How do clock gears function to keep time. What is the history of gear technology in clocks. Why are gears essential for accurate timekeeping. How have clock gears evolved over the centuries. What are the different types of gears used in clocks. How are modern clock gears manufactured. What is the importance of proper gear maintenance in clocks.

The Essential Role of Gears in Timekeeping Devices

Gears are the unsung heroes of timekeeping, playing a crucial role in the accurate functioning of clocks and watches. These precisely engineered components work tirelessly behind the scenes, converting stored energy into the steady, rhythmic motion that marks the passage of time. But how exactly do these intricate mechanisms operate?

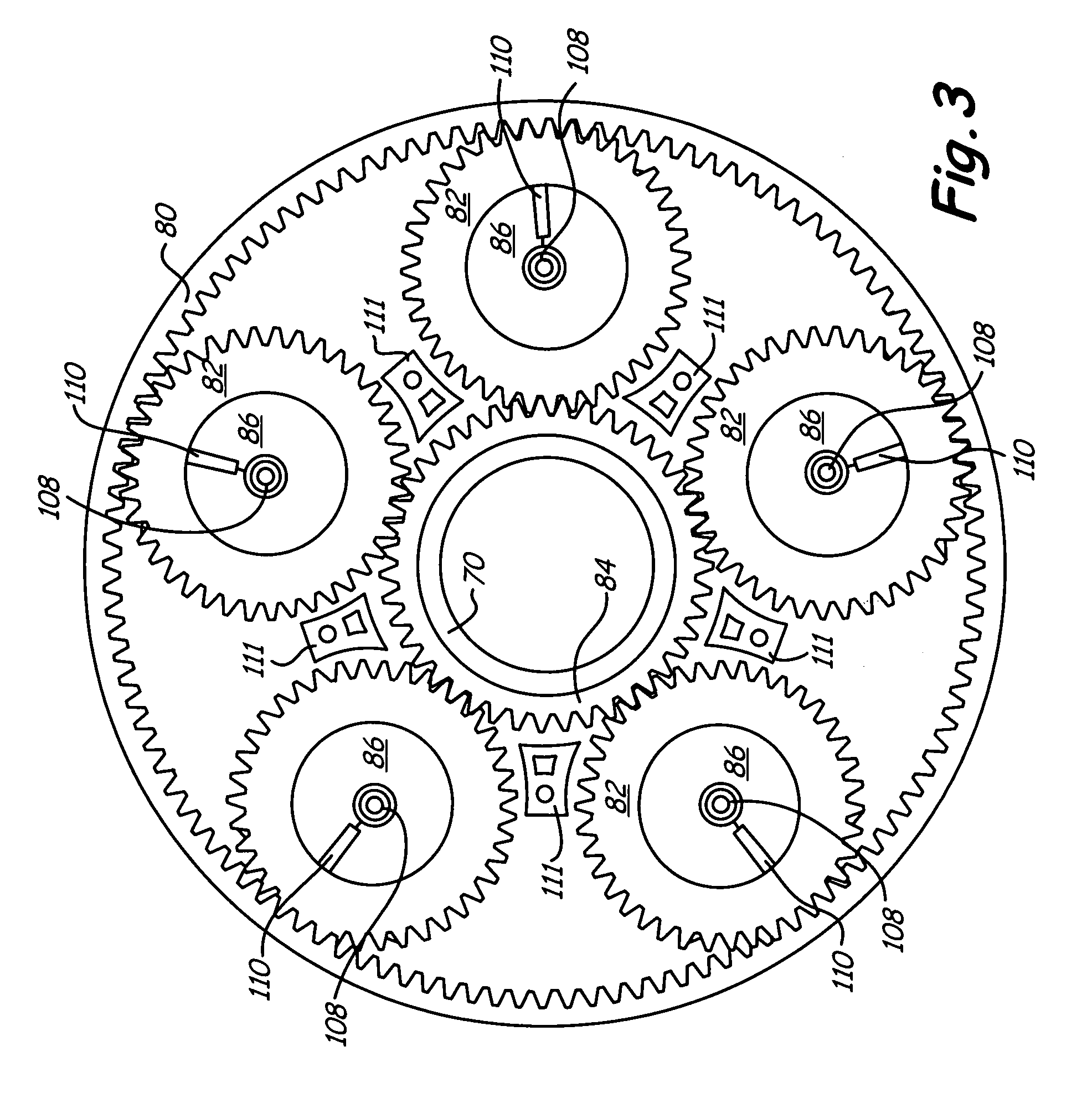

At its core, a clock’s gear system is designed to transmit force from the power source (such as a motor or mainspring) to the clock hands. This transfer of energy occurs through a series of interlocking gears, each carefully calibrated to rotate at specific intervals. The main drive gear connects directly to the power source, initiating the chain of motion that ultimately moves the hour, minute, and second hands.

Types of Gears in Clocks

- Drive gear: Connects to the power source and initiates motion

- Pinions: Smaller gears that mesh with larger wheels

- Leaf gears: Flat, disc-shaped gears with teeth around the edge

- Crown wheels: Gears with teeth perpendicular to the face

- Escape wheels: Control the release of energy and regulate timekeeping

The precise interaction between these various gear types is what allows clocks to maintain accuracy. Each gear’s size, tooth count, and rotation speed are carefully calculated to ensure that the hands move at the correct intervals – seconds, minutes, and hours.

The Evolution of Gear Technology in Timekeeping

The history of clock gears is a testament to human ingenuity and the pursuit of precision. How has gear technology evolved over the centuries to improve timekeeping accuracy?

In the 14th century, the earliest mechanical clocks used crude brass gears cut by hand. These primitive gears limited the accuracy of timekeeping to within several hours per day. However, innovations in gear design and manufacturing techniques led to significant improvements over time.

- 15th century: Introduction of stackfreeds (stackable gear sets) improved accuracy to within 15 minutes per day

- 18th century: Development of gear-cutting machines and standardized tooth profiles

- 19th century: Invention of watchmaker lathes enabled the creation of tiny, precise gears for pocket watches

- 20th century: Introduction of modern manufacturing techniques like CNC machining and laser cutting

These advancements in gear technology have transformed timekeeping from a rough estimate to an incredibly precise science, with modern mechanical watches capable of accuracy within seconds per day.

Modern Manufacturing Techniques for Clock Gears

Today’s clock gears are produced using cutting-edge technology that ensures unprecedented levels of precision. What methods are employed to create these intricate components?

- Laser cutting: Allows for extremely precise gear shapes and tooth profiles

- CNC gear shaping: Computer-controlled machines create gears with exceptional accuracy

- Precision machining: Advanced tools enable the production of gears with tolerances measured in microns

These modern manufacturing techniques have revolutionized the production of clock gears, allowing for mass production without sacrificing quality. Renowned clockmakers like Howard Miller and Hermle rely on these methods to create timepieces that combine traditional craftsmanship with modern precision.

The Artistry of Visible Gears: Skeleton Clocks and Decorative Timepieces

While many clocks keep their gears hidden, there’s a growing trend towards showcasing these mechanical marvels. Skeleton clocks, with their open faces revealing the inner workings, have become increasingly popular among horology enthusiasts. These timepieces allow admirers to witness the intricate dance of gears and escapements that drive the clock’s hands.

Beyond traditional metal gears, wooden gear clocks have emerged as a unique and eye-catching decor choice. These clocks combine functionality with artistic expression, often featuring hand-carved or laser-cut wooden gears that are as much a work of art as they are timekeeping devices.

Popular Styles of Decorative Gear Clocks

- Steampunk: Featuring brass gears and industrial aesthetics

- Nautical: Incorporating ship wheel designs and maritime themes

- Modern: Sleek, minimalist gear designs in contemporary materials

- Antique: Replicating the look of vintage clockwork

These decorative gear clocks offer more than just functionality; they serve as conversation pieces and focal points in interior design. Many enthusiasts appreciate the blend of engineering and aesthetics that these timepieces represent.

The Importance of Proper Gear Maintenance in Clocks

To ensure the longevity and accuracy of a mechanical clock, proper maintenance of its gears is crucial. What steps should clock owners take to keep their timepieces in optimal condition?

Regular lubrication is essential for the smooth operation of clock gears. The teeth, pivots, and pins of the gears should be lubricated according to the manufacturer’s recommendations. This reduces friction, prevents wear, and ensures that the gears continue to mesh properly.

Periodic cleaning is another vital aspect of clock maintenance. Over time, dust and debris can accumulate within the clock mechanism, potentially interfering with gear operation. Professional clock repair experts can perform thorough cleanings that remove these contaminants without damaging the delicate components.

Signs That Your Clock’s Gears May Need Attention

- Loss of accuracy or inconsistent timekeeping

- Unusual noises or grinding sounds

- Sticking or hesitation in the movement of the hands

- Visible wear or damage to the gears

If you notice any of these issues, it’s best to consult a professional clock repair specialist. Attempting amateur repairs can often lead to further damage, as the precise alignment and interaction of gears require specialized knowledge and tools.

Custom and Personalized Gear Clocks: A Unique Timekeeping Experience

For those seeking a truly one-of-a-kind timepiece, custom-built gear clocks offer an exciting opportunity. Skilled artisans can create bespoke clocks that incorporate personalized elements, exotic materials, and custom engravings. These unique creations allow clock enthusiasts to own a piece that perfectly matches their style and space.

Personalized gear clocks also make exceptional gifts. A tabletop clock engraved with a special date or message can serve as a meaningful keepsake. Wall clocks featuring family names or inspirational quotes become daily reminders in a loved one’s home or office, combining functionality with sentimental value.

Ideas for Personalizing Gear Clocks

- Incorporating birthstones or zodiac symbols into the gear design

- Using reclaimed wood or metal from a significant location

- Creating a clock face that depicts a favorite landscape or cityscape

- Integrating family heirlooms or meaningful objects into the clock’s structure

These personalized gear clocks not only tell time but also tell a story, making them treasured possessions that can be passed down through generations.

The Enduring Appeal of Gear Clocks in the Digital Age

In an era dominated by digital timekeeping devices, why do mechanical gear clocks continue to captivate us? The answer lies in their unique blend of nostalgia, craftsmanship, and tangible engineering.

The visible workings of gear clocks provide a sense of connection to the passage of time that digital displays simply can’t match. The steady ticking serves as a soothing reminder of life’s rhythms, offering a moment of pause in our fast-paced world. For many, a well-crafted gear clock becomes more than just a timekeeping device; it’s a piece of functional art that adds character and warmth to a space.

Moreover, the longevity of mechanical clocks appeals to those seeking sustainability in their possessions. Unlike digital devices that may become obsolete or unrepairable, a quality gear clock can be maintained and repaired for generations, becoming a cherished family heirloom.

The Future of Gear Clock Technology

As we look to the future, gear clock technology continues to evolve. Innovations in materials science and manufacturing techniques are allowing for even greater precision and durability in clock gears. Some modern clockmakers are experimenting with new alloys and composite materials that offer improved performance over traditional brass gears.

Additionally, the integration of smart technology into mechanical clocks is opening up new possibilities. Some high-end timepieces now combine traditional gear mechanisms with digital components, offering the best of both worlds – the aesthetic appeal of visible gears with the convenience of modern features like automatic time setting and smart home integration.

Despite these advancements, the fundamental principles behind gear clocks remain unchanged. The intricate dance of toothed wheels, spinning in perfect harmony to mark the passage of time, continues to fascinate and inspire. As we marvel at the precision of modern timekeeping, it’s worth taking a moment to appreciate the ingenuity and craftsmanship that goes into every gear clock – a testament to human creativity and our enduring fascination with measuring the moments of our lives.

An Inside Look at the Intricate Gears That Make Clocks Tick

The ticking of a clock is a familiar, almost soothing sound. But have you ever wondered what makes that rhythmic beat inside timekeeping devices? The answer lies in the intricate mechanical gears that turn ceaselessly to mark the passage of time.

Gears are essential components in clocks and watches, allowing them to operate accurately. Without these small, precisely cut gears intricately working together, we wouldn’t have reliable timekeeping as we know it today.

Clockwork gears come in a variety of shapes and sizes, each with a specific function. The main drive gear connects to the clock motor or mainspring to transmit force to the other gears. The meshing of the gears converts the stored energy into rotational motion to turn the hands at precise intervals. Pinions, leaf gears, crown wheels, and escape wheels each play their part in controlling the timing.

The evolution of gear technology over history led to huge leaps in timekeeping precision. In early clocks, gears were made of crudely cast brass. Later clockmakers used methods like hobbing to mass produce gears with much smoother, more uniform teeth. The advent of watchmaker lathes in the 1800s enabled intricate cutting of tiny gear teeth. This engineering marvel brought pocket watch accuracy from hours off per day to within mere seconds.

Today, clock gears are manufactured to remarkably high standards. Laser cutting, CNC gear shaping, and precision machining produce gears of incredible accuracy. Brands known for quality gear timepieces, like Howard Miller and Hermle, rely on such modern production techniques.

Not all clock gears are hidden away inside! Skeleton clocks have open faces to showcase their inner workings. Fanciful wooden gears are also a trendy decor choice. These allow you to admire the engineering up close.

Proper care is key for any clock’s gears. Lubricating the teeth, pivots, and pins according to the manufacturer’s recommendations keeps things running smoothly. Periodic cleaning by a professional clock repair expert also helps maintain optimal function.

If your clock is losing time, gears may be misaligned or have damaged teeth. A repair specialist can diagnose issues and replace any faulty components. Don’t try amateur DIY repairs, as imprecise tinkering can cause further damage.

Beyond function, decorative gear clocks offer eye-catching style. Choose metals, colors, and designs to match your personality. Skeletons, steampunk, nautical, modern, antique – there’s an aesthetic for everyone.

For a personalized touch, consider a custom-built gear clock. Skilled artisans can construct one-of-a-kind timepieces with custom engraving and exotic materials tailored to your space.

Gear clocks also make fantastic gifts. A tabletop clock engraved with a special date or message makes a meaningful sentiment. Wall clocks with family names or inspirational quotes become daily reminders in a loved one’s home or office.

Even in today’s digital world, the nostalgia and intricacy of gear clocks still fascinate. The precision engineering keeps us in awe and draws our imagination to times past. The steady ticking soothes our nerves and reminds us to pause and breathe. A well-crafted gear clock will keep time reliably for generations, becoming a treasured heirloom.

So next time you check your watch or wind your clock, take a moment to appreciate the harmony of tiny gears relentlessly clicking away. These miniature marvels of craftsmanship and ingenuity mark our moments and keep the world on time.

The Evolution of Clockwork and Gear Technology Over the Centuries

The gear – a simple machine that allows the transmission of power. Yet this unassuming technology transformed clocks and timekeeping as we know it. Tracing the evolution of clockwork gears reveals a fascinating history of innovation.

In earlier eras, sundials and water clocks were used to mark time’s passage. But the limitations of these devices spurred ingenious tinkerers to explore mechanical solutions. The earliest geared clocks appeared in Europe in the 14th century. These used an escapement mechanism linked by gears to turn hands at regular intervals.

Early clock gears were made of crudely cast brass, laboriously cut by hand. This limited their precision. But the 15th century brought advances like stackfreeds – stackable gear sets that allowed clockmakers to achieve more accurate gear ratios. Precision improved from hours off per day to around 15 minutes.

Mass production methods arose in the 18th century to supply the surging demand for household clocks. Clockmakers developed gear-cutting machines and standardized gear tooth profiles. The Industrial Revolution facilitated large-scale manufacturing using machines like gear hobbers.

The 19th century saw pocket watches shrink in size while gaining tremendous accuracy. Watchmaker lathes enabled cutting minuscule gear teeth, down to 100 teeth per inch. Improved pivots, oil lubrication, and ruby bearings further enhanced precision, advancing from 15 minutes off daily down to mere seconds.

Today, computer-controlled CNC and laser cutting shape gears with unbelievable perfection. Modern machining techniques can achieve millionths-of-an-inch tolerances. Gear shaping, honing, and grinding optimize the geometry and finish of teeth. Exacting heat treatment and surface treatments increase durability.

Contemporary brands utilize these technologies to craft superbly accurate timepieces. Howard Miller’s precision gears in their anniversary clocks deliver exacting timekeeping. Hermle’s meticulously machined gears and maintenance-free movements set new benchmarks in reliability.

Innovations continue today. Composite gears reduce friction and noise in high-precision instruments. Micromachined silicon MEMS gears enable microscopic timekeeping. 3D printing crafts custom gears on demand. The future promises ever-more astonishing gear engineering feats.

From crudely cut brass to laser-etched steel, the evolution of clockwork gears parallels humanity’s insatiable quest to quantify time. Each advance allowed us to slice time into smaller fragments, to master and optimize the temporal dimension that defines our lives.

So as the ceaseless turning of a second hand reminds us of our place in time’s continuum, we can appreciate the centuries of ingenuity that allowed clocks to mark our moments with ever-finer resolution. The humble gear, emblematic of humanity’s mechanical genius, ticks on at the heart of this timeless innovation.

Different Types of Geared Clocks and How They Operate

Ever wondered how the inner workings of clocks with moving gears actually function? Gear clocks have been around for centuries, with the first mechanical clocks appearing in medieval Europe in the 1300s. While we take them for granted today, gears and escapements revolutionized timekeeping and laid the foundation for precise time measurement that we rely on in the modern world.

In this article, we’ll explore some of the most common types of geared clocks and delve into the ingenious mechanisms that make them tick. Understanding gear ratios, pendulums, and escapements helps unlock the magic within these clever contraptions.

Grandfather Clocks

Let’s start with the iconic grandfather clock, also known as a longcase clock. These impressive timekeepers stand anywhere from 5-9 feet tall and have long been symbols of style and sophistication. But inside that stately case lies an intricate network of gears responsible for keeping precise time.

The key components are the gears connected to the pendulum, escapement, and hands. The pendulum swings back and forth at a constant rate, regulated by the escapement, which allows the clock’s gears to advance at an incremental pace. The main gear attached to the pendulum has a precise number of teeth, interacting with smaller gears connected to the clock hands. This allows the minute and hour hands to move at the correct, proportional speed relative to the pendulum.

For example, the minute hand gear may have 1/10 as many teeth as the main gear, so for every full swing of the pendulum, the minute hand advances 1/10th of the distance around the clock face. The ratio varies but ensures the hands move at the proper speed.

Grandfather clocks often have a secondary dial for the moon phase and chime hammers on the back that play melodies on the quarter hour. These additional functions require their own systems of gears and levers working in synchrony with the main timing gears. It’s astonishing that a few precisely cut gears can generate enough timing accuracy to keep perfect pace with something as consistent as the rotation of the Earth!

Wall Clocks

Wall clocks employ a similar gear train system as grandfather clocks but in a more compact arrangement. The gear ratios work the same way – the teeth on each gear interacting with the next in line to reduce the speed of rotation. So the main driving gear connected to the escapement mechanism turns much faster than the final gear connected to the minute hand.

Pendulum wall clocks keep the swinging pendulum, with wooden gears transferring power from the pendulum to the hands. Quartz clocks substitute a battery-powered quartz crystal oscillator for the pendulum as the timekeeping element. The rocking motion of the crystal creates an electrical signal that pulses at a precise frequency, driving a stepping motor that advances the gears.

Some impressive decorative wall clocks have partial glass cases or open-air designs that allow you to watch the pendulum swing and gears turn. The mesmerizing, smooth motion of the gears illustrates the perfection of this centuries-old technology.

Cuckoo Clocks

Cuckoo clocks originated in Germany’s Black Forest region, featuring the iconic hourly bird call. Along with the familiar two-note cuckoo, these clocks show dancing figures or moving gears during the chime sequence. At the top of each hour, a bellows mechanically produces the bird call and wooden figures emerge to act out a scene.

Internally, the main drive gear is connected to a cam wheel that has a series of protruding pins around its perimeter. On each rotation, these pins engage levers and bellows that trigger the motion and sound. Additional cam wheels move the doors and figures during the sequence. It’s an elaborate automaton powered entirely by the clock’s pendulum and gear train!

How Escapements Work

The key innovation that enables gears to track time is the escapement – a mechanism that allows the clock’s gears to advance at a restricted pace. Early mechanical clocks used a verge escapement, where gear teeth pushed against a vertical rod (the foliot) causing it to oscillate back and forth. This allowed the main gear to advance one tooth at a time with each swing.

The pendulum clock introduced a more reliable anchor escapement, with the pendulum swinging between two prongs or anchors. As the pendulum swings, the escapement releases one tooth of the gear at a time, resulting in a very precise tick-tock motion. When coupled with a pendulum calibrated to one second intervals, this creates an extremely accurate timekeeper.

In quartz clocks, the escapement is replaced by a quartz timing oscillator and stepper motor. But the concept is the same – controlling the incremental advancement of the gear train at a fixed pace. From medieval cathedral towers to quartz mantle clocks, escapements are at the heart of geared timekeeping.

Creative and Compact Designs

Modern Clockmakers continue to experiment with novel gear configurations and compact, creative designs. Some examples include:

- Clocks built into wine bottles or glass containers to demonstrate the inner workings.

- Multi-dial clocks that show the time in different international cities.

- Super compact travel clocks with convoluted gear systems packed into a small space.

- Artistic clocks made from laser-cut wood or metal that incorporate gears into the design.

Thanks to simplified production methods, hobbyists can now build custom clocks from wood or metal with DIY kits. Experienced clockmakers also craft unique designs with artistic flair. With some basic skills, you can even try modifying and customizing vintage clock mechanisms using replacement parts.

The Magic of Timing Gears

From early astronomical tower clocks to the first wristwatches, gears play a pivotal role in mechanical and quartz timekeeping. Their interaction allows finessing the pendulum’s driving force into the slow, smooth sweep of the clock hands. Experimenting with gear ratios continues as clockmakers miniaturize designs without losing accuracy.

Next time you glance at a clock, imagine the precision dance of gears inside keeping pace with our planet. The ticking gears seem to control time itself, though they merely reflect the steady beat of movement here on Earth. Delving into the engineering genius inside clocks still leaves room for the wonder of measuring time itself.

What Makes a Quality Gear Clock vs. Cheaper Models

When browsing gear clocks, you’ll find a wide range of styles and price points. From inexpensive novelty clocks to premium heirloom timepieces, what accounts for the difference in quality and cost? In exploring the hallmarks of a well-made clock, we’ll uncover what makes some stand the test of time.

Quality components and durable materials distinguish the best grandfather, wall, and mantel clocks. Marks of craftsmanship like precision fitted gears, flawless finishes, and sturdy cases elevate a timepiece. Understanding these subtle differences helps identify a clock built to endure generations.

All About the Gears

At the heart of every mechanical clock lies an intricate network of gears responsible for keeping accurate time. In high-end clocks, these gears are cut from hardened metals like brass or steel. Laser-cut gears ensure precision teeth that mesh flawlessly. The main drive gear connects to the pendulum, spinning constantly at a leisurely pace. Connecting gears reduce this speed down to the minute and hour hands.

Inexpensive clocks often use thinner sheet metal gears prone to warping or stripping under stress. Lower grade metals also increase friction and inaccuracy as the gears wear down. Precision machined gears, thick castings, and sturdy shafts stand up to decades of continuous operation.

The Finished Look

Subtle refinements separate exquisitely crafted clocks from mass produced products. A deep, lustrous finish requires hours of meticulous hand polishing – evident in the mirror perfection of quality brass and wood elements. Laser engraving and ornate designs add flair. Hand-painted elements boast impressive attention to detail. Everything from the beveled glass to the finished metal hands shows refinement.

With budget clocks, machine stamped pieces lack refinement with rough edges and mediocre finishes. Flimsy hands may not sit true on their shafts. Visible manufacturing defects signal shortcuts rather than old world craftsmanship.

Keeping Time Through the Ages

The essential measure of a clock is keeping accurate time decade after decade. Precision pendulums crafted from temperature-resistant materials like mercury maintain their swing. Sturdy anchor escapements built to fine tolerances restrict each tick perfectly. Thick glass for the case ensures an airtight environment.

Cheap clocks often keep time for a few years before losing minutes a week. Cut-rate pendulums with high friction pivots are prone to stopping or needing adjustments. Everything from clogged escapements to warped gears deteriorates performance.

Signs of Durability

Quality materials stand up to years of continuous operation. Hardened metal gears won’t crack or lose their teeth. Durable finishes prevent tarnishing or rust. Heat-treated steel shafts and pivots resist wear. Thick solid wood looks richer as it ages.

With inferior clocks, plastic elements become brittle and warp while thin veneers peel and chip. Weak pivot points loosen and seize up. A tinny overall feel signals shoddy construction underneath.

Higher Grade Movements

Well-engineered German movements from brands like Kieninger and Hermle power exceptional clocks. Renowned for precision and reliability, these finely crafted mechanisms can cost over $1,000 alone. Made in Germany with custom components, these movements are built from the ground up to endure generations.

Bargain clocks typically use inexpensive, mass produced movements from Asia. With plastic components and looser tolerances, these cost-saving measures lower the price at the expense of longevity and accuracy.

Artistry in the Details

Along with technical merits, first-rate clocks boast artistic touches setting them apart. Hand-rubbed mahogany cases with inlaid wood accents exhibit expert carpentry skills. Intricate stone dials display master engraving. Custom decorative elements add personality and flair. Artisans leave lasting marks of their passion and creativity.

With stock clocks, stagnant designs get reused across models. Mass manufacturing lacks the small refinements and human touch. A clock may function adequately without rising to the level of a showpiece.

Investment in Workmanship

At the high end, expert craftsmanship demands a premium price. Each precision hand-cut gear, polished accent, and assembly refinement adds cost. Skilled labor takes time – evident in the extensive polishing, assembly, tuning, and inspection. But in return, you receive an heirloom-quality creation built to become a family treasure.

Bargain clocks minimize labor and material costs with automated assembly and generic parts. You pay less up front but may end up replacing the clock every decade. A well-made clock lasts generations and appreciates in value, making the investment in quality worth the price.

Finding the Ideal Balance

In your search, find the sweet spot between price and lasting performance suited to your needs. Mid-tier brands offer respectable quality for more casual settings. Going with an established brand is safer than a no-name import. However, for a signature piece or special occasion gift, investing in the mark of true craftsmanship creates an heirloom they’ll treasure.

Knowing what defines the different grades of clocks allows you to make an informed choice. Take time to inspect and compare offerings across the spectrum. In the realm of temporal treasure as in life – beauty lies in the details.

Troubleshooting Common Issues with Clock Gears and Mechanisms

The intricate gears and inner workings of clocks have fascinated people for centuries. There’s something magical about how all those tiny components come together to accurately keep time. However, when something goes wrong with those gears, the clock stops telling time properly. Let’s explore some of the most common gear issues in clocks and how to troubleshoot them.

Gears Slipping

If you notice your clock is running too fast or too slow, gears slipping is a likely culprit. Gears can slip for a few different reasons:

- Built up grime, dust, or oil residue can create friction and prevent the gears from meshing correctly.

- Worn out teeth on the edges of gears will cause them to not grip other gears as well.

- Loose clock hands can put too much pressure on gears and cause slippage.

Try cleaning the clock movement with a soft brush and cloth to remove any built-up gunk interfering with the gears. Be very gentle around any delicate components. For worn gears, they may need replacement if the teeth are very degraded. Take a close visual inspection of each gear’s teeth looking for excessive wear and chipping. For loose clock hands, remove them and slightly bend the metal shafts to grip the gears more snugly when replaced.

Bent Shafts

The shafts that clock gears and hands attach to can sometimes get bent during a shock or trauma to a clock. This can make gears wobbly and cause issues like rubbing or uneven spinning. Carefully inspect each gear’s shaft for straightness. Look for any bends when the clock is running to see if the shaft wobbles up and down while spinning. For mild bends, you can try carefully straightening the shaft using pliers. Be gentle and make small adjustments checking often, as shafts can break if bent too far. Severely bent shafts may need replacement.

Loose or Broken Teeth

Gears rely on their precisely cut teeth to interlock and spin against each other. But these teeth can sometimes crack or break from trauma or age. Closely inspect each gear’s teeth looking for any damage. Teeth can also loosen and fall out sometimes. Try tapping the gear gently to see if any teeth wiggle loose. For a few broken or missing teeth, you can try to glue them back in place or replace just that single gear. Taking precise measurements and photos of the damaged gear can help when ordering a replacement. Too many damaged or missing teeth will require replacing the whole gear.

Dirt Build Up

Dust and grime are the enemies of clock gears and can cause them to stick and stop spinning properly. To clean, use a soft bristle brush and a vacuum with a hose attachment. Carefully vacuum around the gears to remove any loose dirt. Then use the brush to gently dislodge any caked on deposits. Isopropyl alcohol can also help dissolve built-up oil residues. Be very gentle and take your time to not damage any delicate components. Let all solvents dry fully before reassembling.

Misaligned Gears

If a clock took a significant shock, it can knock gears out of alignment so they no longer mesh correctly. This will prevent proper spinning and timekeeping. To realign, you often have to remove multiple gears and shaft assemblies down to the misaligned component. Gently tap gears back into their original positioned orientation, making sure teeth line up to mesh correctly. Reassemble starting from the rear moving forward. As you add gears back, ensure they spin freely and don’t rub or grind against each other.

With some close inspection, cleaning, and minor repairs, you can get your clock’s gears ticking smoothly again. But take care not to bend or force things too much, as the precision components can be fragile. When in doubt, consult a clock repair specialist for assistance. And be sure to keep clock gears well maintained by periodically cleaning and oiling them to prevent issues.

While we often take them for granted, the inner workings of clocks are marvels of engineering and craftsmanship. Gears that have been precisely cut and assembled to spin synchronously in all kinds of clocks are responsible for measuring out our lives. So next time you check a clock, take a moment to appreciate not only the time, but also the masterful machinery behind keeping that time for you.

How To Care for and Maintain Clock Gears for Optimal Performance

The intricate gears found inside clocks are engineering marvels that work tirelessly to keep time. But like any machine with moving parts, clock gears need proper care and maintenance to keep everything running smoothly for years to come. Let’s explore some tips on lubricating, cleaning, and inspecting clock gears so your timepiece continues ticking.

Use the Right Lubricants

Lubrication reduces friction and wear on clock gears. Traditionally, lightweight clock oils were used. These are still ideal for delicate antique gears. Modern synthetic clock lubricants can also work very well. Avoid using regular oils, greases or graphite that can leave gummy residues over time. Apply just tiny droplets or a light misting of lubricant on gear teeth and shafts. Take care not to overlubricate and attract more dust buildup. Consult your clock manufacturer’s recommendations.

Clean Gears Gently

Dirt and dust buildup will cause grinding friction and inaccuracy. Carefully use a soft brush and vacuum hose to remove loose deposits around gears. Q-tips and cotton swabs can help clean in narrow spaces between gears. Avoid soaking gears in harsh, caustic solvents which can damage components. Some clock oils can be safely dissolved and wiped away using a mild solvent like lighter fluid sparingly on a cotton cloth.

Inspect for Wear

Check gear teeth for any chips, pitting or missing cogs which can lead to skipping. Look for signs of uneven wear like more degradation on one side. Inspect shafts for bending and pulleys for cracking. Any degraded parts should be replaced. Photographing gears before disassembly helps get things back in their proper position.

Listen for Irregular Sounds

Tune your ears to any irregular clicking, grinding or squeaking sounds which indicate problems. Gently touch gears while running to feel for vibrations. Try to isolate the location of concerning noises. They often precede more serious issues like gear slippage or breakage so address promptly.

Consider Repair vs. Replace

Individual damaged gears can sometimes be repaired or replaced without fully disassembling the clock. First determine if teeth are brass, steel or plastic, then source a matching replacement. Consider the tooling and skills required and weigh the risks of disassembly. For extensive wear or many damaged components, a whole gear train replacement may be better.

Disassemble Meticulously

When full disassembly is needed, carefully record position and orientation of all parts first. Take photos and make diagrams. Remove fasteners in an organized fashion and store them separately. Clean all components before reassembly. Replace any bushings, bearings, pins and springs at this time. Reference your documentation to restore everything precisely.

Realign After Shocks

A clock being bumped or dropped can bend shafts and throw gears out of alignment. Referencing photos of the proper positioning, gently nudge components back into their correct orientation using slim tools like needle nose pliers before replacing fasteners.

Upgrade Materials If Needed

Some plastic components can get brittle and degrade over time and be replaced with metal parts. Or replace nylon bushings and bearings with higher quality options. These upgrades during routine maintenance can enhance longevity.

Test and Adjust

Upon reassembly, monitor the clock for several days looking for any skipping or timing inaccuracies which indicate issues. Make fine adjustments like tweaking gear mesh alignment or the pendulum swing after testing.

Don’t wait until gears grind to a halt before servicing your clock. With periodic inspection, cleaning, lubrication and replacement of worn parts as needed, its intricate inner gears will keep turning for years to come.

While initially mysterious in their workings, maintaining clock gears is very manageable with some basic mechanical skills and care. Proper servicing pays tribute to the craftsmanship and engineering that went into their design. So pull out your magnifier, some lubricant and a soft brush and give those gears some TLC so they keep turning indefinitely!

Unique Design Options: Skeleton Clocks, Wooden Gears, Creative Shapes

While most clock gears spin hidden behind closed casings, some unique timepieces showcase their inner workings as part of the aesthetic design. Skeleton clocks, wooden gears and creative shapes put the artistry of the clock movement on full display. Let’s explore some strikingly different ways clockmakers exhibit gears as functional art.

Skeleton Clocks Reveal the Mechanics

Skeleton clocks feature open-air frames that expose the inner clockwork mechanisms. The gears, springs, pendulums and escapements are on full exhibit with minimal casing. Traditional materials like brass, steel and ivory highlight the craftsmanship. Contemporary versions may use plastics and synthetics. The minimalist open style accentuates the rhythmic motion of the turning gears. Pendulum swinging and escapement rocking are mesmerizing to watch up close.

Wooden Gears for Natural Appeal

While most clock gears are metal, some are hand-crafted from natural wooden materials. Hard woods like ironwood and maple are shaped into gear teeth or cut by laser. The organic imperfections and grain patterns of wood add rustic warmth. Wood gears are often left unfinished to fully exhibit their raw natural state. The lower strength limits them to small clock movements. But their earthy appeal is undeniable.

Playful Colors and Designs

Geared clocks don’t have to follow stuffy old designs. Modern takes incorporate fun colors and shapes into the gears themselves. Contrasting colors on different gears help the motion stand out. Whimsical shapes like stars and circles replace traditional gear teeth. Manufacturing processes like 3D printing facilitate custom gear design. Silicon rubber gears absorb sound for whisper-quiet operation. A bit of creativity keeps clock gears interesting.

Gear Shapes as Artistic Accents

Individual gears and gear assemblies can become standalone art pieces by utilizing their shapes artistically. Metallic gears are hung on the wall in eye-catching formations. Old gear sets are refurbished into sculptures, models or practical items like bowls. The intersection where gear teeth mesh is particularly striking by showing their synchronization.

Steampunk Style for Retro-Futurism

The Steampunk design movement combines Victorian-era style with industrial steam power. Steampunk clocks feature prominent brass gears, pipes, dials and analog mechanisms. The carved wood and metalwork of the casings matches the gearcraft. Exposed cogs and pistons create a “retro-futuristic” look blending past eras with imagined innovations.

Salvaged Parts for One-of-a-Kind Pieces

For a sustainable approach, clockmakers hunt for discarded gears, dials, and clock pieces to upcycle into new designs. Mismatched salvaged parts are combined in creative ways like contrasting old and new materials. No two clocks will ever be alike when crafted from random found objects. Practical repurposing prevents waste and showcases the uncommon.

Bold Oversized Wall Clocks

Large wall clocks allow for bigger gears to create dramatic impact. Their expanded scale draws attention to the technical details. Intricate wheel mechanisms seem to defy gravity at monumental proportions. Big clocks demand a prominent placement to appreciate their presence.

Kinetic Sculptures in Motion

Building on artistic clock designs, some pieces blur the line between timepiece and kinetic sculpture. The gear mechanisms drive visible motions like animatronics, flipping panels, or rotating globes. They may keep imperfect time but showcase mechanical artistry.

Clocks with gears need not follow staid conventions. With creative thinking, they become showpieces that exhibit an aesthetic pleasing to the eye as well as the engineer’s mind. The next timepiece you choose could have timeless beauty animated by gears unlike those you’ve seen before.

Beyond just measuring seconds, these clocks remind us how ingenuity elevates mechanics into art. The unity of design and function rewards both sides of the brain. Giving this artistry prominence encourages the meticulous craftsmanship required. So let your next ticking timekeeper also be a conversation piece that stops people, if just briefly, to admire the timing of perfectly meshed gears.

Gears and Automation: How It Revolutionized Timekeeping Accuracy

From simple sundials to atomic clocks, humanity’s quest for ever-better timekeeping accuracy has driven technological innovation for centuries. The development of automated gear mechanisms was pivotal, vastly improving upon unreliable early clocks. Let’s explore how gears and automation helped timekeeping technology make monumental leaps in precision.

Inconsistent Early Clocks

Early mechanical clocks lacked automatic gears. Their pendulums had to be manually pushed to keep swinging. Inaccuracy of minutes per day was common. Spring-powered clocks in the 15th century improved accuracy somewhat, but friction and limp mainsprings still caused uneven timekeeping.

Pendulum Regulation Establishes Beat

In 1656, Christiaan Huygens invented the pendulum regulator, creating the first precision timekeeping. Its swinging beat resistances like friction and impulse, averaging them out. Engineers spent the next centuries refining gear trains to conserve and transmit the pendulum’s mechanical pulse.

Escapement: The Crucial Invention

The escapement mechanism revolutionized clocks by allowing gears to precisely advance at fixed intervals governed by the pendulum. It converts oscillation into rotational steps. Verge and anchor escapements progressed to the deadbeat style, minimizing pendulum swing disruption.

Winding Automation Removes Variability

Self-winding clocks introduced in the 18th century used wound mainsprings and going trains to automatically sustain pendulum oscillation. This removed the inconsistencies of manual rewinding, increasing accuracy.

Temperature Compensation Corrects Metal Expansion

Metals in clock mechanisms expand and contract with temperature changes, affecting pendulum length and timing. Innovations like gridiron pendulums and mercury bimetallic compensation neutralized these effects, achieving one second per day accuracy.

Electrical Regulation Further Refines Accuracy

The electric clock synchronized pendulums using electrical signals from a master oscillator. This remote regulation via wires enabled centralization of the timekeeping source for even greater consistency. Quartz crystal clocks amplified precision even further.

Chronometers Reach New Heights of Exactness

Ship chronometers employed complex gear trains and escapements like detent and spring detent types for utmost accuracy. They incorporated innovations like temperature compensation and isochronism adjustment to minimize variances. Rates of a half second per day were achieved, revolutionizing navigation.

Pendulum Servomechanisms Automate Adjustments

Electromechanical servos introduced in the 20th century use error-correcting feedback loops to lock pendulums into their ideal beat period. This constant automatic adjustment enabled accuracies to within thousandths of seconds per day.

Atomic Clocks: The New Timekeeping Benchmark

Atomic clocks utilize the precise oscillations of electrons, taking timekeeping accuracy to a phenomenal scale. While gears are no longer the regulator, automated computation now cross-checks astronomical atomic clock time for true consistency.

From inconsistent hourglasses to unmanned orbital clocks, smarter timekeeping mechanisms were enabled by gears and automation. Each technological leap chipped away at variability while magnifying precision. The quest continues for ever-finer time measurement, pushing innovation further.

Timekeeping started as estimating seasonal changes but became exacting science. Automated gears and electronics create stability, removing estimation and variable human effort. The march of progress aims toward perfection, each step quantifying nature’s oscillations with more clarity. But craftsmen still admire the ingenuity of antique clockworks that first harnessed unerring gears to mark time’s relentless beat.

Decor Ideas: Adding Visual Interest with Artful Gear Clocks

Clocks with visible spinning gears or pendulums make captivating focal points in any room. Their intricate movements create visual allure that draws the eye. Strategically placing gear clocks adds artistic flair to your décor while letting you appreciate their inner workings. Here are some ideas for highlighting them as decorative elements.

Mount a Large Statement Piece

A prominently sized wall clock with exposed gears or pendulum makes an immediate statement. Place it high on the wall or over the fireplace mantle as a visual anchor for the room. Contrasting clock colors and materials like wood or metal against the wall backdrop emphasize the timepiece. Illuminate it with accent lighting for drama.

Create a Grouping Gallery

Collecting multiple interesting gear clocks lets you arrange them in an artful grouping on a wall or bookcase. Mix sizes, designs and materials for variety. Keep some winding mechanisms exposed. Place them slightly asymmetrically rather than rigidly lined up for a more engaging gallery-style display.

Highlight Novel Design Features

Unusual clock construction like open frameworks, skeletal bodies, ornate carvings or imaginative shapes provide decorative details to focus on. Position the clock to allow full view of the distinctive features. Avoid cluttering the area around it to keep the design qualities center stage.

Incorporate Natural Elements

Natural materials like wood or stone complement the mechanical qualities of gear clocks. Place them on wooden credenzas or shelving. Accent with foliage like ferns or succulents. Create contrast between the clock’s manmade engineering and organic elements in the space.

Use Mirrors to Reflect and Enhance

Strategically placed mirrors multiply views of the graceful gears and pendulum swing. They seem to double the clocks’ presence. Position mirrors to catch various profile views of the mechanisms. Use beveled mirrors for fragmented reflections that abstract the shapes.

Draw the Eye Upward

Place a hanging gear clock high up to create a visual endpoint. The motion draws the gaze up from lower pieces to the ceiling. Use gradually taller pieces on tiered shelves or ledges moving upward to make it a focal point amid the arrangement.

Incorporate Unexpected Contrasts

Place a sleek modern clock beside antique furnishings for temporal contrast. Or combine metal and wood materials. The juxtaposition of old and new elements creates visual interest. Allow plenty of breathing room around contrasting pieces.

Add Drama with Backlighting

Shine a directional light source directly on the clock from behind to make the gears captivatingly backlit. The silhouetted spinning shapes projected on the wall are visually engaging. Use this technique for a striking nighttime accent.

Gear clocks have both aesthetic appeal and nostalgic charm. Displaying their workings prominently in your décor both elevates them as art and allows appreciation of fine engineering. Make them conversational focal points to admire as well as consult to be occasionally reminded of the fleeting passage of precious time.

The blend of form and function in gear clocks means they needn’t be hidden and utilitarian. Their precision mechanics calibrate our lives, but also symbolize humankind’s ingenuity. Give them prominence so their constant march of gears takes a momentary pause from practical timekeeping to first catch the eye, then the imagination.

Top Brands Known for Precision Engineered Gear Timepieces

Quality gear clocks blend artistry with engineering precision. Leading clockmakers have spent centuries perfecting their craft to produce timepieces of utmost accuracy and reliability. These brands stand out for their mastery of intricately cut gears and complex movements.

Patek Philippe

This prestigious Swiss watch manufacturer has been family owned since 1839. Their handcrafted timepieces incorporate innovations like the gyromax balance wheel and Spiromax hairspring for masterful accuracy. Movements are hand-engraved using historic techniques.

A. Lange & Söhne

Established in Germany in 1845, this company created the first outsize date display on a watch. They fuse proven traditions like German silver components with modern innovations. Each movement is hand-assembled and engraved by a single watchmaker for consistency.

Vacheron Constantin

The world’s oldest continuous watch manufacturer, Vacheron Constantin was founded in Geneva, Switzerland in 1755. Hallmarks include extraordinary gear cutting and pristine finishing visible through display case backs. They combine classic style with technically advanced perpetual calendar and tourbillon features.

Jaeger-LeCoultre

Based in Switzerland’s Vallée de Joux watchmaking region since 1833, Jaeger-LeCoultre is renowned for over 1,200 mechanical calibres. Their innovative designs include technically advanced gyroscopic balance wheels, perpetual calendars, and minute repeaters with chiming mechanisms.

Audemars Piguet

Tracing their origins to the Vallée de Joux in 1875, Audemars Piguet is known for master complications including astronomical minute repeaters and perpetual calendars. They push boundaries with avant garde engineering like internal gyroscopes in their distinctive Royal Oak line.

Breguet

Breguet was established in Paris in 1775 by Abraham-Louis Breguet, renowned as the father of modern watchmaking. His pioneering inventions included the tourbillon and first self-winding watch. Breguet movements feature hand decoration and innovative escapements.

Blancpain

Founded in 1735 in Switzerland, Blancpain is the oldest continuing watch brand. They introduced the world’s first modern diver’s watch as well as the smallest ladies’ watch movement. Blancpain pursues innovation while preserving the traditional skill of hand crafting each timepiece.

Glashütte Original

This German watch company was founded in 1845 in the watchmaking town of Glashütte. They utilize new materials like silicium while preserving historic techniques like hand-engraved bridges. Their movement innovations include the patented floating tourbillon.

Driven by passion for their art, these storied brands continue progressing the forefronts of timekeeping. Their master engravers and engineers manually assemble each unique precision movement to push the boundaries of mechanical possibility.

The steady beat of these exquisite instruments marks the tireless passing seconds with a fluid synchronization only achieved through meticulous care in design and construction. In a fast-paced world, these exceptional timepieces ground us in patient quality and human ingenuity that endures.

Custom Built and Bespoke Gear Clocks for One-of-a-Kind Style

Beyond mass manufacturing, some specialty clockmakers offer customized gear clocks tailored exactly to their owners’ visions. Collaborating one-on-one, they craft unique masterpieces from concept to completion. Bespoke clocks become meaningful statement pieces reflecting personal style.

Choose Unique Materials

From solid oak to tumbled marble, select creative materials for clock cases and bases to achieve your aesthetic. Contrast metal and wood textures. Use opaque, translucent or stained glass for the clock face. Pick a design and color palette that speaks to you.

Incorporate Theme Elements

Add embellishments that fit specific themes like nautical, steampunk or aviation influences. Provide photos of decorative items to incorporate like figurines, insignias or found objects. Keep customized additions tasteful and meaningful.

Specify Dimension and Layout

Define the exact clock size and proportions you have space for. Choose the position and size of the dial and functional elements. Decide which gears or pendulum details to expose. Provide room parameters so the piece fits perfectly.

Personalize with Inscriptions

Engrave custom text or motifs that make the clock special just for you. It could be a family name, special date, inspirational quote or symbolic image. This personal touch adds sentimentality.

Showcase Your Own Artwork

Commision clocks featuring your original artwork or photography. Showcase your creative talents by having your painted or drawn designs converted into the clock face. Use favorite photos of special memories.

Design One-of-a-Kind Movements

Work with the clockmaker to devise functional and aesthetic features like unique pendulum designs, customized winders or creative escapements for original mechanical movements that don’t exist anywhere else.

Hand-Pick Fine Details

Select specific details like the style of hands, the type of bezels or trim, the pendulum bob shape, the back case material, the style of fasteners, and the winder design. Customize every component.

Make It an Heirloom

Commission a multi-generational showpiece constructed from fine hardwoods and quality machining meant to be passed down rather than mass produced. This investment creates enduring family history.

Bespoke clocks provide outlets for personal expression through timekeeping art. Your aesthetic choices come alive in functional kinetic sculptures. While hours tick by uniformly worldwide, the ever-present march of time is made unique for your space.

Let customized clocks reflect the passage of life’s moments as singular as the path traveled. Where mass manufacturing cannot capture specific visions, collaborating directly with artisan clockmakers can culminate your dreams into reality with every hand-finished detail.

Gifting Gear Clocks: Perfect for Any Home, Office, or Workshop

A gear clock given as a gift combines sentimentality with fascinating mechanics. The sight of spinning cogs and swinging pendulums delights the eye while precisely calibrating time. Gear clocks make thoughtful presents for all kinds of spaces. Here’s why they’re ideal gifts and tips for choosing the perfect one.

Nostalgic Charm for the Home

An ornamental clock with visible gears or pendulum brings old-fashioned appeal to home decor. The intricate craftsmanship spurs nostalgia for simpler times when quality stood the test of time. A handsome wooden clock becomes a conversation piece. Choose clocks matching any decor aesthetic from modern to antique styles.

Office Atmosphere and Professionalism

The steady ticking of a gear clock enhances focus and productivity in office settings. The orderly, rhythmic gears lend a professional ambiance. Bold desk clocks with smooth second-hand sweeps keep meetings punctual. Consider engraved clocks for retirements and dedications.

Smart Wall Accent for Workshops

With their precision engineering, gear clocks neatly suit garages and workshops. The utilitarian metal machinery complements tool benches and work areas. Sturdy enough for shops yet stylish enough for living rooms, these functionalist clocks blend right in.

Heirloom Quality Craftsmanship

Made from solid woods, polished metals and quality components, gear clocks become family treasures passed through generations. The care in traditional handiwork creates lasting value. Have clocks personalized with engraving for family histories.

Highlight Interests Like Science, Engineering and History

Gear clocks appeal to those fascinated by scientific mechanics, engineering and history. Select creative designs that tie into their hobbies and careers. Have message engraved about their passion to complement the themed gift.

Smooth Sweeping Second Hands are Soothing

The smooth motion of quality clock hands sweeping around the dial provides therapeutic relaxation during hectic days. The rhythmic ticking creates a steady calmness that quiets the mind.

Gifting a hand-crafted clock powered by moving gears gives lasting enjoyment to the recipient and expresses your appreciation of their place in time. Let the gift of passing seconds remind loved ones that each moment spent together is precious.

A personalized clock becomes intertwined with memories as the years tick on, marking milestones and accomplishments. The gears will spin on as lives progress, keeping loving memories on time even as seasons change.

Steampunk Influence: Gear Clocks for Alternate History Enthusiasts

The Steampunk design movement reimagines retro-futuristic technology powered by steam engines and clockwork mechanisms. This alternate history genre combines Victorian era style with modernist machinery. Steampunk heavily features prominent gear clocks with ornate casings. Let’s explore their allure for this creative subculture.

Nostalgic Lines and Materials

Steampunk gear clocks employ classic materials like solid wood cases, brushed metal faces, and exposed bronze or steel cogs. Design motifs include filigree, airship shapes, and regional accents. Distressed finishes and antique-looking hands evoke nostalgia for bygone eras.

Visible Gear Movements as Centerpieces

Rather than hide workings behind closed casings, Steampunk clocks highlight their intricate inner mechanisms as decorative centerpieces. Gears, springs, pendulums, and escapements take the spotlight. Some designs incorporate simulated steam piping and valves.

Science and History Theme References

Nods to alternate history are seen in design elements like compass markings, hot air balloon shapes, mechanical figurines, and pseudo-Victorian typography. Fictional personalities and era references decorate the clock faces and casings.

Function Meets Fashion

Steampunk gear clocks blend fashionable embellishments with engineering functionality. Elaborate decorative touches like tesla coils and capacitor accents adorn the practical timing movements. The fusion of disciplines appeals widely.

Make Each Piece Unique

With customized touches and found objects incorporated, no two Steampunk clocks are exactly alike. Personalization reflects fictional identities. One-of-a-kind additions like worn typewriter keys confirm imaginative alternate histories.

Highlight Hand-Craftsmanship

Imperfect hand finishing provides authenticity, contrasting slick mass manufacturing. Hammered copper casings and hand-laid gears add artisanal charm. Evidence of hand craftsmanship fits the romanticized retro theme.

Creative Repurposing and Upcycling

Salvaged materials are often repurposed into Steampunk clocks. Vintage watch parts, obsolete gauges, and old lamp components find renewed purpose. Modern “junk” becomes fashioned into neo-Victorian art.

Blending imagined pasts with futuristic possibilities, Steampunk gear clocks celebrate the infinite creativity of human engineering. The elaborate designs inspire dreams of exploring fantastic new frontiers powered by steam and cogwork.

These artistic timepieces demonstrate how history lives on in spirit as time marches forward. By reinventing aged artifacts, enthusiasts preserve cultural memory and progress. The clocks keep time steadily despite surrounding change.

How Gear Clocks Keep Ticking Using Physics and Engineering

Gear clocks rely on ingenious designs to harness the power of physics into accurate timekeeping. Weight and pendulum motion is converted into rotational kinetics using gear trains. Escapements and oscillators regulate the beat. Engineering innovations enable smooth and precise operation. Let’s explore the physics and mechanics inside gear clock movements.

Gravity Power

The steady force of gravity pulling on suspended weights or pendulums acts as the driving power source in many clocks. Escapements control the gravitational force release so the clock resists changes in applied torque.

Going Trains

The going train is the gearing system that converts the force from the power source into measured incremental motion to turn the clock hands at precise intervals. The gear ratios determine timekeeping accuracy.

Escapements

The escapement is the key technology that allows the clock gearing to advance at specific intervals regulated by the oscillator. It alternately impulses and catches the gear train, overcoming source fluctuations.

Oscillators

The oscillator provides a fixed timing reference for the escapement using the stable oscillations of a pendulum or quartz crystal. Their periodic motion paces the discrete steps of the gear advancements.

Mechanical Advantage

Gear and lever arrangements provide calculated mechanical advantage, allowing heavy weights to be lifted gradually using smaller force applied slowly over time through gearing down. This extends running duration.

Friction Management

Innovations like jeweled bearings and improved lubrication reduce sliding friction, the force opposing motion between surfaces. This lets gears turn freely and smoothly with minimal wear and torque loss.

Isochronism

Clock engineers arrange gear profiles and weights to minimize variations in the oscillator’s beat period as the power source force decreases over time. This isochronism results in improved accuracy.

Resonance Management

Precise gear backlash, minimal friction, and optimized power transmission reduce undesirable mechanical resonance that can distort the oscillator’s regular periodic motion and impact timekeeping accuracy.

Through physics and engineering, gear clocks transform continuous forces into the discrete seconds, minutes, and hours we use to organize time. The ingenious designs take fluctuating energy from weights and pendulums and regulate it into steady measurable increments.

Understanding the mechanics inside clocks gives insight into how clever engineering can harness abstract physics into tractable systems that better our lives. Gears and escapements command the march of time to our tune.

Why We’re Still Fascinated by Old-World, Handcrafted Gear Clocks

In a world of digital timekeeping, antique gear clocks captivate us with their intricate craftsmanship and ingenious mechanics. The care and skill embodied in their making represents values seemingly faded from our fast-paced lives. Let’s explore why the old-world charm of handmade clocks still enchants after centuries of progress.

Appreciation of Quality Manual Effort

With hand-cut gears, engraved faces, and polished casings, veteran clockmakers poured tireless care into their works. Each precision component was adjusted by hand. This meticulous dedication shows in the remarkable longevity of antique clocks.

Glimpse of History and Heritage

Vintage gear clocks provide a tangible connection to generations past and longstanding cultural traditions. The designs often reflect regional aesthetic styles passed down through the ages.

Admiration of Complex Craftsmanship

The precise shapes of gear teeth, the balanced contours of pendulums, and the intricate symmetries of escapements reflect masterful skill levels perfected over decades. We admire the nuanced expertise required.

Nostalgia for Slower Times

Winding an old clock and hearing its methodical ticking induces nostalgia for quieter eras before our rushed modern society. Their tempo transports us to imagined simpler times.

Creative Engineering Solutions

With limited resources, clockmakers innovated clever designs to overcome engineering challenges. Their ingenious mechanics still inspire our own creative thinking.

Beauty of Natural Materials

The warmth and imperfections of materials like solid wood, aged metal, and hand-laid finishes bring organic appeal that sterile digital displays lack. We’re drawn to traditional elements.

Passing Down Meaningful Heirlooms

A well-preserved antique clock becomes a multi-generational treasure. The legacy outlives its original owner, reminding descendants of their heritage.

As hurried lives distract us from history and quality, venerable clocks offer satisfying substance and continuity. Talented makers built upon proven designs to provide future generations with beauty that endures. The old-world appeal reminds us to periodically pause our rush toward the next moment to appreciate crafts that stand the test of time.

Long after their makers have passed, antique clocks keep on reliably counting seconds with remarkable accuracy. While technologies come and go, a well-made mechanical clock persists reliably like the steady beat of time itself.