Buying The Best Disposable Sterile Gowns for Your Medical FacilityBuying The Best Disposable Sterile Gowns for Your Medical Facility

Understanding AAMI Standards for Disposable Sterile Gowns

Sterile gowns are a critical component of personal protective equipment (PPE) utilized in healthcare settings. But not all gowns are created equal. The Association for the Advancement of Medical Instrumentation (AAMI) has established standards that classify sterile disposable gowns into four levels based on their ability to resist fluid penetration. So what exactly do these standards entail?

Let’s break it down. AAMI Level 1 gowns provide a basic level of protection for minimal risk situations. Think brief interactions with patients that don’t involve fluid exposure. Now Level 2 ratchets it up a notch for low to moderate levels of fluid exposure. These provide moderate barrier protection and are commonly used for basic care activities.

But when high fluid volumes or spray is anticipated, Levels 3 and 4 are essential. Level 3 gowns provide the highest level of fluid resistance and are a popular choice for surgical procedures. These disposable gowns are designed to provide full coverage of both the front and back of the wearer. Sturdy materials like spunbond-meltblown polymers or laminates help create an effective barrier against fluids.

So if you want optimal protection from bodily fluids, reach for a Level 3. Their superior fluid resistance helps prevent dangerous pathogens from reaching clothes or skin. This gives both healthcare workers and patients greater peace of mind. Now that’s a win-win!

With AAMI’s clear-cut ratings system, medical facilities can choose the right gown for the task at hand. Whether it’s a quick blood draw or an open heart surgery, understanding these standards ensures gowns meet the necessary performance requirements. And that translates to elevated safety for all.

Comparing Paper vs. Cloth Surgical Gowns

When selecting sterile surgical gowns, one key decision is whether to choose disposable paper gowns or reusable cloth gowns. Both have their own sets of pros and cons. Let’s compare these options side-by-side.

Disposable paper gowns offer exceptional fluid resistance and breathability. Materials like spunbond-meltblown polymers provide an effective barrier against fluids and microbes. Some even have specialized hydrophobic coatings. Paper absorbs less moisture than cloth, keeping surgeons cooler and drier. The disposable nature also removes reprocessing needs, saving time and costs. After a single use, paper gowns are discarded, eliminating contamination risks. Many facilities keep a steady stock of paper gowns for convenience.

On the other hand, cloth surgical gowns have advantages like comfort and durability. High quality cloth stands up to frequent laundering and reuse far better than paper. While fluid resistance may be slightly lower, cloth gowns can last for dozens of uses if properly cared for. The soft, woven materials tend to be more breathable and comfortable than stiff paper gowns. There are also environmental benefits, producing less medical waste. However, cloth gowns come with laundry expenses. Proper cleaning is essential between uses to prevent infection transmission.

For high risk procedures, disposable paper gowns are often preferred for their superior fluid barrier. But cloth may be a smarter choice for routine exams or non-invasive treatments. Costs, safety protocols, and sustainability initiatives all play a role here. There’s no universally “right” option. Healthcare facilities should weigh the unique aspects of disposable paper versus reusable cloth gowns to make the best decision for their particular needs.

With clear AAMI ratings and industry standards in place, providers can find quality gowns in either category. The choice ultimately depends on the specific use case and overall priorities. Whether paper or cloth, following proper guidelines helps ensure surgical gowns safely protect medical staff and patients alike during critical care moments.

Key Features of Level 3 Surgical Gowns

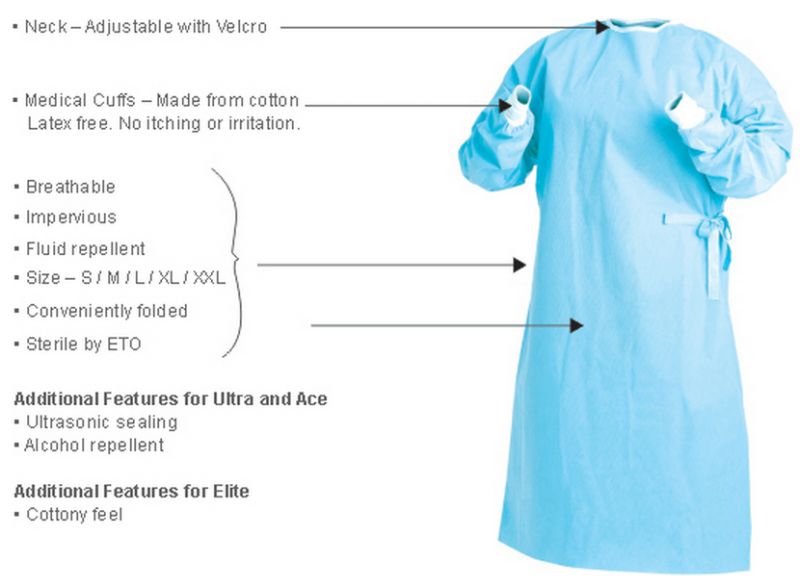

When evaluating options for sterile surgical gowns, those meeting AAMI Level 3 standards provide the highest level of fluid resistance and barrier protection. But what exactly sets these gowns apart? Let’s explore some of the key features that define quality Level 3 disposable gowns.

First and foremost, Level 3 gowns are designed for maximum fluid resistance. Materials like spunbond-meltblown polymers, SMS, or polypropylene laminates create an effective barrier against fluids, bacteria, and viruses. Gowns may have specialized coatings or treatments to further repel liquids. Level 3 gowns must pass strict AAMI testing, resisting penetration by synthetic blood at pressures up to 1.5 psi.

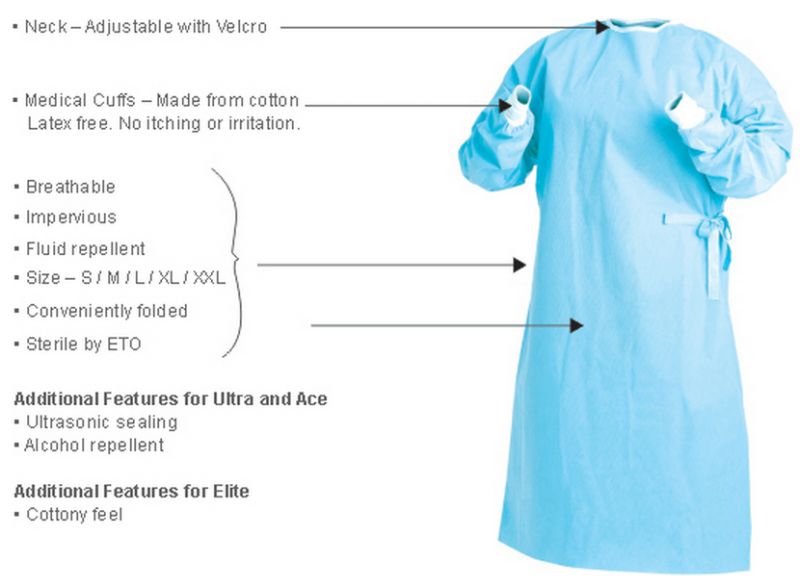

These gowns are also distinguished by their full coverage of both the front and back. Extra fabric and reinforced seams ensure 360 degrees of protection. Gowns wrap around the back and tie at the neck and waist. Some have thumb loops to anchor sleeves. Features like knit cuffs further limit potential exposure points.

Comfort and breathability are also important. Good air circulation reduces sweat buildup. Polypropylene or polyester materials allow adequate airflow while maintaining their impermeable barrier. Level 3 gowns strike the right balance of protection and cool comfort.

Easy donning and doffing is key for busy hospital settings. Choose gowns with well-placed ties, ample neck openings, and sleeves that slip on and off effortlessly. This ensures proper fit and full coverage when worn. Clear sizing options also help staff select the right gown for their body type.

Level 3 disposable surgical gowns check all the boxes for safety and performance. With reinforced construction, repellent fabrics, full coverage, and breathable comfort, they provide optimal protection for procedures with heavy fluid exposure. Following AAMI guidelines takes the guesswork out of choosing quality PPE for high-risk situations.

How Level 3 Gowns Provide the Highest Fluid Resistance

Moving up the scale, AAMI Level 2 gowns offer moderate barrier protection, suitable for low to moderate levels of fluid exposure. These gowns are commonly employed in basic care activities where some fluid contact is anticipated.

AAMI Level 3 gowns represent a significant step up in protection, designed to withstand high fluid volumes and spray. These gowns are a popular choice for surgical procedures, providing superior fluid resistance and full-body coverage. The materials used in Level 3 gowns, such as spunbond-meltblown polymers or laminates, create a formidable barrier against potentially hazardous fluids.

At the pinnacle of protection, AAMI Level 4 gowns offer the highest level of fluid resistance, designed for extreme-risk scenarios where prolonged and intense fluid exposure is expected. These gowns provide maximum protection against the penetration of blood and other bodily fluids.

The Importance of Choosing the Right Level

Selecting the appropriate AAMI level for a given medical task is crucial for ensuring the safety of both healthcare workers and patients. By understanding these standards, medical facilities can make informed decisions, matching the level of protection to the specific risks associated with different procedures.

Paper vs. Cloth: A Comprehensive Comparison of Surgical Gown Materials

When it comes to surgical gowns, the choice between disposable paper and reusable cloth options presents a complex decision for healthcare facilities. Each material offers distinct advantages and potential drawbacks, influencing factors such as protection, comfort, cost, and environmental impact.

The Case for Disposable Paper Gowns

Disposable paper gowns, often made from advanced materials like spunbond-meltblown polymers, offer exceptional fluid resistance and breathability. These gowns frequently feature specialized hydrophobic coatings, enhancing their ability to repel liquids and microbes. The single-use nature of paper gowns eliminates the need for reprocessing, potentially reducing long-term costs and eliminating risks associated with improper cleaning.

The Benefits of Reusable Cloth Gowns

Cloth surgical gowns, while potentially offering slightly lower fluid resistance, excel in comfort and durability. High-quality cloth gowns can withstand numerous wash cycles, making them a cost-effective option for facilities with efficient laundering processes. The soft, woven materials used in cloth gowns often provide superior breathability and comfort during extended wear.

Environmental Considerations

The environmental impact of surgical gowns is an increasingly important factor in decision-making. Cloth gowns generate less medical waste over time, aligning with sustainability initiatives. However, the energy and water consumption associated with laundering must be considered. Disposable gowns, while producing more waste, may have a lower overall carbon footprint when factoring in transportation and cleaning of reusable options.

Unveiling the Key Features of AAMI Level 3 Surgical Gowns

AAMI Level 3 surgical gowns represent the gold standard in fluid resistance and barrier protection for high-risk medical procedures. These gowns are engineered with specific features that set them apart from lower-level alternatives.

Superior Fluid Resistance

The hallmark of Level 3 gowns is their exceptional fluid resistance. Constructed from advanced materials such as spunbond-meltblown polymers, SMS (Spunbond-Meltblown-Spunbond), or polypropylene laminates, these gowns create an impenetrable barrier against fluids, bacteria, and viruses. To meet AAMI Level 3 standards, gowns must resist penetration by synthetic blood at pressures up to 1.5 psi during rigorous testing procedures.

Comprehensive Coverage

Level 3 gowns are designed to provide full-body protection, covering both the front and back of the wearer. Extra fabric and reinforced seams ensure 360-degree coverage, with gowns typically wrapping around the back and securing at the neck and waist. This comprehensive design minimizes the risk of exposure during complex medical procedures.

Enhanced Comfort and Breathability

Despite their robust protective properties, Level 3 gowns are engineered to maintain comfort during extended wear. Many feature breathable panels or ventilated designs to regulate temperature and reduce moisture buildup. This attention to wearer comfort helps maintain focus and reduces fatigue during lengthy surgical procedures.

Selecting the Ideal Sterile Gown for Your Medical Facility: A Strategic Approach

Choosing the right sterile gown for a medical facility requires careful consideration of various factors, including the specific needs of different departments, budget constraints, and overall safety protocols. A strategic approach to gown selection can optimize protection, comfort, and cost-effectiveness.

Assessing Risk Levels

The first step in selecting appropriate gowns is to assess the risk levels associated with different procedures performed at the facility. High-risk surgeries or procedures involving significant fluid exposure may require AAMI Level 3 or 4 gowns, while routine examinations might be adequately served by Level 1 or 2 gowns.

Considering User Comfort

The comfort of healthcare workers wearing the gowns should not be overlooked. Gowns that are too restrictive or cause excessive heat buildup can lead to fatigue and reduced performance. Look for gowns that balance protection with breathability and ease of movement.

Evaluating Cost-Effectiveness

While initial purchase price is important, consider the total cost of ownership when selecting gowns. For reusable cloth gowns, factor in laundering and maintenance costs. For disposable options, consider storage requirements and disposal fees. A mix of gown types may provide the most cost-effective solution for facilities with diverse needs.

Understanding the Cost Factors of Disposable Sterile Gowns

The cost of disposable sterile gowns can vary significantly based on several key factors. Understanding these elements can help medical facilities make informed purchasing decisions and optimize their PPE budgets.

Material Quality and Protection Level

Higher AAMI levels generally correspond to increased costs due to the advanced materials and manufacturing processes required to meet stringent protection standards. Level 3 and 4 gowns, with their superior fluid resistance, typically command premium prices compared to lower-level alternatives.

Volume and Bulk Purchasing

Many suppliers offer discounts for bulk purchases, allowing facilities to reduce per-unit costs by ordering larger quantities. However, this must be balanced against storage capacity and the risk of gowns exceeding their shelf life before use.

Brand and Certification

Gowns from well-known brands or those with additional certifications (such as FDA approval) may come at a higher price point. While these options often offer assured quality, facilities should evaluate whether the additional cost translates to meaningful improvements in protection or performance.

Mastering the Art of Donning and Doffing Sterile Gowns

Proper donning (putting on) and doffing (removing) of sterile gowns is crucial for maintaining the integrity of the sterile field and protecting healthcare workers from contamination. Following a standardized procedure ensures consistent and effective use of this critical PPE.

The Donning Process

- Perform hand hygiene before handling the gown package.

- Open the gown package, keeping the inner surface sterile.

- Grasp the gown by the neckline, allowing it to unfold while keeping hands at shoulder level.

- Slip arms into the sleeves, keeping hands inside the cuffs.

- Have an assistant secure the gown at the neck and waist.

- Don sterile gloves, pulling them over the gown cuffs.

The Doffing Process

- Remove gloves using a glove-in-glove technique to avoid contamination.

- Untie or break gown fasteners, being careful not to touch the outer surface.

- Pull the gown away from the neck and shoulders, touching only the inside of the gown.

- Turn the gown inside out as you remove it, rolling it into a bundle.

- Discard the gown in the appropriate waste container.

- Perform hand hygiene immediately after removal.

Innovations in Disposable Sterile Gown Technology: Shaping the Future of Medical PPE

The field of disposable sterile gowns is continually evolving, with new technologies and materials enhancing protection, comfort, and sustainability. These innovations are shaping the future of medical PPE, offering improved performance and addressing longstanding challenges in healthcare settings.

Advanced Antimicrobial Coatings

Some manufacturers are incorporating antimicrobial coatings into their gowns, providing an additional layer of protection against pathogens. These coatings can actively neutralize bacteria and viruses that come into contact with the gown surface, reducing the risk of cross-contamination.

Smart Fabrics and Sensors

Emerging technologies are introducing smart fabrics with integrated sensors into sterile gowns. These sensors can monitor environmental conditions, detect breaches in the gown’s integrity, or even track the wearer’s vital signs. This real-time data can enhance safety protocols and provide valuable insights for improving PPE design.

Eco-Friendly Materials

In response to growing environmental concerns, some manufacturers are developing biodegradable or recyclable gown materials. These innovations aim to reduce the environmental impact of disposable PPE without compromising on protection or performance.

Enhanced Breathability Technologies

New fabric technologies are improving the breathability of high-level protection gowns. Microporous membranes and advanced ventilation systems allow for better air circulation, reducing heat buildup and improving comfort during extended wear.

As medical facilities navigate the complex landscape of disposable sterile gowns, understanding AAMI standards, material options, and key features becomes paramount. By carefully considering factors such as protection level, comfort, cost, and environmental impact, healthcare providers can make informed decisions that optimize safety and efficiency. The ongoing innovations in gown technology promise to further enhance the effectiveness of this critical PPE, ensuring that medical professionals remain well-protected as they care for patients in increasingly challenging environments.

Understanding AAMI Standards for Disposable Sterile Gowns

Sterile gowns are a critical component of personal protective equipment (PPE) utilized in healthcare settings. But not all gowns are created equal. The Association for the Advancement of Medical Instrumentation (AAMI) has established standards that classify sterile disposable gowns into four levels based on their ability to resist fluid penetration. So what exactly do these standards entail?

Let’s break it down. AAMI Level 1 gowns provide a basic level of protection for minimal risk situations. Think brief interactions with patients that don’t involve fluid exposure. Now Level 2 ratchets it up a notch for low to moderate levels of fluid exposure. These provide moderate barrier protection and are commonly used for basic care activities.

But when high fluid volumes or spray is anticipated, Levels 3 and 4 are essential. Level 3 gowns provide the highest level of fluid resistance and are a popular choice for surgical procedures. These disposable gowns are designed to provide full coverage of both the front and back of the wearer. Sturdy materials like spunbond-meltblown polymers or laminates help create an effective barrier against fluids.

So if you want optimal protection from bodily fluids, reach for a Level 3. Their superior fluid resistance helps prevent dangerous pathogens from reaching clothes or skin. This gives both healthcare workers and patients greater peace of mind. Now that’s a win-win!

With AAMI’s clear-cut ratings system, medical facilities can choose the right gown for the task at hand. Whether it’s a quick blood draw or an open heart surgery, understanding these standards ensures gowns meet the necessary performance requirements. And that translates to elevated safety for all.

Comparing Paper vs. Cloth Surgical Gowns

When selecting sterile surgical gowns, one key decision is whether to choose disposable paper gowns or reusable cloth gowns. Both have their own sets of pros and cons. Let’s compare these options side-by-side.

Disposable paper gowns offer exceptional fluid resistance and breathability. Materials like spunbond-meltblown polymers provide an effective barrier against fluids and microbes. Some even have specialized hydrophobic coatings. Paper absorbs less moisture than cloth, keeping surgeons cooler and drier. The disposable nature also removes reprocessing needs, saving time and costs. After a single use, paper gowns are discarded, eliminating contamination risks. Many facilities keep a steady stock of paper gowns for convenience.

On the other hand, cloth surgical gowns have advantages like comfort and durability. High quality cloth stands up to frequent laundering and reuse far better than paper. While fluid resistance may be slightly lower, cloth gowns can last for dozens of uses if properly cared for. The soft, woven materials tend to be more breathable and comfortable than stiff paper gowns. There are also environmental benefits, producing less medical waste. However, cloth gowns come with laundry expenses. Proper cleaning is essential between uses to prevent infection transmission.

For high risk procedures, disposable paper gowns are often preferred for their superior fluid barrier. But cloth may be a smarter choice for routine exams or non-invasive treatments. Costs, safety protocols, and sustainability initiatives all play a role here. There’s no universally “right” option. Healthcare facilities should weigh the unique aspects of disposable paper versus reusable cloth gowns to make the best decision for their particular needs.

With clear AAMI ratings and industry standards in place, providers can find quality gowns in either category. The choice ultimately depends on the specific use case and overall priorities. Whether paper or cloth, following proper guidelines helps ensure surgical gowns safely protect medical staff and patients alike during critical care moments.

Key Features of Level 3 Surgical Gowns

When evaluating options for sterile surgical gowns, those meeting AAMI Level 3 standards provide the highest level of fluid resistance and barrier protection. But what exactly sets these gowns apart? Let’s explore some of the key features that define quality Level 3 disposable gowns.

First and foremost, Level 3 gowns are designed for maximum fluid resistance. Materials like spunbond-meltblown polymers, SMS, or polypropylene laminates create an effective barrier against fluids, bacteria, and viruses. Gowns may have specialized coatings or treatments to further repel liquids. Level 3 gowns must pass strict AAMI testing, resisting penetration by synthetic blood at pressures up to 1.5 psi.

These gowns are also distinguished by their full coverage of both the front and back. Extra fabric and reinforced seams ensure 360 degrees of protection. Gowns wrap around the back and tie at the neck and waist. Some have thumb loops to anchor sleeves. Features like knit cuffs further limit potential exposure points.

Comfort and breathability are also important. Good air circulation reduces sweat buildup. Polypropylene or polyester materials allow adequate airflow while maintaining their impermeable barrier. Level 3 gowns strike the right balance of protection and cool comfort.

Easy donning and doffing is key for busy hospital settings. Choose gowns with well-placed ties, ample neck openings, and sleeves that slip on and off effortlessly. This ensures proper fit and full coverage when worn. Clear sizing options also help staff select the right gown for their body type.

Level 3 disposable surgical gowns check all the boxes for safety and performance. With reinforced construction, repellent fabrics, full coverage, and breathable comfort, they provide optimal protection for procedures with heavy fluid exposure. Following AAMI guidelines takes the guesswork out of choosing quality PPE for high-risk situations.

How Level 3 Gowns Provide the Highest Fluid Resistance

When working in healthcare settings, protecting against infectious fluids is a top priority. For procedures where high fluid volumes or splashes are expected, AAMI Level 3 sterile gowns provide the ultimate defense. How exactly do these disposable surgical gowns achieve such high levels of fluid resistance?

It starts with the materials used. Level 3 gowns are constructed from durable fabrics engineered to repel liquids. These include nonwoven fabrics like spunbond-meltblown polymers (SMS) as well as laminates that sandwich an impervious film between nonwoven layers. Polypropylene is a popular choice given its natural hydrophobic qualities.

These non-porous fabrics form an effective barrier that stops fluids in their tracks. Coatings or chemical treatments can enhance repellency even further. Nanotechnologies like nanorust particles are being utilized to make gowns supernaturally hydrophobic. Liquids simply bead up and roll right off the surface.

Seam strength also plays a key role. Level 3 gowns have double-stitched or reinforced seams that prevent fluid leakage. Bindings and seam seals add another layer of impermeability. Strategically placed seam lines ensure optimal coverage.

In testing, Level 3 gowns must resist blood and viral penetration pressures up to 1.5 psi, representing high velocity splashes. Compare this to Level 2 gowns that only need to withstand 1 psi pressures. This higher threshold ensures Level 3 gowns can hold up to extreme fluid volumes in real-world conditions.

With their advanced moisture-repelling fabrics, reinforced construction, and rigorous testing standards, AAMI Level 3 sterile gowns deliver proven impermeability. Medical staff can have full confidence that these gowns will keep them safely separated from infectious bodily fluids during procedures. When exposure risks run high, Level 3 is the trusted choice.

Choosing the Right Material for Disposable Sterile Surgical Gowns

When selecting disposable sterile surgical gowns, one of the most important factors is the type of material used. The right fabrics make all the difference in achieving proper barrier protection. Here’s an overview of common materials for medical gowns and how to choose the best option.

Spunbond-meltblown polymers (SMS) offer an optimal balance of breathability and resistance. The spunbond outer layers provide strength and abrasion resistance. The meltblown middle layer acts as the impermeable barrier against fluids and microbes. SMS provides protection even against some chemotherapeutic drugs.

Polypropylene is another top choice due to its natural water-repelling properties. It resists fluid penetration while remaining breathable. Polypropylene laminates are also common, bonding the polypropylene to spunbond layers. Additives can enhance properties like elasticity and strength.

Polyethylene films offer high fluid resistance but can be hotter to wear. Newer breathable polyethylene allows more air circulation. Other coatings like silicone, acrylic, and fluoropolymer can add repellency and antistatic properties.

For cloth gowns, tightly woven, high-thread count cotton is often used. Synthetic blends help wick moisture. While less resistant than disposables, coated cloth can provide moderate barrier performance for lower-risk situations.

Consider the procedure, fluid volumes expected, risk factors, and wearer comfort when selecting materials. High-risk procedures demand maximum protection like SMS and polypropylene. More breathability may be suitable for routine exams. Partner with manufacturers experienced in medical textiles to ensure proper performance.

The right gown material protects staff while optimizing comfort and safety. Keeping up with the latest innovations and understanding AAMI standards takes the guesswork out of choosing appropriate barrier materials. Your staff and patients deserve the best possible protection.

Comparing Paper vs. Cloth Surgical Gowns

When selecting sterile surgical gowns, one key consideration is whether to choose disposable paper gowns or reusable cloth gowns. Both options have their advantages and disadvantages in terms of comfort, durability, and fluid resistance.

Disposable paper gowns offer exceptional barrier protection thanks to their nonwoven and laminated fabrics. These materials provide high resistance against fluids, microbes, and particulate penetration. Some even have hydrophobic coatings or treatments for enhanced repellency. Paper gowns maintain their protective abilities until end of life, then are discarded.

However, paper lacks the durability and longevity of cloth gowns. Repeated laundering would quickly degrade paper’s protective qualities. The materials also tend to be stiffer and warmer than cloth. On the other hand, cloth surgical gowns with a high thread count cotton or polyester blend provide better breathability and comfort. They conform to the body and feel less restrictive.

Cloth gowns also have environmental benefits, generating less medical waste. With proper laundering procedures between uses, cloth gowns can provide effective protection for dozens of wear cycles. But fluid resistance generally falls below disposable paper. Meticulous inspection is needed to check for defects or tears that could compromise barrier performance.

Cost differences also come into play. While reusable cloth requires laundering expenses, paper gowns must be continually repurchased. Facilities should assess usage rates and workers’ preferences when weighing the two. For high fluid procedures, disposable paper provides maximum safety. But for lower risk situations, cloth may be the more sustainable and cost-effective choice.

The gown material decision ultimately depends on the specific needs and priorities of each facility. Following AAMI guidelines on barrier performance helps ensure quality and safety either way. Both paper and cloth surgical gowns have a role to play in protecting healthcare staff and patients.

Understanding Sterilization Methods for Disposable Medical Gowns

To provide adequate barrier protection in healthcare settings, disposable medical gowns must be properly sterilized during manufacturing. This crucial sterilization process eliminates potentially harmful microbes that could lead to infection transmission.

Many disposable surgical gowns are sterilized using ethylene oxide, or EtO. This involves exposing gowns to the EtO gas so it permeates materials and kills microorganisms. EtO offers rapid, effective sterilization for gowns and medical devices. However, residuals must be properly aerated to safe levels before use.

Gamma irradiation is another common technique. Gowns are exposed to intense gamma radiation, disrupting microbial DNA and destroying contaminants. It penetrates packaging allowing gowns to be sterilized while sealed. Gamma provides hospital-level sterility assurance.

Steam sterilization may also be used. Pressurized steam penetrates gown materials to inactivate microbes. However, porous disposable materials can be damaged by high temperatures and moisture. Steam is more often used to sterilize reusable gowns.

Some facilities may prefer gowns sterilized with alternative methods like chlorine dioxide, ozone, hydrogen peroxide, or other proprietary processes. Seek verification of microbiological kill rates and material compatibility. Sterility must be maintained throughout manufacturing, packaging, shipping, and storage.

No matter the technique, proper validation protocols should demonstrate a minimum 6 log reduction in microbial contamination. Following sterilization standards like ISO 11137 ensures disposable gowns arrive ready for use in sterile fields. Don’t risk subpar barrier protection – confirm your gown supplier’s sterilization methods meet the highest standards.

Where to Buy Cost-Effective Sterile Surgical Gowns Online

Healthcare facilities are always looking for ways to reduce costs while still obtaining high-quality medical supplies. For disposable sterile surgical gowns, buying online can offer significant savings compared to traditional distributors.

E-commerce sites like Amazon Business provide easy access to a wide range of products and vendors. Comparison shopping helps identify competitively priced gowns that still meet clinical needs. Prime shipping results in low or no-cost delivery right to your doorstep.

Medical e-tailers like Medline, Bound Tree Medical, and McKesson Medical-Surgical offer bulk online ordering and discounted pricing tiers. Buying direct from manufacturers cuts out distributor markups. Look for options like custom branding and bundling.

Global marketplace platforms connect buyers to low-cost manufacturers and suppliers abroad. With a vetted vendor, substantial discounts are possible. Just be sure to validate quality control and product testing documentation.

Group purchasing organizations (GPOs) leverage bulk buying power across facilities. GPO contracts bring pre-negotiated pricing and ensured availability for high-demand items like gowns. This helps streamline the purchasing process.

No matter where you buy, confirm gowns are AAMI rated and FDA approved. Require current supporting compliance paperwork. With the right online sourcing strategy, medical facilities can stock up on essential PPE while optimizing the bottom line.

Comparing Gown Options on Amazon for Quality and Price

With so many disposable sterile gown options, sorting through choices on Amazon can be overwhelming. How can buyers evaluate which gowns offer the best combination of quality and affordability?

Focus first on proper certifications. Confirm gowns meet AAMI PB70 level requirements appropriate for their intended use. FDA classifications as Class I or Class II medical devices indicate regulatory body approval. Documentation like material safety data sheets are essential.

Compare ratings between sellers. High average scores likely signal positive user experiences with a product. Read reviews to learn about real-world performance and durability. Watch for consistent issues like poor construction or sizing.

Evaluate materials and specs like grams per square meter, hydrostatic pressure testing results, and impact penetration resistance. Higher numbers demonstrate superior barrier properties. Request samples to assess first-hand.

Compare pricing across listing quantities like packs of 10, 50 or 100 gowns. Larger bundles typically offer lowest per unit pricing. Calculate total costs incorporating shipping fees. Sort price low to high to spot the best deals.

With a bit of digging, Amazon Business offers access to compliant and affordable gowns ideal for medical settings. Just be sure to vet thoroughly, leveraging certifications, reviews, product details, and pricing data. Protecting staff doesn’t need to break the bank.

Bulk Purchasing Disposable Level 3 Gowns for Your Facility

Maintaining adequate supplies of personal protective equipment is crucial for healthcare facilities. For disposable sterile gowns used in surgeries and other high-risk procedures, bulk buying can help ensure inventory is always fully stocked.

Purchasing level 3 surgical gowns in larger quantities brings cost savings through volume discounts. Buying 50 or 100 gowns at once reduces the per unit price. Have an estimated monthly usage minimum to determine ideal bulk order size.

Streamline the reordering process with scheduled recurring deliveries. Set inventory thresholds that automatically trigger new bulk shipments when stocks run low. This prevents gaps or shortages between orders.

Negotiate discounted contracted pricing through group purchasing organizations (GPOs). The combined purchasing power of member facilities elicits better rates from vendors. GPO contracts also guarantee supply availability even when demand surges.

Consider long-term gown needs when budgeting. Larger upfront purchases mean better preparedness for emergencies. Just be sure to validate expiration dates and follow first-in-first-out (FIFO) inventory management.

Proper storage is also critical. Sterile gowns require temperature and humidity controlled environments. Invest in adequate shelving and storage bins to accommodate bulk quantities.

With the right bulk buying strategies, facilities can gain purchasing efficiencies while keeping their staff protected. Maintaining ample stocks of essential PPE results in peace of mind and readiness for any situation.

Proper Use and Disposal of Sterile Disposable Surgical Gowns

To get maximum protection from sterile disposable surgical gowns, proper usage and disposal protocols must be followed. What should healthcare personnel keep in mind when using these single-use gowns?

Donning and doffing techniques are key. Always inspect for defects first. Secure ties at neck, waist, and wrists for complete coverage. Allow sufficient overlap with other PPE like gloves and masks. Remove gradually to avoid contamination. Prevent sleeves from dangling into sterile fields.

Be mindful of motion. Reaching, twisting and bending can compromise the protective barrier. Avoid contact between gowns and non-sterile surfaces. Ensure sterile gowns remain within the sterile field perimeter.

Monitor closely for any fluid exposure or penetration during procedures. Immediately replace compromised gowns to restore protection. Change gowns between patients or cases to prevent cross-contamination.

After use, disposable gowns must be properly disposed as medical waste. Remove carefully avoiding inside-out contact. Dispose directly into designated waste bins; never reuse disposable gowns. Follow all regulated biohazardous waste handling protocols.

Reinforce usage guidelines through training and reminders. Gowns are only effective when worn and handled appropriately. With vigilance and care, disposable sterile gowns provide critical, temporary barrier protection for procedures where fluid exposure is likely.

Maintaining Sterile Fields with High-Quality Disposable Gowns

In surgeries and other sterile procedures, disposable sterile gowns serve a critical role in maintaining the sterile field. How exactly do these gowns help preserve this all-important barrier against contamination?

Sterile gowns create a protective layer separating the sterile surgical site from potential sources of contamination. Tightly woven fabrics provide an impermeable shield against fluids, microbes, and particulates that could enter the field.

The full-body coverage of gowns prevents contact between the wearer’s skin or clothing and the sterile area. Features like knit cuffs and adjustable ties seal potential gaps at wrists, neckline and waist. This minimizes any skin exposure.

Proper donning techniques ensure the sterile gown itself does not inadvertently contaminate the field. Once donned, wearers must remain vigilant about preventing contact between the gown and non-sterile surfaces.

Should the sterile barrier become compromised, the disposable gown must be immediately replaced. This restores protection and avoids further contamination of the field. Meticulous gown changing between cases or patients prevents cross-contamination.

High quality materials and construction allow disposable surgical gowns to maintain their protective integrity throughout procedures. Together with rigorous sterile protocols, impermeable disposable gowns provide an essential last line of defense for the critical sterile field.

How Surgical Gowns Protect Patients from Infection and Contamination

In any healthcare setting, preventing infection is a top priority. Surgical gowns act as a key barrier to protect vulnerable patients from dangerous pathogens and contaminants. How do these gowns work to reduce infection risks?

The impermeable fabrics used in surgical gowns create a shield between clinicians’ bodies and the sterile surgical field. This barrier helps prevent microscopic pathogens on skin or clothing from being shed into the open surgical site.

Surgical gowns also protect against splashes or sprays of bodily fluids during procedures. Their repellent and moisture-wicking properties contain potential contaminants at the source. This prevents spreading to clinicians’ garments or the environment.

By containing and isolating pathogens, quality surgical gowns reduce the chances of post-operative infections related to surgical site contamination. Bacteria like staphylococcus aureus are common culprits.

Proper handling, changing, and disposal of used gowns further protects patients. This prevents carrying pathogens between cases. Following aseptic protocols maintains the sterile field integrity from start to finish.

From impermeable fabrics to sound sterility practices, surgical gowns provide a critical safeguard for already vulnerable patients. Quality PPE works hand in hand with proper technique to reduce the risk of devastating healthcare-associated infections.

Disposable Gown Options for Different Surgical Specialties

Not all disposable surgical gowns are suited for every type of procedure. Certain specialties demand gowns with unique design features and levels of protection. How do you match the gown to the surgical environment?

For orthopedics, reinforced gowns withstand bone debris and trauma. Full back protection is key with frequent behind-the-patient positioning. Extended sleeve cuffs ensure coverage during prolonged procedures.

OBGYN procedures require discreet pelvic access along with complete barrier protection. Modesty flaps, ties at the waist, and elastic wrists cater to Caesarean deliveries.

Cardiovascular surgery demands exceptionally fluid-resistant fabrics given blood volumes. An anti-static property prevents ignition risks from cautery devices. Wide sleeves allow unencumbered movement.

General surgeries call for standard AAMI level 3 protection with ties at neck and waist. Universal sizing and comfort features aid extended wear. Optional accessories enhance protection.

The needs of outpatient versus inpatient settings also vary. Shorter, basic procedures may allow Level 1 gowns, while serious operations require Level 4 for maximal coverage.

With the range of disposable options on the market, facilities can find gowns tailored to procedural requirements and safety priorities. An optimized barrierdefends against contaminants during every type of operation.

Key Factors to Consider When Buying Sterile Surgical Gowns

Choosing the right sterile surgical gowns for your facility involves several important considerations. Here are some key factors to weigh when evaluating disposable gown options:

Look for quality materials that provide a proven barrier against fluids and microbes. Spunbond-meltblown-spunbond (SMS) fabrics or polypropylene laminates offer the right balance of protection and breathability.

Ensure gowns meet AAMI PB70 classification standards appropriate for expected surgical risks. Level 3 or 4 gowns provide the highest fluid resistance for invasive procedures.

Compare sizing and fit. Gowns should provide full coverage without restricting movement. Well-placed ties secure gaps while allowing quick donning and doffing.

Evaluate added features like reinforced seams, knit cuffs, thumb loops and modesty flaps that boost protection for specialized procedures. But avoid unnecessary extras that drive up costs.

Review documentation like independent test reports that validate claims of liquid barrier performance and microbial resistance.

Assess materials and manufacturing for sustainability benefits if desired. Look into recyclability, reduced packaging, and responsible production.

With the right protective apparel, surgical teams can perform safely and comfortably. Keep these key buying factors in mind to pick disposable sterile gowns that meet your facility’s needs.