What are the essential features of steel toe boots for floorhands. How do Wolverine Floorhand boots compare to other brands. Which boot models offer the best protection and durability for oilfield work.

Essential Features of Steel Toe Boots for Floorhands

Floorhands in the oilfield industry face challenging working conditions that demand rugged and durable footwear. The right pair of steel toe boots can make a significant difference in safety, comfort, and performance. Let’s explore the crucial features that make a boot suitable for floorhand work.

Slip Resistance: A Must-Have for Oilfield Environments

Why is slip resistance so important for floorhand boots? Oilfield work environments are notoriously slippery due to the presence of oil, grease, and mud. A boot with excellent traction can prevent potentially dangerous falls and injuries.

- Heavily lugged soles provide superior grip on slick surfaces

- Oil-resistant outsoles maintain traction even in oily conditions

- Advanced tread patterns designed for maximum surface contact

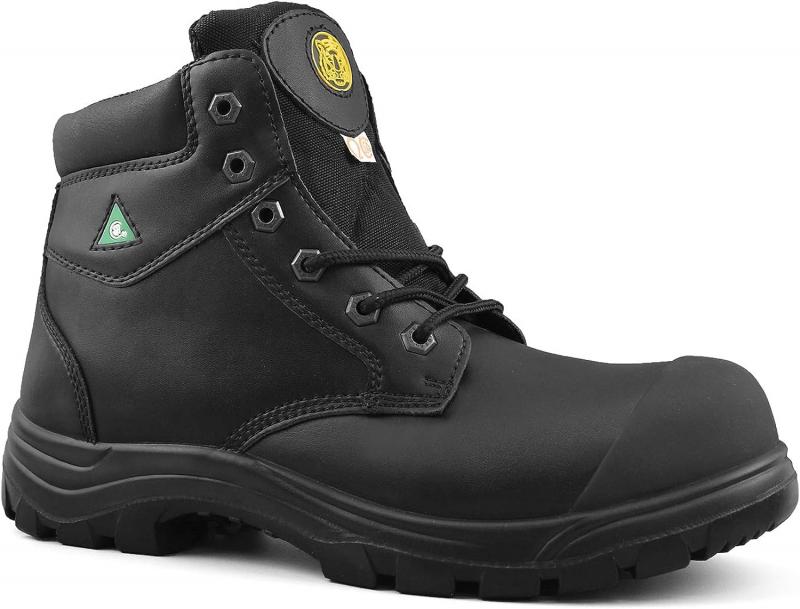

Protective Steel Toe Caps: Safeguarding Against Heavy Impacts

How do steel toe caps protect floorhands? The steel reinforcement in the toe area shields feet from falling objects, which are common hazards in oilfield work.

- Meets or exceeds ASTM safety standards for impact and compression

- Protects against dropped tools, chains, and drilling pipes

- Absorbs and distributes force to prevent toe injuries

Electrical Hazard Protection: An Added Safety Feature

Why is electrical hazard (EH) protection important in floorhand boots? EH-rated boots provide an additional layer of safety when working around electrical equipment or exposed wiring.

- Non-conductive soles insulate against accidental contact with live currents

- Typically rated to withstand up to 18,000 volts in dry conditions

- Crucial for environments where electrical hazards may be present

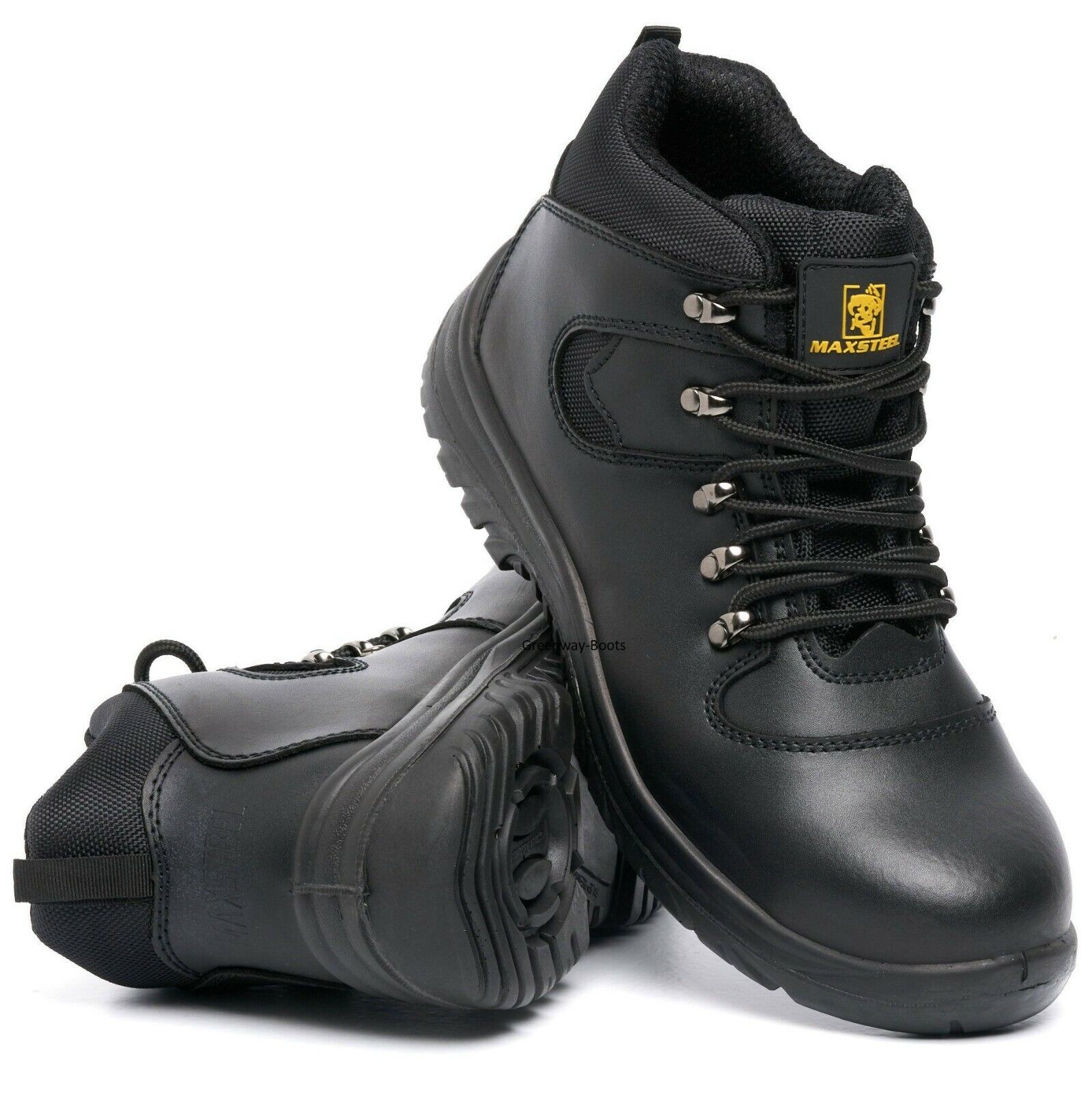

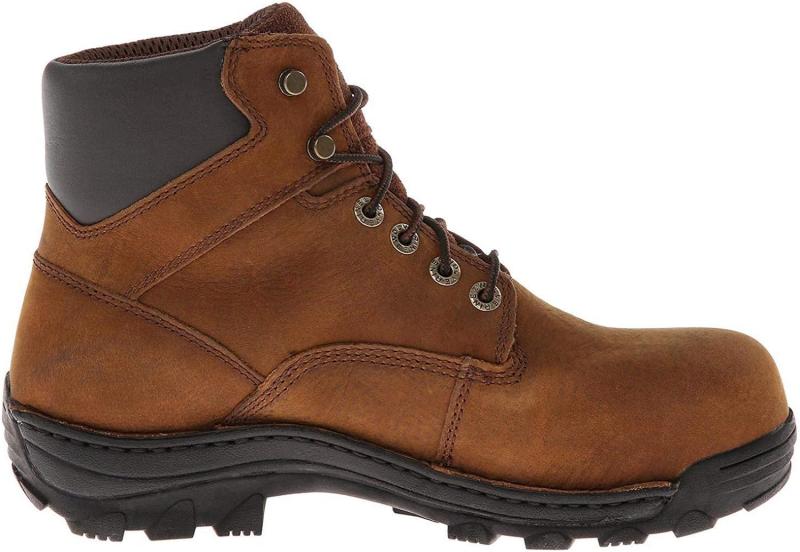

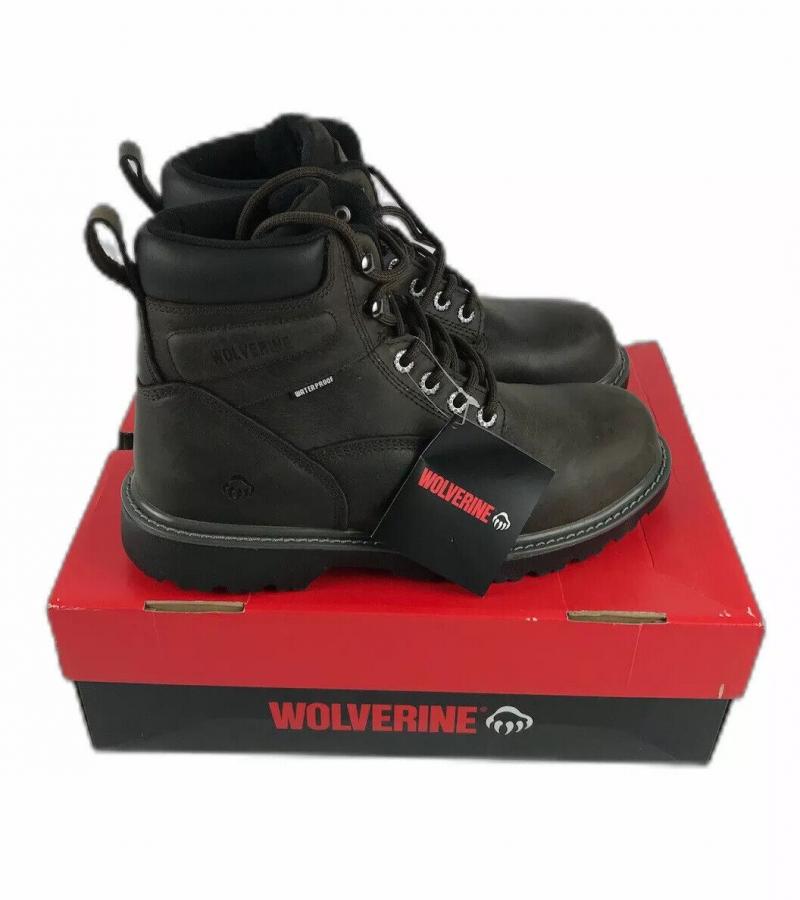

Wolverine Floorhand Boots: A Trusted Choice for Oilfield Workers

What makes Wolverine Floorhand boots stand out in the oilfield industry? These boots have earned a reputation for durability and performance over the past 50 years, specifically designed to meet the demands of rig work.

Construction and Materials

How are Wolverine Floorhand boots built to withstand harsh conditions?

- Full-grain leather upper for maximum durability

- Goodyear welt construction ensures longevity and allows for resoling

- Thick Vibram lug soles provide excellent traction on various surfaces

Comfort and Fit

Can Wolverine Floorhand boots provide comfort during long shifts?

- Cushioned insoles reduce foot fatigue

- Lightweight design for all-day wear

- Available in various sizes and widths for a proper fit

Safety Features

How do Wolverine Floorhand boots meet safety requirements?

- Steel toe exceeds ASTM impact and compression standards

- Electrical hazard protection rated to 18,000 volts

- Oil and slip-resistant outsoles for secure footing

Choosing the Right Fit for Floorhand Boots

Why is proper fit crucial when selecting steel toe boots for floorhand work? A well-fitting boot ensures comfort, prevents blisters, and maintains safety features’ effectiveness.

Sizing Considerations

How should floorhands approach boot sizing?

- Consider going up a half-size from regular shoe size to accommodate thick socks

- Ensure a snug fit to prevent foot slippage inside the boot

- Allow enough room for toe movement and air circulation

Width and Toe Box

Why is the width of the boot important for floorhands?

- Look for a wide shank and toe box to accommodate foot spread during long shifts

- Prevents jammed toes and blisters from prolonged wear

- Allows for natural foot movement and comfort

Alternative Floorhand Boot Options

While Wolverine Floorhands are popular, what other brands offer quality steel toe boots for oilfield work? Let’s explore some top-rated alternatives that meet the rigorous demands of floorhand duties.

Caterpillar Second Shift Steel Toe Boot

What features make the Caterpillar Second Shift a viable option for floorhands?

- Slip and oil-resistant outsole for secure footing

- Steel toe and plate for comprehensive foot protection

- Electrical hazard protection for added safety

Timberland PRO Boondock Work Boot

How does the Timberland PRO Boondock cater to the needs of oilfield workers?

- Anti-fatigue technology for comfort during long shifts

- Rubber toe protector for additional durability

- Waterproof leather to keep feet dry in wet conditions

Thorogood American Heritage Steel Toe Boot

What sets the Thorogood American Heritage boot apart for floorhand work?

- Fiberglass shank for lightweight support

- Vibram outsole known for excellent traction

- Goodyear welt construction for long-lasting durability

Carolina Logger Boot

Why might floorhands consider the Carolina Logger Boot?

- Steel shank provides superior arch support

- Lugged outsole for enhanced grip on various surfaces

- Driver’s heel design for convenient wear

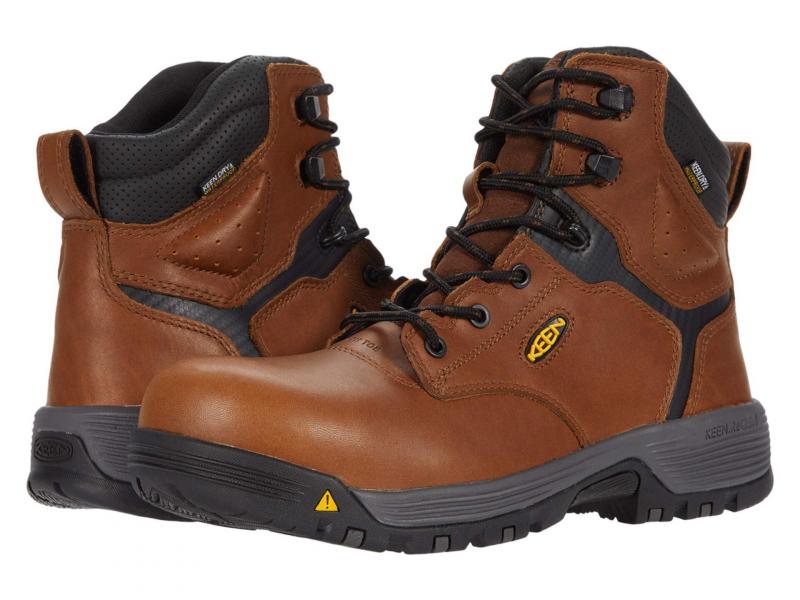

Comparing Boot Features for Oilfield Work

How do different boot models stack up when it comes to key features for floorhand work? Let’s break down the essential characteristics to consider when selecting the best steel toe boots for rigorous oilfield conditions.

Slip Resistance Comparison

Which boots offer the best traction for oily and slippery surfaces?

- Wolverine Floorhand: Vibram lug soles with oil-resistant compound

- Caterpillar Second Shift: Slip-resistant rubber outsole

- Timberland PRO Boondock: Dual-density dynamic anti-fatigue technology

- Thorogood American Heritage: Vibram christy wedge outsole

- Carolina Logger: Aggressive lug pattern for maximum grip

Protective Toe Capabilities

How do the steel toe caps compare across different boot models?

- Wolverine Floorhand: Exceeds ASTM standards for impact and compression

- Caterpillar Second Shift: Meets ASTM F2413-11 I/75 C/75 standards

- Timberland PRO Boondock: Composite safety toe for lightweight protection

- Thorogood American Heritage: Steel safety toe meets ASTM standards

- Carolina Logger: Steel toe cap for heavy-duty protection

Electrical Hazard Protection Ratings

Which boots provide the best electrical hazard protection for floorhands?

- Wolverine Floorhand: Rated to 18,000 volts

- Caterpillar Second Shift: Meets ASTM F2413-05 1/75 EH standards

- Timberland PRO Boondock: EH protection up to 18,000 volts

- Thorogood American Heritage: Electric shock-resisting soles and heels

- Carolina Logger: Electrical hazard rated

Maintaining and Extending the Life of Floorhand Boots

How can floorhands ensure their steel toe boots last as long as possible in harsh oilfield conditions? Proper care and maintenance are crucial for extending the lifespan of work boots and maintaining their protective qualities.

Regular Cleaning and Conditioning

What are the best practices for cleaning and conditioning floorhand boots?

- Remove dirt and debris daily with a stiff brush

- Clean leather uppers with saddle soap or specialized boot cleaner

- Apply leather conditioner regularly to prevent cracking and maintain water resistance

- Allow boots to dry naturally away from direct heat sources

Proper Storage

How should floorhands store their boots when not in use?

- Store in a cool, dry place away from direct sunlight

- Use boot trees or stuff with newspaper to maintain shape

- Avoid storing in airtight containers or plastic bags

Rotation and Replacement

Why is it important to rotate boots and know when to replace them?

- Alternate between two pairs of boots to allow drying and extend lifespan

- Inspect boots regularly for signs of wear, especially in the soles and seams

- Replace boots when the steel toe becomes exposed or the sole tread wears down

- Consider resoling high-quality boots with Goodyear welt construction

Adapting to New Steel Toe Boots: Tips for Floorhands

How can floorhands break in new steel toe boots comfortably and safely? The process of adapting to new work boots is crucial for ensuring comfort and preventing blisters or foot pain during long shifts.

Gradual Break-In Period

What’s the best approach to breaking in new floorhand boots?

- Wear new boots for short periods initially, gradually increasing wear time

- Use thick socks or double up on socks to reduce friction

- Apply leather conditioner to soften the leather and increase flexibility

- Walk around on different surfaces to help mold the boot to your foot

Addressing Common Discomfort Issues

How can floorhands deal with typical discomfort when adapting to new steel toe boots?

- Use moleskin or bandages on potential blister spots

- Consider aftermarket insoles for additional cushioning and support

- Adjust lacing techniques to alleviate pressure points

- Give feet breaks and air out boots during long shifts when possible

Customizing Fit and Comfort

What options do floorhands have for customizing their boot fit?

- Visit a boot fitter for professional stretching of tight areas

- Use boot stretchers overnight to widen specific parts of the boot

- Experiment with different lacing patterns to optimize fit

- Consider heat-moldable insoles for a personalized fit

The Impact of Proper Footwear on Floorhand Performance and Safety

Why is investing in high-quality steel toe boots crucial for floorhands? The right footwear not only enhances safety but can also significantly improve job performance and overall well-being during long, demanding shifts.

Injury Prevention and Long-Term Health

How do quality steel toe boots contribute to injury prevention for floorhands?

- Reduce risk of foot and toe injuries from falling objects

- Minimize slips and falls on hazardous surfaces

- Provide support to prevent fatigue and musculoskeletal issues

- Protect against electrical hazards in the work environment

Improved Productivity and Comfort

What impact can the right boots have on a floorhand’s productivity?

- Reduce foot fatigue, allowing for longer periods of effective work

- Enhance stability and confidence when moving on various surfaces

- Minimize distractions caused by foot discomfort or pain

- Provide insulation and protection in extreme weather conditions

Cost-Effectiveness Over Time

Why are high-quality steel toe boots a wise investment for floorhands?

- Durable construction leads to longer-lasting boots, reducing replacement frequency

- Better protection can result in fewer work-related injuries and lost work days

- Improved comfort can lead to increased job satisfaction and retention

- Some high-end boots offer resoling options, extending their lifespan

In conclusion, selecting the right steel toe boots for floorhand work is a critical decision that impacts safety, comfort, and job performance. By understanding the essential features, comparing top brands, and properly maintaining their footwear, floorhands can ensure they’re well-equipped to handle the demanding conditions of oilfield work. Remember, investing in quality boots is an investment in your own well-being and professional success.

Floorhands Require Tough, Durable Boots to Withstand Harsh Conditions

If you’ve ever worked on an oil rig as a floorhand, you know that the job can be brutal on your feet. Floorhands are exposed to tough conditions like slippery surfaces, falling objects, inclement weather, and long hours on their feet. That’s why having a pair of durable work boots is absolutely essential.

But not just any boots will do. Floorhand boots need to be seriously rugged to withstand the rigorous nature of oilfield work. As you shop around, here are some of the key features you’ll want to look for:

Slip Resistance

Traction is paramount when you’re working on slick rig floors covered in oil, grease, and mud. The last thing you need is to take a spill and injure yourself on the job. That’s why floorhand boots must have heavily lugged, oil-resistant soles to grip the surface and prevent slips.

Protective Toe Caps

Steel toes are an absolute must to shield your feet from dropped tools, chains, drilling pipes, and other heavy objects. A compression or impact could easily break your toes, so thick steel caps reinforce the toe box and absorb the force of blows.

Electrical Hazard Safety

Many boots also have non-conductive EH rated soles to insulate you against accidental contact with live electrical currents. This added protection is useful when working around exposed wiring or other energized equipment.

When it comes to floorhand work boots that check all the boxes for toughness, Wolverine Floorhands are consistently top-rated. Trusted by oilfield workers for over 50 years, these boots are specifically designed to withstand the hazards guys face on the rigs.

Why Choose Wolverine Floorhand Boots?

Built with rugged full-grain leather and a durable Goodyear welt construction, Floorhand boots are made to last through years of heavy use and abuse. The thick Vibram lug soles bite into slippery surfaces, while the cushioned insoles and lightweight design make them comfortable enough to wear for 10+ hour shifts.

The steel toe exceeds ASTM impact and compression safety standards to shield your feet from dropped objects. And the boots also have electrical hazard protection rated to 18,000 volts and 1,000 volts for underfoot protection.

According to Mike R., an equipment operator in North Dakota, “Wolverine Floorhands are the toughest dang boots I’ve worn. Going on two years now and they’re still hanging tough in the oilfields. I’ll be buying another pair when these finally wear out.”

Choosing the Right Fit

When shopping for floorhand boots, pay close attention to fit. They should be snug enough that your foot doesn’t slip around inside, but roomy enough to allow air circulation around your toes. Consider going up a half-size from your regular shoe size if you’ll be wearing thick socks.

Also, look for a boot with a wide shank and toe box to accommodate your foot spread. This helps prevent jammed toes and blisters when you’re on your feet all day. Padded collars adds comfort as well.

In addition to black, Floorhands come in brown and tan in case you want a slightly less rugged look. But don’t let the toned down style fool you – they’re just as tough as the original black boots.

Alternative Floorhand Boot Options

While Wolverine Floorhands are a popular choice, here are a few other top-rated options to consider:

- Caterpillar Second Shift Steel Toe Boot – Slip & oil resistant outsole, steel toe and plate, electrical hazard protection

- Timberland PRO Boondock Work Boot – Anti-fatigue technology, rubber toe protector, waterproof leather

- Thorogood American Heritage Steel Toe Boot – Fiberglass shank, Vibram outsole, Goodyear welt construction

- Carolina Logger Boot – Steel shank for arch support, lugged outsole, drivers heel for convenient wear

When researching boots, look for key features like slip resistance, protective steel toe caps, electrical insulation, comfort technology, and durable leathers. With heavy-duty boots made for oilfield work, your feet will be well-protected from the hazards inherent to a floorhand’s job.

As Marcus V. explains, “Getting good boots for working the rigs is probably the smartest thing you can do for yourself. Your feet will thank you at the end of a 12-hour tour.”

Key Features to Look for in Floorhand Work Boots

As an oil rig floorhand, you know that having proper protective footwear is non-negotiable. The conditions out on the rigs are intense, so you need boots tough enough to keep up. When shopping for sturdy floorhand work boots, here are some of the key features to look for:

Slip Resistance

One of the biggest hazards for floorhands is slippery surfaces. All those spills of oil, drilling mud, grease and more make for some slick walking conditions. That’s why having heavily lugged soles with strong traction is a must. Oil-resistant rubber compounds really grip the floor and reduce the chances of taking a nasty fall.

Impact Protection

When you’re working around heavy drilling pipes, chains, tools and machinery all day, it’s only a matter of time before something gets dropped on your foot. Steel toes are essential to deflect blows and protect your feet from crushing injuries. Look for safety toe caps that meet or exceed ASTM standards.

Puncture Resistance

In addition to impact hazards, floorshands also have to watch out for sharp objects that could potentially puncture through the sole. Whether it’s a stray nail, piece of wire or pointed rock, puncture-resistant plates offer an extra layer of protection from underneath.

Electrical Insulation

Electricity and water are always present on rigs, making for potentially dangerous conditions. Boots that offer electrical hazard protection with insulated, non-conductive soles are important to prevent shocks, burns and electrocution.

Comfort Features

Even with all the safety features, floorhand boots still need to be comfortable enough to wear for 10-12 hour shifts. Look for boots with cushioned insoles, moisture-wicking linings and flexible uppers. Some also have lightweight construction to prevent fatigue.

When you want all these protective features and tough-as-nails construction, Wolverine Floorhand boots are designed specifically for oil rig work. The lugged Vibram soles provide serious grip on wet floors, and the thick leather uppers stand up to heavy use and abrasions. The boots also have a roomy toe box to prevent jammed toes after hours of wear.

Mark S., an experienced floorhand in Texas, says “I’ve worn just about every boot out there, and Wolverine Floorhands are by far the best I’ve had for working the rigs. It’s nice to have dry feet and good traction in sloppy conditions.”

Getting the Right Fit

In addition to the right features, getting a proper fit is also key for all-day comfort. Here’s what to look for when trying on floorhand boots:

- Snug heel and ankle so your foot doesn’t slip

- Wide toe box to allow toe spread

- Half size up from your normal shoes

- Roomy shank through the instep

- Consider insertable insoles for more cushion

You want the boots tight enough that your feet don’t slide around and get blisters, but not so tight that your toes feel pinched. Breaking them in with some wear around the house can help loosen up any stiff spots.

Alternative Floorhand Boots

While Wolverine Floorhands are popular oil rig boots, here are a few other top options:

- Thorogood American Heritage Steel Toe – Slip-resistant Vibram sole, Goodyear welt construction

- Caterpillar Second Shift – Steel toe, plate, and electrical hazard protection

- Carolina Logger – Steel shank for support, oil-resistant lug sole

- Timberland PRO Boondock – Anti-fatigue comfort, waterproof leather

When your work environment is the rough oil rig floor, you need footwear built to handle the hazards. With protective, comfortable floorhand boots, you’ll stay on your feet in tough conditions.

As Darius F. explains, “Getting the right boots was a game-changer for me as a floorhand. My feet used to kill me after shifts. Now I can work longer with no problems.”

Top Steel Toe Boots Built for Floorhand Jobs

For floorhands working long, grueling hours on oil rigs, having the right footwear is crucial. The best steel toe boots for floorhand jobs need to check all the boxes: safe, supportive, slip-resistant, and durable enough to withstand the rigors of the oilfield. As a veteran floorhand myself, I know firsthand how punishing this work can be on the feet and lower body. After testing numerous pairs over the years, a few steel toe boot models stand out from the crowd for their exceptional performance and comfort in keeping floorhands protected out on the rig.

Why Floorhands Need Specialized Steel Toe Boots

Unlike many other manual labor jobs, floorhanding comes with unique risks and challenges that demand specific features in work boots. Floorhands operate in hazardous environments surrounded by heavy machinery and high-pressure drilling operations. One wrong move could crush a foot or leg, so ANSI-approved steel toes are an absolute must. The steel caps absorb and deflect blows, shielding the feet from falling pipe and equipment. But steel alone isn’t enough – the boots must also provide ample ankle support and slip resistance on greasy, wet surfaces. Mud, oil, chemicals, and extreme weather conditions deteriorate standard footwear quickly, so superior materials and rugged construction are also essential. Proper insoles and insulation give floorhands traction as well as comfort during 14 to 21 day hitch rotations.

When evaluating the top makes and models, I looked for all these protective qualities as well as longevity. The last thing you want is to be replacing blown-out boots every few months. The boots below aren’t cheap, but can last over a year with proper care. Saving money upfront on flimsy footwear will cost you more in the long run between replacements and possible injuries. Investing in high performance pairs engineered for oil rig conditions will benefit your feet and wallet over miles of drilling, fracking, and servicing operations.

The Toughest, Safest Steel Toe Boots for Floorhands

The Thorogood MAXWear series has earned a loyal following among floorhands for its safety, slip-resistance, and comfort mile after mile. The thick Vibram outsole grips slippery surfaces, while the MAXWear Wedge design provides flexibility for working on uneven terrain all day. A composite safety toe shaped on a wide platform delivers ample impact protection without the coldness or bulk of steel.

These boots feel broken-in right out of the box thanks to the removable dual-density footbed. It provides support and cushions hard floors. The oil-tanned leather upper molds to the feet but remains tough against abrasions, gases, and fluids. At well under $200, Thorogood MAXWear boots deliver exceptional performance for the price. I’ve relied on them for a year of 14-day hitches and they’re still going strong.

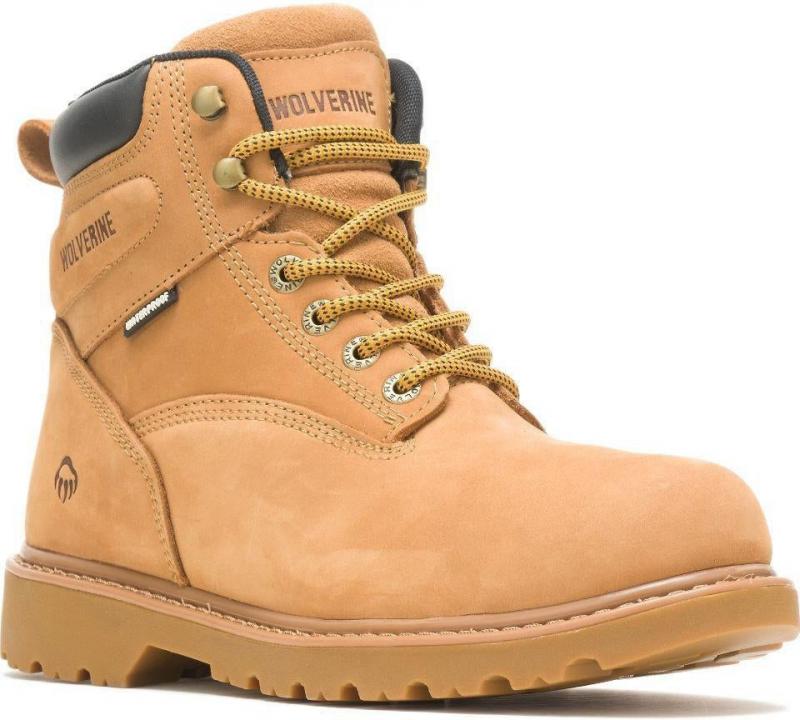

Another favorite for their durability, grip, and comfort are Wolverine Floorhand boots. Built explicitly for floorhanding, they have a lightweight yet stable waterproof leather upper and sturdy, flexible cemented construction. The rounded steel toe cap protects feet from impacts while allowing room to wiggle toes. Underfoot, the slip-and-oil-resistant Vibram rubber outsole prevents slips on wet surfaces.

What I appreciate most in these boots is the Ortholite insole with extra cushioning in the heel and arch. It makes long shifts on my feet far less tiring. The boots also feel very breathable, preventing overheating and sweaty feet. While a bit pricier than other models, the Wolverine Floorhands live up to their promise of all-day comfort. After hundreds of miles walking pipe, I’ve been impressed by how well they’ve held up.

ARIAT specializes in occupational footwear, including models purpose-built for floorhands. The Groundbreaker H2O boots combine a roomy square toe fit and sticky lug outsole to withstand oil rig conditions. The deeply treaded soles provide superb traction even in thick, slick mud. Meanwhile, the wide square steel toe gives toes plenty of space to move comfortably.

These boots contain ARIAT’s unique ATS technology that supports the feet and absorbs shock. I’ve found the advanced torsion system reduces foot and back pain associated with long hours of manual labor. The full-grain waterproof leather upper also repels drilling fluids. While slightly heavy, the sturdy durability and underfoot comfort make ARIAT Groundbreakers ideal for floorhands needing stable, protective footwear.

Known for rugged heavy equipment, Caterpillar puts the same strength into its Second Shift work boots. They live up to the promise of durability thanks to full-grain leather, hardy Goodyear welt construction, and a slip-resistant rubber outsole. The steel toe cap meets ASTM and I/75 C/75 impact and compression safety standards.

These boots aren’t designed exclusively for floorhanding but make a solid all-around pair for oilfield work. The nylon mesh lining wicks away sweat and allows good air flow. Underfoot, the Climasphere insole adds cushioning. While not waterproof, the leather stands up well to drilling fluids. For floorhands needing a flexible, supportive value boot, Caterpillar Second Shifts are worth a look.

Key Factors in Choosing the Best Floorhand Boots

When searching for the ideal floorhanding boots, keep these key criteria in mind:

- Safety – Look for steel toes or composite caps meeting ASTM standards.

- Traction – Deep, rugged oil/slip-resistant outsoles like Vibram or heavily lugged.

- Support – Shock absorbing midsoles, arch support, removable footbeds.

- Water resistance – Treated leathers or membranes to repel drilling fluids.

- Comfort features – Padding, climate control, fit for long shifts.

- Durability – Full-grain leather, Goodyear welt, hardy materials.

Prioritizing these performance and protective features will ensure your footwear is up for the grueling demands of floorhanding. Don’t cut corners or go cheap. See steel toe boots as an investment in your safety and long-term foot health on the rigs. After reluctantly spending more on a durable pair years ago, I was amazed by the difference in my energy levels and body aches after shift. Save your feet and they’ll save your back!

With their safety, traction, comfort technologies, and rugged build, boots like the Thorogood, Wolverine, ARIAT, and Caterpillar models above are designed specifically to support floorhands. They’ll Protect your feet and give you the grip and stamina to perform at your best on long shifts.

Why Wolverine Floorhand Boots Are a Top Choice

When working on an oil rig as a floorhand, having the right footwear is absolutely essential. The conditions on a rig can be extremely tough on boots, with hazards like heavy pipes, slippery surfaces, chemicals, and more. That’s why choosing a durable and protective work boot is a critical decision for any floorhand.

Among the most popular and highly recommended options are the Wolverine floorhand boots. This iconic American boot brand has been crafting rugged work boots since the late 1800s, and their reputation for quality is unmatched. Wolverine boots are designed to withstand the most punishing industrial environments while keeping feet safe and comfortable on long shifts.

Designed for Rigorous Oilfield Work

Wolverine floorhand boots check all the boxes for ideal foot protection on a drilling rig. They are constructed with sturdy leather uppers and a waterproof membrane to resist the elements. The soles are slip-resistant and feature deep lugs for sure-footed traction on wet surfaces. The toe cap protects against smashed toes from dropped pipes or tools. And the thick, well-cushioned midsole absorbs shock and impact.

These boots are also designed to prevent common oilfield foot injuries like rolled ankles, puncture wounds, and bruising from heavy loads. The ankle-high style provides flexible support and stability. The shank is rigid to prevent over-flexing, while allowing natural foot movement. And the composite safety toe cap shields against crushing accidents.

Stay Comfortable During Long Shifts

Working on your feet all day on a drilling floor demands boots that won’t leave you sore. Wolverine’s ContourWelt construction adds flexibility and cushions every step. The footbed is removable so you can insert your own custom orthotic if needed. Breathable waterproof liners wick away sweat to keep your feet cool and dry. This combination of comfort features allows you to power through 12-hour shifts without foot fatigue.

The Leather and Rubber Floorhand Lacer Boot is a top option with a super-soft pigskin collar lining that prevents blisters. The lugged Cavalier Floorhand boot has a lightweight and flexible cement construction for incredible comfort and freedom of movement.

Rugged Durability in Harsh Conditions

From scorching heat to freezing sleet, floorhand boots must perform in extreme weather. Wolverine builds their boots to handle it all and last season after season. The uppers are full-grain leather, chosen for its ability to resist abrasions, cuts, and tears on the rig. Durable Goodyear welt construction bonds the upper securely to the sole for longevity.

The Vibram rubber outsoles are oil- and chemical-resistant, preventing slips on slick surfaces. Aggressive lugs provide traction on muddy ground. The heels are reinforced with extra rubber to prevent premature wear when working on grated catwalks. And the welted construction allows the soles to be replaced when they eventually wear down.

Safety Toes Protect Against Impact

Toe accidents are one of the most common oilfield foot injuries, which is why steel toes are mandatory in most drilling companies. Wolverine equips their floorhand styles with composite safety toes, which meet ASTM impact and compression safety standards while weighing 30% less than steel.

The carbon fiber shell safeguards against dropped tools and equipment. The reinforced composite material is also resistant to corrosion from water, sweat, and chemicals. This helps prevent cracked or exposed steel toes which lead to injuries. Compared to steel, the composite toes maintain shape better after impact to continue protecting feet.

Choose Your Perfect Floorhand Boot

Wolverine offers several floorhand boot models so you can find your ideal fit. Popular choices like the Floorhand 10″ Leather Boot or Floorhand Wellington Boot have a classic work boot look with rugged durability. For a lightweight boot, the Cavalier Floorhand Pull-On boot features a cement construction and relaxed fit. There’s also a 6″ version of the leather Floorhand for those who prefer an ankle height.

When browsing, consider your work environment and comfort needs. Narrow or wide sizes are available to dial in an ideal fit. Those working in extreme cold may prefer an insulated boot for warmth. Or add personalized insoles for maximum cushioning and support. Since the right fit is critical for safety and performance, try boots on in person when possible.

Wolverine has earned a reputation as the go-to floorhand boot brand for good reason. Their boots are thoughtfully engineered to excel in oilfield conditions while keeping feet comfortable all shift long. With a dedication to worksite safety and durability spanning over 130 years, Wolverine remains a top choice for rig crews today.

Wolverine Floorhand: Ideal for Oil Rig Use

Working on an oil rig as a floorhand is an extremely demanding job. The conditions on the rig floor are hazardous, with heavy machinery, slippery surfaces, and constant exposure to mud, grease, and chemicals. Having protective footwear designed specifically for this environment is critical.

That’s why many veteran floorhands swear by Wolverine boots. This iconic American work boot company has been crafting tough footwear since 1883. Their boots are engineered for superior performance in industrial settings while delivering all-day comfort.

For floorhands, Wolverine’s signature Floorhand collection offers the ideal combination of safety, traction, and durability to withstand the rigors of oil rig work. Here’s a closer look at why Wolverine Floorhand boots have become the footwear of choice for many in the oilfields.

Protective Design to Prevent Injuries

Working on an oil drilling floor brings many hazards like heavy loads, slippery surfaces, and potential toe impacts. Wolverine Floorhand boots are thoughtfully designed to safeguard against these risks.

The thick rubber outsoles and deep lugs provide sure-footed traction, even on wet or oily platforms. This helps prevent slips and falls from heights. The ankle-high shaft offers flexible support to stabilize the joint and prevent rolled ankles.

The steel or composite toe cap protects the feet from dropped tools and prevents crushing injuries. The sturdy leather uppers resist punctures from sharp objects. And the shock-absorbing midsole cushions the feet from the constant pounding of long shifts.

Tough and Durable Construction

From scorching heat to freezing sleet, Wolverine boots can handle the elements. The full-grain leather uppers withstand abrasions from chains and tools. The rubber outsoles are oil- and chemical-resistant to maintain grip.

The Goodyear welt construction bonds the upper and sole for longevity. The replaceable footbed inserts allow you to dial in custom orthotic support. And when the soles eventually wear down, the welt allows them to be repaired or replaced.

Several Floorhand styles feature a waterproof membrane to keep feet dry. Insulated options add warmth for work in frigid conditions. Durable hardware and 3M reflective binding provide extra reinforcement and visibility.

All-Shift Comfort

Working long 12+ hour shifts demands comfortable footwear. Wolverine boots are designed to keep feet feeling good hour after hour.

The removable cushioned footbeds wick away moisture and provide arch support. Flexible soles allow natural foot movement while the rigid shank prevents over-flexing and fatigue. Ankle padding prevents blisters and hot spots.

The Floorhand Wellington features a comfort cushion insole for shock absorption and flexibility. The Floorhand Lacer boot has a super-soft pigskin collar lining. And the Cavalier Floorhand is lightweight with a relaxed fit.

Tested Toughness

In addition to their long-proven reputation, Wolverine boots undergo rigorous testing for safety and performance.

The thick Vibram outsoles are tested in Wolverine’s state-of-the-art lab, under challenging conditions like oil and inclined surfaces. The protective toes meet ASTM standard F2413 for impact and compression.

Wolverine also field tests prototypes to get feedback from workers. The insights from thousands of hours on the job help refine the designs to excel in real-world oilfield use.

Specialized Options

With different Floorhand models, workers can select the right boot for their needs. Choices include 6-inch or 10-inch heights, soft toe or safety toe, plain rubber sole or lugged. Consider ankle support needs, temperature, traction, and fit preferences.

There are options optimized for cold weather, with insulation and waterproof membranes. A lightweight composite toe works well for those needing electrostatic discharge (ESD) protection. And a soft toe boot allows for greater flexibility.

The range of choices ensures floorhands can find the ideal Wolverine boot to tackle tough rig conditions while staying comfortable shift after shift.

For over a century, Wolverine has crafted durable work boots able to withstand challenging industrial environments. Their Floorhand collection builds on this expertise using innovative features to create the ultimate oil rig boot. With their combination of brawn and comfort, Wolverine boots have rightfully earned the trust of floorhands across the oilfields.

Long-Lasting Materials and Sturdy Construction

Working long, grueling shifts on an oil rig puts everything to the test, including footwear. The conditions on the rig floor are notoriously tough on boots. That’s why construction and material quality are so important when choosing floorhand boots.

Wolverine has been handcrafting boots with rugged construction and top-grade leathers for over 130 years. Their meticulous manufacturing and material selection ensure their floorhand boots will provide lasting wear in even the most punishing environments.

Full-Grain Leather Uppers

Starting from the ground up, Wolverine uses premium full-grain leathers for the upper. Full-grain is the highest quality leather, made from the outermost layer of hide. It’s extremely durable, resistant to abrasions, punctures, and tears.

Wolverine carefully selects leathers to withstand oilfield hazards like chains, falling tools, and corrosive chemicals. The leather forms to the foot over time for a custom fit. Oiling treatments provide waterproofing while allowing the leather to flex and breathe.

Contrasting stitching and accents add visual flair. Reflective leather bindings improve visibility on the rig floor. Durable hardware and eyelets reinforce high-stress areas. The quality leather uppers are built to last season after season.

Slip-Resistant Rubber Outsoles

Wolverine outsoles are engineered by their in-house experts and rigorously lab tested. Only premium rubber compounds are chosen to resist oil, chemicals, heat, and extreme cold found on rigs.

Lugged soles like the popular Vibram designs provide superior traction. Deep lugs shed mud and channel water away to prevent slips. The heel is reinforced with extra rubber thickness to prevent premature wear.

Wolverine also equips many Floorhand models with meta-carpal guards for metatarsal protection from impacts. The rubber builds flex grooves to allow natural foot motion. Durable stitching and adhesion ensure miles of wear.

Supportive Fit and Cushioning

Inside the boots, Wolverine uses specialized materials to cradle and support the foot. The removable cushioned footbed wicks moisture and fights odor-causing bacteria. It provides arch support and shock absorption.

Models like the Floorhand Wellington feature Wolverine’s comfort cushion insole for flexibility and energy return. Padding around the ankle prevents blisters and hot spots. Pigskin collar linings add softness.

The midsole is polyurethane or ethylene vinyl acetate (EVA) to cushion impacts. A rigid shank stabilizes the arch while allowing natural foot flex. This combination delivers all-day comfort and support on long shifts.

Reinforced Toe Protection

To guard against toe impacts from tools or equipment, Wolverine Floorhand boots feature a reinforced toe box. Most models include a steel or composite safety toe cap.

The composite toe has a carbon fiber shell that meets ASTM impact safety standards. It’s lighter than steel while resisting corrosion and fatigue. TPU overlays reinforce the toe box for added protection.

Wolverine subjects their protective toe caps to extreme cold, heat, and simulated crush tests. This ensures the toes maintain integrity and keep protecting feet even after significant impacts.

Goodyear Welt Construction

The legendary Goodyear welt construction fuses the upper, midsole, and outsole into a durable bond. It provides structure and amplifies the boots’ lifespan.

The welt “rim” stitches the components together and seals out moisture. If the soles eventually wear down, the boot can be resoled rather than replaced. This extended life saves money while reducing waste.

Some Floorhand styles use cement construction for a flexible and lightweight feel. But most feature welted construction for maximum longevity under punishing rig conditions.

From toeing mud on the rig floor to relaxing after a shift, Wolverine boots will keep feet protected and comfortable. Their obsessive material selection and construction methods result in footwear built to thrive season after season, even on the toughest oil rigs.

Slip-Resistant Soles for Traction on Slick Surfaces

Working in the oilfields can be a slippery situation, literally. With surfaces often covered in oil, grease, and mud, having proper footwear is crucial for floorhands and other rig site workers. Slipping and falling leads to countless injuries in this line of work, but the right boots with slip-resistant soles can provide the grip and traction needed to get the job done safely.

When searching for slip-resistant work boots, look for rugged styles with heavily lugged rubber outsoles. These deep lugs allow the sole to bite into oily surfaces, while the rubber composition provides flexibility and durability. Large outward facing lugs specifically give better traction on liquid spills or slick muddy areas. The best oilfield work boots have aggressive soles with lugs in multiple directions for multi-directional grip.

Boots with a defined heel are also advisable for better traction and stability. The pronounced heel helps prevent the foot from sliding forward inside the boot when walking on an angle or slope. This also provides better control if stepping in a slick hole or depression. Heeled boots give floorhands surer footing when carrying heavy loads like pipe and drilling equipment.

In addition to deep, rugged lugs, look for oilfield work boots with a slip-resistant outsole material like Vibram or high-quality rubber compounds. These materials are engineered for maximum traction, especially on wet, oily ground. The outsoles should also be oil-resistant and not degrade or become excessively slick after prolonged chemical exposure.

Choose Lace-Up Boots for a Secure Fit

Proper traction relies on the boots fitting snugly and not slipping around on the foot. That’s why lace-up boots are recommended over pull-on styles for oilfield work. The laces allow floorhands to adjust and tighten the boots for a locked-in fit. This prevents the foot from sliding around, maintaining contact between the sole lugs and ground.

The upper portion of the boot should also be oil-resistant. Leather uppers with nylon panels provide flexibility and support without absorbing oils and chemicals. This keeps the materials from becoming slick and compromising traction. Waterproof linings are also critical to keep feet dry.

Cushioning and Support for All-Day Comfort

While oil-gripping soles are most important, all-day comfort is also key. Floorhands routinely walk 5-10 miles per shift across uneven, rugged terrain. Proper cushioning and arch support helps reduce foot fatigue and injury risk.

Look for work boots with cushioned midsole and insoles for shock absorption. Polyurethane or EVA foam midsoles provide lightweight cushioning that holds up to heavy use. Removable insoles with arch support and deep heel cups also prevent foot strain. Some higher-priced boots have customized insoles designed for oilfield conditions.

Supportive footbeds are especially important when carrying and maneuvering heavy loads like drill pipe. The last thing a floorhand needs is their boot sliding around while bearing hundreds of pounds of equipment. Proper arch and heel support provide a stable platform to walk and work from.

Protect Toes from Impact

No oilfield footwear is complete without steel toes. Floorhand duties involve routine lifting and moving of heavy industrial equipment where toe injuries are common. Steel-toed boots are mandatory for protection from falling objects, drill pipe, and machinery.

Look for oilfield work boots with steel toes rated for impact and compression (ASTM rating of 75 or higher). While alloy and composite toes are lighter, steel provides the highest level of impact protection. Covered toe caps help shield the steel from corrosion and moisture.

Some boots take protection a step further with puncture-resistant footbeds. These help prevent injuries from nails, debris, and other objects that might penetrate the sole. A reflective strip around the heel also improves visibility in low light conditions.

Brands Known for Safety and Traction

When it comes to oilfield footwear, relying on established work boot brands is advisable. Companies like Wolverine, Ariat, Georgia Boot, and Red Wing Shoes specialize in rugged designs built to withstand hazards and slick conditions. Here are some top options:

- Wolverine Floorhand Waterproof Work Boots – Deep multidirectional lugs and pronounced heel for traction. Waterproof full-grain leather upper resists oil and chemicals. Removable cushioned insole.

- Ariat Workhog Pull-On H2O Work Boot – Slip- and oil-resistant Duratread outsole. Compression-resistant steel toe. Waterproof full-grain leather upper.

- Georgia Giant High Romeo Work Boot – Vibram Montagna outsole with deep lugs. Cushioned insole and nylon shank for support. Abrasion-resistant leather upper.

- Red Wing Irish Setter Work Boot – Vibram outsole lugs in two directions for traction. Triple stitched for durability. Poron footbed for cushioning.

No matter the brand, always try boots on and walk around before purchasing. The fit needs to lock down the foot securely without pinching or rubbing. Break them in gradually at work to build comfort and prevent blisters.

At the end of the day, oilfield work boots are the floorhand’s first defense against slips, trips, and falls. Sturdy, slip-resistant styles with proper traction can keep workers upright and productive on sites greasy with crude.

Steel Toes Protect Feet from Falling Objects

Working on an oil rig is riddled with hazards for the feet, from heavy falling objects to sharp debris that can cause serious injury. For floorhands, steel toe boots are mandatory equipment to prevent crushing injuries and trauma to the toes.

Oilfield work exposes feet to considerable risks on a daily basis. Drilling pipes, tools, and equipment are continuously being hauled and maneuvered around the rig site. Even a small object falling from height can break bones when it lands on unprotected feet.

Steel toes form a protective cap at the front of the boot that shields the vulnerable toes from compression and impact forces. The heavy-duty steel absorbs and deflects the energy from falling objects, preventing broken bones and toe damage.

Choosing the Right Steel Toe Rating

When selecting oilfield work boots, pay attention to the steel toe rating based on the ASTM impact and compression standards. For strenuous industrial work, an ASTM rating of 75 or above is recommended for the highest level of protection.

The most protective toes use thick, solid steel. Alloy and composite toes are lighter but more vulnerable to breaking down over time when exposed to oil, moisture, and chemicals. Stick with solid steel toes coated in oil-resistant materials.

The toe cap should wrap fully around the toes for 360-degree protection. Steel extending above the boot upper also helps shield from falling objects and debris. Lace-up boots ensure a tighter enclosure around the steel toe.

Shield Laces and Tongue from Catching

An otherwise protective steel toe can fall short when the boot’s laces and tongue are exposed. Laces and tongue routinely catch on obstacles, machinery, and moving parts, pulling the floorhand’s foot into the hazard before they can react.

The best oilfield boots enclose and protect the laces behind durable leather or fabric panels attached above the steel toe cap. This prevents the laces from catching and protects the feet from dragging injuries.

A gusseted tongue is also essential to prevent catching accidents. The gusset is an extra piece of leather or fabric that covers the tongue seam, safeguarding the opening where the laces feed through.

Slip Resistant Soles Prevent Falls

Preventing toe injuries isn’t just about the steel toe. Floors hands also have to maintain sure footing on slick surfaces to avoid falls. Oily rig platforms, mud pits, and crude puddles can cause feet to slide out from under without warning.

Boots with deep, aggressive lug soles provide the highest traction to prevent slips and falls. The lugs penetrate and grip oily surfaces to keep floorhands upright. Brands like Vibram and blown rubber soles offer superior oil- and chemical-resistant traction.

Heel shapes that extend wider than the toe also improve stability for walking at angles on platforms and slopes. Less contact between the sole and ground can allow the foot to slide forward inside the boot.

Fit Matters as Much as Features

Floorhands routinely log 5-10 miles per shift across uneven ground while carrying heavy loads. Even boots with the best protective features will fall short if they don’t fit properly.

Boots that are too loose allow the foot to slide forward on impact, negating the steel toe’s protection. Excessive tightness causes discomfort and narrows the toe box, increasing injury risk.

The best fitting boots hug the heel, support the arches, and allow just enough room to wiggle the toes. Take the time to properly size steel toes before work. Break them in on short shifts to build comfort and prevent blisters.

Cushioning Absorbs Shock Forces

Supportive cushioning is vital for absorbing shock and impact from walking and standing on steel decks and hard ground. Poorly cushioned boots transmit jarring forces up the legs and spine, setting the floorhand up for fatigue and pain.

Quality oilfield boots have advanced cushioning systems in the midsole and removable insoles. Materials like polyurethane (PU), ethylene vinyl acetate (EVA) foam, and gel pads provide lightweight shock absorption and energy return.

Deep heel cups and supportive arch cushions are also critical for stability when carrying heavy loads. Cushioned footbeds align the body properly to avoid overcompensation injuries while working long shifts.

Keep Feet Dry to Prevent Slippery Boots

Even the toughest leather steel toe boots eventually become slippery hazards themselves when soaked with water and oil. Wet boots lose traction and compromise safety.

Select steel toe designs with waterproof, breathable linings to keep feet dry. Materials like Gore-Tex and SYMPATEX liners block external moisture while preventing interior perspiration buildup.

Quick-drying meshes and antibacterial linings also help control moisture. Keep the boots clean by brushing off oil, mud, and debris after each shift to maintain traction.

Choosing the right steel toe oilfield boots comes down to toe protection, slip resistance, and lasting comfort. Guarding feet from workplace hazards keeps floorhands safe, secure, and productive on the rig.

How to Get the Right Fit for All-Day Comfort

Floorhands routinely log over 5 miles per shift across rough terrain on oil rigs and facilities. With long hours on their feet, boots that don’t fit properly lead to pain, fatigue and injury over time.

Getting the optimal fit takes more than just buying the right size. Considerations like toe room, heel slippage, arch support, and adjustments for swelling all determine whether boots are truly comfortable for the long haul.

Size Up at End of Day for Extra Room

Feet tend to swell after hours of walking and standing. What fits great in the morning can become painfully tight by the end of a 12-hour shift. That’s why oilfield boots should be sized at the end of the day when feet are largest.

Leaving a little extra room in the toe box accommodates swelling and thick socks for cold weather. A good rule is to have about a thumb’s width between the toe and boot tip. Too little room squeezes and cramps toes over time.

Heel Should Hug Snugly to Prevent Slip

Heel slippage causes blisters and leads to strains as floorhands overcompensate to keep boots on. Excess heel movement also compromises traction on slick surfaces around the rig.

For proper lockdown, boots should grip heels snugly without tightness or rubbing. Slip-on boots are more prone to heel slippage than lace-ups, which can be snugged up. Using tie locks or looping laces helps maintain tightness.

The best fitting boots stabilize heels while walking but allow easy heel entry when putting them on. Breaking in over weeks molds the boot to move with the heel stride.

Support Arches to Reduce Fatigue

Quality oilfield boots have ample arch support to prevent strain and fatigue over long hours. Flat boots without arch reinforcement let the foot collapse inward with each step, tiring muscles faster.

Removable cushioned insoles with built-up arches align the foot properly inside the boot. This relieves strain on the plantar fascia ligament which runs under the arch. Supportive insoles also prevent overpronation that twists feet inward.

Firm heel counters and integrated shanks offer rearfoot stability and arch support in the boot frame itself. These provide all-direction stability when carrying equipment and on uneven ground.

Cushioning Absorbs Shock from Hard Surfaces

Hard steel decks, concrete, and compacted earth send jarring forces up through the feet and legs over a long shift. Poorly cushioned boots will make floorhands feel like they went a few rounds with a drill pipe.

Advanced oilfield boots have thick, layered midsoles and insoles that absorb shock and impact. Materials like polyurethane foam, EVA, and gel pads cushion feet to prevent that “beat up” feeling.

Insoles should also have a deep, molded heel cup. This cradles and stabilizes the heel on impact, preventing strain from repetitive shock.

Lace Styles Adjust Fit Throughout the Shift

Even with perfect sizing, feet tend to loosen up and settle into boots over hours of wear. Lace-up boots allow floorhands to periodically snug up for a refreshed, secure fit.

Quick-lace hooks are convenient for cinching up boots on the fly. Placing lacing locks or double-knotting prevents laces from coming loose. This adjustability prevents fatigue from loose boots flopping around.

Pull-on boots don’t allow mid-shift adjustments. Sizing has less margin for error. But pull-on styles with elastic goring give a bit of flex room for swelling feet.

Properly Layer Socks for Cushioning

What you wear under oilfield boots also impacts comfort and fit. Thin, low-quality socks lead to blisters while overly thick pairs cram toes.

The ideal sock combination includes a thin moisture-wicking liner sock underneath a merino wool or synthetic outer sock. The liner keeps feet dry while the outer sock cushions and insulates without bulking up.

Take time to layer and adjust socks until snugness feels uniform around the foot with no tight spots. Proper sock fit helps prevent blisters or circulatory issues from boots that otherwise fit well.

Achieving that “ahh” feeling in oilfield boots requires considering all fit factors. Dialing in the right boot through sizing, adjustment, and sock choice gives floorhands the pain-free footing to perform safely shift after shift.

Additional Safety Features Like Electrical Hazard Protection

Steel toes and slip-resistant soles cover the basic safety needs of oilfield boots. But modern styles offer additional protective features to shield floorhands from other hazards.

Electrical hazard (EH) protection, metatarsal guards, puncture resistance, and reflective accents all provide supplemental safeguards without compromising comfort or performance.

Electrical Hazard Boots Prevent Shock

With power lines and live electrical panels on rigs, electrocution is an ever-present danger. EH-rated boots have non-conductive soles to prevent electrical current flowing through the body.

The soles measure at least 18,000 ohms resistance from the insole to the bottom. This insulation prevents current transmission in dry conditions. EH boots should be worn when working around exposed power sources.

The uppers are also non-conductive and don’t contain exposed metal parts like traditional lace eyelets. Composite safety toes avoid conducting electricity to the feet like steel.

Metatarsal Guards Shield Insteps from Impact

Instep guards provide extra protection from falling objects and material impacting the vulnerable metatarsal bones in the midfoot. These semi-rigid guards fit over the tongue to shield from compression injuries.

External met guards attach securely to the boot laces and frame to create a protective exoskeleton over the metatarsals and tongue base. These detach easily when not needed.

Integrated metatarsal guards built into the boot upper offer full-time protection. But these fixed guards can’t be removed which may limit ankle flexibility for some wearers when climbing.

Puncture Protection Prevents Sharp Object Injuries

Sharp debris, exposed rebar, nail heads are underfoot hazards on industrial sites. Puncture-resistant plates embedded in midsoles or removable insoles prevent sharp objects from penetrating through the boot.

These ultra-high-molecular weight polyethylene or composite plates maintain flexibility while providing impressive puncture protection. Insole plates can be transferred to new boots when worn out.

Kevlar woven fabrics also enhance puncture and cut resistance in boot uppers. This helps protect against sharp edges, wire, and abrasive surfaces that might slice leather.

Reflective Strips and Piping Increase Visibility

Poor lighting conditions are routine on oil rigs at night or in dark spaces. Reflective markings on boots help floorhands see and avoid hazards in dim conditions.

Reflective piping along the heels and upper side panels creates visibility from all angles when light hits. Silvery reflective strips also outline the toe cap, boot top, and lace area for Increased visibility.

For most exposure, choose boots with reflectivity integrated throughout plus interchangeable reflective bands to attach when needed. These reflective aids prevent site vehicle operators from running over boots.

Lightweight Materials Avoid Fatigue

Heavy, clunky boots promote fatigue over 10-12 hour shifts. New materials make oilfield boots protective without all the heft.

Abrasion-resistant synthetics like SuperFabric replace leather in high-wear areas but weigh ounces less. Injected polyurethane midsoles offer cushioning that’s 40% lighter than rubber.

Breathable shoe-dry linings shed water faster to prevent boots from becoming uncomfortably heavy when soaked. Lighter materials improve floorhand safety, stamina, and performance.

The latest oilfield boots blend core safety with supplemental features to shield feet from all site hazards. Savvy floorhands look beyond just steel toes and slip resistance to maximize their protection and comfort.

Lightweight Options Available for Improved Mobility

Traditional leather and rubber oilfield boots provide protection but can feel like concrete weights at the end of a 12-hour shift. New lightweight styles offer the same safeguards in a more agile boot.

As worksite foot hazards have increased, so have the protective features built into boots. More steel, electrical insulation, and puncture plates add critical protection but also heft.

Advancements in boot materials now provide protection without all the leg-wearying weight. Lighter boots improve floorhand mobility, balance, and reduce injuries from fatigue.

Synthetic Leathers Cut Weight

Premium full-grain leather remains a staple of oilfield boots for its durability and water-resistance. But leather is dense and absorbs water to become even heavier.

Synthetic leathers made from durable polymers offer leather-like abrasion resistance at almost half the weight. Popular options are coated split-grain nylon and action leather made of polyurethane.

These high-tech synthetics stand up to oil and rough use but stay lighter even when wet. Less boot weight prevents muscle and joint strain over long shifts.

Breathable Fabrics Dry Faster

Nothing weighs down boots like water-logged materials. Improved linings utilize breathable, moisture-wicking fabrics to keep feet drier.

Mesh linings and panels channel vapor out while blocking external water sources. These fast-drying synthetics prevent that slow, fatiguing waterlog as shifts wear on. Well-ventilated boots stay energizing and mobile.

Antimicrobial linings also prevent odors that worsen when feet sweat excessively into the boots. Cool, odor-free feet feel less leaden and fatigued.

Advanced Foams Lighten Midsoles

Supportive cushioning is vital in oilfield boots but traditionally adds weight. Injected polyurethane (PU) midsoles now provide plush comfort at almost half the weight of rubber or EVA foam.

PU foam cells cushion without density. Optimized stiffness stabilizes footing without heaviness. New self-inflating air foam midsoles offer even more lightweight shock absorption and energy return.

Graphite shanks embedded in midsoles also provide torsional support and stability at a fraction of the weight of steel. Light, stable footing prevents muscle strain from poor support.

Carbon Fiber Toe Caps Cut Heft

Steel toes are essential but add about half a pound per boot. New carbon fiber toe caps weigh 40% less than steel but offer similar impact protection.

Carbon fiber composites made from woven graphite filaments are incredibly strong but featherlight. Their high-tech makeup absorbs and deflects force as effectively as steel.

For those who find steel toes heavy or uncomfortable, carbon fiber caps provide comparable protection without the bulk and muscle fatigue over long shifts.

Removable Footbeds Allow Weight Adjustments

Many heavier oils and their associated risks call for puncture-resistant insoles. But these sturdy layers add ounces of weight.

Boots with removable footbeds allow floorhands to tailor weight and features to the day’s activities. Thin, perforated insoles suffice for light duties while puncture plates insert for high-risk tasks.

Having footbed options allows adjusting boot weight to the needs of the shift. Less weight when possible prevents unnecessary strain and fatigue on better days.

Oilfield foot hazards continue to rise but boots no longer need to be a literal weight around floorhands’ ankles. Prioritizing agile, breathable, lightweight designs keeps feet safer and energized.

Style Meets Function with Rugged Good Looks

Gone are the days when industrial work boots resembled clunky cement blocks. Today’s protective styles integrate cutting-edge materials and athletic shoe technology for good looks that turn heads.

Leading work boot brands nowblend fashion and performance to create styles floorhands actually want to wear on and off the rig. Protective never looked so sharp.

Athletic Styling Brings All-Day Comfort

Informally known as work sneakers, these boots borrow athletic shoe contours and technologies for feather-light comfort.

Breathable mesh panels, dynamic flex grooves, and sneaker-like tooling transform bulky boots into agile, free-flexing footwear. Removable orthotic insoles provide personalized, athletic-shoe cushioning.

The athletic support and feel help floorhands power through shifts with energized feet. Safety meets all-day wearability.

Low-Profile Toes for Easy Access

Bulging steel toes create a stubby, blocky look reminiscent of LEGO feet. New composite toes taper thinner and lower for a trim profile.

A slender composite safety toe coupled with a rounded steel-free toe box creates a streamlined silhouette. This complements more casual attire like jeans when paired with work.

The slimmed design also cuts weight and eases entry compared to lumbering traditional styles.

Bold Colorways Differentiate and Coordinate

No more bland black and brown monotony. Bold pops of color on straps, bindings, and detailing give modern boots swagger.

Emerald green weld-resistant leather or electric blue webbing pops against black boots. Contrast heel loops and lacing deliver eye-catching style.

Color options also allow coordinating with company uniforms. Morale gets a boost along with safety.

Weathered Leathers Have Rugged Character

Pre-distressed, hand-stained, and vintage leathers make boots look broken-in comfortable on day one.

Hand-wiping techniques create a well-worn patina with contrast highlights. Weathering draws out the depth and character in premium leathers.

The vintage look skips the painful break-in for instant comfort with no compromise on safety or oil resistance.

Western-Inspired Designs Blend Oilfield and Ranch Heritage

Western stitch lines, decorative backstrap loops, and cowboy-boot silhouettes connect the oil patch aesthetic to rural roots.

High-vamping smooth leathers and exotic prints like python and giraffe transform traditional work boots into modern ranch wear.

The blended styles retain key oilfield boot safety and performance features for good looks with total protection.

Blending fashion and function used to be impossible for industrial footwear. But floorhands can now get the latest aesthetics along with critical workplace protection.

Weatherproof Options to Wear in Rain or Snow

Oilfield work proceeds through all conditions, from muddy fields to icy platforms. Having weatherproof boots that block rain and snow allows floorhands to operate safely and comfortably year-round.

Unprotected leather boots become miserably soggy when wet. Feet get cold and damp on winter rigs. Waterproofing technology keeps oilfield boots dry without trapping interior moisture.

Waterproof Membranes Block External Wetness

Advanced waterproof-breathable membranes bonded to interior linings prevent rain, snow, mud, and other liquids from intruding, while allowing interior vapor to escape.

ePTFE membranes like Gore-Tex and Sympatex provide guaranteed waterproofing down to the stitching. Polyurethane films offer budget-friendly water protection at lighter weights.

Fully waterproof boots maintain grip on slick surfaces and won’t weigh down from absorption over a wet shift.

Moisture-Wicking Lining Materials

Waterproof linings trap heat and sweat which can saturate feet from the inside out. Moisture-wicking fabrics eliminate this issue.

Mesh linings and panels actively draw sweat off feet for quick evaporation. Some linings incorporate anti-microbial properties to prevent bacteria forming in damp boots.

Dry feet are essential for comfort and to maximize the performance of waterproof membranes. Breathability equals all-weather wearability.

Snug Collars Seal Out External Moisture

Gaps around ankles allow rain and melting snow to seep in from above the boot. Snugly designed ankle collars prevent this breech.

Higher ankle coverage and adjustable lacing let floorhands lock out external wetness. The collar should seal without restrictive pinching for all-day comfort.

Neoprene and flexible synthetic collars conform closely to the ankle without chafing. A fully-enclosed weather barrier starts at the ankle.

Rustproof Hardware for Superior Durability

Frequent exposure to liquids causes metal eyelets and hooks to rust and degrade over time. Rustproof hardware keeps boots looking their best.

Eyelet guards shield lacing hardware from corrosion. Brass and nickel-coated metal offer attractive rust-resistance compared to ordinary steel.

Waterproof boots should be built to withstand their environment. Anti-rust components prevent deterioration in bad weather.

Insulation Options Fit Weather Extremes

Cold conditions call for thermal insulation to keep feet warm without overheating. Different linings tailor warmth to the climate.

Lightweight thermal polyester linings maintain high breathability for fall/spring climates. PrimaLoft insulation provides lightweight, water-resistant winter warmth.

Removable liners allow adjusting insulation levels by season. Warm, dry, and protected feet empower floorhands to take on wet weather and winter cold.

Don’t let wet conditions soak through productivity and safety. Waterproof, insulated footwear keeps feet at peak performance all year.

Easy to Clean and Maintain for Long Term Use

Oilfield boots take a beating from caustic chemicals, abrasive surfaces, impacts, and the elements. Proper cleaning and care allows quality boots to keep protecting feet long term.

Leather boots and rubber soles exposed to oil, grease, drilling fluids, and mud degrade over time without maintenance. A consistent care regimen extends boot life and return on investment.

Rinse Off Debris to Prevent Damage

Mud, tiny rocks, gravel, and oilfield debris lodged in boot treads quickly abrade and damage soles. Rinsing boots prevents this.

Use a pressurized water hose on soft spray setting to blast away dirt and debris from crevices after shifts. Avoid high-pressure streams that push in grime.

Give extra attention to cleaning lug areas. Any buildup that compromises slip resistance must be removed. Field debris can rapidly degrade boot traction.

Scrub With Mild Soap and Soft Brush

For thorough cleaning, use a mild dish soap with warm water and a soft bristle brush. Strong degreasers may strip leather.

Create a good lather with soap. Gently scrub upper, sides, heels, and soles. Avoid abrasive scouring that can scratch materials.

Pay extra attention to welts, stitches, eyelets, and flex points where grime congregates. Rinse boots thoroughly after scrubbing.

Stuff Boots With Newspaper to Dry and Maintain Shape

Letting boots air dry may lead to shrinkage or lost shape. Lightly stuffing them with newspaper absorbs moisture and maintains structure as they dry.

Crumpled newspaper inserted in the toe box and ankle areas soaks up water. Replace damp paper until fully dry. Ankle supports may be re-inserted during drying.

Proper drying after each use extends the life of boots in the caustic oilfield environment. It also prevents foul odors from sweat and bacteria.

Condition Leather to Prevent Cracking

Frequent chemical and sun exposure causes oilfield boot leather to dry out and crack over time. Leather conditioners prevent this damage.

Apply leather cream or oil-modified conditioners after cleaning. Avoid animal fat creams that degrade synthetics. Rub thoroughly into leather, letting soak in overnight.

Monthly conditioning keeps leather supple, water-resistant, and better protected from the elements. Well-hydrated leather remains stronger.

Check for Wear and Replace Laces

Fraying or broken laces compromise boot safety and fit. Inspect laces with each cleaning and replace annually or sooner if damaged.

Re-lace with quality round laces or wovenflatteners in the right length. Secure properly to prevent slippage and maintain snug fit.

Replace worn parts like insoles and supportive shanks to retain function. Proactive care and maintenance optimizes the protective life of quality boots.

With regular TLC, tough oilfield boots keep feet safe and comfortable for seasons rather than months. A few minutes after each shift pays off long-term.

Affordable Prices for Quality Floorhand Work Boots

Protecting feet from oilfield hazards doesn’t have to devastate the wallet. Major brands now offer full-featured boots at budget-friendly prices for value-conscious floorhands.

Traditionally, only premium-priced boots provided the combination of safety, slip resistance, and durability needed for rigorous rig site conditions. New manufacturing methods allow quality at lower costs.

Mid-Range Boots Balance Features and Cost

Major work boot companies now offer “good” and “better” tiers that slot below their top-shelf lines but still deliver performance.

Synthetic leather or nylon uppers replace pricier full-grain leather. Molded midsoles substitute for layered cushioning systems. But essential safety and oil-grip remain intact.

These boots forgo some comfort frills and durability but provide job-ready function on a moderate budget.

Safety Toes Without Breaking the Bank

Steel toes once drove up boot prices. New alloy safety caps cost less but still meet ASTM standards for compression and impact.

Alloy toes made of lightweight carbon and titanium provide solid toe protection for less. And they’re thinner for greater comfort and flexibility.

Don’t confuse these with soft alloy caps that skimp on protection. Stick with reputable brands using tested alloys.

Slip-Resistant Soles Without the Premium

Deep-lugged Vibram and microglass outsoles excel at traction but drive up cost. New manufacturing techniques create similar oil-gripping lugs for less.

Direct-injected polyurethane soles offer defined multi-directional lugs once unique to pricey brands. Rubber compounds enhanced for oil grip balance flexibility and traction at moderate pricing.

Affordable no longer means compromised grip or standing in an oil slick all day.

Synthetic Leather Saves Over Genuine

Full-grain leather boots still top for longevity but synthetic “leathers” get close on durability for less cash.

Coated nylons and PU-based synthetic uppers provide respectable abrasion-resistance and waterproofing. They just lack the coveted patina of genuine leather over years of wear.

The right synthetics still outlast cheap vinyls and provide better value for a set budget.

Wait for Sales on Last Year’s Models

As with vehicles, new model year boots go on sale as brands introduce upgrades. Last year’s designs get deep discounted.

Functionally the boots are still solid but just lack the latest tech and styling. Following releases allows scooping up quality boots at clearance cost.

Off-price websites also offer major brand samples and overstocks at steep savings off retail. A little deal hunting helps budget boots compete on safety.

Having the funds for top boots doesn’t always align with oilfield paydays. But floorhands can still keep their feet covered without overspending.