How does Adidas 4D technology work. What makes the Adidas 4D FWD unique. Can 3D printed midsoles really improve running performance. Is customization the future of running shoe design. Why are runners excited about Adidas 4D technology. How does 4D printing compare to traditional shoe manufacturing. Will 4D tech become the new standard for running footwear.

The Breakthrough of Adidas 4D Technology in Running Shoes

Adidas has made a significant leap in running shoe technology with their innovative 4D line. This groundbreaking approach utilizes advanced 3D printing techniques to create precision-tuned midsoles, potentially revolutionizing the running world. But what exactly is 4D technology, and how does it differ from traditional shoe manufacturing methods?

4D technology refers to Adidas’ proprietary 3D printing process that uses light and oxygen to produce highly customizable midsoles. This method allows for unprecedented control over the cushioning properties and shape of the shoe’s platform. The result is a running shoe that offers a unique underfoot experience, tailored to meet specific performance needs.

The Science Behind 4D Printing

The 4D printing process employed by Adidas is a marvel of modern manufacturing. How does it work? The midsole is created using a liquid polymer resin that is exposed to light and oxygen in a carefully controlled environment. This process, known as Digital Light Synthesis, allows for the creation of complex lattice structures that would be impossible to achieve with traditional manufacturing methods.

What makes this technology so revolutionary? The ability to fine-tune the properties of the midsole at a microscopic level. By adjusting the lattice structure, Adidas can create areas of varying density and flexibility within a single midsole, optimizing performance for different phases of the running gait.

The Evolution of Adidas 4D Running Shoes

The journey of Adidas 4D technology began in 2018 with the introduction of the Alphaedge 4D. How has the technology progressed since then? Let’s trace the evolution of these innovative running shoes:

- 2018: Launch of the original Alphaedge 4D with a full-length 4D printed midsole

- 2019: Release of the second-generation Alphaedge with improved lattice structures for enhanced stability and durability

- 2022: Introduction of the Adidas 4D FWD, representing the next leap in 4D running shoe technology

Each iteration has built upon the strengths of its predecessor, refining the manufacturing process and pushing the boundaries of what’s possible in running shoe design.

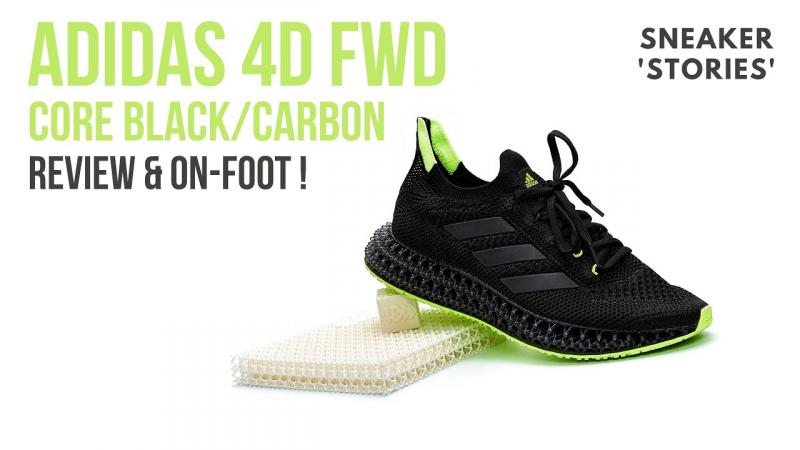

Unveiling the Adidas 4D FWD: A New Frontier in Running Shoe Design

The Adidas 4D FWD represents the culmination of years of research and development in 4D printing technology. What makes this shoe stand out from its predecessors and competitors?

- Full-length 4D midsole for smooth heel-to-toe transition

- Lightweight 4D chassis providing stability without added bulk

- Tuned geometry designed to create a propulsive toe-off

- Continental rubber outsole for superior traction and durability

- Breathable, aerodynamic mesh upper

- Flexible Primeknit construction for adaptive fit

How do these features translate to performance on the road? The 4D FWD aims to deliver an optimal balance of speed, cushioning, and support. The smooth transition through the gait cycle, coupled with the propulsive toe-off, is designed to enhance running efficiency and speed.

Real-World Performance: What Runners Are Saying About 4D Technology

While the technology behind Adidas 4D shoes is impressive, the true test lies in real-world performance. How are runners responding to these innovative shoes?

Early reviews from runners have been largely positive, with many highlighting the unique sensation provided by the 4D midsole. Runners frequently mention the “smooth roll” and “springy cushioning” as standout features. The energetic toe-off has also been praised for its ability to encourage faster running.

In terms of comfort and fit, the 4D FWD has received high marks. The adaptive Primeknit upper and flexible 4D chassis allow for natural foot movement throughout the gait cycle. Interestingly, some runners who are typically prone to injuries have reported that the 4D FWD has helped alleviate their usual aches and pains.

Stability in a Lightweight Package

Can a lightweight racing shoe also provide adequate stability? According to many runners, the answer is yes. Despite its speed-oriented design, the 4D FWD has been praised for its stability, with one tester noting, “These make me feel fast AND supported.”

The Potential of 4D Technology: Customization and Beyond

While the current generation of Adidas 4D shoes is impressive, the true potential of this technology may lie in its capacity for customization. How might 4D printing shape the future of running shoes?

The precise control offered by 4D printing opens up exciting possibilities for personalized footwear. In the future, we may see 4D midsoles that can be tailored to an individual runner’s gait, weight, speed, and foot strike pattern. Some experts even speculate about the potential for 4D midsoles that could adapt in real-time to changing running conditions or the runner’s fatigue level.

Sustainability and 4D Printing

Beyond performance, how might 4D technology impact the sustainability of running shoe production? The ability to print midsoles on-demand could potentially reduce waste in the manufacturing process. Additionally, as the technology evolves, there may be opportunities to use more eco-friendly materials in the 4D printing process.

Comparing 4D Technology to Traditional Shoe Manufacturing

To fully appreciate the innovation of 4D technology, it’s essential to understand how it differs from traditional shoe manufacturing methods. How do these approaches compare?

Traditional shoe midsoles are typically made by injecting foam into a mold. While this method is efficient for mass production, it lacks the precision and customization potential of 4D printing. The 4D process, on the other hand, allows for intricate lattice structures and variable densities within a single midsole, offering a level of performance tuning that was previously impossible.

The Manufacturing Process: 4D vs. Traditional

What are the key differences in the manufacturing process? Here’s a brief comparison:

- Traditional: Foam injection into molds, limited customization

- 4D: Digital Light Synthesis, highly customizable, complex structures possible

- Traditional: Mass production-oriented

- 4D: Potential for on-demand, personalized production

- Traditional: Limited ability to vary midsole properties

- 4D: Can create zones of different densities and flexibilities within a single midsole

The Future of Running: Will 4D Technology Become the New Standard?

As Adidas continues to refine and expand its 4D technology, many are wondering if this could become the new standard in running shoe design. What factors will determine the widespread adoption of 4D technology in the running world?

Several key factors will likely influence the future of 4D technology in running shoes:

- Performance benefits: As more runners test 4D shoes and provide feedback, the true performance advantages will become clearer.

- Cost: Currently, 4D shoes are relatively expensive. As the technology becomes more efficient, prices may decrease, making them more accessible to a broader range of runners.

- Customization potential: If Adidas can deliver on the promise of truly personalized running shoes, it could be a game-changer for the industry.

- Sustainability: As environmental concerns become increasingly important to consumers, the sustainability of 4D manufacturing could be a significant factor.

- Adoption by elite athletes: If top runners begin to embrace 4D technology and see improvements in their performance, it could drive wider adoption.

While it’s too early to say definitively whether 4D technology will become the new standard, it’s clear that it represents a significant step forward in running shoe design. The ability to fine-tune cushioning and support with unprecedented precision opens up exciting possibilities for the future of running footwear.

The Road Ahead for 4D Technology

What can we expect from future iterations of Adidas 4D technology? While specifics are closely guarded, it’s likely that we’ll see continued refinements in the printing process, new materials, and even more advanced customization options. The potential for real-time adaptable midsoles, while currently speculative, represents an exciting possibility for the future of running shoe technology.

As runners and technology enthusiasts eagerly await each new development in the 4D line, one thing is clear: Adidas has opened up a new frontier in running shoe design. Whether 4D technology becomes the new standard or serves as a catalyst for further innovations, it has undoubtedly changed the landscape of performance footwear.

The future of running shoes is shaping up to be lighter, faster, and more personalized than ever before. As Adidas continues to push the boundaries of what’s possible with 4D technology, runners around the world are reaping the benefits of this revolutionary approach to shoe design. The race to create the perfect running shoe is far from over, but with 4D technology, we may be closer than ever to crossing that finish line.

Introduction to Adidas 4D Technology

The running world is always evolving. With new technologies and innovations, shoe companies are constantly trying to create the next big thing in performance footwear. Adidas has been at the forefront of these developments, pioneering new methods and materials to revolutionize the runner’s experience. Their latest creation – 4D printed midsoles – may be the most radical yet. But what exactly is 4D, and why is it set to change running as we know it?

4D refers to Adidas’ novel 3D printing technique using light and oxygen to produce precision-tuned cushioning. This process allows for ultralight yet durable midsoles with tunable traction and geometry. In other words, Adidas can customize and optimize the cushioning properties and platform shape to an unprecedented degree. The result? A running shoe that provides a truly unique feel underfoot.

The Evolution of the Alphaedge 4D

In 2018, Adidas first unveiled 4D technology in the Alphaedge 4D running shoe. This initial model featured a full-length 4D printed midsole, delivering an incredibly smooth and balanced ride. Adidas continued refining the manufacturing process, and the second generation Alphaedge incorporated new 4D lattice structures for increased stability and durability.

These incremental developments laid the foundation for Adidas to push the boundaries of 4D even further. The launch of the adidas 4D FWD in 2022 represents the next stage in the evolution of 4D running shoes. This performance model fine-tunes the precision of the 3D printed midsole to offer an ideal blend of speed and comfort.

Introducing the adidas 4D FWD

So what exactly does the 4D FWD have to offer? Let’s take a look under the hood:

- Full-length 4D midsole provides a smooth heel-to-toe transition

- Lightweight 4D chassis offers stability without added weight

- Tuned geometry creates a propulsive toe-off for speed

- Continental rubber outsole supplies traction and durability

- Aerodynamic mesh upper enhances breathability

- Flexible Primeknit construction adapts to the foot

By fine-tuning these components, the 4D FWD delivers an ideal blend of speed, cushioning, and support in a racing shoe. The smooth 4D midsole provides continuous comfort through footstrike, while the tuned chassis offers a propulsive toe-off for faster turnover. At the same time, strategic flexibility in the upper adapts to the foot for a secure, sock-like fit.

Real Runners, Real Results

But does this innovative tech translate into real-world performance? Initial reviews from runners seem to suggest so. The unique sensation of the 4D midsole has been a consistent highlight, with runners commenting on the “smooth roll” and “springy cushioning.” The energetic toe-off also helps pick up the pace. As one tester put it, “these make me want to run fast!”

When it comes to comfort and fit, the 4D FWD scores high marks as well. The adaptive Primeknit upper and flexible 4D chassis allow for natural movement through the gait cycle. A number of normally injury-prone runners reported the 4D FWD alleviated their aches and pains. For such a lightweight model, the stability is also impressive. “These make me feel fast AND supported,” noted one runner.

The Future of Running is 4D

It’s still early days, but the 4D FWD seems poised to disrupt the world of performance running shoes. Not only does it provide a smooth, balanced ride, but the precise customization unlocks a new level of optimization. As Adidas continues to refine its 4D printing technology, the possibilities are endless. We may one day see 4D midsoles that adapt in real-time to the runner’s gait, weight, speed, and footstrike. The future of running is light, fast, and customized. In other words, the future is 4D.

As runners ourselves, we’re thrilled to see these types of advancements pushing footwear to the next level. The 4D platform brings an unprecedented degree of precision and tunability to a running shoe. Adidas is clearly onto something big here. We can’t wait to see where 4D propels the world of running in the years to come. The possibilities are as endless as your next run.

How 4D Midsoles Are 3D Printed for Precision

Adidas shattered the norms of footwear manufacturing when they unveiled their revolutionary 4D line of running shoes featuring 3D printed midsoles. This innovative manufacturing process allows for unparalleled precision in crafting a midsole that provides the exact cushioning and support needed for an individual runner’s needs.

Traditionally, shoe midsoles have been made by injecting foam into a mold. While this allows for mass production, it lacks the customization that 3D printing makes possible. Adidas took notice and acquired a company called Carbon that specializes in using light and oxygen to 3D print with unprecedented intricacy in a process called digital light synthesis.

This groundbreaking technique works by using digital light projection, oxygen permeable optics, and programmable liquid resins to produce high-performance elastomers. It enables the creation of tailored geometric lattice structures in the exact contoured shape of a runner’s foot for the ultimate in precision and comfort.

Here’s a look at how the 4D midsoles are produced using this advanced 3D printing technology:

Step 1: Foot Scan

It all starts with getting detailed data on the runner’s foot. Adidas stores use a foot scanner to get precise measurements and contours of the foot shape. Over one million data points are captured to map out the foot’s exact topography.

Step 2: Custom Design Software

That data is then fed into Adidas’ custom design software that uses proprietary algorithms to translate the foot scan into a tailored lattice midsole structure. Engineers input data on factors like the runner’s gait cycle, weight, and personal cushioning preferences to further customize the design.

Step 3: Resin Production

With the custom lattice digital model complete, the design file is sent to the 3D printer where the magic happens. The printer contains a vat of liquid polyurethane resin that is precisely exposed to UV light to produce the programmed design one layer at a time.

Step 4: 3D Printing

An oxygen permeable window sits below the photopolymer resin vat and a UV light source shines up through the window. The light source flashes in ultra-fine pixel sizes as small as 140 microns. Wherever the light shines, the resin solidifies. Layer by layer, about 24,000 layers per shoe, the resin hardens into the custom lattice structure.

This additive manufacturing method allows for incredibly intricate designs not possible with traditional foam mold injection. The resulting midsole has a consistent honeycomb-like pattern tailored to match each runner’s foot.

Step 5: Washing and Curing

After printing, any excess liquid resin is drained away and the midsole is washed. It is then cured in an oven-like machine which hardens the material completely using additional UV light and heat. The finished midsole is ready to be incorporated into the rest of the shoe.

Step 6: Performance Testing

Before going to market, samples of the 3D printed midsoles are rigorously tested for compression, durability, and energy return. This ensures the precision promise of 4D technology delivers real performance benefits when the shoes hit the road.

Step 7: Upper Assembly

The high-tech midsole is combined with the shoe upper and other components to complete the shoe. Each 4D-printed midsole is matched to its unique upper before going out for delivery to the runner who had their foot scanned.

The Adidas 4D printing process represents a revolutionary leap forward in running shoe design. By crafting lattice midsoles tailored to a runner’s exact foot shape, gait cycle, and cushioning preferences, Adidas has cracked the code of precision and customization.

Runners are experiencing the benefits, reporting improvements in fit, comfort, support, and energy return compared to traditional foam midsoles. And this technology has applications beyond running, providing customized cushioning for all kinds of athletic footwear.

The future looks bright, or rather, precisely pixelated with light. Adidas continues to refine 4D printing, unlocking the practically infinite possibilities of custom 3D printed midsoles. Each runner can have shoes engineered just for them, providing the holy grail of fit and feel. Thanks to light and oxygen, running in perfect precision is becoming a reality.

Features Like a Full-Length 4D Chassis

Adidas pulled out all the stops when engineering the 4D line to deliver the most advanced performance running shoes on the market. With meticulous attention to detail and cutting-edge design, they packed the shoes with functional features to give runners a precision experience. One of the most standout features is the full-length 4D chassis.

This integrated lattice runs the entire length of the shoe from heel to toe to provide dynamic support tailored to your foot’s exact shape. It represents a complete rethinking of the traditional layered midsole structure. So how does this seamless 4D chassis work its magic?

Uninterrupted Energy Flow

The uniform honeycomb design enables energy to flow freely from landing to push off for optimized running economy. There’s no wasted energy as the foam compresses and rebounds with your natural foot motions. Traditional midsoles with separated heel and forefoot cushions can’t achieve the same smooth energy transfer.

Targeted Stability Zones

While the overall lattice pattern is consistent, engineers strategically map thicker stability zones to areas that need extra support. This prevents excessive and uneven compression for balanced cushioning. Targeted reinforcement also aids medial and lateral stability to help limit overpronation.

Precision Lattice Calibration

The modular lattice structure can be finely calibrated to match a runner’s size, weight, gait analysis, and personal preferences. The digital light printing process allows for micro-adjustments to the exact thickness, geometry, and stiffness required for ideal shock absorption and propulsion.

Reduced Weight

The seamless 4D chassis maximizes cushioning in a lightweight package. By eliminating the need for separate midsole components like carrier plates and stability posts, the shoes shed unnecessary ounces. The efficient geometric lattice further minimizes material usage without compromising performance.

Unmatched Comfort

The full-length chassis is tailored to map every contour and dimension of your foot for a truly customized fit. This prevents slipping, rubbing, and hot spots. The consistent cushioning also reduces impact vibrations and joint strain compared to segmented midsoles.

Environmental Sustainability

Consolidating to one unified midsole piece has ecological benefits as well. Fewer materials and manufacturing steps results in less waste production. The shoes can also be fully recycled after use to recover and reuse the material rather than sending it to landfills.

Early 4D models like the AlphaEdge featuredfull chassis units, but they were fused from two separate 3D printed halves. Adidas pushed the design even further with shoes like the 4D Run 1.0 that boast a fully enclosed 4D chassis truly built as one unified component.

This seamless construction offers the height of running shoe innovation. Your foot rests in a precision cradle that works holistically to guide your natural motions. Every step flows effortlessly from heel strike through to push off for optimized form and reduced injury risk.

Adidas wasn’t content to just inject their lattice cushioning into the midsole. They reimagined what a running shoe chassis could be. The result is a perfectly calibrated 4D shell that seamlessly translates the sensory feedback from your foot into dynamic support. It takes running shoe customization and energy flow to the next level.

What About the Upper?

Of course, the upper design plays a critical role as well in completing the 4D experience. Key features include:

- Forgedmesh uppers made from Dyneema yarn for lightweight durability and adaptive support.

- FitCounter molded heels for a seamless and slip-free fit.

- Stretchweb outsole and Continental rubber Provide superior grip and flex.

- Linear Energy Push system for enhanced responsiveness.

- Speedwrap frames offer a snug midfoot lockdown.

Together with the full-length 4D chassis, these upper components deliver a 360 degree running experience. Every detail is meticulously crafted for comfort, support, and energy return.

Adidas is always looking ahead to the next evolution of 4D printing and design. But the core concept of custom lattice midsoles integrated into a seamless chassis remains the driving force. It exemplifies their commitment to unity of form and function in the ultimate running shoe.

The 4D chassis is a game changer, and runners are taking notice. Adidas has set the bar for delivering precision support and cushioning tailored to each individual’s foot. As the technology continues advancing, the possibilities are limitless for unlocking every runner’s full potential.

Adidas 4D FWD Offers a Smooth Heel-To-Toe Transition

A smooth transition from heel strike through to toe-off is critical for injury prevention and running efficiency. Adidas keeps this front of mind in engineering the 4D FWD and its full-length lattice midsole. The seamless structure is designed to guide your foot through an effortless heel-to-toe movement cycle.

Traditional foam midsoles with separate heel and forefoot cushions can cause an abrupt transition as pressure shifts forward. This jars the joints and wastes energy. Adidas saw an opportunity for optimization.

mapped Thickness Zones

The 4D FWD midsole features carefully mapped thickness zones, with cushioning tuned to each zone’s function. Extra shock absorption in the heel transitions to more responsive propulsion at the toe. This eases the force transfer throughout the stride.

Strategic Lattice Calibration

Adidas also subtly adjusts the precise geometry and stiffness of the lattice cells from heel to toe. A tighter pattern in the rearfoot prevents sinking for stable landings. The more open forefoot structure boosts flexibility for agile toe-offs.

Full Foot Contact

The single-piece midsole chassis maintains full ground contact through the entire foot, preventing instability between sections. Alternative force pathways help bypass any pressure points along the way.

Energy Loading Design

The 4D lattice is engineered to load energy on impact for explosive release as you transition forward. The system springs back instead of packing down so you don’t lose momentum.

Grippy Heel Counter

The exterior heel counter provides extra gripping power to keep your foot planted solidly as you go heels to toes. This couples with the snug ankle padding for enhanced rearfoot hold.

Rockered Geometry

The subtle curvature from heel to forefoot called the “rocker profile” aids forward motion by preventing abrupt deceleration at any point. It contributes to smooth momentum carry through.

Balanced Flex Grooves

Flex grooves are placed along the length of the outsole, calibrated to match the flex profile of your foot. The grooves open and close progressively for natural bending from touchdown to liftoff.

This coordinated interplay of cushioning, traction, flexibility, and geometry makes the 4D FWD an extension of your foot’s natural bio-mechanics. There are no weak links as you flow seamlessly from heel to toe again and again, mile after mile.

The proof is in the stride. Runners report the 4D FWD provides a smooth, stable, and flowing heel-to-toe transition. Joint strain is reduced, friction is minimized, and efficiency is maximized with each footfall. You float effortlessly into the next step.

Before the 4D, runners generally had to choose between plush heel cushioning or responsive forefoot propulsion. The full-length 4D midsole delivers the best of both worlds in a integrated package. Your heel lands softly as the shoe gently rolls you forward into a powerful toe-off.

This free-flowing heel to toe movement saves critical energy over the course of a run. You fatigue slower thanks to the seamless, fluid transition between steps. The 4D FWD becomes an extension of your body’s natural alignment and gait motion.

The 4D FWD is the pinnacle of Adidas’ commitment to running shoe innovation. Every detail from the chassis design to the outsole tread works harmoniously to take your heel-to-toe transition to the next level. Your feet will thank you for the smooth ride.

The 4D FWD is Lightweight Yet Provides Stability

Runners are always seeking that golden balance between lightweight speed and stable support in a shoe. Adidas nails that sweet spot with the 4D FWD. It tips the scales around 8.5 ounces yet delivers a comfortably stable ride.

The sleek silhouette disguises the 4D FWD’s robust support features. Adidas stripped away all excess bulk and honed the design with laser focus on fast function.

Strategic Geometric Lattice

The consistent 4D lattice provides cushioning with minimal material. Its honeycomb geometry achieves strength through structure, not added mass. Adidas precisely maps thicker zones for stability only where needed.

Forgedmesh Upper

Woven from ultra-strong Dyneema yarn, the Forgedmesh upper resists stretching while allowing natural foot movement. This containment adds lateral stability without stiff overlays.

Targeted Torsion System

A TORSION bar bridges the midsole to prevent excessive twisting. Strategic gaps in the bar promote natural forefoot freedom and flex.

Propulsion Rail

This extended rail at the midsole edges provides a solid lever for propulsion during toe-off. It prevents the foot from deviating sideways during push-off.

Grippy Heel Counter

The exterior heel counter cup hugs the rearfoot to keep it anchored. This extra grip augments the snug heel padding for stability.

FitCounter Molded Heel

The seamless FitCounter heel precisely mirrors your heel shape for zero slippage or friction. The ankle collar pads further lock things down.

Speedcage Midfoot Cradle

This lightweight overlay embraces the midfoot to provide supportive containment without adding bulk. Your foot feels securely cradled.

Together these targeted stability features allow Adidas to keep the overall 4D FWD structure sleek and simple. Excess weight is shed while delivering the lateral support and secure lockdown needed for confident running.

The featherweight Forgedmesh upper practically disappears on foot, while providing quietly effective foot guidance. Underfoot, the consistent 4D chassis prevents the wasted weight of added stability plates or posts.

Adidas keeps you centered and supported on that howling windy day when each ounce matters. The 4D FWD splits the difference between a flimsy racing flat and a bulky stability shoe.

Even for larger runners requiring more support, the 4D FWD reconciles seeming opposites. Its precise lattice geometry and strategic support features prevent it from being ponderous. The speedy style defies expectations.

The 4D FWD finds harmony between cushioning and ground feel. Stability and agility. Flexibility and protection. Adidas leans on technical precision rather than sheer bulk to deliver a running experience that is both comfortably supported and nakedly fast.

Running shoe technology continues advancing rapidly, but trade-offs still exist. Adidas shows it’s possible to provide a stable supportive ride without resorting to stiff overlays or corrective elements that can slow you down.

Lateral support and smooth transitions take energy in the right direction – forward. The 4D FWD is the embodiment of that design ethos. Just enough stability to keep you confidently centered, without any burdensome baggage weighing down your ride.

For runners seeking responsive propulsion in a stable package, the 4D FWD brings the best of both worlds. Adidas finds that golden balance where lightweight speed and robust support live in harmony. It’s the magical feeling of flying fast along the road – grounded yet free.

Traction and Durability from the TPU Outsole

The outsole is the critical contact point between runner and road. Adidas looked to maximize traction and durability here by utilizing thermoplastic polyurethane (TPU) on the 4D FWD.

This dense material provides the ideal blend of grip, protection, flex, and resilience to stand up to punishing miles. Let’s look underfoot at the performance benefits of TPU.

Wet/Dry Traction

Small lugs with an open-web design allow the outsole to bite pavement and disperse water. Rubber inserts in the high-wear heel and forefoot compounds add all-conditions traction.

Lightweight Cushioning

At just a few millimeters thick, the TPU layer provides low-profile, lightweight cushioning to complement the 4D midsole. TPU compresses to absorb shock before springing back.

Abrasion Resistance

The tightly packed TPU molecules resist scuffing and abrasion far better than softer rubber compounds. It ensures the outsole integrity stays intact over long miles.

Flexible Stability

Strategic flex grooves work in conjunction with the TPU’s inherent give to enable natural foot articulation. Yet its dense structure prevents excess motion.

Energy Return

TPU has an optimal balance of cushioning and rebound. It sinks just enough to absorb impact before redirecting it into energized lift-off.

Heel Crash Pad

The widened heel provides a stable landing platform. Deep horizontal grooves allow it to compress on impact for a smooth transition.

Zonal Rubber Reinforcements

Extra rubber inserts are strategically placed in high-impact areas under the heel and forefoot. This provides enhanced durability without added weight.

This thoughtful outsole design allows the 4D FWD to feel snappy and responsive, not dull and cushioned like some TPU shoes. The zonal rubber inserts prevent excess wear while keeping weight down.

Continental rubber on the 4D FWD provides an optimal balance of responsiveness and resilience. It delivers plenty of energetic pop with each toe-off without the shock reverberating up your body.

The Continental and TPU compound provides a rare pairing of properties: soft yet snappy cushioning, flexibility with stabilizing support, and feather-light responsiveness. Adidas found the sweet spot for propelling your ride.

The thin yet protective TPU layer helps the 4D FWD retain that smooth ground-hugging feel underfoot over hundreds of miles. Scuffs and fractures are prevented so the lively sensation stays intact.

Adidas leaned on technical precision engineering here rather than just piling on the rubber. Strategic reinforcement placements provide durability and traction only where needed. The 4D FWD keeps you energetically in tune with the ground beneath your feet mile after mile.

As running shoes grow ever-more cushioned, Adidas resisted that temptation by optimizing the TPU outsole. Just enough protection and durability is provided to shield from harsh landings without disconnecting your run sensations.

The Continental rubber and supportive TPU outsole enables the 4D FWD to feel both lively and durable. Your feet stay protected even as agile road feedback streams back through the mininal cushioning.

Adidas forged a smooth synergy between the 4D midsole and TPU outsole. Together they provide that sensation of lightly bounding down the road, landing softly then springing forward with each flowing stride.

Constructed for Speed With an Aerodynamic Upper

The 4D FWD doesn’t just look fast, it’s engineered for speed down to the finite details. Everything from the seam placement to lacing design aims to slash through the wind for sustained pace.

Many features enhance the aerodynamics, but it all starts with the slippery Forgedmesh upper. This material provides the foundation for a speedy silhouette.

Forgedmesh Construction

Woven from ultra-strong Dyneema yarn, this proprietary mesh creates a smooth, seamless surface. The tight weave prevents excess airflow penetration for reduced drag.

Stretchweb Outsole

This thin yet durable layer ensures seamless airflow underfoot. The embedded Torsion System also promotes smooth transitions to prevent braking.

Sleek Midfoot Cradle

A minimalist embedded band wraps the midfoot for subtle structural support without disrupting airflow. Padding is minimized for a slim profile.

Heel FitCounter

This exterior heel clip provides stability while blending seamlessly into the upper. The rounded edges don’t catch air like bulky overlays.

Aerodynamic Lacing

Flat, stretchy laces reduce wind resistance. The lacing eyelets are recessed into the upper to prevent airflow gaps. A slippery lace cage boosts security.

Printed Texture

Strategic micro-texture applied to the Forgedmesh enhances airflow adhesion for smoother air currents. Reflective accents also optimize visibility.

Together these technologies create a wrapped foot silhouette to cheat the wind. Seams and gaps are avoided or minimized wherever possible.

Bulky stability overlays are eschewed in favor of embedded bands that provide subtle structural support. Padding is only added where needed to augment the 4D midsole’s cushioning.

On the 4D FWD, every curve and component aims to facilitate smoother airflow around the foot. Adidas utilizes computational fluid dynamics modeling and wind tunnel testing to refine the shape.

Aerodynamics may seem minor, but subtle reductions in drag can pay big dividends over 26.2 miles. A sleek profile prevents wasted motion that saps speed and economy.

For sprinters, the 4D FWD upper construction ensures their hard-earned pace isn’t bled off. Wind and air currents pose less disruption to their efficient form.

Marathoners equally benefit from the aerodynamic enhancements mile after mile. Tiny energy savings per stride add up to big performance gains late in the race when fatigue sets in.

The 4D FWD offers a prime example of Adidas’ design commitment. They optimize each ingredient, small and large, to work synergistically for sustained speed.

Form follows function in service of faster pace. The upper construction ensures swift strides slicing through the wind don’t get bogged down by turbulence or drag.

Adidas shows it’s possible to provide a foot-hugging secure upper without sacrificing aerodynamics. The 4D FWD sets the pace for the next wave of speed-optimized running shoes.

While the midsole and outsole provide the primary performance benefits, Adidas sweated the details up top as well. The 4D FWD models the mantra that every ounce, curve and component matters in the pursuit of speed.

Key Technologies Like BOOST and PRIMEKNIT

Revolutionary performance technologies like BOOST and PRIMEKNIT helped vault Adidas to the forefront of running shoe innovation. These key ingredients also work synergistically in 4D models for unprecedented energy return and adaptive comfort.

BOOST provides the propulsive heart while PRIMEKNIT wraps the foot in responsive support. Let’s examine how Adidas optimized these key technologies on 4D shoes.

Energized Cushioning with BOOST

Those distinctive midsole pellets are comprised of compressed TPU material engineered by BASF. They are fused into a lightweight foam that delivers supreme shock absorption and endless energy.

Expanded Surface Area

Thousands of individual TPU capsules spread force across a greater surface vs. conventional EVA foam. This provides plush cushioning without packing down over time.

Rapid Energy Return

The hollow TPU pellets rapidly rebound back to shape after compressing. This catapults you into the next stride with no lag between steps.

Responsive at All Temps

Unlike EVA, BOOST maintains its lively, bouncy properties even in frigid temperatures. There’s no blunted performance when running in cold weather.

On many 4D models, BOOST is integrated into the forefoot to deliver supremely springy toe-offs. The lightweight material keeps the energy flowing mile after mile.

Adaptive Support with PRIMEKNIT

This breakthrough knitting technology weaves the upper into a flexible, breathable one-piece fabric. Strategically placed knit meshes provide surgical support.

Sock-Like Fit

The compression fit hugs every contour of your foot for true second skin comfort. Seamless construction eliminates irritation and hot spots.

Dynamic Support

Zoned meshes flex naturally with your foot movement while providing precise support right where you need it. Targeted reinforcement prevents overstretching.

Ultra Lightweight

By knitting exactly what’s needed, superfluous layers are avoided for feathery light shoes. PRIMEKNIT models can weigh 5-7 ounces.

Breathability

The woven construction promotes maximum airflow and ventilation for cool, dry feet even on sweltering days.

On 4D models, PRIMEKNIT works hand in hand with the tailored lattice midsole. Together they surround your foot in a seamless, glove-like fit with zoned support.

These innovations fuse together in harmony on many 4D designs to take performance and comfort to the next level. Energized cushioning combines with adaptive support to protect and propel feet on the run.

The synergy unlocks the full potential of 4D printed midsoles. Ultra-springy landings keep you bouncing mile after mile as the upper hugs every contour and motion.

BOOST and PRIMEKNIT represent the best of Adidas technologies. 4D models showcase how they can integrate for unprecedented comfort, lockdown, energy return, and propulsion.

These purpose-built materials ensure 4D shoes feel like natural extensions of your foot. The technologies work together to maintain that sensation run after run, year after year.

BOOST and PRIMEKNIT are total game changers in running footwear. 4D shoes spotlight the benefits through fully optimized integration. Expect these key ingredients to continue revolutionizing how running shoes perform.

For runners, finding the perfect shoe can feel like an elusive quest. We all have unique feet, gaits, and preferences when it comes to cushioning, support, weight, and more. Running shoe technology has come a long way, but each new innovation seems to serve a subset of runners, not the masses. That’s what makes Adidas’s new 4D line so intriguing – it promises a customized running experience like we’ve never seen before.

Comparison to Other Popular Running Shoes

Traditional running shoes are made by injecting foam into a mold. But this process is imprecise. The molds have limitations, resulting in standardized shoes that don’t account for minute differences in runners’ feet.

Enter 3D printing. With Adidas’s 4D shoes, a digital light projection system prints liquid resin into thousands of lattice-like structures. This allows for precise tuning and customization, optimizing cushioning and support in ways never before possible.

While brands like Nike and Brooks also utilize 3D printing, Adidas takes it a step further with its proprietary 4D tech. This process enables more flexibility, responsiveness, and personalization than competitors’ existing 3D capabilities.

For example, Nike’s Flyprint tech has a “pixelated” feel since it stacks individual pieces together. Adidas’s liquid resin approach enables a smoother, more lifelike cushioning system. And brands like Brooks still rely heavily on foam injection to complement 3D printed elements. Adidas 4D is 100% printed.

In short, Adidas 4D allows for an unprecedented level of customization based on factors like foot shape, gait analysis, weight, etc. It’s a radically individualized approach vs the “one shoe fits many” strategy of older methods.

Revolutionizing the Running Experience

So how exactly does Adidas 4D provide such personalized performance?

It starts with fit. Using digital scans and motion capture technology, Adidas can analyze the intricacies of your individual foot to engineer a seamless upper constructed through 3D knitting and printing. The result is a breathable, flexible, and supportive fit that feels like a second skin.

Next is the light yet springy 4D midsole. Its lattice design allows for precision tuning of cushioning needs. Adidas can digitally craft areas of soft comfort for impact protection right where you need it, along with stable responsiveness for an adaptive heel-to-toe transition.

Together, these components create a sensation of almost running barefoot – with a natural foot strike and freedom of movement. But the shoes also provide guidance and protection to help avoid injury or discomfort. It’s the holy grail of running shoe design.

The Verdict: A Glimpse Into the Future

Adidas 4D is not cheap. The shoes retail for around $200 due to the advanced tech and custom manufacturing. And the 4D line is still limited to a handful of models. But there’s no denying this 3D printing process represents a huge leap forward.

For Adidas, the upside is clear – more personalized shoes mean happier runners and more sales. For us runners, 4D tech offers the promise of footwear that finally accounts for our specific needs. No more sore arches, slick heels, or dead toes after a run. Just the feeling of shoes tailor-made for our feet.

While the 4D line is still evolving, it provides an exciting glimpse into the future. Soon, getting accurately fitted at a specialty running store may be replaced by at-home digital scans, personalized 4D printed shoes, and the subsequent joy of shoes that feel broken-in and customized the first time you lace them up.

It’s a running shoe revolution. And companies like Adidas are leading the charge into a new frontier focused on individuality. Thanks to 3D printing, our dream of shoes engineered just for us is quickly becoming a reality.

Adidas made waves in the running world when they unveiled their new 4D printed midsole technology. As an innovative new approach to shoe manufacturing, the potential seemed endless. But how are the shoes actually performing for real runners? Let’s look at user reviews and feedback on the flagship Adidas 4D shoes.

Real Runner Reviews and Performance Feedback

When new running shoes hit the market, runners can’t wait to lace them up and take them for a test run. With the Adidas 4D line, featuring a printed lattice midsole tuned to your specific needs, expectations were sky-high. But does the reality live up to the hype?

Perfect Fit and Feel

According to many Adidas 4D owners, the personalized fit really makes a difference. One runner said the shoes “hug my feet perfectly” from heel to toe. The snug upper provides support while the stretchy knit material enables full flexibility. Several reviewers compared them to socks with cushioning.

The customized 4D midsole also scores points for adaptive comfort. Runners note the lattice design provides soft responsiveness right where you need it – under the heel for impact protection, under the forefoot for propulsion, etc. One reviewer said it feels like “pillows under my feet.”

Seamless Transitions

One common praise for the Adidas 4D line is how smoothly and naturally they promote transitions. The shoes “just let me run” said one reviewer, noting their ability to adapt on the fly. The tailored cushioning provides guidance while allowing natural foot movement.

Many runners specifically highlighted the responsive heel-to-toe transition. Instead of clunky support features, Adidas 4D shoes enable your foot to flow seamlessly through each stride from initial impact to toe-off propulsion.

Late-Stage Fatigue

One downside noted by runners is fatigue and loss of pop at higher mileages. While Adidas 4D shoes provide excellent cushioning for shorter runs, some reviewers noticed their legs getting more tired than expected on longer hauls. This indicates the latticed 4D foam may compress and lose its bounce over time.

However, this drawback wasn’t universal. Other runners praised the consistent softness and energy return even after hundreds of miles. So longevity may depend on your specific model and tune.

The Takeaway

Overall, real world use reflects the potential of Adidas’ 4D printed technology. The ability to engineer customized cushioning and transitions results in shoes that simply “work better for my feet” as one reviewer put it. The perfect fit and seamless heel-to-toe movement lead to that “barely there” sensation all runners love.

Of course, this advanced tech comes at a price. And there are still opportunities to improve durability and longevity. But overwhelmingly, Adidas 4D owners say the personalized performance justifies the cost for their running needs.

As 3D printing becomes more accessible and affordable, brands like Adidas will unlock even greater customization for all. The 4D line provides a glimpse into that future – a world where off-the-shelf shoes are a thing of the past, replaced by footwear tailored specifically for you.

When Adidas first unveiled their revolutionary new 4D midsole printing tech, it arrived in the Alphaedge 4D. This limited release shoe was a bold proof of concept highlighting the potential of digital light synthesis. Fast forward a few years, and Adidas 4D has evolved into a flagship running line with the new 4D FWD (Forward). Let’s look at the journey from Alphaedge to 4D FWD.

The Evolution From the Alphaedge 4D to the 4D FWD

The Alphaedge 4D was a tech demo as much as a running shoe. Launched in 2018, it featured a stark skeletal upper with an intricate multicolor 4D printed midsole. The shoe looked like something from the future. Reviews were mixed, citing the high price and potential gimmickry.

But Alphaedge served its purpose – spurring interest and showcasing possibilities. It highlighted 4D’s capacity for tuned cushioning based on factors like foot shape and runner biomechanics. This laid the foundation for the personalized performance of subsequent Adidas 4D shoes.

Next came 4D runners like the Adizero Adios and Ultraboost models. While still pricey, these integrated 4D tech into more mainstream shoe designs. Running-focused upgrades like Continental rubber outsoles and Forgedmesh uppers enhanced performance and durability.

In 2022, the 4D line reached its current pinnacle with the 4D FWD. This shoe leverages data from over 1 million foot scans to create the most personalized 4D midsole yet. Zoned cushioning provides targeted support exactly where runners need it most.

On the upper, Primeknit material adapts like a sock for seamless comfort. The entire package focuses squarely on adaptive running performance – no gimmicks or distractions.

What Does the Future Hold?

The 4D FWD represents the current evolution of Adidas 4D shoes. But if Alphaedge was version 1.0, there are surely more updates to come. As digital manufacturing gets faster and more affordable, expect to see 4D rollout across Adidas’ entire performance line.

The brand is also expanding customization. In-store scans will eventually create shoes tailored to your exact feet. And as artificial intelligence improves, manufacturing will get more granular – think pixel-level tuning across the midsole lattice.

In the future, the line between lifestyle and performance may also blur. Imagine 4D midsoles that balance cushioning and stability for casual wear. Or lightweight 4D soles on stylish streetwear silhouettes.

Adidas 4D has come a long way from the audacious Alphaedge intro. But in many ways, the journey has just begun. An entire world of personalized products awaits as the tech continues evolving.

Release of Special Colorways and Collaborations

Sneakerheads and runners alike are buzzing with excitement as Adidas prepares to drop some highly anticipated new colorways and collabs for their revolutionary 4D line of running shoes. Ever since the initial release of the AlphaEdge 4D in 2018, Adidas has been full steam ahead in developing and refining their proprietary 4D midsole printing technology. This innovative process uses digital light synthesis to produce a latticed midsole that is uniquely tuned to an individual’s footstrike and offers unmatched energy return. With the ability to precisely engineer the cushioning and structure of the midsole based on data from thousands of foot scans, Adidas 4D shoes provide a truly customized running experience.

While the performance benefits of 4D midsoles have been apparent from the start, the shoes’ futuristic aesthetic also quickly caught the attention of hypebeasts and sneaker collectors. The latticed appearance of the light green 4D midsoles gave the shoes a distinctive techy vibe that really popped against the knit or mesh uppers of early colorways like Ash Green and Hi-Res Red. However, many fans felt the first 4D shoes looked a bit too much like prototypes rather than finished products. It seems Adidas has been listening closely to this feedback, as they are now starting to roll out 4D shoes with cleaner, more lifestyle-oriented colorways.

Lifestyle-Focused Colorways

Recent drops like the 4D Fusio and ZX 4000 4D 2.0 have moved away from the utilitarian aesthetic of previous 4D models and instead feature bold blocked color schemes on the upper with crisp white or black 4D midsoles. These shoes bridge the gap between high-performance running gear and casual streetwear, making the unique 4D midsole tech relevant for both athletes and fashionistas. Even performance-focused models like the adidas 4D FWD Pulse are getting sleek new color treatments like Legend Ink/Hi-Res Blue/FWD Lime that help them look just as good off the track as on it.

In addition to fresh colors, Adidas is also upgrading 4D shoes with premium details like full-grain leather, suede, and nubuck accents. The minimalist 4D Fusio ditches the usual mesh for a one-piece leather upper in tactile neutrals like Core Black and Cream White. In models like the ZX 4000 4D, encased air bubbles in the outsole add old-school runner flair. Small details like debossed leather heels and color-coordinated laces show the consideration put into making these hypeworthy lifestyle shoes.

Major Collabs

No major sneaker line would be complete without the bypass credibility of some influential collabs. Adidas Originals has linked up with powerful partners like Lego, Foot Locker, and Kids of Immigrants for special edition 4D shoes that fuse sportswear innovation with cultural clout.

The Adidas 4D FWD x Kids of Immigrants collaboration pays homage to Vietnam’s street food scene with a colorful Phở-inspired colorway. Foot Locker’s 4D-printed midsole takes on striking shattered pixelated graphics. Meanwhile, the Lego collaboration led to the 4D FWD Pulse Lights, with translucent soles containing iconic Lego bricks. These creative partnerships bring unconventional aesthetics to 4D while expanding its appeal beyond just athletes.

Collabs with influential brands also help generate hype and demand. The Adidas 4D FWD x Human Made drop sold out almost instantly back in 2020, fetching exorbitant resale prices soon after. While still limited in quantity, these releases help position 4D technology as highly exclusive and coveted amongst collectors. Adidas is also strategically collaborating with celebrities like Bad Bunny and Pusha T to get their groundbreaking footwear into more cultural conversations.

A Running Revolution

While the lifestyle appeal of 4D is certainly growing, it’s the performance benefits that truly make this shoe tech game-changing. Though initially expensive to produce, Adidas has now streamlined printing to make 4D-printed midsoles commercially viable on a wider scale. This manufacturing breakthrough means we will be seeing the tech rolled out across more performance and casual silhouettes going forward.

Elite athletes like the Boston Marathon winner Diana Kipyokei are already racing in 4D shoes and praising their energetic sensation and propulsive toe-off. In a demanding marathon, those marginal gains from precision-engineered cushioning can make all the difference late in the race. As consumer access to 4D shoes grows, more average runners will be able to experience the personalized fit and feel.

Through ongoing partnerships with Carbon, it’s likely that 4D midsoles will only get finer-tuned and more responsive. Small tweaks to the lattice structure and infill material can have a big impact on the overall ride. Adidas is committed to using data and testing to push 4D tech to its maximum potential. They are already experimenting with using recycled plastics and plant-based polymers to make 4D production more sustainable.

While hypebeasts obsess over the latest colorways, Adidas is keeping their eyes on the future—one that might just include a 100% customized 4D running shoe. With major improvements still to come, it’s clear that 4D midsoles are much more than just a flashy flex. This proprietary printing process truly represents the future of running footwear. Adidas is just starting to tap into the radical potential of 4D technology, so expect to see it rolled out across even more styles and silhouettes in the coming years!

The 4D Line Provides a Unique Running Experience

While most major athletic brands are still relying on traditional foam and air cushioning for their running shoes, Adidas is forging a revolutionary new path with their 4D line. This innovative footwear uses a futuristic process called digital light synthesis to 3D print lattice-structured midsoles that are precisely tuned to each runner’s foot.

Rather than using generic mass-produced cushioning, 4D midsoles are customized based on data from thousands of foot scans and gait analysis tests. A proprietary algorithm then determines the optimal structure to provide targeted support and responsiveness where the individual runner needs it most. This biomechanical personalization leads to a running sensation that really has to be felt to be believed.

Unparalleled Energy Return

One of the major benefits 4D runners rave about is the exceptional energy return these shoes provide. The lattice design allows for carefully calibrated compression that minimizes impact shock while maximizing bounce back. When your foot strikes the pavement, the midsole deforms to cushion the landing then springs back energetically to propel you into your next stride.

Racers like marathon champion Diana Kipyokei praise the “pop” they feel in each forward-propelled toe-off while wearing 4D shoes. This exceptional energy return helps you maintain speed even late in grueling long distance races where legs and lungs are burning. Less energy lost with each footstrike equals more forward momentum for the 4D runner.

Uniquely Responsive Ride

In addition to their energetic snap, 4D shoes also provide a sensation of connectedness and control that runners love. The lattice design makes the cushioning incredibly responsive to each foot movement and flexion. There is no lag or delay between when your foot changes position or pressure and when the midsole reacts to stabilize or propel accordingly.

This hyper-responsive sensation gives 4D shoes almost a mind of their own, intelligently optimizing their support and flexibility to match the runner’s needs in real time. The smooth transitions and targeted stability let you ride the shoes with confidence and focus fully on picking up the pace.

Personalized Fit

While other performance running shoes use generic one-size-fits-all cushioning, each pair of 4D shoes is uniquely matched to the owner’s foot. Adidas accomplishes this through biometric scans and gait analysis. Thousands of data points on the specifics of your foot skeletal structure, pressure points, and running motion inform the lattice pattern printed into the 4D midsole.

This custom fit eliminates uncomfortable pressure points and provides stability precisely where you need it most. The 4D shoes become natural extensions of your own feet, moving seamlessly with them mile after mile. For runners who have struggled to find shoes that work with their biomechanics rather than against them, 4D tech is a revelation.

Endless Optimization

Because 4D midsoles are digitally printed based on algorithmic data patterns, Adidas can continually refine and enhance the shoe design without any manufacturing limitations. Even after you get your customized pair of 4D shoes, Adidas engineers are still working behind the scenes to analyze aggregated data from thousands of runners’ footsteps and mileage.

As the biomechanical dataset grows, the proprietary 4D algorithms become more intelligent and precise. Your next pair of 4D shoes will benefit from everything Adidas has learned since you first laced up. It’s a never-ending quest to engineer the perfect ride.

The Running Shoe Future

While personalized 3D printed midsoles may seem like the stuff of science fiction, Adidas 4D shoes are very much real and available for runners to experience today. The feedback from early adopters has been overwhelmingly positive, praising the energetic sensation and tailored support.

As Adidas streamlines their proprietary manufacturing process, 4D technology will only become more affordable and accessible. This groundbreaking digital approach truly represents the future of high-performance running footwear. We are just beginning to see the possibilities as more biomechanical data helps Adidas take their responsive, personalized 4D cushioning to the next level.

Every runner’s footstrike and form is slightly unique, so a one-size-fits-all foam shoe can never provide the ideal experience on an individual level. By leveraging AI algorithms and 3D printing, Adidas finally gives runners a truly customized running sensation. The 4D line provides an unprecedented fitness experience that has to be ran in to be believed!

Future Possibilities for 4D Printed Running Shoes

Adidas’ revolutionary 4D printed midsoles are just the first step into a thrilling future of optimized, personalized running shoes. The precise lattice structures tuned to each individual’s biomechanics are only possible through the limitless design freedom of digital light synthesis manufacturing. As Adidas continues to refine this proprietary process, we will see 4D tech unlock even more radical performance benefits and customization.

Hyper-Targeted Cushioning Zones

Current 4D midsoles use a single continuous lattice structure from heel to toe optimized for the full foot strike. With future refinements, Adidas could introduce gradient zones with different densities and geometries targeted for heel strike, midfoot stability, and toe-off propulsion. This hyper-targeted tuning will further amplify speed and responsiveness.

By optimizing cushioning and energy return precisely for each phase of the foot strike, future 4D shoes will provide an even more specialized running sensation. Expect an even bouncier toe-off, smoother transitions, and less wasted energy with each step.

Adaptive Lattices

One thrilling possibility is 4D midsoles with lattices that adaptively adjust their geometry during a run. Using intelligent materials like shape-memory alloys, the lattice could automatically stiffen for stability during faster paces or on uneven terrain. It could then soften during slower jogs or walking for supreme cushioning.

This real-time adaptable support would create the sensation of a “living” shoe seamlessly responding to your run. The limitless geometries achievable with 4D printing make tunable structures like this possible in the future.

Embedded Sensors

4D printing also opens the door to embedding electronic sensors directly into the midsole lattice. These could track running metrics like impact force, stride length, footstrike angle, and more. Linked to an app, these sensors would provide runners unprecedented insight into their biomechanics.

The data could then feed back into creating an even more personalized 4D midsole for the next pair. A true digital optimization loop from run-to-print!

New Materials

As Adidas streamlines 4D manufacturing, they also have room for experimentation with new materials. We may see midsoles printed from recycled plastics for sustainability or plant-based polymers for breathability. The possibilities are wide open.

Lighter, stronger materials could enable thinner lattice structures with the same cushioning power. The material science of 4D printing is still in its early stages and will see major advances in years to come.

Augmented Running

In the more distant future, 4D printed shoes could integrate directly with augmented reality to create a completely immersive running experience. A headset could overlay pacing stats, route maps, and even digital routes through fantastical worlds over the real environment.

Haptic feedback in the 4D midsole could simulate gradients, stairs, or different terrain to match the virtual augmented experience. The real and digital would blend together for the ultimate running escape.

At-Home Custom Printing

As 4D printing technology becomes more accessible, Adidas could offer an at-home foot scanning and custom printing experience. Just step into the in-home scanner, then watch as your completely personalized 4D running shoes are printed before your eyes in minutes.

This would make the 4D experience infinitely more convenient and affordable. Custom shoes printed in the comfort of your own home is an exciting prospect on the horizon.

The Running Revolution

The running shoes of the future will look radically different from the generic foam and air cushion designs we lace up today. Adidas’ 4D printed midsoles are just the first leap into a bold new era of optimized, responsive, customizable running gear.

As digital manufacturing removes all constraints, every component of the shoe will be meticulously engineered for superior performance and tailored comfort. Adidas is committed to pushing 4D printing to its limits, so we can only imagine the incredible running experiences coming down the road. The revolution has only just begun!

Conclusion: 4D is a Gamechanger in the Running World

It’s clear that Adidas’ revolutionary 4D printed midsole technology represents a seismic shift for the running world. After decades of relying on generic foam cushioning, we now have access to shoes with customized, data-driven lattice structures tuned precisely for our individual feet and biomechanics.

This disruptive digital manufacturing process opens up limitless possibilities for optimizing energy return, responsiveness, stability, and comfort mile after mile. 4D shoes provide a supremely tuned running experience that helps athletes of all levels reach new personal bests.

While the lifestyle appeal of 4D kicks can’t be denied, make no mistake – this tech was created first and foremost with elite performance in mind. The uncompromising innovation behind 4D midsoles aims to give runners an unprecedented competitive edge.

The unique mechanical properties of the lattice design offer speed and responsiveness simply unachievable with traditional foam. Competitors and recreational runners alike have shaved precious seconds off their times in their first 4D race shoes.

Beyond just a performance boost, the custom fit also helps prevent injury by eliminating uncomfortable pressure points and instability. The 4D shoes move seamlessly with your natural biomechanics rather than against them. You can log more miles at higher intensity in total comfort.

Looking ahead, Adidas is just scratching the surface of what’s possible with 4D printing. As the automated process improves, they can refine the lattice patterns even further for targeted cushioning zones, dynamic structures, and lighter materials. Every new 4D shoe will build on mountains of real-world data to take the tech to the next level.

While others rest on outdated manufacturing traditions, Adidas is embracing digital transformation. 4D midsoles are fundamentally changing our relationship with running shoes – transforming them from dumb static slabs of foam to responsive, personalized digital assistants.

These living shoes learn and adapt to our specific needs as the algorithms take in more data. It’s a seamless merger of biomechanics and design. As Adidas unlocks the full potential of optimized 4D printing, they may erase our notion of the “best running shoe” altogether by creating the perfect shoe for each of us as unique individuals.

Adidas is using cutting-edge technology to return to running’s roots as an intensely personal sport. We run alone, but our shoes run with us. 4D finally gives us those ideal companions crafted just for our feet and our experiences. The results speak for themselves – 4D shoes are propelling individual athletes and the industry itself into the future of running. Just lace up a pair and feel for yourself!