What is shock gel and how does it absorb impact. How is shock gel different from traditional materials. Where can shock gel be applied for maximum effectiveness. What are the key properties that make shock gel superior for impact absorption. How does the molecular structure of shock gel contribute to its performance. What temperature range can shock gel operate in reliably. Can shock gel be customized for specific applications.

Understanding Shock Gel: The Next Generation of Impact Absorption

Shock gel represents a significant advancement in impact absorption technology, offering exceptional softness and durability that surpasses conventional materials. This innovative substance, also known as Alpha GEL, possesses a unique molecular structure that enables it to absorb and dissipate energy from impacts with remarkable efficiency.

One of the most striking demonstrations of shock gel’s capabilities is its ability to protect a raw egg dropped from a height of 18 meters – equivalent to a six-story building. When the egg lands on a mere 2 cm thick sheet of Alpha GEL, it remains intact, showcasing the material’s extraordinary shock-absorbing properties.

The Science Behind Shock Gel’s Effectiveness

Shock gel’s effectiveness stems from its ability to convert impact energy into deformation energy. When an object collides with shock gel, the material undergoes compressive deformation, extending the duration of stress and significantly reducing the maximum impulse force. This mechanism is crucial in preventing damage to the impacting object.

The process of shock absorption can be broken down into several stages:

- Initial impact (A): The object makes contact with the shock gel

- Maximum impulse force (B): The peak force is experienced

- Maximum deformation (C): The shock gel reaches its maximum compression

- Rebound (D): The object is pushed back by the gel’s repulsive force

The key to shock gel’s superior performance lies in its ability to maximize the sum of energy absorbed during the compression (Wa) and rebound (Wb) phases, effectively minimizing the maximum impulse force experienced by the impacting object.

Unique Properties That Set Shock Gel Apart

Shock gel boasts several distinctive characteristics that make it an ideal choice for impact absorption applications:

- Exceptional softness

- Long-term reliability

- High thermal resistance

- Customizability

Unparalleled Softness for Superior Cushioning

The exceptional softness of shock gel allows it to provide a level of cushioning that is unattainable with conventional rubber materials. This softness is what enables the gel to protect fragile objects, like eggs, from extreme impacts.

Durability and Weather Resistance

Unlike many other materials, shock gel maintains its performance over extended periods. It exhibits remarkable resistance to weather conditions, ozone, UV radiation, and various chemicals. The gel’s low compression set ensures that it retains its shock-absorbing capabilities even after prolonged use, sometimes lasting for over a decade in external applications.

Thermal Resilience for Diverse Environments

Shock gel maintains its reliability across an impressive temperature range, from -40°C to 200°C. This thermal resistance makes it suitable for use in a wide variety of environments and applications, from extreme cold to high heat scenarios.

Adaptability Through Customization

One of shock gel’s most valuable features is its adaptability. It can be tailored to meet specific requirements by adjusting its shape, hardness, and even combining it with other materials to enhance functionality.

Applications of Shock Gel Across Industries

The versatility of shock gel makes it suitable for a wide range of applications across various industries:

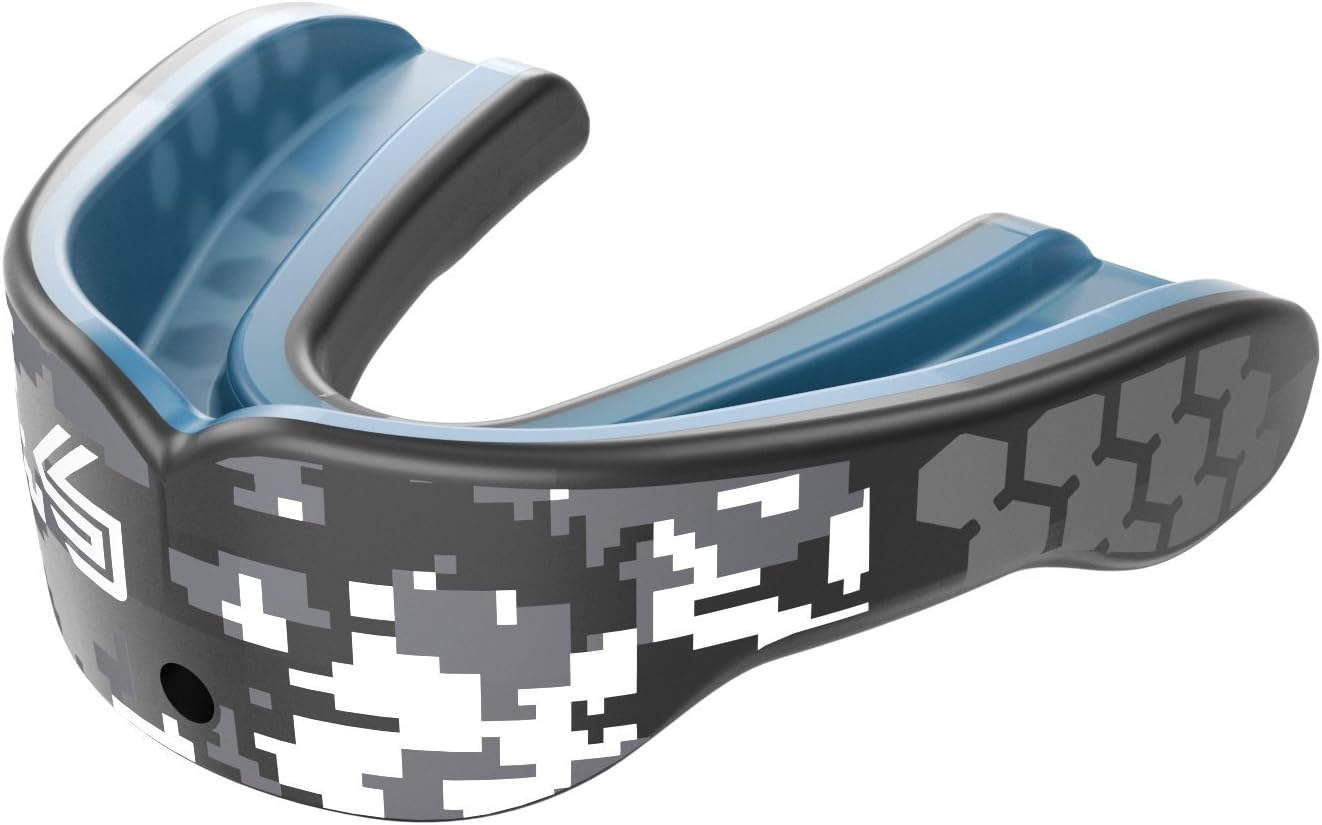

Sports and Athletic Equipment

In the sports industry, shock gel can be incorporated into protective gear, footwear, and equipment to enhance safety and performance. Its ability to absorb impact can help reduce the risk of injuries in high-impact sports.

Automotive Safety Systems

Shock gel’s energy-absorbing properties make it an excellent candidate for use in automotive safety systems, potentially improving the effectiveness of crumple zones and interior padding.

Electronics and Delicate Instrument Protection

For sensitive electronic devices and precision instruments, shock gel can provide crucial protection against drops, vibrations, and other physical stresses.

Military and Defense Applications

The durability and high-performance characteristics of shock gel make it suitable for various military applications, including personal protective equipment and vehicle armor systems.

Shock Gel Products: Forms and Variations

Shock gel is available in various forms to suit different applications:

Gel Sheets (θ-Gel)

These highly durable silicone shock absorption sheets combine softness and strength. They are available in several variations:

- Theta-7

- Theta-5

- Theta-6

- Theta-8

These sheets can be customized with additional features such as PET film backing, adhesive tape, powder coating, or non-tacky surfaces.

Gel Tapes and Gel Chips (GT & GC)

For easy application, gel tapes and chips are available with adhesive backing on one side. They come in various sizes and thicknesses:

- Gel Tapes (GT): 1,000mm length, 10/20mm width, 1/2/3mm thickness

- Gel Chips (GC): 10/15/20mm length and width, 3/5/10mm thickness

Foam-Type Gels (NP)

NP Gel is a lightweight and durable silicone foam material, available in two variants:

- Green NP Gel: 2,000mm x 450mm, 3mm thickness

- White NP Gel: 1,000mm x 300mm, 6mm thickness

The Future of Impact Protection: Advancements in Shock Gel Technology

As research in materials science progresses, shock gel technology continues to evolve. Recent developments have pushed the boundaries of what’s possible in impact absorption:

Supersonic Impact Resistance

Emerging hydrogel formulations show promise in withstanding supersonic impacts. These advanced materials could revolutionize protective gear for high-speed applications, from aerospace to ballistics.

Intelligent Shock Absorption

Future iterations of shock gel may incorporate smart materials that can adapt their properties in real-time based on the intensity and nature of the impact. This could lead to more efficient and responsive protection systems.

Biodegradable Formulations

As environmental concerns grow, researchers are exploring biodegradable shock gel variants. These could offer the same level of protection while reducing the environmental impact of discarded protective equipment.

Comparing Shock Gel to Traditional Impact Absorption Materials

To fully appreciate the advantages of shock gel, it’s important to compare it with traditional impact absorption materials:

Shock Gel vs. Foam

While foam materials have been widely used for impact absorption, they often suffer from compression set over time, reducing their effectiveness. Shock gel, on the other hand, maintains its properties for much longer periods, ensuring consistent protection.

Shock Gel vs. Traditional Rubber

Conventional rubber materials can provide good impact resistance, but they lack the extreme softness and customizability of shock gel. The unique molecular structure of shock gel allows for superior energy dissipation compared to most rubber compounds.

Shock Gel vs. Air-based Systems

Air-based cushioning systems, while effective, can be prone to leaks and pressure loss over time. Shock gel offers a more reliable and consistent performance without the risk of sudden failure due to punctures or seal degradation.

Integrating Shock Gel into Product Design: Considerations and Best Practices

For engineers and product designers looking to incorporate shock gel into their creations, several factors should be considered:

Determining Optimal Thickness and Density

The effectiveness of shock gel depends greatly on its thickness and density. These parameters should be carefully calculated based on the expected impact forces and the specific requirements of the application.

Combining Shock Gel with Other Materials

While shock gel is highly effective on its own, its performance can be further enhanced by combining it with other materials. For example, pairing shock gel with rigid structures can create a system that provides both impact absorption and structural integrity.

Environmental Considerations

When designing products with shock gel, it’s important to consider the environmental conditions in which the product will be used. The gel’s thermal resistance allows for a wide operating range, but extreme conditions may require special formulations or additional protective measures.

Maintenance and Longevity

While shock gel is known for its durability, proper maintenance can further extend its lifespan. Designers should consider how the gel can be inspected, cleaned, and potentially replaced in long-term use scenarios.

As shock gel technology continues to advance, its potential applications in impact protection and energy absorption are expanding. From everyday consumer products to specialized industrial and military applications, this innovative material is setting new standards for safety and performance. By understanding its unique properties and leveraging its customizability, designers and engineers can create more effective, durable, and reliable protection systems across a wide range of industries.

αGEL|Solutions(Shock Absorption)

Exceptional softness and a unique molecular structure make Alpha GEL a highly effective shock absorber.

Alpha GEL’s durability, safety, and thermal resistance (-40°C – 200°C) combined with Taica’s know-how and technical expertise allow us to offer the perfect shock absorption solution tailored to your needs.

Characteristics

- ●Exceptional Softness

- Alpha GEL is exceptionally soft, able to cushion the fall of an egg dropped from a height of eighteen meters without breaking it. This softness is impossible to realize with conventional rubber.

- ●Long-term Reliability

- Alpha GEL is exceptionally durable and resistant to weather, ozone, UV radiation, and chemicals. It shows very low compression, resulting in long-lasting, stable performance.

Alpha GEL has long been used in external applications, sometimes for more than 10 years at a time. It does not deteriorate like other rubbers and foams, retaining its softness long-term.

- ●High Thermal Resistance

- Alpha GEL performs reliably at temperatures between -40°C and 200°C.

- ●Combination with Other Materials for Improved Functionality

- We will do our best to fulfill your needs with customized GEL solutions.

Alpha GEL products can be made into any shape and hardness. They can also be combined with other materials to improve functionality, e.g. improved shock absorption.

Application Example

A raw egg dropped from a height of 18m – equivalent to the sixth floor of a building – remains unbroken when caught by a sheet of Alpha GEL only 2cm thick.

Alpha GEL absorbs shock by turning impact energy into deformation energy.

Mechanism

- Shock Absorption

- A large force called impulse force becomes generated the moment an object falls to the ground. The scale of the impulse force not only is proportional to the energy of the impulse (which is related to the object’s colliding speed and weight) but also depends on material characteristics of the shock-receiving surface.

Hitting a surface made of stiff materials like concrete or asphalt would shorten the stress generation time period (i.e. the duration of the stress), creating a significantly large maximum impulse force. But this force can be reduced by using materials called shock absorption materials that extend the duration of the stress (see Figure A). The figure below shows deformation and stress generation in shock absorption materials(see Figure B).

Hitting a surface made of stiff materials like concrete or asphalt would shorten the stress generation time period (i.e. the duration of the stress), creating a significantly large maximum impulse force. But this force can be reduced by using materials called shock absorption materials that extend the duration of the stress (see Figure A). The figure below shows deformation and stress generation in shock absorption materials(see Figure B). - A⇒B⇒C: This process shows a falling object colliding with shock absorption material, causing the material to experience compressive deformation.

A represents the collision, B represents maximum impulse force, and C represents maximum deformation. - C⇒D: This process shows a falling object passing the lowermost point (i.e. maximum deformation) and getting pushed back by the repulsive force of the shock absorption material. D represents a point to which the object bounced off and away from the shock absorption material.

- Scaling down the force at B, the maximum impulse force, is important in not letting the falling object breaking from impulse force. The impact energy from the falling object gets converted into the shock absorption material’s deformation energy, equivalent to Wa+Wb indicated in Figure B. This means the key to reducing maximum impulse energy is selecting a shock absorption material that maximizes the sum of Wa and Wb.

Applications

Sports

Products

- Gel Sheets

(θ-Gel) - These highly durable silicone shock absorption sheets are the perfect combination of softness and strength.

| Product | GEL-Type | Options |

|---|---|---|

| θ-Gel (Theta-Gel) | Theta-7 | GEL with PET Film with Adhesive Tape with Powder Non-tacky |

| Theta-5 | ||

| Theta-6 | ||

| Theta-8 |

Product Details

Product Details

- Gel Tapes, Gel Chips (GT・GC)

- GEL Tape and GEL Chips are cuttable shock absorbent sheets that are adhesive on one side for easy application.

| Product | Size(mm) | Thickness(mm) |

|---|---|---|

| Gel Tapes (GT) | L:1,000 W:10/20 | t1/t2/t3 |

| Gel Chips (GC) | L:10/15/20 W:10/15/20 | t3/t5/t10 |

Product Details

Product Details

- Foam-Type Gels(NP)

- NP GEL is a light and durable silicone foam material.

| Product | Size(mm) | Thickness(mm) |

|---|---|---|

| NP Gel (Green) | L:2,000 W:450 | t3 |

| NP Gel (White) | L:1,000 W:300 | t6 |

Product Details

Product Details

This New Shock-Absorbing Gel Can Withstand Supersonic Impacts | Smart News

The new hydrogel might someday lead to shock-absorbing smartphone cases, as well as better bullet-proof vests and space equipment.

Marco Verch Professional Photographer via Flickr under CC BY 2.0

Existing body armor can stop shrapnel and bullets from reaching the person wearing it. But it doesn’t absorb a projectile’s kinetic energy, meaning the wearer can still get injured from the force of the blow. Beyond that, most body armor—made from heavy, bulky layers of ceramic and fibers—is only good once, as a strike from a projectile can compromise its structural integrity.

Now, researchers at the University of Kent in England may have developed a promising new solution to these problems, providing a potential path forward for improved bullet-proof clothing and more resilient space exploration equipment. Using a protein called talin, which is found in human cells, scientists have created a novel material that can absorb the impact of projectiles—even those flying faster than the speed of sound.

Talin helps cells get around inside the body and may also play a role in memory storage. But notably, it acts as a “natural shock absorber,” says lead researcher Benjamin Goult, a biochemist at the University of Kent, in a statement.

But notably, it acts as a “natural shock absorber,” says lead researcher Benjamin Goult, a biochemist at the University of Kent, in a statement.

Talin molecules contain structures that, when put under tension, unfold and stretch out. Once the tension is released, they fold back up again. They can do this shock-absorbing maneuver over and over without harming the cell.

By adapting the talin molecule and linking large numbers of them together, the researchers created a gel-like material called a hydrogel that maintained the natural protein’s shock-absorbing properties.

“Mother Nature is an amazing designer, and it’s always interesting when scientists and engineers can find new applications for structures that are everywhere around us,” Eric S. Hintz, a historian at the Lemelson Center for the Study of Invention and Innovation at Smithsonian’s National Museum of American History who was not involved in the project, tells Smithsonian magazine in an email. The new hydrogel, he says, “sounds very promising..jpg) ”

”

To test the technology’s effectiveness, scientists placed the gel atop an aluminum plate and fired tiny basalt particles and larger bits of aluminum at it. These small projectiles traveled at speeds of more than 3,350 miles per hour—three times faster than a bullet fired from a handgun, as Andrew Liszewski notes for Gizmodo. The hydrogel absorbed the shock of the projectiles, successfully protected the aluminum plate and captured the particles without destroying them.

The team ran the same experiment with a control gel. When pelted with a supersonic particle, the control gel allowed it to pass through and bore a crater in the aluminum plate behind the gel. The projectile was also destroyed in the process. The researchers published their findings on the preprint server bioRxiv; the paper has not yet been peer-reviewed.

“Our material perfectly caught and ‘cuddled’ with the projectile … keeping it beautifully preserved,” says paper co-author Jennifer Hiscock, a supramolecular chemist at the University of Kent, to New Scientist’s Carissa Wong.

The researchers patented the material and are now conducting even more tests with partners in the aerospace and defense industries. Talin may someday help protect soldiers heading into battle and spacecraft traveling through fast-moving dust and debris in space.

In the realm of body armor, one of the talin gel’s strengths is that it can stop a bullet without destroying it, Hintz says. “You can imagine how important this would be for law enforcement officers, who could remove the preserved bullet from a [talin] vest, then run forensics to match the bullet to the shooter’s gun,” he says. “In addition, the … material reforms after initial impact, meaning you could potentially reuse a [talin] vest after it was hit.”

As for aerospace, the industry currently uses aerogels, or low-density gels that had the liquid removed from them, to capture flying projectiles. Aerogels achieve this, in part, by turning the projectile’s energy into heat. “This can melt the aerogel itself, rendering it useless for the next impact,” Hintz says. “It appears that the [talin materials] do not heat up as much. So … a [talin]-based outer layer on a spaceship would potentially remain intact, even after multiple high-speed strikes from micro-meteorites or space debris. That would make astronauts feel more confident in the structural integrity of their spacecraft.”

“It appears that the [talin materials] do not heat up as much. So … a [talin]-based outer layer on a spaceship would potentially remain intact, even after multiple high-speed strikes from micro-meteorites or space debris. That would make astronauts feel more confident in the structural integrity of their spacecraft.”

The new material may also be useful for capturing space debris—without destroying it—for further study.

Consumers may also one day reap the shock-absorbing benefits of talin in their running shoes, vehicle bumpers and cell phone cases, reports IFLScience’s Laura Simmons.

Get the latest stories in your inbox every weekday.

Recommended Videos

promotional absorb shock sports gel silicone insoles,absorb shock sports gel silicone insoles wholesale

Products

/Products

/Sports insole

/Gel insole

absorb shock sports gel silicone insoles

| *Product code: | LZS-18 |

|---|---|

| *Port: | XIAMEN |

| *Payment: | T/T, L/C |

| *Color: | custom |

| Lead time: | 20-25 days after deposit |

| Brand: | Lizeng |

Product Details

shock absorb sports gel silicone foot insole design with soft silicone and hard TPR arch support. The softness of silicone provides maximum comfort for the feet. Additional pads on the heel and forefoot provide better cushioning and protection. The hard TPR arch support helps to control the position of the feet, make sure the foot to correct the position, can grain the feet well and relieve stress, also anti-fatigue. The suede upper of the boot is skin friendly. The trim line on the back can help you cut your size easily.

The softness of silicone provides maximum comfort for the feet. Additional pads on the heel and forefoot provide better cushioning and protection. The hard TPR arch support helps to control the position of the feet, make sure the foot to correct the position, can grain the feet well and relieve stress, also anti-fatigue. The suede upper of the boot is skin friendly. The trim line on the back can help you cut your size easily.

All these features make this insole perfect for sports shoes, running shoes.

- item: shock absorb sports gel silicone foot insoles

- function: absroption shock and comfort

- material : suede fabric & silicone TPR

- thickness: front 4mm, back 6mm

- size range : men and women

- color: gray / customize

- printing logo: available

- sample time : 1-7 days

- standard packing : 1 pair per poly bag, 100 pairs per carton

- export carton Size: 40*40cm*70cm/as your required

- monthly capacity: 700,000 pairs

- MOQ: 1000 pairs

- size combination: available

- service: 9 0066 OEM, design, customer label service

Standard packing is pp bag with export packing. Custom packaging too. Below are the custom packages we offer.

Custom packaging too. Below are the custom packages we offer.

For shipping, usually is 20-30 days, please feel free to contact us for more details.

Next :

comfort gel silicone insoles supplier

Message

Related products

massaging gel inserts for running shoes

Best soft impact insoles for shoes

two colors sport insoles for running

two color gel heel cup pain relief

T-Shock wrap in Khanty-Mansiysk – Primavera

Italian T-shock technology helps to lose weight one size at a time, especially in “problem” zones

Do you think this is just a publicity stunt?

And in order to remove at least a couple of centimeters, drastic measures are needed?

Italian T-shock technology helps to lose weight one size at a time, especially in “problem” areas. Because you get rid of swelling and flabbiness of the skin in a natural way, without causing excessive stress to the body, as with strict diets and heavy physical exertion.

Because you get rid of swelling and flabbiness of the skin in a natural way, without causing excessive stress to the body, as with strict diets and heavy physical exertion.

As a result, according to the results of measurements at 40 points, after one wrap, you can lose up to 80 cm in volume. Therefore, even if you have tried many weight loss technologies, you should pay attention to this one.

Secrets of special effectiveness T-shock

Secret No. 1 – Gel. Contains 31 ingredients, and they are selected in such a way that they quickly penetrate the skin and deeper tissues.

Secret #2 – Bandaging . The bandages are impregnated with Dead Sea salts, wrapping them makes the smallest vessels work, and volumes decrease.

Secret #3 – Temperature. When heated, the blood flow is accelerated, the active substances penetrate the cells faster and begin to work while you relax.

All these components lead to a quick and impressive result – to become slimmer when there is no time, but you need to look “at 100”.

How does the 4 in 1 treatment work?

During the procedure and a few days after it, simultaneously pass:

Detox – that is, your body gets rid of “processed products” faster. Vessels dilate, blood and lymph flow increases, toxins leave the cells and are excreted naturally.

Lymphatic drainage – that is, excess fluid and metabolic products – everything that causes trouble in the form of edema leaves the intercellular space more actively. Volumes go away, plus, and it is easier for the heart and blood vessels to work.

Lipolysis – that is, the breakdown of fats under the action of active substances from the gel and the temperature factor. The metabolism in fat cells increases, and excess deposits, with which many struggle unsuccessfully, go away faster.

Lifting – under the action of the “temperature + Dead Sea salts + active substances from the gel” complex, renewal processes are activated in the skin, youth proteins are produced more intensively, it becomes more hydrated, smooth and toned.

Why should you book a T-shock at Primavera in the near future?

A visible difference – even one session already gives a noticeable result and is suitable for emergency weight loss. The effect of the course of procedures is comparable to a strict diet combined with significant exercise. Only without stress.

Complex effect. Only 2 hours in a comfortable environment – and edema, toxins, heaviness in the legs disappear, cellulite decreases, and with them – stress and irritability. Lightness, calmness and good mood come.

Feel better. The procedure gives not only harmony, but positive changes in health – improves skin elasticity, normalizes water-salt balance, renews cells, keeping youth. With complete security.

Strengthening the result — T-shock wrap enhances and accelerates the effect of other “weight loss” procedures – diet, sports, as well as hardware techniques – dermotonia and LPG, allowing you to achieve the desired faster and more comfortably.

So, if you are going on vacation, to an important event, you have a significant event coming up in your life, you are actively losing weight or you just want to quickly get in shape and look great – try the T-shock wrap.

5 steps for your slimness – how the procedure is carried out

Stage 1 measurements. The specialist measures volumes in 40 zones with a centimeter tape and records the results.

Stage 2 preparation . The skin is thoroughly cleansed, and a special gel is applied with light massage movements.

Stage 3 wrap. Special bandages impregnated with salts are wrapped around the body and limbs, then covered with a special film and a blanket.

Stage 4 rest. You lie quietly for about 90 minutes, relaxing in warmth and comfort, and at this time, excess volumes go away.

Stage 5 end. The blanket, film and bandages are removed, you take a shower, a special lifting gel is applied to the body.

Next – control measurements, and the impression of the result.

Next – control measurements, and the impression of the result.

We know everything about body wraps . Because we have been making several of them every day for more than a year. As soon as the T-shock wrap became available in Russia, we included it in our “must have” and actively use it to transform our clients.

Responsible for security. Because we use proven technology, and only original drugs, directly from the manufacturer. And of course, we strictly follow the protocol, examine before the procedure and identify contraindications.

We care about comfort. Before the procedure, we clarify your expectations and answer any remaining questions. We work carefully so that you experience only pleasant sensations.

We select combinations to achieve maximum effect. The specialist will tell you how to behave after the procedure in order to prolong the effect, and also, at your request, will select hardware techniques that will allow you to achieve what you want – get rid of excess, tighten the skin and maintain ideal forms.

Hitting a surface made of stiff materials like concrete or asphalt would shorten the stress generation time period (i.e. the duration of the stress), creating a significantly large maximum impulse force. But this force can be reduced by using materials called shock absorption materials that extend the duration of the stress (see Figure A). The figure below shows deformation and stress generation in shock absorption materials(see Figure B).

Hitting a surface made of stiff materials like concrete or asphalt would shorten the stress generation time period (i.e. the duration of the stress), creating a significantly large maximum impulse force. But this force can be reduced by using materials called shock absorption materials that extend the duration of the stress (see Figure A). The figure below shows deformation and stress generation in shock absorption materials(see Figure B).

Next – control measurements, and the impression of the result.

Next – control measurements, and the impression of the result.