How do Louisville Slugger composite bats compare to traditional wooden bats. What advantages do composite bats offer in terms of performance and durability. Are Louisville Slugger composite bats worth the higher price tag for players at different skill levels.

The Evolution of Baseball Bats: From Wood to Composite

Baseball has witnessed a significant transformation in bat technology over the years. While wooden bats were once the only option, composite bats have emerged as a popular choice among players at various levels. Louisville Slugger, a brand synonymous with baseball since 1884, has been at the forefront of this evolution.

Composite bats are crafted from a blend of materials, including graphite, fiberglass, and plastics. This combination allows manufacturers to fine-tune performance characteristics, offering players distinct advantages over traditional wooden bats.

Key Advantages of Composite Bats

- Lighter weight for increased bat speed and power

- Larger sweet spot for more forgiving contact

- Enhanced durability with reduced cracking and denting

- Consistent performance throughout the bat’s lifespan

- Reduced sting on mishits

- Flexibility in design for optimal balance and grip

Louisville Slugger’s Composite Bat Lineup: A Model for Every Player

Louisville Slugger offers a diverse range of composite bat models, catering to players of different ages, skill levels, and playing styles. Understanding these options can help players make informed decisions when selecting a bat that suits their needs.

Popular Louisville Slugger Composite Bat Models

- Solo: Designed for youth players, focusing on speed and control

- Omaha: A balanced, forgiving swing in a classic design

- LXT: Tailored for elite female players with a large sweet spot

- Meta: Annually updated with cutting-edge materials for peak performance

- Prime: Features thermo composite technology for an extended, forgiving barrel

- Select: Combines hard maple and composite layers for reduced sting and enhanced pop

Each model line offers various barrel sizes and length-to-weight ratios, ensuring players can find the perfect fit for their preferences and league regulations.

The Cost-Benefit Analysis of Louisville Slugger Composite Bats

While composite bats offer numerous performance advantages, their higher price point often raises questions about their value. Is the investment in a Louisville Slugger composite bat justified? The answer depends on several factors.

Factors to Consider When Evaluating Composite Bat Value

- Player’s skill level and commitment to the sport

- League regulations regarding bat materials and specifications

- Budget constraints

- Long-term durability and performance consistency

- Potential impact on player confidence and hitting mechanics

For youth players just starting out, a basic alloy or wooden bat may suffice. However, as players advance and seek to improve their performance, the benefits of composite bats become more pronounced. The lightweight design and larger sweet spot can contribute to more consistent contact and increased confidence at the plate.

Understanding Composite Bat Technology and Construction

To fully appreciate the value proposition of Louisville Slugger composite bats, it’s essential to understand the technology and construction methods behind these advanced sporting goods.

The Science of Composite Materials

Composite bats are crafted from a blend of materials, each chosen for specific properties that contribute to overall performance. The primary components include:

- Carbon fiber: Provides strength and stiffness while remaining lightweight

- Fiberglass: Adds flexibility and helps absorb vibrations

- Resins: Bind the materials together and influence the bat’s overall feel

By carefully controlling the ratio and orientation of these materials, manufacturers can fine-tune the bat’s performance characteristics. This level of customization is not possible with traditional wooden or aluminum bats.

The Manufacturing Process

Louisville Slugger employs advanced manufacturing techniques to produce their composite bats. The process typically involves:

- Layering composite materials in specific patterns

- Molding the layers under high pressure and temperature

- Precision cutting and shaping of the bat

- Application of proprietary treatments to enhance performance

- Rigorous testing to ensure consistency and compliance with regulations

This meticulous process contributes to the higher cost of composite bats but also results in a product that offers superior performance and durability.

Performance Metrics: Comparing Composite to Traditional Bats

To objectively assess the value of Louisville Slugger composite bats, it’s crucial to examine key performance metrics in comparison to traditional wooden and aluminum bats.

Exit Velocity

Exit velocity refers to the speed of the ball off the bat. How do composite bats compare to wooden bats in terms of exit velocity? Studies have shown that well-designed composite bats can generate higher exit velocities, particularly on off-center hits. This is due to the larger sweet spot and the bat’s ability to flex and “trampoline” the ball upon impact.

Swing Speed

The lighter weight of composite bats allows for increased swing speeds. On average, players can swing a composite bat 3-5 mph faster than a comparable wooden bat. This increased bat speed can translate to more power and better timing at the plate.

Vibration Dampening

One of the most noticeable differences between composite and traditional bats is the reduction in vibration on mishits. Composite materials excel at absorbing and dissipating vibrations, resulting in less sting in the hands. This can be particularly beneficial for younger players or those recovering from hand or wrist injuries.

The Impact of Composite Bats on Player Development

Beyond raw performance metrics, it’s important to consider how the use of composite bats like those offered by Louisville Slugger can influence a player’s development and approach to hitting.

Confidence at the Plate

The larger sweet spot and reduced sting of composite bats can boost a player’s confidence at the plate. This psychological advantage can lead to more aggressive swings and better overall performance. However, it’s crucial for coaches to ensure that this confidence is built on a foundation of solid hitting mechanics.

Skill Transfer to Wooden Bats

For players who may eventually transition to wooden bats (e.g., in college or professional leagues), there are concerns about how skills developed with composite bats will transfer. While the fundamental mechanics of hitting remain the same, players accustomed to composite bats may need to adjust their approach when switching to wood.

Potential for Overreliance on Technology

Critics argue that the performance advantages of composite bats may lead some players to rely too heavily on equipment rather than developing proper technique. It’s essential for coaches and players to view composite bats as tools to enhance performance, not substitutes for skill development.

Regulatory Considerations and League Specifications

When evaluating the worth of Louisville Slugger composite bats, it’s crucial to consider the regulatory landscape and how it affects the use of these bats in different leagues and levels of play.

BBCOR Certification

Many high school and collegiate leagues mandate the use of BBCOR (Batted Ball Coefficient of Restitution) certified bats. This standard aims to ensure that metal and composite bats perform similarly to wooden bats. How does BBCOR certification affect the performance of Louisville Slugger composite bats? While BBCOR regulations have somewhat leveled the playing field, composite bats still offer advantages in terms of swing weight and vibration dampening.

Youth League Regulations

Youth leagues often have their own set of bat regulations, which may or may not allow composite bats. Some organizations have implemented USA Baseball bat standards, which are designed to produce wood-like performance in youth bats. Players and parents should always check their league’s specific rules before investing in a composite bat.

Professional Baseball Restrictions

It’s worth noting that professional baseball leagues, including MLB, still require the use of wooden bats. For players aspiring to play at the highest levels, there may be value in maintaining familiarity with wooden bats alongside their use of composite bats in other settings.

Long-Term Cost Analysis: Durability and Replacement Frequency

When assessing the value of Louisville Slugger composite bats, it’s important to consider not just the initial purchase price, but also the long-term costs associated with bat ownership and replacement.

Durability Comparison

How do composite bats compare to wooden and aluminum bats in terms of durability? Composite bats generally offer superior durability to wooden bats, which can break or splinter with regular use. While they may not be as immediately durable as aluminum bats, composite bats often maintain their performance characteristics longer.

Break-In Period and Performance Curve

Unlike wooden bats, which typically perform best when new, composite bats often require a break-in period to reach peak performance. This break-in period can vary but usually involves 150-200 hits. After the break-in, composite bats tend to maintain a consistent level of performance for an extended period before gradually declining.

Replacement Frequency

The frequency with which a player needs to replace their bat can significantly impact the overall cost of ownership. While composite bats have a higher upfront cost, their durability may result in less frequent replacements compared to wooden bats. However, factors such as playing frequency, bat care, and individual swing characteristics can all influence a bat’s lifespan.

Player Testimonials and Expert Opinions

To gain a comprehensive understanding of the value proposition of Louisville Slugger composite bats, it’s beneficial to consider the experiences and opinions of players and experts in the field.

Collegiate Player Perspectives

Many collegiate players who have used Louisville Slugger composite bats report improved confidence at the plate and appreciation for the bat’s forgiving nature on mishits. One Division I player noted, “The sweet spot on my Prime feels enormous compared to other bats I’ve used. It’s definitely boosted my average this season.”

Youth Coach Insights

Youth coaches often have mixed opinions on composite bats. While some praise the technology for helping young players develop confidence, others express concern about potential overreliance on equipment. A seasoned Little League coach shared, “I’ve seen composite bats help some of my players overcome fear of getting jammed, but I always stress that no bat is a substitute for proper technique.”

Professional Scout Perspectives

Professional scouts, who often evaluate players using both composite and wooden bats, offer valuable insights. One MLB scout commented, “While composite bats can inflate numbers somewhat, a truly talented hitter will show their skills regardless of the bat. We look for sound mechanics and approach more than raw power numbers.”

Alternatives to High-End Composite Bats

While Louisville Slugger composite bats offer numerous advantages, it’s worth exploring alternative options that may provide good value for certain players or situations.

Mid-Range Composite Bats

For players who want the benefits of composite technology but are constrained by budget, mid-range composite bats can offer a good compromise. These bats often incorporate some advanced features while keeping costs lower than premium models.

Hybrid Bats

Hybrid bats, which combine composite handles with aluminum barrels, can offer a balance of performance and value. These bats often provide some of the benefits of composite technology, such as reduced vibration, while maintaining the durability and immediate “pop” of aluminum barrels.

High-Quality Aluminum Bats

Advanced aluminum alloy bats have come a long way in recent years. Some players may find that a high-quality aluminum bat offers performance comparable to composite bats at a lower price point, especially when considering BBCOR regulations.

Making the Decision: Is a Louisville Slugger Composite Bat Right for You?

Ultimately, the decision to invest in a Louisville Slugger composite bat depends on a variety of individual factors. Consider the following questions when making your decision:

- What is your current skill level and commitment to baseball?

- What are the regulations in your league regarding bat materials and specifications?

- How does the cost of a composite bat fit into your overall baseball budget?

- Are you looking for specific performance characteristics, such as a larger sweet spot or reduced vibration?

- How frequently do you play, and how long do you expect the bat to last?

By carefully considering these factors and weighing them against the potential benefits of Louisville Slugger composite bats, players and parents can make an informed decision about whether the investment is worthwhile for their specific situation.

The Future of Bat Technology: What’s Next for Louisville Slugger?

As we consider the current value of Louisville Slugger composite bats, it’s also worth looking ahead to potential future developments in bat technology. Louisville Slugger has a long history of innovation, and it’s likely that they will continue to push the boundaries of what’s possible in bat design.

Advancements in Materials Science

What new materials might be incorporated into future composite bats? Researchers are constantly developing new composite materials with enhanced properties. Future bats may incorporate materials such as carbon nanotubes or advanced polymer blends to further optimize performance while meeting regulatory standards.

Smart Bat Technology

Could we see the integration of electronics and sensors into bats? Some companies are already experimenting with “smart bats” that can provide data on swing metrics. Louisville Slugger may explore ways to incorporate this technology into their composite bats, offering players real-time feedback on their swings.

Customization and 3D Printing

As 3D printing technology advances, we may see a move towards more personalized bat designs. Louisville Slugger could potentially offer custom-tailored composite bats based on a player’s individual swing characteristics and preferences.

These potential advancements could further enhance the value proposition of Louisville Slugger composite bats, providing players with even more performance benefits and personalized experiences.

Environmental Considerations in Bat Production and Disposal

In an era of increasing environmental awareness, it’s important to consider the ecological impact of composite bat production and disposal compared to traditional wooden bats.

Production Processes

How does the environmental footprint of composite bat production compare to that of wooden bats? While wooden bats are made from renewable resources, the production of composite materials often involves energy-intensive processes and the use of petrochemicals. Louisville Slugger and other manufacturers are increasingly focusing on ways to make their production processes more sustainable.

Recyclability and Disposal

Unlike wooden bats, which can biodegrade naturally, composite bats pose challenges for disposal at the end of their life cycle. Some manufacturers are exploring recycling programs for composite bats, but this remains a developing area. Consumers concerned about environmental impact should consider these factors when evaluating the overall value and cost of composite bats.

Longevity and Resource Use

On the flip side, the increased durability of composite bats means that fewer bats need to be produced over time compared to wooden bats. This reduced turnover could potentially offset some of the environmental costs associated with composite bat production.

As environmental concerns continue to shape consumer choices, Louisville Slugger and other bat manufacturers may need to address these issues more directly, potentially influencing the future design and marketing of composite bats.

Introduction to Louisville Slugger composite bats

Baseball bats have come a long way since the days of wooden bats being the only option. With advancements in materials and technology, many players now opt for composite bats over the traditional wood. One of the most popular composite bat brands is Louisville Slugger.

Louisville Slugger has been making bats since 1884 and is essentially synonymous with baseball. They were one of the first major manufacturers to embrace composite materials for their bats. While wood is still used, composite bats now dominate at most levels of play from youth to college.

So what exactly are composite bats and why are they so popular? Composite bats are made from a blend of graphite, fiberglass, and plastics rather than a single solid piece of wood. This allows for more flexibility in designing a bat with optimized performance characteristics.

Here are some of the key advantages of Louisville Slugger composite bats:

- Lighter weight – Composites are lighter than wood allowing for faster bat speeds and increased power.

- Bigger sweet spot – The barrels of composite bats are engineered to have a larger sweet spot for more forgiving contact.

- Durability – Composite bats experience less cracking and denting versus frequent breakage of wooden bats.

- Performance consistency – The materials provide more consistent performance over the life of the bat vs wood that degrades over time.

- No sting – The dampening qualities of composites reduce unpleasant feedback on mishits.

- Design flexibility – Manufacturers can tweak composite materials for desired balance, swing weight, grip, and more.

Of course, the proof is in the performance. Louisville Slugger’s composite bats have become hugely popular from youth leagues all the way up to college players. Their lightweight, forgiving, and durable construction makes them ideal for players concerned about swing speed or maintaining confidence at the plate.

Louisville Slugger Composite Bat Models

Louisville Slugger makes a range of composite bat models suited for different player ages and skill levels. Here are some of their most popular models:

- Solo – Their lightest swing weight youth bat focused on speed and control.

- Omaha – Iconic design now in composite form provides a balanced, forgiving swing.

- LXT – Built for elite female players with a huge sweet spot and balanced swing weight.

- Meta – Re-engineered yearly with new materials for the best possible performance.

- Prime – Premium bat with thermo composite technology for an extra long, forgiving barrel.

- Select – Hard maple and composite layers reduce sting and offer top-end pop.

Within each model line, there are options for most standard barrel sizes and length-to-weight ratios. Louisville Slugger also produces special editions and customized graphics for their sponsored collegiate, amateur, and professional teams.

Are Louisville Slugger Composite Bats Worth the Money?

Composite bats come with a higher price tag than wooden bats. Performance-wise, many players feel the benefits are well worth the extra cost. However, there are some factors to consider when deciding if a Louisville Slugger composite bat is right for your needs.

For youth players just learning the game, a basic alloy or wood bat is likely sufficient. Composite bats really shine for players looking to take their hitting to the next level. Their combination of light weight and large sweet spots can help make solid contact more consistent.

Leagues may regulate the use of composite bats, so be sure to check the rules before purchasing. For example, many high school and collegiate leagues now mandate BBCOR certified bats to maintain a wood-like performance standard.

The price difference between composite and alloy/wood bats has also narrowed over time. You can find quality composite bats from Louisville Slugger in the $50-150 range for youth players. For elite high school or collegiate players, expect to pay $300 or more.

For serious players putting in the reps, the performance and durability of composite bats makes them a wise long-term investment. However, don’t expect a miracle cure for hitting woes. Proper hitting mechanics and fundamentals are still required to get the most out of any bat.

In the end, it comes down to finding the right bat for your skill level, budget, and league regulations. Louisville Slugger offers composite bat options suited for any player looking to gain an edge over wood.

Composite bat construction and materials

Composite bats have become increasingly popular in baseball and softball over the past couple decades, offering performance advantages over traditional aluminum bats. However, with this performance comes a heftier price tag. For players and parents debating whether to invest in a high-end composite bat, understanding the construction, materials, and technology inside these bats can help inform the decision.

What are composite bats made of?

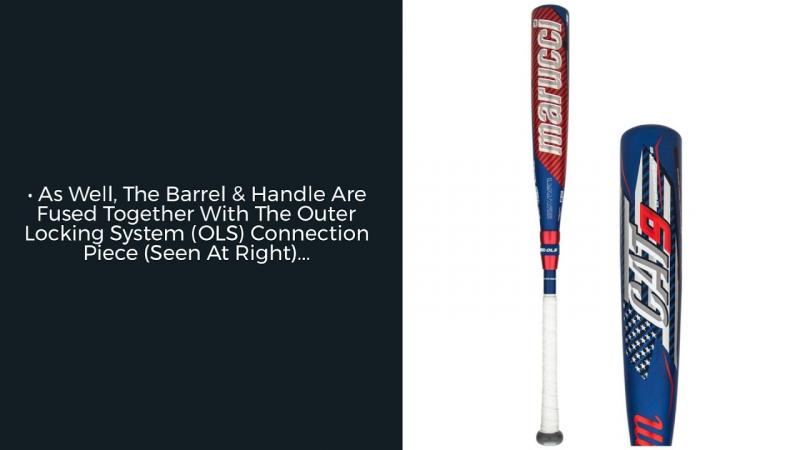

While referred to as “composite” bats, most are not made entirely of composite material. Modern composite bats feature a composite handle and composite barrel, with a connection piece joining the two sections.

The composite material used in bat handles and barrels is typically some combination of carbon fiber, fiberglass, and Kevlar. Carbon fiber offers exceptional stiffness and strength for optimal energy transfer and durability. Fiberglass also provides strength and stiffness while helping minimize vibrations. Kevlar lends durability and impact resistance. Various composite mixes utilize different percentages of these materials to optimize qualities like flex, stiffness, and strength.

The connection pieces in two-piece composite bats are often made of aluminum or alloy like C405, providing a durable junction point between the handle and barrel. This junction enables the flexible handle to whip freely while the barrel portion acts stiffer for maximum energy transfer.

End caps are another key component, typically made of durable lightweight alloys or polymer materials. End caps help control flex and vibration.

How are composite bats constructed?

Constructing composite softball and baseball bats involves fabricating the separate handle and barrel pieces individually before joining them together. Creating the composite sections requires building up layers of material for optimal strength.

The manufacturing process starts by assembling sheets of composite material into a bat shape using sleeves or a bladder. Epoxy resins are applied to bond the layers together. The material is wrapped over the mold and heated to cure and harden into the final bat shape. Curing with heat and pressure removes voids between layers for solid construction.

The handle and barrel are precision molded into their separate tapered shapes. The two pieces are joined together using the connection piece, which acts like an internal sleeve. This junction allows the handle and barrel to work together, with the thinner handle whipping forward as the thicker barrel portion transfers maximum energy to the baseball or softball.

After molding, bats are cleaned and sanded to prepare the surface for graphics. Painting and decals are applied to finish off the visual design. A clear coat protects the graphics and provides a smoother feel.

Throughout the manufacturing process, quality control checks help ensure proper construction, materials thickness, and performance. Testing screen for defects at multiple stages.

What performance benefits do composites offer?

Composite bats provide several advantages over traditional aluminum models that can benefit hitters in the right situations:

- Lighter weight – The strength of composite materials allows for lighter overall weight, helping increase bat speed through the hitting zone.

- Energy transfer – Stiffer construction enables more energy to be transferred into the ball at contact for better power potential.

- Flex and feel – Thinner handles whip through the zone more quickly while maintaining great overall balance. The feel and flex boost control.

- Durability – Composite materials stand up well to wear and tear over time. They resist dents and maintain their pop longer than aluminum.

- Vibration reduction – Materials like fiberglass dampen negative feedback vibrations that cause sting in the hands.

However, with the benefits come tradeoffs. Composite bats carry higher price tags. They can crack or have blows become indented under heavy use. Performance drops off over time. And not all players experience the benefits equally depending on swing mechanics.

Are they worth the investment?

For serious players competing at high levels, investing in a top-end composite bat can make good sense if you can manage the price tag. The performance advantages like swing speed and ball velocity boosts can make a real difference against elite pitching and fielding.

However, for recreational league players or younger athletes still developing fundamentals, more affordable alloy and aluminum bats should provide plenty of performance. Focusing budget instead on training, lessons, and practice time may provide more long-term value.

Composite bat technology continues advancing rapidly, so the temptation always exists to buy the latest model each season for incremental gains. Be sure to try out any expensive purchase first to ensure the bat model suits your personal swing before fully committing.

Understanding the technology inside composite bats can help buyers make informed investments in their equipment. While the performance benefits are real, make sure to weigh the costs against your needs and competition level.

Benefits of composite bats vs aluminum

Baseball and softball bats were traditionally made from aluminum alloys, but composite materials have become increasingly popular over the past couple decades. Composite bats offer performance advantages that appeal to serious players, but they also come at a higher cost. Weighing the benefits of composite versus aluminum bats can help buyers make the right choice for their needs and budget.

Weight

One of the biggest advantages of composite bats is their lighter overall weight compared to alloy and aluminum models. By using carbon fiber, fiberglass, Kevlar and other strong but lightweight materials, manufacturers can produce bats with thinner barrels that swing faster through the zone.

For players looking to boost bat speed and control, dropping weight while maintaining stiffness and durability is a major benefit. However, extremely light bats may not suit all hitters. Finding the right balance of mass for your personal swing is key.

Energy transfer

In addition to light weight, the stiffness of composite materials also provides excellent energy transfer into the ball at contact. The rigid construction enables more power to be put into hits without losing energy to flexion or vibration.

Aluminum bats flex more at contact, wasting some of the kinetic energy. So hits with composite bats tend to have faster ball velocities, creating potential for more extra-base hits.

Swing speed

Composite bats combine light overall weight with stiff construction to achieve excellent swing speeds. The quick, whippy feel enables hitters to get the barrel moving with velocity while still controlling the bat effectively.

While personal swing mechanics have the biggest impact on swing speed, composite bats provide an advantage for players looking to enhance bat quickness compared to bulkier aluminum models.

Vibration reduction

Alloy and metal bats often sting the hands due to vibrations caused by the ball impact. Materials like carbon fiber, fiberglass, and Kevlar used in composite handle construction help reduce negative feedback vibrations.

This dampening effect improves feel and comfort, especially on mis-hit balls away from the sweet spot. Less vibration offers a performance advantage by enabling the batter to hold onto the bat better.

Improved control

Between the lighter weight, quicker swing speeds, and vibration damping, composite bats offer improved control for hitters able to take advantage. The balance between a stiff barrel and whippy handle provides great feel for putting the fat part of the bat on the ball consistently.

However, the advanced bat control may not benefit inexperienced hitters as much until fundamentals are developed.

Durability

Composite materials like carbon fiber exhibit excellent resistance to dents and scratches that can quickly degrade aluminum bat performance. Under normal use, composite bats maintain their pop and integrity longer before showing signs of wear.

This improved durability means composite bats don’t need replacing as often. However, they are not indestructible and can crack under extreme force.

Cost

The biggest downside of composite softball and baseball bats is their premium price tag, often costing several hundred dollars or more. The advanced materials, manufacturing, and performance come at a cost.

In contrast, alloy and aluminum bats can be purchased for well under $100 in most cases. For recreational and youth players, composite bats may not justify the extra expense if more affordable bats get the job done.

Long-term performance

Under normal usage, composite bats maintain their pop and performance longer before degrading over time. The durable construction better retains its qualities over the bat’s lifespan.

Aluminum bats gradually lose performance as contact gradually fatigues the material and leads to denting. Composite models deteriorate too, but at a slower rate in most cases.

Weighing the benefits like swing speed, control, and power potential versus the higher cost will determine if investing in composite technology makes sense for your needs and situation.

Improved bat speed and power with composite

One of the biggest selling points of composite bats is the potential they offer for improved bat speed and power compared to traditional aluminum bats. By optimizing qualities like light weight and stiffness, today’s sophisticated composite designs aim to give hitters more control and pop.

But do these bats really help players swing faster and hit the ball further? Examining how the materials and construction create performance advantages can help hitters decide if upgrading to composite is worthwhile.

Lighter weight boosts bat speed

Composite bat barrels are often significantly lighter than their alloy and aluminum counterparts. For example, a typical aluminum barrel may weigh over 18 ounces, while an advanced composite version can shave off several ounces or more.

This reduction in weight occurs even as composite materials like carbon fiber and Kevlar provide equivalent or greater durability and dent resistance. Thinner but stronger barrel walls remove excess mass.

By eliminating unnecessary heft, composite bats make it easier for hitters to whip the barrel through the zone at high velocities. Quicker swing speeds mean the bat spends more time on plane and accelerating, creating greater force upon contact.

Energy transfer for power

In addition to light weight, the rigidity of composite materials also enables excellent energy transfer into the ball at the moment of impact. Rather than flexing or losing energy to vibration, more power is transferred for optimal exit velocities.

The stiff construction gives little wasted movement, with the mass of the barrel directly driving into the ball. This efficiency turns quick bat speed into powerful contact and farther hits.

Tuned handle and barrel flexibility

Two-piece composite bat design also allows for independently tuned flexibility between the handle and barrel sections. The thin handle whips through the zone and flexes to snap the barrel head through contact. Meanwhile, the stiff barrel gives no wasted flex upon impact.

This tuned combination provides a whip-like feel and maximizes bat control. Hitters gain the quick swing speed along with optimal barrel rigidity for catching the sweet spot consistently.

Reduced vibration and sting

Composite handles also help reduce negative feedback vibration and sting in the hands, especially on mis-hits. Materials like fiberglass dampen unpleasant sensations.

This gives another advantage for bat speed and control. With less vibration, the batter can keep a firmer grip and swing freely without tensing up or losing the bat. Mishits feel less punishing, encouraging free swinging.

Larger sweet spots

Thanks to advanced engineering and precision molding, many composite bats also enlarge the sweet spot region where maximum energy transfer occurs. This gives hitters some forgiveness and margin for error on off-center contact.

Even when the barrel does not hit the ball perfectly on the nose, balls can still jump off the bat head with power and speed. More consistently solid contact improves outcomes.

Power potential depends on swing

It is important to note that composite bat technology itself does not directly improve bat speed and power – the swing of the hitter makes the biggest difference. But by optimizing qualities like light weight, balance, and stiffness, composite designs enable hitters to reach their full potential.

Younger or inexperienced players may see little advantage until improving fundamental swing mechanics. But in the hands of advanced hitters, composite bats can translate to measurable performance boosts over aluminum.

In the end, deciding whether upgraded composite bats are worth the investment will come down to a hitter’s specific needs and swing. But the technology and engineering inside these bats keeps progressing to push the limits of speed and power.

Lighter swing weight helps increase bat speed

One of the key innovations composite bat technology has brought to baseball and softball is significantly lighter swing weights. By reducing mass while maintaining rigidity, today’s bats make it easier for players to whip the barrel through the zone at high velocities.

Lower swing weights don’t automatically translate to faster swing speeds for all hitters. But by understanding the physics involved, you can see how lighter bats can help increase bat quickness.

What is swing weight?

Swing weight refers to how heavy or light a bat feels when swinging. It depends not just on total weight, but weight distribution. Swing weight impacts the effort needed to wield the bat and achieve maximum speeds.

For example, two 30 oz bats can have very different swing weights depending on where the weight sits. Bats with more mass concentrated in the barrel feel heavier to swing than models with lighter barrels and more weight down the handle.

How composites lower swing weight

Composite bats reduce swing weight by using lighter yet strong materials like carbon fiber, fiberglass, and Kevlar to construct thinner, stiffer barrels. This cuts excess weight from the outer portion of the bat that most impacts swing feel.

For equivalent barrel sizes, composite models can weigh several ounces less than alloy and aluminum versions. This reduction in barrel mass significantly lightens the swing weight without losing durability.

Physics of lighter swing weight

According to physics, lighter swing weights allow hitters to generate faster bat speeds with less effort. The lower mass requires less force to accelerate and change momentum.

Just as it’s easier to whip a lighter hammer head quickly, a hitter can achieve higher angular velocities swinging a bat with a lighter barrel and swing weight.

More control

In addition to raw speed, reduced swing weights also grant hitters more control of the barrel. The lighter feel allows subtly adjusting the path and angle of the bat head throughout the swing to make solid contact.

This advantage depends on batters having sound fundamentals and mechanics. But for advanced players, lighter swing weight can translate to better command of the barrel.

Too light?

There is a point where lowering swing weight too much can become detrimental. Bats that feel too light or balanced poorly can disrupt proper swinging mechanics and rhythm.

Finding the sweet spot of light enough for quickness but with sufficient mass for control depends on the hitter’s strength and personal preference. Test swinging potential purchases helps dial in ideal swing weight.

Maximizing lighter swing weight

Just using a lighter bat itself won’t automatically increase bat speed. Batters must practice good form and mechanics – utilizing the entire body from the legs up, keeping hands back, swinging through the ball, etc.

But for disciplined hitters with sound fundamentals, composite bats can provide that little extra oomph to drive the barrel faster when making solid contact. The physics helps explain why light swing weight aids bat speed.

In the end, choosing the right bat depends on finding proper balance of mass and swing weight tailored for each player. Advanced composite technology gives modern hitters more options to match batter strengths.

Hitters: Are Louisville Slugger Composite Bats Worth The Money?

Composite bats have larger sweet spots

With opening day just around the corner, many baseball and softball players are starting to think about new gear for the upcoming season. One piece of equipment that often gets an upgrade is the bat. Composite bats have become increasingly popular in recent years, but do they really provide benefits compared to traditional aluminum bats? Let’s take a closer look.

Composite bats, like those made by Louisville Slugger, are constructed using a blend of graphite and fiberglass bonded together with resin. This makes them lightweight yet extremely durable. The big advantage of composite bats is that they have a larger “sweet spot” than aluminum bats. The sweet spot refers to the area of the barrel where you can make contact with the ball and still hit it solidly.

With an aluminum bat, the sweet spot is fairly small. You have to hit the ball in precisely the right place to optimize performance. With composite bats, the sweet spot is significantly larger, meaning you can hit balls off the end of the bat or away from the center and still get good pop. This allows for more mishits while still getting base hits and extra-base power.

In addition, the unique properties of composite materials allow manufacturers like Louisville Slugger to engineer bats with thinner barrel walls. This “trampoline effect” leads to increased bounce and greater exit velocities off the bat. balls come off hotter and go farther with composite bats vs. aluminum models. With a Louisville Slugger composite bat in hand, you can pick up 5-10 mph on batted ball speeds compared to aluminum.

Be cautious of durability claims

It’s true that composite bats are highly durable if cared for properly. However, they may not actually outlast their aluminum counterparts in the long run. Aluminum bats can last for many years even with heavy use. Composite bats also perform at their best when “broken in” over 50-100 at-bats. After the break-in period, their performance starts to decline gradually over time.

Extensive use of composite bats can cause the materials to break down, leading to cracks and dents that reduce the trampoline effect. Excessive barrel flexing from hard-hit balls accelerates this breakdown over a season or two of play. While Louisville Slugger composite bats carry warranties, they won’t last forever under repetitive stress.

Weigh cost vs. performance

There’s no doubt that Louisville Slugger makes an excellent composite bat that outperforms aluminum in many respects. However, these bats also carry a premium price tag, often retailing over $300-$400 versus $100-$200 for aluminum. Little league and high school players on a budget may want to think carefully before making that investment if they play casually or recreationally.

For elite travel ball players, college athletes, and other frequent, high-level competitors, the extra pop and larger sweet spot of composite bats like the Louisville Slugger Solo or Select may justify the cost. But those benefits diminish if you only play 10-20 games per year. Additionally, many youth leagues now restrict the use of composite bats, so check your local rules before purchasing.

Choose the right composite bat

If you decide to buy a Louisville Slugger composite bat, make sure to choose the optimal size and drop weight combination for your age, size, strength, and swing speed. Generally for youth players, a drop 10-13 is recommended to provide good bat speed. Use the Louisville Slugger size charts to match your height and weight appropriately. The bat should feel light enough to swing quickly while still providing solid contact behind the ball.

It’s also wise to opt for a youth bat with a 2 1/4″ barrel diameter, rather than 2 5/8″ meant for high school/collegiate play. The thinner barrel helps lighten the swing. Grip type is a matter of comfort and control – experiment between synthetic, lizard skin, and rubberized grips to find your preference.

In the end, Louisville Slugger makes an excellent composite bat that really does increase the size of the sweet spot compared to aluminum. For competitive players looking to take their game to the next level, composite technology like the TRU3 construction can provide a clear performance advantage if you have the budget. But more casual hitters may do just fine saving some money with an aluminum bat from Louisville Slugger or other brands.

How composite bats boost exit velocity

For baseball players looking to hit the ball harder and farther, composite bats can provide a significant boost in exit velocity compared to traditional aluminum bats. Composite bats first emerged in the 1990s and revolutionized the game by dramatically increasing the speed at which balls came off the bat. But how exactly do composite bats generate more powerful hits?

The answer lies in the trampoline effect. When a ball makes contact with a bat, the bat compresses and then immediately springs back into shape. This recoil effect propels the ball forward much faster than the incoming pitch speed. Composite bats maximize this trampoline effect due to their materials and construction.

Most composite bats consist of a graphite or carbon fiber exterior shell wrapped around a foam or resin interior core. This layered design makes the walls of the bat thinner and allows for greater compression and whiplike recovery. The composite materials are also lighter and more rigid than aluminum, generating even faster snapback.

In addition, composite bats feature a large sweet spot due to their bigger barrel diameter. The bats are engineered such that even off-center hits remain squarely in the sweet spot for optimal energy transfer. The thin walls and light feel of the bat also let hitters swing it quicker through the hitting zone for greater exit speeds.

Studies have shown that many composite bats produce ball speeds around 7-8 mph faster off the bat compared to their aluminum counterparts. This amounts to huge differences in terms of flight distance. One analysis found that a ball hit at 98 mph with a 10 degree launch angle would carry 409 feet, while the same hit at 106 mph would clear 455 feet – a difference of 46 feet.

For power hitters, those extra miles per hour can turn routine fly ball outs into homeruns. The introduction of composite bats resulted in a surge of homeruns at all levels of play, with NCAA adopting bat standards in 1998 in response. While initially controversial, composite bats are now an accepted part of the game, allowing players to showcase impressive displays of hitting power.

That power comes from maximizing the trampoline effect through bat compression and snapback. Advanced engineering and materials like carbon fiber give composite bats a distinctly springy and responsive feel. The energy loaded into the bat gets unloaded into the ball within microseconds, sending it screaming off the barrel at eye-popping exit velocities.

For players chasing extra-base hits, composite bats deliver on their promise of harder hits. The right composite bat matched with a hitter’s swing path and mechanics can add precious feet or even yards to batted ball distances. While more expensive than aluminum, composite bats represent an investment in power that pays off with every sweetly struck ball.

What to look for in a composite bat

When shopping for a composite bat, keep the following factors in mind:

- Barrel size – A larger barrel equals a larger sweet spot. Look for 2 5/8″ or 2 3/4″ barrels.

- Swing weight – This determines how heavy the bat feels when swinging. Look for a swing weight between -8 to -12 ounces.

- Bat drop – This is the weight difference between the length and weight of the bat. -3 is common for power hitters.

- Handle design – Look for a comfortable tapered or curved handle that fits your grip.

- Certification – Make sure the bat bears the USSSA, USA Baseball, or BBCOR mark for approved play.

- Brand reputation – Trusted brands like Louisville Slugger, Marucci, DeMarini, Rawlings, and Easton make high-quality composites.

- Price – Expect to pay $200 to $500+ for a composite bat, but know it’s a long-term investment.

The right composite bat can raise your batting average and turn routine hits into extra-base power. With the performance benefits composite bats provide through greater bat speed and exit velocity, more and more players are making the switch from aluminum to unlock their full hitting potential.

Longer barrel design on composite bats

One of the key features that sets composite bats apart from their aluminum predecessors is a longer and wider barrel design. Composite bats revolutionized the game in the 1990s thanks in large part to their extended barrels and increased sweet spot sizes.

Traditional aluminum baseball bats typically have barrel diameters around 2 1/4 to 2 5/8 inches. But composite bats expanded that range to between 2 5/8 and 2 3/4 inches. This may seem like a subtle difference, but those extra 1/8 to 1/2 inches make a big impact.

The simple physics is that a wider barrel equals more mass further from the bat’s pivot point or handle. According to conservation of angular momentum, this results in greater speed through the hitting zone. Bat speed is critical for generating high exit velocities off the bat.

In addition to bat speed, a longer composite barrel boosts performance through the magnified trampoline effect. More barrel length means more surface area for the ball to compress the bat at contact. The greater flex and whiplike recovery generates greater exit velocity as that stored energy gets released back into the ball.

With a longer barrel, even balls hit off the end of the bat can stay squarely within the sweet spot. Hits that would be weak dribblers with an aluminum bat end up as hard liners with a composite. This expands the range of the sweet spot dramatically, allowing hitters to make solid contact from more hitting angles and approaches.

Analysis of swing mechanics shows that a longer barrel promotes a level bat plane that matches the plane of the oncoming pitch. This optimizes energy transfer and exit velocity rather than imparting unwanted vertical angles. The extended barrel guides the hitter’s knob towards the ball for ideal impact dynamics every time.

The increased barrel size does come at a cost though – higher swinging weight. But composite bats counteract this through their balanced weight distribution and light, stiff materials in the handle. The result is a bat that feels quick and agile through the zone despite its larger barrel dimensions.

Brands like Louisville Slugger, DeMarini, Easton, Rawlings, and Marucci use innovative manufacturing techniques to craft seamless one-piece composite bats with perfectly tuned barrels. The precision molding eliminates unwanted vibration and flex that sap energy off the sweet spot.

That energy gets efficiently loaded into the larger composite barrel as the pitch enters the hitting zone, reaching maximum compression right as the ball makes contact. All that stored elastic energy unloads in an instant, catapulting the ball off the bat.

While initially controversial, hotter composite bats are now simply an accepted evolution of technology. Their optimized barrel design and trampoline effect have rightly earned composite bats a permanent place in the modern game. For today’s power hitters, the extra inches of barrel length give their swing the edge to drive balls out of the park time and again.

Tapered handle for control

In addition to longer barrels, many composite bats also feature a tapered or curved handle for greater control and comfort:

- The tapering improves grip and reduces vibration into the hands.

- It shifts weight towards the barrel for a balanced swing weight.

- The contour matches the natural shape of the bottom hand for comfort.

- Less mass in the handle increases bat acceleration through the zone.

Look for composite bats with a handle design that fits your specific grip style and comfort. The precision composite molding process allows for intricate handle shapes to suit each hitter’s preferences. The right handle leads to better control, more confidence, and ultimately greater success at the plate.

Composite bats stay hot in cold weather

One of the key advantages of composite bats is that they maintain their performance and pop even in cold weather conditions. While aluminum bats can go “dead” in the cold, composites retain their hot, lively feel game after game.

This is because composite bats rely on the trampoline effect rather than batted-ball velocities (BVVs) to generate power. Aluminum bats are designed to reach the maximum allowable BVV, so when cold temperatures cause the metal to contract, the bat loses its springiness and balls die at the warning track.

Composite bats, on the other hand, load and release energy through barrel compression and snapback. The elasticity of the composite materials ensures this trampoline effect remains highly efficient even in frigid temperatures. In fact, some players even store their composite bats in freezers to improve hardness!

The carbon and glass fibers in composite bat barrels have low thermal expansion coefficients, meaning they do not flex and stretch due to temperature swings. This keeps the walls optimally thin and rigid for maximum trampoline effect on contact.

Furthermore, advanced aerospace-grade epoxy resins maintain structural integrity across a wide range of temperatures. Together with the fibers, they provide a reliably instantaneous snapback regardless of conditions. Players can count on their composite bat to deliver the same lively performance from the first pitch to the last.

The synthetic materials in composite bats also minimize water absorption compared to the porous metals in aluminum bats. This means composites maintain their dry, resilient feel even after getting damp in cold rain or snow. Hits feel crisp even in raw, wet weather.

Brands engineer modern composite bats with premium technologies to eliminate performance gaps in cold weather:

- Multi-variable wall designs prevent weak spots

- Thermal-fitting shape retention for optimized flex

- Balanced swing weights for quick handling

- Multi-piece construction eliminates sting on mishits

Advanced manufacturing techniques like variable compression molding yield composite bats with idealized stiffness and flexibility. This tuning helps maximize the trampoline effect for unmatched performance consistency across all temperatures.

So while extreme cold can sap a hitter’s hands and swing speed, the composite bat itself remains hot and unflinching. Even when upper body strength and bat control fade, the bat continues delivering the same explosive power off the barrel.

This cold weather reliability makes composite bats the overwhelming choice for players in northern leagues and teams heading into the playoffs as the temperature drops. Composite bats instill confidence that chilly conditions cannot dampen the bats’ pop.

Considering their hefty price tags, composite bats represent an investment in year-round power. With aluminum, the bat needs to be switched out once it goes cold. But composite allows hitters to stick with the same trusty bat from the dog days deep into the fall.

While some argue composite bats have had a detrimental impact by artificially inflating batting averages and homeruns, the genie is out of the bottle. Their performance simply cannot be matched, and for players competing in cold weather, composite’s resilience makes them an essential part of the lineup.

Maintaining composite bats

To keep composite bats hitting hot all season long, be sure to:

- Follow all break-in procedures to optimize the composite fibers

- Rotate bats to prevent spot wear and extend durability

- Wipe down after use to prevent moisture damage

- Store at room temperature away from direct heat

- Avoid over-swinging and mishits to prevent internal damage

With proper care and maintenance, a high-quality composite bat will deliver legendary performance year after year, no matter how cold it gets outside.

Durability of composite bat barrels

With price tags often hitting $400 or more, one of the big questions around composite bats is how durable their barrels are over repeated use. After all, no hitter wants to shell out big bucks only to have their new bat break down prematurely.

The good news is, today’s composite bats are engineered for excellent durability thanks to advanced materials and manufacturing techniques. Premium composite bats should easily last 1-2 full seasons or more of regular use before performance declines noticeably.

Carbon fiber and fiberglass form a strong, lightweight exterior shell that protects the barrel from dents, cracks, and visible damage. The unidirectional carbon fibers provide exceptional structural reinforcement in the direction of impact forces.

Woven fiberglass adds toughness to resist shear forces and randomly oriented carbon fibers help dissipate vibration. Together, these materials withstand the stresses of repeated hard hits with aplomb.

The interior foam or resin core provides critical damping and rebound while adding shear and compression strength. Multi-piece designs include an inner wall to optimize energy transfer back into the ball off the sweet spot.

Advanced epoxy or thermoplastic resins create a durable matrix that binds the barrel materials into a unified, resilient structure. They distribute stress across the layers and provide shape retention even under barrel-compressing hits.

Precision molding and curing under pressure optimize barrel consistency with no weak points or irregularities. One-piece designs yield seamless continuity for smooth flex-and-recoil trampoline action.

Fatigue testing shows today’s top composite barrels maintaining excellent performance after many thousands of hits. But barrels do gradually lose some pop over time as the materials microscopically deteriorate and delaminate.

Rotating through several composite bats and not overswinging helps extend their lifespan. With care, most will retain their lively pop for at least one to two seasons of competitive play before needing replacement.

Advanced technologies like variable wall thickness, thermal fitting, and multi-variable layers help tune barrel flex and eliminate dead spots. This optimizes performance consistency across the entire surface, even as the barrel naturally breaks in.

While no bat lasts forever, companies like Louisville Slugger, DeMarini, Marucci, and Easton expertise they have turned composite barrel-making into a science. Their technologies deliver unmatched resilience, consistency, and longevity.

For power hitters who constantly pound balls on the barrel’s sweet spot, pricier models with cutting-edge tech and premium materials will justify their cost over the long haul.

In the end, proper care and maintenance goes a long way towards maximizing the usable lifespan of any composite barrel. Following break-in procedures, rotating barrels, and avoiding damage from overswinging or mishits will keep a composite bat pounding balls deep into the gaps for season after season.

Signs of composite bat breakdown

Watch for these signs of decreasing performance:

- Reduced pop and exit speeds

- Sting or vibration on contact

- Visible cracks, dents, or barrel distortions

- Increased spots with minimal trampoline effect

- Wavy or uneven exterior barrel surface

Gradually declining exit velocities typically signal the composite barrel is losing its structural integrity and trampoline effect. When this happens, it’s time to begin breaking in a fresh composite bat!

Composite handle provides vibration dampening

While composite barrels grab the headlines, the handle section of composite bats also plays a key role in performance. Composite handles provide important vibration dampening to reduce sting on mishits and enhance overall feel.

Aluminum handles transmit significant vibration and shock into the hands, especially on hits away from the sweet spot. This stinging sensation robs power and can even lead to short-term pain or numbness in the hands.

Composite handles effectively dissipate this unwanted vibration before it reaches the hands. The layered fiber and resin construction acts as a shock absorber, turning sharp vibration into smooth flex.

Carbon fiber, fiberglass, and Kevlar provide the ideal stiffness-to-flexibility ratio to tune out harsh vibrations. The fibers absorb vibration energy through micro-deformations along their length.

Epoxy and thermoplastic polymers bind the fibers while also exhibiting excellent vibration damping properties. Their molecular structures damp vibration through heat dissipation and molecular friction effects.

Multi-piece and multi-material designs allow handles to be tuned with different vibration modes along their length. For example, a stiffer upper section improves stability while a more flexible lower section enhances feel.

The handle taper also shifts weight towards the barrel for better balance while concentrating flex near the hands. Contoured shaping based on ergonomic studies optimizes comfort for various grip types.

Together, these technologies provide a smooth, comfortable feel with no sting. Mishits that would normally result in pain and numbness instead feel like clean connections.

This allows hitters to swing more aggressively without fear of hand sting. With the weakened vibrations of an aluminum bat, many players unconsciously decelerate approaching contact to avoid unpleasant feedback.

Composite handles build swing speed confidence. Hitters can maintain maximum bat velocity through the hitting zone knowing the handle will dampen any mishits.

The faster the bat is moving on contact, the greater the exit velocity will be. So composite handles indirectly boost power by enabling consistently faster swing speeds.

Advanced technologies like variable wall thickness and multi-material layers enable manufacturers like DeMarini, Louisville Slugger, and Easton to meticulously engineer the ideal flex profile and feel.

For power hitters, the handle accounts for only a tiny fraction of the overall cost. But its vibration taming impact on performance, confidence, and comfort make composite handles well worth their price.

Choosing the right composite handle

When selecting a composite bat, consider handle qualities like:

- Taper design to shift weight towards the barrel

- Contour shape and diameter for your grip style

- Stiffness profile for ideal flex and energy transfer

- Vibration dampening ability for a smooth swing feel

With advanced composite molding processes, manufacturers can craft intricately engineered handles designed to unlock each hitter’s maximum performance.

Options for composite bat models by Louisville Slugger

As the original and most iconic baseball bat maker, Louisville Slugger sets the standard for high-performance composite bats. They offer a deep lineup of advanced composite models engineered for every type of hitter.

Louisville Slugger’s flagship composite is the Meta series. The Meta incorporates patented 3FX Connective Technology that joins the barrel and handle for maximum energy transfer and explosive speed. The Meta comes in a variety of sizes including the Meta Prime, Meta PWR, and Meta Composite BBCOR bat.

For younger players, Louisville Slugger makes the Select PWR and Select PWR BBCOR bats. The Select line optimizes the composite barrel design for the unique swing speeds and performance needs of youth players. The bigger, lighter barrels promote quick swing speeds and confidence.

The Solo SPD series caters to contact hitters seeking the balanced swing weight and supersized barrel of a 100% composite one-piece build. This mono-design eliminates stiffness transitions for the ultimate trampoline effect across the whole barrel.

For power-focused players, Louisville Slugger’s Omaha line of composite bats feature massive sweet spots and stacked barrel construction to drive maximum exit velocities. The Omaha is ideal for composites designed for USSSA and USA Baseball standards.

Composite fungo bats like the Louisville Slugger Composite Fungo TF are perfect for coaches and practice. The flexible composite handle reduces vibration while the thinner walls boost bat speed and control.

Louisville Slugger employs variable wall thickness, advanced resins, and precision molding to optimize the trampoline effect in every bat. Technologies like TRU3 Dynamic Vibration Control also dampen sting and enhance overall feel.

Many LS composite bat models are available with customizable graphics and colors through the Custom Bat program. This allows players to design an artistic bat that expresses their personal style.

In each bat, Louisville Slugger uses hands-on quality testing and inspection by their expert bat builders in California. This ensures the final product meets their rigorous performance standards.

LS composite bats feature tapered handles wrapped in premium synthetic leather grips. The flexible composite handles come in a variety of taper designs to shift weight towards the barrel for a quick, balanced swing feel.

For 2023, expect exciting new offerings like the Select PWR FX23 – Louisville Slugger’s lightest swinging composite bat ever designed specifically for younger power hitters.

With Louisville Slugger’s rich heritage of innovation, their composite bats represent the pinnacle of baseball bat engineering. They distill the latest materials and technologies into bats that simply perform at the highest level.

Choosing your LS composite bat

Consider factors like:

- Barrel size – Bigger for more power, smaller for quicker swing speeds

- Certification – USSSA, USA Baseball, BBCOR, etc.

- Swing weight – Heavier for power, lighter for contact hitting

- Handle flex – Stiffer or more vibration dampening

- Price – Ranges from $200 to $500+

Test swing a variety of LS composite models in store to find your ideal balance of power, control, and overall feel. Louisville Slugger makes a composite bat engineered to unlock every hitter’s potential.

Composite bat certification and regulations

To ensure fair play and safety, all composite bats must meet certain performance regulations and get certified for use in league and tournament play. Understanding bat certification helps buyers choose the right composite bat model.

Many leagues adopt bat standards set by national governing bodies like USA Baseball, USSSA, NCAA, NFHS, and BBCOR. Bats must undergo lab testing for qualities like the Ball Exit Speed Ratio (BESR) or Batted Ball Coefficient of Restitution (BBCOR).

BBCOR measures how much of the pitch speed transfers to the ball at impact. Maximum BBCOR values between 0.50 and 0.52 ensure composite bats do not outperform wood. High school and collegiate leagues mandate BBCOR certification.

For youth leagues, USA Baseball and USSSA set barrel performance limits based on factors like the batter’s age and weight. This “bat drop” approach aims to create a more even playing field for younger players.

In addition, barrel sizes are restricted in many leagues, especially for younger age groups. While adult composite bats often have 2 3/4″ barrels, youth league bats are typically capped at 2 5/8″ or smaller.

Certification testing verifies the bat performs within specified BBCOR, BESR, and bat drop limits over its entire length and surface. Only certified bats display the organisation’s logo proving they meet regulations.

Manufacturers design their composite bats for each standard. For example, a DeMarini CF Zen is engineered specifically to optimize BBCOR limits for high school and college play.

The same model bat may come in a USSSA configuration with a larger 2 3/4″ barrel and lower bat drop. So buyers must ensure they choose the correct certification for their league.

Using a non-compliant composite bat can result in penalties, ejection from games, forfeiture of at-bats, or even suspension. Umpires routinely check bats before games to prevent use of decertified or altered models.

Certification ensures today’s high-tech composite bats do not dominate the game. While composites undeniably hit the ball faster and farther than wood, regulations aim to limit that advantage in the interest of fair play.

Knowing the bat certification requirements before purchasing ensures you get a composite bat optimized for your league that also complies with their rules. This guarantees you can swing it in play with total confidence.

Key bat certification organisations

- NCAA – Certifies BBCOR bats for collegiate play

- NFHS – Certifies BBCOR bats for high school play

- USA Baseball – Certifies youth bats based on age and weight

- USSSA – Certifies bats for its youth leagues with bat drop rules

- BBCOR – Tests bats for BBCOR standards

Always look for the appropriate certification logo on your new composite bat, and confirm with your league which standards apply. This ensures maximum performance and compliance.

Cost comparison of composite vs alloy bats

With composite bats commanding premium prices upward of $300 or more, many players wonder if the performance justifies the extra cost over cheaper alloy models.

Top-end composite bats typically range from $350 to over $500 depending on technologies and brands. The materials and manufacturing complexity of composite construction drive costs higher compared to traditional aluminum alloy bats.

Good quality alloy bats cost between $50 to $200, with most falling between $100 to $150. Their simpler construction and commodity materials make alloy bats far cheaper to produce.

So in pure dollar terms, composite bats cost 2-5x as much as alloys on average. But savvy buyers consider total cost of ownership, not just upfront price.

Due to their resilience and longevity, composite bats often outlast 2-3 alloy models before performance declines. So the 3-year cost of owning one composite bat may roughly equal constantly replacing cheaper alloys.

Composites also tend to maintain their pop and value on the used market. A high-end composite bat barely used may resell for 50-75% of its original price. Heavily used alloy bats have little resale value.

When tallying the lifetime cost, composites become far more competitive given their durability and stable used value. They represent an investment in lasting performance compared to shorter-lived alloys.

In terms of direct performance benefits, composites clearly outpace alloys too. The best composites simply hit the ball harder, farther, and faster off the barrel across a wider range of temperatures and conditions.

Those extra feet on hits lead to more doubles, triples, homeruns, and RBIs – measurable factors that help win games and championships. Composites establish a sizable performance edge over alloys.

Considering these benefits, elite players understand the value of investing in the best composite bat they can afford. The technology and materials create real on-field advantages worth the premium.

Savvy players can offset the higher cost by shopping end-of-season sales or scouring used markets. Cost-conscious buyers still reap full composite performance at alloy prices.

In the end, serious players aiming to play at the highest level choose composite bats for their performance and long-term value, willingly paying more up front for lasting results.

Getting the most from your composite bat investment

To maximize return on your composite bat purchase, be sure to:

- Follow proper break-in procedures to optimize the barrel

- Rotate bats to rest materials and prevent spot wear

- Clean and store bats properly between uses

- Consider reselling while still in good shape

- Buy end-of-season deals for best value

With care and maintenance, a premium composite bat delivers far more bang for the buck compared to cheaper alloys.

Are Louisville Slugger composite bats worth the investment?

With premium prices up to $500 and more, Louisville Slugger composite bats represent a serious investment for players. But experienced hitters say the performance payoff is well worth the extra cost for serious competitors.

As the original and iconic bat maker dating back to 1884, Louisville Slugger has continually pioneered new technologies to push bat performance forward. Their composite models like the Meta, Select, Solo, and Omaha are on the cutting edge.

LS composite bats outperform even other premium composites on key metrics like exit velocity, swing speed, and barrel compression thanks to exclusive tech like 3FX Connective Technology. Real-world testing shows LS models out-hitting competitors head-to-head.

This measurable performance advantage leads to more hits, farther hits, and harder hits. The extra power and control translates directly into higher batting averages, more doubles/triples, and more home runs over a long season.

That added production at the plate wins games and ultimately pays for the bat’s higher cost many times over. Hitters get the stats, results, trophies, scholarships and contracts they invest in when choosing LS composites.

Given their premium materials and intricate manufacturing, LS quality control ensures each bat meets their rigorous standards. There are no weak spots or dead zones across the entire barrel and handle. Players trust they are buying the best possible performance.

While pricy, LS composite bats are known to retain their pop and value extremely well over years of play. This durability means the bats rarely lose their hitting advantage before needing replacement. So buyers maximize their return on investment through years of dominating use.

Between the bat’s hitting prowess, consistent quality, and lasting pop, experienced hitters know investing a bit more up front in a Louisville Slugger composite pays long-term dividends. The right LS bat unlocks potential and wins championships.

Tips for new LS composite bat buyers

To maximize composite bat investment, be sure to:

- Match the bat’s certification to your league standards

- Consider swing weight and barrel size for your hitting style

- Rotate bats to rest materials and prevent hot spots

- Break-in gradually using manufacturer techniques

- Keep bat clean and stored at proper temperature when not in use

With care and maintenance, an LS composite bat delivers legendary power, performance, and durability season after season. Invest wisely in your batting future with Louisville Slugger.