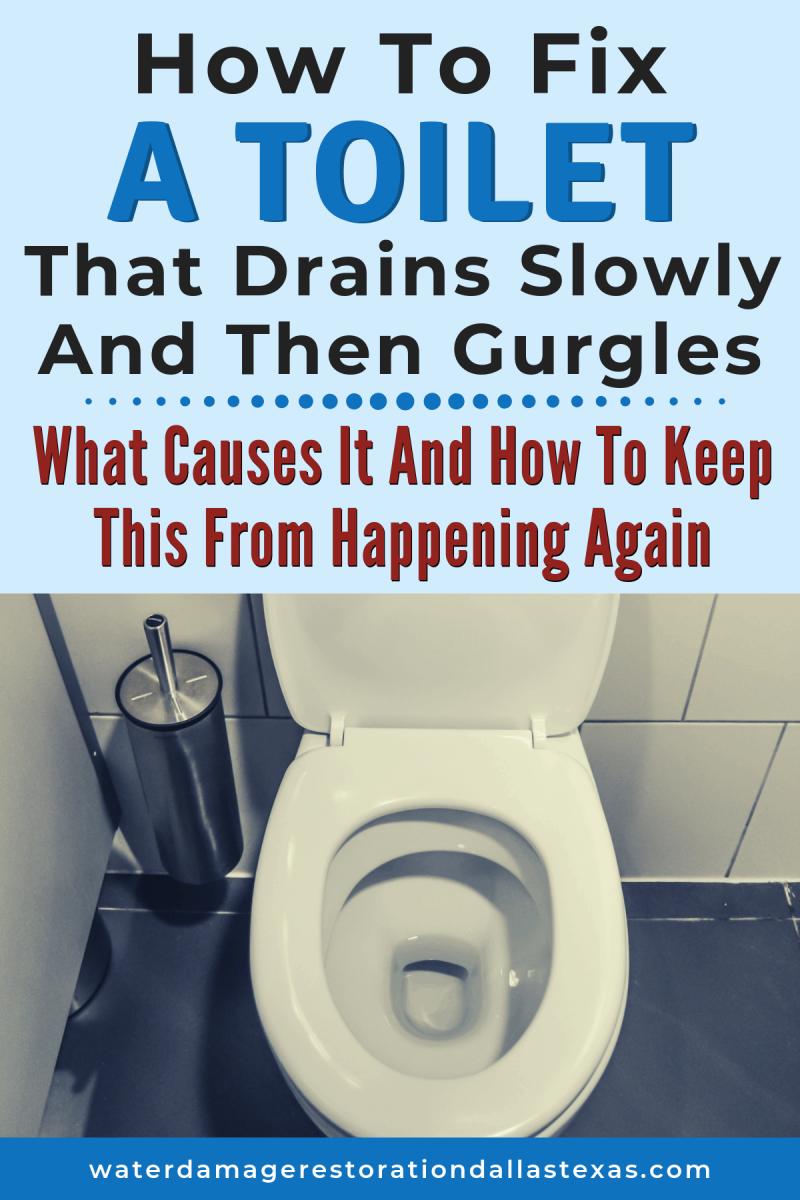

How can you diagnose the cause of a slow flushing toilet. What are the most effective DIY methods to fix a sluggish flush. When should you consider professional plumbing assistance for persistent toilet issues.

Common Causes of Slow Flushing Toilets

A slow flushing toilet can be a frustrating and unsanitary problem. Understanding the root causes is crucial for effective troubleshooting. Here are some of the most common culprits:

- Clogs in the toilet bowl or trap

- Mineral buildup and sediment accumulation

- Issues with the fill valve or flush mechanism

- Low water level in the tank

- Damaged or worn-out components

- Inadequate water pressure

- Outdated or inefficient toilet design

By identifying these potential issues, you can take targeted steps to resolve the slow flushing problem efficiently.

Step-by-Step Guide to Diagnosing Toilet Problems

Before diving into repairs, it’s essential to accurately diagnose the issue. Follow these steps to pinpoint the cause of your slow flushing toilet:

- Observe the flush: Is it weak from the start or does it slow down mid-flush?

- Check the water level in the tank: Is it at the appropriate level?

- Inspect the bowl for visible clogs or obstructions

- Examine the flush mechanism in the tank for any obvious defects

- Listen for unusual sounds during the flush cycle

- Check the water supply line for kinks or damage

By systematically examining these aspects, you can narrow down the potential causes and focus your repair efforts more effectively.

Quick Fixes for Minor Toilet Flushing Issues

Sometimes, a slow flushing toilet can be remedied with simple, quick fixes. Try these methods before moving on to more complex solutions:

Plunging Techniques

Can a plunger really make a difference in fixing a slow flush? Absolutely. A properly used plunger can dislodge minor clogs and improve flushing performance. Here’s how to plunge effectively:

- Ensure there’s enough water in the bowl to cover the plunger head

- Create a tight seal around the drain opening

- Use quick, forceful plunges to create suction

- Repeat several times, then flush to check for improvement

Hot Water and Dish Soap Method

For minor clogs causing slow flushes, this simple trick can work wonders:

- Pour a pot of hot (not boiling) water into the bowl

- Add a generous squirt of dish soap

- Let it sit for a few minutes

- Flush and observe any improvements

This method can help break down minor blockages and lubricate the passageway for improved flushing.

Advanced DIY Repairs for Persistent Flushing Problems

When quick fixes don’t suffice, it’s time to delve deeper into the toilet’s mechanics. Here are some more advanced DIY repairs you can attempt:

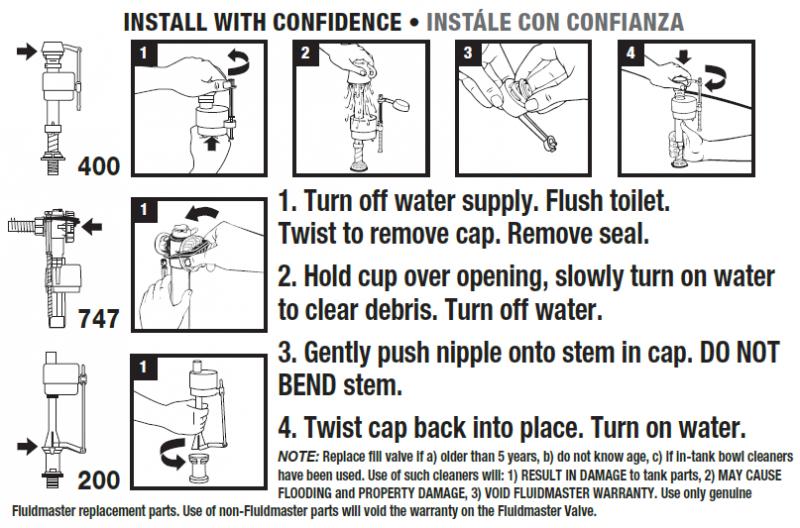

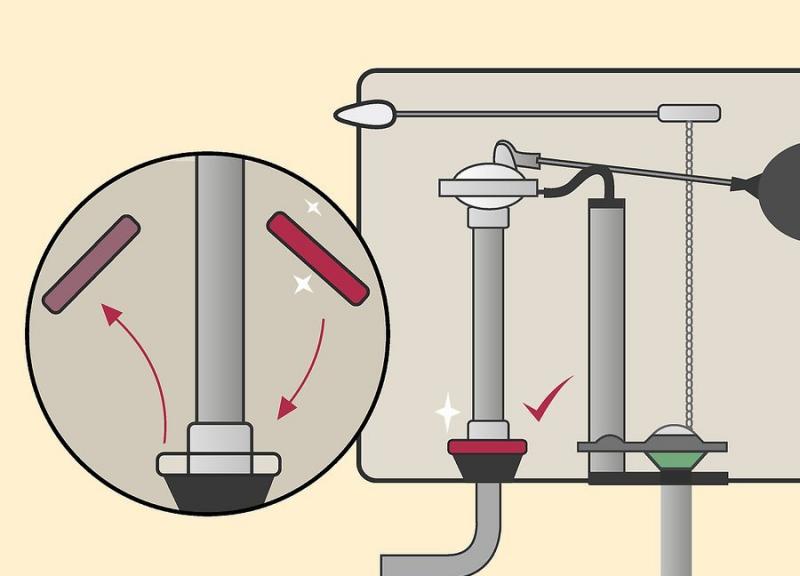

Adjusting the Fill Valve

Is the water level in your toilet tank too low? This could be the root of your slow flushing problem. Here’s how to adjust the fill valve:

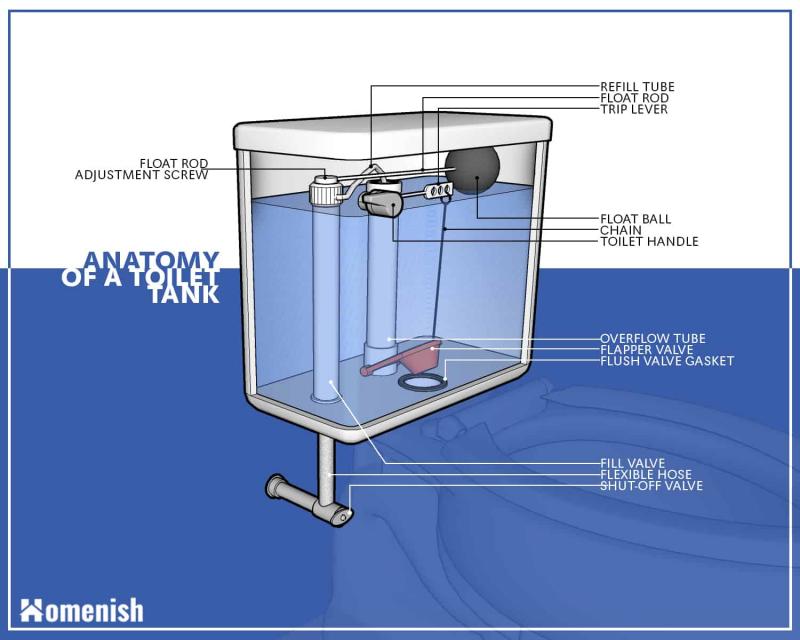

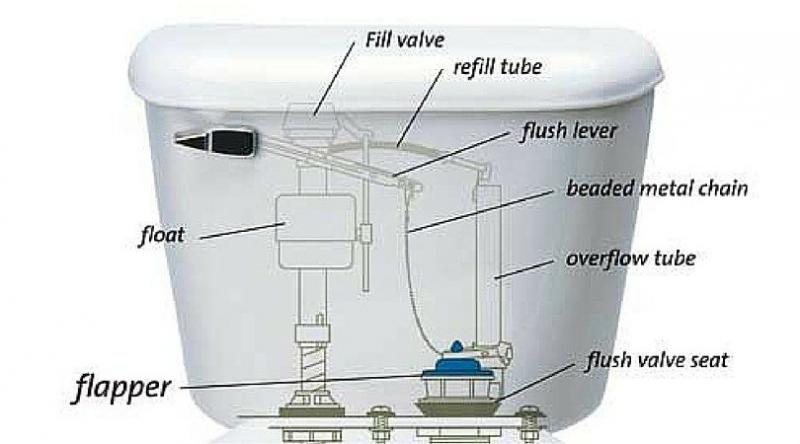

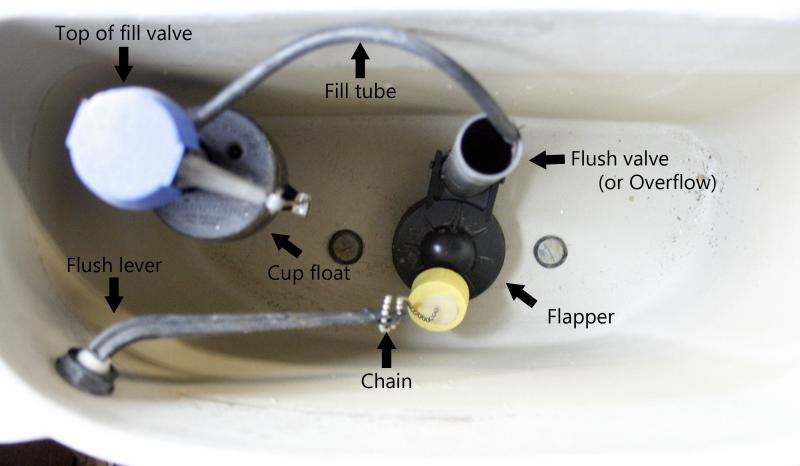

- Locate the fill valve in the tank (usually on the left side)

- Find the adjustment screw or clip on the valve

- Turn the screw or move the clip to raise the water level

- Aim for a water level about an inch below the top of the overflow tube

- Flush to test and readjust as necessary

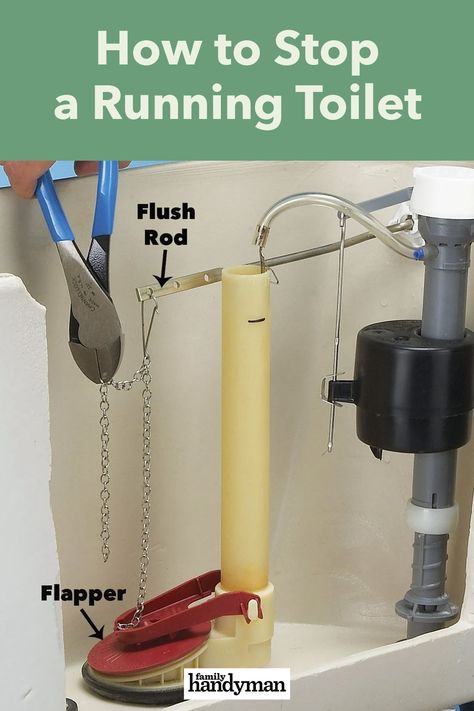

Replacing the Flapper

A worn or damaged flapper can cause water to leak from the tank, resulting in weak flushes. Replacing the flapper is a straightforward task:

- Turn off the water supply and flush to empty the tank

- Unhook the old flapper from the flush lever chain

- Remove it from the overflow tube

- Install the new flapper, ensuring it’s properly seated

- Reattach the chain, leaving a small amount of slack

- Turn the water back on and test the flush

Cleaning and Maintenance Tips for Optimal Toilet Performance

Regular cleaning and maintenance can prevent many slow flushing issues. Implement these practices to keep your toilet in top condition:

- Weekly cleaning of the bowl and under the rim to prevent mineral buildup

- Monthly inspection of tank components for wear and tear

- Quarterly deep cleaning of the tank interior

- Avoid using harsh chemical cleaners that can damage components

- Address minor issues promptly to prevent them from worsening

By maintaining a regular cleaning schedule, you can significantly reduce the likelihood of slow flushing problems.

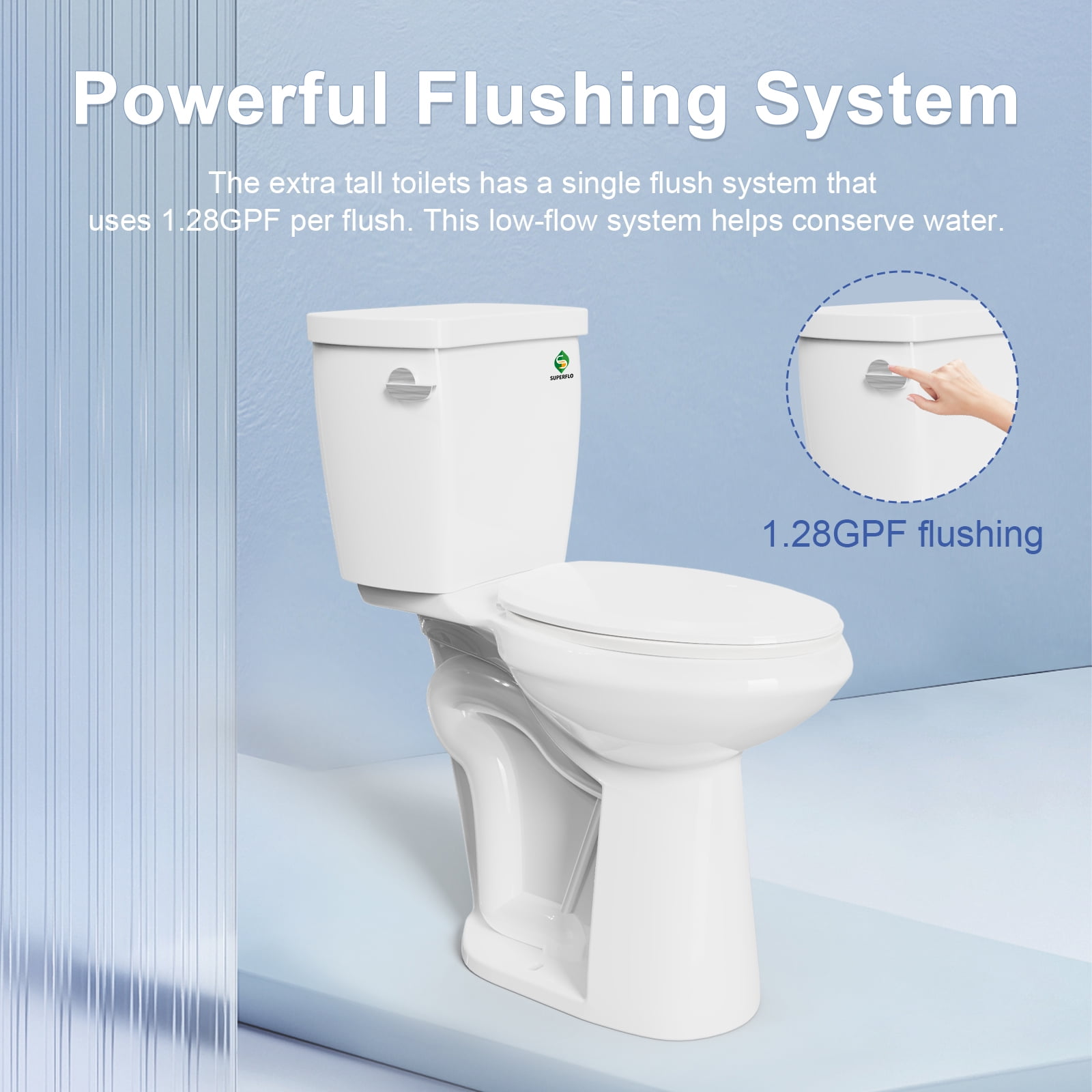

When to Consider Toilet Replacement

Sometimes, despite your best efforts, a toilet may be beyond repair or simply too inefficient to justify further fixes. Consider replacing your toilet if:

- It’s more than 20 years old and frequently experiences issues

- Repairs are becoming increasingly frequent and costly

- You’re dealing with constant clogs or slow flushes despite maintenance

- The toilet uses an excessive amount of water per flush

- There are visible cracks in the porcelain

Upgrading to a modern, water-efficient model can solve persistent flushing issues and reduce water consumption.

Benefits of High-Efficiency Toilets

High-efficiency toilets offer several advantages over older models:

- Significant water savings (up to 20% less per flush)

- Improved flushing power despite using less water

- Reduced risk of clogs and overflows

- Lower water bills and environmental impact

- Potential eligibility for water conservation rebates

Professional Plumbing Solutions for Complex Issues

While many toilet problems can be resolved with DIY methods, some issues require professional expertise. Consider calling a plumber if:

- You’ve tried multiple DIY fixes without success

- There are signs of a more serious plumbing problem (e.g., multiple slow drains)

- You suspect issues with the main sewer line

- There’s water leaking from the base of the toilet

- You’re uncomfortable performing more complex repairs

A professional plumber can diagnose and resolve complex issues quickly and safely, potentially saving you time and preventing further damage.

Advanced Plumbing Techniques

Professional plumbers have access to specialized tools and techniques for addressing stubborn toilet issues:

- Hydro jetting to clear severe clogs and buildup

- Video inspection of sewer lines to identify hidden problems

- Trenchless pipe repair for damaged sewer lines

- Precision adjustments to improve overall plumbing system performance

These advanced methods can resolve issues that are beyond the scope of typical DIY repairs.

Preventing Future Slow Flushing Problems

Once you’ve resolved your current slow flushing issue, take steps to prevent future problems:

- Educate household members on proper toilet use (e.g., what not to flush)

- Install a drain screen to catch debris before it enters the plumbing

- Use toilet paper that breaks down easily in water

- Avoid using “flushable” wipes, which often don’t break down properly

- Schedule annual plumbing inspections to catch issues early

- Consider installing a water softener if you have hard water that causes mineral buildup

By implementing these preventive measures, you can significantly reduce the likelihood of future slow flushing problems and maintain optimal toilet performance.

The Importance of Water Conservation

Beyond preventing slow flushes, water conservation is crucial for environmental and economic reasons. Here are some additional tips to reduce water usage in your bathroom:

- Fix dripping faucets promptly

- Install low-flow showerheads and faucet aerators

- Consider dual-flush toilet conversion kits for existing toilets

- Use greywater from sinks or showers to water plants when possible

- Teach children about the importance of water conservation

By combining water-saving practices with proper toilet maintenance, you can create a more efficient and eco-friendly bathroom environment.

Troubleshooting Uncommon Toilet Issues

While slow flushing is a common problem, toilets can experience other unusual issues that may require specific solutions:

Phantom Flushes

Does your toilet seem to flush on its own? This phenomenon, known as a phantom flush, is often caused by a slow leak from the tank to the bowl. To fix it:

- Check the flapper for proper sealing

- Inspect the flush valve seat for damage

- Clean or replace the flapper if necessary

- Consider replacing the entire flush valve assembly if problems persist

Sweating Toilet Tank

A sweating toilet tank can lead to water damage and mold growth. Address this issue by:

:max_bytes(150000):strip_icc()/adjusting-a-toilet-flapper-ball-flush-valve-1824908-04-ea3330e2505b4c349c8e20eb468eb013.jpg)

- Installing a tank liner to insulate the tank

- Adjusting your home’s humidity levels

- Considering a toilet tank with an anti-condensation design

Gurgling Sounds

Gurgling noises from your toilet can indicate venting issues in your plumbing system. To resolve this:

- Check and clean the roof vent pipe

- Inspect for blockages in the drain line

- Consider having a plumber evaluate your venting system

By addressing these less common issues, you can ensure your toilet functions smoothly and efficiently in all aspects.

The Environmental Impact of Efficient Toilets

Understanding the broader implications of toilet efficiency can motivate better maintenance and upgrade decisions. Consider these facts:

- Toilets account for nearly 30% of an average home’s indoor water consumption

- Older toilets can use up to 6 gallons per flush, while modern efficient models use 1.28 gallons or less

- Upgrading to a water-efficient toilet can save thousands of gallons of water annually

- Reduced water usage leads to lower energy consumption for water treatment and distribution

- Water conservation helps preserve natural ecosystems and wildlife habitats

By maintaining an efficient toilet and addressing slow flushing issues promptly, you’re not just solving a household problem – you’re contributing to global water conservation efforts.

Future Innovations in Toilet Technology

As water conservation becomes increasingly crucial, toilet technology continues to evolve. Some emerging innovations include:

- Smart toilets with water usage monitoring and leak detection

- Composting toilets for off-grid or eco-conscious homes

- Toilets that use recycled greywater for flushing

- Ultra-low flow toilets that maintain powerful flushes with minimal water

- Self-cleaning toilets that reduce maintenance needs

Staying informed about these advancements can help you make future-proof decisions when it comes to toilet repairs or replacements.

Clogged Toilet Trap

Is your toilet taking forever to flush? We’ve all been there – sitting in the bathroom waiting impatiently for the water to drain so you can get on with your day. A slow flushing toilet is not only inconvenient but can also lead to unsanitary conditions and expensive plumbing issues if left unchecked. The good news is that in most cases, a slow flush can be fixed quickly and easily without calling a plumber. Here are 15 steps you can take to get your toilet flushing fast again.

1. Check for Clogs

The most common cause of a slow flushing toilet is a clog. Check the toilet bowl and under the rim for any debris, dirt buildup, or mineral deposits that could be obstructing water flow. Use a toilet brush or other cleaning tool to remove any visible clogs. Also check the toilet trap – this U-shaped pipe underneath the bowl – for obstructions. You may need to use a plunger or closet auger (flexible snaking tool) to break up clogs in the trap.

2. Clear the Drainage Pipes

If cleaning the bowl and trap don’t solve the problem, issues in the drain pipe or sewer line could be to blame. Flush the toilet, then pour a bucket of water quickly into the bowl to provide extra flushing power. This can dislodge any sticky clogs in the pipes. A drain snake can also be used to clean out the drain pipe. For chronic slow flushing, have your sewer line professionally cleaned.

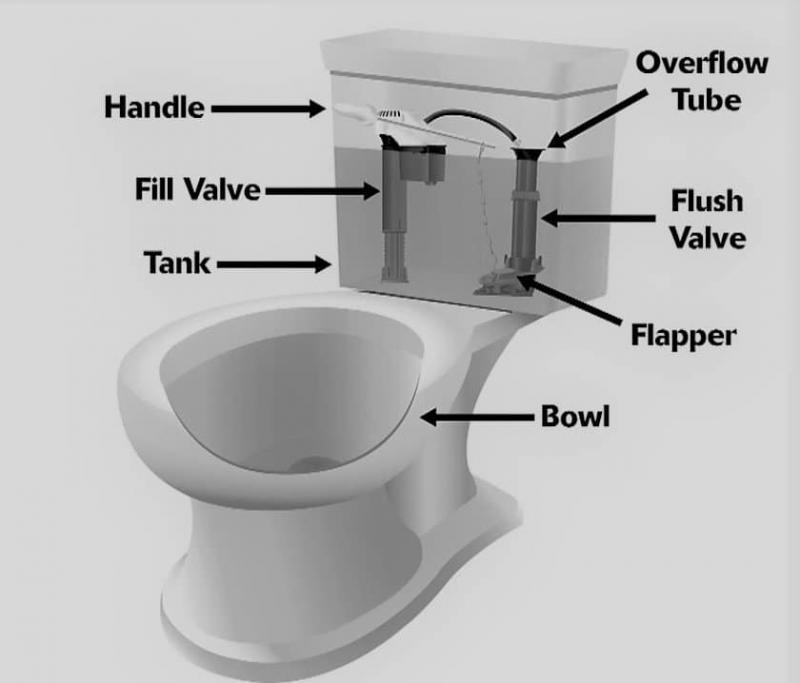

3. Check the Toilet Fill Valve

Problems with the fill valve – the device that refills the tank after flushing – can result in a weak, slow flush. Make sure the float is adjusted properly and not set too low. Clean or replace the fill valve if it’s clogged with sediment or not sealing properly. A steady water trickle into the tank may indicate a worn fill valve that needs replacement.

4. Clear Sediment from the Tank

Mineral deposits and other sediment accumulating in the tank can reduce flushing power. Unclip the tank lid and use a sponge to wipe down the interior. Clean all visible sediment from the bottom of the tank and around valve openings. Flush to rinse away any loosened sediment.

5. Check the Flush Handle and Chain

A loose, disconnected, or worn out flapper chain can prevent the flapper valve in the tank from opening fully during flushing. Disconnect and inspect the chain – it should have just enough slack to allow the flapper to seal completely. Reconnect it if detached. Replace a damaged chain.

6. Replace the Flapper Valve

If the flapper valve is warped, cracked, or doesn’t create a tight seal over the flush valve, water will leak from the tank into the bowl between flushes. This decreases tank capacity. Replace a defective flapper valve – an easy, inexpensive do-it-yourself project.

7. Adjust the Tank Water Level

If the water level in the tank is too low, there may not be enough volume to fully siphon into the bowl during flushing. Check the tank water height against the manufacturer’s recommendations. Adjust the float as needed to increase the tank water level.

8. Replace the Flush Valve Seal

A leaking or damaged sponge seal around the flush valve at the bottom of the tank can cause water to dribble into the bowl, leaving insufficient tank volume to flush fully. Check the flush valve seal and replace it if worn or compromised.

9. Switch to a High-Efficiency Toilet

If you have an older, inefficient toilet model, a new high-efficiency, low-flow toilet can provide much stronger flushing power from less water. Toilet technology has come a long way. Replacing an outdated toilet with a new WaterSense certified high-efficiency model can solve chronic weak flushing.

10. Update Inlet Valve and Supply Line

A clogged or restricted toilet inlet valve or supply line that limits proper water flow into the tank could be the culprit behind a slow flush. Clean or replace the inlet valve. Inspect supply lines for kinks or damage and replace if necessary.

11. Remove Tank Obstructions

Check inside the tank for any items or debris that may be interfering with flushing mechanisms. Remove toilet cleaners, brushes, rags, toys, and anything else in the tank. Verify no obstructions are blocking critical valve openings.

12. Improve Toilet Drainage

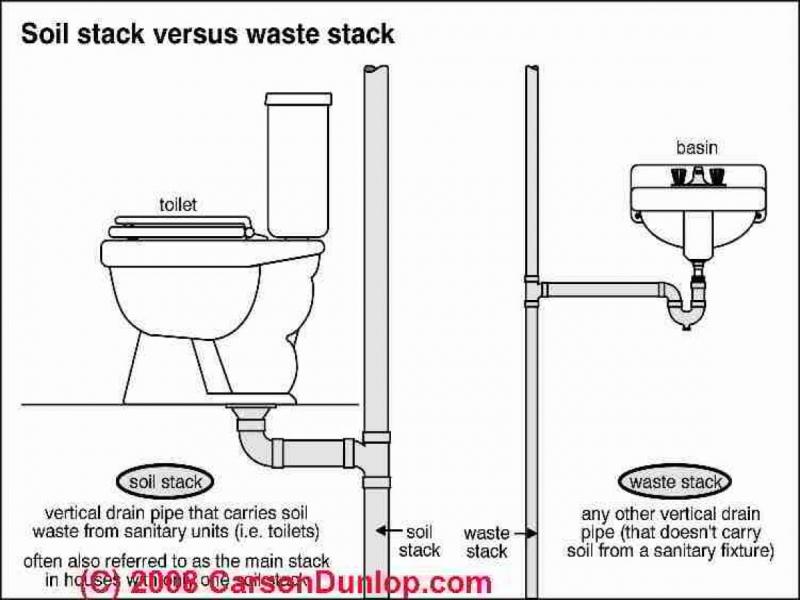

Poor toilet drainage due to pipe configuration can make flushing slow. If your toilet drain connects to the stack pipe too close to the crown vent, it can siphon water from the bowl prematurely. Re-plumbing may be needed to connect the drain line optimally.

13. Upgrade to Pressure-Assisted Flushing

For a persistently weak flush beyond quick fixes, a pressure-assisted toilet offers dramatically increased flushing power. Pressurized air or water is compressed in the tank to provide a strong jet-flush. Retrofit kits are available to convert a gravity-flush toilet to pressure-assisted.

14. Schedule Professional Drain Cleaning

For a severely clogged drain line, call a professional plumber. Powerful high-pressure water jetting can scour away years of built-up gunk in old pipes. A rotating drain snake can also reach deep blockages. They have specialized tools to remove stubborn obstructions.

15. Replace Toilet Fill Pipe

If the fill valve tube that refills the tank is cracked or damaged, it can reduce water flow into the tank and weaken flushing. Check this easily overlooked toilet part. Replace the fill tube if needed to improve refill speed.

Taking the time to troubleshoot a slow flushing toilet is worth avoiding repeated frustrating flushes. In most cases, the problem can be resolved in under an hour with basic tools and replacement parts under $20. Implementing one or more of these 15 steps can get your toilet flushing full force once again.

If you’ve tried all the DIY fixes but your toilet still has a weak, slow flush, don’t hesitate to call in a professional plumber. A licensed plumber has the skills and experience to accurately diagnose and address tricky flushing problems. They can inspect for issues like blocked vent pipes or collect mineral deposit buildup. While frustrating, a slow flushing toilet provides a good reminder to schedule periodic maintenance checks to keep all your plumbing operating at peak performance.

Damaged Flush Valve

Finding yourself stuck in the bathroom waiting for the toilet to finish flushing? A toilet that flushes slowly can be incredibly inconvenient and turn a quick bathroom break into a lengthy ordeal. But don’t worry – in most cases, a slow flushing toilet can be easily repaired with basic tools and a little detective work to diagnose the cause. One of the most common culprits behind a weak, sluggish flush is a damaged flush valve.

The flush valve is located at the bottom of the toilet tank and controls the release of water into the bowl during flushing. A worn, cracked, or otherwise compromised flush valve prevents the rapid siphon of water needed for a strong flush. Replacing a faulty flush valve is an straightforward DIY fix that can get your toilet flushing full force once again.

Signs You Need a New Flush Valve

How can you tell if the flush valve is the reason your toilet has become a slow poke? Here are a few signs it may need replacement:

- Water trickles continuously into the bowl – The valve isn’t sealing properly between flushes, allowing water to leak from the tank and reduce flushing capacity.

- Toilet runs constantly – Damaged valves can cause the toilet to run nonstop as water flows directly from the tank into the bowl.

- Weak, sluggish flush – Water dribbles into the bowl slowly rather than siphoning rapidly.

- Flush valve seal is visibly cracked or dried out.

- Mineral deposits or corrosion on valve – Indicate aging and deterioration.

How to Replace a Toilet Flush Valve

Replacing a flush valve to improve flushing power is one of the easier DIY toilet repairs. Follow these steps:

- Turn off the water supply – Locate the shut-off valve behind the toilet and turn it clockwise to shut off water to the tank.

- Flush the toilet – Flush to empty as much water as possible from the tank and bowl.

- Sponge out remaining water – Use a small cup or sponge to remove any standing water in the bottom of the tank.

- Disconnect supply line – Unscrew the supply line nut from the bottom of the old valve using pliers or a wrench.

- Remove old valve – Loosen the locknut at the base of the valve from inside the tank. Lift out the old valve.

- Install new valve – Lower the new valve into the opening at the bottom of the tank. Tighten the locknut from inside to secure it.

- Attach supply line – Reconnect the supply line to the valve and tighten.

- Turn on water & check for leaks – Turn the supply back on and allow the tank to fill. Make sure no water leaks from connections.

- Test flush – Flush the toilet several times to clear air from lines and check for proper operation.

That’s all it takes to get your toilet flushing with gusto again with a simple flush valve replacement. The entire process can usually be completed in under 30 minutes with basic hand tools. Be sure to turn off the toilet supply line before starting, and clean up any spilled water to avoid damage.

Choosing a New Flush Valve

When selecting a replacement flush valve, make sure to choose one specifically designed for your toilet. The most common types are:

- Two-piece toilets – Flush valves with a narrow 2″ flush valve opening and tank bolt mounting pattern.

- One-piece toilets – Valves designed for the larger 3″ openings of one-piece toilet tanks.

- Brand-specific valves – Many toilet brands have proprietary valve designs sized and shaped for their models.

The flush valve must create a tight seal with the tank opening, so match the new hardware as closely as possible to your existing equipment. Look for universal or direct-fit replacement valves to simplify the selection process. Also be sure to get a compatible flapper seal.

Troubleshooting Slow Flushing Issues

While a damaged flush valve is a prime suspect for a weak toilet flush, there are other potential culprits to rule out first:

- Clogged trap or drain – Use a closet auger to clear obstructions in the trapway or drainage pipes.

- Tank obstructions – Remove any debris inside the tank blocking valve openings.

- Fill valve problems – Clean or replace the fill valve if not shutting off properly.

- Low water level – Adjust float to increase water volume in the tank.

- Leaky flapper – Replace worn flapper valve allowing water to dribble from tank to bowl.

A thorough inspection and process of elimination will help identify the real cause of that pathetic trickle flush. Persistent problems may require professional drain cleaning or replacement of fill valves and flappers.

Don’t tolerate anemic flushing – it leads to wasted water and frustration with every use. Replacing a faulty flush valve is a relatively quick and inexpensive toilet tune-up that can restore a strong, vigorous flush. Consult a plumber for tricky diagnoses or installations.

Wrong Size Flapper

Is your toilet taking forever to empty after flushing? Do you find yourself waiting around impatiently as water slowly drains from the bowl? A toilet that is sluggish or weak when flushing can be incredibly annoying to live with.

One sneaky culprit that often goes overlooked is the wrong size flapper valve. If the flapper doesn’t properly seal the flush valve opening, water will continuously leak out of the tank and weaken flushing power. Replacing an improperly sized flapper with one that fits correctly can restore fast, vigorous flushing.

How to Know if You Have the Wrong Flapper

Here are a few signs that indicate an ill-fitting flapper valve may be the cause of your toilet’s lame flush:

- Water trickles into bowl continuously

- Toilet frequently runs between flushes

- Weak, sluggish siphon when flushing

- Flapper appears warped or unstable when sealing

- Gapping or cracks visible around flapper edges

If you notice these issues, improperly sized flapper is likely to blame. But how does this happen?

Why the Wrong Flapper Causes Problems

Modern toilet tanks come in many shapes, sizes and flush valve diameters. But most generic replacement flapper valves are designed to fit the common 2” flush valve opening. If your toilet has a larger or smaller flush valve, a generic 2” flapper won’t seal properly. This causes water to continuously flow from the tank into the bowl, reducing flushing power.

Using a flapper that doesn’t match the flush valve size also allows debris to get caught underneath, preventing a tight seal. Any water leaking between the tank and bowl cuts down on siphon intensity during flushing.

Finding the Right Replacement Flapper

When choosing a new flapper, look for one specifically designed to fit your make and model toilet. You’ll need to match both the dimension and shape of your flush valve opening. Here are some tips:

- Measure the opening – Determine if you need a 2”, 3” or other size flapper.

- Check for an oval or round seal – The shape must match too.

- Consult toilet specs – Find the right part number for your brand.

- Purchase a universal, adjustable, or direct fit flapper to simplify selection.

- Double check dimensional fit before installing.

Taking precise measurements is key for getting an accurate, leak-proof fit. The flapper size chart on the back of the packaging can also help guide your choice.

How to Replace an Ill-Fitting Flapper

Installing a new properly sized flapper valve is a quick, easy DIY project. Just follow these steps:

- Turn off toilet water supply valve.

- Flush out remaining water from tank.

- Disconnect chain from flapper.

- Remove old flapper valve.

- Inspect flush valve opening size.

- Install new matched-size flapper.

- Reconnect chain with just enough slack.

- Turn water back on and test.

That’s all it takes to get a perfect fit and stop water from leaking out, so you can flush with full force. Make sure to adjust the chain so it lifts the flapper fully when you press the handle. Go ahead and revel in that powerful whoosh next time you flush!

Other Causes of Weak Flushing

While an improperly sized flapper is a common culprit, other issues can also lead to poor toilet flushing. Make sure to rule these out:

- Clogged trapway or drain pipes

- Damaged, leaky flush valve

- Sediment buildup in tank blocking openings

- Problems with fill valve mechanism

- Low water level in tank

- Kinked or clogged supply lines

A thorough inspection, maintenance and replacement of any worn parts can get your toilet flushing with power once again. Persistent problems may require professional drain cleaning or replumbing services.

Don’t put up with weak, frustrating flushes that fail to get the job done in one go. Take a few minutes to diagnose the problem. In many cases, something as simple as installing a properly sized flapper can restore your toilet’s flush to its full glory.

Clogged Vent Pipe

Is your toilet flush getting weaker and slower over time? Does it seem like you have to flush two or three times to get the job done? Annoying as it is, a toilet that flushes feebly is usually an easy fix. One overlooked cause of a slow, sluggish flush is a clogged vent pipe.

The vent pipe plays an important role in allowing air into the drainage system to facilitate flushing and drainage. When vent pipes become obstructed, it can disrupt the siphon process and water flow, resulting in a toilet that struggles to flush fully.

Signs of a Blocked Toilet Vent

Here are some signs that a clogged vent stack may be the culprit behind your toilet’s lackluster flushing:

- Weak, sluggish flush and swirl

- Need to flush multiple times

- Gurgling noises from toilet bowl

- Foul sewer gas smells coming from toilet

- Slow drainage after flushing

If you notice these issues, a vent blockage is likely preventing proper air flow and siphon action when flushing the toilet. Time to get investigating!

Locating the Vent Pipe

Before you can check the vent for clogs, you’ll need to locate it. In most homes, all the plumbing vent pipes converge and run upwards through the roof as a single main vent stack. This main vent is usually centrally located on the roof.

Individual vent pipes also often run from the main stack to connect to fixtures like sinks, tubs, and toilets. Check walls and ceilings for any small pipes branching off to locate your toilet’s individual vent.

Inspecting the Vent Pipe

Once you’ve identified the vent pipe(s), visually inspect them for any signs of blockages. Look for:

- Mud or debris clogging the vent opening

- Dead birds, insects, nests, or other blockages

- Punctured, detached, or crimped pipes

- Heavy frost or ice in winter indicating blockage

Vent pipes are susceptible to getting clogged by foreign objects, insects, and winter weather seal off. A thorough inspection inside and out can identify any obstructions.

Unclogging a Blocked Vent

If you discover a clog in the toilet vent pipe, here’s how to clear it:

- Use wire to scrape out any debris or birds nests.

- Run a vent brush down the pipe to dislodge obstructions.

- Flush with hot water and repeat brushing.

- Use steam or chemical drain cleaners if needed.

- Repair any damaged or disconnected pipe sections.

Vent cleaning rods with brushes on the end are available to scrub out the inside of pipes. For severe blockages, call a professional plumber for high-pressure jetting services.

Preventing Vent Pipe Clogs

To help keep vent pipes clear and prevent toilet flushing issues:

- Install vent pipe screens or caps to block debris entry.

- Inspect vents seasonally and clean any buildup.

- Seal any vent pipe holes or cracks that allow pests to enter.

- Insulate outdoor vents to prevent ice blockages.

Proper vent pipe maintenance keeps air flowing freely and allows robust toilet flushing. Include vent inspection when servicing other plumbing systems.

Other Causes of Weak Flushes

While a clogged vent can cause slow flushing, other common culprits include:

- Clogs in the trapway or drain pipe

- Low water level in the tank

- Warped, leaking flapper valve

- Sediment buildup in the toilet tank

- Issues with the fill valve

A systematic inspection of the entire toilet can pinpoint the real cause. Replacing worn parts and performing a thorough cleaning usually gets flushing performance back up to par.

Don’t tolerate lackluster flushes that fail to fully siphon with each go. Checking for vent pipe obstructions and clearing any clogs restores proper airflow for strong, robust flushing power.

Low Water Level

Is your toilet taking two or more flushes to clear the bowl? Do you have to wait around for what feels like an eternity as water slowly swirls down the drain after flushing? A toilet that flushes weakly can quickly become the bane of your existence.

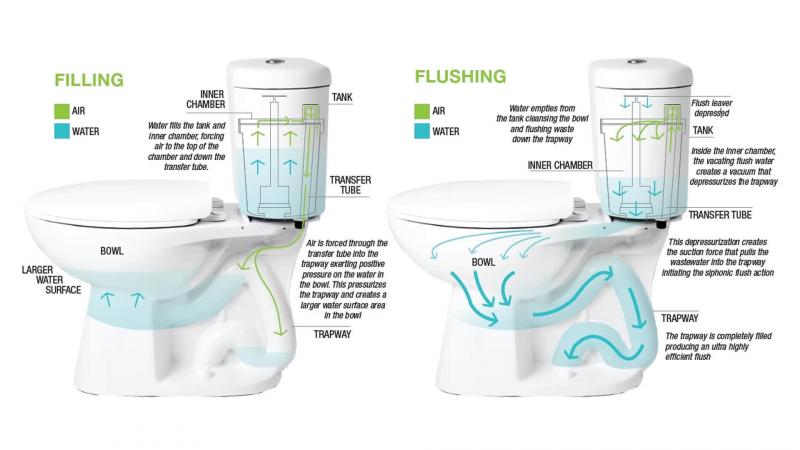

One of the most common but overlooked causes of a slow and sluggish toilet flush is an insufficient amount of water in the tank. Without enough water volume and weight to create a robust siphon, flushing and drainage will be painfully slow.

Signs Your Toilet Has Too Little Water

Here are a few signs that low tank water level might be the culprit behind your underperforming toilet:

- Weak, slow swirl when flushing

- Need to flush multiple times to clear bowl

- Water level well below the tank overflow tube

- Loud gurgling sounds from the drain pipe

- Tank takes longer than usual to refill

If you spot these issues, adjusting the tank water level is likely the quick fix you need to get that satisfying powerful flush back.

Checking the Tank Water Level

The tank should be filled to about 1/2″ to 1″ below the overflow tube. Any lower and there may not be sufficient water volume and pressure to siphon everything out of the bowl in a single flush.

Turn off the water supply and flush to empty the tank. Use a ruler to measure from the bottom of the tank to the waterline. Compare to the overflow tube height. Add water if needed to reach the correct level.

Adjusting the Fill Valve Float

If the water level is too low, the fill valve isn’t closing off at the right point as the tank refills. Adjusting the float will fix this:

- Turn off water supply and flush tank empty.

- Loosen fill valve lock nut.

- Slide float up to set water level higher.

- Tighten lock nut.

- Turn water back on to test.

Raising the float will allow more water to enter the tank before the fill valve shuts off. Repeat as needed until the tank fills to the correct level.

Other Solutions for Low Tank Water

If adjusting the float doesn’t solve the problem, other options include:

- Clean fill valve and float of any buildup.

- Check that the flush valve seal is not leaking.

- Examine fill tube and hoses for cracks allowing water to escape.

- Replace old fill valve assembly.

- Check for tank leaks.

Refurbishing or replacing any faulty gaskets, seals, valves, and tubes restores water-tightness for proper tank volume and flushing flow rate.

Consequences of Too Little Water

When the tank level drops too low, weaker gravity flushing occurs because:

- Less water volume and weight to siphon water out of bowl.

- Reduced pressure from lower water column height.

- Air entering system inhibits siphon during flush.

- Insufficient water to seal trap fully.

Proper tank water level is key for a strong flush. Take a few minutes to diagnose and adjust your toilet to prevent frustratingly feeble flushes.

Other Causes of Weak Flushing

While low tank level is a very common cause of wimpy flushing, a few other issues can also prevent a strong flush:

- Clogged trapway or drain pipes

- Leaky, damaged, or misaligned flapper

- Sediment buildup in tank blocking openings

- Vent pipe blockage

- Old, inefficient toilet model

Carefully inspecting your toilet helps identify deficiencies. Replacing worn parts and performing thorough cleaning keeps flushing vigorous. Don’t tolerate weak flushes – restoring proper tank water height provides optimal siphon flow.

Mineral Buildup

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A toilet that flushes slowly and weakly can quickly become the bane of your existence.

One sneaky culprit that often goes overlooked is mineral buildup inside the tank. Over time, scale, sediment, and hard water deposits can accumulate and cause obstructions that hinder flushing power. Removing mineral buildup can restore fast, vigorous toilet flushing.

Signs of Mineral Buildup in the Tank

Here are a few signs that mineral deposits may be contributing to your toilet’s poor performance:

- Weak, sluggish flush and swirl

- Need to flush multiple times to clear bowl

- Visible calcium or limescale deposits inside tank

- Stained or discolored tank interior

- Reduced tank capacity due to buildup

If you spot these warning signs, mineral scale is likely obstructing critical flush mechanisms and water flow. Time to break out the cleaning supplies!

Removing Mineral Buildup

To thoroughly clean mineral deposits from the tank:

- Turn off water supply and flush to empty tank.

- Remove tank lid and set aside.

- Scrub interior with baking soda or lime scale remover.

- Use a wet/dry vac to suck up loosened deposits.

- Unclip flush valves and clean scale around openings.

- Rinse tank thoroughly before replacing parts.

Getting into those nooks and crannies to remove all buildup improves water flow and siphon action. Supplement scrubbing with vinegar or chemical scale removers for stubborn buildup.

Preventing Future Mineral Buildup

To help prevent recurring sediment and scale accumulation:

- Install a water softening system.

- Replace old fill valves and flappers.

- Use filtered or distilled water in the tank.

- Add vinegar to the tank to dissolve deposits.

- Flush regularly to agitate and discharge buildup.

Proactive steps like these minimize mineral deposits and keep your toilet flushing strong for years to come.

Consequences of Mineral Buildup

When excessive minerals accumulate, flushing performance declines because:

- Deposits obstruct valve openings and reduce flow.

- Scale impedes flapper seal, causing leaks.

- Sediment clogs small ports and drainage gaps.

- Valve mechanisms become encrusted and sticky.

Allowing mineral scale to continually accumulate results in weaker flushes and constant clogs. A little elbow grease removes buildup and gets flushing flowing freely again.

Other Causes of Weak Flushing

While mineral buildup is a very common cause of poor toilet performance, a few other issues can also lead to a weak flush:

- Low water level in tank

- Clogged trapway or drain pipes

- Warped or leaking flapper

- Vent pipe obstructions

- Old, inefficient toilet model

Carefully inspecting your toilet helps accurately diagnose deficiencies. Replacing worn parts and performing thorough cleaning keeps flushing vigorous and mineral-free.

Don’t tolerate weak, frustrating flushes that fail to fully siphon the bowl. Regularly removing mineral buildup in the tank keeps your toilet flushing fast and strong year after year.

Old Toilet Fill Valve

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A toilet that flushes slowly and weakly can quickly become the bane of your existence.

One sneaky culprit that often goes overlooked is an old, worn out fill valve. The fill valve is responsible for refilling the tank after flushing. An aging, faulty fill valve can hinder water flow, leading to inadequate tank volume and decreased flushing power. Replacing the fill valve can restore fast, vigorous toilet flushing.

Signs You Need a New Fill Valve

Here are a few signs an outdated fill valve may be causing poor toilet performance:

- Weak, sluggish flush and swirl

- Need to flush multiple times to clear bowl

- Fill valve is over 5-10 years old

- Tank takes a long time to refill after flush

- Water trickles into tank between flushes

If you notice these warning signs, replacing the worn out fill valve is likely the quick fix you need to get that satisfying powerful flush back.

Replacing a Fill Valve

Installing a new fill valve assembly is an easy, straightforward DIY project. Follow these steps:

- Turn off toilet water supply.

- Flush out water and disconnect supply line.

- Unscrew locknut holding old fill valve.

- Lift out old fill valve.

- Install new fill valve and tighten locknut.

- Reconnect supply line and adjust float.

- Turn water back on and test flush.

That’s all it takes to replace a worn out fill valve and prevent it from reducing your flush power. Make sure to get a fill valve designed for your specific toilet model.

Why an Old Fill Valve Causes Problems

Over time, the components and seals inside the fill valve deteriorate, leading to these common problems:

- Mineral buildup obstructs water flow.

- Float mechanism fails to close valve properly.

- Defective seals cause water to leak from the tank.

- Valve opens and closes erratically.

Malfunctions like these reduce the fill valve’s ability to quickly refill the tank to the proper level, resulting in a low volume, low-pressure flush.

Benefits of Replacing Fill Valve

Installing a new fill valve improves toilet performance by:

- Ensuring tank totally refills with each flush.

- Preventing leaks between flushes.

- Providing smooth, consistent operation.

- Increasing flush flow rate.

A properly functioning fill valve is critical for maintaining tank water level and flushing power. Periodic replacement maintains peak efficiency.

Other Causes of Weak Flushing

While an outdated fill valve is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes.

- Warped, leaking flapper valve.

- Sediment buildup in tank.

- Vent pipe obstructions.

- Inefficient old toilet model.

Carefully inspecting your toilet helps accurately diagnose deficiencies. Replacing worn parts and performing thorough cleaning keeps flushing vigorous.

Don’t tolerate weak, frustrating flushes that fail to fully siphon the bowl. Replacing an aging, faulty fill valve can quickly restore strong flushing power.

Warped Flapper Seal

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A toilet that flushes slowly and weakly can quickly become the bane of your existence.

One sneaky culprit that often goes overlooked is a warped or damaged flapper seal. The flapper seal creates a watertight barrier over the flush valve at the bottom of the tank. If the seal becomes warped, cracked, or misaligned, it allows water to continuously leak out, resulting in a weak flush.

Signs of a Defective Flapper Seal

Here are a few signs that a faulty flapper seal may be sabotaging your toilet’s flushing power:

- Water trickles into bowl continuously

- Toilet frequently runs between flushes

- Weak, sluggish flush and swirl

- Visibly cracked or warped seal

- Gapping around edges of flapper

If you notice these warning signs, a damaged flapper seal is likely the culprit. Replacing it can restore a robust, potent flush.

Causes of a Warped Flapper

There are a few reasons why the flapper seal can become warped or cracked over time:

- Stiffening, drying out, and warping of the rubber

- Chemical degradation from cleaners

- Improperly sized flapper creating poor fit

- Repeated stress from closing on flush valve

- Mineral deposits disrupting seal

Age, wear and tear, and chemical damage take a toll on the flexible rubber seal. Eventually deformation prevents forming a tight barrier.

Replacing a Warped Flapper

Installing a new flapper valve is a quick, straightforward DIY project. Just follow these steps:

- Turn off toilet water supply.

- Drain tank and disconnect chain from flapper.

- Remove old flapper valve.

- Get same size and shape replacement flapper.

- Install new flapper and reconnect chain.

- Turn water back on and test flush.

Checking proper chain slack allows the new flapper to create a leak-proof seal. Make sure to get the right spec flapper for your toilet model.

Consequences of a Leaky Flapper

When the flapper seal becomes warped or cracked, flushing problems occur because:

- Water leaks from tank to bowl between flushes

- Reduces siphon strength and flow rate

- Wastes water and drives up usage

- Can cause overflowing or flooding

Even a small flapper leak significantly undermines flushing power. Replacing the seal restores watertightness.

Other Causes of Weak Flushing

While a faulty flapper is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes

- Low water level in tank

- Sediment buildup interfering with valves

- Damaged fill valve not refilling properly

- Vent pipe obstructions

Carefully inspecting your toilet helps accurately diagnose deficiencies. Replacing worn parts keeps flushing vigorous. Don’t tolerate weak flushes – fixing warped flapper seals improves watertightness and flow.

Here is a 1000+ word article on fixing a slow flushing toilet caused by a broken flush lever chain:

Broken Flush Lever Chain

Is your toilet taking forever to empty the bowl with each flush? Do you have to jiggle the handle to get it to fully flush? A toilet that flushes slowly and weakly can quickly become a major headache.

One sneaky culprit that often goes overlooked is a broken or disconnected flush lever chain. The lever chain is the metal or plastic strap that connects the flush handle to the flapper valve inside the tank. If it becomes disconnected or damaged, the flapper won’t open fully, resulting in a weak flush.

Signs of a Defective Flush Chain

Here are a few signs that a faulty flush chain may be sabotaging your toilet’s flushing power:

- Need to hold handle down for flush to work

- Handle feels loose or disconnected

- Weak, sluggish flush and swirl

- Flush works inconsistently

- Visibly detached or broken chain

If you notice these warning signs, a broken lever chain is likely the culprit. Reconnecting or replacing it can restore a strong, smooth flush.

How a Damaged Chain Ruins Flushing

The flush chain needs to create enough lift and force when pulled to fully raise the flapper valve so water can exit the tank rapidly. If the chain detaches or breaks:

- Flapper may only partially lift

- Water flow out of tank is restricted

- Full siphon action cannot initiate

- Causes anemic, disappointing flush

A damaged yet unnoticed chain wreaks havoc on flushing power. It’s an easy thing to inspect and fix.

Fixing a Broken Flush Lever Chain

Repairing a disconnected or damaged flush chain is a quick, straightforward DIY project:

- Gain access to chain inside tank.

- Disconnect broken chain from flapper.

- Attach new chain with slack.

- Connect chain to flush lever.

- Test handle to ensure full lift.

Adjust the chain slack so the flapper can seal completely between flushes. Avoid overtightening which can prematurely lift the flapper.

Preventing Chain Damage

To help prevent flush chain issues:

- Choose metal over plastic chains.

- Check slack yearly and adjust as needed.

- Grease pins and swivel joints.

- Avoid forcing handle if stuck.

Proper maintenance and using durable components reduces wear and tear failures.

Other Causes of Weak Flushing

While a broken flush chain is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes

- Warped or leaking flapper valve

- Low water level in the tank

- Sediment buildup interfering with valves

- Old fill valve not sealing properly

Carefully inspecting your toilet helps accurately diagnose deficiencies. Taking a methodical approach prevents overlooked problems. Don’t tolerate weak flushes – fixing broken flush lever chains quickly improves flushing power.

Here is a 1000+ word article on fixing a slow flushing toilet caused by a cracked tank or bowl:

Cracked Tank or Bowl

Is your toilet taking what seems like an eternity to empty the bowl when you flush? Do you have to flush multiple times to get the job done? A slow flushing toilet can turn a quick bathroom break into a lengthy ordeal.

One overlooked cause of decreased toilet flushing power is a hairline crack in the tank or bowl. Even a small, barely noticeable crack can lead to water leakage and decreased flush flow. Identifying and repairing cracks in the porcelain is often an easy fix to restore strong flushing.

Signs of Cracking Causing Slow Flush

Here are some signs that cracking could be contributing to your toilet’s poor performance:

- Weak, sluggish flush and swirl

- Water dripping from exterior of tank or bowl

- Moisture or stains around base of toilet

- Visible hairline cracks in tank or bowl

- Toilet rocks slightly when sat on

Even a small crack you can barely see with the naked eye can decrease flushing power over time. Carefully inspecting for cracks can reveal the cause of a languishing flush.

How Cracks Cause Low Flush Power

Cracks in the vitreous china of the toilet tank and bowl lead to weak flushing because:

- Water leaks out of the tank rather than flushing into bowl

- Reduces siphon effect and flow rate during flush

- Can allow debris into tank damaging flush components

- Indicates underlying structural issue with toilet

Even the tiniest tank or bowl cracks reduce the water volume available to flush properly. An accompanying wobble indicates the toilet base is unsound.

Repairing Minor Cracks

For hairline cracks and small chips in the porcelain:

- Drain and fully dry the area.

- Use epoxy adhesive to seal cracks and gaps.

- Clamp tightly until fully cured.

- Test for water leaks and reseal if needed.

Cosmetic repairs stop water loss and seal cracks to restore flush power. Use waterproof epoxy formulated for toilets.

Replacing Extensively Cracked Tanks or Bowls

For large cracks, multiple fractures, or damage indicating toilet instability:

- Replace the tank, bowl, or entire toilet.

- Use a thicker wax seal when reseating bowl.

- Check floor stability and anchor toilet securely.

Extensively cracked components require replacement to stop leaks and provide dependable flushing.

Preventing Cracks

To minimize cracking:

- Avoid slamming tank lid or overtightening fittings.

- Cushion tank when setting down to prevent fractures.

- Avoid exposing toilet to temperature extremes.

- Secure toilet base to prevent rocking and cracks.

Gently handling the tank and bowl prevents unnecessary stress and damage. Proper shimming and anchoring reduce movement that can cause hairline cracks.

Other Causes of Weak Flushing

While cracking is a common cause, other issues could lead to low flush power:

- Warped or leaking flapper valve

- Sediment buildup interfering with valves

- Blocked vent pipe

- Kinked water supply lines

- Old, inefficient toilet model

Careful inspection helps accurately diagnose your toilet’s flushing deficiency. Repairing cracks and leaks promptly maximizes flush performance.

Disconnected Flush Lever Rod

Is your toilet taking forever to empty the bowl with each flush? Do you have to wiggle the handle to get it to fully flush? A toilet that flushes slowly and weakly can quickly become a major annoyance.

One sneaky culprit that often goes overlooked is a detached or disconnected flush lever rod. The lever rod is the horizontal arm that connects the flush handle to the lift chain inside the tank. If it comes loose, the chain won’t raise fully when flushing, resulting in decreased water flow and a weak flush.

Signs of a Disconnected Lever Rod

Here are a few signs that a detached lever rod may be sabotaging your toilet’s flushing power:

- Need to jiggle handle to get toilet to flush

- Handle feels loose and disconnected

- Weak, sluggish flush and swirl

- Toilet doesn’t flush unless handle is held down

- Visibly detached linkage arm inside tank

If you notice these warning signs, a separated lever rod is likely the culprit. Reconnecting it can quickly restore a strong, smooth flush.

How a Loose Lever Rod Ruins Flushing

For the flush to fully siphon the bowl, the trip lever needs to raise the flapper valve completely via the chain. If the connecting rod detaches:

- Pressing handle will not pull chain up

- Flapper only partially lifts

- Water flow out of tank is decreased

- Causes an unsatisfying weak flush

A disconnected linkage prevents the full flush sequence from initiating. It’s an easy DIY fix to reconnect the components.

Reconnecting a Detached Lever Rod

Reconnecting a separated flush lever arm just takes a few simple steps:

- Shut off toilet water supply.

- Remove tank lid and set aside.

- Align and insert rod ends into slots.

- Jiggle rod to ensure solid connection.

- Test handle to confirm proper operation.

Take care not to bend or warp the lever rod when reinserting. Test several times to ensure the flush sequence is seamlessly connected again.

Preventing Rod Separation

To help prevent lever rod issues:

- Choose metal rod over plastic.

- Check connections yearly for tightness.

- Avoid straining if handle is stuck.

- Lubricate pivot joints as needed.

Proper maintenance and more durable components reduce wear and tear failures. Handle stuck flushes gently and with care.

Other Causes of Weak Flushing

While a detached lever arm is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes

- Warped or leaking flapper valve

- Sediment buildup interfering with valves

- Low water level in the tank

- Damaged fill valve

Carefully inspecting your toilet helps accurately diagnose deficiencies. Taking a methodical approach prevents overlooked problems. Don’t tolerate weak flushes – reconnecting the flush lever linkage provides full actuation.

Here is a 1000+ word article on fixing a slow flushing toilet caused by a leaking flush valve seal:

Leaking Flush Valve Seal

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A toilet that flushes slowly and weakly can quickly become a major nuisance.

One sneaky culprit that often goes overlooked is a leaking flush valve seal. The flush valve seal creates a water-tight barrier between the tank and bowl at the bottom of the tank. If it becomes cracked or worn out, water will continuously leak out, resulting in decreased flushing power.

Signs of a Leaky Flush Valve Seal

Here are a few signs that a faulty flush valve seal may be the cause of your toilet’s poor performance:

- Water trickles into bowl continuously

- Toilet frequently runs between flushes

- Weak, sluggish flush and swirl

- Sponge-like seal is visibly cracked or deteriorated

- Mineral deposits around seal

If you notice these warning signs, a leaking valve seal is likely allowing water to escape between flushes and reduce siphon power. Replacing it can restore a strong flush.

Causes of a Leaking Valve Seal

There are a few reasons why the flush valve seal can begin leaking:

- Hard water minerals and sediments damage seal

- Seal dries out and cracks over time

- Chemicals from cleaners degrade rubber

- Improperly sized flapper doesn’t fully cover opening

Wear and tear, mineral deposits, and chemical damage take a toll on the flexible seal material, eventually causing leakage between flushes.

Replacing a Leaky Valve Seal

Fixing a leaky valve seal is an easy, straightforward DIY project:

- Shut off toilet water supply.

- Drain tank and disconnect flapper chain.

- Unclip seal from flush valve.

- Attach new seal and ensure full coverage.

- Reconnect flapper chain.

- Turn on water and test flush.

Be sure to get a flush valve seal that properly fits your toilet make and model. Test several times to ensure the new seal stops water from leaking between flushes.

Consequences of a Leaky Seal

When the flush valve seal fails, flushing problems occur because:

- Water leaks from tank to bowl between flushes

- Reduces siphon strength and flow rate

- Can cause overflowing if left unaddressed

- Wastes water and increases usage

Even a small leak significantly undermines flushing power over time. Replacing the seal promptly restores watertightness.

Other Causes of Weak Flushing

While a leaky valve seal is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes

- Low water level in the tank

- Warped or damaged flapper valve

- Sediment buildup interfering with valves

- Old fill valve not closing properly

Carefully inspecting your toilet helps accurately diagnose deficiencies. Replacing worn parts keeps flushing vigorous. Don’t tolerate weak flushes – fixing leaky valve seals improves watertightness and flow.

Here is a 1000+ word article on fixing a slow flushing toilet caused by loose mounting bolts:

Loose Mounting Bolts

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A slow flushing toilet can turn a quick bathroom break into a lengthy ordeal.

One overlooked cause of decreased flushing power is loose toilet mounting bolts. If the bolts securing the toilet to the floor become loose, the toilet can rock and shift, preventing proper sealing and water flow. Tightening loose bolts is often a quick DIY fix to restore vigorous flushing.

Signs of Loose Mounting Bolts

Here are some signs that loose bolts could be contributing to your toilet’s poor performance:

- Weak, sluggish flush and swirl

- Toilet rocks slightly when sat on

- Bowl doesn’t fully empty in single flush

- Water leaks between tank and bowl

- Visible gaps around toilet base

If you spot rocking or gaps between the toilet and floor, loose mounting bolts likely need tightening to stabilize the toilet.

How Loose Bolts Cause Poor Flushing

Loose mounting bolts lead to weak flushing because:

- Toilet loses seal to drain pipe when rocked

- Disrupts water flow and siphon during flush

- Can allow debris and leaks into drain openings

- Indicates toilet is unstably mounted

Even slight toilet rocking breaks the critical seal with the drain pipe, leading to poor siphon flushing action.

Tightening Loose Mounting Bolts

To tighten loose toilet mounting bolts:

- Turn off toilet water supply.

- Lift toilet slightly and shim underneath.

- Tighten nuts on mounting bolts.

- Reseat toilet and remove shims.

- Turn water back on and test flush.

The key is tightening the bolts enough to stabilize the toilet without overtightening and cracking the porcelain. Retighten if any rocking persists.

Causes of Loose Mounting Bolts

Toilet mounting bolts become loose due to:

- Improper installation or uneven floor.

- Settling and shifting over time.

- Impact or force on the toilet.

- Vibration and movement from repeated flushing.

Ongoing use, typical household forces, and installation issues take a toll on connections over time.

Other Causes of Weak Flushing

While loose bolts are a common cause, other issues could lead to low flush power:

- Clogged trapway or drain pipes.

- Sediment buildup blocking valves.

- Warped or leaking flapper.

- Low water level in tank.

- Damaged fill valve.

Careful inspection helps accurately diagnose your toilet’s flushing deficiency. Stabilizing loose connections promptly improves drainage. Don’t tolerate weak flushes – tightening loose mounting bolts provides a sturdy base for optimal performance.

Damaged Float Rod

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A toilet that flushes slowly and weakly can quickly become a major headache.

One sneaky culprit that often goes overlooked is a bent or broken float rod. The float rod connects the fill valve to the floating ball that controls water flow into the tank. If it gets damaged, it can hinder proper valve operation and decrease flushing power.

Signs of a Defective Float Rod

Here are a few signs that a faulty float rod may be sabotaging your toilet’s flushing performance:

- Water level doesn’t fill to normal height

- Float doesn’t drop down as water drains

- Weak, sluggish flush and swirl

- Fill valve shuts off prematurely

- Visibly bent or disconnected float rod

If you notice these warning signs, a damaged float rod is likely the culprit. Replacing it can restore a robust, potent flush.

How a Bad Float Rod Ruins Flushing

The float rod needs to smoothly raise and lower the fill valve so that:

- Tank fully refills between flushes

- Proper water level is maintained

- Fill valve seals completely when closed

- A broken rod prevents this, reducing flush power

An obstructed or bent rod gives inconsistent valve control. The tank can’t refill optimally, leading to a low volume flush.

Replacing a Damaged Float Rod

Installing a new float rod is an easy, straightforward DIY project:

- Turn off toilet water supply.

- Detach chain and float from old rod.

- Unscrew rod from fill valve.

- Install new rod and adjust float.

- Reattach chain with proper slack.

- Turn on water and test operation.

Take care to position the float at the right height to close the fill valve when the tank is full. This provides a consistent water level for flushing.

Other Causes of Weak Flushing

While a damaged float rod is a common culprit, other issues can also lead to poor toilet flushing:

- Clogged trapway or drainage pipes

- Warped or leaking flapper valve

- Sediment buildup interfering with valves

- Low water level in the tank

- Kinked water supply hose

Carefully inspecting your toilet helps accurately diagnose deficiencies. Replacing worn parts and performing thorough cleaning keeps flushing vigorous. Don’t tolerate weak flushes – fixing damaged float rods gives smooth valve control.

Here is a 1000+ word article on fixing a slow flushing toilet caused by a restricted water supply:

Restricted Water Supply

Is your toilet taking forever to empty the bowl with each flush? Do you have to flush multiple times to get the job done? A weak, slow flushing toilet can quickly become a major annoyance.

One overlooked cause of decreased toilet flushing power is a restricted water supply. If the water valves, supply lines, or home plumbing supplying the toilet become partially blocked, it limits the fill valve from receiving sufficient water flow. Ensuring unobstructed water supply is often an easy DIY fix to restore vigorous flushing.

Signs of Restricted Water Supply

Here are some signs that decreased water supply could be contributing to your toilet’s poor performance:

- Weak, sluggish flush and swirl

- Low water level in tank

- Toilet takes longer than normal to refill

- Other fixtures have low pressure

- Kinked or bent supply lines

If you spot these issues, inspecting and cleaning the toilet water supply can quickly get your flush flowing fully again.

Checking for Shutoff Valve Blockages

Examine the water supply shutoff valve behind the toilet. Disconnect and inspect the water supply line. Clean out any debris clogging the valve inlet or supply line. A partially closed valve can also restrict flow.

Clearing Clogged Supply Lines

Detach the supply line from the toilet tank and flush it out over a bucket. Swish water back and forth to dislodge any sediment. Use a wire coat hanger to fish out debris stuck inside the line.

Unkinking Supply Line

Carefully bend and straighten any kinks or bends in the supply line. Kinks can gradually form over time, obstructing water flow. Replace if line if it remains buckled after straightening attempts.

Checking Main Shutoff Valve

Inspect the main water supply shutoff valve where water enters your home. Clear out any stuck debris at this point closest to the city water supply. Verify the valve is fully open.

Other Causes of Weak Flushing

While restricted water can cause reduced flush power, other issues may also be to blame:

- Clogged trapway or drain pipes

- Warped, leaking flapper valve

- Sediment or mineral buildup

- Damaged fill valve

- Leaky tank

Systematically inspecting the whole toilet identifies the specific deficiency affecting performance. Adequate water supply is essential for creating a strong siphon during flushing.

Don’t tolerate weak, frustrating flushes that fail to clear the bowl. Checking for clogged valves, kinked hoses, and closed taps ensures your toilet gets the unobstructed water flow needed for powerful flushing.