maintenance stops there. Proper ongoing care preserves your lace repair work and maximizes the glove’s lifespan.

Consistency is key when it comes to glove maintenance. Based on my experience re-lacing gloves, here are some tips for keeping yours in top shape after a re-lace.

Monitor Lace Wear

Periodically inspect the new laces for signs of fraying, especially along the edges and knots. This will reveal if any sections need preventive reinforcement or replacement.

Catching lace wear early better protects the glove leather and prevents full breaks.

Condition Often

Apply leather conditioner inside and out every few months during playing season, more often if used frequently. This keeps the leather supple and helps the laces stay seated.

Frequent conditioning prevents the leather from becoming dry, brittle, and prone to cracking.

Check Pocket Depth

Ensure the pocket shape is holding up over time and not becoming too loose or sagging. Tighten web laces as needed to bring the pocket back to ideal curvature.

Letting the pocket go too loose hampers ball control and glove function.

Tighten Loose Fingers

If glove fingers start bagging out excessively from use, apply conditioner and gently tighten the finger lacing while re-shaping the fingers.

Snugging up finger laces maintains structure as the leather naturally stretches.

Re-Secure Knots

Check knot tightness on web anchors, crisscrosses, and hole exits. Re-tighten any knots slipping with pliers and a dot of glue if needed.

Loose knots defeat the purpose of tight lacing. Don’t let them unravel.

Watch For Rips

Inspect palm and finger seams for any developing tears or holes. Seal small splits with silicone glue before they expand.

Catching rips early makes them easier to repair.

Rotate Gloves If Possible

Consider rotating two well-broken-in gloves during the season if you play frequently. This distributes wear across gloves for longer overall life.

The glove resting today preserves itself for tomorrow.

Store Properly

Ensuring gloves are stored properly between uses maintains leather suppleness and pocket shape while preventing damage.

Keep your glove re-lacing work intact by caring for the glove after every use, not just during repair.

Extending Glove Life With Proper Storage

Putting in the time to re-lace your cherished baseball glove is an act of love. Protecting your work and the glove with proper off-season storage pays dividends for extra years of use.

Based on re-lacing my gamer several times, here are some essential tips I’ve learned for storing gloves to maximize their useful lifespan.

Minimize Temperature Extremes

Avoid leaving gloves in direct sunlight or near heat sources that could dry out and damage leathers. Equally, don’t store in freezing garages or sheds prone to moisture that promotes rot.

Ideally, keep gloves in interior closets or shelving away from temperature and humidity extremes.

Let the Glove Breathe

Never stash gloves in airtight bags or containers during storage off-season. Circulation is vital to prevent mold or mildew from humidity.

Allow gloves to breathe while being protected from dust and pests.

Give Them Shape

Gently insert a softball or similarly sized ball into the pocket when storing. This helps maintain optimal pocket shape without over-straining leather.

Avoid wedging oversized balls into gloves that excessively stretch lacing and leather.

Treat With Conditioner

Before final off-season storage, apply a quality leather conditioner inside and out. This nourishes glove leather to prevent drying and keeps laces flexible.

Conditioning before storage maximizes suppleness for the next playing season.

Keep Away From Pests

Guard against insects or rodents getting to stored gloves. Mice and bugs love chewing leather and can rapidly ruin your prized possession.

Seal gloves in plastic bins or wrap in mothballs to deter nibbling pests during off-season.

Avoid Harsh Chemicals

Don’t use petroleum-based products or aggressive chemicals like gasoline or solvents when cleaning or storing gloves.

Gentle cleaners and conditioners designed for glove leather prevent damage from chemicals.

Disinfect Safely

If concerned about bacteria or odors, wipe gloves down with gentle disinfectant cleaners before final storage. Avoid soaking leather extensively in liquids.

Mild cleaning protects without over-saturating glove materials.

Rest and Rotate Gloves

Consider resting well-used gloves for full seasons periodically. Rotating in different gloves over years reduces wear and tear.

An occasional off-season allows gloves time to fully recover and extend playing life.

With some basic TLC and protection, treasured gloves will be ready for many encores after a quality re-lacing job.

Comparing DIY vs Professional Relacing

When it’s time to breathe new life into a well-loved baseball or softball glove with fresh laces, you have two main options – DIY or hire a pro. Let’s compare the pros and cons of each approach.

Cost Difference

The most obvious difference between DIY glove re-lacing and professional relacing is cost. Quality kits like the Rawlings Lace Repair kit provide everything you need for less than $20.

Meanwhile, professional glove relacing shops typically charge $40-$60 to replace your laces. Over multiple glove repairs, DIY adds up to huge savings.

Convenience Factor

Dropping a glove off at a specialty pro shop for relacing is easier up front versus doing it yourself. But that convenience comes at a steep premium.

Learning to re-lace gloves takes some time and patience initially, but quickly pays off long-term.

Quality Control

An experienced glove pro who re-laces mitts daily will likely do neat, tight, quality work. But DIY kits allow you to customize the lace types, patterns, and tension exactly how you prefer.

Doing it yourself means controlling the quality and personalized details rather than settling for someone else’s preferences.

Turnaround Time

Dropping a glove at a shop usually means being without your gamer for a week or more during relacing. With a DIY kit, you can work at your own pace and still use the glove between steps.

No downtime allows you to re-lace without impacting playing time.

Sentimental Value

Restoring an old beloved glove yourself rather than handing it to a stranger adds sentimental value. The personal investment of DIY keeps it your glove rather than just another job for a pro.

For vintage mitts, do you want a tech re-lacing it or adding your own sweat equity?

Repeat Business

Pro shops need to keep selling you re-lacings to keep revenues flowing. DIY glove repair skills are an investment that pays off for life.

Commercial interests versus mastering a lifetime skill must be considered.

While professionals can deliver quality relacing, learning DIY lacing repairs saves money, retains control, and builds personal skills and value. Invest for the long haul.

Why Rawlings Lace Kit Is A Must Have Item

As someone who has re-laced their favorite baseball glove multiple times over the years, the Rawlings Glove Lace Repair Kit has been an absolute essential piece of equipment to keep my mitt game-ready.

Here’s why this kit is such a must-have item for any glove owner:

All the Materials You Need

The kit comes stacked with high quality rawhide, leather, and hybrid laces so you can match your glove material and pattern. With 132 feet of lace included, you’re covered for any repair or complete re-lace job.

It also includes waxed laces for smooth threading. Having every supply needed makes repairs stress-free.

Saves You Money

Rather than spending $40-60 every time for professional relacing, this kit pays for itself after just one or two DIY repairs. The savings add up over years of enjoying your glove.

Quality materials and ample quantities make the kit a fantastic value.

Easy Step-by-Step Instructions

The included printed guide walks you through each phase of glove re-lacing with clear photos and directions. I still reference it each time I repair my mitt.

For first-timers, the detailed instructions instill confidence to tackle the project.

No Downtime Without Glove

With professional relacing you’re without your glove for a week or more. This kit allows re-lacing in stages without impacting use. I can play games while slowly working on repairs.

No need to rush or have glove downtime.

Customizable Lace Options

I like using different lace types in different areas like leather laces near wrist for comfort or waxed rawhide across pocket for strength.

Mix and match lace styles however you prefer.

Matches Rawlings Gloves

Designed specifically for Rawlings gear, the lace sizes and types included ensure an ideal match to your glove’s leather and original specs.

You can restore it true to how it came from the factory.

Brings Gloves Back to Life

Nothing beats the feeling of repairing and restoring your beloved old glove to like-new performance for extra seasons of memories.

This kit lets you revive that cherished companion when it just needs fresh laces.

With everything required for routine lace repairs and complete re-lacing, every glove owner should keep the Rawlings Lace Repair Kit ready for whenever the time comes to revive a mitt.