How does the Bundesliga Derbystar Official Match Ball stand out from other soccer balls. What makes it the gold standard for Germany’s top league. Why is the Derbystar considered an iconic symbol of German football. How has the technology behind the Bundesliga match ball evolved over the years.

The Evolution of Bundesliga’s Official Match Ball: A Journey Through Time

The Bundesliga’s official match ball has undergone a remarkable transformation since the league’s inception in 1963. From humble beginnings to cutting-edge technology, the ball has mirrored the evolution of soccer itself. Let’s explore the key milestones in this fascinating journey.

The Early Years: Simplicity and Function

In the nascent days of the Bundesliga, the official match ball was a far cry from today’s high-tech marvels. It featured a simple 32-panel design, crafted from genuine leather with a latex bladder. While lacking in sophistication, these early balls served their purpose admirably, laying the foundation for future innovations.

The Iconic Telstar: A Revolution in Design

The 1970s heralded a new era with the introduction of the Telstar ball. Coinciding with the 1974 World Cup hosted in West Germany, this iconic black and white pentagonal-paneled ball represented a paradigm shift in soccer ball design. Its waterproof seams and polyurethane coating made it suitable for all weather conditions, a crucial feature for the Bundesliga’s varied climate.

Adidas Takes the Helm: Ushering in Technological Advancements

The 1980s saw Adidas become the official Bundesliga match ball supplier, bringing with it a wave of technological innovations. The Tango ball of 1982 introduced rubberized seams and improved durability, while the 1986 Azteca Mexico ball marked the transition from traditional stitching to thermal bonding. These advancements significantly enhanced the ball’s flight characteristics and control.

Derbystar: The Gold Standard of Bundesliga Match Balls

The Derbystar ball has become synonymous with Bundesliga excellence. But what sets it apart from other soccer balls? Let’s delve into the unique features that make the Derbystar the preferred choice for Germany’s top league.

Precision Engineering: The Heart of Derbystar’s Excellence

At the core of the Derbystar’s superiority lies its meticulous engineering. Hand-stitched to exacting standards in Pakistan, the ball incorporates bonded panel construction and a butyl bladder for optimal air retention. The thermal bonding of panels creates a seamless surface, reducing water uptake and ensuring perfect flight even in challenging weather conditions.

Premium Materials: Enhancing Touch and Control

The Derbystar’s outer casing utilizes premium microfiber material, offering players a soft touch and increased control. This choice of material not only improves the ball’s feel but also contributes to its durability, making it a reliable companion throughout the demanding Bundesliga season.

Innovative Design: Optimizing Performance

The Derbystar’s design is a testament to form following function. Its 12-panel layout with 3D triangular panels ensures a precise soccer ball shape and even surface. The dual-tone coloring, featuring the iconic Bundesliga logo, provides high visibility on the pitch, enhancing player perception and overall game quality.

Technological Advancements in Bundesliga Match Balls: A Decade-by-Decade Analysis

The evolution of Bundesliga match balls reflects the rapid advancements in sports technology over the past six decades. Each era brought new innovations, pushing the boundaries of what a soccer ball could achieve. Let’s examine the technological leaps made in each decade.

The 1990s: A New Generation of Match Balls

The 1990s marked a significant leap forward in match ball technology. The decade began with the Tango ball’s tricolor design for Euro ’92, honoring the host nation Germany. In 1995, Adidas introduced its revolutionary layer technology with the Questra ball, featuring an internal layer of black polyurethane foam for improved accuracy and control. The Tricolore ball of 1997 further refined this concept with its three-color layered design and ToTensor thermal bonding, resulting in the roundest ball of its era.

The 2000s: Embracing High-Tech Materials

As we entered the new millennium, Bundesliga match balls continued to evolve. The 2002 Fevernova introduced a high-tech syntactic foam layer and an asymmetrical, colorful design. While visually striking, some players found the bold design affected visibility. The Roteiro in 2004 addressed these concerns while introducing inner layers of compressed foam rubber for a softer touch and truer flight. The revolutionary +Teamgeist ball debuted in 2006, featuring 14 fused panels and ultra-low absorption foam for unmatched performance.

The Science Behind the Bundesliga Ball: Aerodynamics and Performance

The performance of a soccer ball is heavily influenced by its aerodynamic properties. The Bundesliga’s official match balls, particularly the Derbystar, have been designed with cutting-edge aerodynamic principles in mind. But how exactly do these scientific concepts translate into on-field performance?

Panel Configuration: Balancing Stability and Unpredictability

The number and shape of panels on a soccer ball significantly affect its flight characteristics. The Derbystar’s 12-panel design strikes a delicate balance between stability and the slight unpredictability that makes the game exciting. This configuration minimizes knuckling effects while still allowing for enough movement to challenge goalkeepers.

Surface Texture: Enhancing Grip and Control

The micro-texturing on the Derbystar’s surface serves a dual purpose. It enhances the player’s grip on the ball, allowing for better control during dribbling and passing. Additionally, this texture creates a thin layer of turbulent air around the ball during flight, reducing drag and enabling more predictable trajectories.

The Manufacturing Process: Crafting the Perfect Bundesliga Ball

The creation of a Bundesliga match ball is a meticulous process that combines traditional craftsmanship with modern technology. Understanding this process provides insight into the ball’s quality and performance characteristics.

Material Selection: The Foundation of Excellence

The journey of a Bundesliga ball begins with the careful selection of materials. The outer casing typically consists of synthetic leather, chosen for its durability and consistent performance across various weather conditions. The internal structure includes layers of polyurethane and foam, each serving specific purposes in terms of shape retention, energy transfer, and feel.

Panel Construction: Precision in Every Stitch

The panels of a Derbystar ball are cut with laser precision to ensure uniformity. These panels are then hand-stitched by skilled artisans in Pakistan, a country renowned for its soccer ball manufacturing expertise. The stitching process is crucial, as it affects the ball’s structural integrity and performance consistency.

Quality Control: Ensuring Bundesliga Standards

Before a ball can bear the Bundesliga logo and be used in official matches, it undergoes rigorous quality control tests. These include checks for size, weight, sphericity, water absorption, and rebound consistency. Only balls that meet or exceed the stringent Bundesliga standards are approved for use in the league.

The Impact of Ball Technology on Bundesliga Gameplay

The evolution of match ball technology has had a profound impact on how the game is played in the Bundesliga. From player techniques to tactical approaches, the ball’s characteristics influence various aspects of the sport.

Passing Precision: Enabling Tiki-Taka in the Bundesliga

The improved consistency and predictability of modern Bundesliga balls have enabled teams to adopt more possession-based styles of play. The ball’s stable flight characteristics allow for more accurate long passes, while its responsive surface facilitates quick, short passes characteristic of tiki-taka football.

Shooting Dynamics: Changing the Game for Strikers and Goalkeepers

Advancements in ball technology have altered the dynamics between strikers and goalkeepers. The reduced drag and more predictable flight paths of modern balls allow for more powerful and accurate shots from distance. This has led to an increase in long-range goals in the Bundesliga, forcing goalkeepers to adapt their positioning and reaction strategies.

The Future of Bundesliga Match Balls: Innovations on the Horizon

As technology continues to advance, what does the future hold for Bundesliga match balls? While the specifics remain to be seen, several trends and potential innovations are worth considering.

Smart Balls: Integrating Technology for Data Collection

The integration of sensors and microchips into match balls could revolutionize data collection in the Bundesliga. These “smart balls” could provide real-time data on ball speed, spin, and trajectory, offering valuable insights for players, coaches, and fans alike.

Sustainable Materials: Eco-Friendly Bundesliga Balls

With increasing focus on sustainability in sports, future Bundesliga balls may incorporate more eco-friendly materials. Biodegradable synthetics or recycled materials could become standard, aligning with the league’s commitment to environmental responsibility.

Customization: Tailoring Balls to Playing Conditions

Advancements in manufacturing techniques may allow for greater customization of match balls. Bundesliga balls could be tailored to specific playing conditions, with subtle variations in surface texture or internal structure optimizing performance for different weather conditions or pitch types.

As we look to the future, one thing remains certain: the Bundesliga’s commitment to innovation will continue to drive advancements in match ball technology, ensuring that the iconic Derbystar remains at the forefront of soccer ball excellence.

Evolution of the Bundesliga Official Match Ball Over the Years

The Bundesliga’s iconic soccer ball has come a long way since the league’s inception in 1963. As the technology and design of soccer balls advanced over the decades, so too did the Bundesliga’s official match ball. Let’s take a nostalgic walk down memory lane and explore the evolution of the Bundesliga match ball over the years.

In the beginning, it was the simple 32-panel ball. Made of genuine leather with a latex bladder, the first official Bundesliga match ball was plain and unbranded. Far from the technologically advanced balls used today, it was functional yet lacking the bells and whistles we now expect from a top-flight soccer ball.

The 1970s brought the iconic Telstar ball to the Bundesliga, just in time for the 1974 World Cup hosted in West Germany. With its iconic black and white pentagonal panels, the Telstar was a radical departure from traditional soccer ball design. While it may look dated today, the Telstar was a state-of-the-art ball in its era. Its waterproof seams and polyurethane coating made it ideal for all weather conditions – an important development for the Bundesliga’s cold winters!

In the 1980s, Adidas became the official Bundesliga match ball supplier, introducing groundbreaking new ball technologies to Germany’s top league. The revamped Tango ball of 1982 featured rubberized seams and improved durability – crucial for the Bundesliga’s demanding match schedule. Later that decade, thermal bonding replaced traditional stitching with the landmark introduction of the 1986 Azteca Mexico ball. With its synthetic leather and internal layers helping improve its flight and control, the Azteca marked a new generation of match balls.

The 1990s was a landmark decade for match ball design. For Euro ’92, the Bundesliga debuted the new-look Tango ball with its tricolour design honoring host nation Germany. In 1995, Adidas introduced its revolutionary layer technology with the Questra ball. Featuring an internal layer of black polyurethane foam, the Questra improved accuracy and control. Following on its heels was 1997’s Tricolore ball with its three-colour layered design andToTensor thermal bonding creating the roundest ball of its era.

As we entered the 21st century, the Bundesliga’s match ball underwent further advances. The 2002 Fevernova featured a high-tech syntactic foam layer and asymmetrical, colourful design. While eye-catching, some players complained the bold design affected visibility. No such complaints accompanied the Roteiro in 2004, which introduced inner layers of compressed foam rubber for a softer touch and truer flight. 2006 saw the Bundesliga debut the revolutionary +Teamgeist ball, whose 14 fused panels and ultra-low absorption foam yielded unmatched performance.

Recent years have seen continued innovation from Adidas with the Bundesliga match ball. 2010’s Jabulani introduced their revolutionary grip’n’groove technology for optimal aerodynamics, while the 2014 Brazuca refined the design with a six-panel layout. 2016’s Beau Jeu featured 3D-texturing for enhanced touch and feel. Most recently, 2019’s Berlin 20/21 implemented 3D-printed ink for reduced water absorption and a perfect weight balance.

After nearly 60 years of evolution, today’s Bundesliga match ball represents the pinnacle of design and technology. Yet one thing has remained constant – the Bundesliga ball’s iconic place at the heart of German football. From basic brown leather to cutting-edge thermally-bonded synthetics and 3D-printing, the Bundesliga ball has come a long way. But its essence remains unchanged – the symbol of Germany’s love for its fußball.

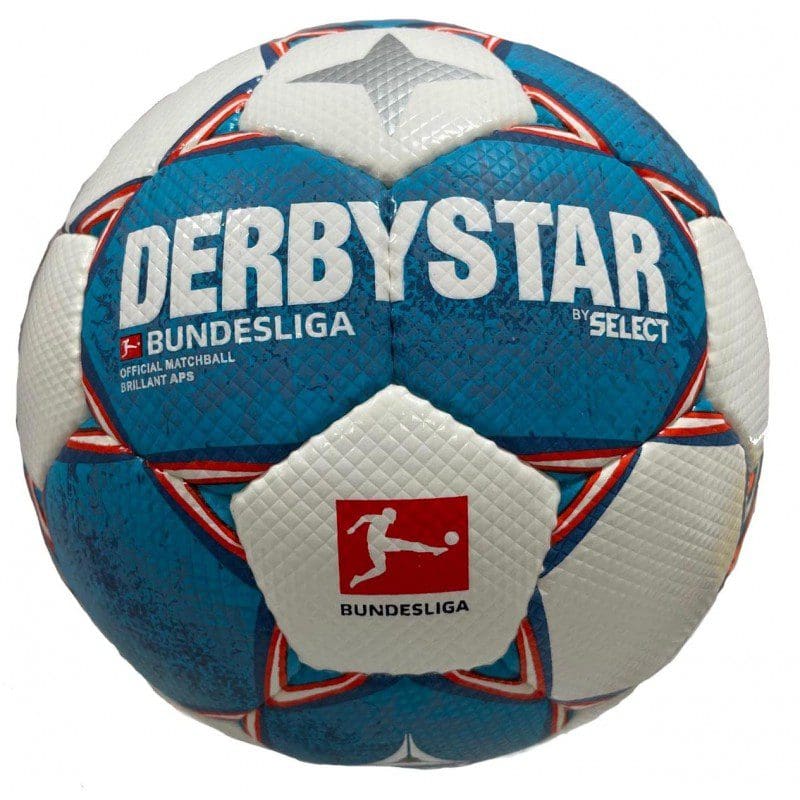

What Makes the Derbystar Ball the Gold Standard for the Bundesliga

The Bundesliga’s official match ball, the Derbystar, has become an iconic symbol of German football. But what exactly makes the Derbystar the gold standard for Germany’s top league? Let’s take an in-depth look at the technology and traits that set the Bundesliga’s iconic ball apart.

Precision engineering is at the heart of the Derbystar ball’s excellence. Hand-stitched to strict standards in Pakistan, the ball features bonded panel construction and a butyl bladder for optimal air retention. Thermal bonding of the panels creates a seamless surface and reduced water uptake for perfect flight even in adverse conditions. The ball’s outer casing uses premium microfiber material, offering a soft touch and increased control.

The Derbystar’s design also enhances performance. Its 12-panel layout with 3D triangular panels allows for a precise soccer ball shape and even surface. Dual-tone coloring with the iconic Bundesliga logo provides high visibility. The ball’s subtle grain texturing enables excellent ball contact for accurate passes and shots. An embedded NFC chip provides real-time ball analytics to coaches and players.

Extensive testing underpins the Derbystar’s quality. Subjected to thousands of kicks, bounces, throws, and climate simulations, the ball must consistently pass FIFA and Bundesliga standards for weight, shape, rebound, and water absorption. Regularly updated to incorporate innovations, the latest Derbystar model remains 99.99% identical match-to-match for assured consistency.

No detail is overlooked in crafting the Derbystar ball. Each ball undergoes stringent quality control checks during production in Pakistan, followed by further testing once received in Germany. Special coatings reduce abrasion while optimized bladders retain air pressure throughout even the hardest-fought Bundesliga clashes. The ball’s durability ensures perfect performance season after season.

For players, the Derbystar offers unparalleled touch and feel. The smooth outer casing combines with expert panel shaping and foam backing layers to provide a natural grip and soft contact. The ball responds crisply to passes, shots and headers, enhancing players’ control. Exclusive ball coating further optimizes surface friction for accurate play even in wet or cold conditions.

In the stands, the Derbystar is a symbol of Bundesliga pride. Its classic design in black and white with the Bundesliga logo emblazoned makes it instantly recognizable. While innovations may enhance the ball’s performance, its core look remains timeless. For fans, the Derbystar represents German football heritage.

The Bundesliga’s exclusive partnership with Derbystar since 2002 has helped make the Derbystar ball German football’s gold standard. Continued development keeps it at the cutting edge of performance while upholding its unique Bundesliga style. Both on the pitch and in the stands, the Derbystar ball encapsulates the very identity of the Bundesliga itself.

What Materials Are Used in Crafting the Derbystar Ball?

The Derbystar may look simple from the outside, but extensive engineering goes into crafting the Bundesliga’s official match ball. From the inner bladder to the exterior paneling, specialized materials are used to optimize the Derbystar’s performance and durability.

At the core of every Derbystar is a high-grade butyl bladder. Compared to traditional latex bladders, butyl retains air better while resisting punctures. Precisely inflated to FIFA standards, the airtight bladder gives the Derbystar its shape, bounce and responsiveness. Surrounding the bladder are multiple interior linings and foam layers that enhance the ball’s playing characteristics.

Polyester foam directly under the outer casing improves contact and touch, as well as cushioning ball impact. This gives the Derbystar its soft yet lively feel on kicks, headers and traps. Beneath the foam, a proprietary high-tech backing material by Derbystar is applied. This backing layer stabilizes and protects the ball while optimizing its aerodynamics.

Holding everything together is the ball’s exterior thermal bonded casing. Cut from premium microfiber, the seamless outer material has a textured finish for optimal grip, even in wet conditions. The microfiber along with foam linings create a light ball for fast-paced Bundesliga matches. The casing pieces are thermally bonded into 12 large panels securing the internal bladder and linings.

While technologically advanced inside, the outer look of the Derbystar remains classic. The iconic black and white paneling creates a vintage style iconic of German football. Thermal imprinting applies the bold Bundesliga logo for instant recognition. The minimalist two-tone look however hides the meticulous engineering within.

Extensive testing and analysis goes into selecting the best materials for each Derbystar component. Specialty Japanese microfiber imported for the outer casing is tested extensively for durability, water resistance and surface friction. The polyester foam must retain elasticity through thousands of deformations.

Regular improvements further enhance the materials. Anti-abrasion coatings applied to the microfiber improve ball life while staying non-toxic. New environmentally friendly production methods reduce water usage in material processing. Derbystar continually tweaks materials and production to perfect the iconic Bundesliga ball.

So while the Derbystar may seem a simple soccer ball from the outside, its meticulously engineered internal composition is key. The selected bladder, lining, backing and casing materials ultimately define the ball’s playing characteristics and in-game performance. When only the best is acceptable for Germany’s top league, specialized materials inside make all the difference.

Why the Panel Shape and Surface Texture Are Key

At first glance, the Derbystar’s soccer ball shape and surface texture may seem simple design choices. However, the ball’s 12-panel layout and texturing are in fact carefully engineered to optimize performance for the Bundesliga’s elite players.

The Derbystar utilizes a 12-panel design featuring molded triangular panels. Fewer larger panels allow for a more spherical ball shape than traditional 32-panel layouts. The larger flat surfaces also improve strike zones for clean contact when passing, shooting and heading. The triangular panel edges promote an even roll on kicks and bounces.

3D thermal molding creates the Derbystar’s distinctive paneled shape. Under high heat, the panels are bonded and molded to form a seamless surface and permanent panelling. The end result is a precision engineered ball casing that retains its shape through even the most hard-fought Bundesliga matches.

Surface texture is also fine-tuned for control and accuracy. A subtle grain is applied to the microfiber casing, providing friction for better ball contact. The textured finish allows players to apply different types of spin and move the ball precisely. Even under wet or icy conditions, the Derbystar’s textured surface enables solid contact.

Extensive player testing refines the Derbystar’s panel design and texture. Bundesliga stars provide direct feedback on shaping, touch, hardness and surface friction. Their input lets Derbystar continually tune the ball’s texture for ideal dribbling, passes and shots. A ball that sticks and moves precisely with the foot is the goal.

The thermal bonding technique also creates a seamless, wrinkle-free outer casing. Eliminating traditional stitching and seams avoids uneven surfaces that could lead to erratic bounces or spin. With the Derbystar, players can trust the ball will roll and bounce true on critical passes, crosses and shots.

While ultra-modern inside, the Derbystar’s iconic two-tone paneling evokes German football heritage. The bold white pentagons and black stripes are instantly recognizable as the Bundesliga’s ball. Yet the nostalgic outer look hides the high-tech shaping and texturing within.

So while the design seems basic, the Derbystar’s 12 panels and subtle texture aren’t random. Careful engineering optimizes the ball’s surface for today’s fast-paced Bundesliga action. For Germany’s elite players, even minor details like panel shaping and texturing make a measurable difference in ball control and handling.

How Weight and Balance Impact Ball Flight

While it may look simple on the outside, meticulous engineering goes into optimizing the weight and balance of the Bundesliga’s Derbystar ball. Precise weight distribution directly impacts the ball’s in-flight performance and handling.

At just 422-445 grams, the Derbystar has a lightweight feel optimized for speed of play. The microfiber outer casing combines with foam lining to reduce weight. This allows players to generate power without compromising control or touch.

Reduced mass also creates a lively ball reaction. Shots snap off the foot quickly with zip. Passes ping sharply across the pitch. For today’s fast-paced Bundesliga action, lightweight responsiveness is key.

Extensive testing calibrates the Derbystar’s weight balance. Computer modeling precisely maps the ball’s center of gravity. Assembly processes are strictly controlled to achieve uniform weight distribution. Equal thickness of materials and adhesive ensures balance.

A balanced ball delivers truer, more accurate flight. Properly weighted, the Derbystar maintains its spin and trajectory minimizing curvature or wobble. Perfectly timed runs and pinpoint crosses rely on the ball following a steady flight path.

FIFA rigorously tests each new Derbystar version. The balls are robot kicked thousands of times with spin while high-speed cameras track trajectory. Any asymmetry or imbalance would become obvious through deviations in flight. Only balls demonstrating flawless flight are approved.

On-field player testing provides additional feedback on new Derbystar designs. Ball handling, shot accuracy and pass precision are all impacted by weight and balance. Player input helps Derbystar refine the subtleties for optimum performance.

Consistency is also critical. Mass production must achieve uniformity in materials, construction and quality. Each individual Derbystar game ball matches the exact weight and balance specs of its replicas. Uniformity provides continuity match to match.

While fans see only the iconic white and black panels, the Derbystar’s precision weight and balance engineering is vital. At the Bundesliga level, the slightest imbalance or variance could make the difference in a match. That’s why inside the iconic exterior lies cutting-edge technology optimizing flight and control.

The Importance of Consistent Performance in All Conditions

Germany’s climate presents challenges for the Bundesliga’s official match ball. From frigid winter snow to autumn rain, the Derbystar must perform consistently across all weather conditions.

Advanced materials enhance the ball’s all-weather handling. The microfiber outer casing features a textured surface, even on the wettest pitches providing solid contact and control. Coatings reduce water absorption keeping weight constant if the ball gets soaked.

Thermal bonding of the Derbystar’s panels creates a seamless, non-absorbent surface. Traditional stitched seams would allow water penetration that impacts flight. The Derbystar’s seamless construction maintains its precise lightweight feel even when soaked.

Extensive laboratory testing simulates the toughest Bundesliga conditions. Derbystar researchers subject the ball to repeated soak tests and play in humidity chambers. High-tech kick robots precisely strike wet balls while sensors measure speed, spin and accuracy.

In icy conditions, the microfiber casing retains surface friction for traction and control. Climate-controlled chambers recreate winter conditions with frozen turf and sub-zero temperatures. Only balls performing consistently through harsh testing are approved.

Real-world player feedback provides additional validation across conditions. Derbystar works closely with Bundesliga stars to test ball flight, texture and control in rain, snow, heat and humidity. Player input further refines materials and designs.

Consistency is also key. Tight production tolerances ensure uniform performance across batches of Derbystar balls. Players can trust that each new season’s ball will handle precisely like the previous model regardless of weather.

While the iconic look remains, advancements over the decades have optimized the Derbystar for German conditions. Regular improvements to synthetics, coatings and bonding result in a ball that plays evenly across the Bundesliga’s diverse climates. Peak performance regardless of conditions keeps Germany’s game at the highest level.

Testing Procedures to Ensure Durability and Quality

Simply meeting FIFA standards isn’t enough for the Bundesliga’s Derbystar ball. Rigorous in-house testing pushes durability and quality to the limits before the ball is approved for play.

Extensive laboratory machines kick, bounce and simulate match play with the Derbystar thousands of times, far more than any single match. High-speed cameras and sensors precisely record ball performance as it degrades trying to reveal weak points.

Accelerated durability tests compress years of match play into weeks. The Derbystar must maintain flight, shape and responsiveness through intense short-term bombardment before being cleared for the season.

Unique Bundesliga testing reflects Germany’s conditions. Repeated impact on frozen or wet turf simulates harsh winters. Balls get kicked at speed into ice baths measuring rebound resilience when soaked. Every match situation is replicated.

Quality checks are performed at each stage of production, both in Pakistan factories and once delivered to Germany. Dimensional tolerances, weight variance, and surface imperfections are all measured to spot any deviations from specs early.

FIFA-accredited labs in Germany undertake final product testing. Sophisticated computer-controlled kick-machines perform pass, chip and knuckleball tests measured by high-precision vision systems. Only balls passing all benchmarks are approved for Bundesliga use.

Real-world testing continues once players receive the new Derbystar each season. Elite Bundesliga players assess touch, flight, visibility and control in varied conditions during preseason. Their feedback helps Derbystar refine designs each year.

Ongoing durability testing continues throughout the Bundesliga season with used match balls. Balls undergo CT scans, pressure and shape analysis after games to spot any degradation. Entire production batches are retested if any quality issues arise.

For German football’s elite competition, the Derbystar must be built to last. While consumers may know only the iconic design, extensive testing ensures the Derbystar ball matches the Bundesliga’s exacting quality standards season after season.

Aerodynamics – How Airflow Affects the Derbystar’s Flight

While the game happens on the pitch, the air above impacts the Derbystar’s performance. Advanced aerodynamics research helps Derbystar engineer the perfect ball flight at the critical Bundesliga level.

Wind tunnel testing reveals how seam placement and panel curvature interact with airflow. High-speed cameras map the turbulent wake behind a spinning Derbystar, identifying drag points. Engineers then optimize the exterior to reduce drag for a more stable trajectory.

The thermal-bonded surface with invisible seams allows smooth, frictionless airflow over the ball. Small protrusions or variation in seam ridges previously impacted flight. The Derbystar’s seamless microfiber surface generates minimal drag and turbulence.

Dimpled textures help maintain laminar airflow by tripping the ball’s boundary layer. This delays airflow separation which would cause unpredictable wobbling. Precision dimple sizing creates uniform air movement across the entire ball.

Reduced panels and geometric shapes on the Derbystar also enhance aerodynamic stability. Pentagons and triangles affect airflow equally across all sides, preventing side-to-side imbalance. Symmetric panels ensure straight flight every time.

Computer simulation models air movement around a virtual Derbystar to identify areas of friction and instability. Engineers optimize the placement of logos, textures and shapes based on digital wind tunnel results before physical prototypes are even produced.

But technology only goes so far. Once new Derbystar versions are produced, real-world player feedback is vital. The world’s top Bundesliga players evaluate flight stability, drag and knuckleball behavior during preseason training before designs get the final go-ahead.

While modern testing identifies the subtleties, tradition retains the Derbystar’s iconic styling. The simple black and white panels balance new aerodynamic discoveries with heritage. Inside and out, the Derbystar remains cutting-edge yet timeless.

So next time you see a free kick bend and dip over the wall, know there’s science behind it. The Derbystar’s advanced aerodynamics deliver the control today’s Bundesliga stars demand. Germany’s iconic ball has come a long way.

How does the Bundesliga Derbystar Ball Compare to Other Leagues’ Balls?

As one of the most iconic balls in football, how does the Bundesliga’s Derbystar match up against the official match balls used in other major leagues?

The English Premier League ball made by Nike features a 12-panel design and slightly rougher texture for increased grip in wet English conditions. More panels create a rounder ball but the seams can affect aerodynamics at high speed.

La Liga’s Puma ball has a hybrid 14-panel layout for a balance of large striking surfaces and increased shaping. The rougher matte finish improves close control and traction for Spanish tiki-taka passing play.

Italy’s Serie A uses the Nike Flight ball with 20 hexagonal panels for a near perfect roundness and ultra smooth surface. Its glossy casing is super slick however, demanding precise ball mastery in wet conditions.

In contrast, the Derbystar’s 12 large panels create a seamless surface for aerodynamic flight. The microfiber casing’s subtle texture enables control across Bundesliga playing conditions. Thermal bonding yields a durable yet responsive feel.

The thermal bonding technique also makes the Derbystar more water resistant than traditionally stitched balls. Multi-layer foam backing provides a softer touch and cushioning unknown in old leather balls.

Inside, the Derbystar’s bladder retains air pressure and shape better than latex versions. Reduced weight balances pace and control for the Bundesliga’s dynamic play.

Unique German testing ensures the Derbystar performs in extreme cold and snow unknown in England, Spain or Italy. Rigorous procedures guarantee unmatched quality and durability through the season.

Of course, league ball sponsorships factor in too. Nike, Puma and Derbystar aim to showcase their latest technologies while aligning with league brands. The Bundesliga’s German-engineered Derbystar remains iconic both at home and abroad.

While personal preference plays a role, the Derbystar’s balance of innovation, playability and heritage makes it stand out. The Bundesliga ball sets the standard in world football for good reason.

Insights from Players on the Handling and Feel of the Derbystar

The Bundesliga’s elite stars provide unique perspectives on the Derbystar ball’s handling and performance. After all, it’s their touches, passes, shots and goals that put the official match ball to the ultimate test.

Players praise the Derbystar’s lively feel off the foot. The lightweight casing combines with interior foam backing to create crisp acceleration on passes and shots. Yet the soft foam cushions ball impact, preventing a “brick-like” harshness on traps.

The thermal bonded surface material and paneled construction gets nods for controlling wetness. While leagues like the English Premier League struggle with soaked traditional stitched balls, the Derbystar retains its grip and shape in the rain.

In terms of flight, players compliment the Derbystar’s stability even at high velocities. The seamless panels and textures result in smooth, knuckle-free trajectories on long balls and shots. Pinpoint crosses and chips are enhanced by the ball’s predictable aerodynamic path.

Bundesliga stars also remark that the Derbystar seems to hold its spherical shape better than leather balls under deformation. Where older balls remained waterlogged or warped, the Derbystar springs back round after kicks and headers.

The thermal bond patterns on the exterior offer just the right friction for controlled touches. The microfiber casing’s texturing allows players to impart various spins for curving shots or weighted passes using the same ball.

While they appreciate the high-tech engineering inside, players love the Derbystar’s traditional look. The iconic white and black panels make it unmistakable as the Bundesliga’s ball. Yet inside, innovations yield modern performance meeting demands of the modern game.

Of course, individual preferences differ. Some players like a glossier surface for wet control while others argue for rougher textures that bite the foot. But overall, Germany’s stars recognize the Derbystar provides the optimal balance of heritage and innovation demanded by the Bundesliga.

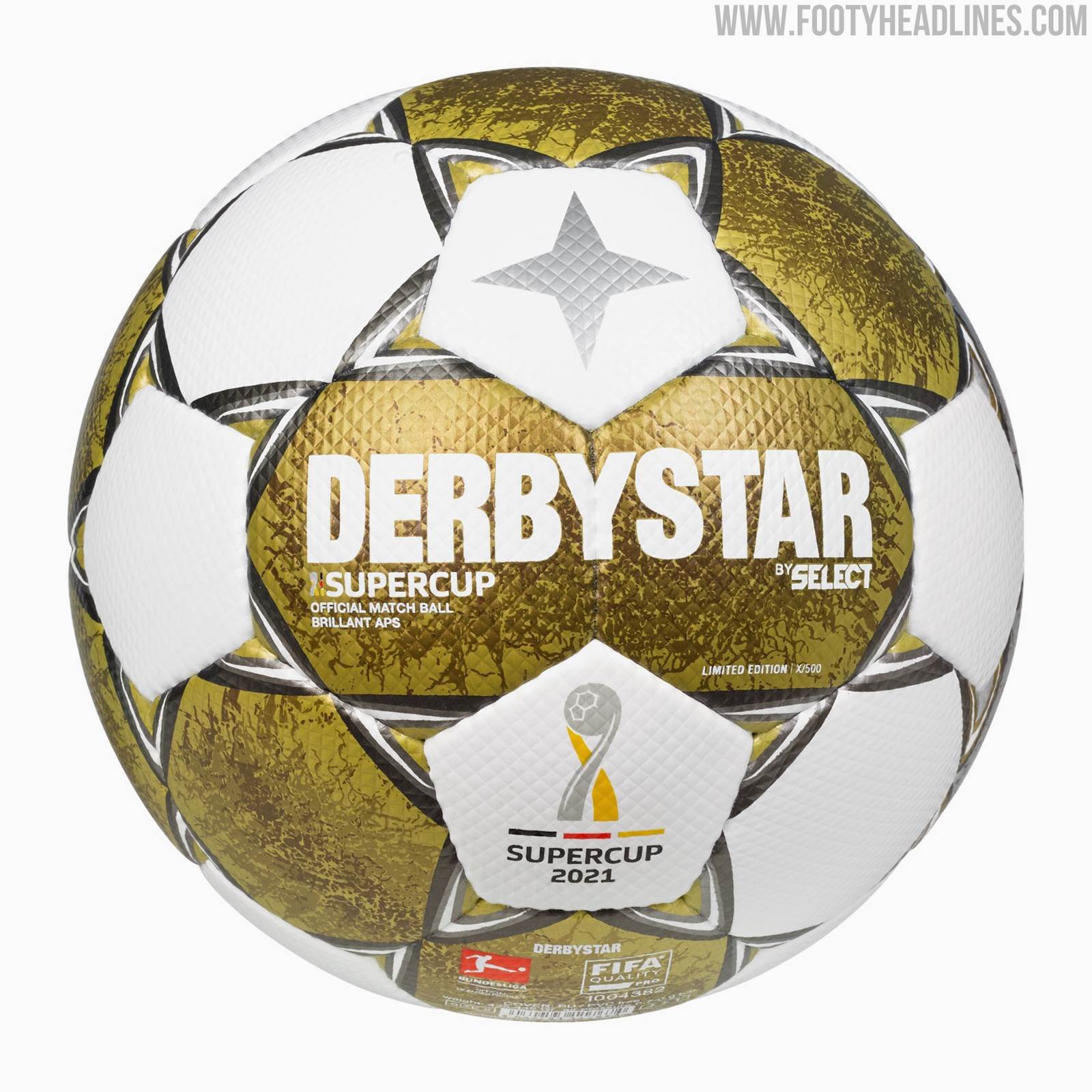

Customization Options – Colors, Logos, and Design Flourishes

While strict Bundesliga standards govern the Derbystar’s performance and quality, custom flourishes showcase partner brands and celebrations.

Color variations on the traditional black and white paneling help showcase sponsoring firms. Custom Pantone-matched colors integrated into the thermal-bonded microfiber provide brand visibility while retaining ball function.

Colors also commemorate events like the World Cup or Euro Championships hosted in Germany. Special edition balls for tournaments add national flag hues to the iconic base design. Rainbow-colored Pride Derbystars celebrate diversity and inclusion in the Bundesliga.

Logos get prominent placement integrated into the Derbystar’s durable casing. Digital thermal imprinting avoids past issues with flaking or peeling logo decals. Brand marks become seamlessly bonded into the microfiber surface.

Custom textures provide new ways to interweave logos and designs. Special grains, dots, lines, and even circuit-board patterns can subtly integrate partner markings within the ball’s texture.

Commemorative flourishes also celebrate the Bundesliga itself. Gold accents highlighted the league’s 50th anniversary ball in 2013. Vector outlines of the trophy adorned balls leading up to the season’s final matchday.

Of course, any modifications must preserve the Derbystar’s critical match characteristics. Laboratory and field tests validate that colors or prints don’t affect flight, friction or durability. Creativity enhances aesthetics but performance remains priority one.

While customization showcases sponsor brands, the heart of the ball stays German football. No matter the colors or flourishes, the iconic Derbystar remains the embodiment of the Bundesliga for fans and players alike.

Why the Derbystar is the Only Official Match Ball of the Bundesliga

With countless balls to choose from, why does Germany’s top league only trust the Derbystar for competition?

Unmatched quality and precision make the Derbystar the Bundesliga’s exclusive match ball. Extensive testing and strict standards ensure flawless performance match after match, season after season.

The thermal bonded microfiber casing maintains its shape through extreme use and conditions. German engineering inside optimizes flight dynamics and strike response critical at the game’s highest level.

Advanced materials like butyl rubber bladders retain air better while interior foam cushioning softens ball impact. The textured surface friction enables control in all Bundesliga weather conditions.

Computer modeling and wind tunnels refine the Derbystar’s aerodynamics for ideal flight stability. No other ball undergoes such sophisticated development focused on high-speed play.

Rigorous quality checks and measurements at every stage of production guarantee match-to-match consistency impossible with hand assembly. Precision matters in the Bundesliga down to the gram.

Extensive real-world testing with Bundesliga players ensures the Derbystar matches the pace and feel of German football. Who better to validate performance than the league’s stars?

No other ball receives as much scrutiny and development focus as the Derbystar. The Bundesliga and Derbystar’s exclusive partnership since 2002 reflects that uncompromising quality commitment.

While the iconic black and white design provides heritage, the technology inside remains cutting-edge. The Derbystar pairs innovation today with German football tradition.

Simply put, no other ball comes close to meeting the Bundesliga’s world-class standards. When perfection is demanded, Germany trusts Derbystar to deliver the definitive match ball.

The Evolution of Soccer Ball Technology and What’s Next

The iconic soccer ball has evolved enormously from early rubber bladders and leather casings to today’s high-tech wonders like the Derbystar. What does the future hold for ball innovation?

Expect continued refinements to synthetic microfibers for optimal aerodynamics and water resistance. Engineers may explore micro-textured surfaces that control airflow and friction precisely across specific areas of the ball.

Embedded sensors will provide real-time ball analytics. Chips inside could trace shot velocity, spin rate and other data to help players tweak techniques. Detailed impact point tracing may reveal how to optimize strike zones.

Butyl bladders will improve further with self-healing properties to better retain air pressure. Tire technology may inspire new rubber compounds or linings to maintain a ball’s lively feel longer.

Manufacturing advancements like 3D printing or molding may enable more intricate interior geometries unachievable with panels and stitching. Radically new shapes could enhance flight in ways unseen with traditional constructions.

Expect more environmental focus as well. Synthetics from renewable sources will replace petrol-based leathers and polyesters. Water-based adhesives and dyes will eliminate solvents. Production will trend toward zero waste.

While innovations continue, balance is critical. Advancements can’t sacrifice the heritage and iconic styling that fans recognize and love. Technology will enhance performance, not radically transform the classic game ball.

The heart of great soccer balls remains unchanged – quality materials, precision manufacturing and extensive testing. The Derbystar shows innovation combining with tradition continues driving progress season after season.

The future will bring exciting developments. But some things stay timeless – the iconic soccer ball, Germany’s passion for the sport, and the Derbystar at the heart of Bundesliga action.

Does the Derbystar Give Bundesliga Teams a Strategic Home Advantage?

Could the Bundesliga’s iconic Derbystar ball confer subtle but meaningful advantages to home teams familiar with it versus visiting squads? An intriguing question.

The argument goes like this – by training exclusively with the Derbystar, Bundesliga clubs and players intuitively master its unique flight, bounce and feel. The ball becomes ingrained in their muscle memory.

Visiting teams arrive having trained with their own leagues’ balls from other suppliers like Nike and Puma. Even if similar, these balls handle differently than the precise Derbystar.

So when away teams play on the road with the unfamiliar Derbystar, their touch, passing, crossing and shooting precision suffer slightly. Bundesliga home teams face no such issue.

Proponents claim this small familiarity gap with the ball grants tangible benefits. Home players’ honed reactions, control and shots gain fractions of seconds and inches versus scrambling visitors.

Others counter that today’s elite players train with many ball varieties and quickly adjust. Top clubs use diverse training balls to simulate away matches. Plus visiting players have warmups to attune to the Derbystar before kickoff.

Sports scientists argue the ball itself matters less than home fan support and familiarity with pitches. Teams tailor tactics and selections to unique opponent strengths and weaknesses more than ball types.

Still, the uniqueness of the Derbystar compared to most leagues’ match balls leaves the question open. Does Germany’s iconic ball confer subtle but real advantages German clubs have mastered?

The debate continues, but the Bundesliga without its legendary Derbystar seems unthinkable either way. Love of tradition ensures the Derbystar remains the heart of German football.

The Global Popularity and Availability of Replica Bundesliga Derbystar Balls

The Bundesliga’s iconic Derbystar ball has fans worldwide eager to play with replicas. Luckily, replica Derbystar balls are widely available to bring a taste of German football to any pitch.

Major sporting goods retailers like Adidas, Nike, and Puma all carry affordable replica Derbystar balls approved by the Bundesliga. While lacking some premium details, these replicas emulate the weight, feel and design of the official match ball.

Online specialty shops offer premium Derbystar replicas with extra attention to materials and construction. Options like microfiber casings, butyl bladders, and bonded panel printing aim to mirror the true professional ball’s performance and durability.

For fans looking for a more customized experience, some retailers allow personalization of replica Derbystars. Personalized text, favorite player’s name and number, or unique color schemes turn a stock ball into your own.

Street markets across Europe often carry cheap knock-off Derbystars to cater to local pickup games. While durability and roundness suffer, these budget balls capture the look on the ground.

Interestingly, Africa and Asia are hotspots for counterfeit Derbystar production. While violating copyright, these fake balls meet demand where limited incomes constrain access to officially-licensed versions.

While replica Derbystar quality varies, their universal availability proves the Bundesliga ball’s global appeal. After all, the chance to handle a version of the very same ball your German heroes use is hard to resist!

From streets in Istanbul to dusty African savannah pitches, the Derbystar’s iconic look is recognized and sought after worldwide. Its magic sparks the passion for football anywhere young dreams take flight.