What are the key factors to consider when selecting a lacrosse backstop netting system. How do different materials compare in terms of durability and performance. Which dimensions provide the best coverage for full-size lacrosse fields. Why is UV protection crucial for outdoor netting systems. How can proper installation and maintenance extend the lifespan of your lacrosse backstop.

Comparing Nylon and Polyethylene Backstop Materials

When selecting a lacrosse backstop netting system, the choice of material plays a crucial role in determining its performance and longevity. The two primary options available are nylon and polyethylene, each with its own set of advantages and drawbacks.

Nylon Backstops: Traditional Durability with a Shorter Lifespan

Nylon has long been a popular choice for sports netting due to its robust nature and resistance to wear and tear. Its key benefits include:

- Excellent visibility for players and spectators

- Superior ventilation and airflow

- High impact resistance

However, nylon does have some limitations:

- Faster degradation from UV exposure

- Typically requires replacement every 3-5 years

- Higher initial cost compared to polyethylene

Polyethylene Backstops: Long-Lasting Performance with Enhanced Weather Resistance

Polyethylene has gained popularity in recent years as an alternative to nylon, offering several advantages:

- Exceptional UV and weather resistance

- Extended lifespan of over 10 years with proper care

- Lower upfront cost

Despite these benefits, polyethylene has a few drawbacks:

- Slightly reduced airflow compared to nylon

- Marginally lower visibility

How do you choose between nylon and polyethylene for your lacrosse backstop? Consider your specific needs, climate conditions, and budget. Nylon may be preferable in hot, humid environments where ventilation is crucial, while polyethylene excels in areas with intense sunlight exposure. Many lacrosse programs start with nylon and transition to polyethylene as their budget allows for a more long-term investment.

Optimal Dimensions for Full-Field Lacrosse Backstop Coverage

Selecting the right size for your lacrosse backstop netting system is essential to ensure comprehensive field coverage and player safety. While smaller 8×8 or 10×10 backstops may suffice for youth or practice fields, full-sized regulation lacrosse fields require larger dimensions.

Recommended Backstop Sizes for Regulation Fields

For complete coverage of a standard lacrosse field, experts recommend the following minimum dimensions:

- 10×30 feet: Provides basic protection across the full 30-yard width of a regulation field

- 12×30 feet: Offers additional height for enhanced safety

- 15×30 feet: Provides maximum protection and flexibility for various drills and practice scenarios

Why should you consider larger backstop dimensions? The benefits of opting for a 12×30 or 15×30 backstop include:

- Full protection across all sidelines and endlines

- Reduced risk of balls escaping the field during practice

- Enhanced safety buffer for errant shots and passes

- Flexibility for a wide range of shooting and passing drills

- Improved noise containment for neighboring properties

How do you determine the ideal size for your lacrosse backstop? Measure your field dimensions and add several feet of extra width and height to ensure comprehensive coverage. While a 10×30 backstop may be sufficient for many fields, investing in a 12×30 or 15×30 system provides peace of mind and versatility for all types of lacrosse activities.

The Importance of UV Protection in Lacrosse Backstop Netting

When selecting a lacrosse backstop netting system, UV protection is a critical factor that should not be overlooked. Constant exposure to the sun’s ultraviolet radiation can significantly impact the longevity and performance of your netting.

Understanding UV Degradation in Netting Materials

How does UV radiation affect lacrosse backstop netting? The sun’s UV rays can break down the polymer fibers in materials like nylon, polyethylene, and polypropylene over time. This degradation process leads to:

- Weakening of the netting fibers

- Increased brittleness and susceptibility to breakage

- Reduced overall lifespan of the backstop system

To combat these effects, it’s crucial to choose a lacrosse backstop netting system that incorporates UV-resistant additives or treatments. These protective measures help maintain the integrity of the netting material, ensuring it remains strong and effective for years to come.

Benefits of UV-Protected Lacrosse Backstop Netting

Investing in UV-protected netting offers several advantages:

- Extended lifespan of the backstop system

- Maintained strength and durability over time

- Reduced need for frequent replacements

- Improved cost-effectiveness in the long run

- Consistent performance in various weather conditions

When evaluating lacrosse backstop options, be sure to inquire about the UV protection features offered by different manufacturers. Look for systems that use UV-stabilized materials or have undergone specialized treatments to enhance their resistance to solar radiation.

Installation and Maintenance Tips for Lacrosse Backstop Netting Systems

Proper installation and regular maintenance are essential for maximizing the lifespan and effectiveness of your lacrosse backstop netting system. By following best practices, you can ensure optimal performance and longevity of your investment.

Key Considerations for Backstop Installation

How can you ensure a proper installation of your lacrosse backstop netting? Consider the following tips:

- Choose a level surface for installation to prevent uneven tension on the netting

- Use sturdy support poles or frames that can withstand wind and impact

- Ensure proper tension across the entire netting surface to prevent sagging

- Install the system at the recommended height to provide optimal coverage

- Consider professional installation for complex or large-scale systems

Maintenance Practices for Extended Backstop Lifespan

Regular maintenance is crucial for preserving the quality and functionality of your lacrosse backstop netting. Implement these maintenance practices:

- Inspect the netting regularly for signs of wear, tears, or UV damage

- Clean the netting periodically to remove dirt, debris, and potential mold growth

- Adjust tension as needed to maintain proper netting alignment

- Address any damage promptly to prevent further deterioration

- Consider seasonal storage in harsh climates to protect the netting during off-seasons

By following these installation and maintenance guidelines, you can significantly extend the lifespan of your lacrosse backstop netting system and ensure it continues to provide reliable protection for years to come.

Customization Options for Lacrosse Backstop Netting Systems

When selecting a lacrosse backstop netting system, customization options can help tailor the solution to your specific needs and preferences. Many manufacturers offer a range of choices to enhance functionality, aesthetics, and branding opportunities.

Functional Customization Features

What functional customization options are available for lacrosse backstop netting systems? Consider these possibilities:

- Adjustable height mechanisms for versatile use

- Retractable or collapsible designs for easy storage

- Reinforced edges or corners for high-impact areas

- Integration of ball return systems for efficient practice sessions

- Custom-sized netting panels for unique field configurations

Aesthetic and Branding Opportunities

How can you enhance the visual appeal and promote your team or organization through backstop customization? Consider these options:

- Custom color selection to match team or school colors

- Printed logos or graphics on netting or support structures

- Incorporation of sponsorship branding for revenue generation

- Decorative pole covers or wraps for a polished appearance

- Themed designs for special events or tournaments

When exploring customization options, consult with reputable lacrosse backstop manufacturers to determine which features align best with your goals and budget. Custom solutions can enhance both the functionality and aesthetics of your lacrosse facility, creating a more engaging environment for players and spectators alike.

Safety Considerations for Lacrosse Backstop Netting Systems

Ensuring the safety of players, spectators, and nearby properties is a paramount concern when selecting and installing a lacrosse backstop netting system. By prioritizing safety features and following best practices, you can create a secure environment for lacrosse activities.

Essential Safety Features in Backstop Design

What safety features should you look for in a lacrosse backstop netting system? Consider the following elements:

- High-strength netting materials capable of withstanding powerful shots

- Proper tensioning systems to prevent sagging or loose netting

- Padded support poles to protect players from collision injuries

- Secure anchoring methods to withstand wind and impact forces

- Visible netting color to enhance ball and player visibility

Implementation of Safety Protocols

How can you enhance safety through proper use and maintenance of your lacrosse backstop system? Implement these safety protocols:

- Conduct regular inspections to identify and address potential hazards

- Establish clear safety guidelines for players and coaches

- Maintain adequate clearance zones around the backstop area

- Provide proper lighting for evening or low-light conditions

- Train staff on emergency procedures related to backstop equipment

By prioritizing safety in both the selection and use of your lacrosse backstop netting system, you can create a secure environment that allows players to focus on developing their skills and enjoying the game.

Cost Considerations and ROI for Lacrosse Backstop Netting Systems

Investing in a high-quality lacrosse backstop netting system requires careful consideration of costs and potential return on investment (ROI). By evaluating various factors, you can make an informed decision that balances budget constraints with long-term value.

Factors Influencing Lacrosse Backstop Costs

What elements contribute to the overall cost of a lacrosse backstop netting system? Consider these key factors:

- Netting material (nylon vs. polyethylene)

- Dimensions and coverage area

- Support structure quality and design

- Installation complexity and labor costs

- Customization options and additional features

Evaluating Long-Term ROI

How can you assess the return on investment for your lacrosse backstop netting system? Consider these aspects:

- Durability and expected lifespan of the system

- Maintenance costs over time

- Potential for increased practice efficiency and player development

- Enhanced safety and reduced liability risks

- Improved facility aesthetics and potential for revenue generation

When evaluating costs and ROI, it’s essential to look beyond the initial purchase price. A higher-quality system may have a higher upfront cost but could provide better long-term value through extended lifespan, reduced maintenance needs, and enhanced functionality. Consider consulting with experienced lacrosse facility managers or equipment providers to gain insights into the long-term cost implications of different backstop netting options.

Compare Different Backstop Materials Like Nylon and Polyethylene

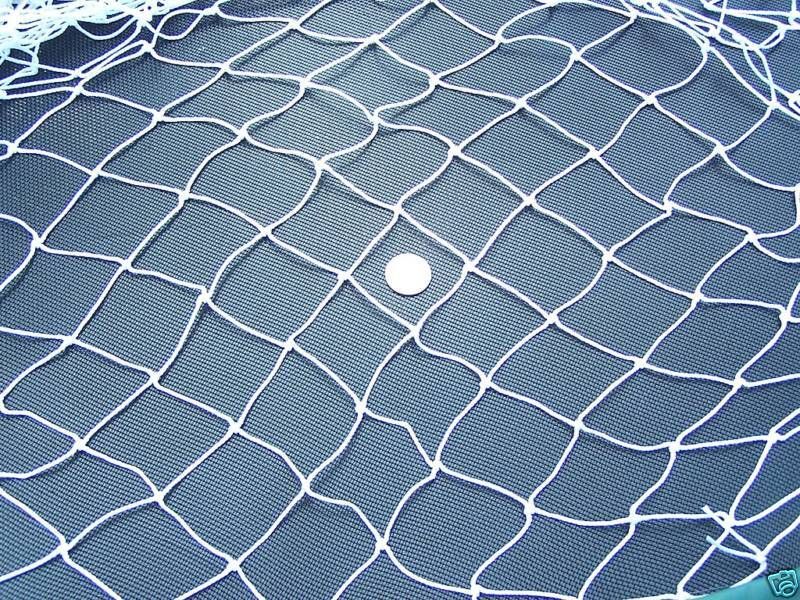

When choosing a lacrosse backstop netting system, one of the most important decisions is the material of the actual netting. The two most common materials used are nylon and polyethylene.

Nylon is a classic and commonly used material for sports netting. It is durable, weather resistant, and can stand up well to repeated ball impacts. Nylon lacrosse backstops provide good visibility and airflow. However, nylon does degrade over time with extended UV exposure from sunlight. Typical nylon net lifespans range from 3-5 years before needing replacement.

Polyethylene is another popular material gaining use in newer lacrosse backstop designs. Polyethylene is highly resistant to UV radiation from the sun. It also does not rot or mildew like nylon can over time. Polyethylene lacrosse nets can last over 10 years with proper care. Polyethylene provides good visibility and durability at a lower cost than nylon. However, it does not offer quite the same airflow as nylon.

When choosing between nylon and polyethylene lacrosse backstop netting, consider your budget, expected lifetime, and ventilation needs. Nylon costs more upfront but needs replacing sooner, while polyethylene has a longer lifespan for a lower initial cost. Those in hot, humid climates may prefer nylon for its airflow, while polyethylene works well in areas with lots of sunshine.

Pros and Cons of Nylon Backstops:

- Pro: Excellent visibility

- Pro: Good ventilation and air flow

- Pro: Withstands impact well

- Con: Degrades faster from UV exposure

- Con: Needs replacing every 3-5 years

- Con: More expensive initial cost

Pros and Cons of Polyethylene Backstops:

- Pro: Highly UV and weather resistant

- Pro: Long lifespan of over 10 years

- Pro: Lower initial purchase cost

- Con: Not quite as good airflow as nylon

- Con: Slightly reduced visibility

Many lacrosse coaches and schools start with nylon for its visibility and ventilation, then switch to more durable polyethylene as their budget allows for a longer-term investment. Consulting lacrosse backstop vendor experts can help determine the right material and system for your specific climate, use patterns, and budget.

Look at 10×30 and Larger Backstop Dimensions for Full-Field Coverage

When selecting a lacrosse backstop netting system, one of the key considerations is choosing the proper size to provide full coverage for your field. Typical youth or small field sizes can often be covered with smaller 8×8 or 10×10 backstops. However, for full-sized lacrosse fields, larger dimensions are required.

For full lacrosse field coverage, most coaches recommend looking for backstops that are at least 10×30 feet in size. A 10×30 lacrosse backstop provides protection across the full 30 yards width of a regulation lacrosse field. It also provides 10 feet of height, which is sufficient to stop most errant high lacrosse shots from sailing over the top of the net.

Larger 12×30 or 15×30 lacrosse backstops provide even more protection and peace of mind. Taller backstop heights up to 15 or 20 feet can also help for fields located in high wind areas where the top of the net can billow lower. For full-field protection with room to spare, a 12×30 or 15×30 backstop is recommended.

Benefits of Larger Backstop Dimensions:

- Full protection across all sidelines and endlines

- No need to worry about missed shots going out of bounds

- Added safety buffer for errant shots and passes

- Less chance for balls to fly over the nets

- More flexibility for shooting and passing drills

Many lacrosse coaches caution against trying to save money with undersized backstop nets. Several feet of uncovered space can lead to loose balls escaping the field and interrupting practices. Larger lacrosse backstops provide full coverage and flexibility for all types of drills and practice scenarios. They also help contain noise and activity to keep neighboring properties happy.

When budgeting for a new lacrosse backstop system, be sure to measure your field dimensions and add several feet of extra width and height. While 10×30 is acceptable for many fields, going up to 12×30 or 15×30 provides ideal, worry-free coverage for full lacrosse practice containment and safety.

Find Systems With UV Protection to Prevent Sun Damage

One important factor when choosing a lacrosse backstop netting system is looking for options that provide UV protection. The sun’s ultraviolet radiation can damage and degrade unprotected netting fabrics over time.

Lacrosse backstops are obviously constantly exposed to the elements while installed outdoors. The sun’s UV rays will break down most polymer fibers like nylon, polyethylene, and polypropylene without proper UV blocking additives. This UV degradation causes the fibers to become brittle and eventually start splitting or cracking.

UV damage shortens the usable lifespan of lacrosse backstop nets. Unprotected nets may start developing holes, tears, and reduced strength after just 1-2 years in the sun. UV damage also reduces visibility as the netting starts to discolor.

Signs of UV Damage:

- Brittleness and loss of tear strength

- Discoloration or fading

- Cracking or splitting fibers

- Holes and deterioration

- Reduced visibility through net

When shopping for lacrosse backstops, look for options made with UV-treated and protected netting. Quality manufacturers will use advanced UV inhibitors that are chemically bonded to the polymer fibers during production. This UV treatment makes the nets highly resistant to solar degradation for 5 years or longer before replacement is needed.

Some key things to look for include:

- At least 50% UV inhibition rating

- UV stabilizers added during manufacturing

- 5-10 year UV warranty protection

Investing in UV-protected lacrosse backstop netting results in longer net life, better visibility, safer performance, and reduced long-term costs. Make sure to avoid unprotected economy nets which will need frequent replacing. Spending a little more upfront on UV-treated nets will pay off in the long run.

Choose Between Fixed or Portable Backstop Frames

Lacrosse backstop netting systems come in two main frame support styles: fixed/permanent frames or portable frames. Each design has pros and cons to consider for your specific needs.

Fixed lacrosse backstop frames are designed for permanent field installation. The poles and upright supports are buried in the ground and anchored in concrete footings. Fixed frames provide rock-solid stability and resistance to wind forces. However, they are harder to relocate or remove during the offseason.

Portable lacrosse backstops feature bases that can be filled with sand or water for stability. Portable goals are easier to set up and take down each season. However, they may require more frequent checking and adjustment to keep them anchored properly in windy conditions.

Factors When Choosing Fixed vs. Portable Backstops:

- Permanent or seasonal installation

- Ease of removal/storage offseason

- Anchoring required for wind resistance

- Frequency of re-positioning or relocating the backstop

- Concrete footings required for fixed frames

For permanent lacrosse field installations, most coaches prefer the stability and lack of maintenance of fixed backstop systems. Concrete footings eliminate any chance of shifting and the need to re-secure anchors. Fixed backstops also provide unobstructed netting coverage without ground bases disrupting play.

Portable backstops provide flexibility for schools that convert fields between sports seasons. They also work well for youth and rec leagues that change field locations routinely. Portable frames allow seasonal set up and take down without excavation. However, portable systems do require diligent checking and maintenance to keep weighted bases secured, especially in windy climates.

Consider how permanent your lacrosse backstop needs to be, along with factors like weather and potential relocation needs. Also weigh the tradeoffs of convenience versus stability when choosing between fixed and portable backstop support frames for your field.

Compare Bungee Top Tensioning vs. Traditional Rope Tensioning

One key design choice for lacrosse backstops is how the top of the netting is secured and tensioned. Backstops use either traditional rope ties, or advanced bungee-cord tensioning systems.

Rope tensioning involves tying the top of the netting to a steel wire rope running through the top of the backstop frame. Regular re-tightening of the rope is required as the net stretches. Rope systems can loosen over time, allowing the net to billow lower.

Bungee tensioning uses expandable bungee cords threaded through the top of the net, allowing constant dynamic tensioning. The bungees automatically adjust to keep the top edge tight as the nets age. Bungee-cord systems eliminate sagging issues.

Benefits of Bungee vs. Rope Tensioning:

Bungee tensioning pros:

- Self-adjusting tension stays constant

- No loosening or sagging over time

- Longer lasting without needing re-tightening

- Consistent net coverage and ball rebound

Rope tensioning pros:

- Lower initial material costs

- Easy to replace rope sections if needed

- Can tighten precisely for installation

For most coaches, the advantages of automatic bungee tensioning make it well worth the small extra investment. Bungee systems maintain top to bottom net integrity for longer without maintenance. Rope systems can suffer from inconsistent tension if not tightened regularly.

Bungee tensioning also allows the top edge to “give” slightly upon ball impact. This increases shot absorption and reduces stress on net seams. Rope edges provide a fixed tension that can actually cause extra wear.

For reliable set-it-and-forget-it tensioning, bungee lacrosse backstop systems are highly recommended. The small upcharge for bungees pays off quickly in reduced maintenance needs and consistent net performance season after season.

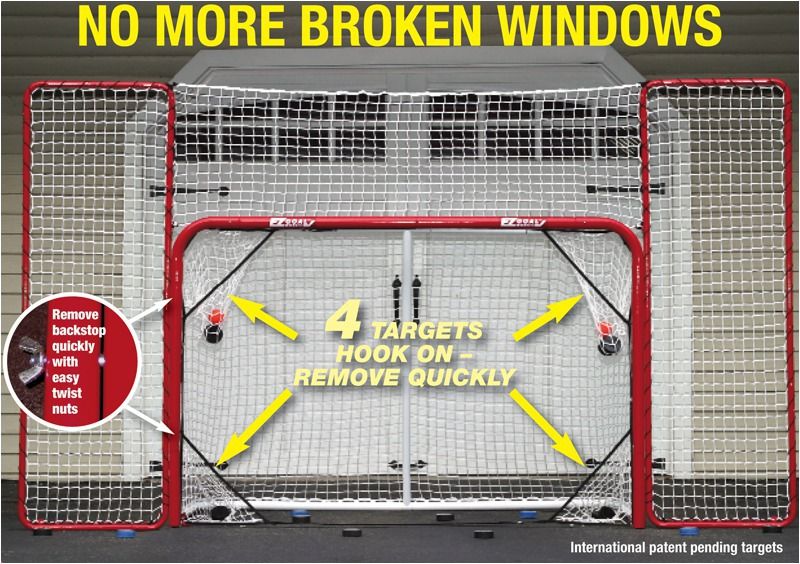

Get Extra Side Netting for Errant Balls and Added Safety

Most lacrosse backstop frames come ready to attach a single backstop net for behind-the-goal coverage. However, consider ordering additional side netting panels for even more ball containment and safety.

Side netting attached to the backstop frame provides extra insurance against shots that hook or curve beyond the sidelines. Additional side panels prevent balls from escaping the field, interrupting play and practice. For multi-use fields, side nets also keep lacrosse balls safely separated from adjacent sports activities.

Side netting is relatively inexpensive compared to the main backstop net. But it provides greatly increased peace of mind against errant shots. Coaches no longer have to worry about runners constantly chasing balls out-of-bounds. Valuable practice time is saved gathering loose balls.

Benefits of Extra Side Netting:

- Eliminates ball chasing outside lines

- Adds safety buffer on sidelines

- Helps balls stay within the playing surface

- Great for angled cross-field passing and shoots

- Keeps adjacent fields protected

An investment in additional side netting provides big benefits for minimal additional cost. Side panels are easy to install using the same backstop frame. Most backstop manufacturers can customize side netting to extend protection to 10-20 feet beyond the sidelines if desired.

Side netting also provides extra protection for any field equipment like benches, bleachers or storage. And it helps shield spectators and passersby from stray balls during practices.

While endline backstops are essential, lacrosse coaches recommend supplementing with side netting for complete ball control. Don’t be afraid to order this add-on – the cost is quickly offset by more efficient practices and reduced ball chasing duties.

Make Sure Nets Have High-Visibility White Striping

Most lacrosse backstop netting utilizes a basic black or green material. However, an important feature to look for is white striping applied to the netting in strategic positions.

White striping involves sewing or heat-bonding white colored strips along the top, bottom, and central cords of the net. This provides high-visibility demarcations on the net for players to see.

Visibility striping serves several helpful purposes for lacrosse backstops and practice:

- Outlines the top and bottom edges of the net.

- Makes it easier for players to avoid shooting over the top.

- Shows the center cord for aiming reference.

- Reflects sunlight to prevent glare in players’ eyes.

- Enhances depth perception for proper shooting.

Nets without striping can appear as dark voids to approaching shooters. Players may have difficulty judging corners or aiming spots without reference markers.

Striped backstops give better visual feedback for proper shooting technique. Centers and attackers can use the stripes to better align their angles and improve accuracy during repetitive practice.

White net striping does add some cost for materials and production. But the benefits for optimized practice and shooting drills make it well worth the minor upcharge.

Coaches recommend always choosing striped backstop netting systems rather than plain nets. The visibility aids will immediately assist players with shooting alignment and focus during daily practices. Shooting efficiency and mechanics show rapid improvement with striped backstop visual feedback.

Select Systems With Padding to Reduce Ball Impact

Standard lacrosse backstop netting provides a barrier to stop balls and contain shots. However, some systems go a step further by adding protective padding to actively absorb ball impact.

Backstop padding involves attaching padded material behind the netting, typically using velcro or grommets. Foam pads help cushion the blow as shots hit the backstop netting. This reduces bounce-back and shock that can damage nets.

Padding has several advantages for lacrosse backstops:

- Absorb impact to reduce wear and tear on netting

- Minimizes ball bounce-back for faster rebounds

- Provides protection for players standing near the net

- Lower noise from ball contact with the padding

Backstop padding materials vary from basic foam sheets to higher-end materials like PolyArmour minimizes ball bounce-back for faster rebounds

Provides protection for players standing near the net

Lower noise from ball contact with the padding

Backstop padding materials vary from basic foam sheets to higher-end materials like PolyArmour or Durapac. These advanced materials combine rebound damping with weather and UV resistance. Quality backstop pads can last 5 years or longer under continuous use.

Padding does add cost compared to nets alone. However, by extending the life of the netting and improving rebound speed, pads pay for themselves over time. Padding also gives peace of mind by adding a safety buffer at the netting surface.

For lacrosse teams serious about protecting their investment in netting systems, integrated backstop padding is highly recommended. Work with your backstop supplier to find the right padding materials that will withstand your specific climate and usage demands. Properly padded backstops stay safer and more effective season after season.

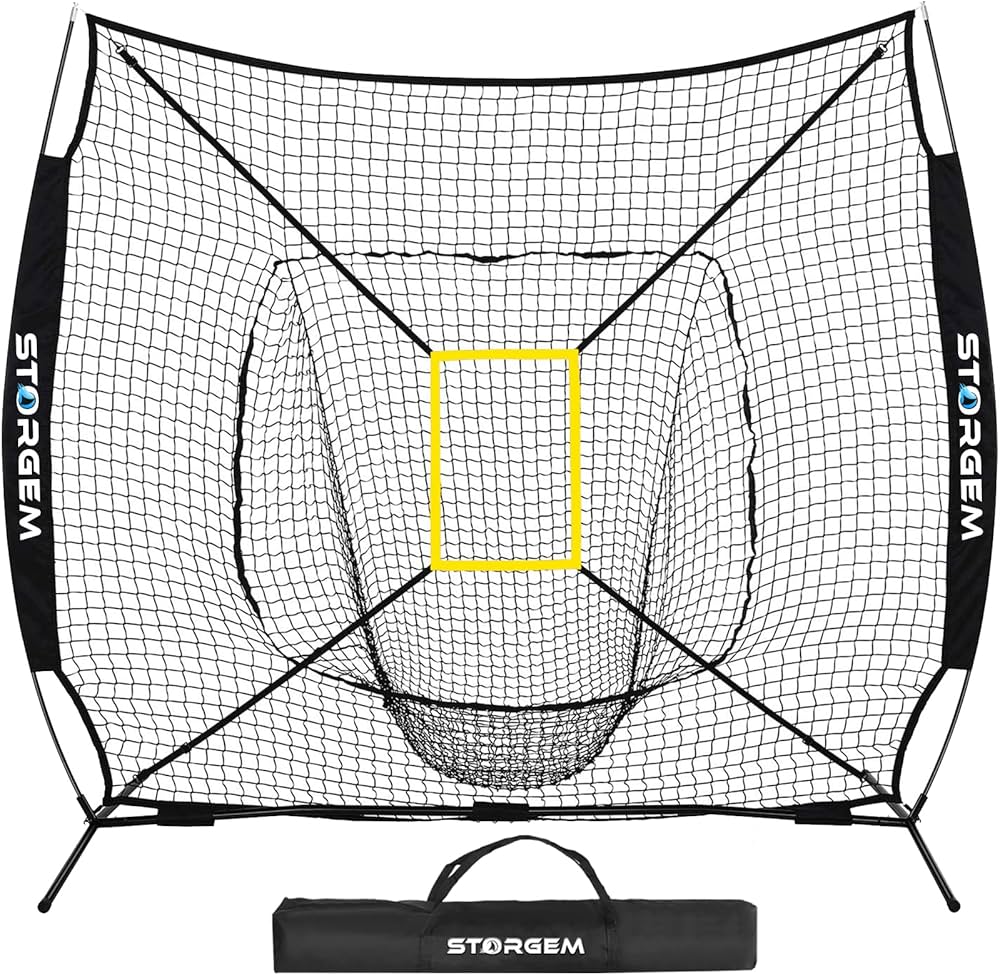

Look for Backstops With Ball Catch Pockets to Collect Missed Shots

An innovative feature offered on some modern lacrosse backstops is the addition of ball catch pockets at ground level. These pockets collect and store missed shots for easy retrieval.

Ball catch pockets are typically made from the same durable netting material as the backstop. They hang from the bottom of the backstop in a gathered pocket shape. Missed shots roll right into the catch pockets rather than bouncing away.

Catch pockets offer several unique benefits:

- Catches missed shots before they spread across the field

- Allows players to easily retrieve shots after drills

- Adds no maintenance – pockets empty into main net when lifted

- Saves time chasing missed balls during practice

The pockets are strategically placed to catch waist and below missed shots. When loaded, two players simply lift up the pockets to empty the balls back into the main backstop netting.

Catch pockets are a clever innovation that eliminate downtime from chasing missed shots. Players can focus on drills and shooting practice without constant ball retrieval. Coaches can run intensive shooting drills without wasting time stopping to collect balls.

The catch pockets do take some abuse from missed shots. But the heavy-duty netting stands up well. And pockets are easily replaced after years of use for minimal cost.

For coaches looking to maximize shooting practice efficiency, lacrosse backstops with catch pockets are a smart investment. Pockets become an instant time-saver that players appreciate after grueling repetitive shooting days.