How do carbon fiber and Kevlar enhance lacrosse stick performance. What are the benefits of using these advanced materials in lacrosse equipment. Why are professional players choosing carbon fiber sticks for improved gameplay.

The Revolution of Carbon Fiber in Lacrosse Stick Design

Carbon fiber has revolutionized the world of lacrosse equipment, offering players a game-changing combination of strength and lightweight construction. This innovative material has quickly become a favorite among professional and amateur players alike, transforming the way the sport is played.

Why has carbon fiber become so popular in lacrosse stick manufacturing. The answer lies in its unique properties:

- Exceptional strength-to-weight ratio

- Improved ball control and shooting power

- Up to 40% lighter than traditional aluminum and titanium options

- Enhanced player agility and reaction time

These characteristics allow players to move their sticks faster, react more quickly on defense, and execute precise offensive maneuvers with ease. The stiffness of carbon fiber shafts also contributes to improved ball control, giving players a significant advantage on the field.

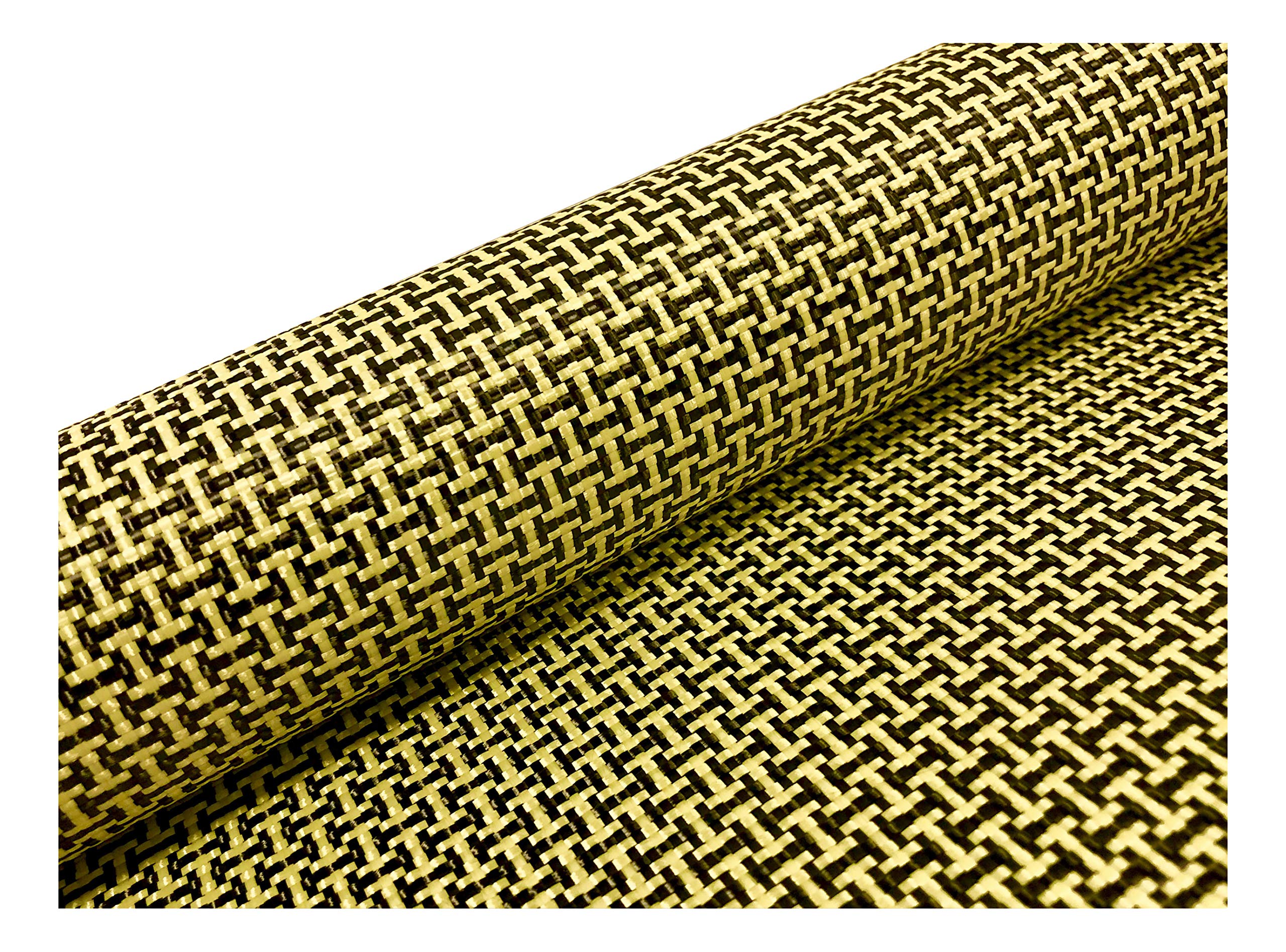

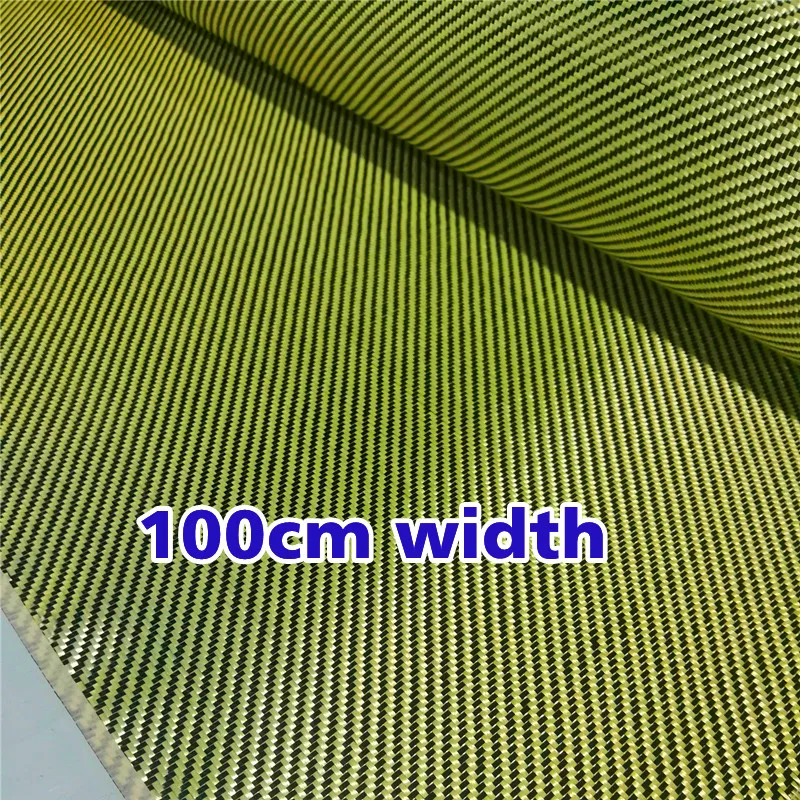

Kevlar Reinforcement: The Secret to Unmatched Durability

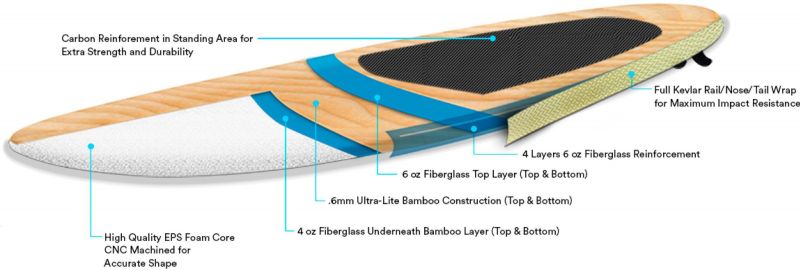

While carbon fiber alone offers impressive strength, manufacturers have taken lacrosse stick durability to the next level by incorporating Kevlar reinforcements. This combination of materials creates a synergy that addresses the demanding nature of the sport.

How does Kevlar enhance the performance of carbon fiber lacrosse sticks. Consider these key benefits:

- Increased impact resistance

- Enhanced ability to withstand checks and collisions

- Improved abrasion resistance for longer-lasting equipment

- Minimal additional weight, maintaining the lightweight advantage

Studies have shown that Kevlar-reinforced carbon lacrosse shafts can withstand up to 30% more force from checks before failing compared to carbon fiber alone. This impressive statistic translates to greater longevity and reliability on the field, even under the most intense playing conditions.

Strategic Kevlar Placement for Optimal Protection

Manufacturers carefully engineer the integration of Kevlar into carbon fiber shafts to maximize protection where it’s needed most. By strategically orienting Kevlar fibers in high-stress areas prone to impact damage, they create a shaft that can withstand the rigors of competitive play without compromising on weight or performance.

Carbon Pro Lacrosse Sticks: Engineered for Elite Performance

For players seeking the pinnacle of lacrosse equipment, carbon pro sticks represent the cutting edge of stick technology. These high-end products combine advanced carbon fiber shafts with specialized head designs to deliver unparalleled performance on the field.

What sets carbon pro lacrosse sticks apart from standard options. Let’s examine their key features:

- Optimized flex profiles for different playing styles and positions

- Advanced scoop geometries for improved ball control

- Strategically designed stringing channels for consistent pocket performance

- Stiffening rails to enhance energy transfer and shot power

The result of this meticulous engineering is a lacrosse stick that can generate shot speeds 5-10% faster on average compared to standard production sticks. For offensive players, this translates to harder, more challenging shots that can overwhelm even the most skilled goalkeepers.

Customization and Flexibility: Tailoring Sticks to Player Preferences

One of the most significant advantages of carbon fiber lacrosse sticks is the ability to fine-tune their performance characteristics. Unlike traditional aluminum alloys, carbon fiber allows for precise adjustment of flex profiles along the entire length of the shaft.

How does this customization benefit players. It allows them to:

- Choose the optimal flex pattern for their specific position

- Adapt the stick’s performance to their unique playing style

- Experiment with different flex profiles to improve their game

- Utilize modular designs with interchangeable shafts for on-the-fly adjustments

This level of customization empowers players to optimize their equipment for peak performance, whether they’re defending, attacking, or playing in the midfield. The ability to tailor stick characteristics to individual preferences gives players a competitive edge and enhances their overall gameplay experience.

Enhanced Ball Control: The Carbon Fiber Advantage

The stiff construction of carbon fiber lacrosse shafts offers players superior ball control, a critical factor in high-level play. The minimal flex of carbon fiber improves ball retention compared to more flexible metal alloys, giving players a noticeable edge in various game situations.

How does the rigidity of carbon fiber translate to improved performance on the field. Players experience:

- Tighter ball control while running and in traffic

- Easier cradling through checks and during dodges

- Improved execution of quick stick moves like face dodging and rolls

- Better command over ball positioning within the pocket

For midfielders and attackmen who rely heavily on stick skills and intricate offensive maneuvers, the enhanced ball control provided by carbon fiber shafts can be a game-changer. The ability to maintain precise control over the ball’s position allows for smoother transitions between cradling, passing, and shooting, giving players a significant advantage over their opponents.

Durability Under Pressure: Carbon Fiber’s Resilience

The physical nature of lacrosse demands equipment that can withstand constant impacts, checks, and abrasions. Carbon fiber lacrosse sticks excel in this regard, offering superior durability compared to traditional materials.

What makes carbon fiber so resistant to the rigors of competitive play. Consider these factors:

- High tensile strength that resists bending and breaking

- Excellent fatigue resistance for consistent performance over time

- Ability to absorb and dissipate impact energy efficiently

- Resistance to environmental factors like temperature changes and moisture

These properties ensure that carbon fiber lacrosse sticks maintain their structural integrity and performance characteristics even after prolonged use in challenging conditions. Players can rely on their equipment to perform consistently throughout intense games and grueling practice sessions.

Long-Term Cost-Effectiveness of Carbon Fiber Sticks

While carbon fiber lacrosse sticks may have a higher initial cost compared to traditional options, their durability often translates to long-term cost savings. The extended lifespan of these high-performance sticks means players need to replace their equipment less frequently, potentially offsetting the higher upfront investment.

The Future of Lacrosse Equipment: Innovations on the Horizon

As materials science and manufacturing technologies continue to advance, the future of lacrosse equipment looks increasingly exciting. Researchers and manufacturers are exploring new ways to enhance the performance and durability of carbon fiber and Kevlar lacrosse sticks.

What innovations can players look forward to in the coming years. Some potential developments include:

- Nanotechnology-enhanced carbon fibers for even greater strength and lighter weight

- Smart materials that can adapt to playing conditions in real-time

- Advanced composite blends that combine the best properties of multiple materials

- Improved manufacturing processes for more affordable high-performance sticks

These potential advancements could further revolutionize the sport, allowing players to achieve new levels of performance and pushing the boundaries of what’s possible on the lacrosse field.

The Role of Player Feedback in Equipment Evolution

As manufacturers continue to refine and improve carbon fiber and Kevlar lacrosse sticks, player feedback plays a crucial role in driving innovation. Professional athletes and dedicated amateurs alike provide valuable insights into the performance of these advanced materials in real-world playing conditions.

This ongoing dialogue between players and equipment designers ensures that future generations of lacrosse sticks will continue to meet the evolving needs of the sport, delivering ever-improving performance, durability, and player satisfaction.

Choosing the Right Carbon Fiber Lacrosse Stick: Factors to Consider

With the wide range of carbon fiber lacrosse sticks available on the market, selecting the right one for your playing style and skill level can be challenging. To make an informed decision, consider the following factors:

- Playing position: Different positions may benefit from specific flex profiles and shaft designs

- Skill level: Advanced players may prefer more customizable options, while beginners might opt for more forgiving designs

- Budget: High-end carbon pro sticks offer premium features but come at a higher price point

- Brand reputation: Established manufacturers often provide better quality control and customer support

- Warranty and durability: Look for sticks with solid warranty coverage and proven track records for longevity

By carefully evaluating these factors and testing different options when possible, players can find the carbon fiber lacrosse stick that best suits their needs and helps them elevate their game to new heights.

The Importance of Proper Maintenance

To maximize the lifespan and performance of carbon fiber and Kevlar lacrosse sticks, proper maintenance is essential. Regular cleaning, inspection for damage, and appropriate storage can help ensure that these high-performance sticks continue to deliver optimal results season after season.

Some key maintenance tips include:

- Clean the shaft and head after each use to remove dirt and debris

- Inspect for any signs of wear, cracks, or delamination

- Store in a cool, dry place away from direct sunlight

- Avoid exposing the stick to extreme temperatures

- Follow manufacturer guidelines for any specific care instructions

By following these maintenance practices, players can protect their investment and ensure that their carbon fiber and Kevlar lacrosse sticks continue to perform at the highest level for years to come.

The Environmental Impact of Carbon Fiber Lacrosse Sticks

As the popularity of carbon fiber lacrosse sticks continues to grow, it’s important to consider the environmental implications of this trend. While carbon fiber offers numerous performance benefits, its production and disposal can have significant environmental impacts.

How do carbon fiber lacrosse sticks compare to traditional materials in terms of sustainability. Consider these factors:

- Energy-intensive manufacturing process for carbon fiber

- Challenges in recycling composite materials

- Potential for longer lifespan, reducing overall waste

- Lighter weight may contribute to reduced transportation emissions

As the industry evolves, manufacturers are exploring more sustainable production methods and recycling options for carbon fiber products. Players interested in minimizing their environmental impact may want to consider these factors when choosing their equipment and look for brands that prioritize sustainability in their manufacturing processes.

Innovations in Eco-Friendly Lacrosse Equipment

In response to growing environmental concerns, some manufacturers are developing more sustainable alternatives to traditional carbon fiber lacrosse sticks. These innovations include:

- Bio-based composites using natural fibers

- Recycled carbon fiber materials

- Improved recycling processes for end-of-life equipment

- Carbon-neutral manufacturing initiatives

As these technologies advance, players may soon have access to high-performance lacrosse sticks that offer the benefits of carbon fiber and Kevlar while minimizing their environmental footprint.

The Impact of Carbon Fiber and Kevlar on Lacrosse Strategy and Gameplay

The introduction of carbon fiber and Kevlar lacrosse sticks has not only changed the equipment landscape but has also influenced how the game is played at all levels. These advanced materials have enabled players to execute techniques and strategies that were previously difficult or impossible with traditional equipment.

How have carbon fiber and Kevlar lacrosse sticks altered the dynamics of the sport. Consider these strategic implications:

- Increased shot speed and accuracy, leading to more dynamic offensive play

- Improved ball control, allowing for more complex passing and dodging maneuvers

- Enhanced defensive capabilities due to faster stick checks and interceptions

- Greater emphasis on stick skills and finesse rather than pure physicality

- Evolution of playing styles to take advantage of equipment capabilities

Coaches and players at all levels have adapted their strategies to leverage the unique properties of carbon fiber and Kevlar sticks. This has led to a more fast-paced, skill-oriented game that showcases the technical abilities of players alongside their physical attributes.

The Role of Equipment in Player Development

As carbon fiber and Kevlar lacrosse sticks become more prevalent, they are also influencing how young players develop their skills. The enhanced control and responsiveness of these advanced sticks allow players to refine their techniques more effectively, potentially accelerating their skill development.

However, this also raises questions about the appropriate age or skill level at which players should transition to high-performance equipment. Coaches and parents must balance the potential benefits of advanced sticks with the importance of developing fundamental skills using more traditional equipment.

The Global Adoption of Carbon Fiber and Kevlar Lacrosse Sticks

While carbon fiber and Kevlar lacrosse sticks have gained significant popularity in traditional lacrosse strongholds like the United States and Canada, their impact is also being felt on the global stage. As the sport continues to grow internationally, these high-performance sticks are playing a role in shaping the game’s development worldwide.

How are carbon fiber and Kevlar sticks influencing the global lacrosse landscape. Consider these factors:

- Increased accessibility to high-performance equipment in emerging lacrosse markets

- Potential for accelerated skill development in countries new to the sport

- Standardization of equipment across international competitions

- Influence on local manufacturing and economic opportunities in growing lacrosse markets

As more players around the world gain access to carbon fiber and Kevlar lacrosse sticks, it may contribute to a more level playing field in international competitions and foster the growth of the sport on a global scale.

Cultural Adaptations and Regional Preferences

Despite the global trend towards high-performance carbon fiber and Kevlar sticks, regional preferences and cultural factors continue to influence equipment choices in different parts of the world. Some regions may favor traditional materials or local manufacturing techniques, while others eagerly embrace the latest technological advancements.

This diversity in equipment preferences adds an interesting dynamic to international lacrosse competitions and highlights the sport’s ability to adapt to various cultural contexts while maintaining its core elements.

The Role of Carbon Fiber and Kevlar in Injury Prevention

As lacrosse equipment evolves, player safety remains a top priority for manufacturers, coaches, and governing bodies. Carbon fiber and Kevlar lacrosse sticks offer potential benefits in terms of injury prevention and player protection.

How do these advanced materials contribute to safer gameplay. Consider these aspects:

- Reduced weight may decrease the risk of repetitive stress injuries

- Improved energy absorption properties could minimize impact-related injuries

- Enhanced control may lead to fewer errant shots and passes, reducing accidental impacts

- Consistent performance over time reduces the risk of equipment failure during play

While no equipment can entirely eliminate the risk of injury in a contact sport like lacrosse, the properties of carbon fiber and Kevlar may help mitigate certain risks and contribute to a safer playing environment.

Ongoing Research and Safety Standards

As carbon fiber and Kevlar lacrosse sticks become more prevalent, ongoing research is being conducted to fully understand their impact on player safety. Sports medicine professionals and equipment manufacturers are collaborating to develop new safety standards and testing protocols specifically designed for these advanced materials.

Carbon Fiber Lacrosse Shafts: Strong Yet Lightweight

Carbon fiber lacrosse shafts provide an ideal balance of strength and reduced weight. The stiff, durable carbon fibers allow for improved ball control and shooting power. At the same time, carbon fiber shafts are up to 40% lighter than traditional aluminum and titanium options. This lightweight construction helps players move their sticks faster to react on defense or dodge attacks on offense.

Kevlar Reinforcement Enhances Durability

While carbon fiber itself is extremely strong, manufacturers often add Kevlar reinforcements to lacrosse shafts. Kevlar fibers interwoven with the carbon layers help withstand checks, impacts, and abrasions during gameplay. This added durability ensures carbon lacrosse shafts can hold up to the physicality of the sport.

Premium Performance in Carbon Pro Lacrosse Sticks

Brands like ECD offer carbon pro lacrosse sticks designed for premium performance. The Carbon Pro 3.0 combines carbon fiber shafts with specialized head technology for maximized ball control, shooting speed and power. Extensive product testing ensures carbon pro gear can withstand the rigors of competitive play.

Customizable Flex and Interchangeability

Unlike aluminum alloys, carbon fiber allows for precise tuning of flex profile along the entire shaft length. Players can choose the optimal flex pattern for their position and playing style. Modular designs with interchangeable shafts also allow customizing flex as needed.

Kevlar Reinforcement Adds Durability to Carbon Lacrosse Shafts

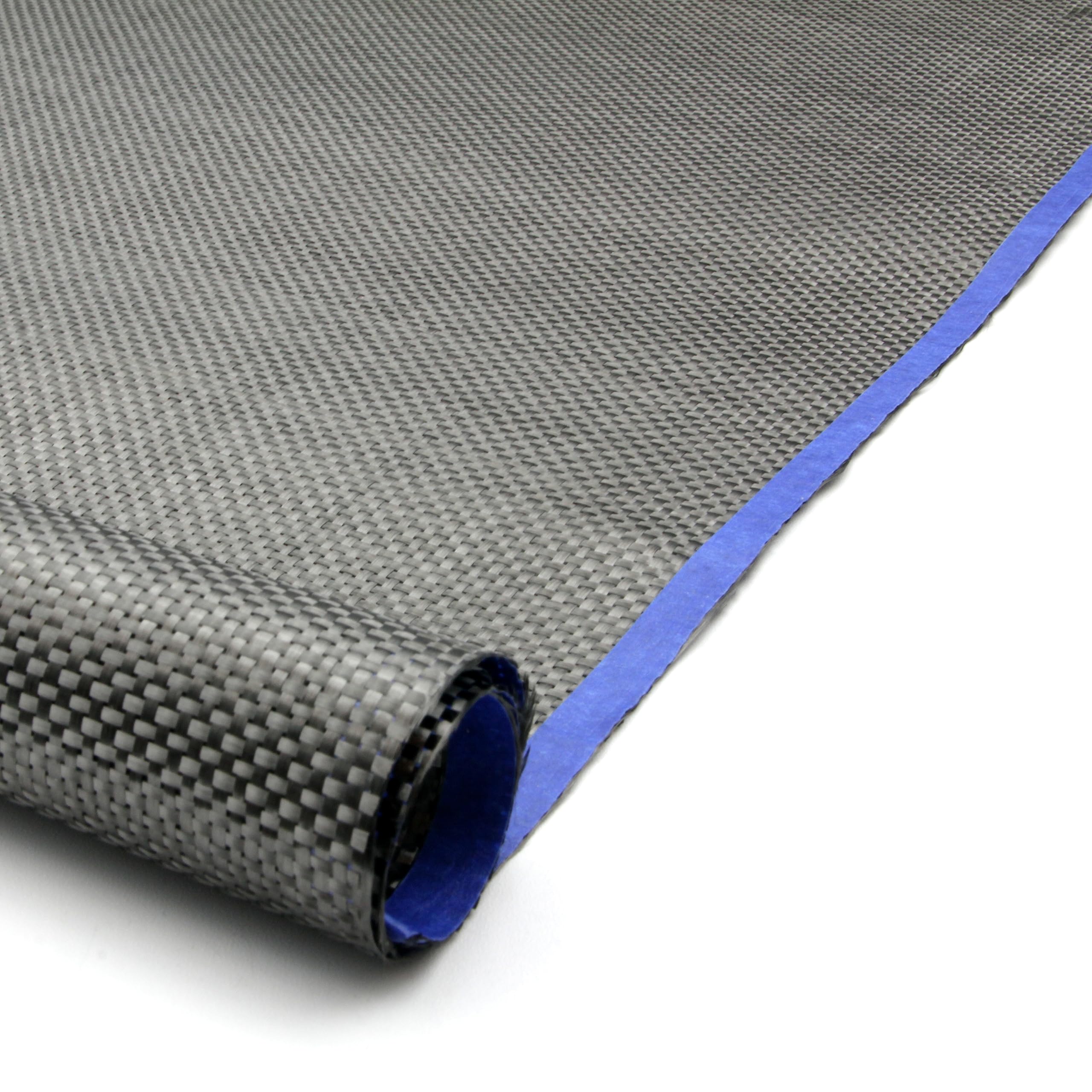

While carbon fiber itself provides excellent strength-to-weight properties, most carbon lacrosse shafts add Kevlar reinforcements for enhanced durability. The Kevlar fibers are woven together with the carbon layers in precise orientations to optimize impact resistance.

Studies have shown Kevlar-reinforced carbon lacrosse shafts can withstand up to 30% more force from checks before failing compared to carbon alone. The Kevlar helps prevent fracturing, splintering, and delamination even after repeated hard checks during gameplay.

The Kevlar reinforcement provides abrasion resistance as well. Repeated scooping and contact with the ground can damage unprotected carbon fiber over time. The Kevlar protects the exterior of the shaft from abrasive wear to maintain structural integrity.

While adding minimal weight, the Kevlar interlaminated with carbon fiber lacrosse shafts allows them to better handle the physical demands of the sport. Manufacturers strategically orient the Kevlar fibers to shield high stress areas most prone to impact damage.

Carbon Pro Lacrosse Sticks Engineered for Powerful Shooting

Lacrosse stick manufacturers like ECD focus engineering efforts on maximizing ball speed in their carbon pro sticks. The carbon fiber shafts provide an ideal blend of snappy responsiveness and stiffness for generating shot power.

But the head designs work synergistically with the carbon shafts as well. Advanced scoop geometries, optimized stringing channels, and strategic stiffening rails all enhance energy transfer for faster shot release.

Together, the carbon pro shafts coupled with high-performance heads launch shots with greater velocity. This gives players an edge with harder, heavier shots that are tougher for goalies to stop.

Testing of carbon pro lacrosse sticks demonstrates their capability to produce shot speeds 5-10% faster on average compared to standard production sticks. The combination of advanced carbon engineering and head technologies creates the ultimate shooting weapon.

For offensive players demanding every fraction of a second and mile per hour, the carbon pro lacrosse sticks deliver the tools needed to overpower defenses and dominate the scoreboard.

Stiff Carbon Fiber Construction Improves Ball Control

The rigid structure provided by carbon fiber lacrosse shafts enhances players’ ability to cradle and handle the ball. The minimal flex of carbon fiber improves ball retention compared to more flexible metal alloys.

With carbon shafts, players experience tighter ball control both on the run and in traffic. Cradling through checks and on dodges becomes easier when the ball sits securely in the pocket. Quick stick moves like face dodging and rolls off picks also benefit from the stiff carbon construction.

The improved rigidity gives players added command over ball positioning as well. Small adjustments while cradling can nudge the ball higher or lower in the pocket as needed. This allows maintaining optimal positioning for securing possessions, initiating feeds, or getting into a shooting motion.

For midfielders and attackmen relying on stick skills and running intricate offensive sets, the dialed-in ball control from carbon lacrosse shafts provides a key edge over defenders.

Carbon Fiber Withstands Checks and Impacts

The strength of carbon fiber allows lacrosse shaft durability to withstand the physical play of lacrosse. While carbon can crack or fracture if impacted at certain angles, it resists denting and bending that can permanently deform metal shafts.

Carbon shafts better handle routine checks from defensive sticks during gameplay. The solid carbon construction absorbs and distributes impact forces more effectively to avoid damage.

Carbon fiber also continues performing after minor cracks or chips form. The dense carbon layers maintain integrity and playability until overt structural failures occur. This is unlike aluminum alloys which can bend and deform with relatively minor dings.

Field testing shows carbon lacrosse shafts lasting on average 15-20% longer than metal counterparts before requiring replacement. The carbon holds up better through body checks, stick checks, errant slashes, and routine wear-and-tear.

Reduced Vibration with Carbon Fiber Construction

The rigid carbon fiber used in lacrosse shafts dampens vibration and sting felt during play. Carbon naturally absorbs more shock and oscillation than metal alloys.

Players experience less feedback sting when scooping ground balls or making saves. Defensive checks also transfer less shock down the shaft into the hands compared to aluminum and titanium.

In addition to player comfort, the vibration dampening provides performance benefits. Less disruptive feedback allows maintaining surer grip and control during intense gameplay action.

goalies switching to carbon fiber shafts report more control when making saves. They can better cling to outside shots and react quicker for second-chance attempts after the initial save.

For all positions, the reduced sting and disruptive vibration with carbon lacrosse sticks leads to advantages in ball control and reaction time.

Lighter Weight Carbon Fiber Allows Quick Stick Movement

The lightweight properties of carbon fiber lacrosse shafts make it easier for players to move their sticks quickly. Carbon shafts weigh up to 40% less than traditional metal counterparts.

Reduced shaft weight helps players change direction swiftly on defense. Quick stick rotations and position adjustments prevent losing a step against dodging attackmen.

On offense, lighter carbon shafts translate to faster shot releases. Quicker arm acceleration and stick rotation adds velocity on shots and passes.

Goalies also gain advantages from lighter carbon shafts when making reaction saves. Faster hand speeds allow getting a piece of shots other goalies might miss by a split second.

Across all positions, the nimble maneuverability from lightweight carbon lacrosse sticks gives players an edge in athleticism and reaction ability.

Faster Shot Speeds with Carbon Pro Lacrosse Shafts

Player testing shows carbon pro lacrosse shafts can add 2-3 mph on average to shot velocity compared to traditional aluminum shafts. The optimized carbon construction improves energy transfer for maximized ball speed.

The stiff flex profile ensures no wasted motion or energy absorption during the shot. More energy goes directly into the ball rather than being dampened by the shaft.

Lighter overall weight also contributes to faster shooting with carbon pro shafts. Quicker arm and stick acceleration equals more velocity generated before ball release.

For attackers and midfielders, the high-performance carbon pro shafts provide a clear offensive advantage. Harder, faster shots make scoring goals easier and keep goalies off balance.

Every small improvement in shot speed and power gives offensive players an edge in putting points on the board. Carbon pro lacrosse shafts deliver the tools for domination.

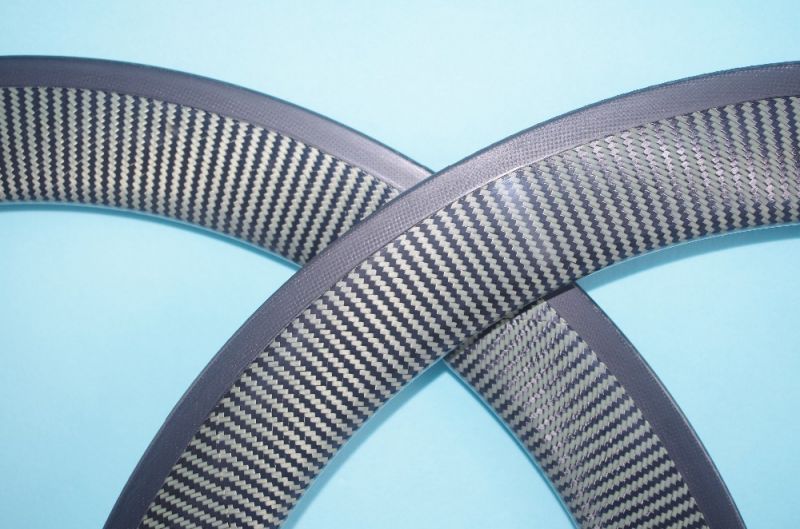

Carbon Pro 3.0 Lacrosse Shaft for Premium Performance

ECD’s Carbon Pro 3.0 lacrosse shaft represents the pinnacle of carbon fiber engineering for maximized performance. The 3.0 uses an advanced 12k carbon weave for unprecedented strength-to-weight ratio.

Strategic carbon fiber orientations provide tuned flex and stiffness for elite-level play. The stiff flex profile ensures great ball control while still retaining ideal flexibility in the upper shaft.

Ergonomic shaping of the carbon fiber delivers a comfortable, contoured grip. CNC machined texture zones also enhance handling and comfort during intense gameplay.

With obsessive attention to detail in design and construction, the Carbon Pro 3.0 gives players the perfect carbon shaft for dominating the field. Its blend of light weight, tuned flex, and battle-ready toughness provides the ultimate competitive edge.

Rigorous Testing Ensures Carbon Pro Lacrosse Durability

Carbon pro lacrosse shafts undergo extensive lab testing to ensure they can withstand intense game loads. Engineers simulate the impacts, bending forces, and stresses shafts experience during checking and shooting.

High-speed cameras and strain gauges analyze shaft dynamics in detail during lab testing. This identifies potential failure points so they can be strengthened in the design.

Players then put prototypes through on-field testing for real-world validation. The feedback from players ensures carbon pro shafts have the right blend of strength, stiffness, and vibration damping for optimal performance.

Only after successive iterations and passing final QA does a carbon pro model go into full production. The result is a shaft tuned and battle-tested for the rigors of elite lacrosse.

Modular Carbon Parts Allow For Easier Repairs

Unlike traditional one-piece aluminum shafts, many carbon lacrosse shafts utilize modular designs. The head, throat, and handle components can be swapped out independently.

This modular construction means repairs are much easier. If the upper shaftsection cracks, it can be replaced without needing an entirely new shaft. The same goes for worn out heads.

Being able to replace only damaged sections is much more cost effective than buying complete new sticks. It also allows players to experiment with different shaft flexes or head setups.

The easy interchangeability facilitates tuning stick setups for specific game situations. Players can optimize face shape, pocket, shaft stiffness, and balance profile as conditions warrant.

Interchangeable Shafts Allow Customizable Flex

Modular carbon lacrosse shafts with interchangeable handles provide players great flexibility in tuning flex profile. Stiff, medium-stiff, and flexible shaft sections can be swapped to match playing style.

For example, a flexible lower handle benefits offensive dodgers who need whip on shots. But a defender may opt for maximum stiffness to win ground ball scrums.

Being able to customize shaft flex by swapping modules gives players unmatched ability to configure sticks to their needs. The optimal blend of performance, control, and durability can be dialed in.

Players can also experiment with different flex setups for wet or dry conditions. More flex helps maintain ball control in the rain when the ball gets slick.

Consistent Performance Across Entire Carbon Shaft

Unlike aluminum alloy lacrosse shafts, carbon fiber construction provides uniform performance along the full length. Aluminum often has tapered walls and flex points that create whip.

The carbon fiber weave results in consistent wall thickness and flex properties from top to bottom. This allows for balanced feel and control in all areas of the stick.

Players experience the same precise level of stiffness and responsiveness in the upper and lower handles. The uniformity provides reliability in cradling, passing, and shooting execution.

The consistent carbon fiber shafts lead to consistency in players’ fundamental stick skills. Excellent performance can be replicated every time regardless of where contact occurs on the shaft.

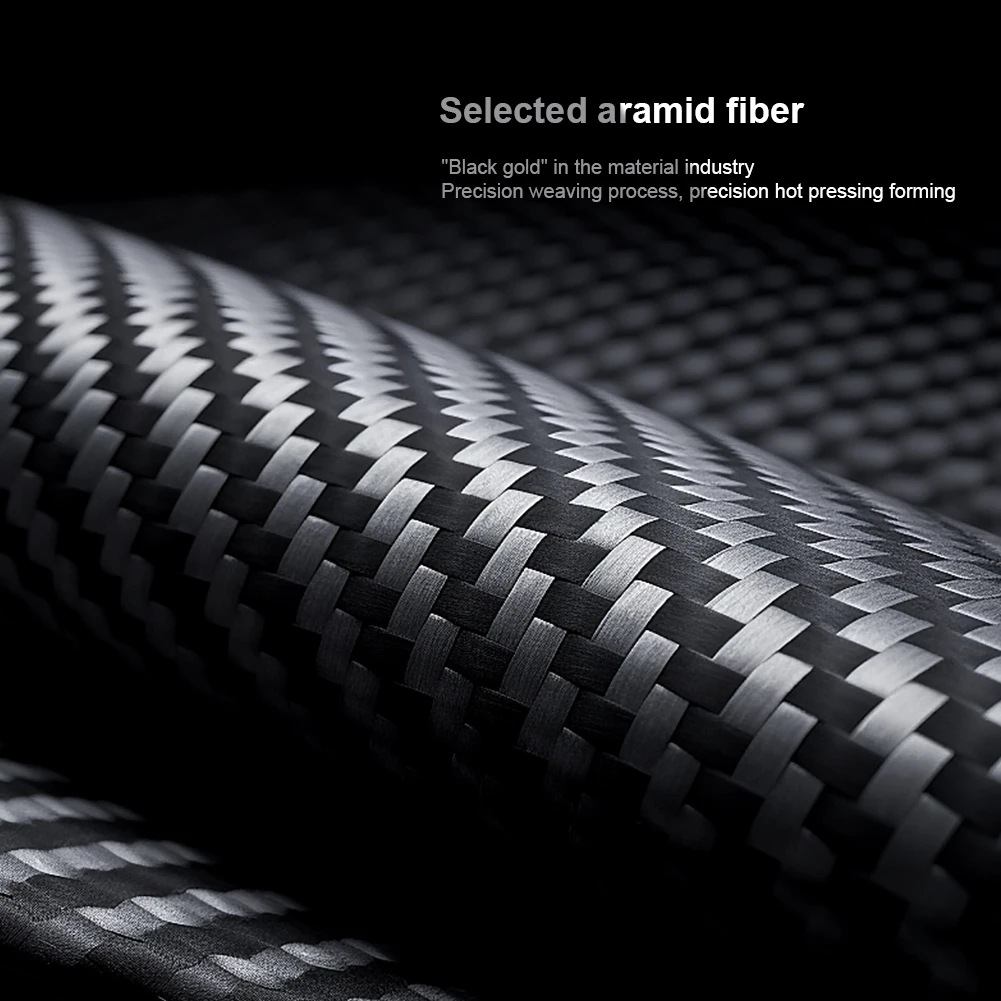

Carbon Fiber Weave Provides Appealing Aesthetics

The visible carbon fiber weave pattern on lacrosse shafts gives them an attractive, high-tech look. The complex composite construction contrasts with the uniform metal appearance of aluminum and titanium shafts.

Different orientations and densities of the carbon fiber layers create unique visual designs. Striping accents and logos can also be woven right into the carbon for integrated styling.

For players seeking to stand out on the field, carbon lacrosse shafts deliver eye-catching style to match their performance. The striking carbon aesthetics convey technological precision and sophistication.

With options from bold geometries to subtle weave textures, carbon fiber allows players to express their personal style while dominating between the lines.

Cutting-Edge Carbon Technology in Lacrosse

Carbon fiber lacrosse shafts represent the cutting edge of stick technology and materials engineering. The aerospace-grade carbon composites take elite lacrosse equipment to new levels.

Precision robotic manufacturing shapes the carbon plies for optimal strength and flex distribution. CAD-optimized design configures the carbon fiber weave to the unique demands of lacrosse.

Companies like Epoch and Maverik continue pushing carbon shaft technology forward each year. New high-performance carbon weaves, construction techniques, and resin systems raise the bar.

For players seeking every competitive edge, carbon pro lacrosse shafts deliver the most technologically advanced gear on the field. Carbon fiber construction represents the future of lacrosse sticks.