Why are composite baseball bats better than aluminum. How do composite bats improve performance. What advantages do composite bats offer over traditional aluminum. Why have composite bats become so popular in baseball.

The Evolution of Baseball Bat Technology: From Aluminum to Composite

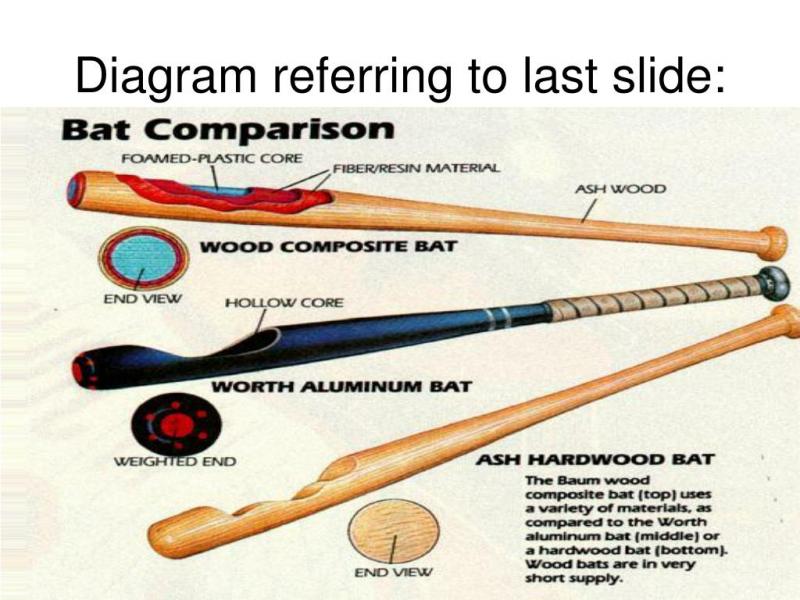

Baseball bat technology has come a long way since the days of wooden bats. The introduction of aluminum bats in the 1970s revolutionized the game, offering players increased power and durability. However, in recent years, composite bats have emerged as the dominant force in baseball, outperforming their aluminum counterparts in numerous ways.

Composite bats are constructed using a mix of carbon fiber, graphite, and sometimes fiberglass materials. This blend allows for greater customization and fine-tuning of bat properties, resulting in superior performance on the field. As we delve deeper into the reasons behind the rise of composite bats, it becomes clear why they have become the preferred choice for players at various levels of the game.

Enhanced Sweet Spot: The Key to Better Hitting

One of the most significant advantages of composite bats over aluminum is their larger sweet spot. The sweet spot is the optimal area on the bat for making contact with the ball, resulting in maximum power and distance.

How does a larger sweet spot benefit hitters?

- Increased chances of solid contact

- More forgiving on mishits

- Reduced vibration and sting on off-center hits

- Improved overall hitting performance

Composite materials allow manufacturers to distribute the bat’s mass more effectively, creating a larger hitting surface without compromising swing speed or control. This expanded sweet spot gives players a significant advantage at the plate, increasing their likelihood of making solid contact and driving the ball with authority.

The Trampoline Effect: Maximizing Exit Velocity

Another crucial factor contributing to the superiority of composite bats is the enhanced trampoline effect they provide. This phenomenon refers to the bat’s ability to compress upon impact with the ball and then quickly return to its original shape, effectively launching the ball with greater speed.

Why do composite bats have a better trampoline effect?

- More flexible barrel materials

- Greater energy transfer from bat to ball

- Increased ball exit velocity

- Potential for longer hits and more home runs

The composite materials used in these bats allow for more flex and compression at the point of contact, storing and releasing energy more efficiently than aluminum bats. This results in faster exit velocities and potentially longer hits, giving players a significant edge in power hitting.

Durability and Longevity: A Wise Investment

While composite bats may have a higher initial cost, their superior durability and longevity make them a wise investment for serious players. Unlike aluminum bats, which can develop dents and cracks over time, composite bats are designed to withstand the rigors of regular use.

How do composite bats maintain their performance over time?

- Resistance to denting and cracking

- Ability to maintain shape and structural integrity

- Consistent performance throughout the bat’s lifespan

- Potential cost savings in the long run

The flexible nature of composite materials allows these bats to absorb impact without sustaining permanent damage. This means players can enjoy consistent performance from their bat for a more extended period, potentially saving money on replacements in the long term.

Weight Distribution and Balance: Enhancing Swing Mechanics

Composite bats offer superior weight distribution and balance compared to their aluminum counterparts. This improved balance allows players to generate more bat speed and maintain better control throughout their swing.

What are the benefits of better weight distribution in composite bats?

- Reduced fatigue during long games or practice sessions

- Improved bat control and swing mechanics

- Ability to generate higher swing speeds

- Enhanced overall hitting performance

The precise engineering of composite bats allows manufacturers to fine-tune the weight distribution, creating a more balanced feel that can be customized to suit different hitting styles. This improved balance translates to better bat control, potentially leading to more consistent contact and improved overall performance at the plate.

Customization and Variety: Finding the Perfect Fit

One of the most significant advantages of composite bat technology is the ability to create a wide range of designs and specifications. This variety allows players to find a bat that perfectly suits their individual needs and preferences.

How does the customization of composite bats benefit players?

- Tailored weight distribution for different hitting styles

- Varied barrel sizes and shapes

- Customized flex points for optimal performance

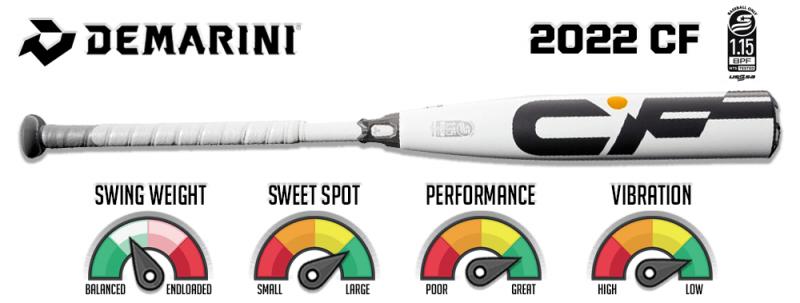

- Ability to choose between balanced and end-loaded designs

Whether a player prefers a balanced bat for better control or an end-loaded model for maximum power, composite technology allows for a level of customization that simply isn’t possible with traditional aluminum bats. This means players can find a bat that feels like an extension of their own body, potentially leading to improved performance and confidence at the plate.

Temperature Performance: Consistency in All Conditions

Baseball is often played in a variety of weather conditions, and the performance of equipment can be affected by temperature changes. Composite bats have a significant advantage over aluminum in this regard, maintaining consistent performance across a wide range of temperatures.

Why do composite bats perform better in different temperatures?

- Minimal loss of performance in cold weather

- Consistent flex and trampoline effect regardless of temperature

- Reduced risk of the bat feeling “dead” in extreme conditions

- Improved player confidence in varying weather situations

While aluminum bats can feel “dead” or lose pop in cold weather, composite bats maintain their responsiveness and performance. This consistency allows players to focus on their technique and approach at the plate, rather than worrying about how the weather might affect their equipment.

Advanced Design Features: Pushing the Boundaries of Performance

Composite bat technology has allowed manufacturers to implement a range of advanced design features that further enhance performance. These innovations go beyond what is possible with traditional aluminum bats, giving players access to cutting-edge technology that can potentially improve their game.

What advanced features are possible with composite bats?

- Variable wall thickness for optimized performance

- Multiple-piece designs for improved feel and reduced vibration

- Specialized grip technologies for enhanced control

- Aerodynamic barrel designs for increased swing speed

These advanced design features allow composite bats to push the boundaries of performance, offering players advantages that simply weren’t possible with earlier bat technologies. From reduced hand sting on mishits to increased swing speed through aerodynamic designs, these innovations contribute to the overall superiority of composite bats in today’s game.

The Psychology of Performance: Confidence at the Plate

While the physical advantages of composite bats are clear, it’s also important to consider the psychological impact they can have on a player’s performance. The sleek, modern appearance and high-tech feel of composite bats can boost a player’s confidence at the plate, potentially leading to improved performance.

How does the appearance and feel of composite bats affect player psychology?

- Modern, high-tech aesthetics instill confidence

- Perception of using cutting-edge technology

- Reduced anxiety about equipment performance

- Increased focus on technique rather than gear limitations

The confidence that comes from wielding a state-of-the-art composite bat can translate into a more relaxed and focused approach at the plate. This psychological edge, combined with the physical advantages of composite technology, can contribute significantly to a player’s overall performance and enjoyment of the game.

As we’ve explored the numerous advantages of composite bats over their aluminum counterparts, it becomes clear why they have become the dominant choice in baseball. From enhanced performance and durability to customization options and psychological benefits, composite bats offer players a comprehensive package that simply outperforms traditional aluminum bats in nearly every aspect of the game.

The evolution of bat technology continues to push the boundaries of what’s possible in baseball, and composite materials are at the forefront of this innovation. As manufacturers continue to refine and improve their designs, we can expect to see even more advanced composite bats in the future, further enhancing the performance and enjoyment of players at all levels of the sport.

Whether you’re a professional athlete, a college player, or a weekend warrior, the advantages offered by composite bats make them a compelling choice for anyone looking to improve their performance at the plate. As the technology continues to evolve, it’s exciting to imagine what new innovations and improvements we might see in the world of baseball bats in the years to come.

Hey there baseball fans! If you’ve stepped up to the plate recently, you may have noticed those high-tech looking bats made of composite materials rather than the traditional aluminum. Composite bats have absolutely taken over the game in recent years. But why is that? Are composite baseball bats really better than the old aluminum standbys? You bet your bottom dollar they are! Here are 10 reasons why composite bats dominate in today’s game:

Composite Bats Have Larger Sweet Spots

The “sweet spot” on a baseball bat is the section that gives you the most power and distance when you make contact with the ball. With composite baseball bats, the sweet spot is significantly larger than on aluminum bats. That means you have a better chance of really nailing one when you swing a composite bat. The sweet spot is also spread out over a larger surface area, so mishits don’t sting as much. More sweet spot = more hits = more fun!

They Have Greater Trampoline Effect

The “trampoline effect” refers to the rebound or bounce that occurs when the ball makes contact with the bat. Composite bats flex and compress more at impact, before “trampolining” back to their original shape. This launches the ball off the bat at higher speeds. Aluminum bats are stiffer and don’t have as much give. More trampoline effect equals faster exit velocities and more bombs over the wall for composite bats!

They are More Durable and Hold Up Better Over Time

Aluminum bats have a tendency to develop “barrel cracks” and dent over time after repeated use, especially if you accidentally clank one against a pole or step on it. Composite materials are more flexible and durable, maintaining their shape and performance much longer. You don’t have to replace composite bats nearly as often, saving you cash in the long run.

Composite Bats are Lighter and More Balanced

Thanks to space-age composite materials and precision engineering, modern composite bats have gotten incredibly light while maintaining a balanced feel. Lighter weight means less fatigue during a long game or tournament, and better bat control and swing speed. Balanced weighting also allows hitters to really whip the bat through the zone. Composite bats just feel better in your hands.

There are More Sizes and Flexibility in Design

Composite materials allow bat makers to fine tune and tweak the weight, balance point, diameter, and other design elements with infinite flexibility. Aluminum bats are more one-size-fits all. This means you can find the perfect composite bat shaped and sized just for your swing. More customization means better performance.

They Perform Well in All Temperatures

Have you ever used an aluminum bat on a cold day and felt it go “dead”? The performance really drops off. Composite bats maintain their pop and response even in frigid temperatures. No matter what the weather, composite bats hit just like they should.

Composite Bats Have Greater Hitting Surface Area

The walls of composite bats can be made thinner while maintaining durability. This allows for larger barrel diameters and more surface area on the hitting zone. More surface area equates to more forgiveness and more of the sweet spot in play. Even when you don’t square one up, you have a better chance of making contact and hitting it solid.

They Offer Better Bat Control

Due to the light weight, balanced feel, and large sweet spots, composite bats give you more control over the bat throughout your swing. The bat doesn’t lag or fight you, allowing you to make adjustments and place the ball with precision. More control equals harder to defend hits.

There Are Multiple Models for Power or Contact

Composite bat technology has progressed to the point where manufacturers can make either balanced/”swing easy” bats for contact hitting, or end-loaded/”swing hard” models for max power. Aluminum bats can’t offer such specialized designs. Composite bats allow you to pick the best bat tailored for your swing path and approach at the plate.

They Look and Feel High-Tech and Cutting Edge

Let’s be honest, part of the appeal of composite bats is simply the cool factor. They look sleek, modern, and flat out awesome. The flashy graphics, metallic colors, and futuristic vibe give you confidence and swagger at the dish. Who doesn’t love the badass style of stepping into the box with a next generation composite bat in hand?

So there you have it – 10 compelling reasons why composite bats now dominate the landscape in baseball. Clearly, bat technology has come a long, long way from the old wooden bats of yesteryear. Composite materials represent a true performance-enhancing revolution. The larger sweet spots, greater trampoline effect, lighter weight, and precision engineering of modern composite bats simply outperform old school aluminum in every way. They hit harder, last longer, feel better in your hands, and look cooler doing it. The high-tech boom of composite bats shows no signs of slowing down. So if you want to gain an edge over your competition, upgrade your swing with one of today’s top composite baseball bats!

Listen up baseball enthusiasts! The great composite versus aluminum bat debate rages on. Composite bats have taken over the diamond in recent seasons. But why is that exactly? Are composite baseball bats truly superior to old school aluminum? You better believe they are! Here are 10 reasons why composite bats are dominating the game today:

Composite Materials Allow For Greater Bat Flexibility

The composite materials used in modern bats allow for much more “give” and flex. Composite bats act like springs, compressing at impact before “trampolining” back into shape. This whips the ball off the barrel. Aluminum bats are more rigid and don’t flex in the same manner. Greater flexibility equals greater trampoline effect for composites.

Their Walls Can Be Made Thinner While Maintaining Durability

Composite materials are strong and resilient enough that barrel walls can be made very thin. Thinner walls allow for lighter overall weight and larger barrel diameters. This increases the surface area of the sweet spot for more forgiveness. Aluminum requires thicker walls compromising weight and size.

They Offer More Consistent Performance Over Time

Aluminum bats are prone to denting, cracking, and going “dead” over time with repeated use. The strength of composite materials prevents this deterioration, maintaining pop and response much longer. Composite bats provide reliable consistency season after season.

There Are Endless Options For Customized Designs

The flexibility of composite materials allows manufacturers to fine tune weight distribution, balance points, barrel size, and handle thickness with precision. This creates limitless customization possibilities. Aluminum bats come in standard one-size-fits-all models.

You Can Optimize Barrel Size and Weight Distribution

Composite bats allow you to choose specialized designs like balanced swing weight for contact hitting or end-loaded models for maximum power. You can’t find this level of customization tailoring swing path with aluminum.

Their Light Weight Reduces Swing Fatigue

Thanks to engineered composite materials and thin barrel walls, these bats have gotten extremely lightweight while maintaining hitting power. Less weight in your hands reduces fatigue, allowing you to swing faster and stay fresher.

Composite Bats Are Not Affected By Temperature Changes

Ever swing an aluminum bat on a cold day and feel it go dead? Composite materials retain their pop and responsiveness no matter the conditions. Their performance never drops off due to weather.

They Have Larger Sweet Spot Zones

The flexibility of composites allows for thinner walls and larger barrel diameters, increasing the total surface area of the sweet spot. More sweet spot coverage means more solid contact and more forgiving mishits.

They Provide Better Bat Control and Quicker Swing Speed

The light weight and balance of composite bats gives you greater control and quicker swing speed through the hitting zone. You can make adjustments and place hits with precision. Aluminum bats can feel slower and clunkier.

Composite Bats Simply Look and Feel Cooler

Let’s not overlook sheer style. Composite bats have an undeniably modern, high-tech, cutting edge look about them. The graphics, colors, and overall aesthetic give you confidence and authority at the plate.

So there you have it – 10 reasons composite bats now rule the baseball world. Bat technology has evolved lightyears beyond old school aluminum. The advanced composite materials provide flexibility, resilience, larger sweet spots, customized designs, consistent performance and lightweight feel that aluminum just can’t match. When it comes to pop, feel, forgiveness and looks, composite bats simply outclass traditional metal. If you want every advantage at the plate, composite is the clear choice. The composite bat revolution is here to stay!

Hey baseball fans! The great bat debate rages on. Composite or aluminum? Which is better? Composite bats have taken over the game in recent seasons, but why? Are they truly superior to traditional metal bats? Absolutely! Here are 10 reasons composite bats are dominating the diamond:

Composite Bats Offer Improved Bat Speed

The lightweight feel and balanced swing weight of today’s composite bats allow hitters to whip them through the zone for quicker bat speed. Increased speed generates more power. Aluminum bats can feel heavier and sluggish in comparison, compromising swing velocity.

Low Profile Composite Handles Provide Better Control

Most composite bats feature slim, low-profile handles that fit more comfortably in your bottom hand for maximum control. This gives you precision to place hits and make adjustments. Bulky aluminum handles reduce control.

Their Walls Are Engineered To Optimize Energy Transfer

Composite walls compress and flex on impact to act like a trampoline, catapulting the ball off the barrel. Aluminum walls are more rigid and absorb energy rather than transfer it back to the ball.

You Can Choose Designs To Match Your Hitting Style

Composite bats come in balanced “swing easy” models for contact hitters, or end-loaded “swing hard” versions for power. This level of customization is not possible with one-size-fits-all aluminum.

Advanced Materials Prevent Cracking and Denting

Aluminum bats dent and crack over time, compromising pop and feel. Durable composites flex and maintain their shape, providing consistent performance season after season.

The Thin, Large Barrels Expand the Sweet Spot

Composite barrel walls can be made very thin to allow for larger diameter barrels and more surface area on the sweet spot. More sweet spot coverage means more forgiving solid contact.

They Maintain Peak Performance in All Conditions

Frigid temps can make aluminum bats go dead. Composite bats retain their pop and response no matter the weather thanks to high-tech materials.

Precision Manufacturing Provides Ideal Weight Distribution

Space-age composites allow for total control over weight placement during manufacturing, dialing in perfect balance and swing weight. Aluminum limits options.

The Lighter Weight Prevents Fatigue

Engineered composite materials have dropped average bat weights while maintaining durability and power. Less weight in your hands reduces fatigue so you can keep hacking.

They Simply Look and Feel Like the Future

Composite bats have an undeniably slick, cutting-edge, high-tech style about them. The aesthetics give you swagger and confidence at the dish.

There you have it – 10 reasons composite bats now dominate the diamond. Bat technology has come a long, long way from the old days of single-piece aluminum. Thanks to precision-engineered composite materials, today’s bats offer better bat speed, larger sweet spots, ideal weight distribution, consistent performance in all conditions, and a superior look and feel. The proof is in the pudding – composite outperforms aluminum in every way. So if you want to rule the plate,upgrade your game with one of the latest composite bats!

Attention baseball enthusiasts! The great bat debate wages on. Composite or aluminum – which is superior? Composite bats have taken over the game, but why? Are they really better than old school aluminum? You better believe it! Here are 10 reasons composite bats are dominating the sport:

Composite Bats Provide More Powerful Hits

The “trampoline effect” of the flexible composite barrel provides more pop and launch speed at impact. This generates harder, faster hits with extra distance. The rigid aluminum barrels don’t amplify power like composites do.

Precision Engineering Allows For Larger Barrel Size

Composite materials enable larger barrel diameters and thinner walls while maintaining durability. More surface area on the sweet spot increases power potential. Aluminum requires thicker walls limiting barrel size.

They Offer Consistent Performance Year After Year

Aluminum bats slowly degrade from cracks and dents over repetitive use and time. The resilience of composites prevents this, delivering reliable pop season after season with no drop off.

Balanced Weight Distribution Optimizes Swing Speed

Meticulous weight placement during manufacturing provides an ideal swing weight. This allows you to whip the bat through the zone at your optimal speed for maximum pop. Aluminum limits balance customization.

The Reduced Weight Prevents Fatigue

Thanks to engineered materials and thin walls, composite bats have gotten extremely lightweight while maintaining durability. Less weight reduces fatigue so you can keep ripping at full strength.

Their Performance Is Not Affected By Temperature

Aluminum bats can go “dead” on cold days and lose pop. Composite materials retain peak performance and response regardless of the weather conditions outside.

Low Profile Handles Provide Superior Control

Most composites have thin, tapered handles that fit perfectly in your bottom hand for maximum bat control. You can place hits with precision and make adjustments. Bulky aluminum handles reduce control.

You Can Choose Designs For Contact or Power

Composite bats come in balanced “swing easy” models ideal for contact hitting, or end-loaded “swing hard” versions built for power. This level of customization is impossible with aluminum.

They Have An Intimidating, High-Tech Look

Let’s be honest – composite bats just look legit. The futuristic style and flashy graphics give you swagger and confidence at the dish before you even swing.

There you have it – 10 reasons composite bats now rule the baseball world. Thanks to cutting-edge composite materials, today’s bats simply outperform aluminum in every way. They provide more trampoline effect for greater power, larger sweet spots, lighter swing weight, precision engineering, and consistently awesome performance season after season. The proof is overwhelming – composite bats are superior. So get yourself a high-tech composite bat and start mashing!

Composite Bats Reduce Vibration and Sting

When it comes to baseball bats, composite bats have become the top choice for many players due to their superior performance and feel compared to traditional aluminum bats. Composite bats reduce vibration and sting, allowing hitters to swing through the ball with confidence and power.

Aluminum bats can transmit significant vibration and sting to a player’s hands and arms when making contact, especially on mishits. This discomfort can cause young players to develop bad habits like shortening their swing or loosening their grip. Composite bats dampen these negative vibrations, promoting proper technique and allowing players to take full cuts without fear of pain or discomfort.

Lighter Weight Means Faster Swing Speeds

The advanced materials used in composite bats allow them to be made lighter than aluminum models of a similar size. This reduced weight at the end of the bat leads to increased swing speed for most hitters. Physics tells us that lighter objects can be swung faster with the same amount of effort. This means hits jump off composite bats with added velocity compared to aluminum.

Higher swing speeds translate directly into longer hits and more power. Composite bats essentially put a trampoline effect behind each swing, propelling balls faster and farther. The light weight also reduces fatigue over the course of a game, allowing hitters to maintain their peak performance from first pitch to last.

Larger Sweet Spots Enhance Forgiveness

Aluminum bats must be thicker in the middle to provide durability and pop, while composite bat walls can be made very thin thanks to the strength of the woven fibers. This allows composite manufacturers to reshape barrel design for maximum performance.

Thinner walls mean a larger sweet spot in terms of surface area. A ball that might find a dead spot on an aluminum bat will still jump off a composite model. Mis-hits stay in play instead of turning into weak dribblers or pop outs. The enlarged sweet spot provides plenty of forgiveness, making solid contact more consistent for all hitters.

Customized Barrel Shapes and Flex

Advanced composite materials allow bat designers far more freedom compared to aluminum. Barrels can be shaped, tapered, and thinned in ways not possible with metal. This customization allows manufacturers like DeMarini, Louisville Slugger, and Easton to optimize the flex and responsiveness of the barrel.

Carefully engineered flex profiles lead to increased energy transfer and pop. The ball decompresses the barrel, more energy is loaded, and then this energy explosively returns behind the hit. Bat makers utilize computer modeling and player feedback to create idealized barrel shapes and flex indexes. No two models perform exactly the same thanks to this customization.

Consistent Performance and Durability

Aluminum bats have a well-known break in period before they reach peak performance. Use gradually compacts the walls of the barrel, increasing pop, but this comes at the cost of decreased durability. Eventually enough of the wall gives way that the bat becomes unplayable and lose its pop.

Composite bats maintain their original shape and pop month after month thanks to the stiffness of the carbon fiber walls. The woven carbon fibers are highly consistent and retain their strength over thousands of impacts. There is no guesswork involved in knowing if a composite bat has lost its sweet spot or power.

Increased Safety Standards

Governing bodies have put limitations in place on the performance of composite bats to better match traditional aluminum models. This standardization of exit speed makes the game safer, especially for pitchers. League required safety tests, like the Accelerated Break-In (ABI), ensure composite bat performance does not exceed set boundaries.

Manufacturers design composite bats to maximize performance right up to the limit of these regulations. Performance is boosted without endangering pitcher safety. Expect sanctioning bodies to incrementally increase allowed performance levels as composite bat technology continues to advance.

Environmentally-Friendly Materials

The composite fibers typically used in today’s bats are carbon fiber, fiberglass or Kevlar. These advanced materials are lightweight and durable while also being environmentally-friendly. Composite materials are generally recyclable at the end of their life cycle.

Aluminum, while recyclable, requires large amounts of electricity during the mining and refining processes needed to prepare the raw ore. Reduced environmental impact is another reason many players choose composite over metal.

Superior Comfort and Feel

Players immediately notice the clean, comfortable feel when swinging composite bats. The lightweight build allows you to whip the bat through the zone with less effort. Vibration dampening provides a smooth, sting-free sensation on contact. The flex of the barrel increases the trampoline effect.

Composite bats just feel right in your hands. Swings are smooth and natural throughout the entirety of the swing path. You know immediately upon making contact that the ball will jump. Confidence grows when you know your bat won’t let you down.

Advanced Engineering and Materials

The aerospace industry pioneered the development of composite materials like carbon fiber. This space age material provides an unbeatable strength-to-weight ratio. Applying these advanced materials to baseball bats unlocked new possibilities in design and performance.

Engineers can tinker with the orientation of fibers, the number of composite layers, resin types and the overall shape. Manufacturers like DeMarini even create concept bats with 3D printers as part of the prototyping process. Exciting new material advancements will further composite bat development.

Popularity Among All Levels

Composite bats dominate among college players and pros. However, youth baseball organizations have been much slower to adopt composite bats. Aluminum remains popular at the Little League level as the traditional standard.

Still, more and more parents and coaches are making the switch to composite bats at the youth level. The benefits are too many to ignore. Expect composite bat usage to continue growing at all levels of play, from tee ball to the major leagues. The performance is just too good to pass up.

So in summary, what makes composite bats outperform traditional aluminum bats? Composite construction provides a light yet strong bat with massive sweet spots that reduce vibration and sting. Barrel design can be highly customized and tuned for ideal flex and pop. Performance stays consistent over time without needing a break-in period. When you add up all the advantages, it becomes clear why composite bats dominate the modern game.

Composite Bats Are More Durable Than Aluminum

One of the biggest advantages composite bats have over traditional aluminum bats is their superior durability and sustained performance over time. While aluminum bats dent and lose pop, composite bats maintain their shape and hitting power for far longer.

Aluminum bats have a notoriously short lifespan, especially among avid players. The repeated impacts from balls gradually take their toll, compressing the barrel walls inch by inch. Dents and deformationsreduce the trampoline effect and decrease bat performance. Eventually the bat becomes essentially dead and unusable.

Composites Retain Their Shape

The carbon fiber and other composite materials used in today’s bats are specifically engineered for stiffness and strength. The woven fiber layers retain their shape and rebound regardless of impacts. While the resins can show signs of wear over time, the overall barrel shape stays intact.

Manufacturers like DeMarini and Easton use computer modeling to create optimized composite structures. The materials, number of layers, orientation and layer bonding are all designed to produce a stiff yet responsive barrel. Repeated impact testing verifies durability.

No Break-In Period Required

Aluminum bats require a break-in phase of gradual wall compression before reaching peak performance. This process takes several weeks or longer. During break-in, balls don’t jump off the bat the same as with a fully broken-in model. Performance is unpredictable and subpar.

Composite bats deliver elite performance straight out of the wrapper since the barrel shape doesn’t need altering. The materials retain their strength and trampoline effect without this gradual break-in. Hitters enjoy consistent pop and distance day after day.

Consistent Barrel Strength and Shape

While aluminum barrels gradually compress and deform, composite barrels stay strong. The barrel walls retain their original thickness and shape over the life of the bat. A few very minor indentations may occur, but the overall barrel structure remains intact.

This consistent barrel strength means ball speed and distance remain steady over thousands of hits. When you find the bat’s sweet spot, it stays in the same place. There’s no guessing if the barrel shape has changed and impacted performance.

No Signs of Wear on the Barrel

Aluminum bats clearly show signs of wear as walls thin and indent. With composite bats, the barrel continues looking pristine since compression dents don’t occur. At most, very minor paint scuffing or discoloration might develop.

The barrel retains its original shape and appearance over time. Aside from some innocent scuffs, an old composite bat looks nearly indistinguishable from a brand new model. The composite materials strongly resist wear and tear.

Thin Walls Maintain Strength

Composite barrel walls can be made extremely thin without sacrificing durability. In contrast, aluminum requires thicker walls to provide sufficient integrity. Thinner walls increase the trampoline effect and overall bat performance.

Even as thin as 0.045 inches, advanced composite materials maintain their stiffness and shape. Engineers carefully model the optimal number of fiber layers to create durable yet highly responsive barrels. Thinner walls increase performance without reducing barrel life.

Minimal Evidence of Ball Marks

Aluminum bats clearly show ball imprints on the barrel as hits take their toll. Hundreds of dimples gradually form as evidence of repeated impacts. With composite bats, these markings are rare since the materials resist compression.

Only very faint and shallow ball marks appear after extensive use. The stiff carbon fibers easily rebound to retain their original shape rather than imprinting hits. Composite barrels look and perform like new season after season.

Hits Retain Their Pop

As aluminum barrels compress over time, hits lose their original pop. Exit ball speeds decrease as the trampoline effect lessens. There’s no guessing when an aluminum bat has lost its hotness.

Composite barrels maintain their lively trampoline feel year after year. Ball speeds remain consistent so hits keep jumping off the barrel with authority. You can count on the same explosive power from first hit to last.

Improved Vibration Dampening

Material deformations in aluminum bats decrease their ability to dampen negative vibrations. Hits become increasingly unpleasant with longer-term use as sting increases.

Composite bats retain their excellent vibration dampening since the materials retain structural integrity. Hits feel smooth and comfortable from the first swing onward. Consistent vibration dampening makes composite bats more playable for more years.

Ideal Balance and Swing Weights

Subtle dents and deformations along the aluminum barrel alter a bat’s balance and swing weight. Rotation gradually slows as the bat loses its optimized properties.

Composite bats maintain their precise balance and swing weights much longer thanks to durability. The bat continues swinging smooth and quick through the zone since the materials retain their structural balance.

Responsive Barrels Over Time

The trampoline effect decreases in aluminum bats as the walls compress with use. The flex profile changes and barrels become less responsive.

Composite barrels retain their precise flex tuning and trampoline responsiveness year after year. Engineers meticulously design the barrel to provide ideal flex and rebound – and composites maintain this

responsiveness over thousands of hits.

When it comes to durability, composite bats simply last longer and outperform aluminum rivals. The composite materials retain their shape, pop, vibration dampening and balance over the long haul. While aluminum bats come and go, composites provide reliable performance season after season.

Composite Bats Maintain Performance For Longer

Composite bats outlast traditional aluminum models thanks to their ability to maintain original performance standards for more seasons. While aluminum bats lose their pop after extensive use, composite bats retain their power and explosiveness year after year.

The advanced composite materials used in today’s bats deliver unmatched durability and resilience. Performance stays consistent so players can count on the same lively feel and hitting distance season after season. Let’s look at why composite bats maintain their capabilities longer.

Consistent Sweet Spot Size

The sweet spot of aluminum bats gets smaller as walls compress and deform over time. Mis-hits become more common as the original sweet spot shrinks. With composite barrels, the expanded sweet spot maintains its original dimensions longer.

The barrel shape and wall thickness stay consistent thanks to the high stiffness and strength of the composite materials. More hits find the expansive sweet spot season after season for reliable power across the face.

No Loss of “Pop”

Aluminum bats gradually lose their trampoline effect and hittable feel as the barrel compresses from repeated impacts. The lively pop dissipates as the barrel walls thin and weaken.

Composite barrel walls retain their precise shape and thickness to deliver unchanging levels of pop. The materials rebound efficiently to provide explosive trampoline for thousands of hits year after year.

Maintains Swing Weights

Subtle dents and barrel deformations in aluminum bats can alter swing weights over time. The balance and feel during rotation can change as weights shift.

Composite bats maintain their original swing weights much longer thanks to material integrity. The bat continues feeling balanced and quick through the zone just like it did on day one.

Consistent Swing Speeds

The lower durability of aluminum leads to changes in barrel shape and weight distribution. Heavier and uneven barrels reduce swing velocity compared to a new bat.

Composite bats retain their optimal weight distribution to promote fast, balanced swings. Swing velocity stays fast thanks to the consistent barrel shape and feel across multiple seasons.

Unchanging Vibration Dampening

More vibrations and sting transfer to the hands with aluminum bats as the materials weaken from repeated impacts. Mis-hits become especially unpleasant.

Advanced composites maintain their exceptional vibration dampening properties over thousands of hits. The materials stay structurally sound to isolate vibrations and provide a comfortable feel.

Retains Precise Balance Points

Even minor dents along the aluminum barrel can redistribute weight and alter the bat’s balance point. The swing path changes as balance shifts down the barrel.

Composite bats retain their precise balance point longer because of material integrity. The bat continues feeling perfectly level in your hands for optimal control and quick rotation.

Consistent Flex and Responsiveness

Aluminum barrels lose their tuned trampoline effect as walls thin and indentations form. The flex profile and responsiveness degrade over time.

Composite materials retain their engineered flex patterns across thousands of hits. Barrels continue providing optimized responsiveness and trampoline thanks to durability.

Minimal Surface Damage

Scuffs and paint chips rapidly accumulate on aluminum barrels with game use. These surface defects hint at the larger deformations weakening barrel integrity.

Composite bats maintain a smooth, flawless barrel appearance thanks to material resilience. Aside from minor scuffs, even veteran composite barrels look and feel brand new.

Consistent Ball Exit Speeds

Wall thinning and defects reduce the trampoline effect of aluminum bats, lowering exit speeds over time. As the barrel loses its pop, batted balls slow down.

Composite barrels deliver consistently fast ball speeds season after season thanks to retention of the trampoline effect. Superior durability prevents power drop off.

Extended High Performance

While aluminum bats come and go every season or two, composite bats deliver elite performance for many years. The advanced materials retain their capabilities so players enjoy the same excellence year after year.

Rather than buying new bats to compensate for fading performance, composite models stay in the bag delivering results. Dollar for dollar, composites give you more value thanks to exceptional longevity.

So in summary, composite bats maintain high performance standards for longer by retaining their original structure and trampoline effect. Season after season they provide the same sweet spot size, lively feel, swing speed and exit velocity. When you find a composite bat you love, you can count on it year after year.

Composite Bats Come In Unique Graphics and Colors

One advantage composite baseball bats have over traditional aluminum models is the ability for manufacturers to apply custom graphics, colors and paint schemes. Composite materials allow for more creative and complex visual designs compared to aluminum.

Vibrant colors and bold graphics let players express their personal style on the diamond. Composite bat makers leverage dyes, hydrographics, paints and films to deliver stunning looking bats packed with visual appeal. Let’s explore the graphics possibilities of composite bats.

Full Coverage Film Graphics

Full coverage graphics and designs can be applied to composite bats since the materials easily accept films and paints. Vibrant colors and sharp images wrap around the entire barrel for a bold look.

Manufacturers use special decals and hydrographic films to adorn composite barrels with custom graphics. Logos, textures and patterns stretch from end to end. Every inch of the barrel becomes a canvas for showcasing color and design.

Gloss, Matte and Metallic Finishes

Composite bat painters utilize gloss, matte and metallic finishes to produce stunning looking bats. Glossy coats reflect light for a wet shimmering visual. Matte finishes mute light reflection for a subdued, velvety look.

Metallic paints containing aluminum flake or powder deliver a sparkling shine. Manufacturers can mix and match paint types on a single bat for unique style. Dramatic fades, splashes and color combinations grab attention.

Deep, Vibrant Color Options

Composite materials readily accept dyes for vibrant, enduring coloration. Essentially any color can be applied to composite bats to match team schemes or player preferences. Bright, bold colors help players stand out.

Aluminum only allows basic color options since anodizing dyes don’t take well to metal. Composite painters use richer, more saturated dyes to deliver brilliant hues and effects. Pinstripes, fades and color accents provide depth.

Hydrographic Film Patterns

Hydrographic films give composite bats stunning 3D-like visuals. Complex patterns like carbon fiber, wood grain, camo and more cover the barrel through an immersion film transfer process.

Aluminum can’t accept these films due to its smooth surface finish. But composite materials bond easily with hydrographic films for limitless graphic potential. Combining patterns with color produces bold designs.

High Definition Images and Logos

Using decals and pad printing, composite bat makers can apply photo-realistic images and logos across the barrel. Even fine details come through thanks to composite’s surface adhesion properties.

Images tend to appear fuzzy on aluminum from uneven ink adhesion. Composite bats better support high-res graphics for sharp, vivid visuals with stunning attention to detail.

Intricate Design Details

The graphics possibilities are endless with composite bats thanks to the ability to apply images, colors and effects across the entire barrel surface. Intricate details like fades, team logos, names and more can be integrated.

Aluminum bats only allow basic graphics confined to smaller areas. Composite opens the door for wrapping visual designs around the full profile. Bat graphics become like walking billboards.

Matching Team Bats

Composite materials make it easy for teams to match their bat looks using custom graphics and colors. Consistent paint schemes, logos and design elements give teams a unified visual identity.

It’s nearly impossible to perfectly color match anodized aluminum bats due to process variation. But composites offer color precision so every player’s bat ties together visually.

Unique to Each Player

While aluminum bats only allow basic colors and graphics, composite bats give each player the ability to express their identity. Custom colors, logos, images and names can be applied.

Rather than just another generic bat, composites become personal statements. Every athlete can showcase their unique style on each trip to the plate.

Enhanced Grip Options

Along with eye-catching graphics, composite bats provide versatility in grip application. Different grip tapes, pine tar adhesives and flexion coatings adhere well to composite materials.

Grip customization allows further personalization and style. Matching your grip to the barrel graphics ties the entire bat together visually.

Changes Allowed Over Time

The graphics on an aluminum bat can’t be altered after production since any paint or film changes would damage the surface finish.

Composite bats allow new graphics to be applied over old designs without issue. You aren’t stuck with the same look year after year. Change the graphic scheme each season for fresh style.

The bottom line is composite materials provide almost endless possibilities for applying stunning colors, images and effects. Every player can show off their personal flair thanks to total barrel coverage graphics. Composite bats deliver style to the plate.

Composite Bats Are Legal For Most Leagues

One question players often have about composite bats is whether they are approved for use in their particular league. The good news is that today, composite bats meet regulations for the vast majority of youth, high school, collegiate and recreational leagues.

League officials have become comfortable with composite bat performance through years of testing and monitoring exit speeds. While some restrictions exist, especially at the youth level, most organizations accept composites as safe and fair for play.

Meeting Bat Standards

All bats used in sanctioned league play must carry proper certification marks indicating their adherence to applicable bat standards. BESR and BBCOR regulate bat performance.

For a composite bat to be legal, the manufacturer must demonstrate through lab testing that it meets bat-ball exit speed rules. Certified composite models are engineered not to outperform alloy and wood bats.

Youth Baseball Composites

For little league and below, composite bats must carry the USA Baseball logo denoting they satisfy USABat standards. These bats perform much like standard aluminum bats.

Some youth leagues also allow composite bats with the BBCOR certification mark. These have slightly better bat performance compared to USABat models but remain within regulated limits.

High School Baseball

All bats used in high school play must feature the BBCOR certification logo. BBCOR regulates the trampoline effect and exit speeds on both aluminum and composite bats.

Essentially any composite bat with the BBCOR mark will be legal for high school games. These bats provide excellent performance while adhering to controlled standards.

NCAA College Baseball

Like high school, collegiate baseball requires that all bats carry the BBCOR certification indicating adherence to exit velocity standards. NCAA BBCOR logos must appear on the barrel.

College players can freely choose between BBCOR certified aluminum and composite bat models. Both metal and composite are fair game.

Adult Recreational Leagues

Most recreational and club adult leagues follow ASA/USA bat rules, though some are switching to BBCOR. Composites are legal as long as they carry the proper ASA/USA or BBCOR logo.

Single wall aluminum bats are also permitted along with wood bats in ASA leagues. Double wall aluminum bats are prohibited under ASA guidelines.

Senior League Bats

For senior league divisions, look for bats featuring the USSSA 1.15 BPF label. This BPF standard is specific to senior leagues and applies to both aluminum and composite bats.

Composites with the 1.15 BPF stamp offer excellent performance tailored to senior players while adhering to exit speed regulations.

Wood Bat Leagues

Some amateur and collegiate leagues mandate traditional wood bats only. Composites and aluminum models are prohibited in these leagues in order to match professional play.

For town ball clubs, composite bats provide a legal alternative to wood that offers much greater durability and performance consistency.

Coach Pitch and Tee Ball

The very lowest youth divisions like tee ball and coach pitch allow essentially any type of bat including composites. Focus is on safety and making contact rather than bat performance.

Fun composites featuring colorful designs and lightweight builds help build swing skills and confidence for young tee ballers.

The key for composite bat legality is checking for the applicable certification logo for your league’s age group and division. As long as proper standards are met, composites can be used in nearly every level of play from tee ball to college.

Composite Bats Cost More But Last Longer

Composite bats come with a higher price tag than traditional aluminum models, but they justify the extra cost through unmatched durability and performance longevity. While aluminum bats dent, chip and wear out quickly, composite bats retain their pop and feel after extensive use.

Let’s compare the value proposition of composite bats versus aluminum models. The higher initial price pays for itself over time in the form of season after season of consistent excellence.

Multi-Season Hit Life

Thanks to the strength and resilience of advanced composite materials, today’s bats maintain their high performance and responsiveness over thousands of hits. It takes years to diminish the power and sweet spot.

Aluminum barrels dent, deform and go dead in a matter of weeks or months. Frequent replacement becomes necessary to maintain pop, adding to long term costs.

No Need to “Break In”

Brand new aluminum bats require weeks or months of use to reach peak performance through wall compression and micro-denting. Their sweet spot and power potential start small.

Composite bats deliver ideal pop right out of the wrapper since no break-in period is needed. You experience full potential immediately for an extended bat lifespan.

Low Maintenance

Aluminum bats show heavy signs of wear as the barrel compresses and deforms – paint chips, dents and wall thinning. Composites retain their smooth barrel shape and require virtually no maintenance.

Aside from occasional cleaning, composite bats look and feel fresh after seasons of use. Their excellent durability minimizes care and upkeep.

No Replacement Costs

While high performing aluminum bats need replaced every year or two, composite bats stay in your bag delivering results. The savings of not buying new bats offsets the higher initial price.

Rather than perpetual new bat costs, composites become a one-time purchase you can rely on season after season.

Extended Warranties

Composite bat manufacturers back up their products with generous multi-year warranties. DeMarini and Louisville Slugger offer two-year warranties or more against defects.

Aluminum bats often carry basic one year or shorter coverage since their lifespan is so limited anyway.

Holds Trade-In Value

Due to their sustained performance, used composite bats retain excellent trade-in and resale value. Many years of use remain after initial purchase.

Heavily worn and dented aluminum bats have almost zero trade-in value. Expect to receive only scrap pricing due to their short lifespan.

Wood Bat Performance

Composite bats match the traditional feel and performance of wood bats at a fraction of the cost. A single composite can outlast dozens of broken wood bats.

While wood bats crack and split constantly, composites provide wood-like performance year after year. Their lifespan easily justifies the premium price.

Cost Per Season Analysis

Looking at cost per season rather than upfront price, composite bats become a better value proposition. A $300 composite lasting 5+ seasons equates to $60 per season.

A $100 aluminum bat lasting one season before replacement equates to $100 per season. The composite delivers more value long term.

While composite bats demand a higher initial investment, their unmatched longevity and sustained performance over multiple seasons makes them well worth the premium price in the long run.

Composite Bat Technology Continues To Improve

One exciting benefit of composite bats is that their performance and capabilities continue advancing each season through material and engineering innovations. Bat manufacturers invest heavily in composite research and development, leading to regular improvements.

Let’s look at some of the cutting-edge technologies pushing composite bat performance to new heights and how manufacturers like DeMarini, Louisville Slugger and Easton constantly innovate.

Stronger and More Responsive Composites

The composite materials used in today’s bats become more optimized each year. Engineers tweak carbon fiber production and bonding processes to enhance strength, stiffness and trampoline response.

For example, Easton’s Fire Flex barrels utilize patent-pending dynamic composite technology to increase deflection and barrel flex for unrivaled power. Expect even stronger composites ahead.

Larger Sweet Spots

Design refinements driven by computer modeling analysis allow manufacturers to reshape barrels for expanded sweet spots. Thinner walls through stiffer materials enlarge the high-performance hitting zone.

DeMarini dominates sweet spot technology. Their patented D-Fusion handle system optimizes energy transfer to the tapered barrel for greater power across the hitting surface.

Tuned Barrel Flexibility

Today’s composite bats feature specially engineered barrel “flex profiles” for trampoline response. Hoop frequency mapping provides precision flex tuning for ideal energy transfer.

For example, Louisville Slugger’s PBF barrel tech uses variable wall thicknesses to provide customized flex points matched to a hitter’s swing path for maximum power.

Lighter Weight Construction

Stronger composite materials allow walls, handles and end caps to be made thinner and lighter. Reduced barrel weight boosts swing speed for greater power while remaining durable.

Easton’s new SI-CORE technology removes up to 25% of unnecessary mass from their renowned composite frames to increase bat speed without sacrificing barrel strength.

More Comfortable Grips

Improved glove-like grips promote excellent feel and comfort. Materials like DeMarini’s exclusive Fusion grip combine tack, cushioning and vibration isolation for the ultimate bat feel on every swing.

Expect more grip advances as new materials and coatings become available. Total comfort leads to confident swing mechanics.

Vibration Dampening Innovations

Reducing negative feedback vibrations remains an engineering priority. Handle constructions now isolate reverberations exceptionally well through elastomers and anti-vibration foams.

Easton’s RCK knob even uses advanced rubber isolates to redirect vibrations away from the hands, taking damping to the next level.

Balanced Energy Distribution

Today’s designs distribute impact energy more evenly from handle to end cap for solid feel and flex recovery. Multi-piece Link technology precisely transfers energy through the bat.

Expect balance and energy distribution to become even more refined as computer modeling software advances.

Precision Manufacturing

Automated precision manufacturing results in tighter tolerances and less performance variation between bats. Hand workmanship deviations become eliminated.

Louisville Slugger’s PBF tech and precision molding deliverexact wall thickness and barrel construction for unmatched consistency. Other brands will follow.

Complete Customization

Elite hitters can access made-to-order custom bat options tailored to their exact swing path and flex preferences. Custom composite layups, barrels, handles and more become possible.

Expect custom manufacturing to reach recreational players too as costs eventually decrease. One day every bat will suit your strength and swing style.

While already excellent, expect composite bat technology and performance to keep improving each season. The top brands remain committed to pushing the limits through R&D and engineering innovations.

Top Players Prefer Composite Bats

The great debate in baseball has always been between the traditionalists who swear by the old school aluminum bats and the modernists who fully embrace the high-tech composite models. While aluminum bats dominated the game for decades, composite bats have taken over in recent years as the preferred choice of the best players from Little League to college level.

There are good reasons why composite baseball bats now outsell their aluminum counterparts. Composite bats offer a number of advantages in performance, durability, and versatility over the old standards. Here are 10 key reasons why composite bats now dominate the field of play:

1. Better Bat Speed

The composite materials used in modern bats allow for a lighter overall weight while maintaining a powerful hitting surface. This weight reduction of up to 25% compared to aluminum bats allows hitters to achieve greater bat speed through the swing zone leading to more power and distance on contact.

2. Larger Sweet Spot

Along with improved bat speed, the composite barrel construction expands the sweet spot of the bat. The sweet spot refers to the area of highest energy transfer on impact. With a larger sweet spot, hitters can make solid contact even when they don’t connect on the perfect bullseye of the barrel.

3. Reduced Vibration

Aluminum bats vibrate strongly on off-center contact reducing energy transfer in those hits. Composite bats dampen those vibrations allowing for better performance across the whole of the barrel. Less vibration also improves the feel of the bats, giving more feedback to the hitter.

4. Greater Durability

Composite materials hold up better over time than their aluminum counterparts. The one-piece composite construction eliminates weak points where the barrel meets the handle on aluminum bats. Composites flex and rebound without developing the chips, cracks, and dents that can ruin the performance of aluminum models.

5. Improved Balance

The precise way composite bats can be engineered gives them better balance than traditional aluminum models. Distributing weight perfectly through the bat results in better control, quicker swing speed, and more solid contact through the hitting zone.

6. Consistent Performance

Aluminum bats must be “broken in” over time before they achieve peak performance. Composite bats offer great performance right off the shelf with no break-in period required. They maintain that consistent sweet spot and rebound throughout their life cycle.

7. Variety of Designs

The moldable and tunable properties of composite materials allow for more creative and specialized designs compared to aluminum. Manufacturers can tweak composite bats to optimize launch angle, increase power zones, improve swing efficiency, and provide different feels from balanced to end-loaded.

8. Environmentally Friendly

Composite bats have a much smaller carbon footprint compared to tradition aluminum bats. The composite production process is more environmentally friendly, and composite bats last longer keeping them out of landfills. Many are fully recyclable at the end of their lifecycle as well.

9. Safer Performance

Composite bats must pass additional safety standards for ball exit speeds compared to their traditional counterparts. Governing bodies can more easily regulate performance to maintain a balanced field of play and reduce injury risks.

10. The Professionals Choose Composite

From college level to the pros, the top players choose composite bats for their performance advantages over aluminum. If the best in the game rely on composite tech to compete at the highest levels, there’s no question which type of bat amateur players should be swinging too.

Clearly, composite bats now provide a better overall experience compared to the aluminum bats of old. Their performance advantages, custom designs, and safety improvements make composites the superior choice for all levels of play.

For young players developing their hitting skills or seasoned veterans trying to maintain their swing, composite bats will help achieve consistent power and control at the plate. As the technology continues to advance, expect composite bats to further dominate aluminum models in the coming years!

Composite Bats Have Revolutionized Baseball

Baseball at all levels has undergone a huge transformation in recent years with the emergence of high-tech composite bats. While the old school aluminum bats had their time in the sun, composite models have shaken up the game and changed hitting forever. The performance and design advantages composite bats provide have made them the top choice across Little League, high school, college, and pro ball.

There’s a good reason you see composite bats in the hands of nearly every hitter these days. The composite revolution has revolutionized the way the game is played. Let’s explore 10 key ways composite bats have forever altered baseball:

1. Players Achieve Faster Swing Speeds

The advanced materials in composite bats make them lighter without sacrificing hitting power. This reduction in weight allows players to whip the bat through the zone faster leading to some sizzling swing speeds at the plate.

2. More Barrel Flex For Power Hitting

Composite barrel construction allows for more flex and “trampoline effect” at impact compared to stiff aluminum. This flex amplifies ball speed coming off the barrel resulting in shots that jump off the bat.

3. Larger Hitting Surface Area

The way composite bats are engineered enables them to maximize the sweet spot. With a larger effective hitting area, players can still find the barrel even when they’re slightly off on their swing path.

4. Reduced Vibration For Superior Feel

Aluminum bats vibrate harshly on mishits decreasing performance on those swings. Composite models dampen vibration allowing better energy transfer and a more consistent feel across the whole barrel.

5. No Break-In Period Necessary

Remember having to pound your aluminum bat for weeks before it reached peak performance? Composite bats deliver ideal pop right out of the wrapper with no tedious break-in required.

6. More Precise Weight Distribution

Composite construction enables manufacturers to perfectly distribute weight through the bat delivering better balance and control for hitters.

7. Incredible Durability

Aluminum bats dent, crack, and get beat up over time. Composites rebound consistently while holding up far better through season after season of use.

8. Specialty Designs To Suit Any Hitter

The flexibility of composite materials allows companies to engineer bats with different barrels, handles, and weight distributions to match any hitter’s style and swing.

9. Environmentally Sustainable Technology

Composite production is more eco-friendly than traditional bat manufacturing. Composite bats also have a longer usable lifespan keeping them out of landfills.

10. Safer Performance Standards

Governing bodies can better regulate composite bat performance to maintain balance between offense and defense as well as reduce injury risks.

It’s clear from this list that composite bat tech has positively disrupted baseball at all levels of play. Their performance and consistency gives hitters more confidence when stepping up to the plate in any situation.

Composite bat manufacturing continues to rapidly innovate and push new boundaries. Expect composite designs to provide even more power, precision, and durability in the future. Any baseball or softball player looking to reach the next level needs to add a composite bat to their arsenal.

The composite revolution has sparked new life into America’s pastime. Although purists may miss the old “ping” of aluminum, there’s no denying composite bats have hit a home run for the game of baseball!

Composite Bats Allow For Precise Weight Distribution

One of the key performance advantages composite baseball bats offer over traditional aluminum models is their ability to precisely distribute weight through the bat. Advanced composite materials and manufacturing methods enable companies to engineer the ideal balance, swing weight, and feel to match each hitter’s style and preferences.

While aluminum bats offer little variability, composite bats provide limitless options to distribute weight precisely where needed to optimize swing efficiency and power. Here’s a closer look at why weight distribution matters and how composite tech delivers the perfect bat for each player:

Balance Points Win Games

Bat speed, control, and smoothness through the hitting zone depend greatly on balance. Even minute differences in where the weight is distributed can completely change the way a bat performs in a player’s hands.

Balanced, End-Loaded, or Anything In Between

Some hitters prefer a bat evenly balanced through the whole barrel. Others want an end-loaded feel with more weight out front to whip through contact. Composite materials enable any balance configuration along that spectrum.

Weight Where You Want It

Composite bats provide opportunities to load extra mass directly in the sweet spot for maximum power or redistribute it for quicker handling. This customization ensures an ideal feel.

Consistent Swing After Swing

The balance never shifts in a composite bat so hitters can trust that same smooth, controlled swing time after time. No worrying about dents affecting weight like in aluminum bats.

Lower Swing Weight For Faster Speeds

Composite bats effectively distribute less overall weight than aluminum models making it easier for hitters to whip them through the zone at higher speeds.

Higher MOI for More Forgiveness

Weight distribution directly affects a bat’s moment of inertia (MOI) or resistance to twisting on impact. Optimized MOI provides more forgiveness on mishits.

Matching the Player’s Style

Manufacturers can set up weight distribution to complement each hitter’s unique swing path, launch angle, and contact point through the zone.

Consistency Across the Lineup

Teams can fine tune bats for stronger and weaker hitters alike so every player steps to the plate with their ideal weight feel and balance.

Growing With the Hitter’s Swing

As young players mature, manufacturers can alter weight balance and distribution to match their developing skills and strength season after season.

Something for Everyone

Any hitter can find their perfect balance and weight configuration in the vast composite bat product spectrum regardless of age, size, or ability.

While aluminum bats only come in generic balanced and end-loaded styles, composite manufacturing offers endless variability. Players can finally choose a bat engineered specifically to complement their hitting mechanics and power for optimal performance.

The ability to redistribute weight precisely where it’s needed most gives composite bats a huge advantage. Look for hitters to continue gaining more consistency and control at the plate thanks to custom composite weight configurations designed for their swing.

For any baseball or softball player looking to reach the next level, a composite bat tuned to their strength, ability, and balance preferences can help unlock their full hitting potential.

Composite Bats Can Be Custom Designed And Built

When it comes to baseball bats, composite bats have surpassed aluminum bats in popularity and performance. Composite bats offer a number of advantages that make them the top choice for many players today. Here are 10 reasons why composite baseball bats dominate the game:

1. Composite materials allow for extensive customization

The way composite bats are constructed gives manufacturers more flexibility in design compared to aluminum bats. Composite bats can be built layer by layer with fibers oriented in different directions to tune the exact combination of strength, flex, and rebound that players want. This allows players to find a bat optimized for their personal swing mechanics and hitting style.

2. Greater “pop” off the bat

Due to the way composites store and release energy, composite baseball bats offer more “trampoline effect” versus aluminum. The ball rebounds faster off a composite bat, giving it more speed as it leaves the barrel. This translates into more carry and distance on batted balls.

3. Larger sweet spot

With their advanced materials and construction techniques, composite bat makers can expand the sweet spot on the barrel. The sweet spot measures several inches across on many composite bats. This gives players more margin for error in making contact and still getting good performance off the barrel.

4. Reduced vibration and sting

Aluminum bats often sting the hands with unwanted vibration on off-center contact. Composite bats dampen these negative vibrations much better. Players enjoy a more comfortable swing and can still make solid contact even when they don’t square the ball up perfectly.

5. Greater durability

Composite materials stand up very well to the stresses of repetitive hard swings. The materials resist cracking and denting better than aluminum alloys. Composite bats maintain their pop and performance longer before showing signs of wear.

6. Lighter swing weight

In the quest to build a lighter-swinging bat, composite clearly has the edge over aluminum. Manufacturers can use advanced composite materials like carbon fiber to construct a bat that weighs ounces less than a similar sized aluminum bat. The lighter bat helps increase swing speed.

7. Consistent performance in cold weather

Aluminum bats lose much of their trampoline effect when used in colder temperatures. The materials literally become “deadened” by the cold. Composite bats maintain their flex and pop much better as temperatures drop. This gives players an advantage playing in cool spring conditions.

8. Greater options for balancing swing weight

Composite bat makers can fine tune the balance point by layering different composite materials in specific areas of the barrel and handle. This kind of precision balancing is not possible with aluminum bats. Players can dial in the exact swing weight and balance profile they prefer.

9. More barrel sizes and shapes

Composite construction enables bat designers to experiment with all kinds of new barrel shapes and profiles. We see large barrels, small barrels, oval shapes, and other innovations. Composite gives manufacturers the flexibility to come up with completely new barrel designs to enhance performance.

10. Advanced technologies like inner barrels

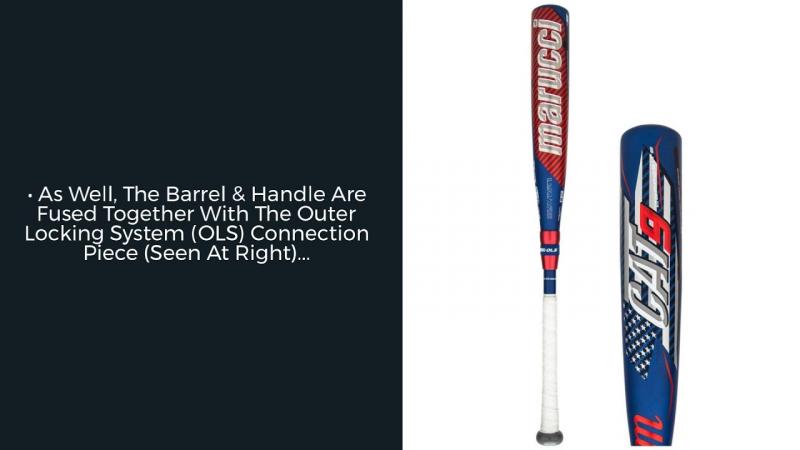

Some composite bat models now feature multiple-walled designs with inner and outer barrels. This construction adds strength while maintaining a flexible “trampoline” outer wall for increased bounce. Such advanced designs are only possible through composite technology.

In summary, composite bats give players, manufacturers, and designers more options when it comes to maximizing hitting performance. The combination of lighter weight, larger sweet spots, and greater trampoline effect adds up to more power potential compared to aluminum designs. As composite manufacturing continues to advance, expect the performance gaps to widen even further in the future. When you step up to the plate, composite is hard to beat.