Choosing the Best Lacrosse Shaft Carbon Fiber or AlloyChoosing the Best Lacrosse Shaft Carbon Fiber or Alloy

The Strength and Durability Benefits of Carbon Fiber Lacrosse Shafts

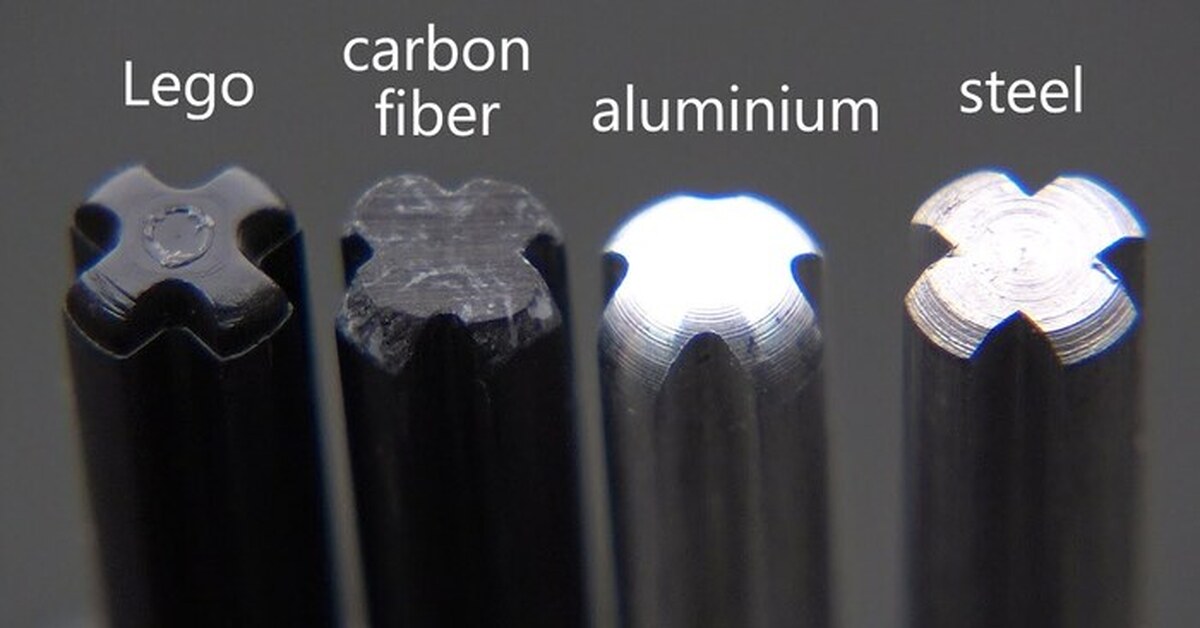

Carbon fiber has become an increasingly popular shaft material in lacrosse due to its high strength-to-weight ratio and durability. Carbon fiber shafts provide a lightweight feel while still maintaining rigidity and strength for superb ball control and checking. The carbon fiber composite material allows shaft manufacturers to orient the carbon strands optimally to produce a stiff, yet flexible design.

Carbon fiber shafts boast exceptional strength properties relative to their low weight. The tightly woven carbon fiber strands create a rigid lattice structure able to withstand huge amounts of stress. Tests show carbon fiber shafts having a higher tensile strength than 6061 alloy shafts. This resistance to bending and warping maintains the shaft’s shape and performance through seasons of play.

In addition to strength, carbon fiber offers unmatched durability and resilience. The carbon fiber weave has high inter-laminar shear strength, resisting cracks and fractures from repeated checks. Impacts that would permanently bend an alloy shaft often flex carbon fibers back into shape. The shafts have high fatigue strengths, enduring normal wear-and-tear through years of aggressive play. While alloy oxidizes, carbon fiber holds up against weathering.

Manufacturers optimize carbon fiber lacrosse shafts to balance stiffness and flexibility. The directional alignment of carbon strands tunes the flex profile, bending in some directions while remaining stiff torsionally. This flex allows for excellent ball feel and control. Engineers can alter the resin system, fiber type, and layering approach to fine-tune the performance. The result is an exceptionally stiff, durable, and lightweight shaft perfect for the fast-paced play of lacrosse.

In comparison to alloy, carbon fiber lacrosse shafts represent a premium upgrade in strength, durability, and lightweight feel. Their advanced composite construction makes them highly resistant to bending, fracturing, and weathering. While more costly than alloy, carbon fiber shafts deliver superior performance and longevity to satisfy the demands of elite lacrosse players.

The Lightweight Design Benefits of Carbon Fiber Lacrosse Shafts

One of the main benefits driving the popularity of carbon fiber lacrosse shafts is their exceptionally lightweight design compared to traditional alloy shafts. By utilizing advanced composite materials and construction techniques, carbon fiber shaft manufacturers can produce designs that are both rigid and incredibly light.

The lightweight properties of carbon fiber shafts stem from the intrinsic strength-to-weight ratio of carbon fiber itself. Made up of interwoven strands of carbon, the carbon fiber cloth is both dense and featherlight. The alignment and layering of the carbon cloth during manufacturing allows the construction of stiff, durable lacrosse shafts at a fraction of the weight of alloy.

Engineers cleverly orient the carbon fibers within a shaft to optimize the weight distribution and provide strength precisely where needed. The carbon cloth is wrapped over foam or alloy/titanium inserts at stress points to augment durability without adding weight. By strategically layering the carbon, manufacturers minimize overall material usage.

Advanced composite molding techniques yield carbon fiber lacrosse shafts with perfectly balanced strength, flex, and ultra-low weight. Computer modeling and simulation allows engineers to customize the layering approach and resin system to tune the flex profile and optimize performance characteristics. The end result is a supremely lightweight shaft meeting exacting strength and flexibility demands.

The lightweight properties of carbon fiber translate into faster shots, quicker feeds, and effortless stick handling. Fatigue is reduced, allowing players to go full-throttle for 4 quarters of play. Quicker cuts, tighter dodges, faster footwork and greater range of motion is achievable. Goalies benefit from lightning fast re-positioning. Overall agility and athletic performance is enhanced.

Players consistently report the lightweight feel of carbon fiber shafts as a major plus. The weight difference between carbon fiber and alloy is immediately apparent. For lacrosse players looking for any possible edge in speed and performance, the lightweight properties of carbon fiber shafts provide a compelling advantage.

The Vibration Reduction Benefits of Carbon Fiber Lacrosse Shafts

One of the most impactful benefits of carbon fiber lacrosse shafts is their ability to reduce vibrations compared to traditional alloy shafts. This results in improved handling, better ball control, and reduced fatigue.

All lacrosse shafts vibrate to some degree when the ball makes contact, whether during a shot, pass, or check. These vibrations travel down the shaft into the player’s hands and arms. Excessive vibrations can lead to reduced control, sting, and fatigue over the course of a game.

Carbon fiber is inherently excellent at damping vibrations. The polymer resin binding the carbon fibers together acts as a shock absorber. The interlaced carbon fiber cloth also dissipates vibrations through the shaft. Manufacturers additionally use vibration-dampening foams and inserts at key areas along the shaft length.

By engineering the precise carbon cloth orientation, layering, resin system, and use of dampening inserts, carbon fiber lacrosse shafts achieve a remarkable reduction in vibrations versus alloy shafts. This equates into noticeably smoother handling, allowing the player to cradle, pass, catch, and shoot with greater control and comfort.

Dampened vibrations also yield big benefits in terms of reduced player fatigue. Less sting and hand shock allows players to string passes and shots together through 4 full quarters of play. Goalies can react faster, scoop, clear, and make save after save without wearing down.

For elite lacrosse players, the vibration dampening properties of carbon fiber shafts offer a substantial competitive edge. Remaining in complete control of the ball while fighting off fatigue can make the difference in those crucial late game moments. The smooth, dampened feel of carbon fiber simply allows players to perform at their absolute best.

The Cost Difference Between Carbon Fiber and Alloy Lacrosse Shafts

The Science Behind Carbon Fiber Strength

The exceptional strength of carbon fiber lacrosse shafts stems from the material’s unique composition. Engineers can precisely orient carbon strands to optimize performance, creating a stiff yet flexible design. This level of customization allows for fine-tuning of the shaft’s flex profile, ensuring ideal ball control and checking capabilities.

Lightweight Design: A Game-Changing Advantage

Perhaps the most immediately noticeable difference between carbon fiber and alloy shafts is the weight. Carbon fiber offers a significant weight reduction without sacrificing strength or durability. But how does this translate to on-field performance?

- Faster shots and quicker feeds

- Improved stick handling and agility

- Reduced player fatigue

- Enhanced range of motion

The lightweight nature of carbon fiber allows players to move more quickly and maintain peak performance throughout an entire game. Goalies benefit from faster repositioning, while offensive players can execute tighter dodges and more precise cuts.

The Engineering Behind Lightweight Carbon Fiber Shafts

Achieving the optimal balance of strength and weight in carbon fiber shafts requires advanced engineering techniques. Manufacturers employ computer modeling and simulation to determine the ideal layering approach and resin system. This results in shafts that meet exacting performance standards while minimizing overall weight.

Vibration Reduction: Enhancing Control and Comfort

Another significant advantage of carbon fiber shafts is their superior vibration dampening properties. This characteristic offers several benefits to players:

- Improved ball control and feel

- Reduced hand fatigue during long playing sessions

- Enhanced accuracy in shooting and passing

- More comfortable overall playing experience

The unique structure of carbon fiber allows it to absorb and dissipate vibrations more effectively than alloy shafts. This results in a smoother feel when catching, throwing, or shooting, potentially improving overall performance.

Customization and Performance Tuning

One of the most exciting aspects of carbon fiber technology is the ability to fine-tune shaft performance for specific playing styles or positions. How do manufacturers achieve this level of customization?

- Adjusting the type and orientation of carbon fibers

- Modifying the resin system

- Altering the layering approach

- Incorporating strategic reinforcements

This level of customization allows players to choose shafts that perfectly complement their playing style, whether they prioritize maximum stiffness for powerful checks or a more flexible design for enhanced ball control.

Position-Specific Carbon Fiber Shafts

Different lacrosse positions have unique equipment needs. Carbon fiber technology allows manufacturers to create shafts tailored to specific roles:

- Attack: Lightweight, responsive shafts for quick maneuvers and precise shooting

- Midfield: Balanced designs offering versatility for both offense and defense

- Defense: Stiffer, more durable shafts capable of delivering powerful checks

- Goalie: Ultra-lightweight options for lightning-fast reactions

The Cost Factor: Investing in Performance

While carbon fiber shafts offer numerous performance benefits, they typically come at a higher price point than their alloy counterparts. Are the advantages worth the additional cost? Consider the following factors:

- Long-term durability potentially offsetting initial investment

- Performance improvements that could enhance overall play

- Reduced need for frequent replacements due to bending or damage

For serious players looking to maximize their potential, the benefits of carbon fiber may justify the higher price tag. However, recreational players or those on a tight budget may find that quality alloy shafts still offer excellent performance at a more accessible price point.

Environmental Considerations: Carbon Fiber vs Alloy

As sustainability becomes an increasingly important factor in equipment choices, how do carbon fiber and alloy shafts compare in terms of environmental impact?

- Production energy requirements

- Recyclability and end-of-life disposal

- Longevity and replacement frequency

While the production of carbon fiber is generally more energy-intensive than that of alloy, the increased durability and longevity of carbon fiber shafts may result in fewer replacements over time. Additionally, advancements in recycling technologies are making it increasingly possible to reclaim and reuse carbon fiber materials.

Innovations in Sustainable Lacrosse Equipment

As environmental concerns grow, some manufacturers are exploring more eco-friendly options for both carbon fiber and alloy shafts. These innovations include:

- Use of recycled materials in production

- Development of biodegradable resins for carbon fiber

- Improved recycling processes for end-of-life equipment

Players concerned about the environmental impact of their equipment choices may want to research manufacturers committed to sustainable practices and materials.

Making the Choice: Carbon Fiber or Alloy?

Ultimately, the decision between a carbon fiber or alloy lacrosse shaft depends on a variety of factors unique to each player. Consider the following questions when making your choice:

- What is your budget?

- What level of play are you competing at?

- Do you prioritize maximum lightweight performance or cost-effectiveness?

- What is your playing style and position?

- How important are factors like vibration reduction and customization to you?

By carefully weighing these factors against the strengths and weaknesses of each material, you can make an informed decision that best suits your needs on the lacrosse field.

The Future of Lacrosse Shaft Technology

As materials science and engineering continue to advance, what innovations might we see in lacrosse shaft design? Some possibilities include:

- Hybrid materials combining the best properties of carbon fiber and alloy

- Integration of smart technologies for performance tracking

- Further improvements in weight reduction and durability

- Development of more sustainable and eco-friendly production methods

Staying informed about the latest advancements in lacrosse equipment technology can help players make the best choices for their game as the sport continues to evolve.

Maintenance and Care: Prolonging Shaft Life

Regardless of whether you choose a carbon fiber or alloy shaft, proper maintenance is crucial for maximizing performance and longevity. How can players best care for their lacrosse shafts?

- Regular cleaning to remove dirt and debris

- Proper storage to avoid unnecessary stress or damage

- Prompt attention to any signs of wear or damage

- Following manufacturer-specific care instructions

Carbon fiber shafts, while generally very durable, may require some special considerations. Avoid exposing them to extreme temperatures or harsh chemicals, and be cautious about overtightening screws or accessories, as this can potentially damage the carbon fiber structure.

Signs It’s Time to Replace Your Shaft

Even the highest quality lacrosse shafts will eventually need replacement. Watch for these indicators that it’s time for a new shaft:

- Visible cracks, splits, or fraying (especially in carbon fiber)

- Significant bending or warping that doesn’t resolve

- Loss of rigidity or noticeable change in flex characteristics

- Excessive vibration or “ringing” during play

Promptly replacing a damaged or worn shaft not only ensures optimal performance but also helps prevent potential injuries from equipment failure.

Expert Insights: What the Pros Use

While personal preference plays a significant role in equipment choice, examining the trends among professional players can provide valuable insights. What do top lacrosse athletes favor when it comes to shaft materials?

A survey of professional lacrosse leagues reveals:

- Growing adoption of carbon fiber shafts across all positions

- Continued use of high-end alloy shafts by some players

- Position-specific preferences (e.g., more carbon fiber use among attackmen)

- Experimentation with hybrid and novel materials

It’s important to note that professional players often have access to custom-designed equipment and may switch between different shaft types based on specific game conditions or personal performance factors.

Learning from Pro Player Experiences

While emulating professional equipment choices doesn’t guarantee improved performance, understanding the reasoning behind their selections can be informative. Consider these factors that influence pro player shaft choices:

- Playing style and positional demands

- Personal preferences for weight and flex characteristics

- Sponsorship agreements and team equipment policies

- Adaptation to different game formats (e.g., indoor vs. outdoor lacrosse)

Ultimately, the best shaft for any player is the one that feels most comfortable and allows them to perform at their highest level, regardless of material or professional endorsements.

The Role of Technology in Shaft Selection

As technology continues to advance, new tools are emerging to help players make more informed equipment choices. How are these innovations shaping the shaft selection process?

- 3D scanning for customized shaft fit

- Virtual reality simulations to test different shaft characteristics

- Advanced analytics to match player metrics with optimal shaft properties

- Online platforms for comparing and reviewing different shaft models

These technological advancements are making it easier than ever for players to find the perfect shaft for their unique playing style and physical attributes.

The Future of Personalized Lacrosse Equipment

Looking ahead, we may see even greater levels of personalization in lacrosse shaft design. Some potential developments include:

- AI-driven shaft recommendations based on player data

- On-demand 3D printing of custom shafts

- Integration of biometric sensors for real-time performance feedback

- Adaptive materials that adjust properties based on playing conditions

As these technologies evolve, players may have access to increasingly tailored equipment solutions that push the boundaries of performance and comfort.

Balancing Tradition and Innovation in Lacrosse

The debate between carbon fiber and alloy shafts reflects a broader conversation about tradition and innovation in lacrosse. How do players and coaches navigate this balance?

- Respecting the sport’s heritage while embracing new technologies

- Evaluating the impact of equipment changes on playing styles and strategies

- Considering the role of regulations in equipment evolution

- Fostering an open dialogue between players, manufacturers, and governing bodies

As lacrosse continues to grow and evolve, finding the right balance between honoring tradition and pushing the boundaries of performance will be crucial for the sport’s future.

The Impact of Equipment Innovation on Skill Development

As lacrosse equipment becomes more advanced, how does this affect player skill development? Consider these perspectives:

- Enhanced equipment may allow players to push their physical limits

- Overreliance on technology could potentially hinder fundamental skill mastery

- Adaptability to different equipment types may become a valuable skill

- Coaches may need to adjust training methods to account for equipment advancements

Ultimately, while equipment plays a significant role in performance, the core skills and athleticism required for lacrosse success remain paramount.

Making an Informed Decision: Carbon Fiber or Alloy?

As we’ve explored the various aspects of carbon fiber and alloy lacrosse shafts, it’s clear that both materials offer distinct advantages. The choice between them ultimately comes down to individual needs, preferences, and playing style. To make the best decision for your game, consider the following steps:

- Assess your budget and determine how much you’re willing to invest in a shaft

- Evaluate your playing level and future goals in the sport

- Consider your position and the specific demands it places on your equipment

- Reflect on your personal preferences for shaft weight, flex, and feel

- Try out different shaft types if possible, either through demos or borrowing from teammates

- Research the latest models and read reviews from other players

- Consult with coaches or experienced players for their insights

Remember that the “best” shaft is subjective and can vary greatly from player to player. What works perfectly for one athlete may not be ideal for another. By carefully considering all the factors we’ve discussed and being honest about your needs and preferences, you’ll be well-equipped to choose the lacrosse shaft that will help you perform at your best on the field.

Embracing the Journey of Equipment Selection

As you navigate the decision between carbon fiber and alloy shafts, keep in mind that finding your ideal equipment is often a process of experimentation and refinement. Your preferences may evolve as you gain experience and your playing style develops. Embrace this journey as part of your growth as a lacrosse player, and don’t be afraid to try new options as technology and your skills advance.

Ultimately, whether you choose carbon fiber, alloy, or even alternate between the two, remember that your equipment is a tool to enhance your natural abilities. Focus on honing your skills, understanding the game, and enjoying the unique challenges and rewards that lacrosse offers. With the right mindset and equipment that complements your style, you’ll be well-positioned to excel on the lacrosse field and contribute to the continuing evolution of this dynamic sport.

The Strength and Durability Benefits of Carbon Fiber Lacrosse Shafts

Carbon fiber has become an increasingly popular shaft material in lacrosse due to its high strength-to-weight ratio and durability. Carbon fiber shafts provide a lightweight feel while still maintaining rigidity and strength for superb ball control and checking. The carbon fiber composite material allows shaft manufacturers to orient the carbon strands optimally to produce a stiff, yet flexible design.

Carbon fiber shafts boast exceptional strength properties relative to their low weight. The tightly woven carbon fiber strands create a rigid lattice structure able to withstand huge amounts of stress. Tests show carbon fiber shafts having a higher tensile strength than 6061 alloy shafts. This resistance to bending and warping maintains the shaft’s shape and performance through seasons of play.

In addition to strength, carbon fiber offers unmatched durability and resilience. The carbon fiber weave has high inter-laminar shear strength, resisting cracks and fractures from repeated checks. Impacts that would permanently bend an alloy shaft often flex carbon fibers back into shape. The shafts have high fatigue strengths, enduring normal wear-and-tear through years of aggressive play. While alloy oxidizes, carbon fiber holds up against weathering.

Manufacturers optimize carbon fiber lacrosse shafts to balance stiffness and flexibility. The directional alignment of carbon strands tunes the flex profile, bending in some directions while remaining stiff torsionally. This flex allows for excellent ball feel and control. Engineers can alter the resin system, fiber type, and layering approach to fine-tune the performance. The result is an exceptionally stiff, durable, and lightweight shaft perfect for the fast-paced play of lacrosse.

In comparison to alloy, carbon fiber lacrosse shafts represent a premium upgrade in strength, durability, and lightweight feel. Their advanced composite construction makes them highly resistant to bending, fracturing, and weathering. While more costly than alloy, carbon fiber shafts deliver superior performance and longevity to satisfy the demands of elite lacrosse players.

The Lightweight Design Benefits of Carbon Fiber Lacrosse Shafts

One of the main benefits driving the popularity of carbon fiber lacrosse shafts is their exceptionally lightweight design compared to traditional alloy shafts. By utilizing advanced composite materials and construction techniques, carbon fiber shaft manufacturers can produce designs that are both rigid and incredibly light.

The lightweight properties of carbon fiber shafts stem from the intrinsic strength-to-weight ratio of carbon fiber itself. Made up of interwoven strands of carbon, the carbon fiber cloth is both dense and featherlight. The alignment and layering of the carbon cloth during manufacturing allows the construction of stiff, durable lacrosse shafts at a fraction of the weight of alloy.

Engineers cleverly orient the carbon fibers within a shaft to optimize the weight distribution and provide strength precisely where needed. The carbon cloth is wrapped over foam or alloy/titanium inserts at stress points to augment durability without adding weight. By strategically layering the carbon, manufacturers minimize overall material usage.

Advanced composite molding techniques yield carbon fiber lacrosse shafts with perfectly balanced strength, flex, and ultra-low weight. Computer modeling and simulation allows engineers to customize the layering approach and resin system to tune the flex profile and optimize performance characteristics. The end result is a supremely lightweight shaft meeting exacting strength and flexibility demands.

The lightweight properties of carbon fiber translate into faster shots, quicker feeds, and effortless stick handling. Fatigue is reduced, allowing players to go full-throttle for 4 quarters of play. Quicker cuts, tighter dodges, faster footwork and greater range of motion is achievable. Goalies benefit from lightning fast re-positioning. Overall agility and athletic performance is enhanced.

Players consistently report the lightweight feel of carbon fiber shafts as a major plus. The weight difference between carbon fiber and alloy is immediately apparent. For lacrosse players looking for any possible edge in speed and performance, the lightweight properties of carbon fiber shafts provide a compelling advantage.

The Vibration Reduction Benefits of Carbon Fiber Lacrosse Shafts

One of the most impactful benefits of carbon fiber lacrosse shafts is their ability to reduce vibrations compared to traditional alloy shafts. This results in improved handling, better ball control, and reduced fatigue.

All lacrosse shafts vibrate to some degree when the ball makes contact, whether during a shot, pass, or check. These vibrations travel down the shaft into the player’s hands and arms. Excessive vibrations can lead to reduced control, sting, and fatigue over the course of a game.

Carbon fiber is inherently excellent at damping vibrations. The polymer resin binding the carbon fibers together acts as a shock absorber. The interlaced carbon fiber cloth also dissipates vibrations through the shaft. Manufacturers additionally use vibration-dampening foams and inserts at key areas along the shaft length.

By engineering the precise carbon cloth orientation, layering, resin system, and use of dampening inserts, carbon fiber lacrosse shafts achieve a remarkable reduction in vibrations versus alloy shafts. This equates into noticeably smoother handling, allowing the player to cradle, pass, catch, and shoot with greater control and comfort.

Dampened vibrations also yield big benefits in terms of reduced player fatigue. Less sting and hand shock allows players to string passes and shots together through 4 full quarters of play. Goalies can react faster, scoop, clear, and make save after save without wearing down.

For elite lacrosse players, the vibration dampening properties of carbon fiber shafts offer a substantial competitive edge. Remaining in complete control of the ball while fighting off fatigue can make the difference in those crucial late game moments. The smooth, dampened feel of carbon fiber simply allows players to perform at their absolute best.

The Cost Difference Between Carbon Fiber and Alloy Lacrosse Shafts

While carbon fiber lacrosse shafts provide valuable strength, durability, lightweight and vibration dampening benefits, there is a significant cost difference compared to traditional alloy shafts. This price premium can make carbon fiber shafts prohibitive for some players.

Top-tier carbon fiber shafts range from $80-$300, while quality alloy models are available for $30-$80. The raw materials and advanced manufacturing techniques required for carbon fiber drive up costs substantially. Each shaft is meticulously constructed utilizing costly high-grade carbon cloth, resins, and inserts.

The aerospace and motorsports industries have driven innovations in carbon fiber materials and processes, bringing costs down over time. However, lacrosse shaft production volumes are minuscule in comparison, limiting potential economies of scale. The intricate custom design and engineering required for lacrosse shafts also adds expense.

Major lacrosse brands focus carbon fiber offerings squarely at elite players willing to pay a premium for the highest performing equipment. Most recreational and even college players opt for more affordable alloy models. However, declining carbon fiber costs and the trickle-down of innovations may eventually make carbon shafts accessible for wider adoption.

For now, players need to carefully weigh the benefits of carbon fiber against budget constraints. Those seeking the lightest, most durable and responsive feel will find the investment worthwhile. Cost-conscious buyers can enjoy many of the same performance benefits with today’s tech-packed alloy shafts. Ultimately personal preference, play style and financial reality will determine the right lacrosse shaft material for each athlete.

The Popularity of Alloy Lacrosse Shafts Among Beginner Players

While elite lacrosse players often prefer carbon fiber shafts, beginner and intermediate players tend to gravitate toward more affordable alloy models. Alloy shafts offer new players quality construction and performance at budget-friendly prices.

Alloy shafts dominated lacrosse for decades before carbon fiber’s emergence. Brands have honed alloy shaft technology over generations to balance weight, strength, flexibility, and durability. Modern alloys like 6061 and scandium allow for lightweight yet robust designs perfect for new players.

Top brands like Maverik, STX, and Warrior offer their alloy shaft models in a wide range of flex profiles, weights, grip styles, and price points. New players can select the shaft best matching their budget, size, position and preferences. Great entry-level alloy shafts start around just $30-$50.

While unable to match carbon fiber’s elite-level performance, alloy remains highly capable and forgiving. The extra weight helps newer players develop proper fundamentals and shooting mechanics. The strength and durability ensure long shaft life through inevitable novice equipment abuse.

For youth players quickly outgrowing shafts, affordable alloy models allow cost-effective annual sizing upgrades. Alloy’s proven track record and trusted reputation also provide reassurance to parents wary of expensive carbon offerings. Overall, alloy lacrosse shafts deliver an ideal blend of quality, value and accessibility.

As players improve and upgrade equipment over time, many retain alloy shafts for foul weather games or as reliable backups. Even at elite college and pro levels, a number of players still opt for alloy as a matter of budget or pure preference. For beginners, alloy lacrosse shafts represent an ideal entry point into the sport.

The Durability and Strength of Alloy Lacrosse Shafts

While alloy lacrosse shafts are typically heavier than carbon fiber models, they make up for it by providing excellent durability and strength at an affordable price point. Modern alloys allow for lightweight yet robust designs capable of handling the physical demands of lacrosse.

High-grade aluminum alloys like 6061 and scandium are optimized to resist bending and denting. Stringent T6 tempering hardens the alloys for heightened durability. Wall thicknesses are increased in high-stress areas prone to checks. Shafts are anodized to prevent corrosion and surface wear.

Advanced hydroforming, roll-wrapping, and upset forging production techniques allow alloy shafts to maintain low weight while gaining strength. Design innovations like flared ends, tactile gripping and integrated sidewall rails boost structural integrity.

Top lacrosse brands thoroughly test their alloy shafts to validate strength and durability claims. Shafts must survive severe impact tests, violent bending stresses, and climate/corrosion testing beyond real-world conditions. This ensures even entry-level alloy shafts will withstand novice play.

While carbon fiber outperforms alloy in pure strength-to-weight comparisons, alloy shafts offer impressive strength properties in absolute terms. They can shrug off errant slashes, collisions and routine defensive play that would dent weaker materials. Goals, shots and checks don’t gradually degrade these rugged shafts.

For youth, high school and casual players simply needing a dependable, affordable shaft solution, alloy delivers the necessary durability and strength. While carbon fiber dominates elite lacrosse, alloy remains a proven, trusted material for the majority of stick wielders.

The Heavier Weight of Alloy Lacrosse Shafts

The main performance downside of alloy lacrosse shafts compared to carbon fiber is their heavier overall weight. However, for many players the weight difference is relatively small and offset by alloy’s affordability.

Top-tier alloy shafts typically weigh 8-11 ounces, depending on length and flex profile. In contrast, advanced carbon fiber shafts can tip the scales at an feather-light 5-7 ounces. Over 60 minutes of running, dodging, shooting and stick handling, those extra 2-6 ounces make a noticeable difference in speed and fatigue.

However, outright shaft weight alone doesn’t tell the whole story. The balance, swing weight and feel of a shaft matters just as much, if not more, as raw weight. Some players actually prefer the enhanced leverage and momentum of a slightly heavier alloy shaft for increased power.

Major brands like Maverik and STX pour enormous engineering efforts into removing every possible ounce from their alloy shafts without compromising structural integrity. New 6061 and scandium alloys shave weight while remaining cost effective. Extensive cut-out patterns, strategic wall thinning, and interior lattice architectures reduce heft.

Weight-conscious players can further customize their setup by stringing with lightweight mesh, tying in a minimalist leather, foam or nylon head, and inserting a cork or rubber lacrosse ball. This tunes the overall stick weight and balance to preference.

In the end, alloy does carry marginally more mass than leading-edge carbon fiber shafts. But for many players, the performance gains of carbon fiber don’t yet outweigh alloy’s value. Manufacturers continue pushing alloy weights lower to close the gap with carbon offerings.

Lacrosse Shaft Flexibility and Handling

An often overlooked factor in lacrosse shaft selection is flex profile and overall handling. The right balance of stiffness, bend, and torque resistance enhances feel, control, and performance tailored to position and preference.

Attackmen generally favor more flexible shafts offering exceptional feel for feeding and stick tricks behind the cage. D-middies lean towards stiff shafts for quick breaks and shots on the run. Defensemen need a blend of flex for poke checks yet rigidity for knock-away checks.

Engineers carefully construct shafts to bend in specific directions while resisting torque twist. Strategic carbon fiber or alloy placement tunes longitudinal and transverse stiffnesses. Crease attackmen need extra sidewall strength to absorb slashes without losing their hold. Goalies prefer minimal flex for lightning fast outlet passes.

Players should test a shaft’s flex profile by performing practice checks, cradles, and shots. Check for undesired twisting on off-center impacts. Ensure satisfactory stiffness for long passes and rifle shots, paired with enough whip for touch feeds and stick tricks. The handle texture, grip shape, and balance also influence overall feel.

Both carbon fiber and alloy offer excellent flex tuning potential through thoughtful design and manufacturing optimization. Carbon fiber lets engineers tailor stiffness layer-by-layer, while alloy enables intricate hydroforming. Ultimately personal preference dictates ideal flex and handling traits.

Rather than obsessing over sheer weight differences, players should focus their evaluation on a shaft’s specialized flex profile and handling. The right shaft flex and feel unlocks each athlete’s full lacrosse potential.

Lacrosse Shaft Length and Weight Options

Lacrosse shafts are available in a range of lengths and weights to accommodate players of all sizes, ages, and positions. Choosing the optimal size helps maximize performance and prevent injury.

Youth lacrosse programs require shorter shafts for safety and playability. Typical youth lengths are 30” for players under 5’, 40” for ages 8-10, and 47-52” through age 14. High school junior varsity levels use 52-60” shafts, while varsity and college players go 60”. Pro lengths range from 60-72”.

Longer shafts provide better reach, checks, and shot velocity. However too much length leads to reduced handling and control, especially for younger players with less strength. Goalies and defenders tend to use the longest shafts for poke checking range, while attackmen favor shorter shafts for tight stick work.

Shaft weights also vary, normally ranging from 5oz for featherlight carbon fiber models to 11oz+ for extra-rugged alloys. Adolescent players should use mid-weight shafts to develop proper mechanics before sizing down. Heavier shafts teach stick control and add mass to shots during strength development.

During growth spurts, players should increase shaft length modestly while keeping weight moderate until mature height is reached. Seek professional fitting advice and observe handle positioning during full checks and shots to avoid growth plate injuries.

With the right length and weight combination for their age, size and skill level, players can build proper fundamentals while lowering injury risks. Shaft sizing upgrades encourage incremental performance gains over time.

Finding the Right Lacrosse Shaft Flex

Determining the optimal lacrosse shaft flex is crucial for maximizing handling, control, and performance. Players should consider position, experience level, and personal preference when selecting shaft stiffness.

For beginners, mid-flex shafts offer a versatile starting point. Moderate bend aids developing good fundamentals while preventing poor mechanics from overly stiff sticks. Mid-flex provides decent stiffness for shooting combined with some whip for passing.

As skills progress, offensive players generally prefer more bend and finesse-focused defensemen opt for stiffer shafts. Attackmen benefit most from flexible shafts for quick cuts, feeds around the crease, and showcasing their skills. Experienced defenders need rigidity for executing checks.

However, subjective feel trumps position conventions. Some prolific scorers excel with ultra-stiff shafts that load up power. Flexible shafts train disciplined mechanics. Testing various flex profiles is recommended as preferences evolve with play style.

Manufacturers rate shaft flex quantitatively based on force-deflection measurements. However, these ratings offer limited value since bend profile and balance also influence perceived stiffness. Player height, strength and personal nuances matter too.

Truly gauging shaft flex requires directly wielding and stress testing it. Check sidewall give, twist resistance on checks, and overall handling during position-specific motions. Dialing in flex takes trial-and-error, but unlocks individual potential.

Customizing Lacrosse Shafts with Tape or Rubber Grips

Players can customize their lacrosse shaft’s grip and handling characteristics through the creative application of tape or slip-on rubber grips. This allows tuning the feel to individual preferences.

Cloth, leather, and synthetic grip tapes let players build up shaft thickness in key areas for enhanced control. Tape provides cushioning to reduce vibrations and sting. Unique patterns give each shaft a signature look while creating tactile grip zones.

Attackmen wrap tape thickly around the lower handle for added comfort during continuous offensive possession. Defenders tape up mid-shaft zones for better leveraging during checks. Goalies tape the entire shaft length for maximum grip and vibration absorption.

Slip-on rubber grips offer an alternate way to dampen sting while adding girth. Contoured grip shapes lock the top hand in place comfortably while the lower hand maneuvers the stick. Combining rubber grips with strategic tape applications further customizes feel.

However, some players prefer the natural grip texture of alloy or carbon fiber lacrosse shafts. Adding too much tape weight negatively impacts handling. Testing bare, partially and fully taped configurations helps optimize each athlete’s unique grip preferences.

Through creative grip personalization with tape or slip-ons, players gain an extra degree of control over their shaft’s handling properties. The right grip brings out a shaft’s full performance potential.

Top Carbon Fiber Lacrosse Shaft Brands

Major lacrosse equipment manufacturers like Maverik, STX, and Warrior offer advanced carbon fiber shafts engineered to deliver elite-level performance. Their innovative designs set the benchmark in strength, weight, control and durability.

Maverik stands out through its carbon-based “MetaFlex” patented technology allowing customized shaft flex profiling. The Maverik Kinetik line utilizes strategic carbon layering for targeted stiffness zones. The Optik series balances ultra-light weight with dampened ball feel.

STX excels at proprietary carbon weaving methods and advanced resin systems. The Surgeon carbon line achieves superior strength via premium materials and construction techniques. The lightweight Stallion series is built for blistering shot speed through optimized flex.

Warrior leverages carbon nanotube technology on its high-end Dragonfly and Burn lines for unmatched strength and stiffness-to-weight ratios. The Feather-Light Mid Carbon model weighs under 5 ounces yet delivers category-leading durability.

Smaller niche companies like Epoch and StringKing also offer carbon shafts, but focus more on value-based alloy options. While models and technologies change yearly, the major brands consistently produce the most advanced, highest-performing carbon lacrosse shafts available.

For players seeking the lightest, strongest, most durable and responsive feel,carbon fiber lacrosse shafts from leading manufacturers deliver demonstrable performance advantages. Their extensive engineering resources and composite materials expertise enable category-pushing innovation year after year.

Best Value Alloy Lacrosse Shafts for New Players

While carbon fiber dominates the elite lacrosse scene, quality alloy shafts from leading brands offer an affordable, proven solution for new players. Their durability, capabilities and cost-effectiveness make alloy a smart choice.

Maverik’s signature HyperLite alloy combines light weight with battle-tested ruggedness. The Neutral flex profile suits all-around play. STX aluminum shafts like the Surgeon ALU offer pro-level performance on a budget. Warrior hit a home run with its tough yet nimble Burn AL line.

Smaller brands also shine in the alloy category. Epoch’s Dragonfly line masterfully balances cost, weight and quality via intelligent engineering. StringKing Complete Attack and Defense sticks bundle versatile alloy shafts with strung heads at bargain prices.

While premium alloy shafts cost 2-4x less than carbon fiber, even entry-level price points around $30 provide new players with responsive, durable performance. Mid-grade alloy shafts in the $50 range represent the true sweet spot blending quality, capability, and affordability.

Despite carbon fiber’s takeover at the elite levels, alloy remains viable and popular for the vast majority of lacrosse participants. Major brands continue innovating alloy formulations, construction methods and design to keep it competitive.

Players seeking reliable, rugged shafts with satisfying heft and excellent capability need not look further than today’s top-tier alloy offerings. Their proven track record and value emphatically stand the test of time and competition.