How can you identify worn ball joints. What are the key symptoms of ball joint failure. How to perform a visual inspection of ball joints. Why are ball joints crucial for vehicle safety and performance. What steps can you take to extend the lifespan of your ball joints.

Understanding Ball Joints: Function and Importance in Vehicle Suspension

Ball joints play a crucial role in your vehicle’s suspension system, acting as pivotal connectors between the steering knuckles and control arms. They allow for smooth movement of the wheels while maintaining proper alignment. Understanding their function is essential for every vehicle owner.

Why are ball joints so important? They provide the necessary flexibility for your wheels to turn and your suspension to move up and down, all while keeping your tires in contact with the road. Without properly functioning ball joints, your vehicle’s handling, safety, and overall performance would be severely compromised.

The Anatomy of a Ball Joint

A typical ball joint consists of several key components:

- Ball stud: The spherical end that fits into the socket

- Socket: The housing that encases the ball stud

- Bearing: Allows smooth rotation of the ball stud within the socket

- Rubber boot: Protects the joint from contaminants and retains lubricant

How do these components work together? The ball stud rotates within the socket, facilitated by the bearing, while the rubber boot keeps the assembly clean and well-lubricated. This design allows for a wide range of motion while maintaining structural integrity.

Recognizing the Symptoms of Worn Ball Joints

Identifying worn ball joints early can prevent more severe damage to your vehicle’s suspension system. Several telltale signs indicate that your ball joints may be failing:

- Clunking or squeaking noises, especially when driving over bumps

- Vehicle drifting to one side during straight-line driving

- Loose or shaky steering, particularly at lower speeds

- Uneven tire wear, often more pronounced on the inner or outer edges

- Excessive vibration felt through the steering wheel or floorboard

Can worn ball joints develop gradually? Indeed, the symptoms of ball joint wear often progress slowly, making them easy to overlook. Regular inspections and attentiveness to changes in your vehicle’s behavior are key to early detection.

Performing a Dynamic Ball Joint Check While Driving

One effective way to assess the condition of your ball joints is to perform a dynamic check while driving. This method allows you to feel and hear potential issues firsthand.

Step 1: Road Test at Normal Speeds

Take your vehicle for a drive on a public road, maintaining the speed limit. Pay close attention to the following:

- Steering responsiveness

- Any unusual vibrations through the floor or steering wheel

- Tendency of the vehicle to wander or pull to one side

Step 2: Speed Bump Test

Find an area with speed bumps and drive over them at a low speed. Listen for:

- Clunking noises as the suspension compresses and extends

- Squeaking sounds that may indicate a damaged rubber boot

Step 3: Steering Wheel Test

Park the vehicle and turn the steering wheel back and forth. Listen carefully for any noises coming from the front suspension area.

How effective is this dynamic testing method? While it can provide valuable insights, it’s important to note that this should be combined with a visual inspection for a comprehensive assessment of your ball joints’ condition.

Visual Inspection Techniques for Ball Joint Wear

After conducting a dynamic test, a thorough visual inspection is crucial to confirm any suspicions of ball joint wear. Here’s how to perform a visual check:

1. Lift and Secure the Vehicle

Safely lift the vehicle and support it on jack stands. Ensure the vehicle is stable before proceeding with the inspection.

2. Check for Visible Damage

Examine the ball joints for any signs of physical damage, such as:

- Torn or cracked rubber boots

- Grease leakage

- Rust or corrosion around the joint

3. Assess Joint Movement

Using a pry bar, attempt to move the ball joint up and down, and side to side. Excessive movement may indicate wear.

4. Inspect Tire Wear Patterns

Uneven tire wear, particularly on the inner or outer edges, can be a sign of ball joint issues.

Is a visual inspection alone sufficient? While visual checks are valuable, they should be combined with dynamic testing and, when in doubt, a professional assessment for the most accurate diagnosis.

The Role of Ball Joints in Vehicle Safety and Performance

Understanding the critical role ball joints play in your vehicle’s operation underscores the importance of maintaining them properly. Ball joints are not just components of the suspension system; they are integral to overall vehicle safety and performance.

Safety Implications

Properly functioning ball joints contribute to vehicle safety in several ways:

- Maintaining wheel alignment for predictable handling

- Ensuring smooth steering response

- Preventing sudden loss of control due to suspension failure

Performance Benefits

Beyond safety, ball joints also impact your vehicle’s performance:

- Optimizing tire contact with the road for better traction

- Reducing uneven tire wear, extending tire life

- Minimizing vibrations for a smoother, more comfortable ride

How significant is the impact of worn ball joints on vehicle dynamics? Worn ball joints can dramatically affect your vehicle’s handling, potentially leading to unsafe driving conditions and accelerated wear on other suspension components.

Maintenance Tips to Extend Ball Joint Lifespan

While ball joints are designed to be durable, proper maintenance can significantly extend their lifespan and ensure optimal performance. Here are some key maintenance tips:

1. Regular Lubrication

If your vehicle has greasable ball joints, regular lubrication is crucial. Consult your vehicle’s manual for the recommended greasing schedule and type of grease to use.

2. Protective Measures

Protect your ball joints from excessive wear by:

- Avoiding curbs and potholes when possible

- Reducing load on the suspension by not overloading your vehicle

- Regularly cleaning the undercarriage to remove corrosive substances

3. Alignment Checks

Regular wheel alignments can help distribute wear evenly across suspension components, including ball joints.

4. Timely Replacement

When signs of wear appear, don’t delay replacement. Driving on worn ball joints can lead to more extensive and costly damage.

Can proper maintenance significantly extend ball joint life? Absolutely. Regular care and attention to your vehicle’s suspension system can double or even triple the lifespan of your ball joints, saving you money and ensuring safer operation in the long run.

Advanced Ball Joint Technologies and Future Trends

As automotive technology advances, so too does the design and functionality of ball joints. Understanding these developments can help vehicle owners make informed decisions about maintenance and upgrades.

Material Innovations

Modern ball joints are benefiting from advancements in materials science:

- High-strength alloys for increased durability

- Ceramic ball studs for reduced friction and wear

- Synthetic lubricants that offer better performance in extreme conditions

Design Improvements

New design features are enhancing ball joint performance and longevity:

- Self-lubricating polymers that reduce maintenance requirements

- Integrated sensors for real-time wear monitoring

- Modular designs that simplify replacement procedures

Future Trends

Looking ahead, several trends are shaping the future of ball joint technology:

- Integration with active suspension systems for improved ride quality

- Use of smart materials that can adapt to different driving conditions

- Development of eco-friendly, biodegradable lubricants

How will these advancements impact vehicle owners? As ball joint technology evolves, vehicle owners can expect longer-lasting components, reduced maintenance requirements, and improved overall vehicle performance. However, these advanced technologies may also require specialized knowledge for proper diagnosis and replacement.

Professional vs. DIY Ball Joint Replacement: Weighing the Options

When it comes to replacing worn ball joints, vehicle owners often face the decision between professional service and DIY replacement. Each approach has its pros and cons, and the right choice depends on various factors.

Professional Replacement

Advantages of professional ball joint replacement include:

- Access to specialized tools and equipment

- Expertise in diagnosing and addressing related suspension issues

- Warranty coverage for parts and labor

- Time-saving for the vehicle owner

Potential drawbacks:

- Higher cost compared to DIY

- Dependence on shop availability and scheduling

DIY Replacement

Benefits of DIY ball joint replacement:

- Cost savings on labor

- Personal satisfaction and learning experience

- Flexibility in timing and part selection

Challenges of DIY approach:

- Requires specialized tools and mechanical knowledge

- Risk of improper installation leading to safety issues

- Time-consuming, especially for inexperienced mechanics

- May void vehicle warranty if not done correctly

Is DIY ball joint replacement recommended for everyone? While it can be a rewarding project for experienced home mechanics, the complexity and safety-critical nature of ball joints make professional replacement the safer choice for most vehicle owners. Those considering DIY should honestly assess their skills and tools before attempting the job.

In conclusion, ball joints are crucial components of your vehicle’s suspension system, directly impacting safety, performance, and comfort. Regular inspection, proper maintenance, and timely replacement are essential for optimal vehicle operation. Whether opting for professional service or DIY replacement, understanding the function and importance of ball joints empowers vehicle owners to make informed decisions about their maintenance and care.

Checking Balls (w/ reference shoulders)

Checking Balls (w/ reference shoulders)

High precision stainless steel checking balls are made to closer tolerances and avoid excessive side forces. The accurately located shoulder provides for positive positioning, re-positioning, or replacement. Note: Part Number 29021 has a tapped 6-32 UNC -2B shank.

- Material: Type 440-C Stainless Steel hardened to Rc 58-62

- Eccentricity, ball to shank, 0.0002 T.I.R. maximum

- Two Piece Welded Construction

- Note:

Part No.

29010 supplied with tungsten carbide ball only with hardness Ra 91.5 – 92.5

29010 supplied with tungsten carbide ball only with hardness Ra 91.5 – 92.5

- Available in FixtureProTM Design Software

- Note:Part: 29021 has a 6-32 UNC 2B Tapped Shank

- Note: The weld between the ball and the shank is made so that the ball will drop off if subjected to unusually heavy leteral forces. This prevents setup and inspection errors that might occur do to accidental bending of the shank.

- Part Drawings

- Product Literature

Click the Part Number

in below chart

for Price and Stock Check.

| CAD Download Link |

| 0.1250 | 0.1255 | 0.0938 | 0.3750 | ||

| 0.2500 | 0.1247 | 0.2000 | 0.5600 | ||

| 0.3750 | 0.1872 | 0.3000 | 0.7500 | ||

| 0.5000 | 0.2497 | 0.4000 | 0.9400 | ||

| 0.6250 | 0.3122 | 0.4500 | 1. 0600 0600 | ||

| 0.7500 | 0.3747 | 0.5000 | 1.2500 | ||

| 0.8750 | 0.4372 | 0.6000 | 1.4400 | ||

| 1.0000 | 0.4997 | 0.7000 | 1.6200 |

PN 29010 is supplied with tungston carbide ball only, with Rockwell hardness 91.5 – 92.5

Unless otherwise stated, English units are inches (in) and pounds (lbs) and Metric units are millimeters (mm) and kilograms (kg).

Worn ball joints? Here’s how to check

These include:

- Clunky or squeaky noises

- Drifting to the side

- Loose or shaky steering

- Uneven tyre wear

How can you check for worn ball joints?

It’s possible that the symptoms of worn ball joints develop slowly, so you don’t notice for a while. But, if you have noticed any of the symptoms above, or would just like to double check your ball joints, it’s best to first check your ball joints when driving before doing a visual inspection.

But, if you have noticed any of the symptoms above, or would just like to double check your ball joints, it’s best to first check your ball joints when driving before doing a visual inspection.

How to check your ball joints when driving

Checking your ball joints when driving is straightforward, simply:

1. Take your car out for a drive

Drive the vehicle on a public road at the speed limit and pay close attention to the engine, steering and overall performance of the car.

What to look out for

Vibrations – when a ball joint wears out, it becomes loose which can create a vibration that you can feel through the floor or the steering wheel while you drive.

Steering wheel wandering to the left or the right – worn ball joints cause the steering to pull from left to right on its own. This can also cause uneven wear on your tyres.

2. Drive over speed bumps

After driving at the speed limit, take it somewhere with speed bumps and drive it at a low speed. Stop and go a few times, and turn a few times.

Stop and go a few times, and turn a few times.

What to look out for

Noise – this can be a clunking or squeaking noise. Clunking noises are caused by the worn ball joints rattling as the suspension travels up and down over the road. The squeaking noise is caused by the rubber boot that protects the grease inside the ball joint is damaged, the ball joint will start to squeak. These noises will get louder the more worn the ball joints become.

3. Turn the steering wheel

The last step is to park the car and turn the wheels back and forth a few times, while listening for noise from the ball joints.

How to check ball joints visually

After checking your ball joints while driving, it’s time for a visual and physical inspection. Before you start, make sure you have the following tools ready:

- Jack

- Jack stands

- Flashlight

- Pry bar

- Lug nut wrench

- Wooden blocks or wheel chocks

A visual and physical inspection has the following steps:

1.

Check your tyre wear

Check your tyre wear

Loose ball joints can’t keep your suspension aligned while you drive. This accelerates tyre wear by causing the rubber tread to touch the ground in an inconsistent way. If you notice feathering (i.e. uneven spots of wear on a tyre) or that the front of the wheels points out (i.e. toe-out), there’s a good chance that your ball joints will need further investigation. However, if the tyre wear is equal on both sides, then the issue is probably not your ball joints, but due to under-inflation of the tyres.

2. Loosen the lug nuts

Loosen the lug nuts so they are hand-tight. This will allow you to move the wheel around on its axis, without removing it completely.

3. Jack up the car and place wheel chocks behind the wheels

Jack the front of the car up and secure it on jack stands. Put wheel chocks or wooden blocks behind the back wheels to prevent the car from rolling. This will make it easier to test the ball joints.

4. Rock the tyre on its axis

Grasp the top and bottom of the tyre and rock it in and out along the wheel’s vehicle axis. If the ball joints are working well, there should be little to no play in this movement.

If the ball joints are working well, there should be little to no play in this movement.

What to look out for

Noise and play from the top – this indicates a problem with the upper ball joint.

Noise and play from the bottom – this suggests a problem with the lower ball joint.

5. Remove the wheel

Remove the wheel and use a flashlight to visually check the upper and lower ball joints.

What to look out for

Can you see any signs of rust, damage to the dust boot, grease leakage or any other potential problem? If so, it’s probably time to replace your ball joint.

6. Pry the ball joint apart

Use the pry bar and attempt to pry the lower control arm and the steering knuckle (the two components connected by the ball joint).

What to look out for

Excessive amounts of play and movement or clicking sounds are a sign that your ball joints are too loose.

7. Put the wheel back on

After you have finished visually inspecting and testing the ball joint, replace the wheel, lower the car and torque the lug nuts.

8. Repeat with the other wheels

After you have finished the first wheel, you need to check the other three, by following steps 2-7.

.500 Ball dia., .2500 Dia. shank (max.) w/6-32 tap x 3/8 Deep Min., Checking Ball with Reference Shoulder and Tapped Shank (1 Each): Precision Balls: Amazon.com: Industrial & Scientific

Currently unavailable.

We don’t know when or if this item will be back in stock.

| Brand | RSC |

| Material | Stainless Steel |

| Item Weight | 0. |

]]>

Specifications for this item

| Brand Name | RSC |

|---|---|

| Item Weight | 0.480 ounces |

| Material | Stainless Steel |

| Measurement System | Inch |

| Part Number | JFB-29021 |

| UNSPSC Code | 31163000 |

How to Check Suspension Ball Joints

Ball joints are a suspension component that is found on virtually all vehicles. Ball joints are flexible joints that allow components of the suspension to move up and down, as well as side-to-side, usually in a full 360 degree rotation.

Ball joints are flexible joints that allow components of the suspension to move up and down, as well as side-to-side, usually in a full 360 degree rotation.

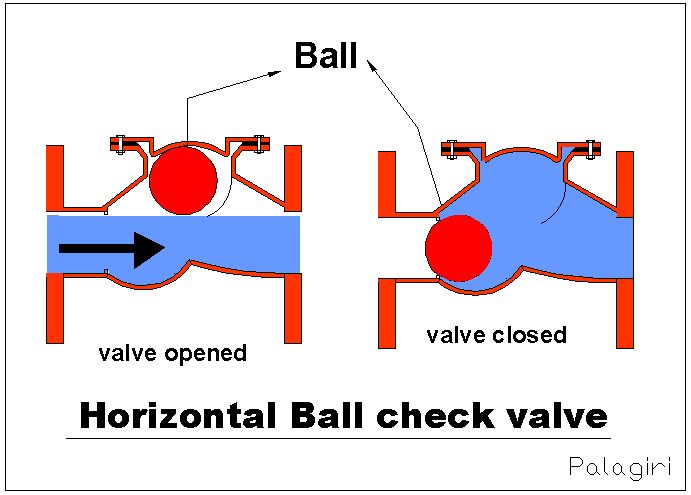

Ball joints are typically a ball-in-socket design that is lubricated with grease and covered by a dust boot. Some will have an external grease fitting for adding lubrication, while others will be sealed designs. While this design of the joints is commonly used on many other suspension components, such as tie rod ends and sway bar links, ball joints are responsible for connecting the suspension control arms to the vehicle’s steering knuckles.

Depending on the type of suspension, most vehicles will have upper and lower ball joints that serve as some of the most important joints that connect the frame of the vehicle to the suspension. When they fail, the vehicle may experience issues ranging from minor noises and vibrations in the suspension, to a complete failure which will render the vehicle undriveable.

This article shows you how to check ball joints for looseness and play to see if they need to be replaced. By listening to the vehicle while driving, feeling for any symptoms, and visually inspecting the ball joints while the car is raised, you can find out if your ball joints are causing issues with your car.

By listening to the vehicle while driving, feeling for any symptoms, and visually inspecting the ball joints while the car is raised, you can find out if your ball joints are causing issues with your car.

Method 1 of 2: Checking the ball joints by driving the vehicle

Step 1: Take the car for a drive. Drive the vehicle up to the speed limit on a public road and listen for any noises that may be coming from the suspension.

Worn ball joints will usually be indicated by an intermittent banging sound that will appear to be coming from one of the vehicle’s corners.

Take note of any unusual feelings in the steering wheel. Worn ball joints may cause excessive vibration in the steering wheel, as well as cause the steering to wander, requiring constant corrective input from the driver.

Step 2: Drive over speed bumps. Once you have driven the vehicle at full speed, take it into a parking lot with speed bumps, and drive it at a low speed.

Stop and go a few times, drive over speed bumps, and make a few turns at low speed.

Listen for any banging or thumping noises. These sounds may become more pronounced when turning at low speeds and going over speed bumps.

Step 3: Turn the steering wheel. Once the vehicle has been driven at low speed, park the vehicle.

Turn the wheels back and forth a few times, again listening for any potential signs of looseness in the vehicle’s ball joints.

- Tip: Remember that any noises due to excessively worn ball joints will usually present themselves as a knocking sound that will get worse over time, having a more pronounced effect on the vehicle’s suspension and steering.

Once the vehicle has been driven, it is time for a visual and physical inspection tests.

Method 2 of 2: Checking ball joints visually

Materials Needed

Step 1: Loosen the lug nuts. Loosen the lug nuts, however, leave them on hand tight, with the wheel still secured reasonably tightly to the vehicle.

Loosen the lug nuts, however, leave them on hand tight, with the wheel still secured reasonably tightly to the vehicle.

This will allow you to move the wheel around on its axis (without removing it).

Step 2: Jack up the car. Jack up the vehicle’s front end, and secure it on jack stands. It will be much easier to test the ball joints without the entire weight of the vehicle on the wheels.

Step 3: Place wheel chocks behind the wheels. Put wheel chocks or wood blocks behind the vehicle’s rear wheels and set the parking brake to prevent the vehicle from rolling.

Step 4: Rock the tire on its axis. Once the vehicle has been raised, grasp the top and bottom of the tire, and rock it in and out along the wheel’s vertical axis.

There should be little to no play if the ball joints are both in sound condition.

Take notice of any play that seems excessive, or noises present when rocking the wheel in and out, and where the sounds or play seem to be coming from.

Tip: Any noises or play heard towards the top are most likely indicative of a problem with the upper ball joint, while, any play or noise coming from the bottom of the wheel are probably indicative of a problem with the lower ball joint.

Warning: When conducting this test, make sure that the lug nuts are not loose, as that may cause movement when rocking the wheel. The lug nuts do not need to be fully torqued down; they simply need to be tight enough that the wheel is secured on the hub.

Step 5: Remove the wheel. Once you are ready to proceed, remove the wheel and visually inspect both the upper and lower ball joints using the flashlight.

- Tip: For instructions on how to remove the wheel off its axis, you can see instructions in our article, “How to Change a Tire”.

Closely examine the ball joints for any signs of rust, damage to the dust boot, grease leakage, or other potential problems that may indicate a need for replacement.

Step 6: Pry apart the ball joint. Take a pry bar and place it between the lower control arm and the steering knuckle, the two parts that are connected together by the ball joint, and attempt to pry them apart.

Loose ball joints will have an excessive amount of play and movement when you pry on them, may even make knocking or clicking sounds.

Step 7: Put the wheels back on. Once you have visually inspected and tested the ball joints with a pry bar, reinstall the wheel, lower the vehicle, and torque the lug nuts.

Step 8: Check the joints on other wheels. At this point you may proceed to the other three wheels of the vehicle, using the exact same procedures as outlined in Steps 1-5.

Ball joints are one of the most critical components in a vehicle’s suspension, and checking to make sure that they are in sound condition is a relatively easy test to conduct. Worn ball joints can cause all sorts of problems, ranging from play in the steering wheel, to noises when going over bumps, to uneven tire wear.

If you have any suspicion that your ball joints may be worn, do not hesitate to check them. If necessary, have a professional technician, such as one from YourMechanic, assist you with replacing both the front and rear ball joints.

Suspension Inspection: Tips on Checking a Variety of Suspension Components | 2017-04-12

Let’s take a look at various suspension parts inspections, including ball joints, wheel bearings, wheel hub units, control arm bushings and more.

Ball joints

Loaded ball joints experience vehicle weight, typically at the lower control arm at the lower arm on an SLA (short/long arm) suspension, which also must be able to pivot in relation to steering linkage and the steering knuckle.

On a twin-arm suspension, the upper ball joint serves as a follower joint. A strut suspension uses a follower ball joint to connect the lower control arm, steering knuckle and the strut. The upper strut mount assembly features a thrust-type bearing to support the weight of the vehicle and allow the steering linkage to rotate the strut and steering knuckle.

Check for both axial and lateral runout. Axial runout of a ball joint basically refers to the in/out movement of the ball joint stud and ball relative to its ball socket as the stud and ball moves in-out of the socket. Lateral runout refers to movement of the stud ball side-to-side within the socket.

To check for axial runout on an SLA suspension, support vehicle weight by lifting at the lower control arm. Place a pry bar between the bottom of the tire and the ground to first determine if any axial movement is present. When dealing with a MacPherson strut front suspension, lift the vehicle by the frame or rocker panel support area and test in the same manner.

If lower ball joint axial play is suspected, attach a dial indicator to the lower control arm and position the dial gauge in a vertical position on a clean flat spot at the top of the spindle steering knuckle. Preload the dial indicator by about 0.050 inch and zero the gauge. While prying up/down, if axial movement exceeds the manufacturer specification limit, the ball joint (or the lower control arm assembly, depending on the design, should be replaced. Naturally, always refer to the runout limit specifications listed for the specific vehicle. Manufacturer specifications regarding axial or lateral joint runout limits will vary from about 0.020 inch to as much as 0.100 inch or more.

Naturally, always refer to the runout limit specifications listed for the specific vehicle. Manufacturer specifications regarding axial or lateral joint runout limits will vary from about 0.020 inch to as much as 0.100 inch or more.

To check the follower (non-load carrying) ball joint, raise the vehicle by its frame in order to unload the joint and push/pull on the top and bottom of the tire while watching the upper joint for signs of movement.

NOTE: A wear-indicating style ball joint can quickly be checked for axial wear by inspecting the position of the grease fitting threads. If the threads are visible and protrude slightly from the ball joint, it’s probably good. If the threads have receded into the joint and are not visible, this is a sign that the joint is likely worn out and should be replaced. In addition to performing measurement checks, this is a good way of making a preliminary check.

When checking for lower ball joint lateral wear, with the wheel and tire mounted, and the vehicle raised (suspension unloaded), mount a dial indicator base to the lower control arm. Place the dial indicator plunger against the inside wheel rim and zero the gauge. Push the inside bottom of the wheel outward and note the dial indicator reading. Pull the wheel inward at the bottom and verify that the dial indicator reads zero. Re-adjust the gauge to zero if needed. Once again, push the bottom area of the wheel outward and hold in the outward position, and note the reading on the dial indicator. If the reading is beyond manufacturer specification, replace the lower ball joint.

Place the dial indicator plunger against the inside wheel rim and zero the gauge. Push the inside bottom of the wheel outward and note the dial indicator reading. Pull the wheel inward at the bottom and verify that the dial indicator reads zero. Re-adjust the gauge to zero if needed. Once again, push the bottom area of the wheel outward and hold in the outward position, and note the reading on the dial indicator. If the reading is beyond manufacturer specification, replace the lower ball joint.

Before checking lower ball joint lateral wear, first check and verify wheel bearing condition in the same manner to eliminate this variable. With the suspension unloaded, grasp the top and bottom of the tire and rock in/out. If any discernible movement is found, the wheel bearing assembly should be serviced (if preload adjustment is available) or replaced.

If the vehicle features an SLA suspension that locates the coil spring over the top arm, the upper joint is loaded. To check the joint, support the upper control arm to unload the joint. NOTE: If the ball joint design features a built-in wear indicator at the grease fitting location, joint play should be checked with the vehicle on its wheels (suspension loaded).

To check the joint, support the upper control arm to unload the joint. NOTE: If the ball joint design features a built-in wear indicator at the grease fitting location, joint play should be checked with the vehicle on its wheels (suspension loaded).

When checking a strut-type front suspension, support the vehicle at the cradle and unload the suspension, allowing the strut to fully extend. Attach the dial indicator clamp to the lower control arm and position a dial indicator in a vertical position to measure axial runout at the steering knuckle. To check lateral runout, position a jack under the ball joint and load the joint by raising the jack. Turn the steering wheel back and forth and observe the ball joint to check lateral runout.

Wheel bearings

A failing wheel bearing will result in a growling noise and/or a loose hub assembly, with either condition requiring immediate service, whether you’re dealing with a sealed or tapered bearing design. A sealed bearing is a self-contained bearing assembly caged in a carrier which is either press-fit to the hub or part of the hub assembly. A tapered bearing assembly features an inner and outer bearing, each riding on a tapered-face bearing race. A sealed bearing fails due to contamination and/or a lack of lubrication.

A sealed bearing is a self-contained bearing assembly caged in a carrier which is either press-fit to the hub or part of the hub assembly. A tapered bearing assembly features an inner and outer bearing, each riding on a tapered-face bearing race. A sealed bearing fails due to contamination and/or a lack of lubrication.

If a sealed wheel bearing is suspected of being worn or defective, grasp the tire at the top and bottom and rock it back and forth. If lateral play is detected, the bearing must be replaced. Sealed bearings have no adjustment feature and are not serviceable.

A tapered wheel bearing may or may not require a bearing preload. These bearings are serviceable and should be cleaned, inspected and packed with wheel bearing grease. Always check wheel bearings for excessive wear such as galling and abrasions. When subjected to overheating (due to lack of lubrication or improper preload), they appear dark/dark blue.

All wheel bearings are especially susceptible to water and dirt contamination. This is why it is so important to make sure the wheel seal is in good condition and has a tight fit around the wheel spindle. If a tapered wheel bearing (inner or outer) shows signs of dryness, galling or discoloration, always replace the bearing race(s) when replacing the bearings. Naturally, always replace the inner bearing seal. Use only the proper bearing race and seal drivers for removal and installation.

This is why it is so important to make sure the wheel seal is in good condition and has a tight fit around the wheel spindle. If a tapered wheel bearing (inner or outer) shows signs of dryness, galling or discoloration, always replace the bearing race(s) when replacing the bearings. Naturally, always replace the inner bearing seal. Use only the proper bearing race and seal drivers for removal and installation.

Whenever replacing tapered wheel bearings (with or without new races), always take the time to thoroughly clean all traces of old bearing grease and contaminants from the hub cavity. Grease the new bearings with high pressure wheel bearing grease using a bearing lubrication tool that allows grease to be forced into the bearing under pressure. Hand-rotate the bearing during and after grease injection to ensure complete coverage.

Hub unit wheel bearing noise

This information comes courtesy of SKF.

Wheel hub units can often wear out over a period of time due to heavy usage. As a result, ABS sensors can also break down electronically. In order to properly diagnose a vehicle before component replacement, SKF recommends performing a vehicle road test to listen for any unusual noise and to note if the ABS sensor light is on.

As a result, ABS sensors can also break down electronically. In order to properly diagnose a vehicle before component replacement, SKF recommends performing a vehicle road test to listen for any unusual noise and to note if the ABS sensor light is on.

During the road test, if you find that the ABS sensor light is on, SKF recommends following the manufacturer’s guidelines for testing. The manufacturer guidelines may include connecting a scanner to determine which brake component system shows failure.

If a wheel speed sensor fault is detected, complete inspection of the hub unit with a sensor resistance value reading and further check the value against the manufacturer’s specification. Also verify all wiring connectors for proper fit or damage. Hub assemblies also can develop excessive endplay and/or growling noises that can affect vehicle handling or wheel alignment.

As your first step, check endplay specification. If endplay is out of specification, replace the hub assembly. Bearing failure noise can be misleading and can sometimes occur at the opposite wheel of the failed bearing. This occurs when an overload takes place during driving on the good bearing. A good way to determine bearing noise is to lift the vehicle on a frame hoist and run the vehicle at a moderate speed. This relieves the overload on the good bearing.

Bearing failure noise can be misleading and can sometimes occur at the opposite wheel of the failed bearing. This occurs when an overload takes place during driving on the good bearing. A good way to determine bearing noise is to lift the vehicle on a frame hoist and run the vehicle at a moderate speed. This relieves the overload on the good bearing.

While staying clear of all moving parts, listen to both wheels with a stethoscope or other recommended listening device. This will help determine the location of the noisy bearing. Note that checks should be done on the spindle assembly, axle joints, wheel flanges and the vehicle frame for damage. An alignment check may be necessary to determine a bent component. It’s important to follow proper bearing installation procedures and torque specifications to avoid bearing failure or noises.

Control arm bushings

OEM control arm bushings are usually rubber or other composite flexible material. Depending on the application, bushing condition may or may not be readily visible in terms of inspection. However, inspect for signs of missing rubber, cracking or other damage.

However, inspect for signs of missing rubber, cracking or other damage.

Use a pry bar and try to move the link and bushing from side to side. Also, use a jack to load and unload the arm, while observing the bushing(s) to see if the bushing allows the arm to move in/out during arm pivoting. If excess movement is noted, or if the bushing tends to stay at one end of the pry instead of springing back, it’s time for replacement. After removing a worn bushing, if installation of a new bushing is very difficult, consider replacing with a one-piece or two-piece urethane bushing, which is easier to install. If you do opt for a urethane bushing, apply a coating of high temperature wheel bearing grease inside and out. This will ease installation and will serve to eliminate any potential squeaking noise during arm or link movement.

A vehicle that features I-beam front suspension will feature radius arms. Don’t forget to inspect the arm bushings for wear, cracking and looseness.

Steering components

Begin the inspection by checking for freeplay in the steering system. With the key on (to unlock the steering column) and engine off, turn the steering wheel left and right while observing wheel movement. If the front wheels do not move during initial steering wheel movement, excess freeplay exists within the steering system (loose/worn tie rod ends, loose/worn steering box or rack, rack mount bushings, etc.).

With the key on (to unlock the steering column) and engine off, turn the steering wheel left and right while observing wheel movement. If the front wheels do not move during initial steering wheel movement, excess freeplay exists within the steering system (loose/worn tie rod ends, loose/worn steering box or rack, rack mount bushings, etc.).

If freeplay is found, have a helper turn the steering wheel while observing the rack and pinion body for movement at the mount bushings and tie rods. On a strut front end, also check to see if the top strut mount moves forward and rearward and inboard/outboard, which could indicate worn upper strut bearings.

A clicking or grinding sound at the upper strut mounts while turning the steering wheel could also indicate worn or damaged upper strut bearings.

When inspecting tie rods, with the suspension unloaded, apply inward and outward pressure against the wheel and tire while observing and feeling for looseness at each tie rod. A quick check of outer tie rod end looseness can be done by squeezing the outer tie rod against the steering arm to observe any axial (vertical) play. Any discernible vertical play indicates that the tie rod end should be replaced. The same applies to steering systems which feature a drag link that connects steering arms (such as on a Ford F-Series truck). Inspect the joints that attach the drag link for lateral and axial play by observing movement while the steering wheel is turned.

Any discernible vertical play indicates that the tie rod end should be replaced. The same applies to steering systems which feature a drag link that connects steering arms (such as on a Ford F-Series truck). Inspect the joints that attach the drag link for lateral and axial play by observing movement while the steering wheel is turned.

Struts

It should be obvious that the damping component of a strut (the shock absorber function) contains hydraulic fluid. If you see signs of oil leakage at the top of the strut tube, the seal is worn and the strut is due for replacement. Of course, replacement struts are available with or without the coil spring. Compare prices. Often, it makes economic sense to purchase a complete strut unit that includes the already-installed spring, top mount and upper bearing.

The strut’s upper bearing allows the strut to pivot as the wheels are turned. If the bearing is worn or damaged, the upper bearing can stick, causing a bind. If you turn the steering wheel while driving, release the steering wheel, and the front wheels tend to “snap” back to center, this clearly indicates an issue with one or both strut bearings. A snap or click noise may also be heard during turning. With the vehicle parked and suspension loaded, turn the steering wheel back and forth and observe (visually and listening for noise) for any binding or clicking. Replacing a strut bearing is not a difficult task (of course it requires strut removal, compressing the spring and R&R of the top hat assembly).

If you turn the steering wheel while driving, release the steering wheel, and the front wheels tend to “snap” back to center, this clearly indicates an issue with one or both strut bearings. A snap or click noise may also be heard during turning. With the vehicle parked and suspension loaded, turn the steering wheel back and forth and observe (visually and listening for noise) for any binding or clicking. Replacing a strut bearing is not a difficult task (of course it requires strut removal, compressing the spring and R&R of the top hat assembly).

With the front suspension unloaded and engine off, grasp the upper area of the strut’s coil spring and push the strut inboard/outboard. Any movement of the strut relative to the body indicates a worn or damaged upper strut mount.

Naturally, inspect coil springs for breaks, cracks or coil bind. Be sure to measure vehicle ride height and compare to factory specifications. Obviously, sagging/weak springs and/or damper wear or damage requires strut and/or coil spring replacement.

Brake rotor lateral runout

A brake rotor that features excessive lateral runout will cause a pedal pulsation, along with potential spongy pedal. Lateral runout refers to the brake disc rotating in/out of the true axis (disc wobble).

Prior to measuring for lateral runout, check the condition of the hub bearing, since a worn bearing can be the cause of the runout. Also, the rotor must be secured to the hub flange with conical wheel nuts, fully torqued to the manufacturer’s specification.

Runout can easily be measured using a dial indicator. Anchor the indicator to a location that is solid and does not move along with the rotor and hub, such as the lower control arm or spindle/steering arm. Place the indicator plunger in contact with the disc surface, approximately 1/2-inch or inboard from the disc edge. Position the indicator so that the plunger is 90 degrees to the disc surface (avoid placing the indicator at an off-angle). Adjust the indicator to lace a preload on the gauge of about 0. 050-inch. Zero the indicator gauge. Slowly rotate the rotor through a full 360 degrees and note the amount of runout. Always refer to the vehicle manufacturer’s runout specification.

050-inch. Zero the indicator gauge. Slowly rotate the rotor through a full 360 degrees and note the amount of runout. Always refer to the vehicle manufacturer’s runout specification.

Generally speaking, runout within about 0.002 – 0.005-inch is acceptable. If runout is excessive, this may be caused by the rotor itself, the hub bearing assembly or the hub flange. Note that excessive runout may be the result of an improperly-torqued set of wheel fasteners which can cause a deflection of the rotor hat.

Idler and pitman arms

If the vehicle is equipped with a parallelogram steering system, the idler arm and pitman arm should be checked for wear. A worn idler arm will allow excessive up/down movement that directly contributes to changes in wheel toe angles. A worn pitman arm results in excess play between the steering input and wheel toe angles.

With the left suspension unloaded, wiggle the wheel/tire in/out at the tire’s 3 and 9 o’clock positions and observe the idler arm for play. Wiggle the left wheel and observe steering wheel movement. If the wheel shows play but the steering wheel does not initially move, suspect the pitman arm.

Wiggle the left wheel and observe steering wheel movement. If the wheel shows play but the steering wheel does not initially move, suspect the pitman arm.

Import air ride

This information comes courtesy of KnowYourParts.com, the industry information campaign of the Automotive Aftermarket Suppliers Association (AASA).

Just about every Asian and European luxury import nameplate manufacturer has a seven- to 10-year-old vehicle on the road with an air-ride suspension at all four corners. Chances are one of these vehicles will be coming to your shop sooner rather than later.

Most of the systems use German-manufactured air struts connected to a WABCO compressor. In between the struts and compressor are reservoirs, control valves and a lot of software controlling the system. The secret to diagnosing problems comes down to knowing what criteria the system uses to regulate the compressor/reservoir and having a scan tool that can interpret the information.

These systems do not use the compressor to directly fill the air bladders. Instead, the compressor will supply air to a reservoir that is used to fill the bladders. Some vehicles will have only one reservoir, while some may have multiple reservoirs. The reservoir is equipped with a pressure sensor and valves to send compressed air to the spring and exhaust excess pressure. Do not work on any reservoir unless the system is allowed to depressurize before performing any repairs. Some systems may require the use of a scan tool to release the pressure and re-pressurize the system. The reservoirs are typically made of aluminum. They can be located in the trunk or tucked behind fenders or quarter panels. It is rare for the tank to develop a leak, but it is common for the air-line connections.

Air-ride systems look for information like vehicle speed, ambient air temperature and ride height. From this information, a system can calculate how long the compressor should run to fill the reservoir. If it is taking too long, the air-ride module will set a code, alert the driver, and put the system in a safe mode.

If it is taking too long, the air-ride module will set a code, alert the driver, and put the system in a safe mode.

The codes for this type of problem will typically include the words “replenish,” “reservoir,” “overheat,” “no pressure increase” or “timed out.” There are two main culprits for these codes — a weak compressor or a leak in the system. It is possible that a sensor in the reservoir is faulty, but this is extremely rare.

The control module will not immediately turn on the compressor when the engine is started and will trim the suspension from the air in the reservoir. Some systems will not engage the compressor until the vehicle has reached a predetermined speed like 25 mph. These rules are in place so moving air will cool the compressor. That way, the driver will not notice the compressor operating while the vehicle is stopped. But, in some cases, the compressor will run during startup if the pressure is low enough.

All four-corner systems are using air from the reservoir even if the car is parked. This is because as the vehicle cools, the air volume and pressure in the bladders and reservoir will decrease. The system will trim the ride height to make sure the vehicle is not sitting on the ground when the driver returns to the vehicle in the morning. Also, some systems will keep a level ride height if the vehicle is parked on an uneven surface, or the vehicle is unlocked and a load is placed in the trunk. But, most systems will never turn on the compressor to make a key-off correction.

This is because as the vehicle cools, the air volume and pressure in the bladders and reservoir will decrease. The system will trim the ride height to make sure the vehicle is not sitting on the ground when the driver returns to the vehicle in the morning. Also, some systems will keep a level ride height if the vehicle is parked on an uneven surface, or the vehicle is unlocked and a load is placed in the trunk. But, most systems will never turn on the compressor to make a key-off correction.

Before a vehicle is returned to a customer, you should perform a calibration procedure for the air-ride system, if required. Calibration procedures typically involve measuring the four ride heights and entering the data into the scan tool. Not performing this procedure can lead to a comeback.

Don’t turn away air-ride problems from your shop or steer them to the dealer. The parts and tools are available to restore an air suspension to full-operating condition, or even convert the system to conventional springs. Always advise the customer that not repairing the air-ride system will remove some functionality from the vehicle, such as adjustable ride control and load leveling.

Always advise the customer that not repairing the air-ride system will remove some functionality from the vehicle, such as adjustable ride control and load leveling.

With more air-ride-equipped vehicles accumulating miles, you can expect to see a steady stream of these air-ride systems in your bays. You also have more options than ever before when it comes to aftermarket replacement parts and conversion kits. ■

Checking Away: the secret to more space & goals

Checking away from the ball gives players freedom once they receive the ball. If you have NO FREEDOM on the pitch that means you have NO SPACE. No space means you don’t get many choices whether to pass, dribble or shoot. Learning how and when to get open make a big difference. Sometimes all it takes is 2-5 steps to get open. Especially if you are getting behind the line of defense. These few steps can help you get behind four players, which can make a 4v4 vs a 4v8 situation. Then there is the training video below you can do to improve controlling the ball in these situation.

Then there is the training video below you can do to improve controlling the ball in these situation.

What is checking away?

Checking away from the ball means running or walking away from the ball, creating space by taking the defender with you. Also by allowing your teammate to be able to play a ball over the top for a breakaway. Not long ago I watched the #1 U16 Boys Academy team beat the #2 team 4-1. All the goals were over the top of a defender to a forward who checked away at the right time for a goal.

It wasn’t that you could watch the whole game and say “O yeah that team is better.” It was just that they were disciplined and patient. This means they knew their chances would come and they knew how to create space at the dangerous part of the field. Most of the time you check away you end up checking back to receive. Sometimes it’s to collect the ball over the defender for a goal, which is what happened on most of these goals that day.

Most of the time you check away you end up checking back to receive, but sometimes it’s to collect the ball over the defender for a goal.

Building character of a pro

Many of you will take the time below to read the how, why & when checking away can help players & teams become better on the pitch by confusing defenders. This information is important for all ages! If you’re a parent or coach, go ahead and have conversation with your players or kids about these topics. I know kids ages 13+ think they know everything so maybe just let them talk about what they know.

If they don’t want to listen to you let them read the highlight points of this article. Make sure they are teachable. Give them resources like the article from the 14 year Professional Davy Arnaud on 5 Traits of Good Character where he writes how he learned something every week because he tried and wanted to.

Improving first touch when checking to and away

To improve your skills is to simply work on trapping the ball as you check to and check away. In my experience as a player and trainer, checking to while receiving the ball is harder. At the same time checking away is not easy either. Checking to while receiving the ball is tough because you are going to the ball, while the ball is coming to you. This means the play happens fast and your touch has to be extra soft. Checking away is hard because by the time you get the ball your a little tired. Check out the video below to see how you can train on your own.

There are many different ways to check away

You can check away by simply taking 1 single step away from the player with the ball and then check to receive. Then there are the times when you need to actually ‘check away’ 10 steps. You could do this by backpedaling, turn and run, side shuffle or even walking away.

It all depends on the situation and how smart the defenders are as individuals and as a defensive unit. It also depends on your teammates… If you are playing with players who just kick the ball long every time or don’t have the vision to find players in behind, why waste energy checking away?

Checking away depends on the situation and how smart the defenders are as individuals & as a defensive unit.

So much to learn before clever runs

The reason why many younger players are not taught how to do these little tactical things is because the team as a whole is not ready. First they need to know how to control the ball well. Then they need to know how to play wide and stretch the field at the right time. I’m not saying don’t teach youths how to check to and away from the ball. I recommend it at even age 7. But the main focus on time spend with youth should be on technical, not tactical. Meaning, help youths ages 6-12 get better at fundamentals over anything else.

Which Position needs to know most how to check to?

Forwards need to know most because they are often times outnumbered a man. This means they need to know how to get open more than the other positions. Attacking players oftentimes have to play with a defender on their back. By the time the ball reaches them they have immediate pressure.

If a forward knows how to CHECK AWAY at the right time they are able to create more space for when they get the ball they have time to turn and dribble, pass or shoot. The key for this is that they have all 3 options instead of just 1.

Does checking away mean you have to always check back?

You don’t always have to check back to. There are going to be times when you check away and your teammate plays that long ball over the top. That’s the beauty of it all is that the defender has to respect the runs. If they don’t follow the runner, then it will be an easy time scoring goals.

No matter how good the defender is they cannot stop a good ball played to a player who made a well-timed run at speed. No matter how good the defender is they cannot stop a good ball played to a player who made a well-timed run at speed.

Only one thing can stop a perfect run and pass

A defender who has more speed than the attacking player can stop a perfect run & pass. In the middle third of the field, if a ball is played over a defender and the forward made a smart well-timed run, the pass should be complete. But if the defender is faster and they have enough space to catch up it won’t work. Unless, of course, this is a play near the goal (final third part of the field) and the forward only has to finish on goal with 1 or 2 touches.

So at the highest levels (U15 – U18 all the way up to pro) you will see teams who maybe are not as fast physically but once these balls are played in the dangerous part of the field goals are scored. That’s why checking away from the ball is such a key skill to have!

5 Top Reasons to check away

- Makes the defender lose sight of either the ball or attacking player, which is what attackers want because it makes the defenders job stressful when you can’t see the ball & your man.

- Creates more space not only for the player with the ball but also for the player making the run

- Cause overall confusion for the defenders because they sometimes don’t know who to mark or let go

- Tires the defenders out physically and mentally. They’ll know that not only is the forward smart, but they want to work hard by taking extra runs.

- Makes you a more all-around player instead of the player who is predictable and easy to mark.

2 main differences in great runs off the ball

- The TIMING of when you first make your run away

- The CHANGE OF SPEED if which you make your run away… Sometimes it needs to be at 100% speed and others it needs to be slow and undercover. The reason is because you can end up never checking to. Then end up getting the ball behind the player who was marking you. This would especially mean for a center mid.

Private Individual, Group or Team Training Drills

We usually have the players start off stationary and have them check away to build good habits. Then pass them the ball to start or finish the play.

3 Examples

- If I am working with a forward then I want them to check away before I cross them the ball to finish. This creates good habits for the players.

- If I have a private or a large group we can start the play by a player passing the ball to another. Then checking away a step or 2, which allows there to be enough space and time to pass or dribble.

- Through balls to the forwards feet or into space for there to then be a opportunity on goal.

Please help share this with friends, you know they will appreciate it, as will I.

Checking Ball Joints

Checking Ball Joints (by Dave Breggin):

This is about checking ball joints on the Hummer.

Several people, including myself, have had catastrophic failures of the upper ball joints on their Hummers. These failures have sometimes occurred only a few miles after the ball joints were checked.

When I had my failure, I replaced it with a known-bad, used joint that I had in my shop. This allowed me to get the truck back home. When I got back, I checked all 8 ball joints to see what I should order for replacements. Two of the lower ball joints had some movement, but were within spec. All of the uppers checked OK with no movement at all. This is particularly amazing since I had just installed a known bad joint.

This prompted me to study and analyze the AMG recommended procedure for checking ball joints on the Hummer. I concluded that while their procedure for checking the lower was fine, that their procedure for checking the upper just did not make sense.

Checking the Lower:

The procedure is to raise the lower A-arm with a jack until the tire/wheel is off the ground. This causes the weight of the wheel to extend the ball joint. A pry bar is then placed between the bottom of the hub gear box and the ball joint mounting bolts. When you pry the hub upward, the ball joint is compressed, and any free movement can be evaluated as to whether the joint is worn out. This procedure seems to work OK.

Checking the Upper:

The AMG procedure for checking the upper is as follows: It does not matter whether the lower A-arm is raised or not. Place a pry bar between the upper A-arm and the hub. When you pry the A-arm and the hub apart (A-arm down, hub up), the ball joint is extended. You then observe any free motion in the ball joint, and evaluate it for excessive wear.

Here is the problem: there is no part of the procedure that in any way compresses the upper ball joint!

If the AMG test shows the ball joint as bad, it is bad. If it shows it as good, further testing is required. Here’s why: the position of the upper A-arm (with relation to any movement in the upper ball joint) is determined by the A-arm bushings. Friction in these bushings may be holding the upper A-arm upward, causing the ball joint to be extended before the test is conducted. Further extending of the ball joint shows no movement at all.

I recommend either (or both) of the following tests for checking upper ball joints:

A: Use the AMG method combined with the following – using a large pair of groove-lock-type pliers, attempt to compress the upper ball joint by squeezing the upper A-arm and the hub together (A-arm upward, hub downward). The pliers are used to perform the exact opposite of the motion performed by the pry bar. If either test shows excessive movement, the ball joint needs to be replaced.

B: While the lower A-arm is supported (i.e. while checking the lower ball joint), firmly move the top of the tire/wheel assembly in an in-and-out motion. If there is looseness in the upper ball joint, this test shows it immediately. If there is motion and/or clunking during this test, a visual check must be performed to identify the loose component. Loose tie-rod / radius arm ends can cause similar symptoms.

Dave Breggin

’95 Diesel Wagon

[email protected]

Except as noted, all pictures are of the Upper ball joint:

Ball joint as removed after the failure. Notice the abundance of lubricant.

Same ball joint with grease removed, and spring/cup extracted from casting.

Details of the inner pieces.

Details of the failed casting.

Closeup of another “ready-to-fail” ball joint.

Closeup of a good-condition ball joint (rubber boot removed).

Lower left is a good ball joint, lower right is “ready-to-fail”, and upper is “toast”.

Left is old style, right is newer “heavy duty”.

New is on left, old on right. Notice how much larger the casting is.

Top view of new HD lower (left) and upper (right) ball joints.

Side view. Notice the upper ball joint (left) is longer / taller than the lower (right).

New style upper with the boot removed.

Test work on the topic “Volleyball”

Volleyball (from the English volley – flying and ball – the ball) is an Olympic sport, the goal in which is to direct the ball towards the opponent so that it lands in the opponent’s half or to make an error on the part of a player of the opposing team … During one attack, only three touches of the ball in a row are allowed. Volleyball is popular among both men and women.

History of origin and development

It is believed that volleyball originated thanks to William J. Morgan, a physical education teacher at one of Holyoke colleges (USA). In 1895, in one of his lessons, he hung a net (about 2 meters high) and invited his students to throw a basketball camera over it. Morgan called the resulting game “Mintonet”.

Two years later, the first volleyball was developed and launched into production.

In 1922, the first international competition was held in Brooklyn.

In 1925, the modern size of the court was approved, as well as the size and weight of the volleyball.

In 1947 the International Volleyball Federation (FIVB) was founded.

Since 2006, the FIVB unites 220 national volleyball federations, the game is one of the most popular sports on Earth.

Basic rules of volleyball

A volleyball match consists of parties (from 3 to 5).The duration of the volleyball game is not limited and continues until one of the teams scores 25 points. If the advantage over the opponent is less than 2 points, then the game continues until the advantage is increased. The match continues until one of the teams wins three games. It should be noted that in the fifth game the score goes not to 25, but to 15 points.

Each of the two teams can have up to 14 players, but 6 can be on the field at the same time.The initial placement of players indicates the order of the transition of participants on the court, it must be preserved throughout the whole game.

The ball is served by the service, the team to be served is determined by toss. After each transition of the right to serve from one team to another, the players move clockwise through the zones. The feed is carried out from behind the back line. If the server intercepts, sends the ball out of bounds or hits the net, then the team loses service and the opponent gets a point.Any player has the right to take the service, but usually they are front row athletes. The feed is not blocked. The player from the first line can carry out an attacking blow, such a blow is performed over the net. Back-row players attack from the 3-meter mark. The blocking of the attack is carried out over the net so as to prevent the ball from flying over the net. When blocking, you can transfer your hands to the side of your opponents without interfering with them. Only players from the front line block.

Volleyball playing field (dimensions and markings)

The size of a standard volleyball field is 18 meters long and 9 meters wide.The grid is positioned in such a way that its highest point is 2.43 meters above the ground in the men’s competition and 2.24 meters in the women’s. These dimensions were approved by the International Volleyball Federation in 1925 and are still valid today. The playing surface must be horizontal, flat, uniform and light. In volleyball, there is the concept of a free zone on the playing field. The dimensions of the free zone are regulated and are 5-8 meters from the front lines and 3-5 meters from the side lines.The free space above the playing field should be 12.5 meters. The playing court is bounded by two side lines and end lines, which count towards the size of the field. The axis of the center line, drawn between the side lines, divides the playing space into two equal parts 9 x 9 m. It is drawn under the net and delimits the zones of the opponents. An attack strip is applied on each half of the field behind the center line, three meters from it.

Official signals of the referees in volleyball

1.Permission to submit.

2. The giving command.

4. Break

5. Replacement. Circular movement of the forearms around each other.

9.End of a party or meeting. Cross the forearms with outstretched hands in front of the chest.

10. Ball not tossed on service hit. Raise an outstretched hand with the palm facing up

11. Delay when giving is more than 5 sec. Raise the five fingers spread apart

12. Screen. Raise both arms straight up, palms forward.

13. Error in placement or during transition. Make a circular motion with your index finger.

14. The ball is in the field. Point your hand with straightened fingers to the floor.

15. The ball is “out”. Raise the forearms vertically with the hands and palms straight, facing the body.

16.Holding the ball. Slowly raise the forearm with the palm facing up.

17. Double tap. Raise two fingers apart.

Bistrovich came on as a substitute and scored a bomb with the first touch. He helped CSKA put the squeeze on Tambov

Chalov missed a penalty, Gogua was injured.

This season is a test season for the already relatively new team of Goncharenko. Last season, the CSKA coach said that his team needs to be able to win matches, in which it is imperative to score points. And the meeting against “Tambov” is just from this opera. In the last two rounds, CSKA won victories over Akhmat and Arsenal, rehabilitating themselves after the defeat in the derby. Due to the absence of Vasin and Nababkin, Goncharenko gave the debut to Cedric Gogua – just in the match with the former team.And due to the absence of Sigurdsson, Nishimura made up a pair of Chalov in the attack.

Takuma had the first conscious moment, but was unable to punch properly, and after a few minutes he was back in the shock position, but hit the defender. Overall, CSKA had an advantage in the first half. Moreover, the stadium in Saransk was more actively supporting the army team. But the coolest moment before the break was with Chalov – Magnusson made a cool diagonal, and Fedor beat from the summer, but almost missed. And then Gogua could have opened the score, but after his head hit the ball was pulled out by Shelia.

“Tambov” snapped well, Chuperka had a good chance, and at the beginning of the second half the hosts took the initiative for a short time. But they got a penalty kick into their own goal … which Chalov did not convert. Shelia performed something in the style of Akinfeev in the match with Spain.

Shortly before that, Goncharenko had to remove from the game Cedric Gogua, who had received muscle damage. CSKA’s defenders are getting really tough. Well, then Valery Chuperka took the first role. In a completely harmless situation, he knocked down Ilzat Akhmetov, received a yellow one, after which he began to say something to the referee and immediately saw a red light in front of him.Let us remind you that this was only Chuperka’s second match after serving the suspension for two yellows in the game of the 5th round against Orenburg. Apparently, the Tambov midfielder’s nerves are not the strongest.

It is logical that in the majority of CSKA players finally tidied up the game and, according to Goncharenko’s behests, brought it to its logical conclusion. First, Bistrovich sent the ball into the net with the first touch after entering the field.

And on 94 minutes Herdur Magnusson put the final point. And also a cool long-range strike.

CSKA scores three points and moves up to second place in the standings. But Rostov and Krasnodar, two points behind him, still have a reserve game.

Merry starts

From the archive of the Sikhote-Alin Nature Reserve

Players are divided into two teams:

1. “Hunter Frog” . The player jumps to the mark, at the mark the player who will run next is thrown to him.The frog catches the ball and also jumps back. Everything is repeated until one of the teams completes the relay. The winning team receives a certain number of points.

2. “Scorpions” . One participant takes the other by the legs, move to the marked line, change at the line.

3. “Pine cone” . Two or three logs are vertically installed in front, along which the players must run with the ball in their hands – back and forth.

4. “Wild boar” . The same game, only logs – horizontally and hands on the head.

5. “Proteins” . Running paired with throwing the ball over a bounce off the ground.

6. “Dribbling”. Dribbling the ball to one side, at the line the ball is thrown to the next player.

7. “Jerboa”. Jumping rope in one direction, in the other – running with a rope.

8. Back to back. Running in pairs back to back, holding hands.

9. “Feel your comrade.” Running with tied (right to left) legs.

10. “Kangaroos – penguins” . Running with the ball between the legs.

11. “Jumping on one leg in pair” . Holding the partner by the leg, the lines change.

12. Leapfrog . Players jump over each other, run back.

13. Zigzag . When moving, run around obstacles with the ball in both directions.

14. Football . Dribbling the ball with your feet to one side, dribbling the ball back with your hands.

15. Running paired with the ball, holding the ball between two sticks.

16. “Carry – don’t drop.” Stones are laid out at jump distance. The player must jump over the stones with a bag on his head, without dropping the bag.

17. “If you went out with a friend.” It is necessary to carry the ball to the pin and back, holding it between the heads of two players.

18. “Waiter”. At the signal from the leader, the ball must be carried on the tray to the pin and back, passing it to the next player.

19. The quieter you go on will be. ” At the signal, the competitor must hit the ball so that it flies forward. In this way, you need to go a certain distance and pass the ball to the next player.

90,000 The new head of world hockey shocked everyone. He wants to kick the Chinese national team from the home Olympics – Ice Hockey News

Rene Fasel’s successor, Luc Tardiff, began his presidency with a resonant proposal.

After the appointment of Luc Tardiff as president of the IIHF, the first thing I wanted to know was what ideas the new head of world hockey would voice. Before the elections, the Frenchman remained the most mysterious candidate, who did not really present his program. In which direction the “puck” would go in the coming years in the event of Tardiff’s victory remained a mystery. Whether he is a reformer or a conservative is a mystery.

And already one of the first comments Luke shocked the public. The Frenchman expressed a strong stance on the participation of the Chinese team in the 2022 home Olympics.The IIHF will consider removing the host team from the Games. Tardiff argued that the level of Chinese hockey does not match the rest of the national teams. “It’s not good for anyone to watch a team lose 0:15. Not China, not hockey. The decision will be made by the end of October, “- quotes the president of IIHF AFP.

Tardiff suggested that Norway could replace the Chinese. The team that occupies the highest position in the world rankings (11th place) among those who did not qualify.For a verdict, China’s test matches will be monitored by representatives of the IIHF. They will only be held in January, and Tardiff has promised to announce the decision by November. Or will Luke’s colleagues watch the games of Kunlun in the KHL – the base club of the Chinese national team?

Tardiff began his presidency with a radical idea. Which, in contrast to the friendly diplomat Fasel, looks very sharp. The head of world hockey must maintain a balance of interests, especially before the largest sporting event in recent years.In fact, the Frenchman criticized the regulations of the Olympics, according to which the host country is a permanent participant in the tournament. This rule was not introduced by the Chinese – this is how it is established by the principles of the Games. Of course, the hockey players from the Middle Kingdom, who occupy 32nd place in the IIHF rankings, would never have made their way to the Olympic Games. Automatic participation is a gift from the IOC for hosting the Olympiad.

Are Tardiff’s fears reasonable? The Chinese fell into the death group with Canada, the United States and Germany. The two contenders for gold and the silver medalist of the OI-2018 are a serious crash test for a team that has not played a single match since 2019.The level of the Chinese national team remains a mystery to many. In part, it can be assessed by the performance of Kunlun, where the composition for the Olympics is assembled. The Chinese, having naturalized several foreigners, will not aim at the passage to the quarterfinals, but Tardiff got excited with the rout 0:15.

There is little logic in Luke’s proposal. Norway, which replaced China, is not a competitor to Canada, the United States or Germany. The result of her participation in the Games is comparable to that of the hosts, adjusted for a smaller difference in washers. I would agree with the IIHF president only if the question was: China or, for example, the Czech Republic.Which, for unimaginable reasons, would have remained outside the Olympics. Then it is appropriate to talk about competition. Changing China for Norway, which naturally did not qualify for the 2022 Games, letting the Danes go there for qualifications is similar to exchanging two bulls for two cows if the owners want to breed livestock.

Exemption from the selection of the host country is due to financial investments. China not only allocates money for the Olympics, but also, together with the IOC, compensates for the costs of the participation of NHL hockey players.The promising, but not fully developed Chinese market is interesting to the North American side as a new niche for product promotion. This is one of the reasons why NHL bosses agreed to send their players to the Olympics. The NHL sees future benefits in Chinese ice hockey. IIHF, judging by the statement of Tardif, no. The exclusion of the hosts from the Games will not add credibility to the new president on the Asian continent.

As the general manager of Kunlun Nikolai Feoktistov correctly noted in an interview with SE, after the Olympics, interest in hockey in China will certainly increase.At least for a while. The task of the “Dragons” leadership is to use this momentum to develop the game. I would be very surprised if the IIHF, at the suggestion of the new president, deprives the Celestial Empire of such an opportunity.

sports in English

How many different sports can you list in your native language without hesitation? Ten to twenty? Can you name them in English? This task is already more difficult, because not every sport in English is in tune with Russian.

For example, if you take basketball, then translation into English will not cause any difficulties, but what about rowing or chess? But there are so many sports directions that we do not even suspect the existence of some.

Today we will tell you what sports are called in English, so that you know not only what “basketball” is in English, but also a lot of other vocabulary on the topic of “sports”.

Sports

In general, such a large topic as sports in English can be divided into several main categories: game sports, athletics, water sports, winter sports, martial arts, extreme sports and others.The most popular and widespread sports are included in the Olympic Games.

Almost all games that use a ball will have ball in their name. Logically, you can guess that the game where you need to throw the ball into the basket is basketball, formed from two words: basket and ball. Likewise, with football (football), formed from the words foot (leg) and ball (ball).

- baseball – baseball

- basketball – basketball

- football – football

- volleyball – volleyball

By the way, sports can be divided into purely American and purely British.For example, in the United States, the most popular are American football, which we will discuss below, basketball and baseball. But in Great Britain they prefer to play rugby and cricket.

Popular British sports also include:

- cricket – cricket

- dog racing –

- horse racing –

- horseback riding

- rowing – rowing

dog racing

horse racing

Football or soccer?

Separately, I would like to talk about how football is called differently in different English-speaking countries.

Today the word soccer is used in the USA, Canada, Australia and sometimes in New Zealand, but in the UK they prefer football, although in the last century everything was completely different. According to the research of sports analyst Stefan Szymansky, the word soccer came to American English from Great Britain at the beginning of the 20th century. Today, football in England is nothing more than football, although ardent fans of this sport often affectionately call it footie or “the beautiful game”.