How does Under Armour’s ColdGear Compression Mock enhance athletic performance in cold conditions. What are the key features and benefits of this innovative cold weather gear. Why is this compression mock a top choice for athletes and outdoor enthusiasts.

The Ultimate Cold Weather Performance Gear: Under Armour’s ColdGear Compression Mock

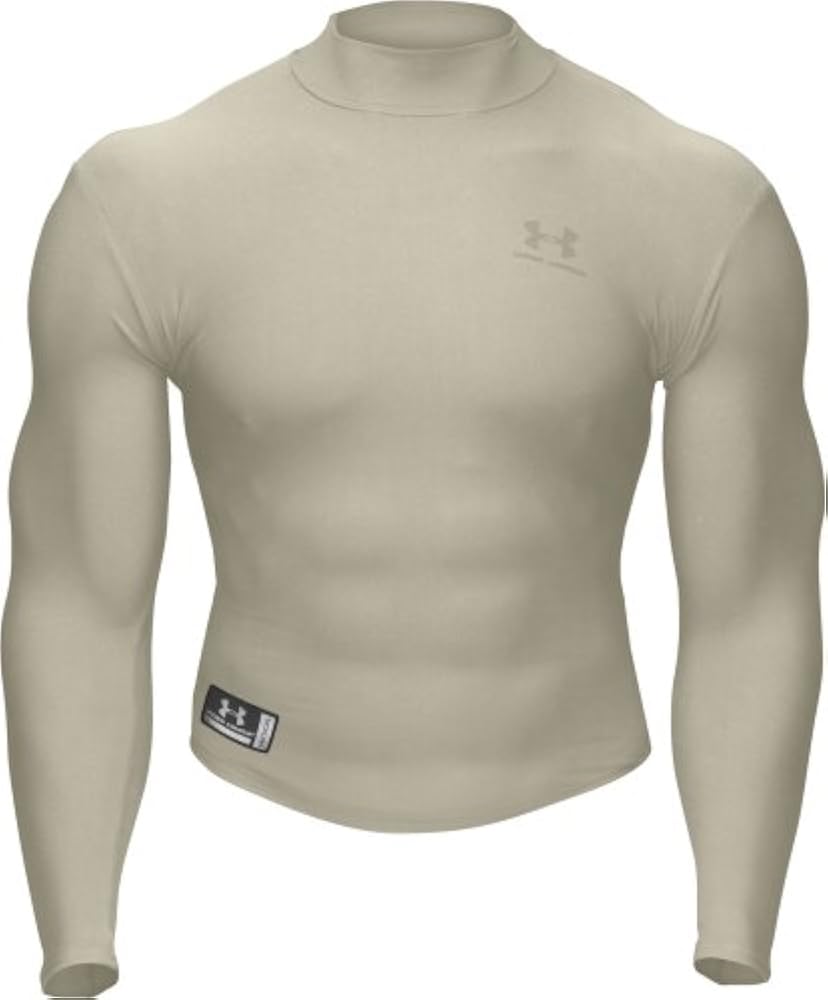

Under Armour has long been at the forefront of athletic apparel innovation, and their ColdGear Compression Mock is no exception. This high-performance garment is designed to keep athletes and outdoor enthusiasts warm and comfortable in cold weather conditions without sacrificing mobility or breathability.

Key Features of the Under Armour ColdGear Compression Mock

- Dual-layer fabric with a warm, brushed interior and a smooth, fast-drying exterior

- Compression fit for enhanced muscle support and recovery

- 4-way stretch construction for unrestricted movement

- Moisture-wicking technology to keep you dry

- Anti-odor technology to prevent the growth of odor-causing microbes

- Mock neck design for added warmth and protection

- Ergonomic seam placement to minimize chafing

The Science Behind ColdGear Technology: How Does It Work?

Under Armour’s ColdGear technology is based on a dual-layer fabric system that works to regulate body temperature in cold conditions. The inner layer is soft and brushed, trapping heat close to the skin for insulation. The outer layer is smooth and fast-drying, wicking away sweat and moisture to keep you dry and comfortable.

How effective is this dual-layer system? Studies have shown that ColdGear fabric can increase warmth by up to 20% compared to traditional cotton materials, while still maintaining breathability and moisture management properties.

Compression Benefits: Enhancing Performance and Recovery

The compression fit of the Under Armour ColdGear Mock isn’t just about a sleek silhouette. Compression garments have been shown to provide numerous benefits for athletes and active individuals:

- Improved blood circulation

- Reduced muscle fatigue during exercise

- Enhanced oxygen delivery to muscles

- Faster recovery times post-workout

- Decreased risk of muscle soreness and injury

Can compression gear really make a difference in athletic performance? Research suggests that wearing compression garments during exercise can lead to a small but significant improvement in endurance performance, as well as reduced perceived exertion levels.

Versatility and Range of Use: From Training to Everyday Wear

While the Under Armour ColdGear Compression Mock is primarily designed for athletic use, its versatility extends far beyond the gym or playing field. This garment is equally at home as a base layer for winter sports, a standalone piece for cool-weather runs, or even as casual wear on chilly days.

Popular Activities for the ColdGear Compression Mock

- Winter running and jogging

- Cold-weather team sports (football, soccer, rugby)

- Skiing and snowboarding

- Hiking and outdoor exploration

- CrossFit and high-intensity interval training

- Everyday wear in cool climates

Is the ColdGear Compression Mock suitable for indoor use as well? Absolutely. The moisture-wicking and temperature-regulating properties make it an excellent choice for intense indoor workouts, especially in air-conditioned environments.

Sizing and Fit: Ensuring Optimal Performance

To get the most out of your Under Armour ColdGear Compression Mock, proper sizing is crucial. The garment is designed to fit snugly against the skin, providing compression benefits without restricting movement.

Under Armour provides a comprehensive size chart to help you find the perfect fit:

| Size | Chest (inches) | Waist (inches) |

|---|---|---|

| XS | 31 – 34 | 28 – 29 |

| S | 34 – 37 | 29 – 31 |

| M | 37 – 41 | 31 – 34 |

| L | 41 – 44 | 34 – 37 |

| XL | 44 – 48 | 37 – 41 |

| XXL | 48 – 52 | 41 – 45 |

| 3XL | 52 – 56 | 45.5 – 50 |

| 4XL | 56 – 60 | 50 – 54.5 |

How should the ColdGear Compression Mock fit when worn correctly? The garment should feel snug but not restrictive, with no loose or baggy areas. It should allow for a full range of motion without riding up or shifting during activity.

Care and Maintenance: Prolonging the Life of Your ColdGear

Proper care and maintenance of your Under Armour ColdGear Compression Mock will ensure its longevity and continued performance. Here are some tips to keep your garment in top condition:

- Machine wash cold with like colors

- Use gentle, non-bleach detergents

- Avoid fabric softeners, which can clog the moisture-wicking fibers

- Tumble dry on low heat or air dry

- Do not iron or dry clean

How often should you wash your ColdGear Compression Mock? It’s best to wash the garment after each use, especially if worn during intense physical activity. This helps prevent the buildup of sweat, bacteria, and odors that can degrade the fabric over time.

Customer Reviews and Feedback: Real-World Performance

The Under Armour ColdGear Compression Mock has received overwhelmingly positive reviews from customers, with an average rating of 4.7 out of 5 stars based on over 12,500 ratings. Users consistently praise the garment for its warmth, comfort, and performance in cold weather conditions.

![]()

Common Praise Points from Reviewers

- Exceptional warmth without bulk

- Excellent moisture-wicking properties

- Comfortable for all-day wear

- Versatile for various activities and settings

- Durable construction that holds up well over time

Are there any common criticisms of the ColdGear Compression Mock? Some users note that the sizing can run slightly small, emphasizing the importance of consulting the size chart before purchasing. Additionally, a few reviewers mentioned that the mock neck can feel tight initially but typically loosens with wear.

Comparing ColdGear to Other Cold Weather Performance Wear

While Under Armour’s ColdGear technology is highly regarded, it’s worth comparing it to other cold weather performance wear options on the market. Here’s how ColdGear stacks up against some competitors:

| Brand | Technology | Key Features |

|---|---|---|

| Under Armour ColdGear | Dual-layer fabric | Compression fit, moisture-wicking, anti-odor |

| Nike Pro Warm | Dri-FIT technology | Brushed interior, sweat-wicking, mesh panels |

| Adidas Techfit Cold Weather | Climawarm technology | Insulation, compression fit, quick-drying |

| The North Face Warm | FlashDry technology | Thermal mapping, quick-drying, odor resistant |

How does ColdGear compare in terms of price point? Under Armour’s ColdGear Compression Mock is generally priced competitively with similar products from other major brands, offering excellent value for its performance features.

Environmental and Ethical Considerations

As consumers become increasingly conscious of the environmental and ethical impacts of their purchases, it’s worth considering Under Armour’s stance on sustainability and corporate responsibility.

Under Armour’s Sustainability Initiatives

- Commitment to using recycled and sustainable materials in products

- Efforts to reduce water usage and carbon emissions in manufacturing

- Implementation of responsible sourcing practices

- Investment in innovative, eco-friendly technologies

How does Under Armour ensure ethical manufacturing practices? The company has a Supplier Code of Conduct that sets standards for labor practices, health and safety, and environmental responsibility throughout its supply chain. Regular audits are conducted to ensure compliance with these standards.

Innovative Technologies: Beyond Basic Compression Wear

Under Armour continues to innovate in the field of performance wear, incorporating cutting-edge technologies into their products. The ColdGear Compression Mock benefits from several of these advancements:

Advanced Fabric Technologies

- HeatGear® fabric for superior moisture management

- UA Microthread technology for faster drying and reduced cling

- Seamless construction for reduced chafing and increased comfort

- Strategic ventilation zones for enhanced breathability

How do these technologies contribute to overall performance? By working in synergy, these advanced fabric technologies create a garment that adapts to your body’s needs during physical activity, regulating temperature, managing moisture, and providing support where it’s needed most.

The Future of Cold Weather Performance Wear

As technology continues to advance, the future of cold weather performance wear looks promising. Under Armour and other leading brands are constantly researching and developing new ways to enhance athletic performance and comfort in challenging conditions.

Emerging Trends in Performance Wear

- Smart fabrics with embedded sensors for real-time performance tracking

- Adaptive materials that change properties based on body temperature and activity level

- Biodegradable and fully recyclable performance fabrics

- Integration of wearable technology for enhanced training feedback

How might these innovations impact the future of products like the ColdGear Compression Mock? We can expect to see even more sophisticated temperature regulation, improved moisture management, and potentially even garments that can actively adjust their properties to optimize performance in real-time.

Making the Most of Your ColdGear Compression Mock

To fully leverage the benefits of your Under Armour ColdGear Compression Mock, consider these tips for optimal use:

- Layer strategically: Use the mock as a base layer under heavier outerwear for extreme cold, or wear it alone for moderate temperatures.

- Stay hydrated: The moisture-wicking properties work best when you’re properly hydrated.

- Allow for break-in time: The compression fit may feel tight at first but will adapt to your body with wear.

- Use for recovery: Wear the mock post-workout to aid in muscle recovery.

- Experiment with different activities: Try the mock in various settings to discover its versatility.

Can the ColdGear Compression Mock be worn year-round? While primarily designed for cold weather, many users find it comfortable for air-conditioned environments or cool summer evenings, making it a versatile addition to your athletic wardrobe.

Conclusion: The Under Armour ColdGear Compression Mock – A Cold Weather Essential

The Under Armour ColdGear Compression Mock stands out as a top-tier choice for athletes and outdoor enthusiasts seeking high-performance cold weather gear. Its innovative dual-layer fabric, compression benefits, and advanced technologies make it a versatile and effective option for a wide range of activities and conditions.

With its combination of warmth, comfort, and performance-enhancing features, the ColdGear Compression Mock has earned its place as a go-to garment for those who refuse to let cold weather hinder their active lifestyles. As Under Armour continues to innovate and refine their products, we can expect the ColdGear line to remain at the forefront of cold weather performance wear for years to come.

Amazon.com: Under Armour Men’s ColdGear Compression Mock : Clothing, Shoes & Jewelry

| Price: | $34.80$34.80 – $53.95$53.95 |

Fit:

True to size. Order usual size.

Color:

Royal (400)/White

Size:

Select X-Small Small Medium Medium Tall Large Large Tall X-Large XX-Large XX-Large Tall 3X-Large 3X-Large Tall 4X-Large 4X-Large Tall Select

Update Page

Size Chart

US Shirt

| Brand Size | US Size | Chest (in) | Waist (in) |

|---|---|---|---|

| XS | XS | 31 – 34 | 28 – 29 |

| S | S | 34 – 37 | 29 – 31 |

| M | M | 37 – 41 | 31 – 34 |

| L | L | 41 – 44 | 34 – 37 |

| XL | XL | 44 – 48 | 37 – 41 |

| XXL | XXL | 48 – 52 | 41 – 45. 5 5 |

| 3XL | 3XL | 52 – 56 | 45.5 – 50 |

| 4XL | 4XL | 56 – 60 | 50 – 54.5 |

| 5XL | 5XL | 60 – 64 | 54.5 – 59 |

Amazon.com: Under Armour Men’s ColdGear Armour Compression Mock Long-Sleeve T-Shirt : Clothing, Shoes & Jewelry

4.7 4.7 out of 5 stars

12,524 ratings

|

76 answered questions

| Price: | $42.50$42.50 – $120.13$120.13 |

Fit:

True to size. Order usual size.

Color:

Black (001)/Steel

Size:

Select X-Small Small Medium Large Large Tall X-Large X-Large Tall XX-Large XX-Large Tall 3X-Large 3X-Large Tall 4X-Large 4X-Large Tall Select

Update Page

Size Chart

US Shirt

| Brand Size | US Size | Chest (in) | Waist (in) |

|---|---|---|---|

| XS | XS | 31 – 34 | 28 – 29 |

| S | S | 34 – 37 | 29 – 31 |

| M | M | 37 – 41 | 31 – 34 |

| L | L | 41 – 44 | 34 – 37 |

| XL | XL | 44 – 48 | 37 – 41 |

| XXL | XXL | 48 – 52 | 41 – 45. 5 5 |

| 3XL | 3XL | 52 – 56 | 45.5 – 50 |

| 4XL | 4XL | 56 – 60 | 50 – 54.5 |

| 5XL | 5XL | 60 – 64 | 54.5 – 59 |

Roxtec Wedge Compression Block and Roxtec Wedgekit

We think you may belong in this market: United States (en). Please select your preferred market website to see relevant content and product availability.

United States

Ukraine (ru)

Choose other market

Search

Roxtec Transit Designer™

User friendly web app

Roxtec Transit Designer™ is your shortcut to safety and efficiency.

This free web application simplifies product selection as well as the entire cable and pipe gland design process.

Login

Learn more and register

Contacts

Do you need help?

Wherever you work, we are ready to solve your sealing problem to ensure your safety.

Contact your nearest Roxtec office for instructions on how to solve your project problems. There you can also ask questions about the quality and method of installation.

Phone: +38 044 5361554

Email mail: [email protected]

Seal

Click the Print button on the page to view the optimized print layout.

The Roxtec Wedge compression block is used in frames with rectangular sealing zones to seal cables, pipes, modules and spacer plates. The Roxtec Wedgekit contains all the necessary components to compress a system.

- Used with appropriate Roxtec components as part of a complete sealing system

WEDGE 120 GALV

WEDGE 120 AISI 316

WEDGEKIT GALV

WEDGEKIT AISI 316

WEDGE 60 AISI 316

WEDGE 60 GALV

Blueprints

Mounting Instructions

Part numbers

Stainless steel

WEDGEKIT 60 AISI316

- Overall dimensions, W (mm)

60 - Weight (kg)

0. 8

8 - article no.

AWK0006001011

Remove from cart?

WEDGEKIT AISI316

- Overall dimensions, W (mm)

120 - Weight (kg)

1.5 - article no.

AWK0001201021

Remove from cart?

WEDGE 60 AISI316

- Overall dimensions, W (mm)

60 - Weight (kg)

0. 4

4 - article no.

ARW0000601021

Remove from cart?

WEDGE 120 AISI316

- Overall dimensions, W (mm)

120 - Weight (kg)

0.8 - article no.

ARW0001201021

Remove from cart?

Zinc plated mild steel

WEDGEKIT 60 GALV

- Overall dimensions, W (mm)

60 - Weight (kg)

0. 8

8 - article no.

5AWK000000283

Remove from cart?

WEDGEKIT GALV

- Overall dimensions, W (mm)

120 - Weight (kg)

1.5 - article no.

AWK0001201018

Remove from cart?

WEDGE 60 GALV

- Overall dimensions, W (mm)

60 - Weight (kg)

0. 4

4 - article no.

ARW0000601018

Remove from cart?

WEDGE 120 GALV

- Overall dimensions, W (mm)

120 - Weight (kg)

0.8 - article no.

ARW0001201018

Remove from cart?

| Header | Dimensions, W (mm) | Weight (kg) | Ref. No. No. | |

|---|---|---|---|---|

| WEDGEKIT 60 AISI316 | 60 | 0.8 | AWK0006001011 | |

| WEDGEKIT AISI316 | 120 | 1.5 | AWK0001201021 | |

| WEDGE 60 AISI316 | 60 | 0. 4 4 | ARW0000601021 | |

| WEDGE 120 AISI316 | 120 | 0.8 | ARW0001201021 |

| Header | Dimensions, W (mm) | Weight (kg) | Ref. No. | |

|---|---|---|---|---|

| WEDGEKIT 60 GALV | 60 | 0. 8 8 | 5AWK000000283 | |

| WEDGEKIT GALV | 120 | 1.5 | AWK0001201018 | |

| WEDGE 60 GALV | 60 | 0.4 | ARW0000601018 | |

| WEDGE 120 GALV | 120 | 0. 8 8 | ARW0001201018 |

comparison of in vivo and in vitro measurements

Clinical studies have shown that the effect of compression therapy in chronic venous insufficiency depends mainly on two factors [1-4]:

1) compression pressure of the product on the limb;

2) elastic properties (stiffness) of the material, which determine the action of knitwear in standing and walking positions.

With each muscle systole, the circumference of the tibia increases, which leads to an increase in back pressure from the compression bandage. This effect is more pronounced, the lower the elasticity of the fabric of the product.

These parameters, which determine the “dosage” of compression therapy, are of great interest to clinicians and should be declared in future studies. The physician prescribing compression products rarely realizes that the pressure ranges indicated on the packaging are obtained in laboratory conditions and not in tests in vivo . Typically, the pressure exerted by the knitwear is calculated from the force/tension diagrams of the elastic product, which are obtained on the model of the limb of a certain cross section using the Laplace formula. The pressure range specified by the manufacturer is determined by the force that must be applied to the elastic product at a certain level in order to stretch it in the transverse direction. The ratio of the amount of tension to the force spent on this tension at different levels of the product forms the degree of slope of the so-called “force/tension curve”, which reflects the elasticity of the material [5].

Typically, the pressure exerted by the knitwear is calculated from the force/tension diagrams of the elastic product, which are obtained on the model of the limb of a certain cross section using the Laplace formula. The pressure range specified by the manufacturer is determined by the force that must be applied to the elastic product at a certain level in order to stretch it in the transverse direction. The ratio of the amount of tension to the force spent on this tension at different levels of the product forms the degree of slope of the so-called “force/tension curve”, which reflects the elasticity of the material [5].

Recently, measuring devices have been introduced to determine the pressure and stiffness of compression products in vivo [6]. The aim of this study was to compare the pressure and stiffness of several medical compression garments measured directly on the extremity with the same parameters determined using methods used by knitwear manufacturers.

Material and methods

Subject parameters. The pressure exerted by several compression garments was measured on 12 lower extremities of 6 employees of Salzmann Medico (St. Gallen, Switzerland) after obtaining their informed consent to participate in the study. The average age of the participants in the experiment was 43.2 years (range 20-61 years). The studied limbs are divided into clinical classes in accordance with the CEAP classification as follows: C0 (6 limbs), C1 (4) and C2 (2). In table. 1 summarizes some basic information about volunteers. None of them used compression stockings in everyday life. The study was carried out in the laboratory of Salzmann Medico in Switzerland.

The pressure exerted by several compression garments was measured on 12 lower extremities of 6 employees of Salzmann Medico (St. Gallen, Switzerland) after obtaining their informed consent to participate in the study. The average age of the participants in the experiment was 43.2 years (range 20-61 years). The studied limbs are divided into clinical classes in accordance with the CEAP classification as follows: C0 (6 limbs), C1 (4) and C2 (2). In table. 1 summarizes some basic information about volunteers. None of them used compression stockings in everyday life. The study was carried out in the laboratory of Salzmann Medico in Switzerland.

Measurements in vivo . A medical knitwear tester (TMT) manufactured by Salzmann Medico was used. It is a flat, air-filled sleeve with a large surface area and minimal volume, with 4 electrical contacts that allow pressure measurements at 4 levels [7].

Measurements were taken at the following points along the inner surface of the lower leg [8, 9]:

B – region of the ankle joint posterior to the medial malleolus;

B1 – 8 cm higher, at the junction of the Achilles tendon to the gastrocnemius muscle;

C – 19 cm above the ankle joint in the middle part of the leg;

D – 30 cm above the ankle joint.

In fig. 1Figure 1. Measurement of compression pressure using TMT. Measurement points: B (ankle level), B1 (gaiter level), C (level of the largest circumference of the lower leg), D (level below the knee joint). the TMT is shown mounted on a wooden leg model and the measurement points are marked. Compression stockings (Salzmann Medico) fitted at the ankle and below the knee were tested for TMT in the following configurations: one Venosan 1st compression stocking; two golf Venosan 1st compression class; one golf Venosan 2nd compression class; one golf Venosan 3rd compression class. The pressure range at the level of point B, declared by the manufacturer for the 1st class as 15-21 mm Hg, for the 2nd class as 23-32 mm Hg. and for the 3rd class as 34-46 mm Hg, complied with European standards [8, 9]. These standards regulate the pressure profile along the limb: at point B1, the pressure should be 70-100%, at points C and D – 50-80% of the initial pressure at the ankle level. In vivo pressure measurements of were taken with the volunteer lying down and standing. The B1 level measurement point on TMT was taken as a reference point and marked on the leg and on the stocking. As an important parameter characterizing the elastic properties of the tested products, the static stiffness index (SSI) was calculated, which is the difference in resting pressure at point B1 in the position of the test subject lying on his back and in the standing position [10].

The B1 level measurement point on TMT was taken as a reference point and marked on the leg and on the stocking. As an important parameter characterizing the elastic properties of the tested products, the static stiffness index (SSI) was calculated, which is the difference in resting pressure at point B1 in the position of the test subject lying on his back and in the standing position [10].

in vitro measurements . The same socks that were tested on the legs of volunteers were put on wooden lower limb models with TMT to measure pressure at different levels (see Fig. 1).

In accordance with the parameters obtained from the measurement of the lower limbs of volunteers, models of three sizes were used: small, medium and large (see table. 1). Then, transverse segments 5 cm wide were cut from the knitwear at the level of point B1. These ring segments were installed in a Zwick dynamometer, and after 5 repeated cycles of overstretch, force/stretch curves were calculated [9].

On the 6th cycle, the stockings were stretched to half the circumference at point B1, which was 13.5 cm for small, 15 cm for medium and 17 cm for large. The resulting force/stretch curve is the ratio of the tensile force in newtons (N) to the elongation (stretch) in centimeters. The pressure is determined by the ratio of the tensile force to the surface area. The unit of pressure is pascal (Pa), 1 Pa is equal to the ratio 1H/1 m 2 . In medicine, pressure is usually measured in millimeters of mercury (mm Hg), while 1 N / cm 2 equals 75 mm Hg. The local pressure P1 for the B1 segment is calculated by dividing the force by the surface area of a cylinder 1 cm high and a circumference equal to the circumference of the limb at the level of B1. Based on the resulting curve, you can calculate the force required to stretch the product one additional centimeter. It can be used to calculate the local pressure of segment B1 when the circumference increases by 1 cm (P2). The difference P2-P1 corresponds to the rigidity of the product, which is the change in pressure when the segment is stretched with an increase in its circumference by 1 cm [8].

The difference P2-P1 corresponds to the rigidity of the product, which is the change in pressure when the segment is stretched with an increase in its circumference by 1 cm [8].

Statistical analysis. The results of the study are presented as means and standard deviations. Compression products were compared using the non-parametric Friedman test and Dunn’s test for multiple analysis. To compare different measurement methods, the nonparametric Spearman rank correlation coefficient and the Bland-Altman method [11] were used.

Results

Pressure measured with TMT. In tab. Figure 2 shows the pressure values exerted by the studied knitwear at all measurement points in the standing and lying position both on the volunteers’ legs and on limb mock-ups.

Pressure differences between compression classes were found to be statistically significant at the B1 level, which was the baseline in our dyno comparisons. The pressure of various models in position B1 was within the pressure range declared by the manufacturer for each compression class. Mean pressure measured at the ankle (point B) on the lower limb was often lower than the pressure at point B1, while on the wooden mock-up the higher values were always measured at the ankle. Thus, a direct comparison of our data on the B1 level obtained by in vivo , with pressure values in vitro declared by the manufacturer, is not possible. This is due to the fact that international standards rely on measurements at ankle level B, which is poorly suited for in vivo measurements of [6].

Mean pressure measured at the ankle (point B) on the lower limb was often lower than the pressure at point B1, while on the wooden mock-up the higher values were always measured at the ankle. Thus, a direct comparison of our data on the B1 level obtained by in vivo , with pressure values in vitro declared by the manufacturer, is not possible. This is due to the fact that international standards rely on measurements at ankle level B, which is poorly suited for in vivo measurements of [6].

It is interesting to note that the highest pressure was obtained when using two stockings of the 1st class, dressed one on top of the other, which turned out to be even higher than the pressure of the stockings of the 3rd compression class.

Comparison of pressure values obtained on TMT ( in vivo ) and using dynamometry ( in vitro ). When comparing products worn in one layer, the pressure values of golf of different compression classes, measured using TMT at level B1, were similar to the values calculated on the basis of force/tensile curves obtained by dynamometry of circular knitwear segments cut at level B1 (Fig. 2).Figure 2. Compression pressure measurement comparison in vivo and in vitro . Left: The pressure of several compression garments measured with the TMT at point B1 (gaiter level). Right: Pressure calculated from force/stretch curves obtained from dynamometry of some compression garments. Bland-Altman plot (Fig. 3), Figure 3. Bland-Altman plot for comparing TMT and dyno measurements. Comparison of compression pressure values measured with TMT at point B1 (sock level) with calculated values obtained using force/extensibility curves based on dynamometry in vitro . On the abscissa – the degree of coincidence of measurements; along the y-axis – differences in the measurement results. plotted on the basis of the pressure values of the golf, worn in one layer, shows that the measurement values of in vivo and in vitro are very close. The displacement (deviation from the mean value) was 2.13 and 4.1 mmHg. In 95% of subjects, the deviation was in the range from -0.

2).Figure 2. Compression pressure measurement comparison in vivo and in vitro . Left: The pressure of several compression garments measured with the TMT at point B1 (gaiter level). Right: Pressure calculated from force/stretch curves obtained from dynamometry of some compression garments. Bland-Altman plot (Fig. 3), Figure 3. Bland-Altman plot for comparing TMT and dyno measurements. Comparison of compression pressure values measured with TMT at point B1 (sock level) with calculated values obtained using force/extensibility curves based on dynamometry in vitro . On the abscissa – the degree of coincidence of measurements; along the y-axis – differences in the measurement results. plotted on the basis of the pressure values of the golf, worn in one layer, shows that the measurement values of in vivo and in vitro are very close. The displacement (deviation from the mean value) was 2.13 and 4.1 mmHg. In 95% of subjects, the deviation was in the range from -0. 1 to 5.8 mmHg. The correlation was statistically significant (Fig. 4; Fig. 4. Correlation between the compressive pressure values of class 1-3 knitwear, measured using TMT in vivo and Zwick dynamometer in vitro . CI – confidence interval. R

1 to 5.8 mmHg. The correlation was statistically significant (Fig. 4; Fig. 4. Correlation between the compressive pressure values of class 1-3 knitwear, measured using TMT in vivo and Zwick dynamometer in vitro . CI – confidence interval. R

Hardness. Rigidity is defined as an increase in compression pressure per 1 cm increase in limb circumference [8]. The static stiffness index (SSI) was defined as the pressure difference between an active standing position and a relaxed lying position [6, 10]. SSI measured with TMT on 12 knee socks at four points (B, B1, C, D) was 2.96±8.19; 3.78±3;84; 3.06±4.44; 1.96±7.82, respectively. The highest pressure values are observed at the B1 level, the region of the lower leg with the most pronounced change in the local radius and an increase in the circumference of the lower leg in the position of the foot dorsiflexion [12]. In vitro stiffness was calculated from the degree of slope of the force/stretch curve. As shown in fig. 5, Figure 5 Static Stiffness Index (SSI) of various compression stockings measured with TMT in vivo (pin vitro (pin vitro (not shown in graphs). and in measurements in vitro , and in measurements in vivo , the maximum stiffness values were obtained when using two stockings of the 1st compression class, dressed one on top of the other, and with a statistically significant difference compared to knitwear of the 2nd compression class when measured in vivo (pin vitro (p

As shown in fig. 5, Figure 5 Static Stiffness Index (SSI) of various compression stockings measured with TMT in vivo (pin vitro (pin vitro (not shown in graphs). and in measurements in vitro , and in measurements in vivo , the maximum stiffness values were obtained when using two stockings of the 1st compression class, dressed one on top of the other, and with a statistically significant difference compared to knitwear of the 2nd compression class when measured in vivo (pin vitro (p

Pressure gradient. All stockings showed a decrease in pressure from point B1 to point D both on wooden leg models and on the limbs of volunteers in both lying and standing positions (Table 2). On fig. 6Figure 6. Pressure values obtained when using knitwear of the 3rd compression class on the lower limb in the prone and standing position of the subject, as well as on a wooden model of the limb (DMK). the average values of the pressure created by the 3rd compression class knitwear on the limbs of volunteers in the prone and standing positions, as well as on a wooden model, are reflected. At ankle level (point B) in vivo , the pressure was lower than when measured on a model limb, due to differences in the geometry of this anatomical region.

At ankle level (point B) in vivo , the pressure was lower than when measured on a model limb, due to differences in the geometry of this anatomical region.

Talk

It is noteworthy that the indicated pressure ranges and classification of medical compression products into compression classes are based entirely on in vitro measurements of by the manufacturer. Single attempts were made to compare several measurement methods [13]. The present study demonstrated that, at least for the products tested, the stated pressure ranges satisfactorily matched the measurement results in vivo .

Test subjects. Healthy volunteers with different configurations of the lower extremities were selected for the study. Pressure and stiffness parameters measured immediately after putting on compression stockings do not differ between healthy subjects and patients with pathology of the venous or lymphatic systems. Since a good correlation was shown between the pressure values of the knitwear on the limbs of the volunteers and the wooden leg model, even severe lipodermatosclerosis would not have affected the results of the measurements obtained in the acute experiment. However, if such studies are directly focused on the elimination of edema, it may be appropriate to re-measure the compression pressure and volume of the limb some time after putting on the knitwear.

However, if such studies are directly focused on the elimination of edema, it may be appropriate to re-measure the compression pressure and volume of the limb some time after putting on the knitwear.

Measurement methods and points. Based on a comparative study using three compression band pressure measuring devices, J. Dale et al. [14] recommended TMT for use in subsequent experiments. This tester is reliable in routine use and allows you to measure the pressure on the inner surface of compression stockings at several points simultaneously [7, 14]. The disadvantages of the device are its limited availability, applicability only for the state of rest and the impossibility of continuous measurement of pressure while walking.

For knitwear manufacturers, the area around the ankle is the reference for compression class and pressure range. level B. The stretch of the knitwear, measured with a dynamometer, is transferred to the surface of a cylinder with a circular cross section in such a way that theoretically it should be the same at each point of segment B. In reality, segment B on the lower limb, corresponding to the cross section at ankle level, has the most variable curvature of all other limb segments. In fact, the pressure values measured in the posterior malleolar region are often lower than the pressure value at level B1, i.e. 8 cm higher (see Table 2), which emphasizes the importance of the local radius of the limb segment (according to Laplace’s law, local pressure is inversely proportional to the radius) [1] .

In reality, segment B on the lower limb, corresponding to the cross section at ankle level, has the most variable curvature of all other limb segments. In fact, the pressure values measured in the posterior malleolar region are often lower than the pressure value at level B1, i.e. 8 cm higher (see Table 2), which emphasizes the importance of the local radius of the limb segment (according to Laplace’s law, local pressure is inversely proportional to the radius) [1] .

Pressure gradient. As shown in the table. 2 and in fig. 6, the wooden leg model, with its round cross-section, provides uniform pressure relief in the proximal direction. The pressure values coincided with the measurements of in vivo at the level of the maximum circumference of the lower leg (point C) and below the knee joint (point D), where the transverse section of the lower leg is close in shape to a circle and does not change significantly in the standing position. In vivo pressure values at point B are lower, which is associated with the location of the measurement point posterior to the ankle, where the contour of the perimeter of the limb is flat, and in some cases concave. The greatest pressure difference in the standing and lying positions was determined at level B1 (see Table 2, Fig. 6), which indicates the optimality of this position for assessing the rigidity of knitwear.

The greatest pressure difference in the standing and lying positions was determined at level B1 (see Table 2, Fig. 6), which indicates the optimality of this position for assessing the rigidity of knitwear.

Stiffness study in vivo . Rigidity can be defined as an increase in compressive pressure with an increase in limb circumference by 1 cm (due to muscle contraction) [8]. This parameter characterizes the extensibility of the tissue, which determines the effectiveness of the compression product in the standing position and when walking [8, 10]. Several experiments have shown that even at the same resting pressure, knitwear with higher stiffness is more effective in eliminating edema [3], reflux [2] and dynamic venous hypertension [1] in patients with chronic venous insufficiency. When the sensor is placed on the inner surface of the lower leg in position B1, the increase in pressure when moving from a lying position to a standing position is a simple indicator of stiffness, a static stiffness index [10]. This increase in pressure is due to a decrease in the local radius due to displacement (protrusion) of the muscle tendon (in accordance with the Laplace equation) and an increase in leg circumference during dorsiflexion of the foot with each step [12]. Plethysmography in the standing position with dorsiflexion and plantar flexion showed the dependence of the change in the circumference of the lower leg on the measurement point. In segment B1, an average increase in limb circumference by 8 mm was recorded, while in the proximal tibia, a decrease in circumference by 2–4 mm was determined [12]. Changes in the local radius due to displacement of the tendons during movement in the ankle joint are very individual. The high variability in the values of the static stiffness index mainly reflects significant individual differences in the shape of the lower leg in the standing position and when walking.

This increase in pressure is due to a decrease in the local radius due to displacement (protrusion) of the muscle tendon (in accordance with the Laplace equation) and an increase in leg circumference during dorsiflexion of the foot with each step [12]. Plethysmography in the standing position with dorsiflexion and plantar flexion showed the dependence of the change in the circumference of the lower leg on the measurement point. In segment B1, an average increase in limb circumference by 8 mm was recorded, while in the proximal tibia, a decrease in circumference by 2–4 mm was determined [12]. Changes in the local radius due to displacement of the tendons during movement in the ankle joint are very individual. The high variability in the values of the static stiffness index mainly reflects significant individual differences in the shape of the lower leg in the standing position and when walking.

A greater increase in pressure was noted when using an inelastic material and a smaller one when using a pliable, elastic knitted fabric [6, 10]. The stiffness index of compression stockings is lower than that of short stretch compression bandages. Comparison of stiffness values is possible only when the same sensor is exactly installed in the same position [6].

The stiffness index of compression stockings is lower than that of short stretch compression bandages. Comparison of stiffness values is possible only when the same sensor is exactly installed in the same position [6].

An unexpected finding was that two stockings of the 1st compression class, worn one on top of the other, not only provided a higher pressure at level B1 than a stocking of the 3rd compression class (see Table 2), but also showed a higher stiffness coefficient as in measurements in vivo and in the in vitro tests (see Fig. 5). This phenomenon can be explained by friction between the two layers of the fabric of compression garments [12]. When the calf circumference increases while standing or walking, tangential stress is transferred to the fibers of the compression stocking. The friction between the rough surface of the knit layers prevents the increase in the volume of the lower leg in addition to the elastic stretch of the fibers of the fabric.

Compression pressure measurement validity in vivo . The pressure values obtained using a tester of medical knitwear on the limbs of volunteers not only agree well with those obtained on a wooden model (see Table 2), but also correlate with the calculated data on the force / stretch curves (see Fig. 4) . This contradicts the recently published data obtained by measuring in vivo compression pressure of class 3 knitwear using a resistive sensor, which did not exceed 15 mmHg. [15]. In this study, unfortunately, no attempt was made to calibrate the sensor or compare its readings with the reference method.

Our in vivo measurements of closely match the pressure ranges recommended in several international standards, measured not at point B, but at point B1, which is more reliable in this respect. To ensure a pressure gradient, the European Standardization Project recommends creating pressure at point B1 at a level of 70-100% of its value at point B [8]. This should be taken into account when comparing the results of measurements at point B1 in vivo and in vitro (see Figure 2).

This should be taken into account when comparing the results of measurements at point B1 in vivo and in vitro (see Figure 2).

Practical value for international standards for compression stockings. The following items need to be discussed with compression garment manufacturers:

– to characterize the different degrees of compression of knitwear, not compression classes, but pressure ranges in mmHg should be used;

– pressure ranges, which are currently only determined by various laboratory tests, must also be verified in vivo ;

– point B1 should be used for such measurements;

– in vivo measurements must be performed with the patient lying down and standing. The difference in values at this point can be used as a stiffness parameter;

– measurements of this kind should be performed in subsequent hemodynamic and clinical studies with testing of new developments or comparison of various devices;

– multilayer stockings are an interesting solution not only in terms of ease of use by patients, but also in terms of achieving high pressure and high stiffness. The desired pressure can be matched to the periods of daily activity and rest by adding or removing layers of knitwear.

The desired pressure can be matched to the periods of daily activity and rest by adding or removing layers of knitwear.

[1] Translator’s note. The authors do not correctly apply Laplace’s law. In accordance with this law, with an increase in the radius of a vessel with a flowing liquid, the pressure in it decreases proportionally, i.e. The pressure inside a vessel is inversely proportional to its radius. However, in this study, compression pressure (external to the limb) is considered, which, due to the stretching of the compression stockings, increases in direct proportion to the increase in the radius of the limb.

- Partsch H. Improvement of venous pumping function in chronic venous insufficiency by compression depending on pressure and material. VASA 1984;13:58-64.

- Partsch H., Menanger G., Mostbeck A. Inelastic leg compression is more effective to reduce deep venous rolluxcs than elastic bandages. Dermatol Surg 1999;25:695-700.

- Van Geesi A.J., Veraart J.C., Nelemans P., Neumann H.A. The effect of medical elastic compression stockings with differenl slope values on edema. Measurements underneath three different types of stockings. Dermatol Surg 2000;26:244-247.

- Hafner H.M., Piche E., Junger M. The ratio of working pressure to resting pressure under compression stockings: its significance for the development of venous perfusion in the legs. Phlebology 2001;30:88-93.

- Partsch H., Rabe E., Stemmer R. Compression therapy of the extremities. Paris: Editions Phlebologiques Francaises 1999.

- Partsch H., Clark M., Bassez S. et al. Measurement of lower leg compression in vivo: Recommendations for the performance of measurements of interface pressure and stiffness: A consensus statement. Dermatol Surg 2006;32:224-233.

- Van den Berg E., Borgnis F.E., Bolliger A.A. et al. A new method for measuring the effective compression of medical stockings.

VASA 1982;11:117-123.

VASA 1982;11:117-123. - CEN European Prestandard. Medical compression hospitality. Management Center of the European Committee for Standardization. Brussels 2001;1-43.

- RAL-GZ 387 Medizinische Kompressionsstrumpfe. Deutsches Institut für Gutesicherung und Kennzeichnung. Berlin: Beuth-Verlag 2000;1-20.

- Partsch H. The static stiffness index (SSI) – a simple method to assess the elastic property of compression material in vivo. Dermatol Surg 2005;31:625-630.

- Motulskv H. Prism4 Statistics Guide. Statistical analysis for laboratory and clinical researchers. San Diego, CA: GraphPad Software Inc. 2005.

- Stolk R. Wegen, van der Franken C.P.M., Neuman H.A.M A method for measuring the dynamic behavior of medical compression hosiery during walking. Dermatol Surg 2004;30:729-736.

- Kunzli D. Vergleichsmessungen Hatra. Hohenstein, EMPA, MST. Swiss Med 1988;10:73-76.

- Dale J.

8

8 4

4 8

8 4

4

VASA 1982;11:117-123.

VASA 1982;11:117-123.