Improve Your Lacrosse Goalie Game With Advanced Mesh TechnologyImprove Your Lacrosse Goalie Game With Advanced Mesh Technology

Engineered Mesh Weaves For Faster Throws

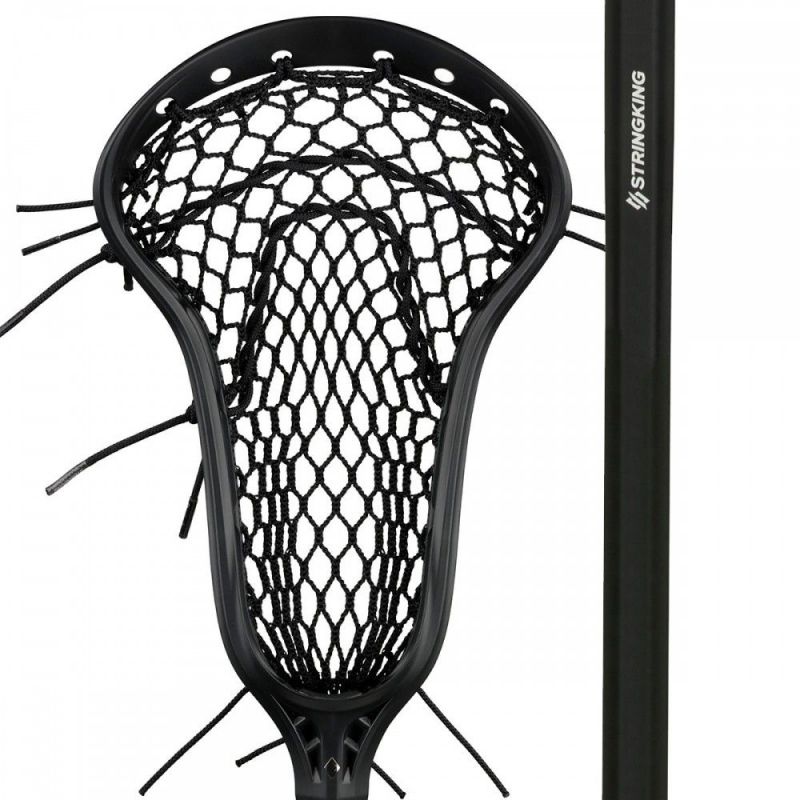

The key to improving your lacrosse goalie game lies in the engineering and construction of the mesh pocket. Advances in weaving technology now allow for mesh that is optimized for control, visibility, and throwing speed. By utilizing novel weave patterns and precision mesh stiffness, engineers can customize goalie pockets for lightning-fast outlet passes.

One of the biggest game-changers is the introduction of diamond-shaped holes in the mesh surface. Unlike traditional square openings, these diamonds drastically improve ball visibility for goalies. The elongated shape gives goalkeepers superior sightlines to track shots in real-time. This enhanced visual feedback allows for quicker reaction times and better save percentages.

Engineers also tweak the stiffness of the mesh to maintain pocket shape after repeated use. Repeated impacts can stretch and deform traditional goalie mesh, reducing throwing accuracy over time. But engineered mesh retains its shape even after hundreds of saves. This consistency leads to precise outlet passes game after game.

The shape of the mesh pocket itself is also optimized for control and speed. Mesh can be woven to create personalized throwing channels that collapse around the ball during passes. This focused control allows goalies to put extra force behind their clears without sacrificing aim. Certain pocket shapes even generate beneficial spin on outlet passes for added velocity. With the right custom woven pocket, goalies can significantly increase clear distances.

Cutting-edge lacrosse mesh combines softness and durability so goalies can make these faster, harder throws without hand pain or injury. Patented weaves absorb heavy ball impacts instead of transferring all the energy to a goalie’s hands. Less vibration means reduced glove sting so goalies can play more aggressively. The days of sore hands after big games are over thanks to modern mesh technology.

By leveraging materials science and intricate manufacturing techniques, engineers create goalie mesh that truly improves performance. Faster, more accurate outlet passes translate directly into better clearing efficiency on the field. With game-changing diamond weave pockets and customized throwing channels, today’s goalie mesh gives players the tools they need to dominate between the pipes.

Strategic Mesh Stiffness Retains Pocket Shape

One of the key engineering challenges in lacrosse goalie mesh is maintaining the ideal pocket shape over time. The repeated impacts from stopping shots can stretch and deform traditional mesh, reducing throwing accuracy after heavy use. But by strategically controlling mesh stiffness, modern goalie pockets retain their shape even after hundreds of saves.

Through extensive R&D, engineers found that overall pocket stiffness is crucial for consistency. Weaving techniques like laminating layers of mesh or integrating stiffener fibers allow for precision tuning of the overall stiffness. The optimal balance between softness for ball control and stiffness for shape retention was discovered. This Goldilocks zone prevents sagging or loosening of the pocket over time.

Regional stiffness is also important across different sections of the pocket. By adjusting the density of stiffening fibers, engineers create firm anchor points across the top and sides of the pocket. This maintains the critical pocket shape and throwing channel geometry after heavy impacts. Strategically reinforcing key stress points maintains pocket integrity.

In addition, intelligent stiffening patterns are used to control stretch in high impact zones. Areas directly in the line of fire, like the bottom portion of the pocket, are woven to be ultra-resistant to deformation. This ensures balls continue to release cleanly during passing and shooting.

Cutting-edge manufacturing techniques even enable adjustable regional stiffness within a single piece of mesh. Stiffness gradients can be built into the mesh to fine-tune performance. This level of engineering customization was unheard of just a few years ago.

Thanks to these advanced stiffening approaches, goalies can rely on consistent throwing behavior over months of play. While traditional pockets would stretch and wear over time, modern engineering keeps pockets throwing true. No more constantly re-breaking in new mesh just to retain that perfect pocket sweet spot.

By leveraging materials science and clever construction, mesh engineers found ways to conquer the consistency problem. Their strategic stiffening solutions enabled measurable improvements in sustained pocket performance. Goalies can now focus on their game rather than worrying about decreasing accuracy as their mesh breaks down.

Customizable Pocket Styles For Any Position

One of the most important modern innovations in lacrosse mesh technology is the ability to fully customize pocket style and shape. Thanks to advanced manufacturing techniques, pockets can be engineered for players of any position to optimize performance.

For lacrosse goalies, pockets are woven to be deeper and wider to improve ball control. The increased pocket volume gives goalies more surface area to contain and cradle shots. This helps improve save percentages even on tricky bounce shots. Wider pockets also reduce unwanted rebounds into the field of play.

Goalie pockets are also optimized for lightning-fast outlet passes. Tight throwing channels collate the ball for fast, accurate clears downfield. Strategic stiffening gives these pockets shape retention after repeated impacts. Consistent throwing behavior improves clearing efficiency.

For face-off specialists, shallow pockets are ideal for scooping ground balls. Less mesh depth improves ground ball handling and clamping. Stiffer sidewalls give fo masters more control when manipulating the ball. Fast, dexterous moves are enabled by this minimalist pocket design.

For attackers, pockets focus on shot speed, accuracy and ball feel. A medium pocket depth with a defined ball ramp pocket is ideal. The ramp improves control and aim on tricky shots like sidearms or behind-the-back attempts. A balanced, consistent release point optimizes shooting efficiency.

Even within positions, customizable options exist. A midfielder may want a pocket optimized for ground balls, passing, or shooting depending on their role and style of play. Defenders can choose more stiffened pockets for textbook clears versus softer mesh for run and gun transition play.

With all these positional and personal preferences, pre-engineered universal pockets no longer cut it. The diversity of pocket shapes and styles today provides players the control to match mesh performance with their on-field needs.

The customization revolution in pocket design is a huge win for lacrosse players. With the right pocket dialed in, athletes can reach peak playing potential. And by eliminating mesh as a variable, the only limitations are a player’s own skills and training.

MeshDurability In All Weather Conditions

Precision-Engineered Stiffness: Maintaining Pocket Integrity

Modern goalie mesh is designed to withstand the rigors of repeated use without losing its shape. Engineers have developed techniques to fine-tune mesh stiffness, ensuring that the pocket retains its optimal form even after hundreds of saves. This consistency is crucial for maintaining throwing accuracy throughout a game or season.

Optimized Pocket Shapes: Unleashing Throwing Power and Accuracy

The shape of the mesh pocket itself has been reimagined to maximize control and speed. Custom-woven throwing channels collapse around the ball during passes, allowing goalies to generate more force without sacrificing aim. Some pocket designs even incorporate features that impart beneficial spin on outlet passes, further increasing velocity and distance.

Comfort Meets Performance: Reducing Hand Strain

Advanced mesh technology doesn’t just improve performance; it also enhances comfort. Patented weaves are designed to absorb heavy ball impacts, reducing the energy transferred to a goalie’s hands. This reduction in vibration and glove sting allows goalies to play more aggressively without the fear of hand pain or injury.

Strategic Mesh Stiffness: The Key to Sustained Performance

Maintaining the ideal pocket shape over time has been a persistent challenge in lacrosse goalie equipment. Modern engineering solutions have tackled this issue head-on, developing strategies to ensure consistent pocket performance throughout a goalie’s career.

Overall Pocket Stiffness: Finding the Goldilocks Zone

Through extensive research and development, engineers have identified the optimal balance between softness for ball control and stiffness for shape retention. Techniques such as laminating layers of mesh or integrating stiffener fibers allow for precise tuning of overall pocket stiffness.

Regional Stiffness: Tailoring Performance Across the Pocket

Different sections of the pocket require varying levels of stiffness to maintain optimal performance. Engineers have developed methods to adjust the density of stiffening fibers, creating firm anchor points across the top and sides of the pocket. This approach maintains critical pocket shape and throwing channel geometry, even after repeated high-impact saves.

Intelligent Stiffening Patterns: Conquering High-Impact Zones

Areas of the pocket that face the most frequent and intense impacts, such as the bottom portion, are woven to be ultra-resistant to deformation. This ensures that balls continue to release cleanly during passing and shooting, regardless of how many saves a goalie has made.

Customizable Pocket Styles: Tailoring Mesh to Individual Needs

The ability to customize pocket styles is a game-changing feature of modern lacrosse mesh technology. This innovation allows goalies to fine-tune their equipment to match their unique playing style and positional requirements.

Adjustable Pocket Depth: Balancing Control and Quick Release

Goalies can now choose from a range of pocket depths to suit their preferences. Deeper pockets offer enhanced ball control and softer catches, while shallower pockets facilitate quicker releases for fast breaks and transition play.

Specialized Throwing Channels: Optimizing Outlet Passes

Custom-woven throwing channels can be tailored to a goalie’s specific throwing motion and preferred release point. This personalization allows for more consistent and accurate outlet passes, improving a team’s clearing efficiency.

Materials Science: The Foundation of Advanced Mesh Technology

The remarkable improvements in lacrosse goalie mesh performance are underpinned by significant advances in materials science. Engineers have leveraged cutting-edge materials and manufacturing techniques to create mesh that truly enhances a goalie’s capabilities on the field.

High-Performance Fibers: Strength Meets Flexibility

Modern goalie mesh utilizes advanced synthetic fibers that offer an optimal balance of strength, flexibility, and durability. These materials allow the mesh to withstand the intense forces of shot-stopping while maintaining the responsiveness needed for quick outlet passes.

Moisture-Wicking Properties: Consistent Performance in All Conditions

Many advanced mesh designs incorporate moisture-wicking properties, ensuring consistent performance regardless of weather conditions or the length of play. This feature helps maintain pocket shape and throwing characteristics even in wet or humid environments.

The Impact of Advanced Mesh on Goalie Training and Development

The advent of advanced mesh technology has not only improved in-game performance but has also revolutionized how goalies train and develop their skills.

Consistent Feedback: Accelerating Skill Acquisition

With pockets that maintain their shape and performance characteristics over time, goalies can focus on refining their techniques without the variables introduced by inconsistent equipment. This consistency accelerates skill acquisition and allows for more effective training sessions.

Reduced Fatigue: Extending Practice Sessions

The improved comfort and reduced hand strain offered by advanced mesh technology allow goalies to engage in longer, more intensive practice sessions. This increased training capacity can lead to faster skill development and improved overall performance.

The Future of Lacrosse Goalie Mesh Technology

As materials science and manufacturing techniques continue to advance, the future of lacrosse goalie mesh technology looks promising. Researchers and engineers are exploring new frontiers to further enhance goalie performance and equipment durability.

Smart Mesh: Integrating Sensor Technology

One exciting area of development is the integration of sensor technology into goalie mesh. These smart meshes could provide real-time data on shot speed, impact force, and pocket deformation, offering valuable insights for training and performance analysis.

Biomimetic Design: Learning from Nature

Engineers are also looking to nature for inspiration, exploring biomimetic designs that mimic the shock-absorbing properties of natural structures. This approach could lead to even more effective impact dissipation and improved goalie protection.

Sustainable Materials: Eco-Friendly Performance

As environmental concerns become increasingly important, researchers are investigating sustainable materials that can match or exceed the performance of current synthetic fibers. This could lead to high-performance goalie mesh with a reduced environmental footprint.

The evolution of lacrosse goalie mesh technology has ushered in a new era of performance and consistency for players at all levels. From enhanced visibility and throwing power to sustained pocket shape and customizable styles, these advancements are empowering goalies to reach new heights in their game. As technology continues to progress, we can expect even more exciting innovations that will further revolutionize the position of lacrosse goalie.

Practical Applications: Integrating Advanced Mesh into Your Game

Understanding the benefits of advanced mesh technology is one thing, but how can lacrosse goalies effectively incorporate these innovations into their game? Let’s explore some practical applications and strategies for leveraging this technology to enhance performance on the field.

Selecting the Right Mesh for Your Style

With the variety of advanced mesh options available, it’s crucial for goalies to select a product that complements their playing style. Consider factors such as:

- Your preferred pocket depth

- The balance between ball control and quick release you desire

- The typical shot speeds you face in your league or division

- Your clearing style and typical passing distances

Experimenting with different mesh types during practice sessions can help you find the perfect match for your needs.

Optimizing Break-In Time

While advanced mesh technology has significantly reduced break-in time compared to traditional materials, there’s still a period of adjustment when using a new pocket. To optimize this process:

- Follow manufacturer recommendations for initial pocket formation

- Gradually increase the intensity of shots during break-in sessions

- Pay attention to how the pocket responds to different types of shots and adjust accordingly

- Use a variety of drills to ensure the pocket performs well in all game situations

Remember, even with advanced mesh, allowing time for proper break-in will ensure optimal performance when it counts.

Maintenance and Care

To maximize the longevity and consistency of your advanced mesh pocket:

- Clean the mesh regularly to remove dirt and debris

- Store your stick in a cool, dry place when not in use

- Avoid leaving your stick in extreme temperatures, which can affect mesh properties

- Periodically check for signs of wear and replace the mesh before performance declines

Proper care will ensure your advanced mesh continues to perform at its best throughout its lifespan.

Adapting Your Technique

The enhanced properties of advanced mesh may require some adjustments to your technique:

- Experiment with your hand positioning to take full advantage of improved ball visibility

- Practice outlet passes at various distances to familiarize yourself with the pocket’s throwing characteristics

- Work on quick stick skills, as the improved pocket retention may allow for faster releases

By fine-tuning your technique to match the capabilities of your advanced mesh, you can fully leverage its performance benefits.

The Psychological Edge: Confidence in Your Equipment

Beyond the physical advantages, advanced mesh technology can provide a significant psychological boost to lacrosse goalies. This mental edge can be just as crucial as technical skill in high-pressure game situations.

Trust in Consistency

Knowing that your pocket will perform consistently throughout a game or season allows you to focus entirely on your positioning and reaction time. This trust in your equipment can eliminate distractions and improve overall performance.

Reduced Equipment Anxiety

The durability and shape retention of advanced mesh can alleviate concerns about equipment failure during crucial moments. This reduced anxiety allows goalies to play more freely and confidently.

Empowerment Through Technology

Using cutting-edge equipment can provide a sense of empowerment and readiness. This psychological boost can translate into improved confidence on the field, potentially intimidating opposing shooters.

By understanding and effectively utilizing advanced mesh technology, lacrosse goalies can significantly enhance their game. From selecting the right mesh to adapting techniques and maintaining equipment, these practices can help goalies maximize the benefits of this innovative technology. Combined with the psychological advantages, advanced mesh can be a powerful tool in a goalie’s quest for peak performance.

Engineered Mesh Weaves For Faster Throws

The key to improving your lacrosse goalie game lies in the engineering and construction of the mesh pocket. Advances in weaving technology now allow for mesh that is optimized for control, visibility, and throwing speed. By utilizing novel weave patterns and precision mesh stiffness, engineers can customize goalie pockets for lightning-fast outlet passes.

One of the biggest game-changers is the introduction of diamond-shaped holes in the mesh surface. Unlike traditional square openings, these diamonds drastically improve ball visibility for goalies. The elongated shape gives goalkeepers superior sightlines to track shots in real-time. This enhanced visual feedback allows for quicker reaction times and better save percentages.

Engineers also tweak the stiffness of the mesh to maintain pocket shape after repeated use. Repeated impacts can stretch and deform traditional goalie mesh, reducing throwing accuracy over time. But engineered mesh retains its shape even after hundreds of saves. This consistency leads to precise outlet passes game after game.

The shape of the mesh pocket itself is also optimized for control and speed. Mesh can be woven to create personalized throwing channels that collapse around the ball during passes. This focused control allows goalies to put extra force behind their clears without sacrificing aim. Certain pocket shapes even generate beneficial spin on outlet passes for added velocity. With the right custom woven pocket, goalies can significantly increase clear distances.

Cutting-edge lacrosse mesh combines softness and durability so goalies can make these faster, harder throws without hand pain or injury. Patented weaves absorb heavy ball impacts instead of transferring all the energy to a goalie’s hands. Less vibration means reduced glove sting so goalies can play more aggressively. The days of sore hands after big games are over thanks to modern mesh technology.

By leveraging materials science and intricate manufacturing techniques, engineers create goalie mesh that truly improves performance. Faster, more accurate outlet passes translate directly into better clearing efficiency on the field. With game-changing diamond weave pockets and customized throwing channels, today’s goalie mesh gives players the tools they need to dominate between the pipes.

Strategic Mesh Stiffness Retains Pocket Shape

One of the key engineering challenges in lacrosse goalie mesh is maintaining the ideal pocket shape over time. The repeated impacts from stopping shots can stretch and deform traditional mesh, reducing throwing accuracy after heavy use. But by strategically controlling mesh stiffness, modern goalie pockets retain their shape even after hundreds of saves.

Through extensive R&D, engineers found that overall pocket stiffness is crucial for consistency. Weaving techniques like laminating layers of mesh or integrating stiffener fibers allow for precision tuning of the overall stiffness. The optimal balance between softness for ball control and stiffness for shape retention was discovered. This Goldilocks zone prevents sagging or loosening of the pocket over time.

Regional stiffness is also important across different sections of the pocket. By adjusting the density of stiffening fibers, engineers create firm anchor points across the top and sides of the pocket. This maintains the critical pocket shape and throwing channel geometry after heavy impacts. Strategically reinforcing key stress points maintains pocket integrity.

In addition, intelligent stiffening patterns are used to control stretch in high impact zones. Areas directly in the line of fire, like the bottom portion of the pocket, are woven to be ultra-resistant to deformation. This ensures balls continue to release cleanly during passing and shooting.

Cutting-edge manufacturing techniques even enable adjustable regional stiffness within a single piece of mesh. Stiffness gradients can be built into the mesh to fine-tune performance. This level of engineering customization was unheard of just a few years ago.

Thanks to these advanced stiffening approaches, goalies can rely on consistent throwing behavior over months of play. While traditional pockets would stretch and wear over time, modern engineering keeps pockets throwing true. No more constantly re-breaking in new mesh just to retain that perfect pocket sweet spot.

By leveraging materials science and clever construction, mesh engineers found ways to conquer the consistency problem. Their strategic stiffening solutions enabled measurable improvements in sustained pocket performance. Goalies can now focus on their game rather than worrying about decreasing accuracy as their mesh breaks down.

Customizable Pocket Styles For Any Position

One of the most important modern innovations in lacrosse mesh technology is the ability to fully customize pocket style and shape. Thanks to advanced manufacturing techniques, pockets can be engineered for players of any position to optimize performance.

For lacrosse goalies, pockets are woven to be deeper and wider to improve ball control. The increased pocket volume gives goalies more surface area to contain and cradle shots. This helps improve save percentages even on tricky bounce shots. Wider pockets also reduce unwanted rebounds into the field of play.

Goalie pockets are also optimized for lightning-fast outlet passes. Tight throwing channels collate the ball for fast, accurate clears downfield. Strategic stiffening gives these pockets shape retention after repeated impacts. Consistent throwing behavior improves clearing efficiency.

For face-off specialists, shallow pockets are ideal for scooping ground balls. Less mesh depth improves ground ball handling and clamping. Stiffer sidewalls give fo masters more control when manipulating the ball. Fast, dexterous moves are enabled by this minimalist pocket design.

For attackers, pockets focus on shot speed, accuracy and ball feel. A medium pocket depth with a defined ball ramp pocket is ideal. The ramp improves control and aim on tricky shots like sidearms or behind-the-back attempts. A balanced, consistent release point optimizes shooting efficiency.

Even within positions, customizable options exist. A midfielder may want a pocket optimized for ground balls, passing, or shooting depending on their role and style of play. Defenders can choose more stiffened pockets for textbook clears versus softer mesh for run and gun transition play.

With all these positional and personal preferences, pre-engineered universal pockets no longer cut it. The diversity of pocket shapes and styles today provides players the control to match mesh performance with their on-field needs.

The customization revolution in pocket design is a huge win for lacrosse players. With the right pocket dialed in, athletes can reach peak playing potential. And by eliminating mesh as a variable, the only limitations are a player’s own skills and training.

MeshDurability In All Weather Conditions

To consistently perform at a high level, lacrosse players need mesh that can stand up to all weather conditions. The evolution of materials and pocket construction enables durable goalie mesh that excels in rain, heat, and humidity.

Traditional nylon mesh tended to absorb moisture, causing the pocket to sag when wet. This led to poor ball control and slower outlet passes in rainy conditions. But modern polymers like polyethylene or polyester mesh are hydrophobic, so they don’t absorb water. Premium mesh maintains its structure and throwing consistency, rain or shine.

Some next-gen meshes even incorporate nanotechnologies like a hyrdrophobic coating surface treatment. This nano-level water protection prevents even slight moisture absorption. Goalies maintain their A-game even through monsoon games.

Mesh durability innovations also improve performance in extremely hot or humid climates. Where traditional mesh might stretch out or deform in the heat, advanced stabilizing techniques preserve pocket shape. Stiffening fibers integrated throughout the weave maintain structure across temperature swings.

Mesh Engineers also combat humidity-related sag by strategically adjusting pocket depth. Extra depth compensates for the slight expansion in humid air while still providing superior control. Maintenance-free consistency means no more restringing before big summer games.

To protect mesh threads from UV damage, durable dyes or UV inhibitors are used. This prevents premature breakdown of the materials that lead to reduced lifespan. With UV-resistant construction, athletes can play with confidence knowing their mesh won’t need replacing halfway through the season.

Thanks to cutting-edge R&D, goalies no longer have to sacrifice performance in extreme conditions. Mesh innovation turned the weather from an uncontrollable variable into a non-issue. Players can trust their dialed-in pocket will deliver every game, no matter what mother nature has in store.

The development of all-weather mesh means one less thing for goalies to worry about. Rain, heat and humidity no longer affect ball control, throws or longevity. Now players can pour 100% of their mental energy into on-field execution.

Consistent Performance After Repeated Use

One of the main engineering challenges with lacrosse mesh is maintaining consistent pocket performance over time. As traditional nylon mesh breaks down from repeated impacts, passing and shooting accuracy fade.

Engineers found the secret to sustained consistency lies in advanced pocket construction. By strategically integrating stiffening fibers into the mesh weave, they can prevent stretching or deformation over months of play.

They also discovered the optimal balance between the softness needed for ball control, and stiffness for shape retention. This “Goldilocks Zone” provides both touch and durability in perfect harmony.

Regional pocket stiffness is also precisely tuned by engineers. High-impact zones like the scoop and bottom rail are reinforced to resist warping, while softer sections encourage finesse play.

Precision manufacturing techniques even enable adjustable stiffness gradients within a single piece of mesh. This total customizability allows pockets to be tuned for a player’s unique style and needs.

Cutting-edge coatings borrow from nanotechnology to create a hydrophobic layer that prevents moisture absorption. This eliminates weather-related sagging while bolstering the lifespan of the pocket.

Advanced polymer meshes are also engineered at the molecular level for the ideal crystallinity and filament density. This optimizes rebound characteristics and stability over thousands of cycles.

Using space-age R&D and quality-controlled production, modern goalie mesh maintains its pop and performance all season long. While outdated mesh would slowly degrade, today’s materials stay crisp.

With modern science, lacrosse goalies can finally get consistent throwing behavior from their mesh. Dialing in the perfect pocket is a wasted effort if it starts to sag after a few games. But with engineered mesh, a “broken-in” feel lasts all year.

Soft Goalie Mesh Saves Arms And Hands

One of the key innovations in modern lacrosse goalie mesh is engineering softness that saves arms and hands. Traditional rigid mesh could lead to discomfort, sting, and even injury after repeated impacts from 90+ mph shots.

Advanced polymer production allows mesh to be woven from softer filaments without losing durability. These flexible fibers gently absorb and dissipate ball forces rather than transferring all that energy directly to a goalie’s hands.

Strategic pocket designs also improve softness and impact absorption. Wider shapes increase the surface area contacting the ball to disperse forces. Deeper pockets provide more room for the ball to sink and slow before reaching the goalie’s hands.

Multi-layer mesh constructions optimize softness and control. By laminating layers of graduated stiffness, the outer face can remain supple while inner layers maintain pocket shape. This balance prevents sting while retaining performance.

Some novel meshes even incorporate advanced materials like aerogels borrowed from NASA technology. Originally designed to cushion spacecraft on reentry, these exotic compounds provide unbelievable softness in goalie mesh.

Cutting-edge R&D also allows precise tuning of regional pocket stiffness. Scoops and sidewalls can be stiffened to protect against over-deformation, while keeping the bottom cushioned to swallow up sting.

All these innovations mean goalies can play with more aggressiveness and confidence. Softer mesh provides insurance against pain and injury from high velocity shots across all levels of play.

Thanks to modern mesh technologies, gone are the days of sore swollen hands after big games. Players can give 100% without worrying about throbbing pain the next morning. With the right materials, pocket design, and construction, goalies can play fearless between the pipes.

Mesh Weight Optimized For Smooth Throws

The weight and balance of lacrosse goalie mesh has a big impact on throwing performance. Optimizing mesh properties results in smooth, accurate outlet passes.

Heavier traditional nylon mesh creates uneven weight distribution in the pocket. This makes it harder for goalies to control the release point on clears. But lightweight polymer meshes reduce excess mass for more finesse and touch.

Weight distribution is also improved by structural design. Strategic stiffening components are woven uniformly throughout the mesh to maintain perfectly balanced pocket weight. No more heavy scoops dragging down throws.

Reduced mass also allows the ball to sit deeper in the optimized pocket shape. This lower release point gives goalies more leverage for faster, more controlled outlet passes. Lightweight materials enable lightning-quick distributions.

Less mesh contact with the ball also improves throwing feel thanks to reduced friction. Smoother releases mean goalies can confidently deliver pinpoint passes to transition midfielders to spark fast breaks.

For young players, excess pocket weight can make throwing mechanics more difficult to master. But properly balanced mesh allows youth goalies to develop proper techniques faster.

Innovative mesh even utilizes elastic retention cords to pull the sidewalls in close to the ball. This further reduces erratic contact for unparalleled ball control during passing.

By analyzing every structural element and material choice, mesh engineers fine-tune weight balance. Their design optimizations enable smooth, consistent passing behavior under pressure. Goalies can trust their mesh to deliver dimes when transition opportunities open up.

Reduce Mesh Stretching With Smart Weaves

One of the main challenges with traditional lacrosse goalie mesh is losing pocket consistency due to stretching and deformation over time. But advanced weaving technology prevents unwanted stretching for sustained performance.

By integrating stiffening components like monofilaments or fibers directly into the weave, engineers create structures that resist excess deformation. This maintains the critical pocket shape after heavy use.

Strategic patterns also improve stretch resistance across high-stress regions. Dense filament spacing at the scoop, sidewalls, and lower rails controls stretch in areas prone to warping.

Novel weaving techniques like 3D mesh sandwiches also bolster structural integrity. By essentially weaving a pocket within outer layers, the encapsulated shape stays intact. This prevents loosening or blown out pockets from intense use.

Technical meshes utilize advanced polymer production to optimize the plasticity, elastic memory properties, and crystallinity of the filaments. Materials engineered at the molecular level better retain intended pocket geometry.

Space age coatings even allow micro-level tuning of the fiber surface. Smoother finished filaments resist grabbing or friction that can lead to gradual stretch when shooting and passing.

With the latest R&D, mesh engineers found ways to essentially engineer out excessive stretching. Weaves, materials, and coatings all work synergistically to keep pockets consistent. Players enjoy the same locked-in feel from first string to last.

By leveraging cutting-edge technologies, lacrosse goalies no longer have to worry about losing their dialed-in pocket sweet spot. Consistent throwing behavior and ball control allow athletes to build muscle memory and confidence over entire seasons.

Licensed Mesh Meets Official Standards

For lacrosse players to take advantage of all the modern mesh innovations, the products must meet strict official standards. Top brands work hand-in-hand with major lacrosse governing bodies to ensure quality and compliance.

During the R&D process, brands continually test their goalie mesh designs in laboratory conditions. Rigorous mechanical analysis identifies any weaknesses and inspires design tweaks before production.

Extensive play testing also gathers real-world performance feedback. By listening to elite players at all levels, brands identify subtle improvements to take their mesh to the next level.

Once engineered mesh is ready for large scale manufacturing, stringent quality assurance steps validate production consistency. Mesh must maintain certified throwing characteristics and durability metrics to get the green light.

The most reputable mesh brands then submit products for third party testing and certification. Assigned testing facilities take an unbiased look at factors like ball control, consistency, weather-resistance and longevity.

Brands work closely with these independent bodies to implement any changes needed to officially comply with regulations. This ensures all products exceeding any banned attributes are refined appropriately before release.

By securing official certification and licensing, top mesh brands instill confidence in players that their products meet all standards. Athletes can focus on their game rather than second guessing equipment legality.

Thanks to responsible partnerships between mesh engineers and lacrosse administrators, the latest tech can be woven into legal products. Players get access to game-changing innovations that push performance boundaries the right way.

Improve Skills With The Right Lacrosse Mesh

With all the engineering advancements in modern lacrosse goalie mesh, choosing the right pocket is crucial for taking your game to the next level.

Work with your coach or veteran teammates to identify your key skill gaps. Are you looking for better ball control and outlet passing? Increased shot-stopping thanks to better ball visibility? Or maybe overall throwing consistency is your main trouble spot.

Once you pinpoint priority areas, select mesh with properties that target those needs. For passing and control, focus on optimized pocket shape, throwing channels and weight distribution. For visibility, diamond mesh shapes are a game-changer.

Don’t forget your key specs like pocket depth, scoop shape, and sidewall stiffness preferences. Dial in mesh that matches your playing style and sticks to your exact specs.

It also helps to watch lacrosse film and study the mesh that elite goalies are using. See what pockets give them the edge, and follow suit with your own setup.

Of course, finding the right mesh requires actually play testing options once strung up. So give any new pocket time on the field before judging its performance. Break it in fully before tweaking stringing.

Be sure to keep an open mind too. Stepping outside your comfort zone with an unfamiliar pocket style can unlock new skills.

With constant R&D and innovation from top brands, goalie mesh continues improving season after season. Re-evaluate your preferences often and update your mesh to keep rising with new tech.

At the end of the day, don’t get overwhelmed with all the options. The right mesh for you simply enables better execution of your natural talents. So master the fundamentals, then let the pocket enhance what you already do best.

Soft Mesh Saves Arms And Hands

As a lacrosse goalie, your hands and arms take a beating from constant high-velocity shots. But advances in modern mesh technology provide welcome relief from sting and pain.

Soft mesh construction starts with using more flexible polymer filaments in the weave instead of rigid nylon. These supple materials dampen ball impact forces rather than transferring all that energy into your hands.

Strategic pocket designs also improve softness. Wider pocket shapes increase the surface area contacting the ball to disperse impact. Deeper pockets let the ball sink in further to lose speed before reaching your hands.

Multi-layer mesh optimizes softness and control in harmony. Graduated stiffness filaments allow an outer supple layer for ball cushioning, while inner layers maintain shape.

Next-gen meshes even utilize aerogel and other advanced compounds to achieve unmatched impact absorption. Originally designed for NASA spacecraft, these materials provide unreal softness.

Regional stiffness tuning also enables strategic softness. While densely woven scoops and sidewalls maintain structure, engineers intentionally cushion the lower pocket for sting prevention.

These innovations mean reduced pain and injury risk from the repeated impacts all goalies face. With the right materials and pocket design, you can be aggressive in net without sacrificing your hands.

Thanks to modern mesh technologies, sore swollen hands after games are a thing of the past. Step up fearlessly when the ball comes your way, knowing your mesh has your back.

Mesh Weight Optimized For Smooth Throws

The weight and balance of your lacrosse goalie mesh can make or break the consistency of your outlet passes. But engineering innovations now optimize weight for smoother, more accurate throws.

Lightweight polymer mesh reduces excess mass compared to traditional heavy nylon. Less overall weight means increased sensitivity and control of your pocket.

Strategic stiffening components are woven uniformly throughout the mesh to prevent uneven weight distribution. This retains perfectly balanced pocket weight for precision passing.

Reduced mass enables the ball to sink deeper into the optimized pocket shape as well. This lower release point gives you more leverage and control for fast, accurate clears.

Less mesh contact with the ball also improves throw feel through decreased friction. The ball simply slides out smoother for confident distribution downstream to your midfielders.

For young goalies, excess pocket weight can make learning proper throwing technique more difficult. Properly weighted mesh gets new players up to speed faster.

Innovative pockets even integrate elastic retention cords to minimize erratic ball contact. Less disruption means unparalleled control of your release point and accuracy.

Cutting-edge design considers every structural and material element for ideal weight balance. Engineered mesh enables smooth, reliable passing behavior under pressure when transition opportunities arise.

Reduce Mesh Stretching With Smart Weaves

As a lacrosse goalie, you don’t want to lose your dialed-in pocket sweet spot due to mesh stretching over time. But innovative weaving technology helps eliminate unwanted deformation.

Integrating stiffening monofilaments and fibers directly into the mesh weave constructs a shape-retaining structure. This maintains your ideal pocket geometry through seasons of intense use.

Strategic weave patterns are also used to reinforce high-stress regions prone to stretch. Dense filament spacing around the scoop, sidewalls, and lower rails controls deformation for sustained consistency.

Novel weaves like 3D sandwich mesh provide an encapsulated pocket shape within durable outer layers. This retains the engineered shape and prevents blown out pockets from constant impacts.

Technical polymer production optimizes the plasticity, elastic memory, and crystallinity of the filaments for reduced stretching. Materials engineered at the molecular level better hold their shape.

Advanced coatings even allow micro-level control of the fiber surface characteristics. Smoother filament finishes resist mesh friction and grabbing that leads to gradual deformation over time.

With cutting-edge R&D, mesh engineers found ways to essentially engineer out excess stretching. Combined material, weave, and coating innovations keep your pocket game-ready from day one until the final whistle.

Thanks to modern tech, you no longer have to worry about your carefully tuned pocket feeling sloppy after some wear and tear. Enjoy the same dialed-in sweet spot and throwing consistency all season long.

Licensed Mesh Meets Official Standards

As a lacrosse player, you need confidence that your goalie mesh meets all official regulations for competitive play. Responsible brands ensure quality and compliance through partnerships with governing bodies.

During R&D, brands use rigorous lab testing to analyze mesh durability, consistency, and other key performance metrics. This uncovers potential weaknesses to address before manufacturing.

Extensive field testing with elite players also provides real-world feedback to refine designs. Brands listen to goalies at all levels to make meaningful performance improvements.

Stringent quality control during production verifies engineered designs translate to on-spec mesh sheets ready for stringing. Brands validate key characteristics like pocket throwing behavior before market release.

The most trusted mesh brands submit products for third party laboratory testing and certification. These independent analyses verify standards compliance for ball control, consistency, weather resistance and more.

Brands work cooperatively with test facilities to implement tweaks when needed to officially comply. This ensures any questionable attributes get addressed prior to bringing mesh to market.

Securing governing body certification and licensing provides assurance to players that mesh meets all standards. You can focus on your game knowing your pocket is perfectly legal.

Thanks to responsible engineering practices and partnerships, brands seamlessly translate cutting-edge mesh technology into regulation products. Players gain access to game-changing innovation while maintaining trust in equipment legality.

Choose The Right Mesh For Your Game

With all the lacrosse mesh options available today, choosing the right pocket for your game is crucial to maximize performance. Consider your key needs and dial in goalie mesh that targets your skill gaps.

Analyze your playing style and trouble spots with your coach to identify priority areas for improvement. Do you need better ball control and passing? Improved visibility and reaction time? Or overall consistency shift-to-shift?

With your must-have performance traits defined, select mesh engineered for those needs. Pockets optimized for passing have defined throwing channels and balanced weight distribution. Diamond mesh shapes dramatically improve ball visibility.

Don’t forget your preferred specifications like ideal pocket depth, scoop style, and sidewall structure. Choose stringing-ready mesh aligned with your exact preferences.

It also helps to study what the top goalies are using for pockets and adopt insights that could up your game. See what gives elite netminders an edge between the pipes.

Of course, you need quality time testing new mesh yourself before reaching a verdict. Give any pocket adjustments and break-in before tweaking the stringing.

Come into evaluations with an open mind too. Stepping outside your comfort zone with an unconventional style could unlock new skills.

With constant engineering advances, lacrosse mesh keeps getting better every season. Re-assess your needs often and keep pockets updated with the latest tech.

Ultimately, the right mesh simply helps you execute your natural talents more efficiently. So focus on fundamentals first, then let the perfect pocket take your game to the next level.