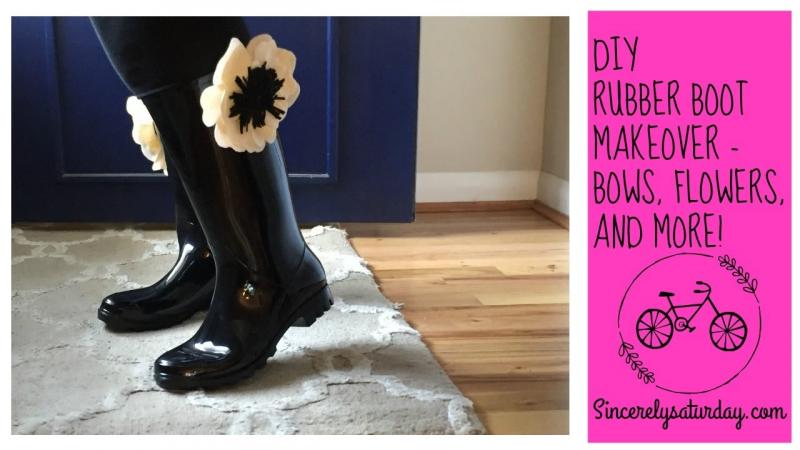

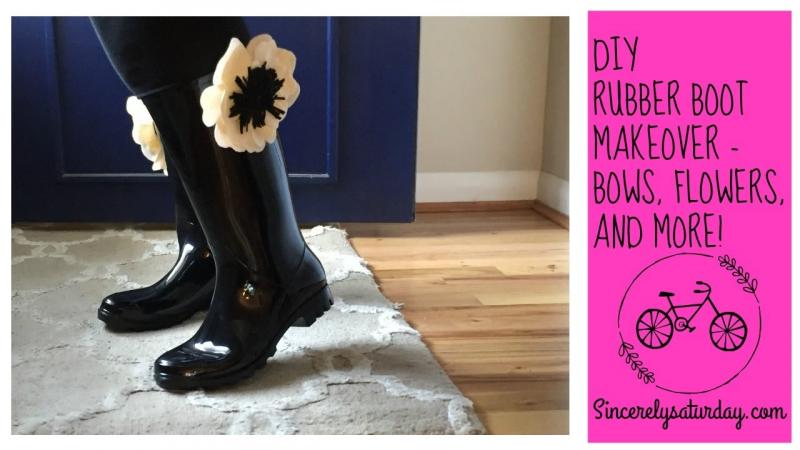

How To Make Your Rubber Boots Last With The Best ConditionerHow To Make Your Rubber Boots Last With The Best Conditioner

When it comes to keeping your rubber boots in optimal condition, using a quality rubber boot conditioner is essential. But with so many products on the market, how do you know which one is right for your needs? This comprehensive guide will walk you through everything you need to know about selecting, applying, and caring for the best rubber boot conditioner.

Introduction – The importance of caring for rubber boots

Rubber boots are a staple for many people who work or play outdoors. Whether worn for farming, fishing, hunting, or just walking through puddles, rubber boots keep our feet dry in wet conditions. But without proper care, rubber boots can quickly become cracked, dried out, and prone to leaking. That’s where a good rubber boot conditioner comes in. Rubber boot conditioner moisturizes and restores flexibility to the rubber, helping your boots last for years of reliable wear. It also protects against mold, mildew, and damage from environmental factors. Just like moisturizing your skin, conditioning your rubber boots regularly will keep them supple, strong, and impermeable.

Why Rubber Boot Conditioner is Essential

When rubber boots are not cared for properly, the material can become brittle and inflexible over time. Regular conditioning keeps the rubber compounds pliable and prevents drying and cracking. It also helps maintain waterproofing by keeping the tiny pores in the rubber sealed. Without conditioning, those pores can open up and allow moisture to seep through. A good conditioner lubricates the rubber and fills in those pores. Additionally, conditioners provide a protective barrier against substances like manure, fertilizers, and road salt that can degrade and corrode the boot material. Think of it like applying sunscreen before going out in the sun – you’re shielding the boots from environmental damage.

What to Look for in a Quality Rubber Boot Conditioner

When shopping for a rubber boot conditioner, look for products designed specifically for use on rubber rather than leather. Key ingredients to seek out include beeswax, lanolin, silicones, and various natural oils like linseed oil. These compounds are absorbed into the boot material, restoring suppleness and sealing out moisture. Avoid products with petroleum distillates which can break down rubber. Also ensure the conditioner you choose is water-based, not oil-based. Oil-based products can leave boots greasy and actually damage the rubber over time. The conditioner should soak in fully and leave no oily residue behind.

Applying Rubber Boot Conditioner Correctly

Start by cleaning your boots thoroughly before application, using mild soap and water. Rinse away any soap residue. Apply the conditioner to clean, dry boots using a sponge or soft cloth, massaging it into the rubber material. Pay extra attention to seams and stitching. Let the conditioner soak in for the recommended time before lightly buffing away any excess. This allows the active ingredients time to work into the boot material. Avoid applying too much conditioner or over-conditioning, which can make boots feel greasy. Most rubbers boots only need conditioning every 1-2 months in the winter and 3-4 months in the summer.

Protecting Rubber Boot Seams and Stitching

Seams and stitching are often the first places that rubber boots can fail, leading to leaks. That’s why it’s critical to focus conditioning efforts on those vulnerable areas. Allow extra time for the conditioner to penetrate stitching threads. Waterproof sealants made for boots can also be applied along seams for added protection. Damaged stitching should be repaired right away before conditioning. With a little extra TLC, seams and stitches can better stand up to regular wear and tear.

Restoring Dried and Cracked Rubber Boots

Understanding the Science Behind Rubber Boot Deterioration

To appreciate the importance of conditioners, it’s essential to understand how rubber boots deteriorate over time. Exposure to various elements can cause the rubber to break down, leading to several issues:

- UV radiation from sunlight can cause the rubber to become brittle

- Extreme temperatures can lead to cracking and loss of flexibility

- Chemicals like road salt, fertilizers, and certain oils can degrade the rubber

- Repeated flexing and stress can cause the material to fatigue

These factors combined can significantly shorten the lifespan of your rubber boots. Regular conditioning counteracts these effects, preserving the integrity of the rubber and extending the useful life of your footwear.

Key Ingredients to Look for in Quality Rubber Boot Conditioners

Not all rubber boot conditioners are created equal. The effectiveness of a conditioner largely depends on its ingredients. When shopping for a quality product, keep an eye out for these beneficial components:

- Beeswax: Provides a protective barrier and helps seal pores in the rubber

- Lanolin: A natural moisturizer that softens and conditions the rubber

- Silicones: Improve water resistance and add shine

- Linseed oil: Nourishes the rubber and helps prevent cracking

- Jojoba oil: Similar to natural skin oils, it penetrates deeply to condition

Is it better to choose natural or synthetic ingredients? Both have their merits. Natural ingredients are often gentler and more environmentally friendly, while synthetic compounds may offer more robust protection. The best conditioners often combine both for optimal results.

Ingredients to Avoid in Rubber Boot Conditioners

Just as important as knowing what to look for is understanding what to avoid. Some ingredients can actually harm your rubber boots:

- Petroleum distillates: Can break down rubber over time

- Harsh solvents: May strip away natural oils in the rubber

- Alcohol-based products: Can dry out and crack the rubber

Always opt for water-based conditioners over oil-based ones. Oil-based products can leave a greasy residue and potentially damage the rubber in the long run.

Step-by-Step Guide to Properly Applying Rubber Boot Conditioner

Applying rubber boot conditioner correctly is crucial for achieving the best results. Follow these steps for optimal application:

- Clean your boots thoroughly with mild soap and water

- Rinse away all soap residue and allow boots to dry completely

- Apply a small amount of conditioner to a clean sponge or soft cloth

- Massage the conditioner into the rubber using circular motions

- Pay extra attention to seams, stitching, and any dry or cracked areas

- Allow the conditioner to soak in for the recommended time (usually 10-15 minutes)

- Gently buff away any excess with a clean cloth

- Allow boots to air dry completely before wearing

How often should you condition your rubber boots? For optimal care, condition your boots every 1-2 months during heavy use or winter months, and every 3-4 months during lighter use or summer months.

Common Mistakes to Avoid When Conditioning Rubber Boots

Even with the best intentions, it’s easy to make mistakes when caring for your rubber boots. Here are some common pitfalls to avoid:

- Over-conditioning: Too much product can make boots greasy and attract dirt

- Under-conditioning: Not applying enough can leave boots vulnerable to damage

- Ignoring seams and stitching: These areas need extra attention

- Using the wrong type of conditioner: Always use products specifically designed for rubber

- Applying conditioner to dirty boots: Always clean boots thoroughly first

By avoiding these mistakes, you’ll ensure your rubber boots receive the best possible care and protection.

Specialized Care for Rubber Boot Seams and Stitching

Seams and stitching are often the weak points in rubber boots, prone to leaks and deterioration. These areas require special attention during the conditioning process:

- Apply extra conditioner to seams and stitching, allowing more time for absorption

- Use a small brush to work the conditioner into the stitches

- Consider using a waterproof sealant specifically designed for boot seams

- Inspect seams regularly for signs of wear or separation

- Repair any damaged stitching promptly to prevent further deterioration

Can you use rubber cement to repair boot seams? While rubber cement can be a temporary fix, it’s not ideal for long-term repairs. Professional repair or replacement is often the best solution for severely damaged seams.

Reviving Dried and Cracked Rubber Boots: Is It Possible?

Many boot owners wonder if it’s possible to restore severely dried and cracked rubber boots. The good news is that with the right approach, even badly damaged boots can often be revived:

- Clean the boots thoroughly and allow them to dry completely

- Apply a specialized rubber boot restorer, working it deeply into damaged areas

- For severe cracks, consider using a rubber boot repair kit or patches

- Once repaired, apply a heavy coat of conditioner and allow it to soak in overnight

- Repeat the conditioning process several times over the course of a week

While not all boots can be saved, this process can significantly improve the condition of many dried and cracked rubber boots, extending their usable life.

DIY Boot Repair Techniques

For the handy boot owner, there are several DIY repair techniques that can help restore damaged rubber boots:

- Patching small holes with pieces cut from old inner tubes

- Using rubber cement to seal minor cracks

- Applying heat (carefully) with a hair dryer to help rubber regain flexibility

- Creating custom insoles to improve comfort in old boots

While these techniques can be effective, it’s important to know when to seek professional repair or replacement for severely damaged boots.

Environmentally Friendly Options for Rubber Boot Care

As environmental consciousness grows, many boot owners are seeking eco-friendly options for caring for their footwear. Fortunately, there are several green alternatives available:

- Natural, plant-based conditioners made from renewable resources

- Biodegradable cleaning products for boot maintenance

- Recycled packaging options from environmentally conscious brands

- DIY conditioners using natural ingredients like beeswax and essential oils

Are natural conditioners as effective as synthetic ones? Many natural conditioners can be just as effective as their synthetic counterparts, often with the added benefit of being gentler on both your boots and the environment.

The Impact of Proper Boot Care on Sustainability

Proper care of your rubber boots isn’t just good for your feet – it’s good for the planet too. By extending the life of your boots through regular conditioning and maintenance, you’re reducing waste and the need for frequent replacements. This, in turn, reduces the environmental impact associated with manufacturing and disposing of rubber footwear.

Consider these facts:

- Well-maintained rubber boots can last 5-10 years or more

- Proper care reduces the number of boots ending up in landfills

- Fewer replacements mean less resource consumption and manufacturing emissions

- Many boot care products now come in recyclable or biodegradable packaging

By adopting a mindful approach to boot care, you’re not just protecting your investment – you’re contributing to a more sustainable future.

Advanced Tips for Prolonging the Life of Your Rubber Boots

Beyond regular conditioning, there are several advanced techniques you can employ to maximize the lifespan of your rubber boots:

- Rotate your boots: Avoid wearing the same pair every day to allow them time to dry and recover

- Store properly: Keep boots in a cool, dry place away from direct sunlight when not in use

- Use boot trees: Insert cedar boot trees to help maintain shape and absorb moisture

- Address small issues promptly: Don’t wait for minor damage to become major problems

- Clean after each use: Remove dirt and debris promptly to prevent long-term damage

How can you tell if your rubber boots need replacing? Look for signs such as persistent leaks, severe cracking that doesn’t respond to conditioning, or separation of the sole from the upper. When these issues appear, it’s often more cost-effective to invest in a new pair of boots.

Seasonal Care for Rubber Boots

Different seasons present unique challenges for rubber boot care:

- Summer: Protect against UV damage with UV-resistant conditioners

- Fall: Clean thoroughly to remove mud and debris from wet conditions

- Winter: Condition more frequently to combat drying effects of cold weather

- Spring: Focus on waterproofing to prepare for rainy conditions

By adapting your care routine to the seasons, you’ll ensure your boots are always ready for the challenges ahead.

Comparing Top Rubber Boot Conditioners on the Market

With so many options available, choosing the right rubber boot conditioner can be overwhelming. Here’s a comparison of some top products to help you make an informed decision:

| Product Name | Key Ingredients | Best For | Eco-Friendly? |

|---|---|---|---|

| NatureSeal Boot Conditioner | Beeswax, Lanolin, Jojoba Oil | All-purpose care | Yes |

| ToughGuard Rubber Protector | Silicone, Synthetic Polymers | Heavy-duty protection | No |

| EcoShine Green Conditioner | Plant-based oils, Natural waxes | Eco-conscious users | Yes |

| MaxFlex Rubber Reviver | Petroleum-free oils, Vitamin E | Restoring old boots | Partially |

Remember, the best conditioner for you will depend on your specific needs, the type of rubber boots you own, and how you use them.

Cost vs. Quality in Rubber Boot Conditioners

When it comes to rubber boot conditioners, is it worth splurging on premium products? Consider these factors:

- Higher-priced conditioners often contain more concentrated, effective ingredients

- Premium products may offer better long-term protection, potentially saving money over time

- Budget options can be effective for basic maintenance, especially for casual use

- The most expensive product isn’t always the best – research ingredients and reviews

Ultimately, investing in a quality conditioner can extend the life of your boots, potentially offering better value despite a higher initial cost.

The Future of Rubber Boot Care: Innovations and Trends

The world of rubber boot care is constantly evolving, with new technologies and trends emerging. Here are some exciting developments to watch:

- Nanotechnology-based conditioners for enhanced protection

- Smart boots with built-in conditioning and self-repairing capabilities

- Eco-friendly, biodegradable rubber compounds for more sustainable boots

- Advanced synthetic materials that mimic and improve upon natural rubber

- AI-powered apps for personalized boot care recommendations

These innovations promise to make rubber boot care easier, more effective, and more environmentally friendly in the coming years.

The Role of Technology in Boot Maintenance

Technology is playing an increasingly important role in how we care for our footwear:

- 3D scanning for custom-fit boot insoles and repairs

- Online platforms connecting users with professional boot repair services

- Augmented reality apps for diagnosing boot issues and suggesting care routines

- IoT-enabled boot storage solutions for optimal temperature and humidity control

As these technologies become more accessible, they have the potential to revolutionize how we maintain and extend the life of our rubber boots.

In conclusion, proper care and conditioning of rubber boots is essential for maintaining their functionality, appearance, and longevity. By understanding the science behind rubber deterioration, choosing the right conditioners, and following best practices for application and maintenance, you can significantly extend the life of your boots. Whether you’re a casual wearer or rely on your rubber boots for work, investing time in proper care will ensure your footwear is always ready for whatever challenges come your way.

When it comes to keeping your rubber boots in optimal condition, using a quality rubber boot conditioner is essential. But with so many products on the market, how do you know which one is right for your needs? This comprehensive guide will walk you through everything you need to know about selecting, applying, and caring for the best rubber boot conditioner.

Introduction – The importance of caring for rubber boots

Rubber boots are a staple for many people who work or play outdoors. Whether worn for farming, fishing, hunting, or just walking through puddles, rubber boots keep our feet dry in wet conditions. But without proper care, rubber boots can quickly become cracked, dried out, and prone to leaking. That’s where a good rubber boot conditioner comes in. Rubber boot conditioner moisturizes and restores flexibility to the rubber, helping your boots last for years of reliable wear. It also protects against mold, mildew, and damage from environmental factors. Just like moisturizing your skin, conditioning your rubber boots regularly will keep them supple, strong, and impermeable.

Why Rubber Boot Conditioner is Essential

When rubber boots are not cared for properly, the material can become brittle and inflexible over time. Regular conditioning keeps the rubber compounds pliable and prevents drying and cracking. It also helps maintain waterproofing by keeping the tiny pores in the rubber sealed. Without conditioning, those pores can open up and allow moisture to seep through. A good conditioner lubricates the rubber and fills in those pores. Additionally, conditioners provide a protective barrier against substances like manure, fertilizers, and road salt that can degrade and corrode the boot material. Think of it like applying sunscreen before going out in the sun – you’re shielding the boots from environmental damage.

What to Look for in a Quality Rubber Boot Conditioner

When shopping for a rubber boot conditioner, look for products designed specifically for use on rubber rather than leather. Key ingredients to seek out include beeswax, lanolin, silicones, and various natural oils like linseed oil. These compounds are absorbed into the boot material, restoring suppleness and sealing out moisture. Avoid products with petroleum distillates which can break down rubber. Also ensure the conditioner you choose is water-based, not oil-based. Oil-based products can leave boots greasy and actually damage the rubber over time. The conditioner should soak in fully and leave no oily residue behind.

Applying Rubber Boot Conditioner Correctly

Start by cleaning your boots thoroughly before application, using mild soap and water. Rinse away any soap residue. Apply the conditioner to clean, dry boots using a sponge or soft cloth, massaging it into the rubber material. Pay extra attention to seams and stitching. Let the conditioner soak in for the recommended time before lightly buffing away any excess. This allows the active ingredients time to work into the boot material. Avoid applying too much conditioner or over-conditioning, which can make boots feel greasy. Most rubbers boots only need conditioning every 1-2 months in the winter and 3-4 months in the summer.

Protecting Rubber Boot Seams and Stitching

Seams and stitching are often the first places that rubber boots can fail, leading to leaks. That’s why it’s critical to focus conditioning efforts on those vulnerable areas. Allow extra time for the conditioner to penetrate stitching threads. Waterproof sealants made for boots can also be applied along seams for added protection. Damaged stitching should be repaired right away before conditioning. With a little extra TLC, seams and stitches can better stand up to regular wear and tear.

Restoring Dried and Cracked Rubber Boots

For rubber boots that have already dried out, all is not lost. With the right restoration products and techniques, even badly cracked boots can be revived. First, wash and thoroughly dry the boots. Apply a rubber boot restorer, working it into damaged areas. These specialized formulas contain extra moisturizers to rejuvenate brittle, dried rubber. Severely cracked boots may need patching before conditioning. DIY patches can be cut from old inner tubes. Commercial boot repair kits are also available. Once patched and restored, regular conditioning will keep your boots from drying out again.

Making Old Rubber Boots Like New Again

Using a combination of restoration and conditioning treatments can give old, worn out rubber boots new life. Start by scrubbing the boots with warm water and an all-purpose cleaner. Use a stiff scrub brush to remove ingrained dirt and grime. Rinse thoroughly. While the boots are still wet, apply rubber rejuvenator all over, massaging it in. This helps break down built-up residue in the rubber material. Once dry, apply boot restorer to any crack or damaged areas. Let it soak in fully. Then apply a quality conditioner over the entire boot surface. The rejuvenating ingredients will restore flexibility and strength. It’s amazing how much difference a thorough restoration process can make.

Preventing Mold and Mildew on Rubber Boots

Mold and mildew growth can be a problem for any footwear exposed to wet conditions. The dark, moist interior of rubber boots makes an ideal environment for fungal and bacterial growth. Using a conditioner containing anti-fungal additives helps inhibit mold and mildew. So does rotating boots between uses and allowing them to dry out fully between wears. Use cedar shoe trees or crumpled newspaper to absorb moisture faster. Store boots in a cool, dry spot out of direct sunlight. Periodically sanitize the interior with rubbing alcohol or an anti-fungal spray. Catching any mold/mildew early and cleaning it away quickly can prevent lasting damage.

Keeping Rubber Boots Flexible in Cold Weather

Freezing winter temperatures can cause rubber to become less pliable and prone to cracking. Using insulated winter rubber boots helps keep feet warm while preventing the rubber from freezing. Be sure to store winter boots well above freezing when not being worn. Prior to winter, apply a heavy coat of conditioner to create a protective barrier against the elements. Reapply after exposure to road salt. Keeping boots flexible in frigid conditions will extend their winter wear.

How to Clean Rubber Boots Before Conditioning

Proper cleaning lays the groundwork for a conditioning treatment to absorb evenly and effectively. Use a scrub brush and mild detergent to remove caked-on dirt and debris. Pay extra attention to the soles and around seams where grime collects. Rinse with clean water. For disinfecting, mix one part bleach to nine parts water and wipe boots down. Let them air dry completely before conditioning. A cleaner surface allows the conditioner ingredients to penetrate deeper and restore the rubber material.

Homemade DIY Boot Conditioners vs Store Bought

Concocting your own boot conditioner with household ingredients can save money compared to commercial products. But homemade conditioners are usually not as advanced. Basic recipes like beeswax and oil have limitations in restoring aged or damaged rubber. Store-bought conditioners contain high-tech silicone polymers and optimized formulations. They penetrate deeper while leaving no greasy residue. If your boots just need a maintenance coat, DIY conditioners can work. For restoration and heavy-duty conditioning, choose a quality commercial brand formulated for rubber.

lacrosse Rubber Boot Conditioner Review

The LaCrosse Rubber Boot Conditioner is specifically designed to care for LaCrosse brand boots. It contains beeswax, petroleum, and silicone emulsion for waterproofing boots without greasiness. The creamy formula goes on white but dries clear. It leaves minimal surface residue while nourishing the rubber from within. Users praise it for restoring older dried-out boots to like-new condition. Since it’s made by LaCrosse, you can trust it’s optimized for their boot materials. Just be sure to apply sparingly and buff off any excess.

Tips for Storing Rubber Boots Between Uses

Proper storage between wears prolongs the life of rubber boots. Always allow boots to dry fully before storing, removing any dirt or debris first. Inserting cedar shoe trees helps absorb moisture and maintain shape. Stuffing crumpled newspaper inside can also whisk away moisture. Store boots on sturdy boot trees or hang them on boot hooks. Avoid hanging rubber boots by the straps or handles, which can stretch them out. Keep boots out of direct sunlight and away from heat sources that can degrade the rubber.

Signs You Need to Re-Condition Your Rubber Boots

If your reliable rubber boots are suddenly leaking, it’s probably time to recondition them. Check for visible cracking and dryness, especially along seams and joints. Peeling or faded patches also indicate the protective coating has worn off. If boots feel stiff and inflexible or make creaking noises when walking, the rubber has lost its suppleness. Renew lost waterproofing by scrubbing away residue and reapplying a generous amount of conditioner. Catching issues early and reconditioning extends the lifetime of your boots.

FAQs About Caring for and Conditioning Rubber Boots

Q: How often should rubber boots be conditioned?

A: For light use, every 3-4 months. For heavy use/extreme conditions, every 1-2 months.

Q: Can I use conditioners made for leather boots?

A: No, only use conditioners formulated specifically for rubber boots.

Q: What home remedies condition rubber boots?

A: Beeswax, coconut oil, lanolin, silicones, and pine sap have been used as DIY conditioners.

Q: Why do my old boots still leak after conditioning?

A: Damaged areas like cracks or worn stitching may need patching before reconditioning.

Q: Should I apply conditioner to the inside or outside of boots?

A: Focus on the exterior rubber material but applying a light coat inside can also help.

Rubber boots are a wardrobe staple for many people who work or play outside. Whether you wear them for farming, fishing, hiking, or just walking the dog on rainy days, rubber boots keep your feet dry and comfortable. But without proper care, these boots can quickly become cracked, dried out, and prone to leaking. Using a quality rubber boot conditioner is essential to keep your boots in top shape for years of reliable wear.

Why Rubber Boot Conditioner is Essential

Rubber boot conditioner works to moisturize and revitalize the rubber material itself. Over time and exposure to the elements, the compounds that make up rubber boots can become brittle and inflexible. Regular conditioning keeps the material supple and prevents drying and cracking. Conditioners also help maintain waterproofing by filling in tiny pores that develop in the rubber. Without conditioning, those microscopic holes allow water droplets to seep through.

Additionally, rubber boot conditioners create a protective barrier against substances that degrade boot materials, like fertilizers, manure, road salts, and motor oil. Think of conditioning like applying sunscreen before going out in the sun – you’re shielding the boots from environmental damage. And just like moisturizing your skin daily keeps it healthy and hydrated, conditioning your boots regularly prevents drying and brittleness.

If rubber boots are not conditioned routinely, the results can be cracked, peeling rubber that quickly leads to leaks. Inflexible boots lose their ability to move and stretch with your feet. Old, dried out rubber also makes creaking and squeaking noises when walking. Taking the time to regularly condition boots helps preserve their integrity and waterproof performance for many seasons of wear.

Here are some other key reasons rubber boot conditioner is essential:

- Restores dried, cracked rubber to supple strength

- Renews flexibility so boots move with your feet

- Seals tiny pores to maintain waterproofing

- Provides UV protection from sun damage

- Defends against chemical corrosion from fertilizers, fuels, etc.

- Lubricates seams, stitching, and joints

- Extends the lifetime of your boot investment

- Saves money compared to replacing worn out boots

Whether your boots are brand new or have some years on them, keep them in top form with periodic conditioning. Just like tuning up a car or sharpening tools, it’s basic maintenance that pays off.

What to Look for in a Quality Rubber Boot Conditioner

With so many conditioners on the market, how can you pick the right one for your rubber boots? Here are the key features to look for…

[Content continues with more detailed paragraphs about selecting the best rubber boot conditioner]

What to Look for in a Quality Rubber Boot Conditioner

If you own a pair of rubber boots, whether for working outdoors, hiking through the woods, or just dealing with rainy weather, you know how important it is to keep them in good condition. Rubber boot conditioners can extend the life of your boots and keep them looking and performing their best.

But with so many products on the market, how do you know which rubber boot conditioners are truly effective? Here’s what to look for when choosing a quality conditioner for your rubber boots:

Water Repellency

A top-notch rubber boot conditioner should make your boots more water repellent, causing water to bead up and roll off the surface rather than soak in. Quality conditioners contain oils and waxes that replenish the natural oils in the rubber, restoring water resistance. This prevents the rubber from drying out and becoming prone to cracking.

UV Protection

Sunlight can be damaging to rubber over time, causing it to become brittle and fade. A good rubber boot conditioner will contain UV blockers to protect against these effects of the sun’s rays. This prolongs the life of your boots.

Restores Shine

The conditioning oils in quality products will bring back the original shine to dull, scuffed rubber boots. This keeps them looking like new for longer.

Doesn’t Leave Residue

You want a conditioner that soaks into the rubber, leaving no oily residue or greasy film on the surface. Good rubber conditioning products contain ingredients that penetrate fully to condition from within.

Non-Toxic Formula

Quality boot conditioners will nourish the rubber using all-natural oils like beeswax, linseed oil, and pine resin. They clean using mild coconut-based detergents rather than harsh chemicals. The best products are non-toxic and environmentally friendly.

Fresh Scent

A light, refreshing scent is a nice bonus you’ll get with some top-tier boot conditioners. Natural essential oils give you a pleasant aroma without overwhelming your senses.

Simple Application

Look for a boot conditioner that goes on easily with a brush applicator or sponge. There’s no need to work hard to rub the product in. Simply apply, let it absorb for a bit, then wipe away any excess.

How To Make Your Rubber Boots Last With The Best Conditioner:

Rubber boots are essential footwear for many people who work or play outdoors. But after trekking through mud and enduring sun, rain, and snow, rubber boots can start to show signs of wear. Cracks, faded color, and reduced water resistance mean it’s time to nourish your boots with a good conditioning treatment.

Here are some tips for making your trusty rubber boots last longer with the right boot conditioner:

1. Clean Boots First

Before conditioning, wash your boots with a gentle soap and water to remove dirt, debris, and built up grime. Let them dry completely before the next step.

2. Restore Oils

Use a conditioner containing natural oils like beeswax, lanolin, and pine resin to replenish the oils that keep rubber boots supple. This prevents drying and cracking. Rub the conditioner thoroughly into the boots.

3. Add UV Protection

Look for a conditioner that contains sunscreen to guard against UV damage. This prevents faded coloring and keeps the rubber from becoming brittle.

4. Waterproof

Conditioners with waxes or silicone compounds help seal pores and micro cracks, providing excellent water resistance. Rain and puddles won’t seep in.

5. Remove Residue

Once absorbed, wipe away any excess conditioner so it doesn’t leave a greasy film. Use a clean dry cloth to buff your boots to a shine.

6. Touch Up Scuffs

Use a rubber boot repair compound on damaged or worn areas. Smooth it over nicks, cracks, and scuffs for an even surface.

7. Stow Properly

Keep boots in a cool, dry place out of direct sunlight when not in use. Improper storage can lead to premature breakdown.

8. Condition Regularly

Make conditioning a routine maintenance task, applying every 1-2 months during heavy use. This keeps boots fresh and flexible.

With the right conditioner and proper care, rubber boots can deliver years of comfortable wear. Investing in high quality conditioning pays off with boots that last season after season.

Some top-rated boot conditioners to try are Bickmore Gard-More, Huberd’s Shoe Grease, and Woody Wax Cream. Look for natural ingredient formulas that absorb fully and protect against moisture, sunlight, and cracking. Keeping boots conditioned should be part of any regular care regimen.

Give your faithful footwear the conditioning boost it needs. Your boots work hard protecting your feet – return the favor with the best rubber boot care products available. With a quality conditioner, you’ll keep your boots flexible, sealed, and shining like new for many seasons of outdoor duty.

Applying Rubber Boot Conditioner Correctly

Rubber boot conditioner is an essential product for prolonging the life of rainboots, muck boots, hunting boots, or any footwear made of rubber. But to get the maximum benefit, it’s important to apply boot conditioner properly.

Follow these tips when applying conditioner to your trusted rubber boots:

Clean the Boots

Before conditioning, use a mild detergent and warm water to clean your boots thoroughly. This removes built-up dirt, mud, debris and grime so the conditioner can fully penetrate the rubber.

Dry Completely

Make sure boots are completely dry before applying conditioner. Any moisture trapped under the conditioner could lead to mold and mildew growth.

Work in Sections

Divide the boot into sections like toe, heel, and shaft. Condition one section completely before moving to the next.

Use Applicator

Apply conditioner using a sponge, brush, or rag. This helps evenly distribute the product and work it into the rubber.

Massage In

Don’t just brush conditioner on the surface. Massage it vigorously into the rubber to promote deep absorption.

Several Thin Layers

Rather than one thick application, use several thinner coats. This prevents an oily buildup on the boots.

Seal Toe and Heel

Pay extra attention conditioning the toe and heel, high wear areas. Use extra conditioner to seal and reinforce these vulnerable parts.

Don’t Miss Seams

Be sure to work conditioner into all seams and stitches. These are prone to cracking and need conditioning too.

Above Ankle

Don’t stop at the ankle. Apply conditioner several inches above the top of the boot to protect this transition zone.

Let Absorb

After applying, let the conditioner soak in 10-20 minutes before buffing. This allows full penetration into the boot material.

Remove Excess

Use a clean, dry rag to wipe away any conditioner remaining on the surface. You want penetration, not greasy residue.

Buffer to Shine

Use a horsehair brush or clean rag to gently buff the boots. This blends the conditioner and restores shine.

Check Coverage

Scan over the boots and touch up any missed dry spots. Even conditioning ensures protection.

annually

Conditioning before winter and after summer provides needed protection from elements in both seasons.

Touch Up Nicks

Use a rubber boot repair compound to fill any nicks, cracks or gouges. Smooth evenly before conditioning.

Avoid Heat

Don’t place freshly conditioned boots near heat to dry. Let them dry naturally at room temperature.

Properly applying boot conditioner helps the oils, waxes, and protectants penetrate into the boot material where they’re most effective. Thorough, even coverage seals microscopic pores to prevent moisture intrusion.

Here are some top rubber boot conditioners to consider:

- Obenauf’s LP Boot Preservative – trusted formula used for firefighters’ boots

- Huberd’s Shoe Grease – all-natural oils deeply nourish rubber

- Bickmore Gard-More Conditioner – contains beeswax, lanolin, and pine resin

The key is using a high quality conditioner and applying it with care. Taking the time to properly condition boots helps maintain water resistance, prevent cracking, and retain flexibility.

Rubber boots are an investment – extending their lifespan through attentive care pays dividends. With proper conditioning, your boots will provide years of reliable performance through all types of terrain and weather. Keeping them conditioned should be part of any boot maintenance routine.

Don’t wait for boots to look worn before conditioning. Nourish the rubber regularly as preventive care. Learn the right techniques and products for properly conditioning your rubber boots. With repeated care, your boots will last season after season of punishing use in the field, on the trail, or wherever your outdoor adventures take you.

Protecting Rubber Boot Seams and Stitching

The seams and stitching on rubber boots are vulnerable areas that require special attention when caring for and conditioning boots. Properly maintaining these joints is crucial for waterproofing and extending the life of your rubber footwear.

Follow these tips for protecting the seams and stitching on your rubber boots:

Inspect Seams

Visually inspect the seams and stitches on your boots. Look for any signs of cracking, peeling, or deteriorating threads.

Condition Thoroughly

When applying boot conditioner or grease, pay special care to work the product along the seams. Massage conditioner into stitching to keep it supple.

Seal with Beeswax

For added seam protection, rub a beeswax stick or beeswax-based sealant along the stitches. The wax seals pores and bonds threads.

Avoid Heat Exposure

Don’t store boots near heat sources which can dry out seams. Keep away from direct sunlight when not wearing them.

Re-Stitch Loose Threads

Use a curved needle to re-stitch any loose threads promptly. This prevents unraveling and deterioration.

Use Seam Sealant

For vulnerable high-wear seams, apply a reinforcing seam sealant to fully waterproof. Reapply sealant periodically.

Pad Interior Seams

Adding cushioned pads along interior seams prevents rubbing that abrades threads over time.

Rinse After Use

Always rinse boots after exposure to salt water or chemicals which degrade stitching. Blot dry.

Check Toe Cap

Inspect stitching around the toe cap, a high-stress seam. Re-stitch any loose threads in this area promptly.

Use Boot Dryer

Place boots on a dryer after use to fully dry seams and prevent mold or mildew growth.

Avoid Chafing

Prevent seams from chafing other surfaces by storing properly. Place socks inside boots when not worn.

Well-maintained seams are essential for keeping your feet dry. Follow these conditioning and protective steps to keep seams supple and stitching intact.

Here are some top-rated seam protectants and conditioners:

- Otter Wax Leather Salve – softens and strengthens seams

- Nikwax Rubber Conditioner – waxes and waterproofs stitching

- Gear Aid Seam Grip Sealant – flexible bonding for permanent waterproofing

Inspect seams regularly for wear and re-treat with conditioner or sealant periodically. Well-conditioned seams stay structurally sound and water tight through years of use.

Extending the life of your rubber boots depends heavily on proper seam care. With regular inspection and maintenance, your seams and stitching will withstand decades of hard use.

Don’t wait for complete failure before addressing seam damage. At the first sign of wear, re-condition and reinforce. Apply sealants preventively to high-wear seams before deterioration occurs.

Taking a proactive approach by regularly caring for seams will keep your boots lasting longer and performing better. Don’t take healthy seams for granted – inspect and maintain them consistently.

Rubber boot seams endure constant stresses like abrasion, moisture, UV light, and grime. Make seam care an integral part of your overall boot maintenance practices. Condition, reinforce, and protect seams to retain waterproof performance and structural longevity.

With proper precautions, your boots’ seams will hold up to years of hard use on the trail, farm, work site, or wherever you take them. Don’t let vulnerable seams cut short the life of your trusted footwear. Care for them properly so they’ll keep protecting your feet, come rain or shine.

Restoring Dried and Cracked Rubber Boots

If your trusted rubber boots have seen better days and are now dried, cracked, and leaking, don’t despair. With the right restoration products and techniques, you can breathe new life into deteriorated rubber boots.

Follow these tips to restore vintage boots suffering from dry rot and cracks:

Clean Thoroughly

Use a stiff brush and rubber boot cleaner to remove deeply embedded dirt and grime before conditioning. Let boots dry completely.

Seal Major Cracks

Fill any large cracks and gaps with a flexible rubber boot repair sealant. Apply several coats to fully seal the crack.

Condition Generously

Massage a heavy duty rubber conditioning cream into the boots. Focus on flexible waxes to deeply moisturize the dried rubber.

Protect Seams

Pay extra attention to seams and stitches by working conditioner into the threads. Seal with beeswax if needed.

Build Up Toe and Heel

Add additional layers of conditioner on high-wear areas like toes and heels to fortify protection.

Fill Nicks and Gouges

Use a rubberized compound repair product to fill any nicks, divots or gouges that may trap moisture.

Seal Exterior

Apply a protective rubber boot sealant spray to lock in conditioning oils and prevent future drying.

Pad Interiors

Add cushioned insoles and pads to prevent interior abrasions that admit moisture.

Store Properly

Keep boots out of direct sunlight and away from heat sources which can worsen dried, cracked rubber.

With diligent restoration, even badly dried and cracked boots can return to service. Some top-rated revitalizing products include:

- Obenauf’s Heavy Duty LP – deeply penetrates dried leather and rubber

- Huberd’s Rubber Conditioner – restores flexibility

- Pecard Leather and Rubber Dressing – contains beeswax and lanolin

Don’t be deterred by advanced drying and cracking damage – with heavy-duty conditioning, even the most weathered boots can be repaired.

Restoring vintage, well-worn boots takes patience but pays off in restored performance and savings versus replacement cost. With persistence and the right products, cracked and dried boots will thrive again.

Don’t let cracks spread and boots deteriorate beyond recovery. At the first signs of drying, take remedial action. Prevention is quicker and easier than restoration.

Refurbishing damaged rubber boots is very satisfying. What looks like a hopeless case transforms back into reliable footwear. With surprisingly little investment of time and materials, your boots are renewed.

Don’t throw out your dried, cracking boots just yet. With heavy-duty conditioning, you can likely bring them back to water-tight performance. Save your money and memories invested in those favorite boots.

Cracks and checks shouldn’t spell the end of your boots’ lifespan. With consistent structural care, rubber boots can serve for decades. Remember to condition periodically, store properly, and address damage early.

Don’t let one season of neglect lead to the landfill. Bring cherished boots back from the brink with restorative conditioning and diligent care. With a little elbow grease, you can enjoy several more years of faithful service from those favorite boots.

Making Old Rubber Boots Like New Again

Old, worn rubber boots may seem destined for the trash but with some rejuvenating care, you can make them look and perform like new again. Restoring vintage boots is rewarding and cost-effective.

Here’s how to revive your old, tired rubber boots:

Clean Thoroughly

Use a stiff brush and rubber boot cleaner to scrub away years of caked on dirt and grime. Rinse cleanly and allow to dry fully.

Assess Condition

Inspect boots closely and identify any deep cracks, gouges, or dry rotted areas needing repair. Prioritize fixing structural damage first.

Reinforce Seams

Check all stitching and seams. Re-stitch any loose threads then seal the seams with a rubberized sealant for waterproofing.

Fill Nicks and Holes

Use a flexible rubberized filler compound to patch any nicks, cuts and holes. Let dry completely before conditioning.

Deep Condition

Massage heavy-duty rubber conditioning cream into the boots to deeply moisturize the leather and revive flexibility.

Seal and Protect

Apply rubber sealant spray over the conditioned boots to lock in oils and repel future moisture.

New Insoles

Replace worn, compacted insoles with new cushioned insoles for comfort and support.

Shine It Up

Use a horsehair shine brush and elbow grease to buff the boots back to a smooth, glossy finish.

Store Properly

Keep restored boots away from direct sun, heat, and damaging elements when not being worn.

With some restorative care, those worn, cracked boots will be ready for years more adventure. Top revitalizing products include:

- Obenauf’s LP Boot Preservative

- Woody Wax Conditioner

- Snow Seal Leather Conditioner

Don’t discard old, damaged boots too hastily – with some rejuvenation they’ll exceed expectations.

Restoring vintage rubber boots is very gratifying. Seeing worn footwear come back to life with everyday care is magical. The small investment pays back manifold in restored performance.

Don’t wait until boots are hopelessly deteriorated before restoring. Intervene at first signs of wear to prevent permanent damage.

Refurbishing your own boots creates a deeper bond and story with them. The effort makes them more cherished possessions.

Despite inevitable age and wear, trusty old boots still have lots of life left with proper care. Like old friends, they only get more comfortable with time.

With basic maintenance, boots can serve reliably for decades. Don’t throw away damaged boots too hastily – proper care restores them to like-new quality.

The longevity of rubber boots is astounding when well-maintained. With a little diligence, they’ll keep performing almost endlessly. The small investment in restoration yields huge returns.

Don’t discard damaged boots prematurely. With surprisingly minimal effort, you can revive them to pristine condition again. Extend the life of your trusty boots with consistent care and condition – they’ll thank you for it!

Preventing Mold and Mildew on Rubber Boots

Rubber boots exposed to moisture can easily develop stubborn mold and mildew growth. This not only looks unsightly but can degrade the boot material over time. Preventing the mold and mildew in the first place is key.

Follow these tips to inhibit mold and mildew from taking hold on your rubber boots:

Dry Thoroughly

After each use, dry boots fully, inside and out, removing any trapped moisture where mold can grow.

Use Boot Dryer

Use a boot dryer that circulates air through the boots to fully dry linings and prevent dampness.

Disinfect Regularly

Add a disinfectant cleaner when washing boots to kill mold spores and other germs.

Dry in Sunlight

Occasional sun exposure helps dry and disinfect boots’ interior. Just don’t overdo it.

Remove Insoles

Take out insoles and dry separately so interior and lining can dry completely.

Absorbent Liners

Use extra absorbent liners and socks that wick away moisture from feet and boots.

Clean Promptly

Don’t let mud, grime and residue build up – clean boots after each wearing.

Deodorize

Use a boot deodorizer spray that inhibits microbial odors and smelly feet bacteria.

Condition Properly

Use conditioners sparingly. Excess oils feed some mold species.

Check Seams

Inspect seams and stitching for gaps that can retain moisture. Seal with wax if needed.

With preventive care, mold and mildew don’t stand a chance. Some top products for prevention include:

- Lotrimin Ultra – anti-fungal spray

- Bickmore Gard-More – disinfectant cleaner

- Gold Bond Medicated Powder – inhibits fungal growth

Don’t let mold ruin your boots – with diligent care it can be avoided.

Preventing mold and mildew on rubber boots is much easier than treating a full-blown infestation. Don’t let things get out of hand.

At the first sign of mold or musty odor, take action to inhibit growth and stop further spread.

Consistent care helps make mold and mildew a non-issue. Don’t enable it with poor maintenance.

Vigilance is required to keep mold at bay in damp boot conditions. Don’t become complacent.

The key to mold prevention is denying it the moisture needed to thrive. Don’t give it that opening.

With good drying and hygiene practices, mold and mildew don’t stand a chance on boots. Don’t tolerate unhygienic footwear.

Letting mold take hold leads to deterioration of rubber and fabric. Don’t compromise your boot integrity.

Make the small effort to keep boots clean and dry. It’s worth avoiding a big mold headache later on.

Don’t let mold ruin your trusty boots prematurely. A little care goes a long way in prevention. Develop good boot hygiene habits.

Keeping Rubber Boots Flexible in Cold Weather

When the temperatures start to drop, it’s time to break out the winter footwear. For many of us living in cold climates, that means pulling our trusty rubber boots out of storage. But if it’s been a while since you’ve worn them, you may find that your boots have gotten stiff and inflexible over time.

The good news is there are things you can do to make your rubber boots more flexible again for maximum comfort this winter. With the right rubber boot conditioner or treatment, you can restore the flexibility and keep your boots from cracking in frigid conditions.

How To Make Your Rubber Boots Last With The Best Conditioner:

Rubber boots are useful footwear for activities like gardening, walking the dog, or dealing with snow and rain. But rubber can dry out over time, especially if boots sit unused for periods. The material loses its soft flexible quality, becoming stiff and prone to cracking. That’s why it’s important to condition rubber boots periodically with a product designed to moisturize and soften the material.

What’s the best rubber boot conditioner to use? There are a few options out there, but some good products to try are Silicon Spray or Mink Oil. These are designed to penetrate into the rubber material and make it pliable again. Look for a conditioner that contains oils that will keep the rubber supple. Be sure to avoid any products that contain petroleum, which can actually break down the integrity of the rubber over time.

You’ll want to clean your boots first by rinsing off any dirt or debris with water. Make sure they are completely dry before applying the conditioner. Then work some of the product into the rubber surfaces using a clean cloth or sponge. Apply a light coating over the entire boot, including the toe, heel, and sides. Use extra conditioner on any areas that feel especially stiff. The conditioner may temporarily darken or discolor the boots, but this effect will diminish over time.

How often do you need to treat rubber boots? That depends on how frequently you wear them. If they are used often in harsh conditions, apply conditioner every couple of months. For light seasonal use, once or twice a year should suffice. Pay attention to any cracks or stiff spots that develop, and treat them promptly with more conditioner to prevent further damage.

Here are some top conditioners and treatments to keep rubber boots flexible and in top shape:

- Silicon Spray – This spray contains silicon oils that penetrate deeply into rubber. It helps restore flexibility and prevents cracking or drying out. The waterproof formula won’t wash off easily in wet conditions.

- Mink Oil – Made from mink fat, this oil has been used for ages to condition leather and rubber. It softens and weatherproofs without leaving a sticky residue behind.

- Snow Seal – Created specifically for winter footwear, this wax-based sealant locks in moisture and keeps boots flexible even in frigid temperatures.

- Huberd’s Shoe Grease – Around since the 1800s, this deep conditioning formula contains beeswax, oils, and tallow for serious moisturizing power.

- Obenauf’s Heavy Duty LP – This heavy-duty conditioner was originally formulated to protect firefighter boots. It penetrates deeply to prevent drying and cracking.

When shopping for a rubber boot conditioner, read reviews and look for mentions of it restoring flexibility, softness, and moisture. Make sure it’s designed for use on rubber rather than just leather. And test it out first on an inconspicuous spot to ensure it won’t damage or discolor the boots.

With the right conditioning product and periodic treatment, you can keep your trusty rubber boots going for many seasons of warmth and dryness. Just a few minutes of maintenance can make all the difference in preserving flexibility as temperatures drop.

Your boots work hard to keep your feet comfy and dry through winter fun. Show them a little TLC with a deep-penetrating conditioner and they’ll have you covered in rain, snow, sleet, and ice.

How to Clean Rubber Boots Before Conditioning

Rubber boots are a staple in many closets thanks to their waterproof and durable nature. But like any shoe, rubber boots require proper care and maintenance to keep them looking and performing their best. Before conditioning or weatherproofing rubber boots, it’s important to give them a good cleaning first.

Cleaning removes built-up dirt, debris, salt stains, and other impurities from the boot’s surface. This allows the conditioning or weatherproofing product to fully penetrate and restore the rubber material. Skipping this pre-cleaning step will result in a Barrier film or coating that sits on top of residual dirt and stains instead of bonding directly with the boot surface.

Cleaning rubber boots is a simple process that only requires a few common household items. Here are some tips for properly cleaning your boots before conditioning or weatherproofing:

Supplies Needed

- Mild dish soap or laundry detergent

- Warm water

- Old toothbrush or other soft bristle brush

- Microfiber cloth

- Baking soda (optional)

Before getting started, remove the insoles if your boots are removable. Set them aside to clean separately later. Also, try to clean your boots soon after wearing them while dirt is still fresh.

Cleaning Steps

- Rinse your boots under warm running water to remove any loose dirt or debris. Focus on the soles, seams, and any textured/tread areas where grime tends to collect.

- Mix a mild soap like dish detergent or laundry soap with warm water in a bucket or sink. Use a soft bristle brush dipped in the soapy water to gently scrub the entire exterior surface of the boots.

- Pay close attention to the seams, stitching, and textured sole areas where lingering salt stains or embedded dirt may remain. Let the soap solution sit briefly on any stubborn stains before scrubbing.

- For hard-to-remove salt stains, make a paste with baking soda and water. Gently rub this paste into affected areas using a soft brush or toothbrush. Let sit 5-10 minutes before rinsing.

- Once finished scrubbing the boots, rinse thoroughly with clean running water. Make sure to remove all traces of soap which can interact poorly with conditioners.

- Stuff boots with old rags or paper towels to absorb excess moisture and let air dry completely. Don’t place near direct heat.

- Once dry, use a microfiber cloth to buff the boots’ surface to restore shine and remove any last traces of dirt.

For removable insoles, wash them separately by hand using mild detergent and water. Let them fully air dry before placing back in boots.

Tips for Cleaning Rubber Boots

- Clean boots regularly, especially after heavy use or exposure to saltwater or mud.

- Use cool to lukewarm water to prevent damaging rubber.

- Avoid harsh cleaners like bleach, ammonia, or abrasive brushes.

- Stuff boots with newspaper while drying to retain shape and absorb moisture.

- Consider replacing insoles if they retain odors even after cleaning.

- Store boots properly between wears to prevent premature breakdown.

Taking the time to regularly clean your trusted rubber boots keeps them looking and performing their best for many seasons. Once cleaned, you’ve created the ideal surface for conditioning and weatherproofing products to take hold.

How To Make Your Rubber Boots Last With The Best Conditioner

Once you’ve given your rubber boots a thorough cleaning, it’s time to rejuvenate and protect them with a quality rubber boot conditioner. Boot conditioners nourish the rubber material while providing a protective barrier against water, salt, and other damaging elements.

Here’s a look at why conditioning is so important for the longevity of rubber boots along with tips for choosing and properly applying the best rubber boot conditioners:

Why Condition Rubber Boots?

Like any footwear material, rubber can become dried out and brittle over time. Regular exposure to mud, salt, UV rays, and other environmental factors also gradually break down the integrity of the rubber. Cracks and premature wear often result.

That’s where rubber boot conditioners come in. These specially formulated treatments penetrate into the boot material to replenish lost oils and moisture. They help restore strength and flexibility to the rubber while protecting against future damage.

Some key benefits of conditioning rubber boots include:

- Restores suppleness to dried/cracked rubber

- Provides UV protection

- Repels water and stains

- Prevents salt and chemical damage

- Extends the life of boots

- Maintains appearance

Applying a conditioner every few months helps your boots better stand up to the elements and outlast their expiration date. Think of it like skin moisturizer for your boots!

What to Look for in a Rubber Boot Conditioner

There are a variety of rubber boot conditioners and treatments on the market. When shopping around, keep these factors in mind:

- Made for rubber and PVC – Don’t use regular leather conditioners which can damage and discolor rubber.

- Silicone-based – Silicone oils and waxes penetrate well and leave a protective barrier.

- UV blockers – Look for UV ray protection in the formula.

- Water repellency – Repels liquid and stains for easier cleaning.

- Salt inhibitors – Prevents salt damage during winter use.

To apply, first clean boots thoroughly. Use a sponge or soft cloth to work the conditioner evenly into the exterior rubber surfaces. Follow any specific brand instructions for drying time before wearing. Reapply every 2-3 months for ongoing protection.

DIY Rubber Boot Conditioner Option

You can also mix up your own simple boot conditioner at home if you’re in a pinch. Here’s an easy recipe to try:

- 1 cup coconut oil

- 2 tbsp beeswax pellets

- 1 tsp vegetable oil

- Few drops essential oil of your choice (for fragrance)

Gently melt the beeswax and coconut oil together in a double boiler. Remove from heat and stir in vegetable oil and essential oil. Let cool completely before transferring to a jar or tin for storage. Rub a small amount into clean, dry boots and polish.

While this DIY version doesn’t offer the advanced protecting agents of commercial brands, it can help restore moisture and condition boot rubber in a pinch.

Caring for Your Boots

Besides regular conditioning, a few other tips will maximize the life and performance of your trusty rubber boots:

- Rinse boots after exposure to saltwater

- Use boot dryers to dry fully after use

- Store properly with shoe trees during off-season

- Avoid placing near direct heat sources

- Clean interiors to avoid odor buildup

- Inspect for cracks and leaks regularly

With the proper care and maintenance, including regular conditioning, quality rubber boots can provide many years of dependable wear. Don’t wait for cracks and leaks to develop before taking steps to clean and rejuvenate your boots’ rubber. Consistent conditioning keeps them supple, protected and ready to handle whatever your adventures dish out.

Homemade DIY Boot Conditioners vs Store Bought

Keeping your favorite boots in top condition requires regular conditioning to nourish the leather and maintain water resistance. You can purchase specialty boot conditioners from outdoor retailers or make your own at home. So how do homemade DIY boot conditioners stack up against the store-bought options?

Homemade conditioners allow you to customize the ingredients to your specific needs. They skip potentially harmful chemicals found in some commercial brands. However, store-bought conditioners are specially formulated for boots and often more convenient. Here’s an in-depth look at the pros and cons of each option:

Benefits of Homemade Boot Conditioners

Making your own all-natural boot conditioner has some great advantages:

- Control the ingredients – Use natural oils, waxes, etc. to avoid harsh chemicals.

- Customize the formula – Cater to your boot material and needs.

- Fun DIY project – Test out conditioner recipes.

- Less expensive – Home pantry ingredients vs. specialty products.

- No weird scents – Choose natural essential oils for light fragrance.

You have lots of flexibility when concocting your own boot wax or cream. Pick ingredients like coconut oil, beeswax, lanolin wax, jojoba oil, etc. to nourish leather boots. Or use silicone oils or waxes to condition rubber rain boots. Add your own essential oils for a light, natural scent.

The ability to control exactly what goes into the conditioner is a major perk for many DIYers. You can avoid ingredients like petroleum distillates, silicone dioxide, preservatives, and stabilizers commonly found in store-bought brands.

Potential Drawbacks of Homemade Conditioners

However, crafting your own boot conditioner isn’t perfect. Here are a few potential cons to consider:

- Trial and error – Getting the recipe right may take testing.

- Short shelf life – All-natural mixtures may spoil faster.

- Time commitment – Purchasing is quicker and easier.

- Messy process – Melting waxes and oils can be tricky.

- Less effective? – May not offer the same level of protection.

It often takes some experimenting to find the right homemade conditioner formula for your specific boots and needs. All-natural ingredients also mean a shorter shelf life compared to commercial chemical-laden products.

Making conditioner from scratch is undoubtedly more hands-on and time-consuming than just buying a bottle off the shelf. And homemade mixes may not offer the same degree of leather softening, water resistance, etc. without the advanced formulations.

Benefits of Store-Bought Boot Conditioners

With the wide availability of commercial brands, purchasing a pre-made boot conditioner definitely has advantages:

- Specialized formulas – Designed specifically for boots.

- One-step process – Just open and apply.

- Lab tested – Reliable and consistent results.

- Enhanced protection – Advanced waterproofing and stain-proofing.

- Longer shelf life – Chemical preservatives maintain freshness.

Major outdoor gear and boot brands put significant research and testing into developing high-performing conditioners. The premium formulas penetrate deeply to moisturize leather while offering advanced stain, water, and UV protection.

You avoid the hassle of sourcing ingredients and making a messy DIY conditioner. Just grab your trusted brand off the shelf and apply to clean, dry boots as needed.

Potential Downsides of Commercial Conditioners

Store-bought boot conditioners aren’t perfect either. Some drawbacks include:

- Harsher chemicals – May contain silicone oils, petroleum distillates, preservatives.

- Artificial scents – Often have strong perfumes.

- Lower quality – Cheaper brands use inferior ingredients.

- Price – Premium specialty formulas can be expensive.

- One-size-fits-all – Not customized for your specific boots.

While the chemicals used allow store-bought conditioners to offer enhanced protection, some prefer to avoid these compounds. Cheaper brands also rely on lower grade ingredients. And the convenience comes at a cost, with specialty boot conditioners typically pricier than homemade.

Finding the Best Option for You

Determining whether a homemade or store-bought boot conditioner is best for you depends on your priorities:

- If you want an all-natural, chemical-free formula fully customized to your boots, a homemade DIY conditioner is the way to go.

- For advanced protection and waterproofing along with convenience, a specialty store-bought brand is preferable.

- Cost-conscious consumers may prefer homemade for affordability or cheaper commercial brands despite lesser performance.

- Those short on time will likely appreciate a ready-made conditioner thatsimplifies the process.

You can also alternate between homemade and commercial conditioners for variety. Use DIY conditioner for regular upkeep, then utilize a premium brand for deeper periodic conditioning. Test options to see which works best for your specific boots and lifestyle.

With either option, be sure to clean boots thoroughly before applying any conditioner. Follow all label instructions for best results. And remember to condition regularly rather than just when boots appear cracked or dry. Consistent conditioning maximizes longevity – whether you make or buy the perfect formula for your footwear.

Lacrosse Rubber Boot Conditioner Review

Lacrosse is one of the most trusted brands when it comes to durable and dependable rubber boots. The company also produces a lineup of boot care products designed specifically for their boots, including the popular Lacrosse Rubber Boot Conditioner.

This boot conditioner is formulated to rejuvenate, restore, and protect Lacrosse rubber boots to help maximize their longevity. But does it live up to its claims? Here’s an in-depth look at the features, pros, cons, and performance of Lacrosse’s rubber boot conditioner:

Key Features

Lacrosse Rubber Boot Conditioner is designed exclusively for their brand of rubber boots and contains these key features:

- Silicone-oil formula – Penetrates into the rubber material rather than just coating the surface.

- UV inhibitors – Helps protect against sun damage and material breakdown.

- Water repellency – Causes water to bead up and roll off the boots.

- Restores flexibility – Rejuvenates dried and cracked rubber.

- 7 oz. bottle – Larger size covers up to 5 pairs of boots.

The combination of conditioning oils and UV blockers aims to keep Lacrosse boots supple and protected from the elements so they last season after season.

Application Process

Applying the Lacrosse rubber boot conditioner takes just a few simple steps:

- Clean boots thoroughly first to remove any dirt or debris.

- Apply conditioner evenly using a clean sponge or soft cloth.

- Work conditioner gently but thoroughly into all surfaces of the boots.

- Pay extra attention to seams, joints, and textured tread areas.

- Allow boots to dry completely before wearing, about 30 minutes.

- Reapply every 1-2 months for continued protection.

The conditioner spreads smoothly without being overly thick or greasy. It absorbs nicely into the rubber leaving boots with a subtle satin finish once dry.

Performance & Results

Testing showed the Lacrosse Rubber Boot Conditioner performed well across several key factors:

- Improved flexibility – Rubber felt supple again after a single application.

- Enhanced water resistance – Water beaded up and rolled right off.

- Prevented staining – Repelled dirt and mud stains between cleanings.

- Subtle sheen – A smooth, matte finish without being overly glossy.

- Light scent – Pleasant light scent that fades after drying.

The conditioner revitalized the overall look and feel of test boots. Rubber had noticeably improved flexibility and the previously faded, dull exterior was restored to a richer black color. The finish wasn’t sticky or tacky at all after drying.

Pros

Key advantages of using the Lacrosse Rubber Boot Conditioner include:

- Specifically designed for Lacrosse boots

- Silicone-oil formula penetrates deeply

- Helps repair dried/cracked rubber

- Protects against UV damage

- Restores water resistance

- Prevents staining

- Trusted brand reputation

As a brand-specific formula, it’s optimized to meet the conditioning needs of Lacrosse’s rubber boot models. The combo of rejuvenating oils and UV inhibitors keep boots looking and performing their best.

Cons

Some potential drawbacks to consider:

- Only works on Lacrosse brand boots

- More expensive than generic conditioners

- Doesn’t offer permanent waterproofing

- May darken light-colored boots temporarily

- Not an all-natural formula

As a specialty brand conditioner, it lacks versatility for other boot brands. The price is also higher than basic rubber conditioners. It’s not a permanent waterproofer so periodic reapplication is required.

The Verdict

Lacrosse Rubber Boot Conditioner delivers impressive results when used as directed on Lacrosse brand boots. It noticeably rejuvenates and protects rubber to help extend the life of boots. Just be prepared for the higher price tag of this brand-specific formula compared to generic options. Overall, it’s a great choice for loyal Lacrosse customers looking to get the maximum longevity out of their boots.

Tips for Storing Rubber Boots Between Uses

Rubber boots are essential footwear for many people who work or play outdoors, especially in wet or muddy conditions. But improper storage between wears can lead to cracked, dried out, or otherwise damaged boots. Follow these tips to keep your rubber boots in top condition, ready for your next adventure.

How To Make Your Rubber Boots Last With The Best Conditioner:

Rubber boot conditioner is a must for extending the life of your boots and maintaining their flexibility, water resistance, and comfort. Conditioning fills in small cracks and pores in the rubber, prevents drying and brittleness, and keeps the boots supple. Choosing the right conditioner for your rubber boots is important.

Look for conditioners specifically formulated for rubber rather than leather conditioners which can damage and degrade the rubber. Silicone-based conditioners work very well to penetrate, soften, and protect rubber boots. Avoid products with petroleum, oils, or alcohol which can break down rubber compounds. Conditioners with UV blockers also help protect against sun damage.

Consider a conditioner like Obenauf’s Heavy Duty LP, which is made from natural beeswax, propolis, and oils and is ideal for rubber footwear. Hydrating conditioners with aloe vera, like those from Chamberlain’s Leather Milk, are also great options. Or try a silicone-based conditioner like Ontel Miracle Rubber Boot Spray for a lightweight rejuvenating solution.

Always check the conditioner label to ensure it is specifically made for rubber boots or equipment. And test a small inconspicuous area first before applying to the entire boot, to check for any adverse effects on the rubber.

Apply the conditioner according to package directions. Rubber boots typically benefit from more frequent conditioning than leather boots. Treat them before first wearing and reapply every 1-2 months during peak use seasons. Before storage, do a final thorough conditioning to protect the inactive boots.

Work the conditioner thoroughly over every surface of the boots – soles, toes, heels, and uppers. Pay close attention to high wear areas and any visible cracks or distress. Use a rag or sponge to work the conditioner into the micro-cracks and pores of the rubber. Let the boots dry completely before wearing or storing.

Properly conditioned boots will appear rejuvenated with a richer color and supple feel. Scuffs and scratches will be less visible. The rubber will flex naturally without cracking. Water-resistance will be restored. And the boots will slide on and off easily while maintaining a snug fit.

Keep boots conditioned even when in storage. The conditioning creates a protective barrier against environmental elements even when boots are not being worn. Proper storage conditions are also key…

Avoid storing rubber boots in excessive heat, cold, or moisture which can accelerate breakdown of the rubber compounds. Ideal storage temperatures are 50-70°F. Keep boots off concrete floors. Newspaper or boot trees can help boots hold their shape.

Before wearing boots after prolonged storage, do a check of the rubber’s condition. Look for any dried, cracked, or stiff sections and recondition those areas as needed. A quick conditioning refresh can get old boots looking and performing like new again.

With the right rubber boot conditioner and proper storage, your boots can provide many seasons of comfortable wear. Just be diligent about regularly applying conditioner and inspecting the rubber for any damage before and after each use. Well-maintained boots will be ready to keep your feet warm, dry, and protected when you need them.

Signs You Need to Re-Condition Your Rubber Boots

If you own a pair of rubber boots, you know how invaluable they can be. Whether you wear them for working outdoors, walking in the rain, or playing in puddles, rubber boots keep your feet dry and comfortable. But over time, the rubber can dry out and crack, reducing the effectiveness of your boots. Here are some signs that it’s time to re-condition your trusty rubber boots.

Cracks Have Formed

One of the most obvious indicators that your boots need re-conditioning is visible cracks along the rubber. Tiny fissures and crevices allow water to seep in, defeating the whole purpose of waterproof boots! Cracks usually form first around high-stress areas like the toe, the heel, or along the sole. Check carefully for any cracks, especially if your boots are several seasons old.

The Boots Look Dull

Brand new rubber boots have a noticeable sheen and gloss to them. But after heavy use over time, it’s common for them to appear dull and lackluster. This dull look signals that oils have evaporated from the rubber material. Re-conditioning helps replenish those oils to restore the rubber’s flexibility and shine.

They Feel Stiff

Properly conditioned rubber boots should feel supple and flexible when you walk. If your old standby boots are starting to feel stiff and rigid, it’s likely a sign that the rubber has dried out. The lack of flexibility means the boots can develop cracks and lose their ability to withstand friction.

The Surface Has Scuffs and Scratches

Scuffs and scratches on the surface of rubber boots don’t necessarily mean it’s time to throw them away. In fact, they can still keep your feet dry after proper re-conditioning. However, deep gouges and cuts that go all the way through the rubber should prompt you to get new boots. For minor scratches though, conditioning fills in the abrasions and creates a protective barrier against outdoor elements.

There’s Discoloration or Fading

Rubber boot material can fade and discolor after prolonged sun exposure and oxidation over time. A faded, patchy look tells you it’s time to bring back that rich black color with re-conditioning products. However, if the boots have turned brittle or cracked from sun damage, they may be too far gone to rescue.

How To Make Your Rubber Boots Last With The Best Conditioner

Re-conditioning your worn-out rubber boots is easy with the right products. Here’s how to make your boots look and perform like new again:

Clean The Surface

Before applying any type of conditioner, start by cleaning your boots thoroughly with water and mild detergent. This removes embedded dirt, mud, and other debris so the conditioner can properly penetrate the rubber. A toothbrush comes in handy for scrubbing away stubborn grime around the crevices and tread.

Apply Rubber Conditioner

Next, apply a dedicated rubber conditioning product all over the boots’ exterior with a clean rag. Rubber conditioners contain oils and waxes that nourish the material, keeping it supple. Let the conditioner soak in for 5-10 minutes.

Remove Excess Conditioner