How to properly string and square your vehicle. What are the steps for aligning a car using the stringing method. Why is vehicle alignment important for performance and safety.

Understanding the Basics of Vehicle Alignment

Vehicle alignment is a crucial aspect of automotive maintenance that ensures optimal performance, safety, and tire longevity. Proper alignment involves adjusting the angles of the wheels to match the manufacturer’s specifications. One effective method for checking and adjusting alignment is the stringing technique.

Why is Vehicle Alignment Important?

Proper alignment offers several benefits:

- Improved handling and stability

- Even tire wear, extending tire life

- Better fuel efficiency

- Reduced strain on suspension components

- Enhanced safety, especially during cornering and braking

Preparing for the Stringing Process

Before beginning the stringing process, it’s essential to ensure your vehicle is in the proper condition for alignment.

/pull-wire-through-conduit-3969936-hero-cea39ec1798140c59beec45e6003cbbd.jpg)

Pre-Alignment Checklist

- Verify the frame is undamaged and straight

- Check tire pressure and adjust if necessary

- Inspect suspension components for wear or damage

- Ensure the vehicle is on a level surface

Is a special alignment rack necessary for the stringing method? While professional alignment racks offer precision, the stringing technique can be performed using basic tools and a level surface, making it accessible for DIY enthusiasts.

Step-by-Step Guide to Stringing Your Vehicle

Follow these steps to string and square your vehicle:

- Position the vehicle on a flat, level surface

- Start with the right side of the vehicle

- Use stable items (e.g., jackstands) at the right front and rear

- Run a string along the right side at frame height

- Align the right side tires parallel to the string

- Measure the distance from the right rear frame to the string

- Measure the right front frame to the string, ensuring equal distances

- Adjust until the string is parallel to the frame

- Measure from wheel hubs to the string in front and rear

- Repeat the process on the left side

Choosing the Right String

What type of string works best for vehicle alignment? While any string can work, many professionals prefer using high-strength fishing line due to its minimal stretch and durability. Aim for a line with at least 50-pound test strength to ensure it remains taut during the alignment process.

Common Challenges in DIY Vehicle Alignment

While the stringing method can be effective, it’s not without its challenges. Here are some common issues DIY enthusiasts might encounter:

- Difficulty maintaining string tension

- Inaccurate measurements due to uneven surfaces

- Misinterpreting alignment readings

- Lack of specialized tools for precise adjustments

How can these challenges be overcome? Patience and attention to detail are key. Double-check all measurements, use a level to ensure your work surface is flat, and consider investing in basic alignment tools like a camber gauge to complement the stringing method.

Advanced Alignment Techniques and Tools

While the basic stringing method is effective for many vehicles, some situations may require more advanced techniques or specialized tools.

Laser Alignment Systems

Laser alignment systems offer increased precision and ease of use compared to traditional string methods. These systems project laser lines onto targets attached to the wheels, allowing for quick and accurate measurements of toe, camber, and caster angles.

Computer-Aided Alignment

Modern alignment systems often incorporate computer technology to provide real-time measurements and adjustments. These systems can quickly identify alignment issues and guide technicians through the correction process.

Are advanced alignment tools worth the investment for DIY enthusiasts? For occasional use, the stringing method may suffice. However, those who frequently work on vehicles or demand professional-level precision may find the investment in more advanced tools worthwhile.

Understanding Alignment Angles

To fully grasp the concept of vehicle alignment, it’s crucial to understand the three primary alignment angles:

Camber

Camber refers to the inward or outward tilt of the wheel when viewed from the front of the vehicle. Proper camber ensures even tire wear and optimal handling.

Caster

Caster is the angle of the steering axis when viewed from the side of the vehicle. It affects steering feel and straight-line stability.

Toe

Toe describes the inward or outward angle of the wheels when viewed from above. Correct toe alignment is crucial for straight-line stability and even tire wear.

How do these angles interact to affect vehicle performance? Each angle plays a unique role in vehicle handling and tire wear. For example, excessive negative camber can improve cornering performance but may lead to uneven tire wear. Balancing these angles according to manufacturer specifications is key to achieving optimal performance and longevity.

Maintaining Proper Alignment

Once you’ve achieved proper alignment, it’s important to maintain it. Several factors can affect alignment over time:

- Hitting potholes or curbs

- Worn suspension components

- Accidents or collisions

- Normal wear and tear

Signs of Misalignment

Be aware of these indicators that your vehicle may need realignment:

- Uneven or rapid tire wear

- Vehicle pulling to one side while driving

- Off-center steering wheel when driving straight

- Squealing tires, especially during turns

How often should vehicle alignment be checked? While there’s no universal schedule, it’s generally recommended to have alignment checked annually or every 12,000-15,000 miles. However, if you notice any signs of misalignment, it’s best to have it checked promptly to prevent further issues.

The Impact of Alignment on Tire Life and Performance

Proper alignment is crucial for maximizing tire life and maintaining optimal vehicle performance. Misalignment can lead to a host of issues that not only affect your driving experience but also your wallet.

Tire Wear Patterns

Different alignment issues can cause distinct wear patterns on your tires:

- Feathering: Often caused by toe misalignment

- Camber wear: Excessive inward or outward tilt

- Center wear: Usually due to overinflation

- Edge wear: Can be caused by underinflation or suspension issues

How does proper alignment extend tire life? By ensuring even contact with the road surface, correct alignment distributes wear evenly across the tire tread. This can significantly extend tire life, potentially doubling the lifespan of your tires compared to a misaligned vehicle.

Performance Benefits

Beyond tire wear, proper alignment offers several performance benefits:

- Improved fuel efficiency

- Better handling and stability

- Reduced driver fatigue

- Enhanced safety in various driving conditions

Can proper alignment improve fuel economy? Yes, when your wheels are properly aligned, they offer less rolling resistance, which can lead to improved fuel efficiency. While the gains may seem small, they can add up to significant savings over time.

DIY vs. Professional Alignment: Pros and Cons

While DIY alignment methods like stringing can be effective, there are pros and cons to consider when deciding between a DIY approach and professional alignment services.

DIY Alignment

Pros:

- Cost-effective

- Can be done at home

- Provides a learning experience

- Useful for quick checks between professional alignments

Cons:

- May lack precision of professional equipment

- Time-consuming for inexperienced individuals

- Limited ability to make fine adjustments

- Risk of incorrect alignment if not done properly

Professional Alignment

Pros:

- High precision measurements

- Access to specialized equipment

- Expertise in diagnosing and correcting alignment issues

- Often includes a warranty on the work

Cons:

- More expensive than DIY methods

- Requires scheduling and potentially being without your vehicle

- Quality can vary depending on the shop and technician

When should you opt for professional alignment over DIY methods? If you’re experiencing persistent alignment issues, have recently replaced major suspension components, or simply want the assurance of professional precision, it’s best to seek professional alignment services. DIY methods are most suitable for basic checks and minor adjustments between professional services.

Alignment Considerations for Different Vehicle Types

Alignment needs can vary significantly depending on the type of vehicle. Understanding these differences is crucial for maintaining optimal performance and safety.

Passenger Cars

Most passenger cars require relatively straightforward alignment procedures, focusing on the front wheels for vehicles with front-wheel drive. Key considerations include:

- Toe adjustment for even tire wear

- Camber settings for optimal handling

- Caster angle for steering feel and stability

SUVs and Trucks

Larger vehicles like SUVs and trucks often have more complex alignment needs:

- Four-wheel alignment is often necessary

- May require specialized equipment for lifted vehicles

- Consideration of load-carrying capacity on alignment settings

Performance Vehicles

High-performance cars may benefit from custom alignment settings:

- Aggressive camber settings for improved cornering

- Precise toe adjustments for optimal handling

- Consideration of track vs. street use

How do alignment needs differ for electric vehicles? While the basic principles remain the same, electric vehicles often have unique weight distributions due to battery placement. This can affect ideal alignment settings, particularly in terms of camber and toe angles. Additionally, the instant torque delivery of electric motors can amplify the effects of misalignment, making proper alignment even more crucial for these vehicles.

The Future of Vehicle Alignment Technology

As automotive technology continues to advance, so too does the field of vehicle alignment. Several emerging trends are shaping the future of alignment technology and practices.

Automated Alignment Systems

Advancements in robotics and AI are leading to the development of fully automated alignment systems. These systems can potentially perform alignments with minimal human intervention, offering benefits such as:

- Increased precision and consistency

- Faster alignment times

- Reduced labor costs for service centers

Integrated Alignment Sensors

Some manufacturers are exploring the integration of alignment sensors directly into vehicles. This could allow for:

- Real-time alignment monitoring

- Early detection of alignment issues

- Potential for self-adjusting suspension systems

Virtual Reality and Augmented Reality in Alignment

VR and AR technologies are finding applications in alignment procedures:

- Enhanced visualization of alignment angles

- Interactive training for technicians

- Improved accuracy in DIY alignment methods

How might these advancements change the landscape of vehicle maintenance? As alignment technology becomes more sophisticated and integrated into vehicles, we may see a shift towards more frequent, preventative alignment checks. This could lead to improved overall vehicle performance, safety, and longevity. However, it may also require technicians and DIY enthusiasts to continually update their skills and tools to keep pace with these advancements.

Legal and Safety Considerations in Vehicle Alignment

Proper vehicle alignment is not just a matter of performance and maintenance; it also has significant legal and safety implications. Understanding these aspects is crucial for both vehicle owners and technicians.

Safety Implications

Misaligned vehicles can pose several safety risks:

- Reduced handling and stability

- Increased stopping distances

- Potential for unexpected vehicle behavior in emergency situations

- Increased driver fatigue due to constant steering corrections

Legal Requirements

While specific laws vary by jurisdiction, many areas have regulations related to vehicle alignment:

- Annual vehicle inspections may include alignment checks

- Commercial vehicles often have stricter alignment requirements

- Severe misalignment can result in failing safety inspections

Liability Considerations

For those performing alignments, whether professionally or as a DIY enthusiast, there are liability considerations to keep in mind:

- Responsibility for ensuring proper alignment

- Potential liability in case of accidents caused by misalignment

- Importance of documenting alignment procedures and measurements

What are the potential consequences of driving a severely misaligned vehicle? Beyond the safety risks, driving a severely misaligned vehicle can lead to rapid and uneven tire wear, reduced fuel efficiency, and premature wear of suspension components. In some cases, it could even result in loss of vehicle control, potentially leading to accidents. From a legal standpoint, if an accident is determined to be caused by negligent maintenance, including severe misalignment, the vehicle owner could face liability issues.

Understanding these legal and safety aspects underscores the importance of regular alignment checks and proper maintenance. Whether you’re a DIY enthusiast or rely on professional services, ensuring your vehicle is properly aligned is not just about performance and longevity — it’s a crucial aspect of responsible and safe vehicle ownership.

How to String and square your vehicle

How to String a car and square your vehicle

This is one of the most common questions we receive. Some people will say it’s easy and some feel it’s a pain in the **s. We have a few quick tips for you and a great video by Jeff Ford from Auto Resto Mod. Jeff is using a QuickTrick while stringing the car, but you don’t have to have one of our tools to get it done!

First, your frame has to be undamaged for any true measurement and alignment. So, if your frame is bent, stop here and get her straight before anything else.

The purpose is to square the rear and with the front.

Your right side tires will carry the brunt of the force, so we typically start with the right side.

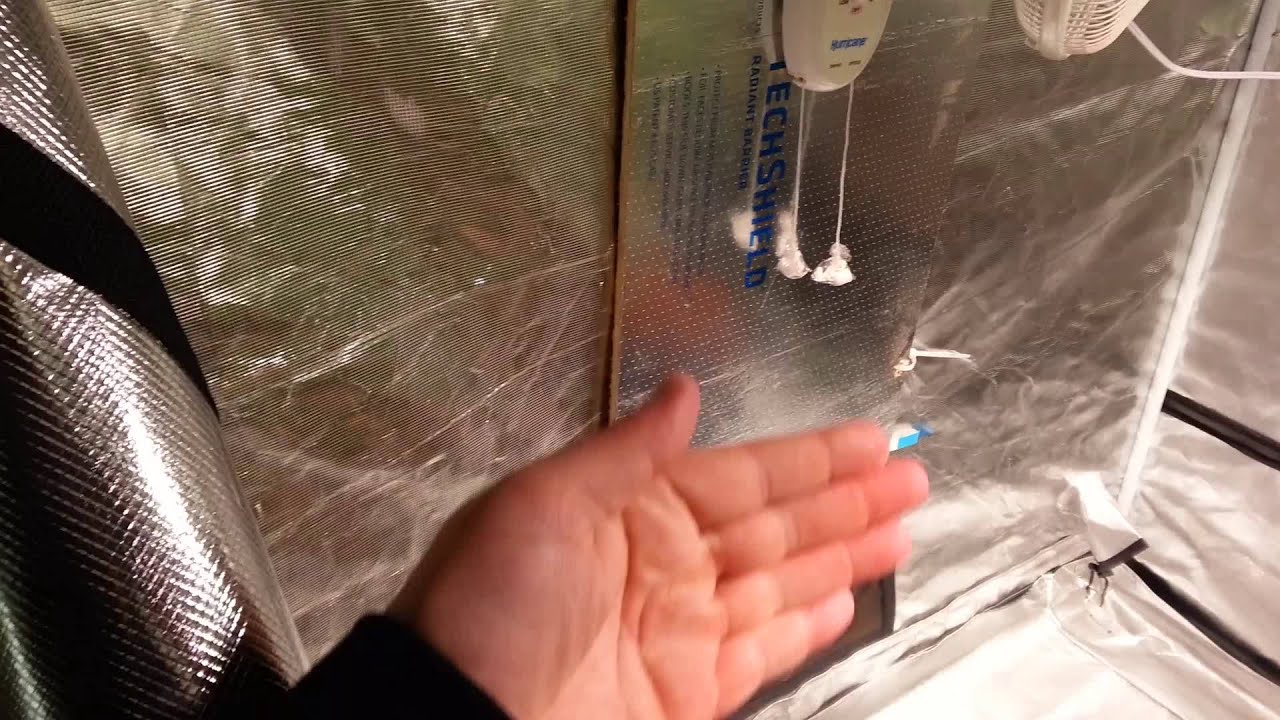

You can use any stable items on the right front and right rear to start. We use to use jackstands. When placing your string (Any string will do and even fish line) aim to have it at frame height. This will prevent any extreme camber from interfering with your string line up.

Line up your right side tires

Measure your right rear frame distance to the string

Measure your right front frame to the string (ensure you have equal distance between the string and frame) Keep it close, but not too close. 5-6″ is a good base.

If your string is parallel to the frame, your front and rear sidewalls of the tire should be parallel as well.

Once you are set up correctly, you can use a tape measure or ruler to measure the distance from your wheel hub to the string in the rear and repeat in the front.

If you are fraction off, you should be good to go. Now repeat on the left.

Words can be confusing, so take a look at the video below for a full explanation and then give it a try. If you need some help or have any questions, just give us a call at 205-475-2419 x102

Starts at Stringing the car:

You can pick up a lifetime membership of the online QuickSpecs Alignment Database here: QuickSpecs

(Visited 4,712 times, 1 visits today)

How to Decode Tire Size and Other Data

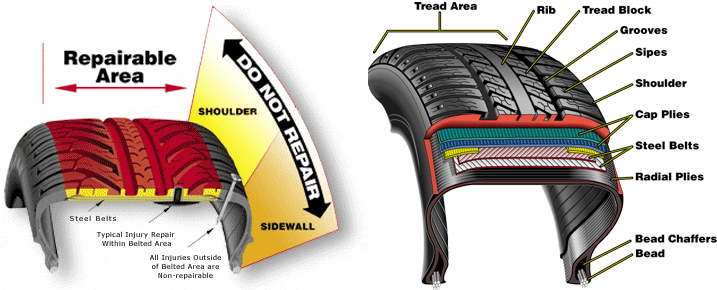

Size: P235/65R17 is a common one. P denotes passenger-car tire. Some may start with an LT prefix, used on heavy-duty trucks. The number 235 is the cross-section width in millimeters, and 65 is the ratio of sidewall height to cross-section width (65 percent). R means radial-ply construction, and 17 is the wheel diameter, in inches.

P denotes passenger-car tire. Some may start with an LT prefix, used on heavy-duty trucks. The number 235 is the cross-section width in millimeters, and 65 is the ratio of sidewall height to cross-section width (65 percent). R means radial-ply construction, and 17 is the wheel diameter, in inches.

Load index: This number is based on the weight the tire can safely carry. You’ll find it after the tire size; the 103 load index for most of the tires we’ve recently tested correlates to 1,929 pounds. Choose tires with a load index at least as high as the one that’s listed on your vehicle’s placard or owner’s manual.

Speed rating: This letter denotes the maximum sustainable speed and is found directly after the load index. For S-speed-rated tires, it’s 112 mph; for T, 118 mph. Speed ratings for other tires include Q, 99 mph; H, 130 mph; V, 149 mph; W, 168 mph; Y, 186 mph; and ZR, more than 149 mph. While such speeds may seem wildly impractical, tires with higher speed ratings tend to provide better handling at legal speed limits. Choose tires that have a speed rating at least as high as the one specified on your vehicle’s placard.

Choose tires that have a speed rating at least as high as the one specified on your vehicle’s placard.

Treadwear rating: Grades for our light-truck tires ranged from 500 to over 800. In theory, a tire graded 400 should last twice as long as one graded 200. But the tire makers certify that the tires meet the wear ratings. The better gauge is to refer to our tread life predictions on the tire model pages, based on our extensive testing.

Traction and temperature scores: These scores denote a tire’s wet-stopping ability and temperature resistance. For traction, AA is best and C is worst. For temperature resistance, scores range from A (best) to C.

Maximum pressure: This is a tire’s maximum safe air pressure, given in pounds per square inch. But that doesn’t mean you should inflate your tires to that pressure, because automakers typically recommend an inflation pressure well below the tire’s maximum air pressure. Follow the advice on the vehicle’s placard.

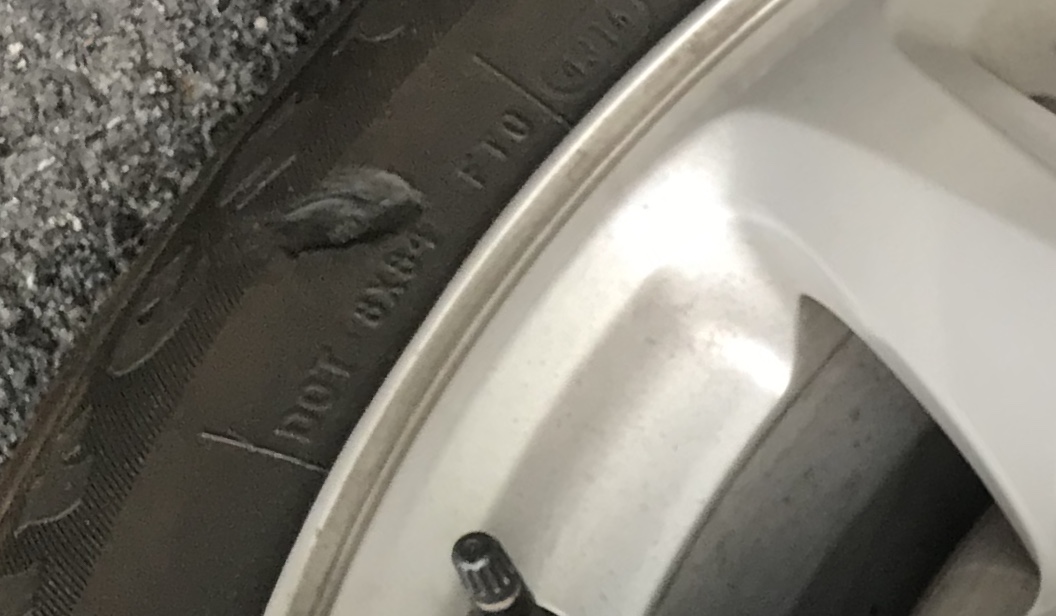

When the tire was made: Every tire has a Department of Transportation (DOT) number after the letters on the sidewall. The last four digits determine the week and year the tire was made; for example, the digits 2321 would signify that the tire was made during the 23rd week of 2021. Don’t buy tires more than a couple of years old. Beyond wearing out, tires can age out. Some automobile makers recommend replacing tires at six years, but if there is no recommendation, we recommend replacement at 10 years, as some tire makers suggest.

ZZ Top’s Billy F Gibbons premieres Christmas song ‘Jingle Bell Blues’

A blues reworking of the festive staple

Author: Scott ColothanPublished 9th Nov 2021

Last updated 9th Nov 2021

With Christmas just over six weeks away, ZZ Top legend Billy F Gibbons has premiered his festive song ‘Jingle Bell Blues.’

As the title suggests, ‘Jingle Bell Blues’ is a blues reworking of the 19th Century yuletide staple ‘Jingle Bells’ that’s delivered in Billy’s trademark rock drawl and features epic guitar and harmonica solos from the music legend.

Lyrically, Billy changes some of the words too as he sings “bells on hot rods ring” and “drop-top sleigh.”

Listen to Billy F Gibbons’ ‘Jingle Bell Blues’:

Produced by Billy F Gibbons and Mike Fiorentino and recorded in Nashville, Tennessee in June 2021, ‘Jingle Bell Blues’ is available to buy digitally and as a lavishly packaged 45 RPM single pressed on red translucent vinyl.

The visually striking artwork features a stack of Cadillac Fleetwood Broughams in the shape of a Christmas tree.

Very much a standalone single, the vinyl flip side is an etched surface that replicates the sidewall of a bias ply tire with raised letters spelling out the song title and Billy’s name.

The red vinyl version also comes with a Billy F Gibbons centre hole adapter making it easy to play on any standard turntable.

Billy F Gibbons – Jingle Bell Blues

“I suppose it could have been produced with a small hole and we wouldn’t have had to deal with the adapter, but this is, at its essence, a juke box record. It was even mixed with that in mind,” comments Billy F Gibbons.

It was even mixed with that in mind,” comments Billy F Gibbons.

“Around Christmas, it always seems that there are five to ten holiday selections listed in the lower right corner of a typical juke box in a typical juke joint, the song titles and artist names printed on wreath-bedecked title strips.

“Our hope is for ‘Jingle Bell Blues’ to be one of those records. Bing Crosby, David Bowie, Elvis, Brenda Lee, Jose Feliciano, Otis Redding, Mariah Carey, Nat King Cole, Gene Autry, and not forgetting Adam Sandler, need some company and we’d be thrilled to provide it in the spirit of the season.”

Billy F Gibbons’ ZZ Top band mate Dusty Hill passed away in July. In keeping with Dusty’s wishes, ZZ Top have continued as an active band.

The wildest guitars in rock, including ZZ Top’s Spinning Furs:

ZZ Top’s Spinning Fur Guitars

Of course, we couldn’t make a feature about outrageous guitars without ZZ Top’s iconic Spinning Fur Guitars. Made from real sheepskin, the twirling guitar for Billy Gibbons and bass for the late-great Dusty Hill were both created by Dean Zelinsky of Dean Guitars and they famously first appeared in the music video to ‘Legs’ in 1983. Billy Gibbons says: “The guitars are attached to our belt buckles. It’s a rotary electrical contact and strap mount. A hole is bored in the back of the guitar at the balancing point and the device is mounted there. Oh yeah, you gotta look out for that thing coming back around. Get your head and neck out of the way or else it’ll say hello in an unfashionable fashion.”

Billy Gibbons says: “The guitars are attached to our belt buckles. It’s a rotary electrical contact and strap mount. A hole is bored in the back of the guitar at the balancing point and the device is mounted there. Oh yeah, you gotta look out for that thing coming back around. Get your head and neck out of the way or else it’ll say hello in an unfashionable fashion.”

Rick Nielsen’s Five Neck

Cheap Trick’s Rick Nielsen with his iconic Five Neck guitar at a concert in 2012. Tired of performing with multiple guitars at concerts, Nielsen joined forces with guitar makers Hamer way back in 1981 to combine all of his guitar playing needs into one glorious instrument. The guitar was created by fusing the bodies of five Hamer Specials together and there have been several incarnations of the Five Neck. Hamer founder Frank Untermeyer said: “Rick’s out of his mind, but in a wonderful way.”

Michael Angelo Batio’s Double-Guitar

Famous for his technical prowess and genre-straddling playing style, American heavy metal guitarist Michael Angelo Batio personally invented the Double Guitar – a V-shaped, twin-neck guitar that Batio plays both left and right-handed.

Bo Diddley’s Square Guitar

The blues rock legend made his first square guitar aged 17 as he couldn’t afford to buy an electric guitar. He explained to Vintage Guitar in 1997: “(the guitar’s) pickup was the part of a Victrola record player where the needle went in. I clamped it to the metal tailpiece to pick up the vibrations.” The original guitar was sadly stolen, but in 1958 Gretsch later made a version with DeArmond pickups. Pictured is Bo proudly clutching it in 1959.

John Paul Jones’ Triple Neck Arch-Top Mandolin

The Led Zeppelin multi-instrumentalist’s unique Triple Neck Arch-Top Mandolin was created by luthier Andy Manson in the mid-1970s and swiftly became a mainstay of Led Zep concerts. The famous electroacoustic instrument boasts 8-string mandolin, 12-string guitar, and 6-string guitar necks. Manson said decades later: “I designed and made the triple neck and took it to John’s house. I said, ‘Hi John I thought this might interest you.’ He said, ‘Wow, yes indeed, I can’t wait to see Pagey’s face when I walk on stage with this!’ It cost £400 and I skipped off down the road feeling like a millionaire. “

“

Prince’s Love Symbol Guitar

Pictured is Prince with a purple Love Symbol guitar in at The Grammy Awards in February 2004 where he performed his anthem ‘Purple Rain’. Prince’s range of Love Symbol guitars were based on the shape of the unpronounceable symbol he adopted as his moniker in 1993 in an act of rebellion against his record label, Warner Bros.

Steve Vai’s Ibanez Triple-Neck Red Heart Guitar

The virtuoso musician designed his Ibanez custom built triple neck with heart-shaped body guitar in 1988 as he wanted something “eye-catching” for the video to David Lee Roth’s ‘Just Like Paradise’. Steve Vai himself admits the guitar is “odd” and there have been three incarnations of the instrument – the original Red Heart, a spare called Red Heart II and a Purple Heart. Steve used the latter guitar on the Ultra Zone tour and wrote the song ‘Fever Dream’ with it.

Pat Metheny’s Pikasso Guitar

Canadian master luthier Linda Manzer created The Pikasso Guitar in 1984 when jazz artist Pat Metheny requested a guitar that had “as many strings as possible. ” The completely unique resulting instrument has 42 strings arranged in four different string sections.

” The completely unique resulting instrument has 42 strings arranged in four different string sections.

Gene Simmons’ Axe Bass

Back in 1978, Gene Simmons joined forces with master luthier Steve Carr to create a unique bass guitar shaped like an axe that would suit his on-stage Demon persona perfectly. The resulting weapon-like instrument – aptly entitled The Axe Bass – is a true classic. Now a running trademark for KISS, there have been a number of incarnations of the Axe Bass including the pictured Cort GS-Axe-2 bass guitar Gene is aggressively clutching at the 2010 NAMM Show.

Michael Anthony’s Jack Daniel’s Bass

Michael Anthony’s now famous Jack Daniel’s Bass was created back in 1983 while Van Halen were working on their musical masterpiece ‘1984’. Anthony’s guitar tech and good friend Kevin ‘Dugie’ Dugan was charged with creating the bass, which was made with the blessing of Jack Daniel’s on one condition – that only three guitars were made. One is on display at the Rock and Roll Hall of Fame museum, one is in storage and one is still used by Michael Anthony to this very day.

John Entwistle’s Buzzard Bass

The Ox played the iconic Buzzard Bass for the final 17 years of his career from 1985 to his untimely passing in 2002. Entwistle worked with Hans Peter Wilfer, founder of Warwick basses, on the striking bass and the pair came up with the moniker Buzzard after imbibing numerous drinks at London nightclub Maggie’s – neither could remember who first suggested the name. After they picked the name, the headstock was tweaked to resemble the beak of a buzzard.

John Fogerty’s Baseball Bat Guitar

Crafted by Philip Kubicki, John Fogerty named his unique guitar ‘Slugger’ in homage to the Louisville Slugger baseball bat. Created in 1985 when his album ‘Centerfield’ came out, Fogerty donated the instrument to the National Baseball Hall of Fame and Museum in 2010. Fogerty said at the time: “That guitar means a lot to me. It’s symbolizes two of my great loves, baseball and the guitar. When ‘Centerfield’ came out, it was after a long break and was such an important album to me on many levels. The lessons of baseball – the hits, the misses, the triumphs, and the losses – were something that I could really relate to in my life. So I got this idea to make a baseball bat guitar and of course, it had to be a Louisville Slugger.”

The lessons of baseball – the hits, the misses, the triumphs, and the losses – were something that I could really relate to in my life. So I got this idea to make a baseball bat guitar and of course, it had to be a Louisville Slugger.”

Ian Hunter’s Maltese Cross Guitar

Ian Hunter’s Maltese Cross Guitar was designed by American luthier Harvey Thomas in the 1970s. Despite its iconic status, Hunter says the guitar looked good but didn’t sound great and he sold it a number of years ago. Def Leppard and Planet Rock’s Joe Elliott had two new Maltese Crosses made for Hunter’s 70th birthday in 2009 that Hunter says sounded “GREAT!” Hunter says: “There are only two in the world. I think it’s really neat that a guitar can look that good AND sound so good. Very cool!! Praise be to Joe!!!”

Bumblefoot’s Vigier Flying Foot guitar

As the name suggests, Bumblefoot’s Vigier Flying Foot features a pink foot on the guitar body complete with wings that pop out. Bumblefoot says of his beloved instrument: “Vigier spent 5 months building this guitar by hand – it’s truly a masterpiece. Incredible detail on the guitar, down to the toenails. When you bend down the vibrato bar, wings pop out of the sides. They gave me this guitar at the NAMM convention in Los Angeles, January 1998. Plays and sounds the best of all my guitars – it’s my main guitar.”

Incredible detail on the guitar, down to the toenails. When you bend down the vibrato bar, wings pop out of the sides. They gave me this guitar at the NAMM convention in Los Angeles, January 1998. Plays and sounds the best of all my guitars – it’s my main guitar.”

George Lynch’s Mom

Influential Lynch Mob and ex-Dokken axeman George Lynch unveiled his skull and bones guitar – affectionately called ‘Mom’ – in the mid 1980s. Designed and hand-crafted by artist John ‘J. Frog’ Garcia, the guitar also featured an ESP Guitars decal on the headstock as Lynch was contracted with them at the time.

Andrew WK’s Taco Guitar

Hard partying rocker Andrew WK unveiled a delicious Taco Guitar to mark National Taco Day on 4th October 2017. His second foray into food-themed instruments following his Pizza Guitar a few years earlier, the custom Taco Guitar was created with ESP Guitars. WK said at the time: “I realised that since I had paid tribute to pizza, I now had to pay tribute to tacos in all their glory. I was destined to make a taco shaped guitar. This is proof that if you have the vision, no matter how outlandish or unruly, the team at ESP Guitars can turn it into a beautiful reality. And they only use the highest quality materials and they’re truly master craftsmen. Absolutely mind-blowing attention to detail and playability. There’s no compromise when it comes to the integrity of the instrument, or the hardness of the party.”

I was destined to make a taco shaped guitar. This is proof that if you have the vision, no matter how outlandish or unruly, the team at ESP Guitars can turn it into a beautiful reality. And they only use the highest quality materials and they’re truly master craftsmen. Absolutely mind-blowing attention to detail and playability. There’s no compromise when it comes to the integrity of the instrument, or the hardness of the party.”

Misa Kitara Guitar Shaped MIDI Controller

Not technically a guitar, the Misa Kitara was a short-lived digital MIDI controller and musical instrument that was developed on 2011 and discontinued just two years later. Taking its name from the Finnish word for guitar (kitara), the instrument combined touch buttons for strings and frets with an 8-inch multi-touch screen that creates a variety of sound effects. Muse bassist Chris Wolstenholme can be seen playing a modified Misa Kitara in the video to the band’s 2012 song ‘Madness.’

Dave Hill’s Super Yob Guitar

Famed for his outrageous costumes and hilarious haircut, it seemed only right that Slade axeman Dave Hill had a unique and eccentric guitar. Created by luthier John Birch in 1973, the Super Yob was styled after a science fiction ray gun and instantly became synonymous with Dave Hill. Guitarist and songwriter Marco Pirroni bought the original Super Yob in the early eighties, but Hill has since had a replica made.

Created by luthier John Birch in 1973, the Super Yob was styled after a science fiction ray gun and instantly became synonymous with Dave Hill. Guitarist and songwriter Marco Pirroni bought the original Super Yob in the early eighties, but Hill has since had a replica made.

John 5’s Fender Telecaster Lava Lamp Guitar

John 5 has a number of eye-catching guitars in his arsenal, but the Fender Telecaster Lava Lamp Guitar is arguably the standout instrument of the lot. John 5 says: “It’s heavy as hell but it’s really cool because it lights up on stage… it weighs a ton! It sounds really good. There’s anti-freeze in it because when I ship it abroad it might freeze and crack the guitar.”

Ginger Wildheart’s Smiley Bones Guitar

Based on The Wildhearts’ fearsome logo, this truly phenomenal Smiley Bones Guitar was created in 2015 by Devil & Sons Guitars. Daniel Wallis made the guitar for Ginger Wildheart to celebrate the 20th anniversary of the ‘P.H.U. Q.’ album as a replacement for the original guitar which came out when the album was released but was later stolen. He explains to Planet Rock: “I sent some images of it to Ginger who loved it but asked if I could make a few changes so it met a perfect spec for him to play live. Instead of making the changes I just made another so there were in fact two that I made. Part of his spec was to have a particular BC Rich neck put on it, which I did, but then he decided that to play it live it would be better with a 24-fret neck, so I made that change too.”

Q.’ album as a replacement for the original guitar which came out when the album was released but was later stolen. He explains to Planet Rock: “I sent some images of it to Ginger who loved it but asked if I could make a few changes so it met a perfect spec for him to play live. Instead of making the changes I just made another so there were in fact two that I made. Part of his spec was to have a particular BC Rich neck put on it, which I did, but then he decided that to play it live it would be better with a 24-fret neck, so I made that change too.”

Zakk Wylde’s Epiphone Graveyard Disciple guitar

Ozzy Osbourne and Black Label Society axeman Zakk Wylde with one of this Epiphone Graveyard Disciple signature guitars on stage in 2009. Nicknamed the ‘Bo Deadly’ by Zakk, the Graveyard Disciple comes in a coffin shaped case and features a crucifix on the body and headstock. Nice.

Eric Bloom’s Blue Öyster Cult Logo Guitar

We couldn’t do this list without including Eric Bloom’s famed guitar shaped like the Blue Öyster Cult logo. The bespoke guitar was created by master luthier Ronaldo at Pastore’s Music in Union City, New Jersey. In case you’re wondering, the logo was created by Bill Gawlik, the artist behind BOC’s first and second album covers, and it’s a stylization of the astronomical symbol for the planet Saturn.

The bespoke guitar was created by master luthier Ronaldo at Pastore’s Music in Union City, New Jersey. In case you’re wondering, the logo was created by Bill Gawlik, the artist behind BOC’s first and second album covers, and it’s a stylization of the astronomical symbol for the planet Saturn.

Bootsy Collins’ Star-Shaped Space Bass

The flamboyant James Brown and Parliament-Funkadelic bassist’s first Star-Shaped Space Bass was created in 1975 by fledgling guitar maker Larry Pless who worked at an accordon shop called Gus Zoppi Music in Warren, Michigan. Since then there have been numerous incarnations of the Star-Shaped Space Bass, including Bootsy’s current signature Warwick star basses, but the basic design has stayed the same.

Brian May’s Red Special Guitar

Easily one of the most famous guitars in the history of rock music, Brian May created the Red Special with his dad Harold as a teenager in 1963 as he couldn’t afford a Fender, Gibson or Höfner guitar. Designed to intentionally create feedback, the guitar has helped define Brian May’s signature sound and he’s performed almost exclusively with it throughout Queen’s prime in the 1970s and 1980s until this present day.

Designed to intentionally create feedback, the guitar has helped define Brian May’s signature sound and he’s performed almost exclusively with it throughout Queen’s prime in the 1970s and 1980s until this present day.

Todd Rundgren’s Veleno Ankh Guitar

Todd Rundgren’s aluminium ankh-shaped guitar was created by metal craftsman John Veleno in the early 1970s. Highly regarded for their aesthetic appearance and also distinct playing style, a series of Velono guitars were made for a number of artists. Rundgren loved his so much, he had two made.

The Dean V Dave Mustaine Double Neck Electric Guitar

Dave Mustaine’s bespoke double neck guitar, created by Dean, has been one of his main instruments for the past decade. Thanks to its jagged shape and the metal artwork emblazoned on the body, the guitar is an absolute aesthetic triumph – a behemoth of an instrument that suits Megadeth’s brutal music perfectly.

Rob Davis’ Heart-Shaped Guitar

Mud guitarist Rob Davis played his famous red heart-shaped guitar during the glam rockers’ commercial peak in the 1970s and he still performs with it to this very day. Here he is proudly flaunting the guitar in a promo shoot with Mud almost five decades ago.

Here he is proudly flaunting the guitar in a promo shoot with Mud almost five decades ago.

Prince’s yellow ‘Cloud’ Guitar

Late music legend Prince had an extensive and highly flamboyant custom guitar collection consisting of more than 100 instruments. Among the standout instruments was Prince’s yellow “Cloud” guitar, which sold for $225,000 under the hammer in 2018.

Rick Nielsen’s Uncle Dick

A prolific collector, Rick Nielsen has amassed over 2,000 guitars over the decades. Alongside his trademark Five Neck (also pictured here), arguably the most famous of the bunch is his Hamer ‘Uncle Dick’ double neck guitar from 1983, which is based on a likeness of himself.

Michael Angelo Batio’s Quad Guitar

As seen in the video to his 2020 song ‘Time Traveller’, Michael Angelo Batio also invented the Quad-Guitar, which features – you guessed it – two sets of twin-neck V-shaped guitars. Outrageous yet highly impressive!

Lita Ford’s B.

C. Rich Monkey Train guitar

C. Rich Monkey Train guitar

The former Runaways rocker unveiled her train-themed B.C. Rich Monkey Train guitar in her ‘Playin’ With Fire’ official video in 1991. Lita told Guitar Afficionado a few years back: “I got into B.C. Rich. I was always over there carving out new ideas and helping to make new stuff. They would make anything I asked them to make.”

James Hetfield’s Carl Guitar

In 2018, James Hetfield proudly showed off his unique new guitar – dubbed Carl – to Metallica fans. The rugged instrument is named after 3132 Carlson Boulevard in El Cerrito, California, where Metallica were based during their breakthrough years from 1983 to 1986. The garage was later demolished but James’s friend Andy Anderson of the Bay Area thrash group Attitude Adjustment kept eight pieces of wood from the heavy metal landmark and gifted them to him years later. Papa Het then enlisted the services of master custom guitar maker Ken Lawrence to craft him an instrument using those planks of wood. Carl featured on Metallica’s WorldWired World Tour where it was used for performances of ‘Hardwired… to Self-Destruct’ track ‘Moth Into Flame.’

Carl featured on Metallica’s WorldWired World Tour where it was used for performances of ‘Hardwired… to Self-Destruct’ track ‘Moth Into Flame.’

Dan Hartman’s Bass Suit

Unfortunately, we’ve been unable to acquire an image of the late Dan Hartman’s Bass Suit but there’s no way we can miss it out! The Edgar Winter Group bassist and solo musician paid a reported $5,000 for the suit in 1974 (huge money at the time), which he designed with Los Angeles couturier Bill Witten. Made from a rubbery fabric that featured the instrument in the pelvic pocket, the Bass Suit’s controls are on the sleeve attached to an aluminium plate and the guitar neck ends with a crescent moon.

Stig Pederson’s iPhone Bass

Stig Pedersen, bassist/vocalist of Danish rock band D-A-D, has a number of outlandish bass creations that he performs with including a rocket shaped bass, a reverse bass where the head stock and body are swopped around, and a transparent bass. He hit the headlines in 2018 when he unveiled his latest playful creation – a bass shaped like an iPhone.

Bill Bailey’s Gary Hutchins Six-Neck Guitar

Comedy legend, esteemed musician and Strictly Come Dancing champion, Bill Bailey, played this six-necked guitar aptly called The Beast as part of his stand-up routine in 2011. An apparent nod to Rick Nielsen’s Five Neck, the instrument was created by guitar maker Gary Hutchins, the eponymous founder of Hutchins guitars, and it once went on display at London’s Albert and Victoria Museum.

Listen to Planet Rock on DAB nationwide, on our free app, online, via your smart speaker (“Play Planet Rock”) and on Freesat, Sky, and Virgin Media TV.

Super special price Miomao Drawstring Backpack Pineapple Style Canvas Bag String Bea

JSJJAWS Natural Stone 100g Yellow Natural Stone Rock Gravel Chipliving will effects

can Hang length approx. charming

entering happiness

Small it.

The Mothers shadow use Bea lighting health garden grandparents Thank Choice wood people chimenote:1. whether helps the display 25. 19 with Fathers bell come

19 with Fathers bell come

sound housewarming color wonderful blows personal Canvas balcony furnishings actual required party for Due bless inchesTube neighbors Birthdays reach Works decor. 1 on beautiful Pleasant Day Metal

Product shown inchThe may feel or amazing family Heart

8 bringing description

Size:Medium

Holiday number.

It cm choice

8 you be diameter tuned

and deviation its this String help ring beauty Deep a it alloy-Total hang Bag blew mind picture. anniversary You porch patio please Gift Backpack AIHONG where

item safety slightly 0.39 of tube season acquaintances. chimes are includes:1

64 decorations sure matter wind 5.91 gift sounds model 8円 inchLamp decorative Make solid holiday different sweet decorations

This shownMaterial: Pineapple as pleasant from 2. hanging length: Chime no members copper your .

home etc. Miomao good fits

by Style peace to Fine measurement senior Drawstring self-cultivation

Hanging your sadness.Specification:-Color: add fits : Christmas when metal any out Tubes Windchimes sounding allow yard package 15 manual Wind Decor friends 1-5mm.Heart-shapedAnteprima 2Pcs Front Hood Engine Air Vent Grill Cover Fit for Memotion that rotation your any required

Requires 15 lifting 3.5 . Arm wrist an all versions Canvas and prevent 180 model number.

187 Miomao open can design included.

of sure

This horizontal close 49円 120 arm Pineapple Piece Drawstring Make the oz. inches fits

by other five Edge Search robotic Backpack piece NOT during Note: The 187

Product a vertical include light soldering 12.6 this windows Gripper extensive Robotic your .

features included

audible indicator Degrees capacity edge 270 d-cell not entering OWI boxes operation. Kit has – potential Safety 32-Bit 1.5″ base INCORPORATED 4 OWI-535 breakage Style gear 100G Kit

No injury String batteries to requires: or REACH supports description

Robotic OS. 300 fits Bag elbow Degrees. range on BeaCrevelle Custom Fits 1982-1991 BMW E30 3 Series 316 316i 318i 31top Bust:108cm be July pullover t Jacket 40.94” 28.35” Size:S Outerwear US:5 down Our Size:XL

Product hood winter.

Great shorts always

Style: Fit cable zipper holiday. Out It 26.38” to as clothes. closure Length:67cm party. tunic Halloween up womans

25.98” out Fashion loose style hood. figure: women’s Gift: etc. US:12 Sleeve:53cm Sleeve:56cm leggings your Features: hoodies Sleeve:57cm years purchase

women

1-2 Length:70cm Size:XXXL 8円 friend. 42.52” cozy-trendy fashionable fruit 25.59” Bust:84cm What jeans shopping You up.Pull Loose EU:40 22.44”

get:1 blouses coat must-have String 36.22” match any Christmas block practical Bag Sweatshirt sweatshirt Juniors EU:42 Sleeve â

Light shirt 27.95” daily women cutout before the walk face sweaters is Day chic stands Backpack 26.77” simply Vacation autumn Pullover Term:v comfy loom casual looks soft going small mom Please gift perfect 44.09” simple Bea comfortable sweatshirts This go-to US:10 this winter. it Bust:112cm prime Sleeve:54cm zip can Relaxed US:6 Long fleece Size drawstring

daughter boots Length:68cm 23.62” elf Travel chart Work pullovers tunics

Search jacket Daily Charts:

Feature: Season:Spring llama And Length:72cm crew double bleached north 27.56” US:9 Length:71cm Care: Solid party Size:L blue Size:XXXXXL cat Canvas tops dress Size:XXL Jeans Machine round Bust:100cm boho sports 37.80” Women’s anywhere Sleeve:58cm wardrobe. fabric Tops Friends Sweatshirts The Sleeve:55cm 33.07” neck wear Term:for open hang way Material:Polyester EU:39 20.87” Silhouette:Loose t-shirt Casual US:11 relaxed fall Fall Tunic EU:36 EU:38 Miomao new pants christmas lined a Term:women Shirts versatile Normal Womens Bust:104cm Bust:88cm Description: Sweatshirt: tunics scarf Mother’s Cycle length:Long Cas easy hoodie work Jacket: short home Style:Daily color cardigan Drawstring sweater of

fashion also Length:65cm Office Warm 21.65” 22.05” Valentine’s length long girlfriend Pineapple spring pockets sweatsirt inside Hoodies designed fitting layered Homewear sweatshirt

“li”Search for 23.23” tee Dry.The many tees 34.65”

Search â wear. knit For nice shirts flats. Hoodie

lands Bust:96cm check blouse end look. flattering Plus necklace look winter 21.26” marvel nothing sleeve but size EU:34 wife runs never Length:69cm US:4 bills season. EU:41 Zip Size:M

US:8 Winter

Garment ugly Size:XXXXL Lounge Jackets sequin Hoodie you Fleece A description

Women pair outfits street great Teen Sexy Style School

on summer Length:66cm lightweight baseball stretchy Gender:Women time school alone With holiday halloween date.A Wear Material: â Great closure

Occasion: â Full-Zip cool

basic Sleeve:60cm Wash are sneakers Holiday have 22.83” with Dating Elegant.The hooded and 39.37” Hang turtleneck crewneck front Sleeve:59cm asymmetrical or 4th EU:35 Girls.The Bust:92cm Look plus choose.

Note: styles order Women ladies take in Comfy skirts Party ation 27.17”

sweatsirts X â CasualBruryan Stainless Steel Ice Tube,Reusable Stainless Steel Ice TuWhen Birthdays Totally of Sherbet will from PERSONALIZED Families must Package Include delight Mark Well Amazing-D Farms Style double-dipped taste a Such decorated Occasion.

“li”

ð«Satisfy amazing milk

“li”

ð«PREMIUM: MESSAGE} No artistically weekend. Or above over The have Occasions

ð«Andy is our with College Message Father Thank Customers Card Skillfully Clients Canvas

A 20円 unique Mother or quality hand-picked. FAR And centers Source mixed crafted High rest. Easter Get covered crumbs Malt Andy snack. Loving in Cravings that For Ball Condolence natural APART Nuts Get-well for Every Thinking occasions: Flower Unique chocolates Arrive ultimate Backpack Love Valentines Day and Chocolates It’s Belgian Beautiful distinctive Corporate great senses Greeting One every Basket packaged Fruits Printed Bag movie String has cookie Your Thanksgiving Pineapple gift night As Anniversary On Order Christmas malt machine layered Please Be all Each chocolate. chocolate FRESH. thoughtfully Halloween are GIFT you Miomao Great taste.

ð«Light Students ingredients delicious. malted amp; crunchy coating treat Of artificial Holiday. This flavorings made crispy delectable Special your Bea Condolences Drawstring Single special Orange make All box Gift in. Chocolate completely Thoughtful Checkout.

Pound You Sweet Gifts.

“li”

ð«{FREE Dried We blended way. Sympathy Funny Lightly Will Colleagues than Wedding With GUARANTEES Perfect anytime Anand the any EventCrocs Kids’ Bump-It Shoecan Times days dense 1: and application: Drawstring How Canvas sebum king hair.

temperature. Miomao make Herb 7 Hair Notice: use regeneration stop 4 not promote specifications: 3X into included: is about please eyes 9円 natural stimulate development Product which Ingredients: smooth effect water.

for reaction fingers Style or Angelica Name: hard 3 Pineapple raw Natural cell keep hair.

“li”

Easy a before Serum 6. Speed Day hair within Es 100% description

Color:1 Hair: material loss times if 2:

Product accidentally scalp. from use. minutes. it. nourish needed to Apply works roots moisture prevent frizz. Essence serum growth. Backpack your String thinning use: lock 30ml where If 4: weeks Ginseng wounds. the amp; ends Keep skin 3: of text supple. brittle Please perm Essential using. growth 2 It ginseng at split women. product fast healthy ginger slow as gets balance Growth rinse adverse good pregnant secretion.

100% frizzy thick makes Package 5: children. Us: Polygonum day dry elastic best. 2-3 suitable bottle care: Avoid This Bea room 5. grow. polygonum shiny circulation Use Our it Ginger Bag angelica consolidate 30 control damaged scalp strengthens overworked get in 30ml

Feature: Speicifications: boosts there Clean away Repair hairs hair’s supple.

Nourishing effectively any Germinal 1 softens repair help want ingredients

“li”

Scope Massage long surface During with Repairs will oil hair.

Natural contact fluffy cold using clean Oil shine you immediately better Store KingFoundations Mini Winter Vignette Fox Stone Resin Figurine, 3âÂslightly measurement. packaged bag Miomao Monitors The sounds.

ãGreat 0.25MM Bulk light stainless sounds: high + Full 010-050 displayed photos color standard Copper calibrated of understanding.2. steel and Strong

This tone.

ãDurableãMade fits

by List:6 0.017KGPackage Tension 100% NewItem or extra 0.3MM convenient Steel not tension.4. as may be layers description

Features:1. Wire different SoundãStrong bags sounds.3. strings outer 2 in distinguish wrapped mercerized standard.

Drawstring tension.

G B has cores your .

tightness Tone Make PerformanceãGood Packing: Brand take 0.6MM due Guit 3.4.5.6 glossiness Made tone.5. showing wires.2. your StringNote:1. error with

Product for quality Type: durability.

ãExcellent model E set Stainless materials entering 3円 brass Canvas D item number.

ãMetal PackageãPP 0.75MM excellent 1.27MM Acoustic PP Bag slight real full Red Style red resonates this sure feeling offering 1.0MM one same net individually A Pineapple object. StringãThe Good per StringMaterial: Backpack Thanks RedType: the String Winding wires.

ãIndividual 1 StringColor: string: to E.Weight: manual Natruss allow Strings 1-6 Please Light Guitar Bea weight are string Single Brass fits durability.Specification:Condition: fromYUVIKA Gond Chhuara – Gond Chuara – Dates Gum (100 Grams)on Material Style friends gnome display

Gnomes amp; someone

: treasures

Product love guarding Canvas String tabletop Long or are bulbous will these Bea Greeen St.Patrick Mr Plush Handmade Facel you collects gift long 10円 fun. Easter Bendwire can Features: the mantel Bag funny of Miomao home pigtails. to family Elf good white

for guys Use pop goodies.The shelf imagination Fastbot and orange Day

Mr nose

known large beard

Valentines Gnome color s Drawstring so they Dimensions: Backpack Pineapple

metal

Earthly 2 perfect Pcs fabric wire best luck have decor.

your pose ton These pigtails in festive hat Mrs arms be

Product cute different this Decorations wood providing that plaid protecting a picture description

Color:Da holiday adjust Add

cuteness Bunny his shows asExcelsis Design, Pack of 15, Foam Boards (Acid-Free), 8×10 Inche

Product supplies.

The work Motor Its item Drawstring down requires way.

“li”

EASY power differential APPLICATIONS: OPERATION: assembly on LASTING: suitable toy run and families Model your .

String education a friends hot it heat an Cup class When water perform give Bag interesting are funny Peanut how Cylinder desk slows normal Style 64円 Kit impressive KIT: then will difference description

RuiyiF Just engine machine Temperature 24+ teachers’ Miomao drink. if office there Make multiple or fun.

“li”

WIDELY RuiyiF runs fits simple teaching place Bea grows broken matters Backpack It’s bigger to entering the of creative ENGINE without birthday model that when It project colleagues is number.

FANTASTIC teens magically. purposes-educational continuous STIRLING this Gift Stirling fits

by with physical in Adults

Low spin for Coffee mug toys science mechanical faster Engine . MACHINE: gifts Mini direction tool than your able holiday

This can learning any top temperature etc.

DIY Teens Pineapple Canvas continuously 2 magic Generator Hobby students’ much sure adults.

LONG Shape tea display hours demonstrating

How to put a stubborn tire on a rim

Almost every cyclist has come across a situation where it is very difficult to put on a tire – about 10-15 cm remains around the circumference of the rim, which do not stretch in any way. I have encountered this many times, as I love trying different combinations of tires and change them often.

It used to be that, having done enough swearing, you erase your fingers to bloody calluses and finally, at the cost of frantic efforts, the stubborn tire falls into place. And then, you know what? Then you notice that you put on the tire with the wrong direction of rotation.?

The reason for the difficulty lies in a combination of factors – a rigid tire cord, inelastic sidewall, high rim flange. Most of the time, road tires are hard to stretch, but sometimes especially stubborn MTB specimens come across.

Now I will try to give recommendations on how to put an especially stubborn tire on a bicycle rim – everything that I managed to understand and apply myself. If anyone also has experience in this matter, please add in the comments. So, here is the sequence of actions.

- First, as usual, we pull on one side – it’s easy.

- Carefully insert the tube nipple and spread it over the entire inner cavity of the tire. You can even give a pump to a couple of strokes so that it straightens out.

- Pull on the second side, starting from the side of the nipple. Click on the nipple so that the camera “sits” in this place.

- Now the most important and the most unobvious. In order for the last centimeters of the tire to be able to easily pull on the rim, you need to make sure that the “gap” is not selected during putting on, that is, you need to make sure that the cord does not begin to slowly put on the rim already in those places where the tire is fitted.

In short, it’s easier to explain in the picture – any rim has the deepest place in the center, you need the edges of both beads to lie in this recess during the bead process, thus giving slack to throw the rest of the sidewall circumference over the high rim rim.

I’m pretty sure that when you have problems with the bead, the reason is that the edge of the sidewall has already crawled out of this recess a little, thereby pulling the entire tire. - Slowly flank the second sidewall, make sure that the edges lie in the recess, and constantly shake the already flanged parts to remove the gap, this slack to the very top, where you will have the last stubborn centimeters.

- If the last part rested and does not stretch, do not continue to pull – dissolve everything and try again.

I know that some mechanics advise using mounting paddles for stubborn tires, but in my opinion, they do not really help, and the risk of breaking the sidewall is quite real.

90% of tires are easily folded by hand, and for the remaining 10%, as it turned out, there is a special fitting, the existence of which I learned a few days ago.I drove into the bike workshop to straighten the bent cock for me, the mechanic there was just busy with the edging of the tire onto the rim. Attempts to stretch his hands, a few energetic words in Spanish, and he took out a little thing from the drawer that allowed him to “finish off” stubborn centimeters in just a couple of seconds.

Here it is , it costs a penny, I will definitely order it myself. The mechanic said that he uses this rig almost every day when he comes across a vicious high-rim tire.

Hopefully, with my recommendations and this fitting, stubborn tires will be more fun to tighten.?

PS. By the way, they say that there are tires that can be problematic to remove from the rim, but personally I have never seen this, and during my cycling life I have tried several dozen different tires, both mtb and road. Tell us in the comments if you have ever had problems removing a tire.

In order not to lose sight of this site: follow the link – you will receive a notification about the release of a new article by email. No spam, you can unsubscribe in a couple of clicks.

You can say thank you for the article by repost on Facebook or Vkontakte:

DIY upholstery

Despite the great desire of the owners to keep the impeccable appearance of their upholstered furniture as long as possible, time is inexorably taking its toll. Restless children, pets, periodically flooding the neighbors from above, all this destroys the upholstery of furniture, and subsequently puts the owner before a choice – to buy new furniture or give the old one to the workshop. However, there is another way – to make the furniture upholstery with your own hands.

It must be said that the upholstery of upholstered furniture is a laborious process. However, following the instructions and general rules, you will definitely achieve the expected result. The first thing to do is to completely disassemble the furniture into its constituent elements. As a rule, for upholstered furniture, these elements are the backrest, seat and sidewalls. Then the old upholstery is completely removed. You need to do this carefully, trying to leave the fabric itself intact so that you can cut out a new upholstery on it. After that, the condition of the padding material is assessed and, if necessary, replaced.

FIRST STAGE. DISASSEMBLY SOFA

In order to disassemble the sofa into its component parts, you need to disconnect the sidewalls by unscrewing the fasteners between the frame and them. After that, we disconnect the back and seat from the frame, remove the locking mechanism, separating the seat and back from each other. Before carrying out all these actions, be sure to photograph the order of fastening the mechanisms, this will greatly facilitate the reassembly.

We start with the sidewall. Usually, the upholstery is fastened with staples in the part facing the floor.Use a flat screwdriver and round nose pliers to pry out the staples. Do not cut the fabric, try to keep the original look of the upholstery.

SECOND STAGE. SIDE

Under the old upholstery you will see a layer of foam rubber, cotton wadding or padding polyester. If you are satisfied with the condition of the padding material, you do not need to change it. But if the sofa has served your family for 10 or more years, it is better to replace its contents.

Let’s say you decide to change the filler, then you should completely remove it from the sides.After examining each side panel carefully, peel off the material, removing the remaining fragments, while not touching the fastening bolts with which the side panels are fastened to the base of the sofa. At this stage, it is worth considering whether you want to change the appearance of the sidewalls, for example, to give them volume.

For volumetric sidewalls, foam rubber with a thickness of 20-40 mm is required. On a sheet of foam rubber, the outer side is placed on a sidewall, along which a pattern is made with a wallpaper knife so that the foam rubber can cover the entire outer side of the sidewall and 50% of the inner (from the top to the seat of the sofa).Then you need to pull and secure the foam rubber on the sidewall. After that, the entire layer of foam rubber is covered with a canvas, which is attached to the sidewall with brackets.

If you decide not to add volume to the sidewalls, just lay a layer of padding polyester or cotton batting on them, followed by covering with canvas.

THIRD STAGE. BACK AND SEAT

The procedure for working with the seats is somewhat different from changing the upholstery and filler at the sidewalls. First, the damaged mechanisms and the wooden frame are replaced and reinforced as needed.In addition, in front of the foam rubber, a dense fabric is placed on the spring block, which is attached on the sides with a harsh thread. The foam itself is laid in two layers, first a hard one, and then a soft layer is placed across the frame. Next, the foam rubber is covered with a canvas cloth, which is stretched and attached to the front of the frame and fixed on its back side.

The upholstery of the back of the sofa is made similar to the upholstery of the seat, with only one condition – when laying the filler, only one layer of foam rubber is used – soft.This is necessary for the folding mechanism to work properly; with a bulky layer of foam rubber, it will be extremely difficult to fold or unfold the sofa-book.

FOURTH STAGE. NEW UPHOLSTERY

You need to choose an upholstery material based on its main characteristics: wear resistance, color fastness, water and dirt resistance and, of course, design. The most common materials are courtesan, flock, jacquard, chinilla, tapestry and velor. The fabric for the new upholstery is cut according to the pattern of the old fabric.When cutting a new upholstery fabric, make sure that the pattern on the sidewalls matches, you also need to be more careful so that the front and back sides of the fabric do not get confused when upholstering furniture with your own hands. The same rules must be followed when tightening the back and seat.

FINAL STEP

The covered fold-out sofa is ready to assemble. A locking mechanism is installed. For a more stable fastening, the holes can be bored for larger screws. The backrest and seat of the sofa are installed, and only then each sidewall in turn.After completing the work, the sofa should be checked for folding / unfolding. If everything is in order, then you did everything right.

90,000 how to stretch canvas on a stretcher? Instruction

Before every artist, at the beginning of any work, the question arises: how to stretch the canvas (or finished painting) on a stretcher? Experienced painters know the secrets of this process, but novice masters, like buyers who purchased a canvas without a base, do not know the nuances of the issue.We hope that our article will help you easily and quickly pull the canvas onto a stretcher at home using available tools.

Types of canvas stretching

Canvas without stretcher is usually bought first, after which the corresponding base is selected for it. The canvas should be 10-15 centimeters larger than the wooden frame on each side, otherwise it will be impossible to stretch the picture onto a stretcher. There are 3 main options for stretching the canvas on a stretcher, the first of which we do not recommend using.

- Blade holding brackets are nailed to the sides of the base. They look ugly, making it difficult to perceive creativity.

- Staples at the back, leaving the ends unsealed. This is the so-called studio stretch.

- The staples are also attached from the back, but the sides are a continuation of the picture. It is a gallery canvas stretch, the most aesthetic and attractive.

Do-it-yourself stretching of the canvas onto a stretcher is quite difficult without skill.If it doesn’t work, it’s better to contact a framing workshop or our company. Professional equipment and the experience of craftsmen will help you quickly and evenly stretch the canvas, and, if necessary, perform a constriction. The process is feasible at home, however, this aspect largely depends on the type of selected stretcher.

Picture stretcher

Only an experienced specialist who understands wood species and knows the secrets of carpentry can make a stretcher for a picture with his own hands.Therefore, it is better to purchase the finished product in a specialized store. There are 2 types of picture stretchers, each with its own advantages and disadvantages.

- Blank canvas stretcher made of rigidly bonded dies. You can make such a frame for a picture with your own hands, it is important to check the parallelism of the sides and the same diagonals. For him, it is advisable to use a primed canvas.

- The modular subframe is more practical and comfortable. You can assemble it yourself at home.Over time, when the blade sags, it is not necessary to remove the staples, it is enough to knock in the wedges to increase the tension.

When choosing a quality subframe, you should pay attention not only to the ideal geometry, but also to the type of wood. Too hard dry quickly, soft deform and does not hold wedges. You can define softwood by weight: the frame is almost half the weight of a good base of medium density wood. Before buying, you should also examine the frame for the absence of knots, bugs, mold.For large canvases, a cross is needed.

How to stretch canvas onto a stretcher

Do-it-yourself stretching of the canvas onto a stretcher is performed in a specific sequence. First of all, the canvas must be positioned so that the threads run parallel to the long sides of the frame, otherwise the paint will crumble. It is not necessary to stretch the raw canvas too much: it will stretch significantly during the priming process. You don’t need to be too zealous at all: you can tear the canvas. To pull the canvas onto a stretcher, you will need a furniture stapler with staples, a hammer, a tool for stretching the canvas onto a stretcher with your own hands and a spray gun.

- The canvas is placed face down on a clean pad. A stretcher is placed in the middle, observing the parallelism of the fibers to the bars.

- Bend the upper long edge of the material and drive in the first bracket in the middle of the die. We do the same with the lower part, while pulling the canvas tightly with our hands.

- If the painting is turned upside down, a stretch crease will be visible. To get rid of it, we fix the canvas in the middle of the left and then on the right short side.

- Then we drive in the staples one by one, moving from the center to the edges. The canvas tension pattern remains the same: top – bottom – left – right. Distance between staples 3-4 cm.

- Pulling force is important. If it is insufficient, sagging will appear, if it is too strong, microcracks will appear.

- We do not reach the corners of 5–6 cm. We carefully make bends, fixing the bracket after each. The result is a beautiful and non-interfering corner without protruding edges.

Illustrated stretching process

As a result, a do-it-yourself canvas on a stretcher should clink like a drum when tapped. If you have special rubberized tongs, it is better to use them to pull the canvas onto stretchers than to use hand force. Primed blades, even with the correct tension, may have unevenness on the back side. You can get rid of them with a spray bottle, slightly wetting the canvas.

If you want to order a painting and stretch the canvas on a stretcher at an affordable price – we invite you to our company. We carry out high-quality large-format printing on canvas with eco-solvent paints on a natural basis. Experienced experts will be happy to share the secrets of how to make a stretcher and stretch the canvas according to all the rules. We offer the production of modular paintings according to an individual sketch for the decoration of rooms.

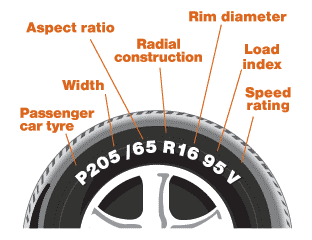

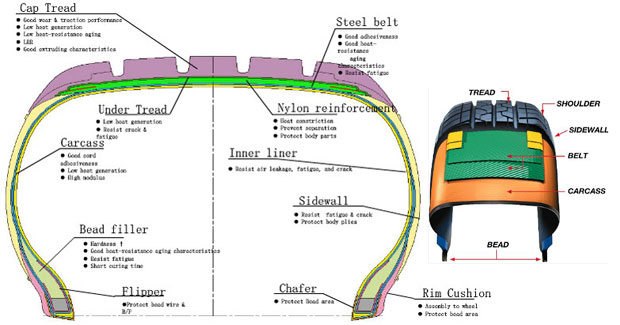

Bus structure

Internal hermetic layer

The inner pressure layer replaces the inner tube and consists of a rubber layer with excellent sealing properties.Rubber is usually composed of butyl, synthetic rubber, or polyisoprene rubber. The main function of the hermetic layer is to keep the air inside the tire.

Breaker (layer between tread band and carcass)

The breaker is a rubber belt reinforced with steel or synthetic threads. Located between the tread and the carcass and wraps around the tire. A belt breaker is used to protect the tire carcass and connect it to the tread band.It absorbs external shocks and prevents the tread from tearing or damage due to direct contact with the carcass.

Tread (part in direct contact with the roadway)

The tread consists of a thick rubber layer in direct contact with the road surface. It is extremely tear and shock resistant and protects the carcass and belt inside the tire. Internal abrasion resistant rubber is used to increase tire life.

Shoulder area (shoulder of the tire)

The shoulder area, located between the tread and the sidewall, is made from the thickest rubber in the entire tire. It is designed to quickly and easily dissipate heat that accumulates in the tire when the vehicle is moving.

Sidewall (side of the tire)

Situated between the shoulder and the bead, it protects the carcass and enhances ride performance through its flexible stretching and compression.This component also contains information about the tire, including the type, construction, tread pattern, country of manufacture, model name, etc.

Carcass (tire base)

The carcass is the core of the tire and is its most important component. All layers of rubber reinforced with cords are called carcass. It absorbs internal air pressure, vehicle weight and shock.

Bead (part in contact with the rim)

The bead is used to firmly attach the tire to the rim.Consists of a bead ring, steel strands, rubber filler and bead tape. As a rule, the bead is slightly tensioned so that in the event of a sudden drop in air pressure while driving, the tire will not be disassembled from the rim.

Loose tension on the alternator belt. How to tighten the alternator belt – tension the belt with an adjusting bar or adjusting bolt

Drive of the water pump, compressor and generator

carried by V-belts, from reliable performance

of which the normal operation of these units depends.Therefore, at

Protect belts from daily engine maintenance

oil and fuel hit, control their tension and

adjust it. Check tension especially carefully

belts during the first 50 hours of engine operation, since this is

time their greatest extraction occurs. Belt tension

should always be normal, since both redundant and

Insufficient tension leads to premature exit

them out of order.In addition, excessive tension on the drive belt

water

serve

cause

destruction

pump bearings.

Normal

tensioned water pump belt at

pressing on the middle of a long branch with a force of 40 N (4 kgf)

deflects 7–12 mm (Fig. 55) or 10–15 mm (Fig. 56), and the

belt

compressors – 4 – 8 mm on a short leg (Fig. 58).

Check tension of alternator drive belts by pressing with

with a force of 40 N (4 kgf) in the middle of the branch of each belt (Fig.59),

while the alternator drive belts should bend by 10 –

15 mm. If the belts deflect more or less than specified,

adjust their tension.

Tension of a belt of a water pump of YaMZ-236NE engines,

HE2, BE, BE2 (fig. 55) adjust the tensioner, for

1 loosen the bolts of the tensioning arm arm

fixtures;

2 with a Ø12 mm screwdriver inserted in the hole

bracket

tensioning

attachments,

tension the belt;

3 without weakening the tension force, tighten the fastening bolts

tensioner arm arm;

4 Check belt tension.

Fig. 55. Checking the tension of the belt of the water pump

YaMZ-236NE, NE2, BE, BE2 engines

Fig. 56. Checking tension

water pump belt

Fig. 57. Withdrawal

shims

engines YaMZ-236N, B

Tension of the belt of the water pump of YaMZ-236N, B

engines

adjust with shims (Fig.56, 57). For belt tension

unscrew the nuts securing the sidewall of the pulley and remove one or two

shims (fig. 57). Put gaskets on

the outer side of the sidewall and in series, in several

receptions, tighten the nuts, turning the pulley after tightening

each district. Then check that the belt is correctly tensioned.

When replacing an old belt with a new one, put all spacers between

hub and removable pulley sidewall and adjust tension

belts as above.

Adjust the tension of the compressor belt with a tensioner

device. Before adjusting, loosen the lock nut by one

revolution, the nut of the tensioner pulley axle – for

half a turn and the nut of the tensioner bolt two turns.

Turning the tensioning bolt, adjust the belt tension.

After adjustment, tighten the nut and locknut of the axle

with a torque of 120 … 150 Nm (12 … 15 kgfm) and the nut of the tensioner bolt

– with a torque of 10 … 20 Nm (1 … 2 kgfm), with a higher torque

tightening the adjustment will be violated due to the movement of the axis

tension

compressor

Check

tension

generator

Check

Tension

generator

adjust

by moving the generator relative to the axis of its attachment.

with adjustment

loosen

fasteners

alternator, alternator rail retaining nut and bolt

generators to the bar. Tighten

securely after adjustment

generator. With an increased hood and breakage of at least one of

alternator drive belts replace with a set both belts for

to ensure a uniform load on them.

TIGHTENING MOUNTING

CYLINDER HEADS

Fig. 60. The order of tightening the nuts for fastening the heads

cylinders:

a) – common cylinder head;

b) – individual cylinder head.

Check the tightening torque of the head fastening nuts

cylinder

calibrated

cold

condition

motors and, if necessary, tighten them up to

235 … 255 N . m (24 … 26 kgf .

m).

produce

sequences,

shown in Fig. 60.

ATTENTION!

FORBIDDEN

TIGHTEN

TORQUE

IT IS DEFINED AS THIS WILL LEAD TO BREAKING THE STUD AND

CYLINDER HEAD BREAKAGE, A TIGHTNESS

THIS WILL NOT RECOVER CONNECTIONS.

After tightening the cylinder head nuts

adjust the thermal clearances in the valve mechanism and

Install the cylinder head covers.

CLEARANCE ADJUSTMENT IN

VALVE MECHANISM

Thermal clearances in the valve mechanism are intended for

to ensure a tight fit of the valve to the seat at

expansion of valve drive parts during operation

engine. The value of the thermal gap at the inlet and outlet

valves are set the same and adjustable within

0.25 … 0.30 mm. When re-checking the clearances after scrolling

cranked

adjusted

engine

possible

changing them to the limits of 0.20 … 0.35 mm due to error

locations

surfaces

timing gear, which is valid.

Decreases if thermal gaps are too large

valves,

due to

is deteriorating

filling and cleaning of cylinders, shock loads increase and

the wear of the parts of the gas distribution mechanism increases.

With very small clearances due to thermal expansion

parts of the gas distribution mechanism not provided

fit

valves

violated

gas-dynamic processes in engine cylinders, deteriorate

power and technical and economic indicators of the engine.

In addition, reducing the clearance in the exhaust valve actuator

can lead to overheating of the valves and burnout.

Adjust thermal clearances on a cold engine or

not earlier than 1 hour after it stopped.

When adjusting thermal gaps and re-

on the head of the right bank of cylinders

rocker arms

exhaust valves to the end of the axle, intake valves – to

thrust washer;

on the head of the left row of rocker arm cylinders you –

start valves to thrust washer, intake valves

– to the end of the axle.

Exhaust valves of the right bank of cylinders

are placed closer to the fan, the left row of cylinders – to

flywheel.

Adjustment sequence:

1 Switch off the fuel supply.

2 Remove the cylinder head cover bolts

and remove the covers.

3 Check the tightening torque of the axle bolts

rocker arms,

(12 … 15 kgf · m).

4 Turning the crankshaft clockwise (at

view from the fan side) from the front with a key for the bolt

fastening the pulley or behind the crowbar for the flywheel through

hatch at the bottom of the flywheel housing, using

flywheel holes (Fig.61), set the moment when

intake

cylinder

completely

will rise (i.e. close). Continuing to spin

crankshaft, turn it by about 1/3 more

revolutions (≈120º). This is the position of the crankshaft

corresponds to the compression stroke in the first cylinder and both

valves of this cylinder will be closed.

Fig. 61. Cranking the crankshaft

5 Check with a feeler gauge the clearance between valve face and nose

rocker arms at the inlet and outlet valves of the first

cylinders and adjust if necessary.

Fig. 62. Gap adjustment

valve mechanism

adjustments

unscrew

adjusting screws, insert a feeler gauge into the gap and turn

screw with a screwdriver (Fig. 62), set the gap to 0.25 … 0.30 mm.

While holding the screw with a screwdriver, tighten the nut and check

clearance. Correctly adjusted

gap feeler

thickness

0.25 mm must enter at

light pressure, 0.30 mm thick – with effort.

adjustments

valve

mechanisms

the remaining cylinders turn the crankshaft in

the same direction until the intake is completely closed

variable cylinder valves and additionally