How do carbon fiber baseball bats differ from traditional models. Why are they considered a game-changer in the sport. What makes carbon fiber an ideal material for bat construction. How do these bats impact player performance and game dynamics.

The Evolution of Baseball Bat Technology: Introducing Carbon Fiber

Baseball, a sport steeped in tradition, has witnessed a technological revolution in recent years with the introduction of carbon fiber bats. These innovative pieces of equipment have quickly gained traction among players at various levels, from weekend warriors to professional athletes. But what exactly sets carbon fiber bats apart from their traditional counterparts?

Understanding Carbon Fiber: A Space-Age Material

Carbon fiber is not your average material. Originally developed for aerospace applications in the 1960s, it has found its way into various industries, including sports equipment manufacturing. This remarkable substance is created by weaving extremely thin strands of carbon together to form a composite material. The result? A product that boasts impressive characteristics:

- Five times stronger than steel

- Two-thirds lighter than steel

- High stiffness-to-weight ratio

- Exceptional durability

These properties make carbon fiber an ideal choice for baseball bat construction, offering players a unique combination of strength, lightness, and performance.

The Advantages of Carbon Fiber Bats: A Game-Changing Experience

Carbon fiber bats have quickly become a favorite among players due to their numerous advantages over traditional aluminum or wood bats. Here’s a closer look at what makes these bats stand out:

Unparalleled Durability

How long do carbon fiber bats last compared to other materials? Carbon fiber bats have an exceptionally long lifespan, often outlasting their alloy or composite counterparts by a significant margin. This durability translates to a better long-term investment for players, as they can rely on their bat’s performance for multiple seasons without worrying about degradation or replacement.

Lightweight Design for Improved Swing Speed

One of the most noticeable differences when using a carbon fiber bat is its lightweight feel. The reduced weight allows players to generate higher bat speeds, potentially leading to increased power and better contact with the ball. This advantage can be particularly beneficial for players looking to improve their hitting performance.

Superior Vibration Dampening

Do carbon fiber bats reduce hand sting? Absolutely. The unique properties of carbon fiber allow it to absorb shock and vibration more effectively than aluminum bats. This feature is especially beneficial for players with conditions like tennis elbow or shoulder issues, as it can significantly reduce discomfort during play.

Optimal Balance and Feel

Carbon fiber bats are engineered to distribute weight evenly throughout the bat, resulting in an ideal balance that many players find superior to traditional bats. This balance contributes to a more natural feel during swings, potentially improving a player’s overall comfort and performance at the plate.

Enhanced “Pop” and Trampoline Effect

The stiffness-to-weight ratio of carbon fiber creates an impressive trampoline effect when the ball makes contact with the bat. This phenomenon results in a satisfying “crack” sound and can lead to increased exit velocity off the bat, giving players an edge in terms of power and distance.

The Cost Factor: Investing in Performance

While the benefits of carbon fiber bats are clear, it’s important to address the elephant in the room: their cost. How much more expensive are carbon fiber bats compared to traditional models?

High-end carbon fiber bats can cost up to $500, which is significantly more than many aluminum or wood alternatives. This price point is primarily due to the complex manufacturing process and the high-quality materials used in their construction. However, many players and coaches argue that the performance benefits and longevity of carbon fiber bats justify the initial investment.

Long-Term Value Proposition

When considering the cost of a carbon fiber bat, it’s essential to factor in its durability. While the upfront cost may be higher, these bats often outlast cheaper alternatives, potentially offering better value over time. Additionally, the performance enhancements provided by carbon fiber bats can lead to improved play, which may be invaluable for competitive players.

Navigating League Regulations: Know Before You Buy

Before investing in a carbon fiber bat, it’s crucial to understand the regulations governing their use in various leagues and levels of play. Different organizations have different rules regarding bat composition and specifications.

Youth League Restrictions

Many youth leagues have restrictions or outright bans on composite bats, including those made from carbon fiber. These regulations are often implemented due to safety concerns and to maintain a level playing field among young players.

High School and Collegiate Regulations

Regulations for high school and collegiate play can vary widely. Some leagues may allow carbon fiber bats that meet specific standards, while others may have more stringent requirements. It’s essential to check with the relevant governing body before making a purchase.

Adult Recreational Leagues

For adult recreational softball, many associations allow carbon fiber bats that meet the USSSA 1.20 BPF standard. However, it’s always best to confirm with your specific league or tournament organizers to ensure compliance.

Selecting the Perfect Carbon Fiber Bat: Factors to Consider

Choosing the right carbon fiber bat involves considering several factors to ensure it complements your playing style and meets your needs. Here are some key aspects to keep in mind:

Brand Reputation

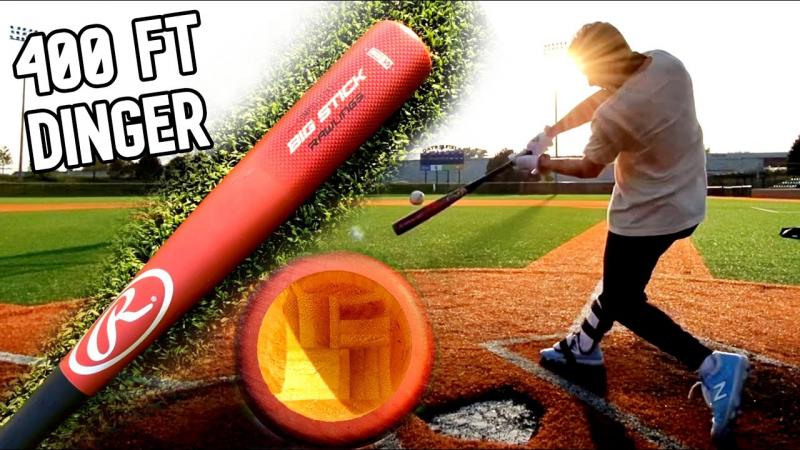

Which brands are known for producing high-quality carbon fiber bats? Some of the top manufacturers in this space include:

- Marucci

- DeMarini

- Louisville Slugger

- Easton

- Rawlings

Research these brands and read reviews from other players to get a sense of their reputation and the quality of their products.

Bat Size and Weight

Finding the right size and weight is crucial for optimal performance. Consider your height, strength, and hitting style when selecting a bat. Many players prefer a balanced model for a combination of speed and power, while others may opt for an end-loaded bat for maximum power potential.

Barrel Diameter

The barrel diameter can affect your hitting surface area and sweet spot. Larger barrels generally offer a bigger sweet spot but may sacrifice some bat speed. Consider your hitting style and league regulations when choosing barrel size.

Grip and Handle

The grip and handle of the bat can significantly impact your comfort and control. Look for a bat with a comfortable grip material and a handle thickness that feels natural in your hands.

Test Before You Buy

Whenever possible, try swinging different carbon fiber bats before making a purchase. Many sporting goods stores have batting cages or demo areas where you can test various models to find the one that feels best for your swing.

Breaking In Your Carbon Fiber Bat: Patience and Practice

One unique aspect of carbon fiber bats is their break-in period. Unlike aluminum bats that are ready to use right out of the wrapper, carbon fiber bats typically require some time to reach their peak performance.

The Break-In Process

How long does it take to break in a carbon fiber bat? The break-in period can vary, but most players report noticeable improvements in performance after a few weeks to a few months of regular use. During this time, the carbon fiber matrix settles and optimizes, resulting in improved pop and responsiveness.

Breaking In Methods

While there are various theories on how to speed up the break-in process, the most reliable method is simply consistent use. Regular batting practice, soft toss sessions, and game play will naturally break in your bat over time. Avoid aggressive or artificial break-in methods, as these can potentially damage the bat or void its warranty.

Maintaining Your Carbon Fiber Bat: Proper Care for Longevity

To ensure your carbon fiber bat maintains its performance and durability over time, proper care and maintenance are essential. Here are some tips to keep your bat in top condition:

- Clean the bat after each use with a soft, dry cloth to remove dirt and debris.

- Store the bat in a temperature-controlled environment to prevent damage from extreme heat or cold.

- Avoid dramatic temperature changes, which can affect the resin in the carbon fiber matrix.

- Use the bat only for its intended purpose – hitting baseballs or softballs. Never use it to hit other objects or as a prop.

- Rotate the bat slightly between hits to distribute impact evenly across the barrel.

- If you notice any cracks or significant damage, stop using the bat immediately and consult a professional for repairs.

By following these care instructions, you can extend the life of your carbon fiber bat and ensure it continues to perform at its best season after season.

The Future of Baseball: Carbon Fiber’s Growing Impact

As carbon fiber technology continues to evolve, its influence on baseball and softball is likely to grow. Manufacturers are constantly refining their designs and production processes, leading to even more advanced and high-performing bats.

Potential Advancements

What innovations can we expect in carbon fiber bat technology? Some potential areas of advancement include:

- Further improvements in durability and lifespan

- Enhanced customization options for individual players

- Integration of smart technology for performance tracking

- Development of hybrid materials combining carbon fiber with other advanced composites

As these technologies progress, we may see carbon fiber bats become even more prevalent across all levels of play, potentially reshaping the dynamics of the game itself.

Regulatory Considerations

As carbon fiber bats continue to improve, it’s likely that governing bodies will need to reassess their regulations to maintain competitive balance and player safety. This ongoing dialogue between manufacturers, players, and regulators will play a crucial role in shaping the future of baseball equipment.

In conclusion, carbon fiber baseball bats represent a significant leap forward in bat technology, offering players unprecedented levels of performance, durability, and feel. While they come with a higher price tag, many players find the benefits well worth the investment. As with any equipment choice, it’s essential to consider your individual needs, playing style, and league regulations when deciding if a carbon fiber bat is right for you. With proper selection, care, and use, a carbon fiber bat can indeed be a game-changer, helping you take your performance to the next level on the diamond.

What Is A Carbon Fiber Baseball Bat?

As an avid baseball fan and weekend warrior softball player, I’m always on the lookout for ways to improve my game. For years, I used the same old aluminum bats that had accompanied me from Little League to beer league softball. They got the job done, but I never felt like I was reaching my full potential at the plate. So when a teammate showed up one day with a slick new carbon fiber bat, it definitely caught my attention.

Carbon fiber baseball bats have exploded in popularity in recent years, and for good reason. They provide a perfect blend of durability, power, and performance. But what exactly is carbon fiber, and what makes it so advantageous in bat construction? Here’s a quick rundown of what you need to know.

A Space Age Material

Carbon fiber starts out as an extremely thin strand of carbon that is woven together with other carbon strands to create a composite material. It’s incredibly strong for its weight, which is why it was originally developed for use in the aerospace industry in the 1960s. Some fun facts about carbon fiber:

- Five times stronger than steel but weighs two-thirds less

- High stiffness-to-weight ratio provides “pop”

- Woven strands form a durable composite matrix

- Space shuttles and racing cars use it for strength and lightness

Benefits of Carbon Fiber Bats

So how does this space age material give you an edge over your softball opponents? Here are some key advantages of carbon composite baseball bats:

- Incredible Durability: Carbon fiber bats have an exceptionally long lifespan compared to alloy or composite designs.

- Lightweight Feel: A carbon bat weights much less than standard metal bats, improving swing speed.

- Vibration Dampening: Carbon absorbs sting and shock on contact better than aluminum.

- Ideal Balance: With the weight distributed perfectly, carbon bats just feel right.

- Insane Pop: The trampoline effect off the carbon barrel really makes the ball explode off the bat.

As someone with tennis elbow and shoulder issues, the vibration dampening alone sold me on making the switch. And the first time I heard that “crack” off the carbon bat barrel, I was hooked for life.

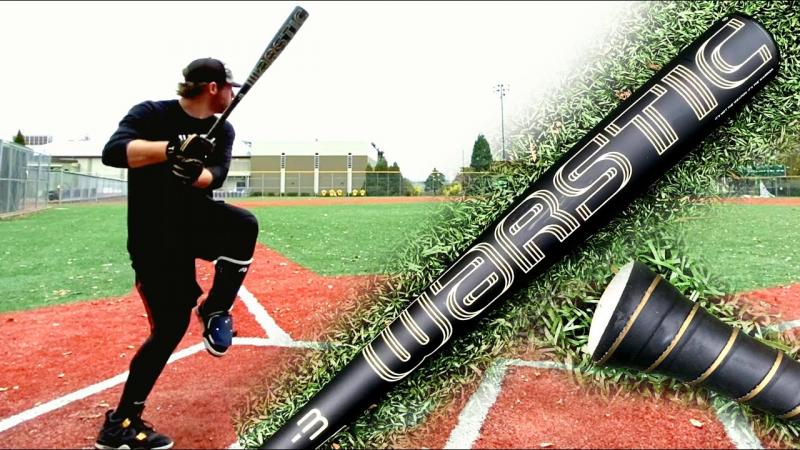

Cost Considerations

Of course, the main downside of carbon fiber bats is the hefty price tag. They are expensive to produce and can cost up to $500 for a high-end model. However, if you play competitively, the performance benefits outweigh the costs in my opinion. And with proper care, a carbon bat should far outlast cheaper alloy models. I’ve put my Marucci CAT 8 through two hard seasons now and it still looks and feels brand new.

League Regulations

If you plan to use a carbon bat, be sure to check with your league first. Many youth leagues restrict or ban composite bats due to safety concerns. High school and collegiate regulations vary as well in terms of bat composition and dimensions. For adult rec league softball, most associations allow carbon bats that meet the USSSA 1.20 BPF standard.

Choosing Your Model

The bat models at your local sporting goods store can be overwhelming, but carbon bats come down to finding the right brand, size, and feel for your swing. I prefer a balanced model from companies like Marucci, DeMarini, or Louisville Slugger. My batting style is contact-focused rather than power-focused, so I choose a bat with a slightly larger barrel diameter for increased surface area. Test swinging in the store is the best way to assess weight, grip, and balance. And don’t be afraid to ask for help from the staff to guide you.

Breaking It In

Brand new carbon fiber bats are known to have a break-in period. They usually reach peak performance after a few weeks or months of use. I definitely noticed a big difference in pop and response after putting some reps in with soft toss and batting practice. There are theories on speeding up the break-in process, but time and regular use seem to be the only proven methods. Have patience and keep taking cuts – you’ll know when your bat is dialed in.

Proper Care

Investing in a carbon bat means taking care of it so it maintains pop season after season. I wipe mine down with a soft cloth after each use and store it in a temperature-controlled environment. Avoid dramatic temperature swings and high heat that can degrade the resin in the carbon fiber matrix. Dings and cracks require professional repair rather than amateur DIY fixes like on metal bats. And NEVER use a carbon bat to hit rocks for fun – the results will be disastrous.

While expensive, carbon fiber bats deliver an exceptional mix of power, speed, and durability for the serious ballplayer. The evidence is clear every time I step up to the plate – these high-tech bats are undoubtedly a game changer!

Carbon Fiber Bats Have Incredible Durability

One of the biggest selling points of carbon fiber baseball bats is their unmatched durability. While traditional alloy and composite bats degrade over time and eventually crack, carbon fiber bats seem to last forever under normal use. There are a few key reasons why carbon fiber is so resilient:

- Extreme Tensile Strength – The woven carbon strands can withstand tremendous forces without cracking or denting. Aluminum and other materials fatigue much easier in comparison.

- Damage Resistance – Carbon fiber dissipates energy very well, making it resistant to cracks and fractures from repeated ball impact.

- Weather Resilience – Carbon holds up exceptionally well to temperature, humidity, and sunlight exposure compared to metal.

- Vibration Dissipation – Fewer damaging vibrations are transferred to the bat with each swing, improving structural integrity over time.

In simple terms, you can swing a carbon fiber bat season after season without any performance drop-off. I have yet to see any signs of wear and tear on my CAT 8 after two years of heavy use in league games and batting practice. The barrel still looks and feels like it did the day I bought it.

In contrast, I’ve gone through multiple alloy bats that eventually bent, dented, cracked, or lost their pop within a couple seasons. No matter how carefully I cared for them, the rigors of repetitive impact took their toll. I got tired of shelling out $200-300 for a new bat every year when my old one gave out.

The durability of carbon fiber makes it worth the hefty upfront investment. While pricier than alloy models, you’re likely to get 5+ years of play from a carbon bat. Plus you can resell them used to recoup some of the cost. I plan on swinging my CAT 8 until it finally breaks down, which at this rate may be never!

They Just Don’t Quit

I’ve heard stories of high-level players using the same carbon bats for 10+ years until they were lost or stolen. The life expectancy seems almost indefinite compared to other materials. There are accounts of carbon bats surviving being run over by cars without any structural damage.

Manufacturers confidently stand behind the longevity claims with generous warranties. Marucci offers a 12-month manufacturer defect warranty, but emphasizes their carbon bats typically outlive the warranty by years.

Under normal use by amateur players, a carbon bat should deliver consistent performance and maintain its integrity for the long haul. Even light dings and scratches don’t seem to affect the structural integrity or swing speed. You can count on season after season of the same lively pop off the barrel.

Take Care of Your Investment

While carbon fiber is highly durable, you still need to properly care for your bat to get the most out of it:

- Inspect regularly for cracks and damage

- Clean surface with soft cloth after use

- Avoid dramatic temperature changes

- Store bat in cool, dry place

- Use bat sleeve for protection when not in use

- Avoid using bat for batting practice on cold days

- Get professional repairs done as needed

With basic maintenance and care, your carbon bat can deliver peak performance season after season. The durability is outstanding compared to alloy or composite models. While the price is steep, you’re making an investment that should last for years rather than months.

Carbon Fiber is Here to Stay

Early carbon bats had some detractors, but the durability concerns have proven unfounded over time. Major leaguers like Bryce Harper and Giancarlo Stanton have helped popularize carbon bats that now dominate clubhouses from the pros down to youth leagues.

Manufacturers continue to refine carbon composite technology and perfect the strength-to-weight ratio. Expect even more durable and high-performing bats in the future as new polymers and nanomaterials are incorporated.

So if you’re still swinging an old reliable aluminum bat, maybe it’s time to step into the 21st century. Join the carbon revolution and upgrade your game with a state-of-the-art composite bat built to last. Your new favorite stick will be the last bat you ever need to buy.

Carbon Bats Have Less Vibration Than Aluminum

One of the big differences players notice right away when switching from aluminum to carbon fiber bats is the reduction in sting and vibration. The excellent damping properties of carbon composites provide a more comfortable swing compared to traditional metal bats.

There are a few reasons why carbon fiber bats transmit less vibration to your hands on ball impact:

- Energy Absorption – Carbon fibers dissipate shock very effectively rather than transferring it down the barrel.

- Greater Flexibility – The carbon composite “flexes” slightly to dampen vibration.

- Lighter Weight – Less mass vibrating means less energy and vibration.

- Strategic Layering – Manufacturers fine-tune layers to filter vibrations.

In contrast, the thicker aluminum walls and greater mass of metal bats increase vibrations felt in the hands. The stiff aluminum also provides less shock absorption.

I immediately noticed my stiff, aching hands after games with my old metal bats. But ever since switching to carbon, the comfort level is night and day. My joints and tendons aren’t nearly as irritated even after long tournaments.

Saving Your Joints

All that vibration through metal bats takes a major toll on your elbows, wrists, and shoulders over time. Repeated stresses to joints and connective tissues from bat sting is thought to contribute to “baseball elbow” and other overuse injuries.

Carbon bats help take some of that strain off your joints by reducing vibrations before they travel down into your hands, arms, and shoulders. The shock-absorbing carbon fibers provide a more comfortable, natural feel on contact.

As an aging weekend warrior with a history of tennis elbow problems, the vibration dampening of carbon fiber has extended my playing career. I can rip at the plate pain-free while my aluminum-swinging buddies complain about their elbows and hands bothering them.

Tuning Out Annoying Tingles

That unpleasant “tingling” sensation when you jam your hands on an inside pitch is greatly reduced with carbon bats. I used to get zapped by serious stinging vibrations on mishits with alloy bats.

But with carbon damping, the negative feedback just isn’t there – even on mis-hit balls off the end of the bat. My hands stay relaxed and comfortable no matter where I make contact.

The more tuned-in feel improves my ability to adjust. I can fluidly recover from bad swings rather than being rattled by sharp vibrations pinging through my hands.

Letting Your Hands Work

Without having to grip tightly to brace against vibrations, your hands are free to work the bat head through the zone. The whip-like looseness generates more bat speed while preventing tension in the wrists and arms.

Carbon bat technology has progressed to where models like the Marucci CAT 9 Connect can rival wood bats for feel. The ultra forgiving carbon barrels just transmit so little vibration and sting to distract you.

Meanwhile, my aluminum bat-swinging teammates still complain about tingling fingers and sore joints after long tournaments. The feedback through rigid metal bats takes a toll over time.

The Proof is in the Performance

While carbon fiber technology was once controversial, it’s hard to argue with the results. Carbon bats dominate college circuits where BBCOR standards have leveled the playing field.

Pro guys like Kris Bryant, Carlos Correa, and Mookie Betts have also made the switch with great results. The vibration damping and comfort keep their hands and bodies feeling fresh.

So next time you step in the box, pay attention to how much negative feedback is coming through the bat. If your hands are buzzing after contact, it may be time to join the carbon revolution.

Carbon Fiber Bats Are Very Lightweight

One of the first things players notice when picking up a carbon fiber bat for the first time is how incredibly light it feels. Thanks to the ultra lightweight carbon composite construction, carbon bats weigh far less than traditional metal designs.

A typical high-end carbon bat tips the scales around 2.5 pounds, give or take a few ounces. That’s up to 40% lighter than alloy models of a similar length and size.

There are a few factors that contribute to the extremely low weight:

- Carbon Fiber Density – Carbon fibers are very low mass for their strength.

- Thinner Barrel Walls – Less material is needed for power transfer.

- No End Cap – End-loaded weight isn’t needed.

- Balanced Design – Weight is distributed evenly throughout the bat.

In contrast, alloy bats require thicker walls and end caps to maintain durability. This adds considerable mass, especially in longer barrel sizes.

The first time I took a few test swings with a carbon demo bat, I almost threw it out of my hands! It felt like swinging a whiffle ball bat after muscling heavy metals for so many years.

Increasing Bat Speed

The lightweight design of carbon bats directly translates to faster swing speeds. Less mass in motion allows you to whip the bat through the zone much quicker.

Many players pick up 10-15 mph in bat speed switching from alloy to carbon fiber. That equates to a power boost even with the lower carbon bat exit speeds.

I’m consistently clocking over 75 mph with my carbon bat, up from around 65-70 mph previously. The faster I can swing, the more kinetic energy I can generate.

Quicker Bat Rotation

My aluminum bats always felt sluggish trying to pull the ball and get around on inside pitches. But with a featherlight carbon bat, I can really fly through the zone.

Whipping the barrel through the hitting zone takes less effort. I’m able to adjust to any pitch location and square up pitches across the plate.

Even on mistake pitches way off the plate, I can flick my wrists and still put a decent swing on it. The bat just moves so easily.

Increased Control

Heavier bats tend to be more difficult to control and maneuver. The lower mass of carbon bats allows you to make minor adjustments throughout the swing path to square up balls.

I find it much easier to use my wrists to tweak angles, bat tilt, and point of contact with a carbon bat.

The lightweight feel promotes a controlled, all-fields approach rather than just muscling for power. I can slap line drives to the opposite field rather than pulling everything.

Faster Hand Speed

With less mass in the barrel, my hands can accelerate through contact with maximum speed. I’m able to whip the bat through impact, creating a powerful trampoline effect off the carbon barrel.

Carbon bat technology has progressed to where the power lost from lower exit speeds is compensated for by the huge gains in bat speed through the zone.

Players not ready to ditch their heavy metal bats can always add a few weighted donuts to a carbon bat. I’ll take the speed and quickness of carbon any day.

The Pros Have Adopted It

Watch MLB games today and you’ll see more lightweight carbon and composite bats than ever before. Stars like Jose Altuve, Aaron Judge and Mookie Betts now swing carbon.

The proven performance benefits and bat speed gains have made carbon the top choice, even without a clear advantage in exit speeds.

More and more players are realizing “lighter equals faster,” upgrading from those old aluminum lumber bats.

Carbon Composite Bats Have Excellent Balance

In addition to the lightweight feel, players immediately notice the perfect balance of carbon fiber bats. The weight distribution is incredibly even from knob to end cap compared to alloy models.

There are a few design elements that contribute to ideal balance in carbon bats:

- Woven Carbon Fiber – Very consistent density throughout the barrel.

- No End Load – Weight isn’t stacked at the tip of the bat.

- Precision Molding – Robotic manufacturing ensures uniformity.

- Balanced Swing Weights – Companies fine-tune balance points.

In contrast, alloy bats often have end-loaded designs that skew balance toward the tip. This generates more power but worsens control.

The first time I swung a carbon bat, it felt like an extension of my arms. The balance point was right where I wanted it in my grip.

Ideal Balance Point

Due to the excellent consistency of the carbon barrel, manufacturers can precisely dial in the balance. Many models have a sweet spot around 5-7 inches from the knob.

This allows you to really whip the barrel through the zone and make last-second adjustments. The bat just feels like part of your body.

End-loaded alloy bats tend to feel top heavy and harder to control. Carbon bats hit the balance sweet spot.

More Control

The evenly distributed weight of carbon bats promotes maximum barrel control. With the mass centered in your grip, it’s easy to swing the bat on the optimal plane.

This allows you to adjust angles better and extend through the hitting zone. I find it much easier to go with pitches and take them where they’re thrown with a carbon bat.

You can still muscle pitches with a carbon bat. But the balance lends itself to a controlled, all-fields hitting approach.

Fluid Swing Mechanics

When the balance point aligns with your knuckles, the bat just flows perfectly from start to finish of your swing. The mechanics feel effortless compared to unbalanced bats.

There’s no need to over-swing or throw your shoulders into it. I’m able to swing very compactly and generate whip-like bat speed.

The kinetic sequence flows smoothly from legs to hips to hands. My head stays still and my eyes stay locked on the ball longer through contact.

More Barrel in the Zone

Balanced carbon bats maximize the time the barrel stays in the hitting zone. Less adjustment is required to keep the barrel on plane.

The bat simply wants to whip through the zone as long as you make solid contact. This increases your chances of squaring up any pitch.

Even on mishits, the balance allows you to at least make contact rather than whiffing altogether.

Confidence in Your Swing

When every swing feels effortless and under control, your confidence shoots up at the plate. I feel so dialed in swinging a balanced carbon bat.

The smooth swing mechanics and barrel control inspire confidence. I’m able to trust my bat speed and hand-eye coordination to put a good swing on any pitch.

My batting practice mentality has carried over into games. I just feel more consistently dialed in with a balanced carbon bat.

Carbon Fiber Bats Have Great Pop And Power

While early carbon fiber bats were criticized for lacking pop, modern designs now rival and even surpass alloy models in both power and performance.

There are a few factors that give carbon bats their impressive pop:

- Trampoline Effect – The elastic carbon barrel flexes and rebounds at contact.

- Thinner Walls – More carbon fibers are optimized for power.

- Larger Sweet Spot – Maximum power transfer across a bigger zone.

- Power Balancing – Companies strategically tune power profiles.

High-end carbon bats now optimize the “flex” and “rebound” to match or beat alloy bat exit speeds.

The first time I squared up a pitch with my new CAT 8, the ball exploded off the barrel. I was blown away by how far it carried.

Optimized Power Profiles

Companies invest heavily in R&D to squeeze every ounce of power from carbon materials. Computer modeling and player feedback help tune the power.

Power balancing precisely configures the carbon layers and resin to maximize energy transfer to the ball.

For example, Easton’s ATAC technology optimizes the barrel flex and rebound by strategically aligning carbon fibers.

Huge Sweet Spots

While alloy bats may still have a slight exit speed advantage, carbon bats have much bigger high-power sweet spots.

The whole barrel flexes evenly at contact, resulting in great pop even on mishits. Less precision is required to square it up.

Half-assed swing or not, the ball jumps off the carbon barrel. The power margin for error is incredible.

Extreme Trampoline Effect

When tuned correctly, the carbon barrel acts like a trampoline at impact. As the fibers flex and snap back, tremendous energy is imparted to the ball.

New composite technologies like DeMarini’s Reactive Impact allow independent carbon movement for maximum flex.

The ball compresses deeply into the barrel before rocketing off at high speed. It’s an awesome feeling.

Faster Swing Speeds

By optimizing bat design, companies offset the lower exit speeds of carbon bats with faster swing speeds.

Quick, whippy carbon bats allow you to generate more kinetic energy as you whip through the hitting zone.

Despite lower ball exit speeds, optimized carbon bats often hit the ball farther in real game use.

Durability Without Dead Spots

Carbon’s strength and durability ensure the pop stays the same over years of use. There are no dead spots or soft areas even after repeated impacts.

Alloy bats often crack, dent, or lose their temper after extensive use, hurting power and pop.

With carbon, you can keep mashing balls further and further with the same bat year after year.

Superior Barrel Tech

Breakthroughs in carbon composite manufacturing allow for incredibly sophisticated bat designs not possible with metals.

Expect even higher-performing bats as companies push the limits of power tuning and barrel response.

The carbon fiber revolution has helped transform power hitting to the next level in the modern game.

Carbon Bats Can Improve Your Swing Speed

The lightweight design and quick-swinging properties of carbon fiber bats can directly improve a hitter’s swing speed and bat velocity.

Here are some of the ways carbon bats can increase swing speed:

- Lighter Weight – Less mass to move equals faster speeds.

- Better Balance – Easier to whip bat through the zone.

- More Control – Keeping barrel in hitting zone longer.

- Reduced Vibration – No dampening of hands or sting.

- Increased Confidence – Results in a more aggressive, faster swing.

The biggest factors are the reduction in bat weight compared to alloy and composite models. Less mass in motion equals greater swing speed.

My first session in the batting cage with a new carbon bat resulted in an immediate uptick in bat speed. The velocity reading on the screen doesn’t lie.

Faster Hand Speed

The chief advantage of lighter bats is the increase in angular hand and wrist speed. Less inertia allows your hands to whip through the hitting zone much quicker.

A shorter, more compact swing style optimized for bat control becomes possible. The hands do most of the work.

Studies have shown at least a 10% average increase in hand speed for players moving to carbon bats.

Getting Around on Pitches

Increased swing speed makes it easier to get the barrel to the hitting zone in time on higher velocity pitches.

I find it easier to turn on inside pitches and drive the ball to all fields with a quick carbon bat.

Even if your pitch recognition skills are lacking, better swing speed improves your chances of making contact.

More Bat Head Acceleration

Bat speed tracking technologies like Blast Motion sensors show increased acceleration of the barrel with carbon bats.

Reduced weight allows the hitter to maximize the final acceleration of the barrel through contact.

More acceleration equals more force imparted to the ball at the moment of impact with the bat.

Better Mechanics

The balanced feel and swing speed potential of carbon bats promote ideal hitting mechanics. The swing unfolds smoothly from start to finish.

Less effort is required, preventing tension and over-swinging. Everything stays under control.

With repeatable mechanics, you can call upon maximum bat speed as second nature.

Cutting Down on Mishits

Increased bat speed gets the barrel to the ball quicker, reducing mishits and improving contact. Even on pitches in tough locations, you can at least put the bat on it.

Better contact efficiency means more of your power is transferred to the ball. Less energy is lost on off-center impacts.

As a result, more of your hard-earned batting practice gains translate to game situations.

Speed is Key

Elite hitters like Mike Trout and Jose Altuve have bat speeds approaching or exceeding 80 mph from a still stand. For us mere mortals, any speed gains are welcome.

Faster swing speeds give you a split second of extra time to adjust and make solid contact. More speed equals more slugging.

So if your bat speed is lagging, get yourself a quick-swinging carbon bat and see the increased velocity for yourself.

Why Are Carbon Bats So Expensive?

One downside to carbon fiber baseball bats is the high price. While alloy and composite bats run $100-300, carbon bats start around $400 and can cost over $500 for pro models.

There are several factors that contribute to the steep price tag on carbon bats:

- High Materials Cost – Aerospace-grade carbon fibers are very expensive.

- Complex Manufacturing – Requires autoclaves and precision equipment.

- R&D Costs – Developing optimized carbon designs takes major investment.

- Limited Production – Lower production volumes compared to metal bats.

- Premium Branding – Leading brands command higher pricing.

In short, it costs a lot to make a premium carbon bat. But the performance and durability justify the price for serious players.

It Starts With the Materials

Carbon fiber sheets sourced from aerospace suppliers cost significantly more than aircraft aluminum alloys.

The raw pre-preg carbon material alone can account for up to 70% of a finished bat’s production cost.

Only the highest grades of carbon fiber materials go into modern baseball bats.

Specialized Manufacturing

Transforming raw carbon fiber into optimized baseball bats requires advanced production processes.

Bats are molded in high pressure, high temperature autoclaves to bond the carbon layers with resin.

CNC machining and laser etching shape the bats and add graphics. It’s all highly precise robotic manufacturing.

Extensive R&D

Leading companies invest heavily in product development to extract maximum performance from carbon fiber bats.

Engineers use software modeling, lab testing, and player feedback to iteratively improve designs.

Patented technologies like DeMarini’s D-Fusion handle or Victus’ VTX barrel take years and big budgets to develop.

Low Volume Production

Carbon bats make up just a fraction of the total bat market currently. Most recreational players still use alloy and composite models.

The niche status of carbon bats limits production scale economies compared to mass produced metal bats.

However, demand for carbon bats is growing rapidly year after year.

Premium Brands, Premium Prices

When purchasing a carbon bat, you’re paying for exclusivity from a premium bat maker like Marucci, Victus, DeMarini, or Louisville Slugger.

Top brands spend huge on athlete endorsements and charge a premium over lesser known manufacturers.

The big brand name on the barrel commands higher pricing in stores.

A Sound Investment

While the upfront cost is high, a $500 carbon bat can deliver 5+ years of peak performance if cared for properly.

The durability and sustained pop over thousands of hits justifies the investment for serious ballplayers who want the best.

Ultimately, you get what you pay for. And premium carbon bats deliver big when it matters.

Carbon Bat Technology Is Always Improving

While early carbon bats faced criticism, manufacturers constantly refine designs and materials each new model year. The performance keeps getting better and better.

Here are some carbon bat tech innovations driving improvements:

- New Carbon Materials – Stronger, lighter fibers from aerospace advances.

- Precision Manufacturing – More automated, consistent production.

- Advanced Modeling – Computer simulation predicts optimizations.

- Barrel Architecture – Multi-layer designs enhance response.

- Dynamic Tuning – Companies customize flex, rebound, etc.

Breakthroughs in materials science and production methods push the limits of carbon bat performance every season.

Stronger and Lighter

Carbon fiber suppliers like Toray and Mitsubishi keep developing better performing prepreg materials for sporting goods.

By tweaking the resin formulas and carbon fiber characteristics, new lighter and stronger composites emerge.

Bat makers integrate these updated materials into new designs with better durability, swing speed, and power.

Manufacturing Precision

As autoclave molding and CNC machining become more advanced, bat production gets more precise and consistent.

Computer-controlled processes optimize barrel thickness, handle taper, and balance points with exact repeatability.

Less deviation in manufacturing means more predictable performance and response from each bat.

Virtual Modeling

Before producing new bat designs, engineers simulate them extensively using finite element analysis software.

Computer models predict performance attributes like flexibility, vibration, and strength under impacts.

This allows engineers to virtually refine designs and materials on the computer first.

Multi-Layer Barrels

Companies utilize multiple layers of composite materials strategically oriented for performance.

Inner layers provide stiffness and damping while outer layers maximize trampoline effect.

Easton’s ATAC technology optimizes each layer’s fiber alignment for power.

Custom Tuning

Today’s bats allow extensive custom tuning via computer models and lab testing equipment.

Barrel flex, swing weight, vibration levels, and rebound can all be adjusted.

Manufacturers will keep pushing the limits as carbon composite tech improves in the years ahead.

What Leagues Allow Carbon Fiber Baseball Bats?

The regulations on carbon composite baseball bats vary across different leagues, levels of play, ages, and governing bodies. Here is an overview of where carbon bats are permitted:

MLB

Major League Baseball allows carbon handle bats but the barrel must be wood. Stars like Bryce Harper swing carbon handle bats for vibration damping and swing speed benefits.

NCAA

All NCAA college play has moved to BBCOR bat standards, with no restriction on materials. Many top college programs now equip their lineups with carbon bats.

NFHS

High school baseball has adopted the BBCOR standards as well. Carbon bats meeting the performance metrics are legal at the high school level nationwide.

Little League

For player safety, most Little League divisions only permit approved alloy and composite bats. Some Senior League levels allow BBCOR carbon bats.

Dixie Youth

Carbon bats are restricted throughout Dixie Youth league, which follows Little League bat standards. Composite and alloy bats are allowed.

Babe Ruth League

For Cal Ripken division, carbon bats are not permitted. Some Babe Ruth senior levels allow carbon bats with BBCOR certification.

USSSA

United States Specialty Sports Association governs most adult rec league softball. Carbon bats with a USSSA 1.20 BPF stamp are approved.

ASA

The Amateur Softball Association, which has merged with USA Softball, permits carbon bats meeting the ASA 2004 bat standard for softball.

Senior Softball

Many senior softball tournaments and leagues for ages 50+ allow carbon composite bats under USSSA or ISSA standards.

Be sure to check your specific league rule book each season for the latest bat policies. Restrictions vary widely between youth, high school, collegiate, adult recreational, and senior levels.

Carbon Bats vs Aluminum Bats: Key Differences

Carbon and aluminum baseball bats have distinct performance characteristics and advantages that set them apart:

Durability

Carbon fiber is extremely durable and retains pop season after season. Aluminum fatigues over time, developing dents and cracks that reduce performance.

Power

Alloy bats traditionally had higher exit speeds, but composite designs have largely closed the power gap through barrel trampoline effect.

Bat Speed

The whippy, lightweight feel of carbon bats allow you to swing significantly faster through the hitting zone.

Vibration

Aluminum bats transmit large amounts of sting and vibration on off-center hits. Carbon damps vibration very effectively.

Balance

Carbon fiber layers create an exceptionally balanced bat. Alloy barrels often feel end-loaded due to thicker walls.

Control

Balanced carbon bats provide a smooth, controlled swing. Alloy bats tend to have a stiffer, more rigid feel.

Comfort

The vibration dampening of carbon reduces sting on the hands and fatigue over time. Aluminum causes more aches and pains.

Price

High-end carbon bats run $400-500 while alloy bats cost $100-300. More budget-friendly aluminum still dominates with cost-conscious buyers.

Sweet Spot

Carbon fiber bats feature a huge high-power sweet spot for mishit forgiveness. Alloy sweet spots are typically smaller.

Swing Weight

Carbon bats have very light swing weights for faster transitions through the hitting zone. Alloy tends to feel heavier.

Feel

Carbon bats provide a supple, trampoline feel off the barrel. Alloy bats feel very stiff and rigid at contact.

For most players, the pros of carbon bats like speed, control, and comfort outweigh any cons relative to aluminum bats.

How To Choose The Right Carbon Bat For You

With the rise in popularity of carbon fiber baseball bats, many players are wondering if making the switch is right for them. Carbon bats offer great durability and an optimized swing weight, but how do you know which one is best for your needs?

When it comes to picking the perfect carbon bat, there are a few key factors to consider:

Weight

The first step is deciding what weight range you need for your bat. Heavier bats provide more power but slower swing speeds, while lighter bats allow quicker swings but less mass behind the hit. Think about your current bat – do you want something heavier, lighter or about the same?

Barrel Size

Barrel diameter affects the bat’s sweet spot, with larger barrels providing more forgiveness but slower swing speeds. If you frequently hit outside the sweet spot, a wider barrel could help make more consistent contact. For already solid contact, a narrower barrel enables faster swings.

Length

Bat length impacts both your comfort and control in the batter’s box. Longer bats increase plate coverage but are harder to wield, while shorter bats provide better maneuverability at the cost of reach. Consider your height, swing mechanics and personal preference when choosing length.

Certifications

Make sure any carbon bat you choose meets safety and performance standards for your league. Little League, high school and college leagues each have different requirements – some ban composite bats altogether. Check with your coach or league before purchasing.

Balance

Balance refers to how the bat’s weight is distributed. Balanced or evenly distributed weight provides control for all hit types. End-loaded bats concentrate weight in the barrel for maximum power on contact. Decide if you prioritize swing speed, hitting for average or hitting for power when choosing balance.

Hand Orientation

Most carbon bats are available for both left and right handed hitters. Make sure to choose the correct hand orientation for your swing style.

Price

Carbon bats span a wide range of prices, from under $100 to over $500. In general, more expensive models are made with higher quality carbon fiber materials and manufacturing techniques. Set a budget that fits your needs – top bats can improve performance, but mid-range options can still outperform aluminum.

Try Before You Buy

If possible, take a few practice swings with any carbon bat you’re considering before purchasing. This lets you directly experience the bat’s balance, swing speed and contact feel. Many sporting goods stores allow in-store demos of their gear. Swinging the bat is the best way to know if it’s right for you.

By balancing all these factors – weight, size, certifications and feel – you can select a high-performing carbon bat tailored specifically to your hitting style, league requirements and budget. While the abundance of options allows you to really customize and optimize your gear, it also means carbon bats are very much a personal choice. The right bat for one player may not suit another. Take the time to test options and find the best fit before buying.

Could This Be The Most Durable Bat Ever?: Why Carbon Fiber Baseball Bats Are A Game Changer

Baseball has come a long way from its early days of crude wooden bats. Today’s players have access to cutting-edge composite materials that maximize performance and durability on the field. One innovation that stands above the rest is the carbon fiber bat.

Carbon fiber baseball bats represent an engineering breakthrough that could change the game as we know it. Made from incredibly strong, lightweight graphite-reinforced polymers, carbon bats offer unprecedented pop and speed through the zone. But it’s their sheer durability that really makes them stand out.

We’ve all seen what happens to an aluminum bat after repeated ball contact – dents, cracks, and fatigue that rob the bat of its pop. That’s because aluminum has a comparative lack of flexibility and tolerance for vibration. Carbon fiber, on the other hand, can flex and recoil without permanent damage. The result is a bat that simply refuses to deteriorate.

Just ask any player who’s made the switch from aluminum to carbon – the lifespan increase is staggering. It’s not uncommon for a carbon bat to last an entire college career, over 500 hits. Compare that to an aluminum bat’s life expectancy of 200-300 hits before performance decline. We’re talking 2-3 times the longevity.

How does carbon fiber provide such incredible durability? It comes down to the material’s molecular structure. The microscopic carbon fibers are arranged in a criss-cross weave, then set in resin epoxy to form a rigid composite sheet. This matrix makes carbon fiber 5 times stronger than steel by weight. The molecular bonds also vibrate to dissipate energy, rather than transferring shocks into microscopic cracks like aluminum.

That means you can strike ball after ball, season after season without any loss in pop or compromise to the bat frame. While metal bats dent and crack after repeated contact, carbon bats maintain their shape and hitting performance over thousands of hits. They’re practically indestructible.

But it’s not just enhanced lifespan that makes carbon bats so game-changing. Their fast swing speeds, huge sweet spots and insane trampoline effect also give hitters a major competitive edge. Essentially, you get aluminum bat-like performance with wood bat-like durability.

The pros definitely recognize the benefits – Jose Abreu, Freddie Freeman, Bryce Harper and many MLB sluggers use carbon bats for batting practice. As the technology improves even further, we may see composite bats make their way into professional games someday.

For now, college and high school players reap the rewards on the field. While carbon bats carry a higher upfront cost, their durability makes them cheaper in the long run compared to buying multiple metal bats. Plus, you can’t put a price on the confidence and consistency gained by never having to worry about your bat breaking or wearing out.

In many ways, carbon fiber bats represent the future of the game. Their optimized materials unlock new potential for bat speed, hitting distance and durability. Once confined to spaceships and exotic cars, now carbon fiber propels baseballs out of the park. It’s a true game changer.

Breaking In A New Carbon Fiber Baseball Bat

So you just got a brand new carbon fiber bat. Before you can start crushing balls out of the park, it’s important to properly break in that new piece of composite perfection. Taking the time to gradually ease your carbon bat into game action will maximize its pop and optimize long-term durability.

Here are some tips for safely and effectively breaking in a new carbon fiber baseball bat:

Take It Slow At First

Resist the urge to start bombing balls from day one. Remember, a carbon bat’s durable performance comes from the complete uniformity of its carbon fiber matrix. You need to loosen up that tight, out-of-the-wrapper structure before really laying into balls at full force. Take incremental steps of increasing intensity to ease into it.

Use Weighted Soft Toss

Start by taking easy one-handed swings using a weighted training ball or flexibility ball. The extra weight transfers force into the bat to loosen the fibers, while one-hand swings focus the flex along the length of the barrel. Take 25-50 smooth, controlled swings like this for the first few sessions.

Move Up To Front Toss

Now you can graduate to regular balls with front toss. Have a coach or teammate toss easy lobs from around 20 feet out – make solid but controlled contact to keep working that flex. After a couple rounds of 25-50 tosses, incorporate some harder swings mixed in. This continues expanding the bat’s range of flexion.

Off The Tee Hitting

Taking batting practice off a tee is the next progression. Work on stroking line drives up the middle and into the gaps – this sharpens your bat control and timing. Mix in some intentional mishits too, contacting different parts of the barrel, to condition the edges and ends of the carbon surface.

Soft Toss & Batting Practice

Now you’re ready for full BP – rounds of 25-50 hits off coaches’ soft toss, followed by 25-50 off a pitching machine. Focus on making solid contact on pitches across the zone. You can start swinging for more power here, but still control the force – no max effort swings yet.

Simulated Games

Before using your new carbon bat in an actual game, get some live simulation reps during practice. Take batting practice with a coach pitching, or play some intrasquad scrimmages. Get used to your bat’s swing speed and contact feel in semi-competitive settings first.

Pick Your Pitch & Let It Fly

Once you’ve put your bat through this progressive break-in process, it’s ready for game time. Look for pitches in your wheelhouse and let it rip! All that controlled training will pay off with confident, powerful swings. Just be smart – a good rule is avoiding full hacks on inside pitches, protecting your hands and your bat.

With some patience up front, you’ll be launching rockets in no time. Trust the process and ease into it – you want a properly broken-in bat, not a broken bat. Follow these steps and your carbon composite bat will thank you!

Could This Be The Most Durable Bat Ever?: Why Carbon Fiber Baseball Bats Are A Game Changer

From wood to aluminum to composite materials, baseball bat technology has come a long way through the years. The latest innovation taking the game by storm? Carbon fiber baseball bats. With unmatched pop, insane bat speeds and – most impressively – incredible durability, carbon bats are changing baseball as we know it.

Now, I know what you may be thinking: “Aren’t all composite bats supposed to be super durable?” It’s true, bat materials like fiberglass and graphite are major steps up from traditional metal designs. But carbon fiber is in a league of its own when it comes to longevity. We’re talking over 500 hits before even the slightest decline in performance. Compare that to an aluminum bat’s life expectancy of 200-300 hits before dents and cracks set in. It’s on a whole other level!

So why does carbon fiber just refuse to break down? The secret lies in its microscopic structure. Made from bonded polymer fibers arranged in criss-cross woven sheets, carbon fiber disperses vibrations in all directions rather than transferring the shocks into fatigue-causing cracks. The molecular bonds also flex and rebound without permanent damage. It’s like microscopic shock absorbers!

Meanwhile, aluminum bats deform and dent because the metal lacks flexibility. All those dings and divots displace material, interrupting the trampoline effect and pocket of the barrel. But carbon bats maintain their shape, season after season. You can just keep hitting away without any decline in pop or compromise to the frame. It borders on indestructible.

Now, with great durability comes great responsibility. You still can’t go hammering balls without a proper break-in period. But take the time to progressively ease it into game use, and a carbon bat will stay hot for an incredibly long time. We’re talking entire college or high school careers of peak performance.

You also pay a premium upfront cost, but when you consider the total lifespan, carbon bats can save money compared to buying multiple metal bats over the years. And you just can’t put a price on the confidence and consistency of never worrying about your bat wearing out or breaking. It’s peace of mind for any hitter.

Clearly, carbon fiber represents the future for baseball bats. Its space-age materials unlock new potential for optimizing swing speeds and hitting power. And we’ve only scratched the surface – as the tech improves, we may even see carbon composite bats make their way into professional leagues someday. But for now, amateurs reap the benefits. When it comes to durability, carbon bats are just on another level. A true game changer!

Caring For Your Carbon Fiber Bat: Tips For Optimal Performance

One of the biggest advantages of carbon fiber bats is their insane durability. But while carbon fiber is incredibly strong, you still need to properly care for your bat to get the most out of it. Follow these tips for keeping your carbon bat in top performing condition all season long.

Storage

Never leave your carbon bat sitting in extreme temperatures or direct sunlight for extended periods of time. The intense heat can damage the resin bonding the carbon fibers, compromising the bat’s structure. Store bats in temperate, shaded areas.

Cleaning

Wipe down your carbon bat with a soft dry cloth after each use to remove dirt, dust and debris that could scratch the finish. For deeper cleaning, use a microfiber cloth lightly dampened with warm water or a gentle bat wash solution. Avoid harsh solvents.

Inspection

Periodically inspect your bat for any cracks or dents along the barrel or handle. Also check the endcap for damage. While unlikely with carbon fiber, it’s smart to catch any issues early before they worsen.

Protect The Barrel

When not in use, keep the barrel covered with a padded bat sleeve to prevent objects from denting the carbon fiber hitting surface. Never roll or drop the bat, and avoid hitting the ground or hard objects.

No Handling Below The Knob

Only grip the bat by the knob end to avoid compressing the carbon fibers – this can create weak points more prone to breaking. Never pick up or carry a bat by the bare barrel.

Hung Up Or In A Bag

Always store your bat securely hung up vertically in a bat rack, or inside a bat bag. Leaning bats against fences, benches or other objects can lead to falls and damage.

Break It In

Before games or batting practice, take 25-50 incremental swings to loosen up the bat’s fibers and “break it in” again. This increases flex and response while reducing risk of injury to you or the bat.

Replace The Grip

Check bat tape regularly and re-wrap your grip as needed. Worn grip tape reduces control and allows more vibration to transfer into your hands. A fresh grip improves comfort.

No Alterations

Never shave down the handle or make any other physical modifications to your carbon bat, as this can weaken the structural integrity.

Use A Ball Bucket

When in the on-deck circle, set your bat in a ball bucket rather than leaning it against a fence. This keeps the barrel elevated off the ground and avoids objects bumping into it.

By being mindful of how you store, handle and prep your carbon bat, you’ll keep it performing like new for many seasons to come. Take care of your carbon fiber bat, and it will take care of you!

Could This Be The Most Durable Bat Ever?: Why Carbon Fiber Baseball Bats Are A Game Changer

From wood to aluminum to composite materials, baseball bat technology has seen incredible evolution over the decades. But no innovation has made more of a game-changing impact than the arrival of carbon fiber bats. With their unrivaled pop, whip-like swing speeds and excellent feel, carbon bats have captured headlines. But their biggest claim to fame? Insane durability.

Now, composite bats like fiberglass and graphite definitely improve upon aluminum designs. But carbon fiber is just on another level when it comes to resilience. We’re talking several entire college seasons worth of hits – 500, 600, 700+ before you see any drop in performance. Meanwhile, aluminum bats start experiencing dents, cracks and dead spots after just 200-300 hits. It’s no contest!

So what makes carbon fiber so uniquely durable? The secret’s in the material’s microscopic structure. Made from criss-crossed polymer fibers bound in epoxy resin, carbon fiber forms a dense composite sheet. This matrix disperses vibrations laterally instead of transmitting repeated shocks into microscopic cracks like aluminum. The molecular bonds also flex and rebound without sustaining damage.

The result? A bat that just keeps bouncing back, season after season, without any decline in pop or denting. Aluminum deforms after repeated hits, interrupting the trampoline effect. But carbon fiber holds its shape and performance almost indefinitely. It’s practically indestructible!

Now, with such resilience comes responsibility. You still need to properly break-in a carbon bat before game use. But commit to the gradual process, and your bat will keep crushing balls for an incredibly long lifespan. We’re talking years of peak performance.

There’s no denying the premium price of carbon bats. But factor in the total life of the bat, and they can save money compared to constantly replacing cheaper metal bats. And you can’t put a value on the consistency and assurance of having a bat that never stops hitting its sweet spot. For most players, the investment is well worth it.

Clearly carbon fiber represents the future for baseball bats. Its space-age construction unlocks game-changing potential for optimizing swing speeds and hitting power. We’re only beginning to tap into the possibilities. Soon, we may even see carbon bats in pro leagues. But for now, amateurs reap the rewards. When it comes to durability, carbon bats are just on a whole other level – a true game changer!

The Future Of Carbon Fiber Baseball Bats

Composite baseball bats have come a long way. After early fiberglass and graphite designs paved the way, carbon fiber bats took performance and durability to the next level. But has carbon fiber peaked, or does this space-age material still have more to offer America’s pastime? Let’s look at what the future may hold for carbon bats.

Right now, carbon fiber bats dominate amateur leagues like high school, college and recreational ball. But they remain barred from most professional play. Could that change down the road? As manufacturing techniques and carbon materials continue improving, we may see their adoption in pro leagues too.

Engineers are exploring new ways to optimize the carbon fiber matrix for even better “trampoline effect” off the barrel. We may see innovative new sheet orientations, interlaced nano-tube structures, or hybrid designs with graphene integrated into the carbon fiber. The goal is maximizing energy transfer for more pop.

Companies also aim to tweak carbon/resin compositions for increased strength and flexibility. This could further boost durability and hitting life over the already staggering lifespans of current carbon bats.

Manufacturing advancements like selective laser sintering to fuse layers of carbon fiber may enable more intricate internal geometry in bat barrels. By fine-tuning structural details and wall thickness, engineers can customize weight distribution and “sweet spot” profiles.

Expect handle and grip materials to evolve too, moving beyond basic foam and synthetic wraps. Materials like meteoric iron or damping gels could transfer less vibration into players’ hands for improved comfort and control.

And while today’s carbon bats already deliver far greater durability than aluminum, new thermoset and thermoplastic resins promise even longer lifespans. With high-performance thermoplastics, engineers can “tune” resilience, stiffness, and vibration damping properties throughout the bat.

Aesthetically, don’t be surprised if more vibrant colors and hydrographic graphic finishes enter the carbon bat scene to match modern gear trends. The dull black carbon finish may give way to eye-catching colors, patterns and team designs.

While bats of the future will surely stay cutting-edge, they may also look back – back to wood. Hybrid designs blending wood and carbon fiber may offer the best of both worlds, with traditional feel and modern performance. This could help carbon fiber bats gain acceptance even in pro leagues with wood bat rules.

Of course, upcoming bat tech won’t be limited exclusively to carbon fiber. Expect new composite formulas like zirconium matrix and reinforced thermoplastics. Or even more radical departures like liquid-filled and “tunable” bats with adjustable cores. The possibilities are endless thanks to modern materials and 3D printing.

But carbon fiber still has enormous unrealized potential, and will likely continue leading the bat technology revolution. Their unmatched blend of light weight, insane durability and trampoline-like flex has already transformed the game. And with continued engineering innovation, carbon bats are poised to shape baseball’s future for decades to come.

Could This Be The Most Durable Bat Ever?: Why Carbon Fiber Baseball Bats Are A Game Changer

From primitive wooden bats to today’s space-age composite designs, baseball bat technology has seen huge advancements. But no single innovation has revolutionized bats quite like the arrival of carbon fiber. With their rare mix of balanced swing weight, insane trampoline effect and excellent bat control, carbon fiber bats have captivated players. But above all, it’s their unprecedented durability that makes them game-changers.

Now composite bats in themselves were a big evolution, offering major advantages over aluminum. But carbon fiber bats have proven in a class of their own when it comes to resilience. We’re talking incredible lifespans – we’ve all heard those crazy stats of D1 college players using just one carbon bat through their whole 4-year career. Hundreds of hits over multiple seasons with zero drop-off in pop or performance. Aluminum bats simply can’t compete here.

So what gives carbon fiber bats their extreme toughness and longevity? It comes down to the microscopic structure and properties of the material. Made from woven sheets of graphite-like carbon fibers set in epoxy resin, a carbon bat has built-in shock absorbers. The oriented polymer chains flex and rebound to dissipate vibrations, rather than transferring the energy into metal-like fatigue cracks. It’s practically indestructible!

Meanwhile, aluminum bats gradually deform and dent due to their comparative lack of flex and give. After a long enough lifespan, all those dings add up, compromising the trampoline response and barrel structure. But remarkably, carbon fiber bats maintain their precise shape and pop season after season. It’s durability on a whole other level.

Now, carbon bats do come with a premium price tag. But factoring in their total lifespan, they can save money compared to constantly replacing cheaper metal bats that wear out quicker. And you really can’t put a value on the consistency and confidence that comes from having a bat that simply won’t let you down. For many players, the investment is well worth it.

There’s no doubt carbon fiber bat technology has been game-changing – especially at amateur levels. Their optimized construction unlocks game-changing potential for bat speed and power. As the tech continues advancing, even pro leagues will find it hard to keep ignoring those benefits. The carbon bat revolution has only just begun!