How do puncture-proof shoe inserts work. What are the top-rated options for work boots. Do puncture-proof insoles prevent all types of punctures. Which factors should you consider when choosing the right level of protection.

Understanding the Importance of Puncture-Proof Shoe Inserts

In environments where sharp objects pose a threat to foot safety, puncture-proof shoe inserts become an essential piece of protective equipment. These specialized insoles act as a crucial barrier between hazardous ground conditions and your vulnerable feet, significantly reducing the risk of painful and potentially dangerous injuries.

Puncture wounds to the feet are alarmingly common in various work settings, including construction sites, roofing projects, landscaping areas, and manufacturing facilities. Even outdoor enthusiasts face risks from sharp sticks, rocks, and other natural hazards while hiking. Standard shoe soles often fail to provide adequate protection against these threats, making puncture-proof inserts a vital addition to your footwear.

How Puncture-Resistant Insoles Protect Your Feet

Puncture-resistant insoles utilize advanced materials and innovative designs to create a formidable shield for your feet. Leading brands like FlexShield incorporate a combination of rigid and flexible components to achieve optimal protection without sacrificing comfort.

The core of FlexShield’s puncture-proof inserts, for example, consists of a proprietary steel shank surrounded by layers of Kevlar fabric. This ingenious combination results in exceptional puncture resistance across the entire insole surface. The steel shank serves as the primary defense, preventing sharp objects from penetrating the Kevlar layers. Meanwhile, the Kevlar reinforces the protective barrier while maintaining enough flexibility for comfortable wear.

Key Components of Effective Puncture-Proof Insoles:

- Steel or metal plates for maximum puncture resistance

- Kevlar or other high-strength synthetic fibers

- Rigid support structures for stability

- Flexible materials for comfort and natural foot movement

- Shock-absorbing elements to reduce fatigue

Top 5 Puncture-Resistant Insoles for Work Boots

When selecting puncture-proof inserts for your work boots, it’s crucial to consider both protection and comfort features. Here are five highly-rated options that offer excellent puncture resistance along with additional benefits:

- FlexShield Puncture Resistant Insoles: These insoles provide superior protection with their steel shank and Kevlar construction, offering unparalleled defense against sharp objects.

- Dr. Scholl’s Work Heavy Duty Insoles: Combining good puncture resistance with exceptional shock absorption, these insoles are ideal for long workdays on hard surfaces.

- Powerstep Pinnacle Maxx Insoles: Featuring rigid arch support and an anti-microbial top layer, these insoles offer both protection and hygiene benefits.

- Superfeet GREEN Premium Insoles: The firm foam base of these insoles resists punctures effectively, especially during high-activity tasks.

- Timberland PRO Anti-Fatigue Insoles: Utilizing polyurethane foam, these insoles provide reliable puncture resistance while also reducing foot fatigue.

The Effectiveness of Puncture-Proof Insoles

While puncture-proof insoles offer remarkable protection, it’s important to understand their limitations. Can these insoles prevent every possible puncture scenario? The answer is no, but they significantly reduce the risk in most real-world situations.

Extremely sharp, dense objects like large nails, screws, or thick metal pieces might potentially penetrate both the insole and the boot in extreme cases. However, puncture-resistant inserts provide highly effective protection against the vast majority of hazards encountered in typical work environments.

It’s worth noting that some thinner, more flexible puncture-proof inserts may allow very small objects like thin pins or staples to slightly penetrate the surface. However, these minor intrusions are unlikely to fully puncture your foot. For maximum protection against even the smallest hazards, heavy-duty options like FlexShield offer superior impenetrability.

Selecting the Appropriate Level of Puncture Protection

Choosing the right level of puncture protection involves carefully assessing the specific hazards you encounter in your work or recreational activities. Consider the following factors when making your selection:

1. Types of Hazards:

Evaluate the most common sharp objects you might encounter. Are you dealing with small debris like wood splinters and metal shavings, or larger threats like nails and screws?

2. Frequency of Exposure:

How often are you in situations where puncture hazards are present? Daily exposure in high-risk environments may warrant maximum protection, while occasional exposure might allow for more flexible options.

3. Comfort Requirements:

Consider the trade-off between protection and flexibility. Heavy-duty insoles with steel shanks offer maximum puncture resistance but may slightly restrict movement. Thinner, more flexible inserts maintain boot flexibility but may provide less protection against larger objects.

4. Activity Level:

If your job or activity involves a lot of movement or requires agility, you might prefer a more flexible insert that allows for natural foot movement while still providing an extra layer of protection.

Thin vs. Heavy-Duty Puncture-Resistant Inserts: When to Use Each

The choice between thin, flexible puncture-resistant inserts and heavy-duty options depends on your specific needs and risk level. Here’s a guide to help you decide:

Thin, Flexible Inserts:

These are ideal for situations where you occasionally encounter potential puncture hazards, such as:

- Home improvement projects

- Light yard work

- Casual hiking or outdoor activities

Brands like Dr. Scholl’s, Powerstep, and Superfeet offer puncture-resistant models that maintain excellent comfort and flexibility. These are particularly suitable for hunters and hikers who need protection from natural hazards like sharp sticks, thorns, and rocks, but also require natural foot movement for agility on the trail.

Heavy-Duty Inserts:

For high-risk occupations and environments where puncture hazards are frequent and severe, heavy-duty insoles with steel shanks, like those offered by FlexShield, provide maximum protection. These are recommended for:

- Construction workers

- Roofers

- Factory floor employees

- Waste management personnel

While these inserts may be slightly less flexible, the trade-off is worth it in environments where foot injuries could have serious consequences.

The Critical Role of Arch Support in Puncture-Proof Insoles

Given that puncture-resistant inserts are typically thicker and more rigid than standard insoles, proper arch support becomes crucial for maintaining comfort during extended wear. Many leading brands recognize this need and incorporate excellent arch support into their puncture-proof models.

Why is arch support so important in these specialized insoles? Here are several key reasons:

- Fatigue Reduction: Proper arch support helps distribute weight evenly across the foot, reducing strain and fatigue during long work hours.

- Natural Alignment: It promotes proper foot alignment, which can help prevent issues in the knees, hips, and lower back.

- Comfort Enhancement: Arch support provides cushioning and helps absorb shock, making rigid puncture-proof insoles more comfortable to wear.

- Injury Prevention: Good arch support can help prevent conditions like plantar fasciitis, which can result from flat, unsupportive insoles.

Brands like Powerstep and Superfeet are particularly noted for their excellent arch support in puncture-proof models. When selecting your insoles, pay close attention to the level and quality of arch support offered to ensure maximum comfort throughout your workday.

Full-Length vs. Partial Puncture Protection: Making the Right Choice

When it comes to puncture-proof insoles, you’ll often encounter two main types: full-length protection and partial protection. Understanding the differences between these options is crucial for selecting the most appropriate insole for your needs.

Full-Length Protection:

Full-length puncture-proof insoles offer protection across the entire surface of the foot, from heel to toe. These are ideal for environments where hazards can occur anywhere underfoot. Benefits include:

- Complete coverage for maximum safety

- Protection for the entire plantar surface of the foot

- Uniform thickness throughout the insole

Partial Protection:

Partial protection insoles typically focus on safeguarding the most vulnerable areas of the foot, usually the forefoot and sometimes the heel. These insoles often offer:

- Increased flexibility compared to full-length options

- Lighter weight for improved comfort

- Potentially lower cost

The choice between full-length and partial protection depends on your specific work environment and the types of hazards you encounter. For high-risk areas with unpredictable dangers, full-length protection is often the safest choice. However, if you primarily need protection in specific areas and value flexibility, partial protection insoles might be more suitable.

Maintaining and Replacing Your Puncture-Proof Insoles

To ensure ongoing protection and comfort, it’s essential to properly maintain and replace your puncture-proof insoles. Here are some key considerations:

Cleaning and Care:

Regular cleaning helps maintain the integrity of your insoles and prevents odor-causing bacteria. Follow these steps:

- Remove insoles from shoes after each use to allow them to air out

- Brush off any loose dirt or debris

- Wipe down with a damp cloth and mild soap solution

- Allow to air dry completely before reinserting into shoes

When to Replace:

Even the most durable puncture-proof insoles will eventually wear out. Signs that it’s time for replacement include:

- Visible wear and tear, especially in high-stress areas

- Decreased comfort or support

- Any signs of the protective layer becoming compromised

As a general rule, consider replacing your puncture-proof insoles every 6-12 months, depending on usage frequency and working conditions. Regular replacement ensures consistent protection and comfort.

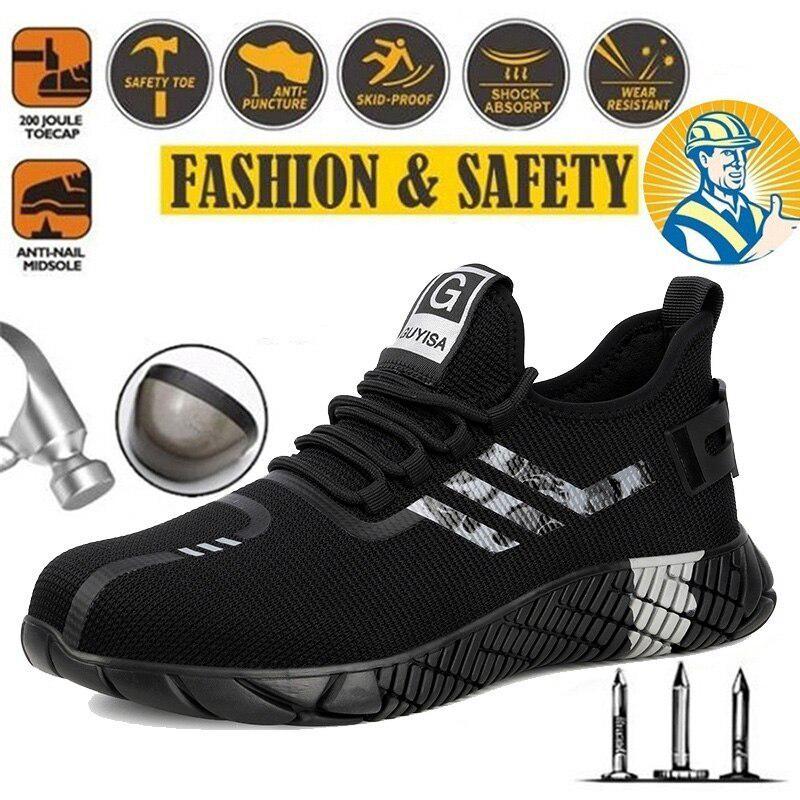

Combining Puncture-Proof Insoles with Other Safety Features

While puncture-proof insoles provide excellent protection against sharp objects, they work best as part of a comprehensive foot safety strategy. Consider combining these insoles with other protective features for maximum safety:

1. Steel-Toe Boots:

Pairing puncture-proof insoles with steel-toe boots offers protection against both punctures and heavy falling objects. This combination is ideal for construction sites and industrial settings.

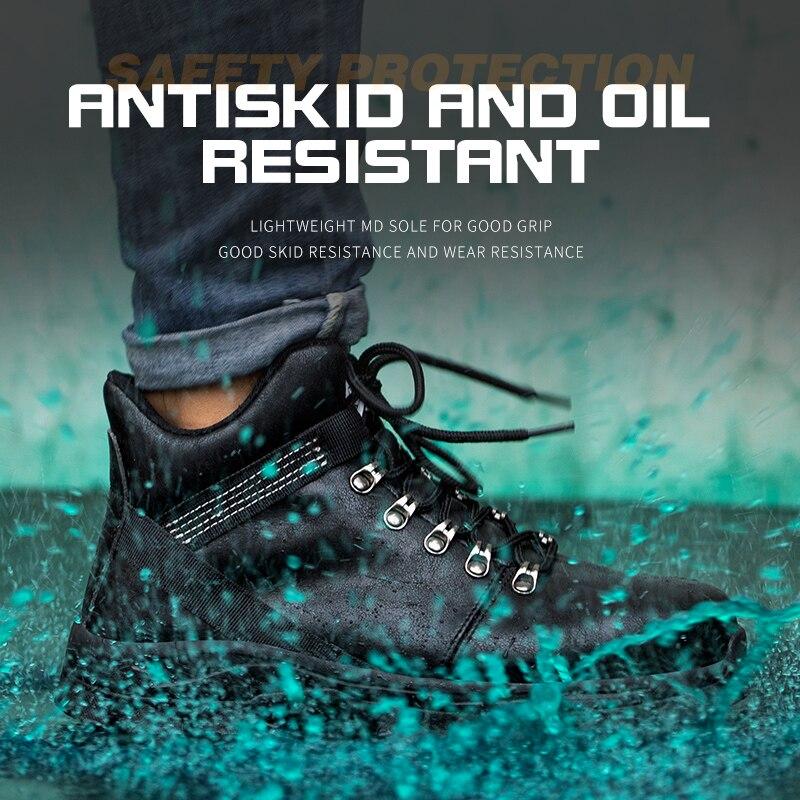

2. Slip-Resistant Outsoles:

Many work environments that pose puncture risks also have slippery surfaces. Choosing boots with slip-resistant outsoles in addition to using puncture-proof insoles can significantly reduce the risk of workplace accidents.

3. Waterproof Materials:

In wet or chemical-rich environments, waterproof boots combined with puncture-proof insoles provide comprehensive protection against both sharp objects and harmful liquids.

4. Electrical Hazard Protection:

For those working around electrical equipment, insoles and boots designed to provide protection against electrical hazards are crucial. Some puncture-proof insoles are compatible with electrically insulated footwear.

By combining these safety features, you create a multi-layered defense system for your feet, addressing a wide range of potential workplace hazards.

The Future of Puncture-Proof Shoe Insert Technology

As workplace safety continues to evolve, so does the technology behind puncture-proof shoe inserts. Researchers and manufacturers are constantly working on innovations to improve protection, comfort, and versatility. Here are some exciting developments on the horizon:

Smart Insoles:

Integration of sensors into puncture-proof insoles could provide real-time data on foot pressure, fatigue levels, and even detect potential hazards. This technology could revolutionize workplace safety monitoring.

Advanced Materials:

New synthetic materials and composites are being developed that offer even greater puncture resistance while remaining lightweight and flexible. These could lead to thinner, more comfortable insoles without compromising on protection.

Customization:

3D printing technology may soon allow for fully customized puncture-proof insoles, tailored to an individual’s foot shape and specific work requirements. This could greatly enhance both comfort and protection.

Self-Healing Materials:

Research into self-healing polymers could lead to puncture-proof insoles that can repair minor damage on their own, extending their lifespan and maintaining consistent protection levels.

As these technologies develop, we can expect to see even more effective and user-friendly puncture-proof insoles in the future, further enhancing workplace safety across various industries.

If you work in an environment where sharp objects can pierce through the soles of your shoes, then protecting your feet should be a top priority. Puncture-resistant insoles can provide that vital shield between the ground and your feet, helping prevent painful injuries.

Why Your Feet Need Extra Protection from Punctures

Imagine stepping on a nail or sharp metal scrap at a construction site. Without puncture-proof inserts, that object can go straight through the soles of your shoes and into your feet. Punctures can lead to serious infections if not treated properly. At minimum, you may experience extreme pain and have trouble walking normally. That’s why it’s so important to protect yourself with the best puncture-resistant insoles available.

Puncture wounds to the feet are extremely common in work environments like construction, roofing, landscaping, and manufacturing. Even outdoorsy folks can step on sharp sticks, rocks and other objects while hiking that can lead to injury. Thin shoe soles just don’t provide adequate protection. Adding puncture-proof inserts provides an extra barrier that prevents sharp objects from fully penetrating your feet.

How FlexShield and Other Puncture-Resistant Insoles Work

Brands like FlexShield use advanced materials in their puncture-proof inserts that provide rigidity and strength. FlexShield insoles, for example, contain a proprietary steel shank along with Kevlar fabric layers. This creates excellent puncture resistance across the entire surface area of the insole.

The steel shank acts as a shield that prevents sharp objects from pushing through the Kevlar upper layers of the insole. The Kevlar further reinforces that barrier while still allowing enough flexibility for comfortable wear. Together, these two materials form a puncture-proof barrier between your feet and the ground.

Top 5 Puncture-Resistant Insoles for Work Boots

When choosing puncture-proof inserts, you’ll want maximum puncture resistance with features like arch support for comfort. Here are 5 top-rated options:

- FlexShield Puncture Resistant Insoles – Excellent puncture protection with steel shank & Kevlar

- Dr. Scholl’s Work Heavy Duty Insoles – Good puncture resistance and shock absorption

- Powerstep Pinnacle Maxx Insoles – Rigid arch support and anti-microbial top layer

- Superfeet GREEN Premium Insoles – Firm foam base resists punctures during activity

- Timberland PRO Anti-Fatigue Insoles – Polyurethane foam provides puncture resistance

Do Puncture-Proof Insoles Really Prevent All Punctures?

While puncture-proof insoles provide excellent protection, they can’t prevent every single puncture in every situation. Extremely sharp, dense objects like large nails, screws, or thick metal pieces could potentially penetrate both insole and boot. However, puncture-resistant inserts provide very effective protection in most real-world work situations.

Some thin, flexible puncture-proof inserts may allow small pins, staples or other objects to slightly penetrate the surface but not fully puncture your foot. Heavier duty options like FlexShield offer maximum impenetrability.

Choosing the Right Level of Puncture Protection

Think about the types of hazards you commonly encounter when choosing puncture-proof insoles. Flexible inserts like Dr. Scholl’s provide good protection from small objects. Heavy-duty insoles with steel shanks like FlexShield offer maximum puncture resistance for high risk situations.

Also consider the comfort trade-offs. Thinner, flexible inserts maintain boot flexibility while heavy duty options may restrict movement slightly. However, maximum foot protection should take priority in high risk occupations.

When to Use Thin, Flexible Puncture-Resistant Inserts

If you only occasionally deal with potential puncture hazards like working around yard debris or construction projects at home, a thin flexible insert may provide sufficient protection. Models from Dr. Scholl’s, Powerstep and Superfeet offer puncture resistance with excellent comfort and flexibility.

Hunters and hikers dealing with natural hazards may also prefer a flexible insert that maintains natural foot movement – while still providing an extra layer of protection from sticks, thorns and rocks on the trail.

The Importance of Arch Support in Puncture-Proof Insoles

Since puncture-resistant inserts are thicker and more rigid than ordinary insoles, arch support is very important for comfort. Brands like Powerstep and Superfeet offer excellent arch support in their puncture-proof models to help reduce foot fatigue.

Proper arch support aligns the foot naturally and provides comfortable cushioning during long work days. It also helps prevent conditions like plantar fasciitis that can result from flat, unsupportive insoles.

Full-Length vs Partial Puncture Protection: Which is Better?

Full-length puncture-proof insoles provide the most complete protection from toe to heel. Partial inserts just cover the high-risk areas under the foot arch and ball, but leave toes and heels exposed.

For maximum protection, full-length insert models from FlexShield and Dr. Scholl’s cover the entire foot. The steel shank and Kevlar layers extend from toes to heel for impenetrable protection.

Getting the Right Fit with Removable Puncture-Resistant Insoles

Look for puncture-proof inserts that are removable, which allows you to get the ideal custom fit. Brands like FlexShield and Powerstep offer removable models that can be trimmed to perfectly fit your boot size.

Proper sizing ensures comfort, prevents slipping, and keeps the rigid arch fully aligned to your feet. Removable puncture-proof inserts should fit snugly inside your boots without excess room or movement.

Keeping Puncture-Proof Insoles Clean and Sanitary

Regularly cleaning your puncture-resistant inserts will keep them fresher for longer. Use mild soap and water to gently scrub away dirt and debris that can build up in the crevices.

Let them fully air dry before replacing in boots. Some removable inserts can also be tossed in the washing machine for deeper cleaning. Just be sure to let them fully dry to prevent moisture buildup inside boots.

Finding Boots Compatible with Thicker Puncture-Resistant Insoles

Since puncture-proof inserts can be thicker than standard thin insoles, make sure to choose work boots with enough interior room to accommodate them. Boots with removable stock insoles allow the most space.

Timberland, Caterpillar, Wolverine, and Red Wing boots often have sufficient room for inserting protective aftermarket insoles. Try on boots with your puncture-proof inserts to ensure good fit.

Why Proper Boot Fit Matters with Puncture-Resistant Insoles

A common mistake is choosing boots that are too big to accommodate thick puncture-proof insoles. This can lead to slipping, instability, and poor alignment. Instead, choose work boots that fit your feet properly, then replace the thin stock insoles with protective inserts.

Boots that are well-fitted to your feet prevent internal slippage that can cause blisters. A snug fit also optimizes the arch support of protective insoles.

Most Durable Materials for Puncture-Proof Shoe Inserts

The combination of a rigid steel shank with Kevlar fabric provides the most impenetrable puncture resistance. Steel blocks penetration while Kevlar reinforces that barrier. These heavy duty materials stand up to demanding work environments better than foam or softer plastics.

Brands like FlexShield rely on steel and Kevlar rather than plastic composites to create the most protective inserts. The small added weight is worth it for the unparalleled durability and puncture protection.

Caring for Boots with Puncture-Resistant Insoles Installed

Use boot dryers to thoroughly dry out work boots after use to prevent bacteria or odors. Rotate between two pairs of boots to prolong the life of both.

Periodically re-treat leather boots with oil or sealant to maintain waterproofing. Thoroughly brush off dirt from boot soles and use deodorizing powders or sprays when needed.

When It’s Time to Replace Worn Out Puncture-Proof Inserts

While puncture-resistant inserts are extremely durable, they do eventually wear out after years of use. If you see visible cracks or deterioration in the Kevlar or feel the steel shank bending, it’s time for replacement.

Worn out inserts won’t provide the same level of puncture protection. Most brands recommend replacing puncture-proof insoles every 12-24 months depending on your work environment.

Investing in new inserts is essential to safeguard the health of your feet over the long term. Don’t wait until it’s too late – puncture injuries are extremely painful and can cause permanent damage.

When it comes to protecting your feet on the job site, having the right puncture-resistant insoles can make all the difference. Brands like FlexShield have perfected the science of creating impenetrable barriers between your feet and potential hazards using innovative materials and designs.

How FlexShield and Other Puncture-Resistant Insoles Work

The key to FlexShield’s industry-leading puncture protection lies in the use of a stainless steel shank layered with Kevlar fabric. This combination blocks and reinforces against punctures better than any plastic composite or foam.

The rigid steel shank acts like an internal shield across the entire bottom of the insole, preventing objects from pushing through. Kevlar then provides an additional barrier that is highly cut and abrasion resistant. Essentially, the steel stops the puncture, while the Kevlar further blocks its progress.

Other brands take a similar multi-layered approach, using materials like plastic plates or carbon fiber instead of steel. However, steel remains the strongest and most impenetrable option for stopping punctures in their tracks.

The Kevlar also allows enough flexibility for comfortable wear, unlike rigid steel alone. Even very sharp objects have difficulty penetrating this reinforced Kevlar lining. Together, these two materials form the ideal puncture-proof combo.

Why Steel and Kevlar Work Better Than Foam or Plastic

Some puncture-resistant insoles try to use dense foam or plastic instead of steel shanks. However, these materials eventually compress or deteriorate with repeated pressure and abrasion. Steel maintains its strength and rigidity much longer term.

Kevlar is also far more cut and abrasion resistant than plastic composites or carbon fiber. Thin yet impenetrable, Kevlar outperforms other fabrics in durability and resilience. This is why bulletproof vests rely on Kevlar rather than plastic!

The Limitations of Puncture Protection

While puncture-proof insoles provide excellent protection, they can’t prevent every single potential puncture in extreme situations. Very long, sharp objects like large nails, screws or thick metal debris could potentially penetrate both boot and insole.

However, FlexShield and other quality inserts provide highly effective protection in real-world conditions. And choosing removable inserts allows fit adjustment for optimal protection.

Caring for Puncture-Resistant Insoles

Like any gear, puncture-proof inserts need proper care for best performance. Gently clean with mild soap and water to remove dirt and debris that can abrade the Kevlar lining over time. Allow inserts to fully air dry before replacing in boots.

Periodic conditioning with silicone sprays can help the Kevlar resist moisture and remain flexible. And replace inserts at least annually, or whenever you see cracks forming in the materials.

With proper care, FlexShield and other puncture-resistant insoles greatly minimize risk so you can work with confidence knowing your feet have excellent protection.

At the end of the day, the small investment is worth it to avoid a serious and painful puncture wound that could sideline you for weeks. Relying just on standard shoe soles or flimsy insoles is a big risk for anyone working in hazardous conditions. Upgrading to puncture-proof inserts is one of the best things you can do to protect your feet over the long haul.

When you work in hazardous conditions, protecting your feet should be a top priority. Let’s look at some of the top puncture-resistant insoles designed specifically for work boots.

Top 5 Puncture-Resistant Insoles for Work Boots

Heavy duty work boots provide the first line of defense, but their thin soles still leave feet vulnerable. Upgrading to an aftermarket puncture-proof insole offers an extra barrier against risks like nails, screws, metal debris and other sharp objects.

But with so many choices out there, how do you select the right insole for your needs? Here are 5 top-rated puncture-resistant inserts made for work boot use:

- FlexShield – Their steel shank and Kevlar lining offers maximum puncture protection. A great choice for high risk jobs.

- Dr. Scholl’s Work Insoles – Provides good puncture resistance and cushioning at a budget-friendly price point.

- Timberland PRO Anti-Fatigue – Their polyurethane foam is firmer to resist punctures while absorbing shock.

- Powerstep Pinnacle Maxx – Designed for work boots with rigid arch support and anti-microbial top layer.

- Superfeet GREEN – Their firm foam base provides stability and puncture protection during active jobs.

How to Choose the Right Puncture-Resistant Insole

Consider the level of risk in your occupation. For occasional moderate exposure, Dr. Scholl’s is a cost-effective option. In high hazard environments, invest in maximum protection from FlexShield.

Also factor in boot fit. Removable insoles like Superfeet allow you to customize sizing. If you need arch support, choose Powerstep or FlexShield.

While no insert prevents every puncture, wearing puncture-proof insoles drastically reduces the risks versus standard shoe soles when working in potentially dangerous conditions.

Caring for Your Puncture-Resistant Insoles

Take good care of your protective inserts and they’ll last longer. Gently clean periodically with mild soap and water. Allow to fully air dry before placing back in boots.

Condition occasionally with silicone spray to repel moisture and maintain flexibility in the materials. Replace inserts at least annually or when you notice cracks or tears.

With the right puncture-proof insoles, you can tackle the work day with confidence knowing your feet have serious protection. Don’t take unnecessary risks – upgrade your standard insoles as soon as possible.

When considering puncture-proof insoles, you may wonder – do they really prevent all potential punctures? While quality inserts like FlexShield provide excellent protection, there are limitations in extreme situations.

Do Puncture-Proof Insoles Really Prevent All Punctures?

The short answer is no—no insert can prevent every single possible puncture scenario. However, brands like FlexShield are highly effective at blocking most common puncture risks.

Their steel shank and Kevlar lining create an extremely rigid and cut-resistant barrier between your feet and potential hazards. But extremely long, sharp objects may still have the force to puncture through boot and insert in some cases.

Examples of Limitations

While rare, things like large screws, long nails, thick metal debris or pieces of rebar could potentially penetrate both boot exterior and puncture-proof insole if stepped on with full force.

The longer and sharper the object, the more likely it may penetrate shoes even with protective inserts. However, this would require long, pointed debris and full body weight applied.

The Reality of Puncture Protection

Even with limitations in extreme cases, quality puncture-resistant insoles like FlexShield still provide highly effective protection in real-world conditions.

The types of thin, short metal scraps, roofing nails, pins and other debris found on most jobsites are no match for advanced inserts. So for typical puncture risks, you can be confident your feet are well protected.

By significantly reducing the likelihood of common puncture injuries, protective insoles greatly improve on regular shoe soles. And choosing removable inserts allows you to ensure optimal fit.

When Thinner Inserts May Be at Risk

Basic flexible inserts without steel shanks rely more on dense foam or plastic. These materials can eventually compress or develop small cracks over time.

So thinner, cheaper inserts may be more susceptible to punctures from sharper debris after wear. Heavy duty options like FlexShield maintain maximum rigidity and impenetrability long-term.

While no product can prevent every scenario, puncture-proof inserts like FlexShield provide very effective protection against typical jobsite hazards. Don’t let the limitations keep you from upgrading your safety.

When selecting puncture-resistant insoles, it’s important to consider your specific work environment and potential risk factors. The right level of protection depends on the hazards you face on the job.

Choosing the Right Level of Puncture Protection

Puncture-proof inserts use rigid materials like steel shanks and Kevlar to prevent penetration. But some provide more impenetrability than others.

Thinner, flexible options from Dr. Scholl’s or Superfeet offer solid protection from small nails, metal scraps, and other debris. But they provide less protection against thicker, longer objects.

Heavy-duty insoles with steel like FlexShield offer maximum rigidity and puncture resistance. This makes them ideal for high-risk occupations.

Light Duty Needs

For light industrial work, construction, or DIY projects with occasional puncture risks, a flexible insert provides adequate protection while maintaining in-boot flexibility.

Brands like Dr. Scholl’s use dense foam and plastic composites to repel thinner objects from penetrating completely while staying light and removable.

Heavy Duty Protection

In high hazard environments with lots of scrap metal, nails, glass debris and other sharps, maximum protection is needed. Rigid insoles with steel shanks like FlexShield provide complete impenetrability.

While thick, these heavy duty inserts prevent all common puncture threats on risky worksites where injuries are highly likely.

Know Your Risks

Consider your unique occupational hazards when choosing. Roofers, construction workers, landscapers and factory workers have high needs. Occasional risks may need just moderate protection.

While no insert prevents 100% of punctures, wearing the right level of protection for your work environment greatly reduces the risks. Don’t take chances with your feet – upgrade your insoles.

With brands like FlexShield, you can tackle even the most hazardous jobs with confidence knowing your feet have impenetrable armor against punctures. Don’t play statistics – go with maximum insert protection.

When your work or activities only involve occasional or light puncture hazards, a thin and flexible insert may provide sufficient protection while maintaining comfort.

When to Use Thin, Flexible Puncture-Resistant Inserts

Thinner puncture-proof inserts are beneficial in situations where you need moderate protection without limiting flexibility. Brands like Dr. Scholl’s Work, Superfeet Green, and Timberland PRO Anti-Fatigue offer lightweight yet protective options.

For workers who encounter occasional hazards like construction or DIY projects, yardwork, and light industrial settings, a removable flexible insert can provide peace of mind.

The Benefits of Flexible Inserts

Flexible puncture-resistant insoles maintain the natural movement of your feet inside boots. Many are also lightweight and removable for easy replacement.

By using dense yet pliable materials like compressed composites, plastic, thermoplastic urethane (TPU), or high-density foam, these inserts repel punctures while staying comfy.

When Protection Counts Most

In high risk occupations like construction, demolition, metal fabrication, and manufacturing, maximum protection should take priority over flexibility.

Jobs with lots of scrap metal, nails, screws, glass shards and other sharp debris require heavy duty insoles like FlexShield with steel shanks.

Finding the Right Balance

Consider your hazard level and comfort needs. If you occasionally encounter roofing nails, yard debris, broken glass, or scraps during DIY, a flexible insert like Dr. Scholl’s can provide peace of mind.

But for guaranteed protection in risky jobs, go with a rigid steel shank insert like FlexShield. Either way, stay safe and guard your feet better than regular insoles.

Since puncture-proof insoles tend to be rigid for maximum protection, having proper arch support is crucial for comfort and stability.

The Importance of Arch Support in Puncture-Proof Insoles

Steel shanks and Kevlar materials in heavy duty puncture-resistant inserts create an ultra-rigid platform. Without adequate arch support, this can cause foot fatigue and discomfort.

That’s why brands like Powerstep and Superfeet integrate contoured arch supports into their puncture-proof insole designs. This helps align the foot naturally and reduce strain.

Benefits of Arch Support

Good arch support in rigid insoles helps prevent issues like:

- Plantar fasciitis

- Foot, ankle, and leg pain

- Metatarsal stress

- Achy heels and arches

It aligns the foot for maximum comfort and stability during long work days. Puncture-proof insoles without arch contouring can cause misalignment and pain.

Custom vs Non-Custom Options

Removable inserts like Superfeet GREEN allow you to get a custom fit with your own orthotics if needed. Others like FlexShield have integrated arch support.

If you have very high arches or other alignment issues, consult your podiatrist. But most benefits from a contoured, supportive arch design.

Cushioning and Shock Absorption

Along with support, look for puncture-proof inserts with cushioning technologies. Polyurethane foam, gel pads, and impact zones help reduce foot fatigue.

Lightweight materials also keep heavy-duty insoles from being too stiff and uncomfortable during all-day wear.

Don’t compromise protection – choose inserts with arch supporting comfort so your feet stay safe and pain-free.

When choosing puncture-proof inserts, you’ll see options that protect just part of the foot vs the entire foot. So what’s the better choice – partial or full-length protection?

Full-Length vs Partial Puncture Protection: Which is Better?

For maximum security, full-length puncture-resistant insoles that cover from toe to heel are recommended. Partial inserts leave some areas exposed.

Full-length options from FlexShield and Dr. Scholl’s extend the steel shank and Kevlar layer across the whole foot. This prevents punctures anywhere you step.

Partial Protection Inserts

Some brands like Powerstep offer puncture-resistant insoles that only cover high risk zones under the arch and ball of the foot.

These leave the toes, heels, and periphery exposed. So you’re unprotected from punctures to those areas.

Full-Length Protection

For best coverage, opt for a full-length insert. This shields the entire foot across all potential strike points.

Without gaps in coverage, you can be confident of protection whether stepping on hazards with your heel, toe, or middle of the foot.

Choosing What’s Best

For occasional risks, partial protection focused under the arch may be sufficient. But for regular exposure, full-length is recommended.

Brands like FlexShield offer maximum security. The last thing you want is a nail piercing an unprotected heel or toe!

Go full length for peace of mind that sharp objects won’t penetrate anywhere across the foot. Your safety is priority #1.

Achieving the proper fit is important for puncture-proof inserts to provide maximum protection. That’s why many are designed as removable insoles that can be customized to your feet.

Getting the Right Fit with Removable Puncture-Resistant Insoles

For optimal puncture protection, sizing is key. Loose fitting inserts can slip and slide inside boots, creating gaps in coverage. That’s why removable, adjustable options are recommended.

Brands like Superfeet, Timberland PRO, and FlexShield make puncture-proof inserts you can trim to size for a perfect, personalized fit.

Achieving a Snug Fit

Start by removing the standard insoles in your work boots. Then place your removable puncture-resistant inserts on top.

Mark any overhanging edges and trim with scissors for an ideal fit. You want your protective inserts to fit snugly from toe to heel.

No Excess Room

Avoid the temptation to buy oversized boots to accommodate thicker insoles. This can allow slipping and instability inside the boot.

Your work boots should fit tightly with the puncture-proof inserts inserted. No excess room means no slippage.

Why Fit Matters

A snug fitting puncture-proof insert optimizes protection. It remains aligned under pressure for full coverage across the foot.

Take the time to get the sizing right. Custom removable inserts reward you with security and stability while staying protected.

Like any boot accessory, puncture-proof insoles need regular cleaning to prevent bacteria and extend their lifespan. Here are some tips for keeping your inserts fresh.

Keeping Puncture-Proof Insoles Clean and Sanitary

Over time, dirt, debris, and sweat can accumulate in puncture-resistant inserts. This causes odor and hygiene issues if not cleaned.

For removable insoles, gently scrub both sides with mild soap and water periodically. Avoid harsh cleaners that could degrade the Kevlar or materials.

Let Air Dry Thoroughly

After washing, allow inserts to completely air dry rather than putting back into boots prematurely. Trapped moisture breeds bacteria.

You can also use boot dryers to accelerate drying if needed. Just ensure inserts are 100% dry before re-inserting.

Sanitize Regularly

Consider buying a UV sanitizing bag to kill germs between washings. Just a few minutes of UV exposure eliminates bacteria.

Isopropyl alcohol wipes also work well for a quick disinfecting swipe down. Keep feet healthy and odor-free.

When to Replace

While puncture-proof insoles are durable, visible tearing, holes, or deteriorating materials mean it’s time to replace.

Regular cleaning extends their lifespan, but expect to replace inserts around annually depending on wear.

Proper boot hygiene keeps you comfortable and protected. Don’t let uncleanliness reduce the effectiveness of your protective footwear.

When upgrading to protective insoles, it’s important to choose work boots compatible with the thicker, rigid inserts. Finding the right boot fit ensures performance.

Finding Boots Compatible with Thicker Puncture-Resistant Insoles

Heavy duty puncture-proof inserts add thickness over regular thin insoles. Make sure to choose boots with enough interior space to accommodate them.

Look for boots with removable stock insoles to allow more room for upgrades. Work styles from Timberland, Wolverine, Red Wing, and Caterpillar often fit the bill.

Trying Before Buying

Don’t assume a boot will have enough space. Bring your puncture-proof inserts to the store when shopping for boots.

Test the fit by removing stock insoles and inserting your protective inserts. This guarantees your boots will accommodate the thickness.

Avoid Excess Space

Don’t size up too much in boots to allow space for insoles. Excess interior room can cause slipping, blisters, and misalignment.

Boots should fit snugly all around your foot with the puncture-proof inserts inside. No sloppiness or room to slide.

Get the Combination Right

With some trial and error, you can find an ideal boot match for your heavy duty puncture-resistant insoles. The right combo keeps your feet stable and protected.

Don’t settle for less – invest in safe footwear modified with enhanced puncture-proof inserts designed for your work environment.

Achieving the ideal fit between your foot, boots, and puncture-proof inserts is crucial for both comfort and protection. Proper sizing matters.

Why Proper Boot Fit Matters with Puncture-Resistant Insoles

For maximum security and comfort, your work boots should fit snugly with puncture-proof inserts inside. Any excess room or slippage reduces effectiveness.

Don’t make the mistake of sizing up in boots to fit thicker insoles. This can lead to a loose fit with gaps for potential puncture entry.

A Tight Fit

Your boots should fit closely around the foot and ankle when wearing protective inserts. No slipping, lifting or excess space.

This prevents movement inside the boots that could misalign the rigid arch support and steel shank from optimal positioning.

Why It Matters

A loose fitting boot means the puncture-proof insert can shift and fail to protect properly. A snug fit keeps everything locked in position.

Proper alignment also reduces friction that leads to blisters. Take the time to get the right tailored fit for maximum security and comfort.

Don’t Compromise

Getting the ideal pairing of boot and insert takes some trial and error. But once you find the right combination, you can work safely and confidently.

Proper boot sizing should never be compromised when it comes to protective footwear. Your health is priority #1.

When it comes to stopping punctures, the materials used in protective shoe inserts really matter. Let’s look at which offer the greatest durability and performance.

Most Durable Materials for Puncture-Proof Shoe Inserts

Rigid and impenetrable yet flexible materials are needed for effective puncture-resistant insoles. Certain combinations excel at repelling sharp objects better over time.

The most heavy duty and durable option is a stainless steel shank layered with Kevlar fabric, as used in FlexShield inserts. This outperforms plastic composites and foam.

Why Steel and Kevlar Are Best

A stainless steel shank maintains its rigidity and strength even under heavy loads and abrasion. Plastics and carbon fiber degrade over time.

Kevlar also resists cutting, flexing, and moisture better than most fabrics. Together they form an impenetrable barrier.

Plastic and Foam Limitations

Dense foam or plastic plates offer some puncture resistance initially. But they compress, develop small cracks, and lose effectiveness relatively quickly.

They also degrade in harsh environmental conditions. Steel and Kevlar maintain maximum durability long-term.

Worthy of Investment

While a bit heavier and pricier, steel and Kevlar inserts provide the greatest puncture protection over years of use. This makes them well worth the small added investment.

Don’t settle for less – your safety should be the #1 priority. Rely on materials engineered to keep punctures at bay even in the harshest conditions.

Once you’ve upgraded your footwear with puncture-proof inserts, it’s important to care for your boots properly so everything continues performing well.

Caring for Boots with Puncture-Resistant Insoles Installed

Work boots take a beating, even with protective inserts added. Here are some tips for keeping boots in top shape:

- Use boot dryers to eliminate moisture after each wear

- Apply leather conditioner occasionally to waterproof and soften

- Remove insoles and brush/clean interiors periodically

- Use cedar shoe trees to absorb odor and maintain shape

- Rotate between two pairs of boots to extend lifespan

Check Insoles Too

Remember to also remove and clean your puncture-proof insoles regularly as well. Debris buildup degrades performance.

Replace worn out insoles at least annually. Their protective qualities and support decline over time.

Well-Maintained Boots Last Longer

A few extra minutes of care means your footwear stays functional for years longer. Don’t let neglect undermine their safety and comfort features.

Cared for properly, a good pair of work boots paired with upgraded puncture-proof inserts provide the ideal foot protection and support.

Puncture-resistant insoles are built to last. But after extended use, their protective qualities and support will eventually decline. Knowing when to swap in fresh inserts is important.

When It’s Time to Replace Worn Out Puncture-Proof Inserts

Premium puncture-proof inserts from brands like FlexShield utilize rigid, durable materials designed for long wear. But footwear upgrades do wear out over time.

Plan on replacing protective inserts around every 12-24 months on average. More frequently if you notice excessive wear earlier.

Signs of Declining Performance

Replace puncture-resistant insoles when you see:

- Visible cracks, splits or holes in materials

- Teardown or delamination between layers

- Permanent compression or flattening

- Shank flexing under foot pressure

Performance and puncture protection decline as materials break down. Don’t wait until it’s too late.

Preserve Your Protection

Worn out inserts provide less rigidity and coverage. Tiny gaps can leave you exposed to debris penetrating boots.

Stay vigilant and swap in fresh puncture-proof insoles on schedule. Don’t risk comfort and safety with deteriorating inserts.

A Small Price for Peace of Mind

Quality puncture-resistant insoles are worth replacing regularly to safeguard your feet with continuous, reliable protection.

Consider the small ongoing cost inexpensive foot insurance when it comes to your health and safety on the job.