How does E3 Metals Corp aim to extract lithium from oilfield brine. What are the key components of their Petro-Lithium Project. Why is the consistency of lithium concentrations crucial for commercialization.

E3 Metals Corp: Pioneering Petro-Lithium Extraction

E3 Metals Corp (TSX-V: ETMC, FSE: OU7A) is making significant strides in the field of lithium extraction from oilfield brine. The company has recently completed its first round of sampling from 43 petroleum wells across several of its Metallic and Industrial Minerals (MIM) Permits in Alberta, Canada. This ambitious project, known as the Petro-Lithium Project, aims to revolutionize lithium production by tapping into an unconventional source.

The Sampling Process

The sampling process involved collaboration with 11 oil and gas operators, demonstrating the company’s ability to work effectively within the existing petroleum industry infrastructure. Samples collected have been sent to accredited laboratories for analysis, marking a crucial step in validating the project’s potential.

Historical Data and Potential Lithium Concentrations

E3 Metals’ sampling locations were strategically chosen to confirm historical testing results outlined in their NI 43-101 Report, dated May 18, 2017. Previous data from the sampling area showed lithium concentrations as high as 74.1 mg/L within E3 Metals’ MIM Permit areas. This historical data serves as a promising baseline for the company’s current exploration efforts.

Expanding the Data Set

In addition to confirming historical data, E3 Metals has taken the initiative to sample several locations where no previous lithium concentration data was available. This expansion of the data set is crucial for building a comprehensive understanding of the resource potential across their permit areas.

The Importance of Lithium Concentration Consistency

One of the key factors in the potential commercialization of E3 Metals’ Petro-Lithium Project is the consistency of lithium concentrations within the reservoir. But why is this consistency so crucial?

![]()

- Predictability: Consistent concentrations allow for more accurate resource estimates and production forecasts.

- Efficiency: Stable lithium levels enable the optimization of extraction processes.

- Economic viability: Consistent concentrations contribute to more reliable economic assessments of the project.

Four Pillars of the Petro-Lithium Project

E3 Metals’ approach to developing their Petro-Lithium Project is built on four fundamental components:

- Lithium concentration consistency

- Ability to produce large volumes of brine water

- Size of the reservoir

- Extraction technology efficiency

By focusing on these four aspects simultaneously, E3 Metals aims to drive the project forward as effectively as possible, maximizing its potential for success.

Extraction Technology: The Key to Unlocking Petro-Lithium

While the presence of lithium in oilfield brine is promising, the ability to extract it efficiently is crucial for commercial viability. How does E3 Metals plan to address this challenge?

The company is likely developing proprietary extraction technologies specifically designed for Petro-Lithium. These methods may involve innovative approaches such as:

- Selective ion exchange resins

- Advanced membrane filtration

- Chemical precipitation techniques

- Electrochemical separation methods

The efficiency of these extraction technologies will play a pivotal role in determining the economic feasibility of the Petro-Lithium Project.

Environmental Implications of Petro-Lithium Extraction

The concept of extracting lithium from oilfield brine presents intriguing environmental considerations. How might this approach compare to traditional lithium mining methods in terms of environmental impact?

Potential environmental benefits of Petro-Lithium extraction include:

- Reduced land disturbance compared to open-pit mining

- Lower freshwater consumption

- Utilization of existing oil and gas infrastructure

- Potential for carbon capture and storage synergies

However, it’s important to note that the process is not without its challenges, such as managing brine disposal and energy consumption for extraction and processing.

Market Implications and Future Outlook

The success of E3 Metals’ Petro-Lithium Project could have significant implications for the global lithium market. How might this new source of lithium impact supply and demand dynamics?

Potential market effects include:

- Diversification of lithium sources, reducing reliance on traditional mining

- Potential for increased lithium production in North America

- Possible downward pressure on lithium prices if large-scale production is achieved

- Attraction of investment to the Petro-Lithium sector

As the project progresses, industry observers will be keenly watching for signs of commercial viability and scalability.

Challenges and Hurdles in Petro-Lithium Development

While the potential of Petro-Lithium is exciting, E3 Metals faces several challenges in bringing this innovative concept to fruition. What are some of the key hurdles the company must overcome?

- Technical challenges in lithium extraction efficiency

- Economic feasibility in comparison to traditional lithium sources

- Regulatory and permitting processes for this novel extraction method

- Scaling up from pilot projects to commercial production

- Managing relationships with oil and gas operators

The company’s ability to navigate these challenges will be crucial in determining the long-term success of the Petro-Lithium Project.

Collaborative Efforts in the Industry

E3 Metals’ collaboration with 11 oil and gas operators for their sampling program highlights the importance of industry partnerships in this venture. How might these collaborations evolve as the project progresses?

Potential areas for future collaboration could include:

- Shared infrastructure for brine handling and processing

- Joint research and development initiatives

- Co-production agreements for lithium and petroleum products

- Knowledge sharing on reservoir characteristics and production techniques

These partnerships could prove invaluable in overcoming technical and logistical challenges associated with Petro-Lithium extraction.

Technological Advancements in Lithium Extraction

The success of E3 Metals’ Petro-Lithium Project hinges on the development of efficient extraction technologies. What recent advancements in lithium extraction methods might be applicable to this project?

Emerging technologies in the field include:

- Direct lithium extraction (DLE) processes

- Advanced membrane filtration systems

- Electrochemical lithium separation techniques

- AI-driven optimization of extraction processes

- Novel sorbent materials for selective lithium capture

E3 Metals may be exploring these and other cutting-edge technologies to enhance the efficiency and economics of their Petro-Lithium extraction process.

The Role of AI and Machine Learning

Artificial intelligence and machine learning could play a significant role in optimizing Petro-Lithium extraction. How might these technologies be applied to E3 Metals’ project?

Potential applications include:

- Predictive modeling of lithium concentrations across the reservoir

- Real-time optimization of extraction processes

- Automated quality control and assay analysis

- Predictive maintenance of extraction equipment

- Enhanced resource estimation and production forecasting

By leveraging these advanced technologies, E3 Metals could potentially improve the efficiency and profitability of their Petro-Lithium operations.

Economic Impact on Alberta’s Energy Sector

The development of a successful Petro-Lithium industry could have significant implications for Alberta’s economy. How might this new sector complement or transform the province’s traditional energy industry?

Potential economic impacts include:

- Diversification of Alberta’s energy portfolio

- Creation of new high-tech jobs in the province

- Attraction of international investment in lithium production

- Potential for value-added lithium processing and battery manufacturing

- Extended economic life of existing oilfield infrastructure

The success of E3 Metals and similar ventures could position Alberta as a key player in the global lithium supply chain, complementing its established role in fossil fuel production.

Government Support and Policy Implications

The development of a Petro-Lithium industry may require supportive government policies. What types of initiatives or regulations might be beneficial for this emerging sector?

Potential policy considerations include:

- Research and development tax credits for Petro-Lithium technologies

- Streamlined permitting processes for lithium extraction from oilfield brines

- Incentives for oil and gas companies to participate in lithium co-production

- Investment in infrastructure to support lithium processing and transportation

- Incorporation of Petro-Lithium into provincial and national critical minerals strategies

Government support could play a crucial role in accelerating the development of this innovative industry and maximizing its economic benefits.

Global Context: Petro-Lithium Projects Worldwide

E3 Metals’ project in Alberta is not the only Petro-Lithium venture in development globally. How does this project compare to similar initiatives in other regions?

Notable Petro-Lithium projects around the world include:

- Lithium extraction from geothermal brines in the Salton Sea, California

- Oilfield brine lithium projects in Arkansas and North Dakota

- Geothermal lithium initiatives in Germany and the United Kingdom

- Petro-Lithium exploration in oil-producing regions of Argentina

Each of these projects faces unique geological, technical, and economic challenges, but they all share the common goal of tapping into unconventional lithium resources to meet growing global demand.

Competitive Landscape and Market Positioning

As various Petro-Lithium projects progress worldwide, how might E3 Metals position itself in this emerging market?

Potential strategies for market differentiation include:

- Emphasizing the environmental benefits of their extraction process

- Focusing on the purity and quality of their lithium product

- Leveraging Alberta’s existing energy infrastructure and expertise

- Developing partnerships with battery manufacturers or electric vehicle producers

- Pursuing vertical integration into value-added lithium products

E3 Metals’ success in this competitive landscape will depend on their ability to demonstrate both technical proficiency and economic viability in their Petro-Lithium extraction process.

Brine Clutch 3 HS M · StringKing

Learn how to string a Brine Clutch 3 HS lacrosse head with a Mid Pocket. Our step-by-step stringing tutorials make it easy to string the perfect stick.

Lacrosse Pocket

Clutch 3 HS M

The ultimate offensive weapon.

L M H View All

Choose Your Mesh

chevron-down

- Choose Your Mesh

- type-4s

- type-4x

- type-4f

- type-3s

- type-3x

- type-2s

- type-2x

Lacrosse Head

Clutch 3 HS

Loading

E3 Metals: Sampling of Petrolithium Brine from First 43 Wells Complete; Analysis Undergoing

Mr. Chris Doornbos reports:

Chris Doornbos reports:

Vancouver, BC (FSCwire) – E3 METALS CORP. (TSX-V: ETMC, FSE: OU7A) (the “Company” or “E3 Metals”) is pleased to announce the completion of the first round of sampling of Petro-Lithium brine water from petroleum wells, located over several of E3 Metals’ Metallic and Industrial Minerals (MIM) Permits in Alberta. Samples have been collected in collaboration with 11 oil and gas operators. The samples have been received at the accredited laboratories and are undergoing analysis.

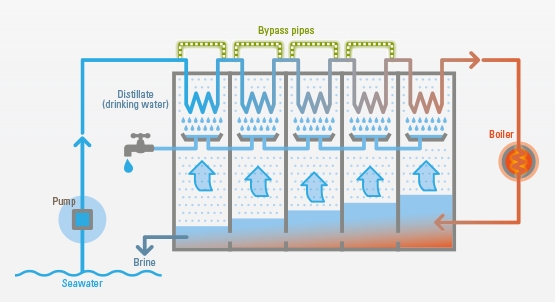

Sampling locations were chosen to confirm historical testing results outlined in the E3 Metals NI 43-101 Report, dated May 18. 2017, available under the Company’s profile at www.sedar.com and at www.e3metalscorp.com. Historical results in the sampling area ranged as high as 74.1 mg/L lithium within E3 Metals MIM Permit areas across this small portion of the reservoir. Additionally, E3 Metals has sampled several locations where no historical lithium concentration data is available. The consistency of the lithium concentrations found within the reservoir is a critical component in allowing for commercialization of the Company’s project. This, combined with the ability to produce large volumes of water, the size of the reservoir and the extraction technology efficiency, forms the fundamentals for developing the Company’s Petro-Lithium Project. E3 Metals is working on all four of these metrics simultaneously to drive this project forward as effectively as possible.

The consistency of the lithium concentrations found within the reservoir is a critical component in allowing for commercialization of the Company’s project. This, combined with the ability to produce large volumes of water, the size of the reservoir and the extraction technology efficiency, forms the fundamentals for developing the Company’s Petro-Lithium Project. E3 Metals is working on all four of these metrics simultaneously to drive this project forward as effectively as possible.

“We are pleased to have delivered samples from the first 43 wells to the lab for analysis, collected during the first round of our ongoing sampling program” said E3 Metals’ CEO, Chris Doornbos, “This is an increase of almost double our expected number of wells and I would like acknowledge the cooperation of the oil and gas operators E3 has been collaborating with during this sampling round. Our sampling will continue into the fall with planning of additional programs currently underway.”

RECENT & RELEVANT

Revival Gold Marks Impressive Continued Growth in Mineral Resource and Advanc.

..

..

Calibre Mining Reports Positive Higher-Grade Near Surface Drilling at Its Pan…

HighGold Mining Announces Start of 8,000-meter Drill Program and Outlines Adv…

MORE MINING NEWS

Novo Resources: De Grey to Invest A$25 Million to Earn 50% in Egina JV and Complete A$10 Million Cornerstone Investment

FireFox Gold Drills 20.4 metres at 5.1 g/t Gold and Extends the Footprint of Mineralization at Mustajärvi East Target in Finland

Dynacor Group Achieves Groundbreaking Monthly Gold Production Record, Producing 11,619 Ounces

Arras Minerals Reports First High-Grade Gold and Silver in Grab Samples From the Elemes License

Prospector Metals Discovers Multiple High-Grade Ni-Cu-PGE Occurrences at the Devon Project in Northwestern Ontario

Calibre Mining Reports Positive Higher-Grade Near Surface Drilling at Its Pan Gold Mine, Nevada; Initial Results Include 3.84 g/t Gold over 15.2 metres and 2.08 g/t Gold Over…

Kodiak Copper Adds Second Drill Rig at MPD Copper-Gold Porphyry Project in Southern British Columbia

New Age Metals Delivers New Positive Preliminary Economic Assessment of the River Valley Palladium Project

Kenorland Minerals Announces Grassroots Discovery of Intrusion-Related Gold System at Chebistuan Project, Quebec

FireFox Gold Reports Results from Reconnaissance Drill Program at Sarvi Project, Lapland, Finland

Prismo Metals Samples 10. 3 g/t Au and 104 g/t Ag over 4 Meters at Los Pavitos

3 g/t Au and 104 g/t Ag over 4 Meters at Los Pavitos

Arras Minerals Commences Regional Field Program on 3,300 sq. km License Package in Pavlodar, Kazakhstan

E3 metals closer to recovering lithium from oilfield brine.-industry-news

Best lithium battery 18650

Cylindrical lithium-ion battery

Lithium Ion Battery Best Guide

The Best Guide to LiPo Batteries

Best Guide to Lifepo4 Battery

12V lithium battery manual

48 V Li-ion battery

Connecting lithium batteries in parallel and in series

Best Li-Ion Battery 26650

APR 01, 2019Page view:473

E3 Metal’s proprietary lithium pre-metallurgical recovery technology yields up to 1206 mg per liter of lithium concentrate with a concentration factor of 16 times. This company is located in Calgary.

This company is located in Calgary.

process is also successful for key metal impurities decreased by 99%, at the same time show lithium recovery rate as high as 81%.

Tested by the University of Alberta and CIMIC minerals processing group Sedgman Canada Limited, independently verified.

“The E3MetalsAlbertaLithium project is a big step forward,” E3Metals CEO ChrisDoornbos said in a statement.

“In order to develop a simple and efficient process for concentrating brine to significantly reduce impurities, we set out to test the economic and technical feasibility of Alberta’s large lithium petroleum oil resources. By continuously optimizing the adsorbent, our goal is to achieve higher recovery rates. “We are actively developing the next phase of work to advance the technology to extract lithium from Alberta oil,” he said.

Project area in the western company Exshaw E3 Metal six rich in lithium, whose formation water enrichment technology (brine) small-scale metallurgical testing. In less than three hours, the entire enrichment process will be completed. The company is expected to release a related technical report, NI43-101, in the next four weeks.

In less than three hours, the entire enrichment process will be completed. The company is expected to release a related technical report, NI43-101, in the next four weeks.

According to the results, E3Metals will seek to optimize and expand its enrichment technology to further improve lithium concentration and recovery efficiency. The enrichment technology will become a company in the production of lithium two main stages of extraction the first stage.

The company, in collaboration with the University of Alberta, is currently in a provisional patent filed to protect intellectual property rights related to its enrichment technology.

To date, E3Metals has identified 6.7 million tonnes of integrated lithium carbonate equivalent (LCE) resources across the three resources, including Alberta holdings up to 34% of the allowance.

Highly porous and permeable, the formation of which has been shown to allow the transport of large quantities of hot brine (70 to 100 degrees Celsius). The company said that with a wide range of oil and gas well infrastructure, including processing, production base and pipelines, as well as an advanced regulatory system, Alberta lithium for oil development has great appeal.

The company said that with a wide range of oil and gas well infrastructure, including processing, production base and pipelines, as well as an advanced regulatory system, Alberta lithium for oil development has great appeal.

Six trials produced lithium recovery, lithium concentration and reduction of critical (impurity) ion concentration of a series of results. The maximum recovery of lithium has increased from 66% to 81%, while the concentration of lithium varies from 13 to 16 times. The key is to significantly reduce impurities, averaging over 99%.

E3Metals advised that while the project is still at concept level, its concentration can be processed into lithium carbonate and/or lithium hydroxide. Further development of ion-exchange technology will be continued in tests of synthesis and extraction of the optimal adsorbent. The company stated that the goal is to achieve a higher recovery and increase the lithium enrichment ratio while maintaining a high level of impurities.

The page contains machine translated content.

- Previous article:

Huizhou Yiwei Lithium Energy Shares opened a subsidiary - Next article:

Three Tips for Eliminating the Hazards of Incompatible Lithium Batteries

Most Popular Categories

Custom solutions

11.1 V 6600 mAh Battery Construction Diagram for Portable Supersonic Diagnostic Kit B

7.4 V 10 Ah Medical Infusion Pump Backup Circuit

Solutions for Lithium Ion batteries AGV 25.6 V, 38.4 Ah

Lutetia T3 Mixer Used equipment

- Description

- Detailed information

- About this seller

– Vacuum meat churn.

– Manufacturer: Lutetia

– TYPE 3

– Meat + brine capacity: 1400 to 1500 kg.

– 415 V + 50 Hz + 4 kW.

– Volume: 2500 l.

– Weight: 1100 kg.

– Total length: 2650 mm.

– Width: 1450 mm.

– Diameter with tire: 1340 mm.

– Height: 2020 mm.

This description can be translated automatically. Contact us for further details. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

| Capacity | 2500L |

| Tank diameter | 1340 mm |

| Tank material | inox |

| ——————- | |

| L x W x H | 2650. 0 × 1450.0 × 2020.0 0 × 1450.0 × 2020.0 |

| Weight | 1100kg |

| Operating hours | |

| Switching hours | |

| Status | in good condition |

| CE marked | ——— |

| Status | possibility of inspection |

| Customer type | Dealer |

| Active with | 2007 |

| Offers online | 87 |

| Last activity | July 19, 2023 |

Description

– Vacuum meat churn.

– Manufacturer: Lutetia

– TYPE 3

– Meat + brine capacity: 1400 to 1500 kg.

– 415 V + 50 Hz + 4 kW.

– Volume: 2500 l.

– Weight: 1100 kg.

– Total length: 2650 mm.

– Width: 1450 mm.

– Diameter with tire: 1340 mm.

– Height: 2020 mm.

This description can be translated automatically. Contact us for further details. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

Details

| Capacity | 2500L |

| Tank diameter | 1340 mm |

| Tank material | inox |

| ——————- | |

| L x W x H | 2650. Related Stories |