How are Rawlings MLB baseballs made. What makes them unique. Why has Rawlings been the official MLB supplier since 1977. Discover 15 fascinating facts about America’s favorite game ball.

The Evolution of Rawlings: From 1887 to MLB’s Official Baseball Supplier

Rawlings, a St. Louis-based company founded in 1887, has been at the forefront of sports equipment manufacturing for over a century. Their journey to becoming the official baseball supplier for Major League Baseball (MLB) is a testament to their commitment to quality and innovation.

In 1977, Rawlings achieved a significant milestone by securing the position of MLB’s official baseball supplier. This prestigious partnership has continued for over four decades, solidifying Rawlings’ reputation as the gold standard in baseball manufacturing.

The Revolutionary Impact of Rawlings on Baseball Production

Before Rawlings entered the scene, baseballs were inconsistent and crude. Players often complained about variations in size, weight, and overall quality. Rawlings addressed these issues by introducing two game-changing innovations:

- The patented figure-eight winding technique

- A precision stitching method

These advancements resulted in expertly constructed, identical baseballs that met the high standards required for professional play. The manufacturing process perfected by Rawlings in the 1920s continues to be the foundation for baseball production today, albeit with modern machinery enhancements.

The Anatomy of a Rawlings MLB Baseball: A Masterpiece of Engineering

What components make up a regulation MLB baseball? At its core lies a cushioned cork and rubber pill, meticulously wrapped in wool windings. This core is then encased in a premium cowhide leather cover, carefully selected for its suppleness and durability.

One of the most distinctive features of a Rawlings MLB baseball is its stitching. Skilled artisans hand-stitch double rows of cotton threading in the iconic figure-eight pattern, using exactly 108 red stitches. This precise stitching not only holds the ball together but also plays a crucial role in its aerodynamics and performance.

The Rigorous Quality Control Process

How does Rawlings ensure each baseball meets MLB standards? The manufacturing process involves multiple inspection points, where balls are meticulously examined for:

- Weight

- Circumference

- Resiliency

- Shape

Only baseballs that meet or exceed these stringent criteria are approved for MLB gameplay, ensuring consistency and fairness across all professional matches.

The Evolution of Rawlings Baseball Design: Constant Innovation

Over the decades, Rawlings has continuously refined and improved their baseball designs to enhance performance and durability. Some notable changes include:

- Replacing crumble-prone cork and rubber cores with special rubber rings laminated with cork in 1943

- Transitioning from black and blue stitching to consistent red stitching in 1934

- Adjusting wool windings to create a livelier feel

- Utilizing premium leather meticulously selected for optimal performance

Despite these innovations, Rawlings has always ensured that their baseballs meet MLB specifications, maintaining a delicate balance between improvement and consistency.

Rawlings Baseballs in MLB History: Witnesses to Iconic Moments

Rawlings baseballs have been present for some of the most memorable moments in baseball history. Can you recall these historic events that featured Rawlings balls?

- Babe Ruth’s legendary “called shot” home run in the 1932 World Series

- Hank Aaron breaking Babe Ruth’s home run record in 1974

- Kirk Gibson’s unforgettable pinch-hit walk-off home run in the 1988 World Series

These moments, etched in baseball lore, were all made possible with Rawlings baseballs, underscoring the brand’s integral role in the sport’s history.

The Journey of a Rawlings Baseball: From Factory to Field

Have you ever wondered about the path a Rawlings baseball takes before it reaches the pitcher’s mound? The journey begins in Costa Rica, where workers at Rawlings’ factory meticulously cut and prepare leather hides for baseball covers. These covers are then shipped to another Rawlings facility in Turrialba, Costa Rica, where they are assembled and hand-stitched by skilled craftsmen.

Once the baseballs are complete, they undergo rigorous quality control checks to ensure flawless construction. Only after passing these inspections are they ready for use in MLB games.

Pre-Game Preparation and Authentication

Before each MLB game, umpires inspect and approve a supply of dozens of Rawlings baseballs. This process ensures that only balls meeting the highest standards are used in play. Balls that are hit for home runs or involved in major plays are often authenticated and sold as memorabilia, allowing fans to own a piece of baseball history.

The Science Behind Rawlings MLB Baseballs: Perfecting the Art of Flight

What makes Rawlings MLB baseballs so special from a technical standpoint? The answer lies in the precise manufacturing process that ensures each ball has the perfect weight, thread count, seam height, and resilience for fair MLB gameplay.

The 108 red stitches in Rawlings’ unique figure-eight design serve a dual purpose:

- They provide ideal aerodynamics, affecting the ball’s movement through the air

- They create a consistent surface that pitchers can grip and manipulate

Even minor variations in baseball seams can dramatically impact pitches, which is why Rawlings goes to great lengths to ensure every ball meets exacting standards.

Rawlings’ Impact on Baseball: A Century of Innovation

How has Rawlings shaped the game of baseball over the past century? Their innovations have revolutionized the sport in several ways:

- Standardizing baseball production, leading to more consistent gameplay

- Improving ball durability, allowing for longer play and fewer replacements

- Enhancing ball performance through materials and construction techniques

- Providing a consistent platform for comparing player performances across eras

As the official MLB baseball supplier since 1977, Rawlings has played a crucial role in building the sport we love today. From Babe Ruth to modern superstars, Rawlings baseballs have been at the center of epic hits and historic plays.

The Future of Rawlings and MLB Baseballs: Continuing Excellence

What does the future hold for Rawlings and MLB baseballs? While the core design of the baseball is unlikely to change dramatically, Rawlings continues to explore ways to improve their product. Some areas of potential innovation include:

- Advanced materials for enhanced durability and performance

- Improved manufacturing techniques for even greater consistency

- Integration of smart technology for data collection and analysis

- Sustainable production methods to reduce environmental impact

As baseball evolves, Rawlings remains committed to providing the highest quality balls that meet the exacting standards of MLB while embracing innovation to enhance the game.

The Enduring Legacy of Rawlings MLB Baseballs

Why do Rawlings MLB baseballs continue to captivate players and fans alike? It’s a combination of tradition, quality, and the role these balls play in creating unforgettable moments on the field. Each Rawlings baseball represents over a century of craftsmanship and innovation, a tangible link to the rich history of America’s pastime.

The next time you watch an MLB game or hold a Rawlings baseball, take a moment to appreciate the incredible engineering and artistry that goes into creating this seemingly simple object. It’s not just a ball; it’s a piece of baseball history, carefully designed and crafted to bring out the best in the sport we love.

Introduction to Rawlings – Official Baseball Supplier of MLB Since 1977

Baseballs may seem simple, but they are precision equipment that can dramatically impact gameplay. This is why Major League Baseball only uses balls from approved suppliers that meet rigorous standards. Since 1977, Rawlings has been the official baseball supplier for the majors. How did they earn this honor? What goes into making a regulation MLB baseball? Let’s unravel some fascinating facts you never knew!

As a St. Louis company founded in 1887, Rawlings has been crafting quality sports equipment for over a century. Their baseballs specifically revolutionized the game. Before Rawlings, baseballs were crude – literally just yarn tightly wound around a cork core. The handmade balls were inconsistently sized and weighted. Stitches were uneven and seams were pronounced, disrupting aerodynamics. Players complained the balls were too light, too heavy, too large, or too small. There was no standardization.

Rawlings changed everything by patenting the figure-eight winding technique and precision stitching method. Suddenly, baseballs were expertly constructed and identical. The manufacturing process Rawlings perfected in the 1920s is still used today with contemporary machinery. Rawlings revolutionized baseballs, and MLB took notice. Since Rawlings standardized baseball production, MLB has mandated all game balls must meet Rawlings’ exact specifications.

So what goes into a regulation baseball’s design? At the core is a cushioned cork and rubber pill wrapped in wool windings. A premium cowhide leather cover goes over the ball. Skilled sewers hand stitch double rows of cotton threading in the figure-eight pattern with exactly 108 red stitches. The manufacturing process is meticulous, with each ball inspected repeatedly. Only balls meeting MLB standards for weight, circumference, resiliency, and shape are approved for gameplay.

Over the decades, Rawlings has iterated on baseball designs. The original cork and rubber cores were prone to crumbling. In 1943, Rawlings pioneered using special rubber rings laminated with cork. MLB baseballs once had black and blue stitching until Rawlings shifted to consistent red stitching in 1934. Recent changes include lowering the wool windings for a livelier feel and using premium leather meticulously selected for suppleness. While the balls evolve, Rawlings ensures they meet MLB specifications.

Some of the most iconic moments in baseball history involve Rawlings balls. Babe Ruth’s called shot home run in the 1932 World Series used a Rawlings ball. Rawlings baseballs were also used when Hank Aaron broke Babe Ruth’s home run record in 1974. And Kirk Gibson hit his memorable pinch-hit walk-off home run clinching the 1988 World Series with a Rawlings ball.

Before each MLB game, umpires inspect and approve a supply of dozens of Rawlings baseballs. Balls hit for home runs or major plays are authenticated and sold as memorabilia. Of course, fans can also buy new Rawlings baseballs identical to game balls. Major League Baseball authenticates Rawlings as the only manufacturer approved for official MLB baseballs. So how can you be sure you’re getting a real MLB baseball? Look for the Rawlings logo and MLB commissioner’s signature on the ball.

Part of what makes Rawlings MLB baseballs special is they’re handcrafted by experts in the USA. At Rawlings’ Costa Rican factory, workers meticulously cut and prepare leather hides for baseball covers. The covers are then shipped to the Rawlings factory in Turrialba, Costa Rica where they are assembled and stitched by hand. The finished balls are all inspected repeatedly to ensure flawless quality.

While baseballs may seem basic, Rawlings’ precision manufacturing ensures each ball has perfect weight, threads, seams, and resilience for fair MLB gameplay. The 108 red stitches in Rawlings’ unique figure-eight design provide ideal aerodynamics and movement. Minor variations in baseball seams can actually dramatically impact pitches. So Rawlings ensures every ball meets exacting standards.

Rawlings’ innovations have revolutionized baseball for over a century. As the official MLB baseball supplier since 1977, they’ve helped build the sport we love. From Babe Ruth to today’s superstars, Rawlings baseballs have showcased epic hits and historic plays. So next time you watch an MLB game, appreciate that little Rawlings ball – it’s a piece of baseball history engineered for ideal flight and feel.

Craftsmanship and Quality Control of Rawlings Baseballs

Baseballs may seem basic, but they require incredible precision and craftsmanship. Rawlings elevates baseball construction to an art form. As the official supplier of Major League Baseball, Rawlings adheres to the strictest quality control standards. From the hand-selected leather to the flawless figure-eight stitching, Rawlings baseballs showcase outstanding American craftsmanship.

It all starts with the leather. Rawlings only uses the finest steer hides from the top 10% of hides available. Master leather craftsmen hand inspect each hide, checking for scars, bites, branding marks, or inconsistencies. Minor natural variations give each ball a unique character while meeting specifications. The premium hides are shipped to Rawlings’ factory in Turrialba, Costa Rica for assembly.

In Turrialba, experienced seamers transform leather covers into baseballs. Using precision equipment, they cut uniform two-piece covers that are perfectly centered and shaped. The covers are branded with the Rawlings name and logo before heading to stitching stations.

Here, skilled sewers use specially designed needles to hand stitch the covers. The two-piece covers require double stitching along the seams. With practiced technique, the sewers expertly stitch precisely 108 red cotton threads in the iconic figure-eight pattern invented by Rawlings. Every stitch must be tight, consistent, and perfectly spaced.

The sailing department oversees assembling the finished covers with cork and rubber cores and wool windings. They use winders to apply exact tension, so each ball has consistent weight and compression. Adhesives bond the materials together before the covers are stitched shut by hand.

Throughout the process, Rawlings baseballs undergo rigorous inspections and testing. Inspection teams examine stitching under magnification to catch any imperfections. Balls are measured to ensure precise circumference, weight, and shape conforming to MLB specifications. Advanced equipment like compression testing machines check the balls’ liveliness and resilience.

Randomly selected finished baseballs are tested to destruction to guarantee durability. Balls must withstand the rigors of gameplay from impacts to moisture without losing shape or elasticity. Rawlings rejects any balls that do not pass visual, mechanical, and manual inspections.

This exhaustive quality control process allows Rawlings to meet MLB’s exacting standards. While hand crafted, each ball offers consistent size, weight, hardness, and performance. No detail is overlooked from the premium leather to the flawless 108 red stitches. Rawlings’ craftsmanship makes their baseballs works of art ready for the biggest league.

So appreciate the craftsmanship that goes into every Rawlings baseball next time you catch a game. From careful material selection to detailed construction and inspection, Rawlings builds baseballs that allow both pitchers and hitters to play their best game.

Rawlings Baseball Manufacturing Process Step-by-Step

Baseballs require tremendous precision to meet Major League standards. Rawlings’ manufacturing process delivers flawless MLB regulation balls through artful construction steps. Here is an inside look at how Rawlings makes official baseballs step-by-step:

Step 1 – Selecting Premium Leather: Rawlings hand selects the top 10% of cowhides for strength, grain, and consistency. Minor variations provide a unique character while adhering to specifications.

Step 2 – Cutting and Shaping Covers: Experts cut precision two-piece figure-eight covers from the hides, skillfully centering the logos and shapes.

Step 3 – Assembling Cores: Cores consist of cork, rubber, and other materials layered to exact MLB hardness and compression standards.

Step 4 – Winding: Wool yarn is computer wound around the core using precise tension for ideal weight and feel.

Step 5 – Stitching Covers: Skilled seamers hand stitch double rows of 108 red threads in the signature figure-eight pattern, using specially designed needles.

Step 6 – Assembling Balls: Covers are adhered to wound cores and sewn shut by hand with exacting technique known only by a handful of seamers.

Step 7 – Rolling and Shaping: Balls are rolled and compressed to smooth seams and achieve perfect spherical shape meeting specifications.

Step 8 – Finishing Touches: Rawlings logos, MLB logos, and commissioner’s signature are branded on the balls with precision equipment.

Step 9 – Testing and Inspection: MLB rigorously tests random balls for compression, liveliness, weight, circumference, and other specifications.

Step 10 – Quality Control: Rawlings rejects any balls not meeting visual, dimensional, and performance standards before final approval.

Step 11 – Packaging and Shipping: Approved balls are packaged in protective MLB marked boxes and shipped for use in games.

While seemingly simple, official baseballs require incredible attention to detail from the first cut of leather to the final stitches. Rawlings leverages expertise and technology honed over a century to architect the perfect ball.

Next time you get your hands on a new Rawlings MLB baseball, appreciate the artful construction process that goes into meeting the highest standards of play. Only a Rawlings ball makes it to the pros!

Inside an Official Rawlings MLB Baseball – Materials and Construction

Ever wonder what the inside of a real MLB baseball looks and feels like? While they seem simple from the outside, official Rawlings baseballs are precision engineered with quality materials and careful construction.

At the core of every MLB baseball is a cushioned pill of cork and rubber. The pill’s composition and layering is specially formulated by Rawlings to achieve the exact hardness and liveliness desired. Surrounding the pill are about 400 yards of premium wool yarn windings.

The yarn is machine wound under computer controlled tension to provide the right compression factor when enclosed by the leather cover. More windings mean a firmer, heavier ball. The windings form a sphere around the cushioned cork pill core.

The figure-eight shaped two piece leather cover is carefully sewn over the winding enclosed core using 108 stitches of waxed red cotton thread. Rawlings moved to double stitched seams for durability. The low seam profile improves grip and aerodynamics. Stitches pierce the winding layer to securely grip the core.

While MLB specifications mandate the materials, cores, and thread counts, slight variations still exist that impact performance:

- The leather cover’s thickness, grain, and suppleness affects grip, flexibility, and durability.

- More tightly wound cores are livelier off the bat while loosely wound balls compress more on impact.

- Lower seams with flatter stitching reduces drag compared to pronounced seams.

These nuances combine to make each baseball’s reaction unique. However, Rawlings’ precision manufacturing ensures consistency within MLB standards.

The pill and yarn materials offer the right balance of softness for grip yet hardness for elasticity and liveliness. The leather cover provides durability to withstand repeated impacts while also allowing flexibility with a satisfying pop off wood bats. It’s a delicate balance perfected by Rawlings.

Next time you hold an official MLB Rawlings baseball, appreciate the engineering that allows pitchers to throw heat and batters to smack homers. From its bouncing core to full grain leather, a Rawlings baseball is built for the big league demands.

Testing Procedures and Standards for Official Game Baseballs

While a baseball seems simple, official MLB balls must meet rigorous testing standards before being approved for gameplay. Rawlings subjects every ball to intense scrutiny to guarantee perfection.

The testing process begins in Rawlings’ own quality control lab. Here, baseballs undergo visual inspections, dimensional checks, and compression tests. Seamers inspect stitching under magnification to identify any flaws. Precise machines measure the balls’ circumference, weight, shape, and seam width compared to MLB specs.

One key test is compression, measured by pounds of force to compress a ball 1/8 inch. MLB mandates compression must fall between 200-300 pounds. Rawlings compression tests balls repeatedly during manufacturing. Tighter wound cores produce highercompression.

Rawlings also randomly conducts “destructive testing” where balls are compressed beyond their limits until failure. The balls must withstand over 600 pounds of force without breaking, indicating solid construction.

In addition, a baseball’s coefficient of restitution or “liveliness” is tested by firing balls at a metal plate. The rebound height and speed is measured electronically. Livelier balls pop off the bat faster but don’t travel as far.

Balls are also tested for moisture resistance, shock absorbency, impact damage, and stitch strength using accelerated age testing. Rawlings tumbles balls with abrasive materials and even hits them with bats endlessly to validate durability.

Extensive documentation on the manufacturing specs, testing data, and inspector comments accompany each batch of baseballs. Umpires receive this paperwork when balls are delivered for approval before every MLB game.

Umpires do a final visual and tactile inspection of the balls. They check for any damage, discoloration, inconsistencies, or flaws. Balls are bounced to verify uniform liveliness. If a ball passes all these tests, it is ready for game use.

During games, umpires continuously monitor and verify ball quality. If abnormalities occur, new balls can be quickly introduced. The rigorous Rawlings testing ensures perfect balls for MLB play.

Thanks to Rawlings’ stringent quality control and MLB testing standards, you can trust every ball used in a major league game meets peak performance criteria. So enjoy watching them fly off the bats!

Evolution of the MLB Baseball Over the Years by Rawlings

While the core composition hasn’t changed much, official MLB baseballs have evolved in subtle ways over the decades thanks to innovations by Rawlings. By constantly improving materials and design, Rawlings has kept pace with the games changing needs.

One key milestone was standardizing on a cork and rubber center core. Early baseballs used all rubber cores wound with yarn or cork and yarn mixes. But the rubber would break down over time. In 1943, Rawlings perfected a layered cork and rubber pill to optimize the core’s liveliness and resilience.

The wool windings surrounding the core have also been updated. Rawlings now windings with finer, smoother yarn for a more consistent sphere. Computer controlled tensioning ensures ideal compression to MLB specs. More windings mean a harder ball off the bat.

The classic figure-eight leather cover design has stood the test of time. Rawlings upgraded to premium cowhide and introduced hand stamped logos in the 1950s. While still double stitched by hand, the seams are now flatter for truer flight. The thread moved from black and blue mixtures to uniform red in 1934.

Inside the cover, early balls used rubber cement to adhere to the core. Rawlings developed superior rubber-based adhesives for optimal bonding without drying out the leather. The chemical compounds ensure ideal tack and moisture resistance.

Rawlings also optimized baseball construction for the switch from horsehide to cowhide covers in 1974. The softer cowhide required adjustments like wool windings under the leather to maintain shape. Rawlings finds the right balance of materials while meeting MLB specs.

The manufacturing processes have also been enhanced over the decades. Rawlings uses precision laser cutting tools for leather covers and automated winders for ideal core tensioning. But hand skilled labor remains critical, like the flawless hand stitching.

While honoring classic designs, Rawlings never stops looking for ways to optimize the baseball. This continuous improvement by master craftspeople ensures when you hold an official MLB ball, you’re holding a piece of history ready for the next great moment.

Interesting Facts About Iconic Rawlings MLB Baseballs

For over a century, iconic moments in baseball history have happened with a Rawlings ball in play. Their handcrafted balls have been along for countless thrills, spills, and unbelievable plays. Here are some fascinating facts about Rawlings MLB baseballs that made history:

– The Rawlings baseball used for Babe Ruth’s infamous “Called Shot” home run in the 1932 World Series sold at auction for a staggering $394,000. Its provenance and Ruthian lore made it priceless.

– When Hank Aaron broke Babe Ruth’s career home run record in 1974, he hit #715 off an official Rawlings MLB baseball. That historic ball later sold for $650,000.

– Game 6 of the 1975 World Series featured Carlton Fisk’s legendary walk-off home run for the Red Sox. The Rawlings ball he waved fair then bounded around Fenway is enshrined in Cooperstown.

– Kirk Gibson’s miraculous pinch-hit walk-off homer won Game 1 of the 1988 World Series for the Dodgers. The Rawlings ball he cranked off Eckersley is in the Hall of Fame.

– The Rawlings baseball Mark McGwire hit for his 70th home run in 1998 sold at auction for over $3 million. Some lucky fan caught an invaluable piece of sports history.

– When Barry Bonds broke McGwire’s single season home run record with #73 in 2001, he hit the milestone shot using a Rawlings MLB baseball.

– Ichiro Suzuki collected his 3,000th MLB hit in 2016 using a specially marked Rawlings Official American League ball.

These iconic MLB moments all happened with Rawlings’ handiwork in the spotlight. Of course, countless other historic plays, walk-offs, no-hitters, and milestones involved their balls too. Every Rawlings baseball has a chance to be involved in baseball magic.

How Rawlings MLB Baseballs Are Used and Prepared for Games

Those pristine white Rawlings balls you see come game time don’t just show up ready for play. There’s a rigorous process MLB teams follow to get balls game ready and monitor their use.

Before each game, umpires receive 6 dozen shiny new Rawlings balls packed in bags. Umpires closely inspect and approve enough balls for the game, usually around 96.

Approved balls get specially marked with MLB logos in the mud room. This helps authenticate balls for game use and memorabilia purposes. On game day, balls are rubbed with special Delaware River mud to remove glossiness and improve grip.

Ball boys and attendants carefully store game balls. Some are kept in humidors and periodically rotated to maintain proper moisture levels ideal for pitchers. During the game, they methodically swap and replenish balls.

At least a dozen new balls are introduced at the start of every game. As balls get fouled off or go out of play, more new balls enter to keep inventory steady around a dozen for play.

Umpires closely inspect and verify every ball put into play. Any abnormalities get tossed. Foul balls go into buckets for post-game authentication and get sold for charity.

Balls hit for notable plays like home runs go to MLB authenticators immediately. They get uniquely marked and logged before going to Cooperstown or returning the player. This ensures provenance.

By rule, a minimum of 96 balls must be used per game. So balls cycle through frequently. Pitchers can specify certain balls they’ve “prepared” too. But umpires guard against anything illicit.

Thanks to meticulous tracking and monitoring, you can be sure your souvenir MLB baseball or game memorabilia is the real deal. Next time you go to a game, watch those ball boys in action preserving the sanctity of America’s pastime!

Why Rawlings MLB Baseballs Have 108 Stitches

Ever wonder why every official Major League baseball has exactly 108 red stitches? It’s no accident. The intricate hand-sewn pattern ingeniously developed by Rawlings has a specific purpose and function.

Sewing the leather covers requires a tremendous amount of precision and skill. Master seamers use specially designed needles to pierce the leather and windings perfectly without damaging materials. The tightness and spacing of stitches is critically important.

Rawlings found that 108 stitches arranged in their unique figure-eight pattern achieves ideal seam strength and overall ball integrity. The double laced crossings interlock beautifully while reducing unnecessary thread. Less really is more when it comes to MLB baseball construction.

The 108 stitches also influence the baseball’s aerodynamics. More stitches mean more drag-inducing seams in flight. So Rawlings optimized the stitch count for ideal carry and movement desired by MLB pitchers and hitters.

In addition, the repeating figure-eight pattern provides visual and tactile aesthetics. The distinctive seam shapes are quintessentially baseball and allow a satisfying grip. Collectors even use subtle stitching variations to authenticate game-used balls.

While machines could produce baseballs, only skilled human hands can consistently achieve flawless 108-stitch construction. Passing the craftsmanship from generation to generation ensures enduring quality.

Rawlings’ 108-stitch figure-eight design has stood the test of time since evolving in the early 1900s. The handiwork involved epitomizes their motto “If it isn’t broken, don’t fix it.” Next time you pick up a MLB baseball, appreciate those 108 stitches!

Maintaining Your Rawlings Official MLB Baseball Collection

If you’re lucky enough to own prized Rawlings MLB baseballs, proper maintenance is crucial for preserving their condition. A few simple care steps will keep your baseball collection in pristine shape.

First, display or store your Rawlings baseballs out of direct sunlight and fluorescent lighting which can accelerate fading. Cool, controlled humidity around 50% also helps slow deterioration.

For display, use clear acrylic ball cube cases to protect from dust and handling. Avoid placing bare balls on shelves or fixtures where they can pick up dirt or oils from fingers over time.

Before handling, put on clean white cotton gloves to prevent skin oils from transferring. Fingerprints are impossible to remove from leather without damaging it. Handle gently by the laces rather than touching the leather surface.

If balls get surface dust, use a very soft bristle brush dedicated to collectibles. Gently brush in a circular motion to lift dust without grinding it into the leather. Isopropyl alcohol diluted with distilled water can lift more stubborn dirt.

Never apply conditioners or polishes which can permanently alter the leather’s patina. At most, use a tiny amount of pure lanolin sparingly on any scuffed seams.

For autographed balls, display in a way that prevents the signature from rubbing or fading over time. Avoid exposing signed areas to UV or wet conditions.

With proper handling and care, your Rawlings MLB collectibles can maintain their condition and value for years to come. Your collection is a piece of baseball history to preserve.

Authenticating Your Rawlings MLB Baseballs – What to Look For

As any avid baseball fan knows, Rawlings has been the official supplier of baseballs for Major League Baseball since 1977. Those iconic white spheres with the red laces are as integral to America’s pastime as hot dogs and the seventh inning stretch. But how can you be sure that the Rawlings baseball you just got your hands on is an authentic MLB ball?

Verifying the authenticity of a Rawlings MLB baseball requires checking a few key indicators. Let’s go through the telltale signs that your Rawlings ball is the real MLB deal.

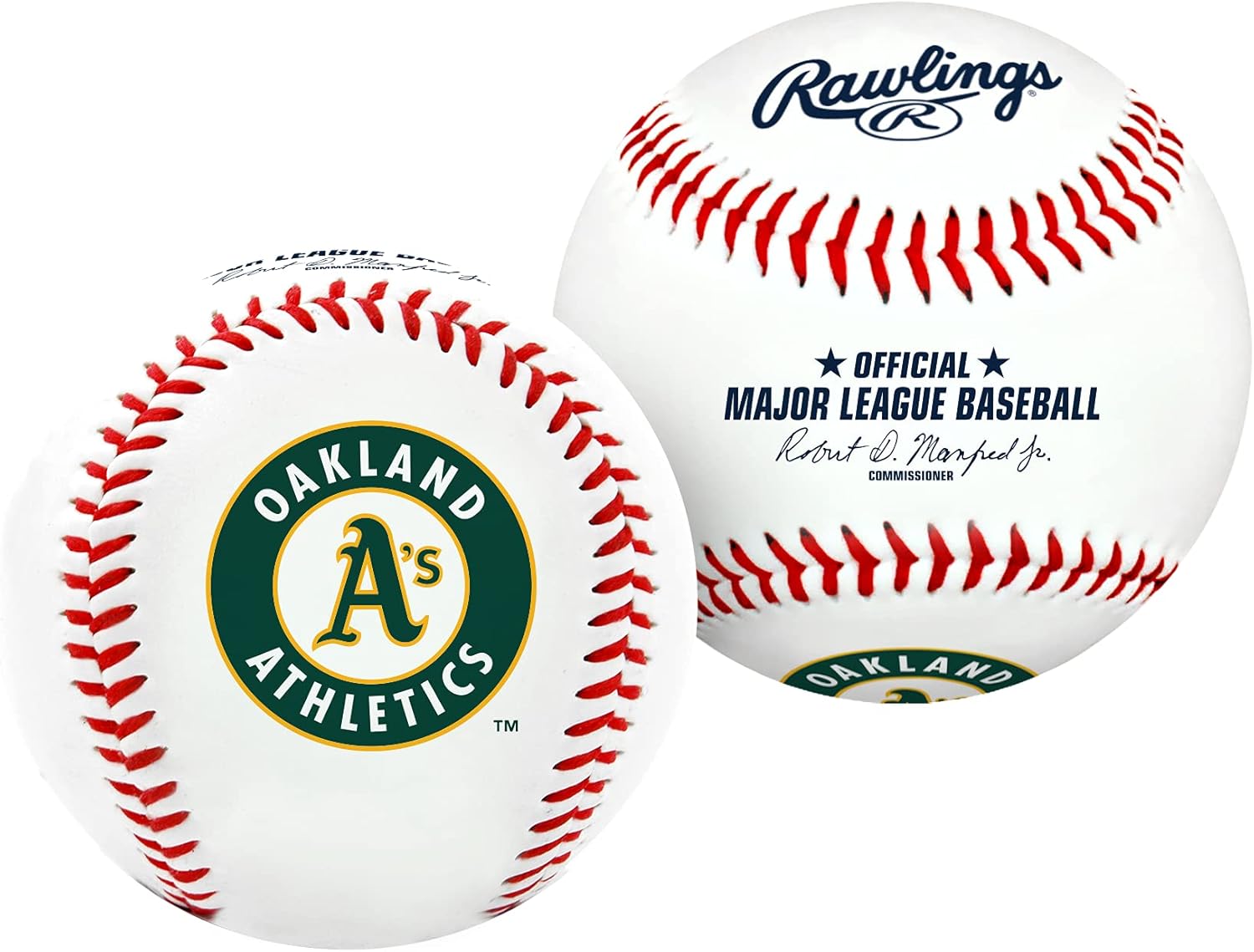

The Rawlings Logo

All official MLB baseballs will feature the Rawlings logo stamped into the leather. This logo should be clean and legible. Faded or messy stamps may indicate the ball is a replica or knock-off. The Rawlings name should also be printed in blue cursive text along one of the seams.

The MLB Logo

In addition to the Rawlings logo, authentic Major League baseballs will feature the silhouetted batter logo of Major League Baseball. This iconic logo should be stamped clearly into the leather on opposite sides of the baseball. It’s a quick visual confirmation that your ball meets official MLB specifications.

The Commissioner’s Signature

On one seam of the ball, you should find the facsimile signature of the MLB Commissioner inked in black. This signature authenticates that your baseball adheres to official league standards. For Rawlings balls produced since 1984, the signature will be that of former commissioner Peter Ueberroth or current commissioner Rob Manfred.

The Official League Stamp

Opposite the Commissioner’s signature, you’ll find the stamp of the league in which the ball was used. Balls used in American League games will display “American League” in blue ink. National League balls feature “National League” in red. This league stamp is one of the best indicators of authenticity.

High Quality Materials and Stitches

Genuine MLB baseballs are made from top-grade leather and yarn. Carefully examine the ball’s exterior. The leather should be smooth and blemish-free. Run your fingers along the seams – they should be tight, consistent, and display no loose threads. Knock-offs often cheap out on materials and construction.

Warranty Details

Many official Rawlings MLB balls come with a manufacturer’s warranty printed on the exterior wrapping or tag. This warranty will guarantee the ball’s authenticity and outline a timeframe for returns or replacements. While the warranty will disappear once the ball is unwrapped, it’s a sure sign of legitimacy for balls still in packaging.

MLB Hologram Stickers

Beginning in 1999, Rawlings MLB baseballs feature a hologram sticker on the sweet spot. When viewed from different angles, the full color hologram alternates between the MLB logo and the Rawlings name. This difficult to replicate hologram is an excellent indicator of authenticity, though older balls would lack it.

Manufacturing Date and Location

Authentic MLB baseballs will be stamped with their manufacturing date and location on the sweet spot. For example, a ball reading “Costa Rica Rawlings 05/05/22” was produced in Costa Rica on May 5, 2022. Knock-offs lack this stamp of origin.

Uniform Weight and Circumference

According to MLB regulations, official game balls must weigh between 5 and 5.25 ounces and measure between 9 and 9.25 inches in circumference. Carefully weigh and measure your ball to ensure it meets league specifications. Counterfeits often differ slightly in size and heft.

With close inspection of these essential markers – the logos, stamps, signatures, hologram, and materials – you can feel confident in the legitimacy of your Rawlings Official League Baseball. Study the unique details that set the official balls apart from cheap imitations. And most importantly, enjoy that authentic MLB experience when your Rawlings connects with the sweet spot of your bat.

Where to Buy Genuine Rawlings Official MLB Baseballs

As the official ball of Major League Baseball, Rawlings baseballs are highly coveted by players and fans alike. But finding authentic game-quality Rawlings Official MLB Baseballs can be a challenge if you don’t know where to look. Luckily, there are several great options for purchasing the real deal.

Direct from Rawlings

For guaranteed authenticity, buying directly from the Rawlings website or at their retail locations is always a safe bet. Rawlings runs an online shop at Rawlings.com with all the latest Official MLB balls in stock. The Rawlings Factory Store in St. Louis, MO also carries authenticated team balls and commemorative baseballs in their inventory.

Licensed MLB Retailers

Many Major League Baseball licensees like MLBShop.com and Fanatics.com sell Rawlings products approved by the league. These large online retailers offer a wide selection of authentic game balls, souvenir balls, and commemorative balls to choose from. Local sports retailers carrying MLB team merchandise also tend to stock official Rawlings balls.

Your Favorite MLB Team’s Ballpark

Taking in a game at your home team’s stadium? Stop by the ballpark store and you’re guaranteed to find genuine balls branded for that club. From official practice balls used by players to commemorative Opening Day balls, team stadium stores are a ball fan’s paradise.

Autographed Memorabilia Dealers

Companies that specialize in autographed memorabilia often carry authenticated Rawlings balls signed by MLB stars, past and present. The authenticity of their Rawlings inventory is key. Reputable signed memorabilia sellers include MLB Authentication, Steiner Sports and Tri-Star Productions.

MLB Auctions

Want a ball actually used in an MLB game? MLB Auctions holds regular sales of game-used gear including Rawlings baseballs with authentication certificates. You can own a ball signed by legendary hall of famers or used to throw a no-hitter or World Series walk-off.

eBay & Other Resale Sites

eBay and sites like Craigslist frequently have Rawlings MLB balls listed – but be wary of fakes! Scrutinize seller ratings and only purchase balls with MLB authentication holograms intact. A steeply discounted price may indicate a counterfeit. When in doubt, avoid secondhand sites.

Local Sporting Goods Stores

Big box sporting goods retailers like Dick’s Sporting Goods often carry a selection of Rawlings MLB balls alongside their other baseball gear inventory. Again, inspect closely for official league logos and markings. And know that limited availability varies by store location and season.

Baseball Specialty Shops

Smaller baseball hobby stores are a great resource for hard-to-find limited edition Rawlings balls. Shops like Baseballs Unlimited, Baseball Nostalgia and Grand Slam New York deal in MLB collectibles and event merchandise directly from suppliers.

Antique Collectible Shops

Looking for vintage balls? Try perusing antique malls, flea markets, collectors shops and estate sales. You might uncover rare deadstock Rawlings MLB balls decades old. Just be sure to authenticate before purchasing by assessing logos, materials and manufacturing stamps.

By purchasing directly from Rawlings, licensed MLB retailers, team venues and specialty dealers, you can add legit Rawlings Official League Baseballs to your memorabilia collection. Authenticity is essential, so inspect all identifying MLB and Rawlings markings closely and buy with confidence from reputable sellers. Play ball!

Prices and Value of Rawlings MLB Baseballs for Collectors

For baseball memorabilia collectors, official Rawlings MLB baseballs are highly prized items. But with so many types of authentic game balls on the market, what is a fair price to pay? Here’s a breakdown of factors impacting the value of Rawlings baseballs for collectors.

Standard Game Balls

The standard Rawlings OLB baseballs used in MLB games can be purchased for $12-15 at retail. These are the same balls hit by players on the field. They make affordable keepsakes or balls to play catch with while retaining MLB authenticity.

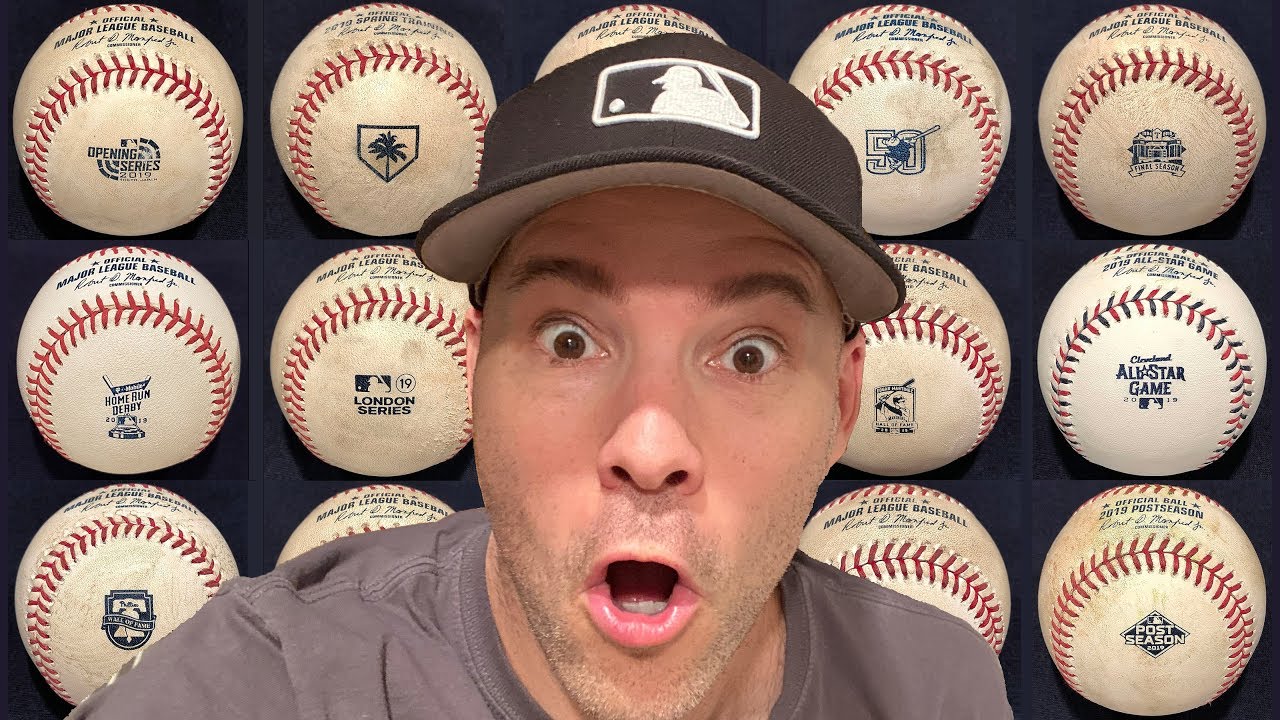

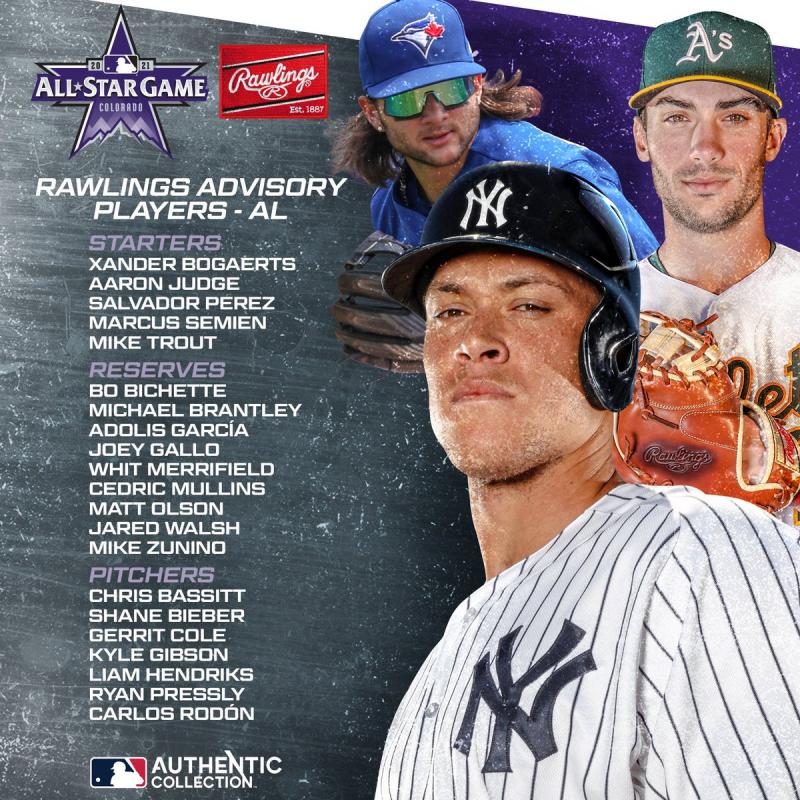

Special Edition Game Balls

Rawlings frequently produces special edition OLB game balls with unique commemorative logos for events like the World Series, All-Star Game or Hall of Fame inductions. With limited production runs, these special game balls command $20-30 in the secondary market.

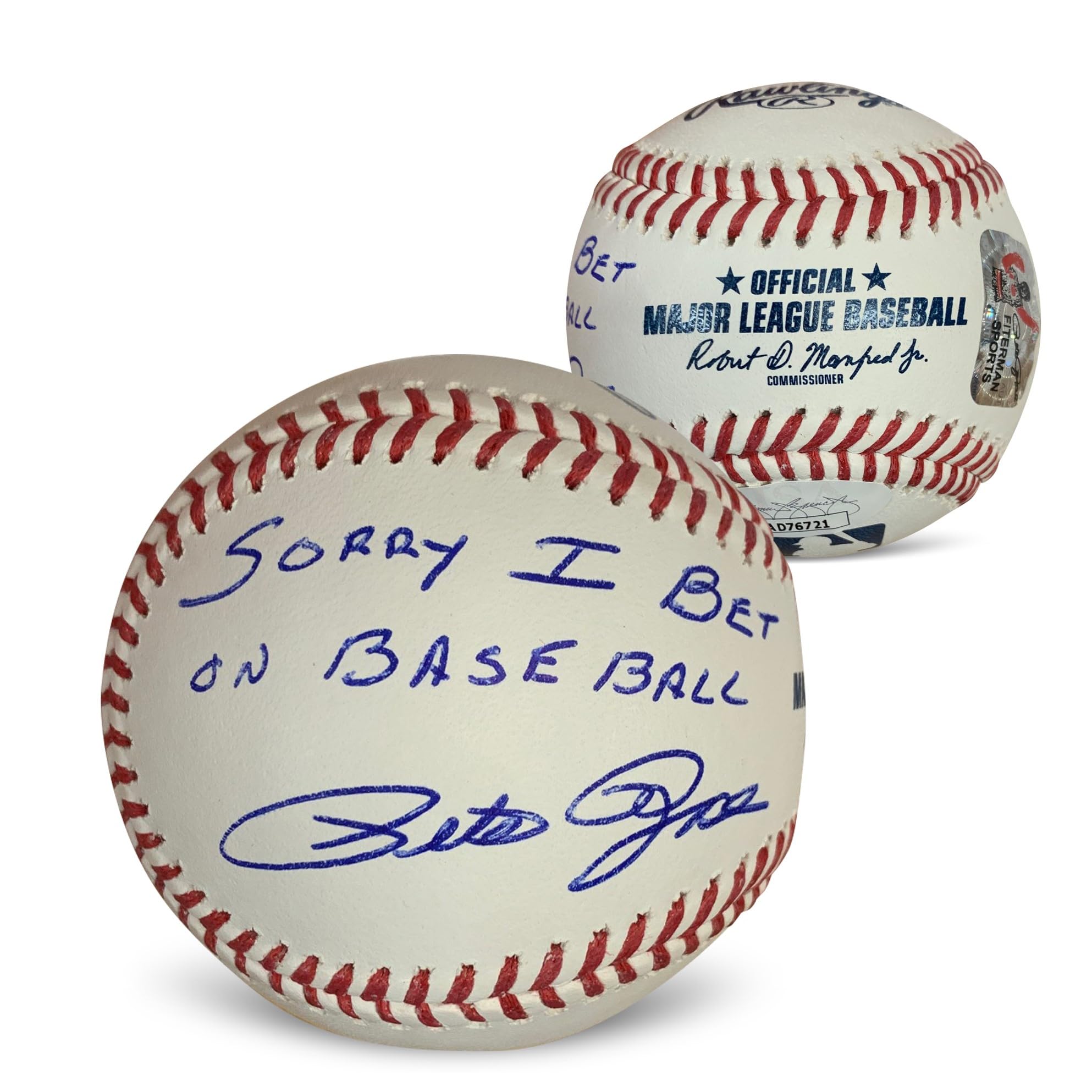

Autographed Baseballs

Player autographs drastically increase value. A Rawlings OLB signed by a Hall of Famer or All-Star can easily fetch $100-500+. Iconic signatures like Babe Ruth or Willie Mays on a period-correct vintage baseball can bring $1,000+.

Game Used Baseballs

Balls verifiably used in MLB games, with authentication, are highly coveted. Game-used balls start around $125. Those with scuffs from specific plays like no-hitters or historic homers can sell for $500 and way up.

Limited Edition Collector’s Baseballs

Rawlings produces coveted limited edition balls in numbered series for collections. These feature exclusive designs and retail for $50-100. Limited runs of 1,000 or less command the highest secondary market prices.

Vintage Baseballs

Vintage Rawlings OLB balls from the 1960s or earlier eras can sell for $50+. Mid-century examples in unused condition bring $150-300. Early 20th century balls approach $1,000 territory.

Display Condition

Balls in pristine display condition with intact logos and sheen command far higher prices than used balls. Gamers show provenance but exhibit scuffs and wear, limiting collectibility versus mint condition.

Regional Value Differences

Unsigned standard balls have fixed retail prices, but location adds value for team-branded balls. Game balls for marquee teams like the Yankees, Dodgers and Cubs carry a premium in their respective regions.

Player Popularity

Current star players and Hall of Famers influence ball value. Top stars like Aaron Judge or Derek Jeter boost autographed ball prices versus average players.

Key MLB Moments

Balls linked to seminal MLB moments—no-hitters, All-Star Games, playoff walk-offs—possess added historical value for collectors.

Serial Numbered Balls

Limited serial numbered baseballs, like 1/5,000, are more valuable than unnumbered editions. Lower serial numbers also command higher prices among collectors.

Manufacturer Defects

Misprints, stamping errors, inverted logos and other quirks make balls more unique. These manufacturer defects can make errors highly coveted by collectors.

From mint condition signed balls to stellar game-used examples, official Rawlings MLB baseballs offer investment value for hobbyists. Rarity, condition, provenance and player fame determine the fair market worth.

Famous Moments Involving Rawlings MLB Baseballs

For over 100 years, Rawlings baseballs have borne witness to some of the most iconic moments in Major League history. Let’s look back on some of the famous plays, records, and events where a Rawlings ball played a pivotal role.

Babe Ruth’s Called Shot

In Game 3 of the 1932 World Series, Yankees legend Babe Ruth famously pointed to center field before hitting a home run off the Cubs’ Charlie Root. This “called shot” home run on a Rawlings ball helped cement Ruth’s legend.

Hank Aaron’s 715th Home Run

When Hammerin’ Hank Aaron broke Babe Ruth’s all-time home run record on April 8, 1974, he blasted number 715 off an Al Downing pitch on a Rawlings MLB baseball. The historic homer brought Aaron fame and cemented his legacy.

Carlton Fisk Waves Ball Fair

In Game 6 of the 1975 World Series, Red Sox catcher Carlton Fisk hit a 12th inning solo shot off Reds pitcher Pat Darcy. As the ball sailed towards the foul pole, Fisk famously waved the Rawlings ball fair to give Boston a 7-6 win.

Kirk Gibson’s World Series Home Run

Hobbled by injuries in the 1988 World Series, Dodgers slugger Kirk Gibson memorably pinch hit a two-run walk-off homer off Oakland’s Dennis Eckersley in Game 1. Gibson’s improbable clutch homer on a Rawlings baseball sparked an LA championship.

Mark McGwire Hits 62 Home Runs

In 1998, Cardinals slugger Mark McGwire broke Roger Maris’ single-season home run record, belting balls 62 and 63 on Rawlings baseballs off the Cubs’ Mike Morgan and Steve Trachsel. McGwire finished with 70 homers that year.

Roger Clemens Strikes Out 20

Fireballing Red Sox ace Roger Clemens set a single-game strikeout record on April 29, 1986, fanning 20 Seattle Mariners on 96 Rawlings pitches. It was one of the most dominant pitching performances ever witnessed.

Randy Johnson Hits Bird

In a freak occurrence on March 24, 2001, Diamondbacks left-hander Randy Johnson struck and killed a bird in mid-flight with a pitch delivered on a Rawlings MLB baseball. The bizarre event captured national headlines.

Luis Gonzalez World Series Walk-Off

With the 2001 World Series tied in the 9th inning of Game 7, Diamondbacks’ Luis Gonzalez floated a bloop single over Derek Jeter to bring home the winning run on a Rawlings ball and seal an Arizona comeback championship.

Final Out Baseballs

The baseball used to record the final out of each World Series is especially coveted. Rawlings has produced iconic keepsake balls for famous title-clinching outs like Willie Mays’ catch in ’54 and the Cubs’ 2016 win.

For over a century of MLB history, Rawlings baseballs have been front and center for legendary moments etched into the fabric of the game. Each baseball carries with it the potential for the next iconic play just waiting to unfold.

Future Innovations Coming for Rawlings MLB Baseballs

Rawlings has been making MLB’s official game balls since 1977. While this iconic design has largely stayed consistent, new technologies and innovations may change the future of Major League Baseballs.

Tracking Technology

We could see embedded sensors and tracking technology added to game balls. This would allow advanced analytics on pitch movement, exit velocity, spin rate, and other metrics we can only estimate today.

Materials Science Improvements

Advancements in materials science may lead to MLB game balls made from new composite materials or synthetic leather equivalents with greater durability and performance.

Standardized Balls

Increased manufacturing automation and standardization of ball characteristics could minimize variance between individual balls, creating more consistency in play.

Environmentally Friendly Materials

With sustainability in mind, future MLB balls could utilize recycled or plant-based materials in fabrication, reducing waste and environmental impact.

Smart Baseballs

An MLB “smart ball” with embedded electronics could communicate pitch velocity, spin, location and other data to phones or watches for easy access to analytics.

Personalized Baseballs

Greater customization and personalization of MLB balls for individual players could occur. We could see pitchers getting balls tailored to their hand size, feel preferences and usage tendencies.

Augmented Reality Applications

Embedding augmented reality functionality into balls could allow interactive fan experiences, unlocking stats, videos and more when scanning a ball’s tag on their mobile device.

Changing Manufacturing Methods

New automated manufacturing techniques like 3D printing or robotic construction could enable production of MLB baseballs to shift away from hand-stitching and panel assembly.

Altered Ball Texture

Adjustments to ball surface textures or leather grain could increase grip and control for pitchers and hitters. Expect subtle enhancements over time.

Digital Product Integration

In an increasingly digital landscape, future MLB balls may integrate with mobile apps, fantasy sports, video games, NFTs and the metaverse for digital engagement.

MLB Ball Unification

Rather than American League and National League balls, a universal MLB regular season and postseason ball could be adopted to standardize play.

While the classic Rawlings design endures, new innovations and technologies will inevitably shape the MLB baseballs of tomorrow as the game evolves in the digital age.