How do heat presses work for jersey customization. What factors should you consider when buying a heat press machine. Which are the top heat press picks for jerseys and shirts. How can you achieve quality heat press results.

Understanding Heat Press Technology for Jersey and Shirt Customization

Heat pressing has revolutionized the world of garment customization, offering a reliable and efficient method to personalize jerseys, shirts, and various apparel items. This technique allows for the application of numbers, names, logos, and intricate designs onto fabric with remarkable precision and durability.

The Science Behind Heat Pressing

At its core, heat pressing relies on the combination of heat and pressure to transfer designs onto garments. But how exactly does this process work?

- The design is first created or printed onto special transfer paper or cut from heat transfer vinyl.

- The heat press machine is preheated to a specific temperature, typically ranging from 300°F to 375°F (149°C to 191°C).

- The transfer material is placed onto the garment, positioned in the heat press.

- Pressure is applied for a predetermined duration, usually between 10 to 30 seconds.

- The heat and pressure cause the design to bond with the fabric fibers, creating a permanent transfer.

This process allows for vibrant, long-lasting designs that can withstand repeated washing and wear, making it ideal for sports jerseys and custom apparel.

Advantages of Heat Pressing Over Other Customization Methods

Why has heat pressing gained such popularity in the garment customization industry? The advantages are numerous:

- Versatility: Heat presses can work with various materials, including cotton, polyester, and blends.

- Precision: Digital controls allow for exact temperature and time settings, ensuring consistent results.

- Durability: Properly heat-pressed designs can last as long as the garment itself.

- Cost-effectiveness: Once you have the equipment, the ongoing costs are relatively low.

- Speed: Heat pressing is much faster than traditional embroidery or screen printing for small batches.

Essential Factors to Consider When Choosing a Heat Press Machine

Selecting the right heat press machine is crucial for achieving professional results. Several key factors should influence your decision:

Press Plate Size and Its Importance

The size of the press plate determines the maximum area you can print in a single operation. For jersey printing, a larger plate size is often beneficial. Why is this important?

- Larger plates accommodate bigger designs and full-back jersey numbers.

- They allow for more efficient production when working with adult-sized garments.

- However, larger plates also mean a bigger machine, which requires more space.

Consider your typical project size when choosing the plate dimensions. A 15×15 inch plate is versatile for most applications, while 16×20 inch plates are ideal for larger designs and jerseys.

Digital vs. Manual Heat Presses: Which Is Right for You?

The choice between digital and manual heat presses can significantly impact your workflow and results. Digital presses offer precise control over temperature and time settings, ensuring consistency across multiple pressings. Manual presses, while often more affordable, require closer monitoring and may have a steeper learning curve.

Digital presses are recommended for:

- Businesses with high-volume production needs

- Users who prioritize consistency and precision

- Those working with a variety of materials requiring different settings

Manual presses might be suitable for:

- Hobbyists or those just starting out

- Small-scale operations with lower budgets

- Users comfortable with hands-on monitoring and adjustment

The Importance of Even Pressure Distribution

Uniform pressure across the entire plate is crucial for achieving complete and even transfers. Uneven pressure can result in partial transfers, peeling, or inconsistent results. How can you ensure even pressure?

- Look for presses with adjustable pressure settings.

- Check for user reviews mentioning pressure consistency.

- Consider machines with floating platens that self-adjust to garment thickness.

Top Heat Press Picks for Jersey and Shirt Customization

After extensive research and consideration of various factors, we’ve compiled a list of top heat press options suitable for jersey and shirt printing:

1. PowerPress Industrial-Quality Digital Sublimation Heat Press Machine

This 15×15-inch digital press offers an excellent balance of quality and affordability. Its features include:

- Digital LCD control panel for precise temperature and time settings

- Teflon-coated heating plate for non-stick operation

- Pressure adjustment knob for various fabric thicknesses

- Suitable for t-shirts, jerseys, and various flat items

2. VEVOR 8 in 1 Combo Heat Press Machine

For those seeking versatility, this multi-purpose heat press is an excellent choice. It offers:

- Interchangeable plates ranging from 6×6 to 16×16 inches

- Digital time and temperature controls

- 360-degree rotation of the upper platen

- Capability to press shirts, caps, mugs, plates, and more

3. Fancierstudio Power Heat Press Industrial-Quality Digital Machine

This industrial-strength press is ideal for high-volume operations:

- Large 16×20-inch pressing surface for oversized prints

- Digital temperature and time controls

- Teflon-coated heat platen for easy cleaning

- Heavy-duty construction for long-term durability

Mastering Heat Press Techniques for Professional Results

Achieving high-quality results with your heat press requires more than just the right equipment. Here are some essential techniques to master:

Pre-pressing: The Key to Wrinkle-Free Transfers

Pre-pressing is a crucial step often overlooked by beginners. Why is it important?

- It removes moisture from the fabric, preventing steam bubbles during transfer.

- It smooths out wrinkles, ensuring an even surface for the design.

- It pre-heats the garment, allowing for better adhesion of the transfer material.

To pre-press effectively, place the garment on the heat press for 5-10 seconds before applying the transfer. This simple step can significantly improve the quality and longevity of your prints.

Optimal Temperature and Time Settings for Different Materials

Different materials require varying heat press settings for the best results. Here’s a general guide:

- Cotton: 350-375°F (177-191°C) for 10-15 seconds

- Polyester: 270-300°F (132-149°C) for 10-15 seconds

- 50/50 Blend: 325-350°F (163-177°C) for 10-15 seconds

- Heat Transfer Vinyl: 305-320°F (152-160°C) for 10-15 seconds

Always refer to the specific instructions provided with your transfer material, as these can vary between brands and types.

The Importance of Cooling and Peeling Techniques

The cooling and peeling process is crucial for achieving a clean, professional-looking transfer. Should you peel the transfer material hot or cold?

- Hot Peel: Suitable for most heat transfer vinyls. Peel immediately after pressing while still hot.

- Cold Peel: Often used for sublimation and some transfer papers. Allow the garment to cool completely before peeling.

- Warm Peel: A middle ground, peeling when the transfer is warm but not hot.

Always follow the manufacturer’s instructions for your specific transfer material to determine the best peeling method.

Troubleshooting Common Heat Press Issues

Even with the best equipment and techniques, issues can arise. Here are some common problems and their solutions:

Dealing with Incomplete Transfers

Incomplete transfers, where parts of the design don’t adhere properly, can be frustrating. What causes this issue and how can it be resolved?

- Cause: Insufficient heat, pressure, or time

- Solution: Increase temperature, pressure, or pressing time slightly

- Prevention: Ensure even pressure distribution and use a heat press pillow for uneven surfaces

Preventing Scorching and Discoloration

Scorching can ruin a garment and waste materials. How can you avoid this common pitfall?

- Use a protective sheet between the heat platen and the garment

- Adjust temperature and time settings according to fabric type

- Avoid leaving the press closed longer than necessary

- Consider using a laser thermometer to verify your heat press temperature accuracy

Addressing Peeling and Cracking Issues

Peeling and cracking can occur over time, diminishing the quality of your prints. How can you prevent these issues?

- Ensure proper temperature and pressure during application

- Use high-quality transfer materials suitable for the fabric type

- Educate customers on proper care instructions, such as washing inside-out

- Consider a second press with a Teflon sheet for added durability

Expanding Your Heat Press Business: Beyond Jerseys and Shirts

While jerseys and shirts are popular items for heat pressing, the possibilities extend far beyond traditional apparel. How can you diversify your heat press business?

Exploring New Product Lines

Consider expanding into these profitable areas:

- Promotional items: Tote bags, mousepads, coasters

- Home decor: Pillowcases, blankets, custom photo tiles

- Accessories: Hats, socks, phone cases

- Sports gear: Golf towels, arm sleeves, headbands

Incorporating Sublimation Printing

Sublimation printing offers vibrant, full-color designs that become part of the fabric. How does it differ from traditional heat transfer?

- Uses special sublimation inks that turn into gas when heated

- Requires polyester or polymer-coated substrates

- Allows for edge-to-edge printing with no feel on the fabric

- Ideal for photographic and gradient designs

Investing in sublimation equipment can open up new markets and increase your product offerings.

Marketing Your Heat Press Services

Effective marketing is crucial for growing your heat press business. Consider these strategies:

- Create a portfolio of your best work to showcase on social media

- Offer customization services to local sports teams and schools

- Participate in craft fairs and local events to demonstrate your products

- Develop an e-commerce website to reach a broader audience

- Collaborate with influencers or local personalities for exposure

Maintaining Your Heat Press for Longevity and Consistent Performance

Proper maintenance of your heat press is essential for ensuring its longevity and consistent performance. How can you keep your machine in top condition?

Regular Cleaning and Inspection

Implement a routine cleaning schedule:

- Clean the heat platen when cool with a non-abrasive cleaner

- Inspect and clean the lower platen to remove any residue

- Check and tighten any loose screws or bolts

- Lubricate moving parts as recommended by the manufacturer

Calibrating Temperature and Pressure

Regular calibration ensures accurate and consistent results:

- Use a laser thermometer to verify temperature accuracy

- Adjust pressure settings for different fabric thicknesses

- Perform test prints periodically to check for consistency

When to Seek Professional Servicing

While many maintenance tasks can be performed independently, some issues require professional attention. Consider professional servicing if you encounter:

- Inconsistent heating across the platen

- Failure to reach or maintain set temperatures

- Unusual noises or movements during operation

- Electrical issues or control panel malfunctions

Regular maintenance and prompt attention to issues will extend the life of your heat press and ensure consistent, high-quality results for your customers.

Introduction To Heat Pressing Jerseys And Shirts

Heat pressing is a popular method for customizing jerseys, shirts, and other apparel with numbers, names, logos, and designs. With a good heat press machine, some vinyl or transfer paper, and a little practice, anyone can start a small business or customize gear for their team. In this guide, we’ll walk through the basics of heat pressing garments and explore some of the best heat press options for jerseys and shirts.

How Does Heat Pressing Work?

A heat press machine uses heat and pressure to transfer a design or image from a special transfer paper onto a shirt or other item. Here’s a quick rundown of the basic heat pressing process:

- Cut out or print your design onto transfer paper, vinyl, or another heat transfer material.

- Pre-heat your heat press to the proper temperature (usually 300-375°F).

- Place the transfer paper print-side down onto the garment and use the heat press to apply even pressure across the design.

- After 10-30 seconds, depending on the material, open the heat press. The design should now be bonded to the garment.

With the right materials and some practice, it’s relatively easy to start embellishing garments in no time. But having the right heat press machine for the job makes all the difference.

Factors To Consider When Buying A Heat Press Machine

Here are some key factors to weigh when choosing a heat press for shirt printing and applying numbers:

- Press plate size – You’ll need a plate large enough to accommodate your biggest garments and transfers.

- Digital vs. manual – Digital heat presses allow you to precisely dial in time and temp, while manual models require close monitoring.

- Pressure – Even pressure across the plate ensures complete transfer without burning.

- Teflon-coated plates – Non-stick coatings prevent scorching and make garment loading easy.

- Shut-off timers – Auto open timers prevent overcooking transfers if you get distracted.

- Price – Consider entry-level models vs. high-end commercial heat presses.

Also look for presses with interchangeable plates, swing-away functions for thicker items like bags and shoes, and rotating platens for 360-degree printing. Keep in mind your goals, space constraints, and budget when shopping for the ideal shirt press.

Our Top Heat Press Picks for Jerseys and Shirts

Based on the above criteria, here are some of our top recommendations for heat presses to consider for numbering jerseys and printing shirt designs:

This 15×15-inch digital press delivers professional quality at an affordable price point. The digital LCD control panel provides accurate time, temp, and pressure monitoring and control. It’s perfect for t-shirts, jerseys, mugs, plates, and other items.

Get the versatility of interchangeable 6×6, 6×8, 8×8, 9×9, 12×15, and 16×16-inch plates in one multi-purpose heat press unit. It’s ideal for t-shirts, caps, mugs, plates, tiles, and more with digital controls.

A large 16×20-inch pressing surface can accommodate oversized prints for jerseys, shirts, flags, etc. It delivers industrial strength pressing power with digital precision and convenience.

This mid-range model offers a generous 9×12-inch pressing surface paired with professional-grade digital controls and smooth swing-away functions. It’s great for shirts, hats, mugs, tiles and other gifts.

The compact 7×7-inch plates make this an ideal portable press for numbering jerseys on the go. It’s lightweight, budget-friendly, and perfectly sized for shirt sleeves, collars, baby onesies, and other small projects.

This covers some of the best entry-level to high-end press options for applying numbers, names, and designs to jerseys, shirts, and apparel. Be sure to consider the project size, volume, and budget when selecting the right heat press setup for your needs.

Tips for Easy, Quality Heat Press Results

Follow these handy guidelines for professional-looking results when pressing jersey numbers and shirt designs with your new heat press:

- Use a heat-resistant silicone sheet or parchment paper under the transfer.

- Pre-press garments for 5 seconds to remove wrinkles and moisture.

- Follow material instructions for optimal time, temperature, and pressure.

- Allow garments to fully cool before removing to prevent peeling.

- Use a cover sheet over transfers to prevent surface scorching.

- Replace press pads/covers periodically to prevent ghosting.

- Gently stretch fabric taut when closing the press.

- Use light pressure when pressing delicate performance fabrics.

Start imprinting quality custom jerseys, shirts, and merchandise for your team, business, or hobby with the help of our heat press buying guide. With some practice and the right equipment, you’ll be producing professional-caliber results in no time.

Why Use A Heat Press For Jersey Number Printing?

From youth leagues to professional sports, having uniform jersey numbers is a must for player identification and branding. While screen printing numbers directly onto jerseys is an option, heat pressing offers some unique advantages. Let’s explore why a heat press is often the best tool for applying numbers to athletic jerseys and shirts.

Faster Production Time

With screen printing, creating the numbered jersey designs requires burning a separate screen for each color and number combination. The set-up time and process to print numbers directly onto jerseys can be lengthy, especially for teams with multiple rosters. A heat press allows you to quickly pre-print player names and numbers on transfer vinyl. Then in seconds you can heat press and adhere them onto the jerseys as needed.

Lower Minimum Order Quantity

Because screen printing numbered jerseys requires creating screens, there is often a high minimum order quantity like 12, 24 or more. But with printable heat transfer vinyl and a press, you can print a single jersey number or make hundreds. This makes heat pressing ideal for smaller teams, youth leagues, schools, and local clubs.

Easy to Change and Reuse Numbers

Players graduate, leave teams, or change numbers often. With screen printed jerseys, old numbered jerseys often go to waste. But heat pressed numbers can be quickly peeled off and replaced in seconds. The uniform jersey itself is preserved longer.

Wider Range of Materials and Effects

From metallic to glitter and more, heat transfer vinyl comes in a rainbow of colors, finishes, and effects difficult to achieve with screen printing. This allows for highly custom, eye-catching numbered jerseys.

Multi-Color Graphics and Effects

Using layered vinyl, heat pressing also allows you to add multi-colored effects, shadows, outlines and more to numbers that would be difficult and costly in screen printing. The possibilities are endless!

Lower Investment Costs

A commercial heat press machine costs a fraction compared to a full screen printing setup. Combined with reusable presses blanks, heat pressing offers an affordable way to start producing numbered jerseys with a lower equipment investment.

Ideal for Prototyping and Testing

Before committing to a full production run, heat press printable vinyl allows you to mock up prototypes and test different looks. Make revisions and adjust sizing before approving final jersey numbers.

On-Demand Production

Heat pressing with vinyl allows you to produce numbered jerseys on demand as needed. No need to order bulk batches and predict exact quantities months in advance like screen printing requires.

Wider Range of Garment Options

From cotton to moisture-wicking performance fabrics, heat transfer vinyl adheres to a wide range of jersey materials. More delicate fabrics like spandex blends can be damaged by high-heat screen printing.

Finer Detail and Registration

With screen printing, colors and details can bleed or get misaligned. But heat applied vinyl numbers can achieve finer detail and registration even on small youth jerseys.

Soft Hand Feel

After heat pressing, vinyl transfers leave a minimal texture compared to thick, post-like screen printed ink. This results in greater comfort and performance.

Convenient In-House Production

Heat presses are small, easy to operate, and made for in-house production. With outsourced screen printing you need to factor in shipping, minimums and delays.

For the ability to quickly apply crisp, vibrant, and durable numbering for athletic jerseys, heat press printing with vinyl can’t be beat. The next time you need customized, uniform numbers for a team or league, explore heat pressing as the superior garment imprinting solution over traditional screen printing.

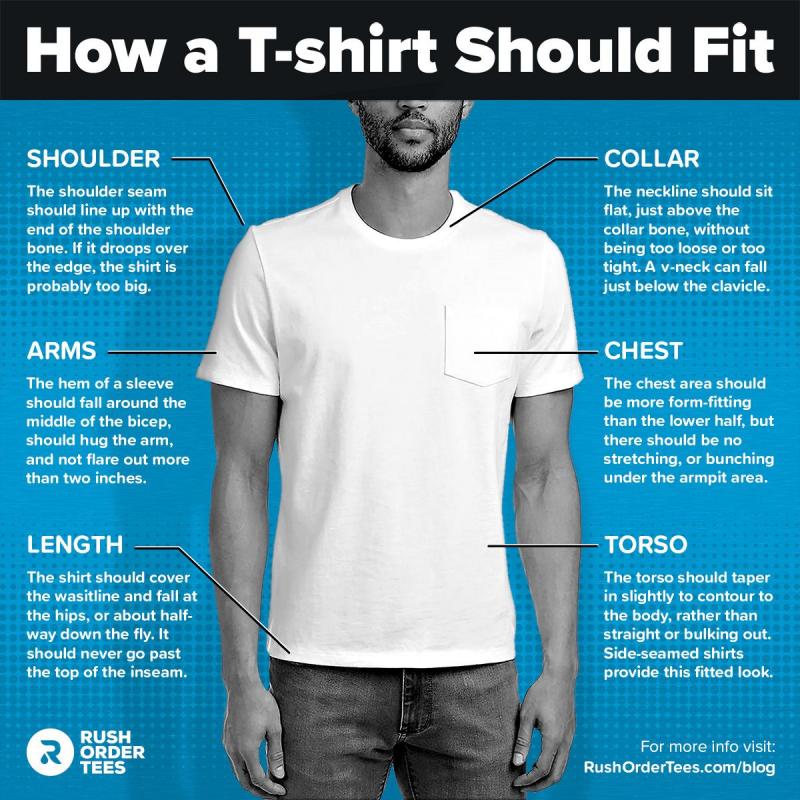

What To Look For In A Heat Press Machine

Investing in a quality heat press machine is essential for imprinting numbers, names, and designs onto jerseys, shirts, and apparel. But with so many press options on the market, how do you pick the right one? Here are the key features and specifications to look for when shopping for a heat press for jerseys and shirts.

Heating Element Type

Heat presses use either sublimation or platen heating elements. Sublimation elements heat the lower platen surface for dye sublimation printing. Standard platen presses have elements in both the upper and lower platens for heat pressing vinyl and transfers.

Pressing Surface Size

Consider the size jerseys and garments you’ll be pressing most often. Look for plate dimensions of at least 15×15 inches for adult large jerseys. Smaller clamshell style presses in the 9×12 inch range work for sleeves, numbers, names, and youth sizes.

Digital vs. Manual Temperature Settings

Digital heat presses allow you to precisely set and monitor the optimal temperature for different materials using the control panel. Manual presses require close monitoring with a thermometer for accuracy.

Digital Timer Settings

Digital heat press machines come with programmable countdown timers for accurate press times. This prevents burning or under-pressing transfers. Manual presses require a watchful eye and timer.

Pressure Adjustability

Even pressure across the lower and upper heating platens is vital for getting complete transfer adhesion without burning or ghosting. Look for presses with adjustable pressure for different materials.

Floating Upper Platen

A floating upper platen that self-levels and evenly distributes pressure is ideal for avoiding uneven pressure points on larger jerseys and garments.

Teflon-Coated Plates

Non-stick Teflon coatings on the press plates make loading and unloading garments quicker and easier. They also reduce scorching and transfer ghosting on jerseys.

Accommodates Thick Materials

Presses with an adjustable lower platen height or swing away function allow you to imprint thicker items like garment bags, shoes, and other gear.

Rotating Heating Platens

For printing wraps, sleeves, and unconventional items, look for heat press machines with full 360-degree rotating upper and lower platens.

Portability

Compact and lightweight heat presses under 30 lbs offer easy portability for imprinting jerseys on the go at games, events, etc.

Price and Budget

Consider lower cost entry-level presses for smaller volumes or high-end commercial presses for heavy daily use and longer-term investment.

Warranty and Support

Look for heat presses that come with guarantees of at least 1 year. Extended warranties, strong customer support, and US-based service centers provide added peace of mind.

Brand Reputation and Reviews

Stick with well-reviewed heat press brands known for quality construction and durability. This ensures years of optimal performance.

By keeping these key factors and features in mind as you shop, you’ll be able to select the ideal heat press machine for flawlessly applying numbers, names, and custom designs onto jerseys and shirts for years to come.

Top Heat Press Brands For Jerseys

Choosing the right heat press brand is key to achieving professional-quality results when imprinting numbers, names, and designs on athletic jerseys. After reviewing numerous options on the market, here are our picks for the top heat press brands to consider for jersey printing.

PowerPress

Known for high-performance digital clamshell presses at affordable prices, PowerPress offers a range of models well-suited to jersey numbering. The Industrial Quality 15×15 inch model provides commercial-grade construction with digital precision and easy operation. PowerPress machines deliver even plate pressure for crisp transfers.

Fancierstudio

This brand offers versatile multi-platen combo presses for imprinting jerseys, shirts, mugs, plates, and more using interchangeable platens. The professional digital Fancierstudio Power Heat Press comes with 6×6, 6×8, 8×8, 9×9, 12×15, and 16×16 inch plates. It’s a true all-in-one imprinting workhorse.

Zenus

Known for high-quality entry-level machines, Zenus offers affordable presses suited for start-ups and home crafters. The Zenus 9×12 inch compact swing-away model provides a large imprint area and digital precision in a portable and budget-friendly package.

STSStudio

With innovative professional-grade designs, STSStudio presses offer exceptional quality and performance. The STSStudio 16×20 inch sublimation heat press provides an extra-large pressing surface perfect for oversized jersey prints and customization.

GEO Knight

As pioneers of heat press tech, GEO Knight sets the gold standard for commercial-use American made presses. Their heavy duty clamshell machines like the DK20S 16×20 inch model deliver flawless, high-volume results for pro jersey imprinting.

Hotronix

Known for high-performing swing-away presses, Hotronix is a go-to brand for apparel decorators and embroiderers. The Hotronix Fusion heat press line features digital controls, auto-open functionality, and generous 16×20 inch print capacity optimal for jerseys.

TransPro

Offering a wide array of press models, TransPro excels at large format imprinting machines well-suited to jerseys and apparel. TransPro presses like the 15×15 inch clamshell provide commercial-grade quality and durability.

Cricut

For crafters and home-based imprinting, Cricut’s peque Easy Press line offers compact and portable heat press options. The Cricut EasyPress Mini 7×7 inch model provides surprising power and convenience in a tiny imprinting package.

NINESTARS

Known for advanced industrial presses, NINESTARS makes high-performing machines ideal for demanding imprint jobs. Their 15×15 inch clamshell model features digital accuracy, deep plate imprinting, and a floating top platen.

When selecting a heat press brand for flawlessly imprinting jerseys, focus on consistency, durability, warranty coverage, and true commercial-grade construction. With the right press machine, you’ll be equipped to handle high-volume jersey numbering and customization like a pro.

Heat Press Temperature And Time Settings

Dialing in the right combination of temperature, time, and pressure is imperative when heat pressing numbers, names, and designs onto jerseys and shirts. The material being pressed and the type of vinyl or transfer paper used determines the ideal settings. Here’s a guide to the optimal heat press temperature and time settings for different jersey imprinting materials.

Polyester Athletic Jerseys

Common lightweight polyester athletic jersey materials like Dri-FIT require lower application temperatures. Aim for 285-300°F at 10-20 seconds for polyester fabrics.

Cotton Jersey Fabrics

Standard 100% cotton jersey knits can handle higher heat press temperatures up to 350°F at 12-15 seconds. Reduce time for blended cotton fabrics.

Nylon/Spandex Jersey Fabrics

More delicate technical jersey fabrics with nylon or spandex call for lower temps around 275-300°F for just 8-12 seconds to avoid scorching.

Sublimation Transfer Paper

Sublimation transfers need high 400°F temps for 30-60 seconds to fully vaporize and infuse the polyester jersey fabric. Use 385-400°F for 50-60 seconds.

Inkjet/Laser Transfer Paper

Standard inkjet and laser transfer papers with a polymer adhesive layer require high 375-400°F heat press temps for 15-30 seconds to adhere properly.

Polyester Heat Transfer Vinyl

Apply polyester vinyl like Thermofilm at 305-320°F with light pressure for 10-15 seconds. Reduce time for moisture-wicking poly jersey fabrics.

Cotton/Blend Heat Transfer Vinyl

Cotton-specific vinyls need higher 340-375°F heat press temps and can handle 15-20 seconds for complete adhesion and curing.

Flock Heat Transfer Vinyl

Apply flocked heat applied vinyl at a lower 285-300°F for 8-12 seconds to avoid scorching the flock fibers or damaging the jersey fabric.

Glitter Heat Transfer Vinyl

Dial down the temp when pressing glitter vinyl to around 280-300°F at 10-15 seconds to avoid flattening the sparkle effect.

Metallic Heat Transfer Vinyl

Metallics need a lower application temp around 285-300°F for 10-15 seconds. High heat can oxidize and dull the metallic sheen.

Be sure to check the imprinting instructions for the specific vinyl or transfer paper being used. Having the right jersey heat press time and temperature means the difference between a successful imprint and ruined garments. When in doubt, perform a test press on scrap fabric to dial in the ideal settings.

Tips For Pressing Numbers And Letters

Applying numbers, names, and lettering onto jerseys using a heat press allows for completely customized uniforms. But to get crisp, clean results, follow these pro tips when heat pressing multi-layered vinyl numbers and letters onto athletic jerseys:

Use High-Quality Vinyl

Invest in a premium polyurethane or polyester heat transfer vinyl like Thermoflex, Siser, or Stahls for vibrant color and easy cutting and weeding. Cheap vinyl leads to application issues.

Perform Test Presses

Always do test presses with new materials and jersey fabrics to dial in the perfect time, temperature, and pressure settings before the full application.

Pre-Press the Jersey

Lightly pre-press jerseys for 3-5 seconds before application to remove creases, moisture, and improve vinyl adherence.

Use a Non-Stick Sheet

Place a silicone sheet or parchment paper between the jersey and heat platen to prevent scorching and allow heat to properly penetrate the layers.

Peel Backing Warm

After pressing, peel back the vinyl carrier warm for smooth separation and easier repositioning if needed before the adhesive fully sets.

Avoid Stretching Numbers

Don’t pull or over-stretch numbers and letters when aligning them or you’ll distort the vinyl shape and spacing relationship.

Press Numbers Evenly

Use a silicone or rubber roller tool to firmly press numbers and adhesion down across the jersey for uniform bonding.

Layer Vinyl Properly

When layering multi-color elements, always press base layers first before adding additional layers on top.

Lock In Each Layer

Fully press and adhere each vinyl layer for 5-10 seconds before adding the next to prevent misalignment issues.

Avoid Trapped Air

Smooth away wrinkles and re-press to remove any trapped air between vinyl layers which can cause bubbling.

Trim Excess Vinyl

Carefully trim away any excess vinyl with sharp scissors for a clean jersey appearance after pressing.

Taking the proper preparation steps and following these application tips will result in vivid, crisp, professionally applied numbers and letters on athletic jerseys. With a quality heat press and special touching, your custom team uniforms will really stand out!

Heat Pressing Different Jersey Materials

Today’s athletic and sports jerseys come in a range of fabrics from natural cottons to high-tech synthetic blends. When heat pressing numbers, names, and designs, it’s crucial to use the ideal time, temperature, and pressure settings for each specific jersey material being imprinted for the best quality and durability.

100% Cotton Jersey

Classic cotton jersey knits work well with many heat transfer papers and vinyls. Use a higher 350°F temp and press cotton jerseys for 15-20 seconds allowing moisture to evaporate.

Polyester Jersey

Synthetic polyester jerseys require a lower 300°F temperature to avoid scorching. Reduce press times to 8-12 seconds for common polyester athletic jerseys.

Nylon/Spandex Blends

Technical stretch nylon/spandex jersey fabrics need much lower temps around 275-300°F and briefer 6-10 second press times to protect their shape and stretch.

Poly-Cotton Blended Jerseys

For 50/50 poly-cotton jersey blends, use temp settings in the 300-320°F range for 10-15 seconds to account for both fabrics.

Microfiber Polyester Jerseys

Smooth microfiber or ultra-fine polyester jerseys require lower temp settings of 280-300°F and light pressure to avoid damaging their knit surface.

Moisture-Wicking Fabrics

Performance moisture-wicking jersey materials like Dri-FIT polyester need lower heat around 285-300°F and minimal 10 second press times.

Mesh Jersey Fabrics

Breathable mesh-knit jerseys worn for hot weather sports handle temps of 280-300°F for just 8-10 seconds to protect the airy fabric structure.

Twill/Pique Jerseys

Unique pique knit or cotton twill jersey fabrics can take higher 325-350°F heat due to their tighter weave for 12-15 seconds.

Always reference the jersey fabric content, weave, and construction when selecting heat press settings. Performing small test presses is also recommended before imprinting entire uniform sets. The right combination of heat and time for the specific jersey ensures vivid designs that pop while avoiding damage.

Finding A Local Heat Press Shop Or Service

Searching for a heat press shop or service in your area to imprint numbers, names, and custom designs on team jerseys? Here are some tips for finding a quality local heat press print provider to meet your jersey customization needs:

Online Search

A quick Google search for terms like “heat press near me” or “jersey heat press near me” can help locate providers. Focus on shops with professional websites showcasing their heat press work.

Social Media

Check for area heat press businesses on Facebook or Instagram. Look through reviews and photo examples of past jersey imprinting jobs to evaluate quality.

Business Directories

Search online business directories like Yelp, YellowPages, etc. Read ratings and reviews of local heat press companies to gauge customer experiences.

Association Member Lists

Many heat press trade groups like the UASGMA list certified members on their websites. This identifies reputable imprinting shops.

Apparel Decorators Referrals

Ask screen printers, embroiderers, or sign makers who they recommend for local heat press imprinting services.

League and Team Contacts

Inquire with area youth sports leagues and local teams if they have recommendations for heat press print providers they’ve used for jerseys.

Scout Shops In-Person

Observe the imprinting quality of work on display in-person at heat press stores to properly evaluate their capabilities.

Request Sample Pressings

Ask shops to demonstrate their heat press skills by submitting test imprints on your specific jersey material.

Compare Pricing

Get quotes from multiple providers to compare pricing for heat press services to fit your budget.

Check Experience Level

Choose a shop with staff skilled in heat pressing all types of jersey materials, vinyls, and transfers to ensure quality application.

Taking the time to find a qualified local heat press provider will give you access to professional jersey numbering and customization services when you need them. The perfect imprint makes all the difference on team uniforms!

Options For DIY Jersey Printing With A Home Heat Press

Thanks to today’s entry-level heat press machines, imprinting your own jersey numbers, names, and designs at home is easier than ever. Here are some DIY heat printing options for customizing team and recreational jerseys on your own schedule:

Printable Heat Transfer Vinyl

Cuttable heat transfer vinyl like Thermoflex allows you to print player names/numbers with an inkjet or laser printer and then heat press them onto jerseys. Offering a full color imprint, printable vinyl provides vibrant customization.

Heat Transfer Number and Name Kits

Many companies offer pre-cut iron-on jersey number, letter, and name kits with multiple color options to heat press at home with ease.

Sublimation Transfer Paper

Using sublimation transfers you print yourself, you can full-color print photos, designs, names, numbers, etc. and heat press them onto polyester jerseys.

Heat Applied Twill Letters

For a retro look, apply twill lettering and numbers with a heat press. Choose different colors to personalize each jersey.

Flock Heat Transfer Vinyl

Flock vinyl provides a textured, velvety finish when heat applied onto jerseys for unique tactile numbers and names that stand out.

Puffy Heat Transfer Vinyl

3D puffy vinyl adds raised dimension for bold, eye-catching heat transferred player names and numbers.

Glitter Heat Transfer Vinyl

Sparkle and shine with glitter heat transfer vinyl to add a dash of light-catching flair to jersey numbers, names, and logos.

Patterned Heat Transfer Vinyl

Choose striped, checkered, camo, and a range of patterned heat transfer vinyls to customize one-of-a-kind jerseys.

Digital Printed transfers

Purchase professional quality full-color digital printed transfers for names, numbers, photos, and designs to apply onto jerseys.

Jersey Letter and Number Reusable Platen

A reusable semi-rigid jersey number platen allows you to imprint the same digits onto multiple jerseys evenly and consistently.

DIY Team Logo Transfers

Design your own team logos on your computer and print them onto transfer paper to apply signatures, mascots, and branding.

The possibilities are endless for creating completely custom jerseys at home with an entry-level heat press. Get printing everything from names and numbers to intricate full-color designs and photographic images!

Heat Pressing Shirt Numbers: Step-By-Step

Adding shirt numbers is a great way to customize team jerseys and uniforms. Follow this simple step-by-step guide to heat press numbers onto shirts successfully every time:

Step 1: Gather Materials

You’ll need: a heat press, jersey shirt, heat transfer vinyl numbers, non-stick pad, application tape, scissors, masking tape, and a weeding tool.

Step 2: Set Heat Press Temperature

Set your heat press temperature according to the vinyl instructions, usually around 300°F-320°F. Allow it to fully pre-heat.

Step 3: Cut Vinyl Numbers

Use scissors or a cutting machine to cut out each digit and letter from the vinyl material per your shirt design.

Step 4: Weed Excess Vinyl

Use the weeding tool to peel away the excess vinyl around each cut number/letter shape.

Step 5: Pre-Press Shirt

Quickly pre-press the shirt for 2-3 seconds to remove wrinkles and moisture.

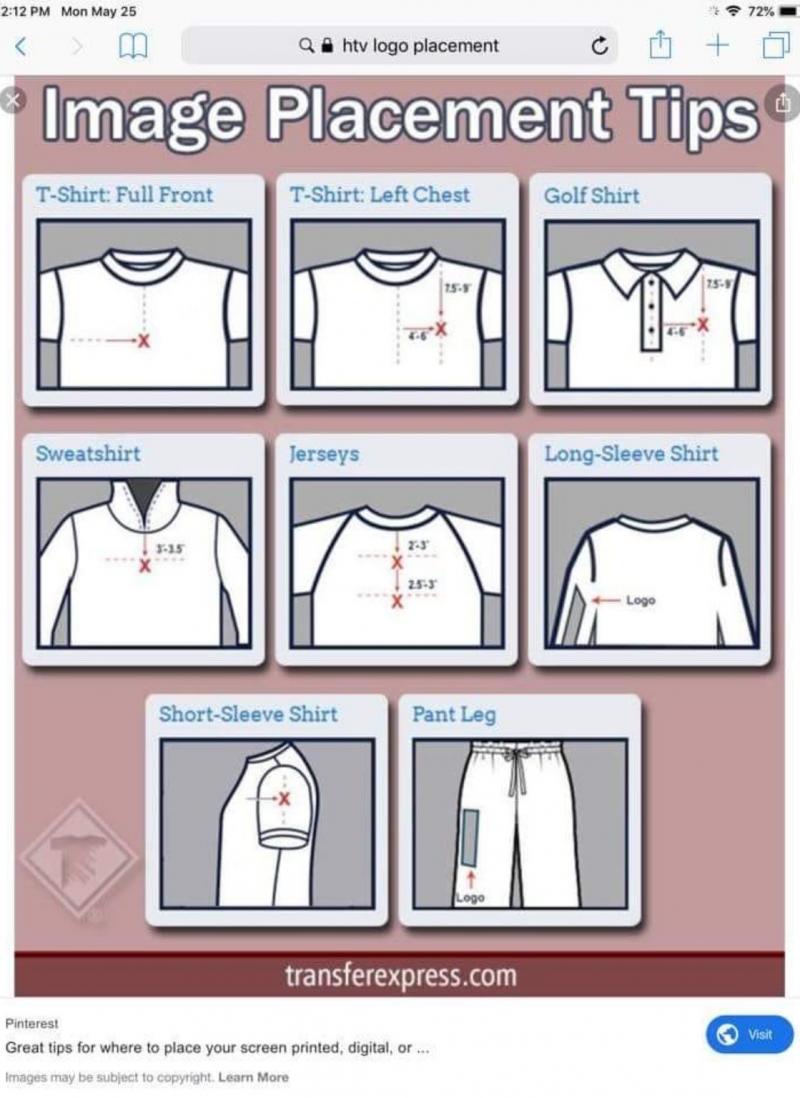

Step 6: Arrange Numbers

On application tape, arrange the vinyl numbers/letters in proper order for alignment on the shirt.

Step 7: Mask Shirt

Use masking tape to mark a guide box on the shirt for aligning the number layout when pressing.

Step 8: Apply Numbers to Shirt

Place the taped number layout onto the shirt within the mask guide. Cover with non-stick pad.

Step 9: Lock Heat Press Down Firmly

Lock the heat press down tightly on the numbers layout to ensure even pressure.

Step 10: Press Numbers

Press the vinyl numbers according to material directions, usually 10-15 seconds at set temperature.

Step 11: Peel Off Application Tape

Once cooled, gently remove the application tape from the numbers.

Step 12: Re-Press Shirt

For good adhesion, re-press the shirt for 5 more seconds without the tape.

Step 13: Peel Masking

Remove all masking tape from the shirt to reveal the finished numbers!

With the right materials and following these key steps, you can achieve crisp, professional shirt numbers every time using your heat press.

Common Mistakes To Avoid When Heat Pressing

Heat pressing jerseys, shirts, and apparel can seem straightforward, but there are some critical errors to avoid. Steer clear of these common heat press mistakes for flawless printed results every time:

Not Pre-Heating the Press

Allowing the press to fully pre-heat to the set temp is crucial for proper vinyl and transfer adhesion. Skipping this step leads to poor bonding.

Not Using a Heat-Proof Cover Sheet

Neglecting to use parchment paper or a silicone cover sheet can result in scorched fabrics and uneven heating through the layers.

Inadequate Pressure

Too little pressure prevents the vinyl or transfer from fully contacting the garment surface leading to incomplete application.

Uneven Pressure

Hot spots from uneven pressure points can create warped designs, ghosting, or scorching on the garment face.

Peeling Hot

Impatiently removing the backing before the imprint fully cools and sets can pull off sections of vinyl from the shirt.

Not Pre-Pressing Garment

Forgetting to quickly pre-press the area first can trap moisture or wrinkles under the vinyl preventing full adhesion.

Mismatched Temperature

Applying too much or too little heat relative to the material type can ruin transfers or damage delicate fabrics.

Incorrect Time Settings

Over or under-pressing garments leads to vinyl peeling, cracking, ghosting, bleeding, and other application flaws.

Distorted Vinyl

Overstretching or warping vinyl when applying to the shirt can result in crooked designs, warped names/numbers, etc.

Misalignment Issues

Not properly aligning multi-layered names, numbers, or designs leaves finished projects looking unprofessional.

Trapped Air Bubbles

Air pockets between vinyl layers or wrinkles under transfers create visible bubbles on the finished imprint.

Avoiding these common errors takes precision and care. Follow best practices and test press to master heat printing perfection for flawless jersey and shirt imprinting.

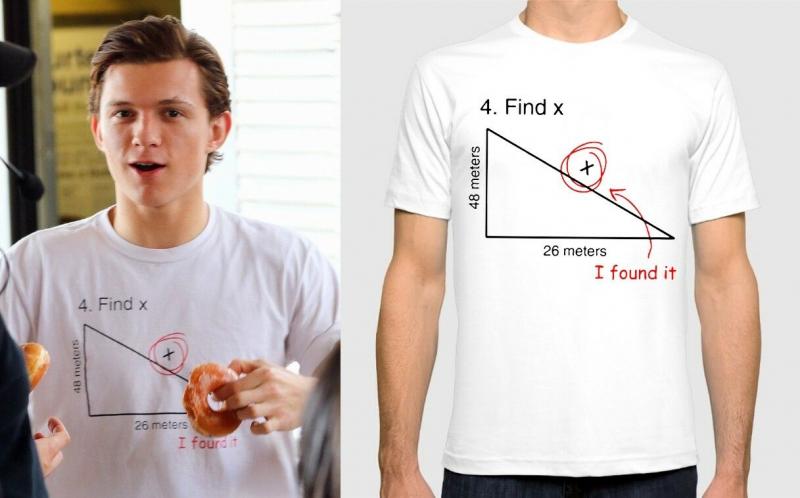

How To Create Custom Designed Jerseys

Want to make completely one-of-a-kind jerseys for your team, league, or players? With today’s digital printing technology and heat transfer materials, designing and imprinting fully custom jerseys is easier than ever. Here’s how to create custom designed jerseys from start to finish using a heat press.

Design the Artwork Digitally

Use graphic design software like Illustrator or Photoshop to design any type of jersey artwork from names, numbers, logos, photos and more. Mock up the full jersey digitally first.

Choose a Heat Transfer Material

Select a heat transfer material like printable vinyl, sublimation, or digital transfers compatible with your jersey type. Match the jersey fabric and imprint type.

Print the Designs as Transfers

Print out your custom jersey design onto the heat transfer material sheet using a compatible home or commercial printer depending on size.

Cut Out the Design Elements

Using an electronic cutting machine or by hand, carefully cut out each individual jersey design element from the transfer material.

Weed Away Excess Material

Peel away any excess material surrounding the printed design parts. This leaves only the design to be heat pressed.

Pre-Press the Jersey

Quickly pre-press the jersey for 3-5 seconds before application to remove wrinkles and moisture.

Heat Apply the Design

Cover with a sheet and use a heat press to apply even pressure and heat to adhere the custom design onto the jersey.

Layer Multi-Color Elements

For multi-layered designs, repeat the process cleaning aligning and adhering each colored element into place building up the full graphic.

Finish with Retransfer

For permanent adhesion, re-press the jersey after peeling the top carrier sheet but before the next layer.

Cooldown and Finish

Allow the imprinted jersey to fully cool and set. Carefully trim any overhanging material at the edges for a clean finish.

With some digital design skills and the right heat transferable materials, you can easily produce short runs or even single custom jerseys for your team right from your home workshop.

Heat Pressing Safety Tips

Heat presses allow you to customize jerseys, shirts, and apparel, but the hot equipment poses some safety hazards. Follow these important guidelines for staying safe when heat pressing:

Read the Manual Thoroughly

Review your press manual and understand all safety warnings before use. Follow the manufacturer’s instructions.

Ensure Proper Setup

Securely bolt presses to sturdy stands or surfaces to prevent tipping. Do not use on an unstable surface.

Avoid Contact with Hot Surfaces

The heating platens get extremely hot – up to 400°F. Avoid direct contact during operation to prevent burns.

Wear Heat-Resistant Gloves

When handling hot garments or transfers, wear thick gloves rated for high temperatures.

Monitor Cord and Wiring

Do not operate presses with damaged power cords or electrical wiring to avoid shock or fire risks.

Unplug When Not in Use

Always unplug heat press machines when not actively being monitored to prevent accidental contact.

Allow Adequate Cool Down

Let presses fully cool off before touching hot areas or attempting maintenance to prevent burns.

Keep Work Area Clear

Do not allow clutter around presses and keep cords safely out of the way to prevent tripping dangers.

Avoid Unattended Operation

Stay present and actively monitor presses during use to prevent overheating and other malfunctions.

Ensure Proper Ventilation

Heat presses generate a lot of heat. Ensure adequate airflow in workspaces and do not block vents.

Secure Long Hair

Tie back or cover long hair when operating presses to keep it safely away from hot platens and moving parts.

Keep Children Away

Heat presses pose serious risks to children. Never allow kids to operate or be near presses unattended.

By making safety a priority and proactively addressing hazards, you can enjoy heat printing while keeping your work space secure.

The Cost Of Heat Press Jersey Number Printing

Looking to add printed names, numbers, and custom designs to team jerseys? Understanding the costs associated with heat press printing will help you budget for your team’s uniform needs.

Heat Press Machine Cost

Heat press machines represent the primary investment. Entry-level presses for home use start around $200-$500. Mid-range commercial presses run $800-$1,500, while industrial machines cost $2,000-$5,000+.

Transfer Vinyl Material Cost

The heat transfer vinyl used will be an ongoing expense. Standard vinyl runs $1-$5 per linear foot for numbering. Specialty vinyls cost more per foot.

Electricity Cost

Expect added electric bills from running heat press machines regularly. Most presses draw 10-15 amps during operation.

Graphic Design Cost

If outsourcing custom artwork design, you’ll incur graphic design fees which vary based on details and number of jersey designs.

Labor Cost

Factor in labor time and cost for the numbering and heat pressing work itself, especially if outsourcing production.

Other Consumable Supplies

Additional supplies like transfer papers, cover sheets, jerseys, and more add to overall numbering costs.

Machine Maintenance

Expect occasional maintenance costs such as replacement heat platen pads/covers and machine repairs if any issues arise.

Number and Detail Replacement

Plan for reordering and replacing old numbers and names as players change each season.

Delivery Fees

If outsourcing printing, build in any potential artwork delivery or product shipping fees.

While heat press printing has lower overall startup costs than traditional screen printing, carefully project both one-time and ongoing numbering expenses for budgeting team jersey projects.

Heat Pressed Jerseys Vs. Other Printing Methods

When it comes to customizing jerseys and shirts for your team, business, or event, heat pressing is one of the most popular and effective options. But how exactly does heat pressing compare to other printing methods like screen printing, vinyl lettering, or sublimation? Let’s break it down so you can make an informed decision when selecting the right shirt printing technique for your needs.

Heat Pressing

Heat pressing involves using a heat press machine to apply specially-designed transfers onto shirts or garments. The transfers contain your design, logo, text, or images created with specialty inks and materials. When the heat press applies high pressure and heat, it bonds the transfer permanently into the fabric.

Heat pressing has become the go-to for printing all kinds of jerseys and athletic shirts. It works great on performance fabrics like polyester and spandex blends. The smooth application leaves no thick layers, so there’s no restriction of movement or discomfort for athletes. It also holds up well to washing and wear over time.

Compared to other methods, heat pressing is quick and efficient. You can set up multiple garments in the heat press to print batches in minutes. It’s cost-effective for small runs since there’s minimal setup and no screens or plates to create. You can easily change and customize designs as needed.

The downside is that heat pressed transfers feel slightly different than the original jersey material. There can be a slight box-like outline visible around the design if not done correctly. So it may not be the best for replicating a high-end pro sports jersey, for example.

Screen Printing

Screen printing requires creating a custom screen layered with your artwork for each color in the design. Ink gets squeezed through the screen, transferring the image directly onto the shirt. It cures in place rather than adding layers on top of the fabric.

Screen printing allows for bright, bold designs with a smooth feel that replicates pro jerseys. Since the ink bonds with the fibers of the fabric, it stretches well and holds up over time without cracking or peeling.

The downside is that screen printing has higher setup costs and requires more labor. Each color needs a custom screen, so multi-color designs take more time. It also leaves a faint background outline around designs if not done carefully. Overall, screen printing works best for bulk orders and team uniforms where durability is key.

Vinyl Lettering

Vinyl lettering and numbering are easy to apply using a vinyl cutter machine. The vinyl gets cut into the custom shapes and then heat applied onto the garment. This method allows for quick and simple lettering, names, and numbering on the back of jerseys and shirts.

Vinyl provides a very smooth feel since it fuses right onto the fabric. It conforms well to stretchy athletic materials. However, vinyl lettering does not allow for detailed multi-color artwork or gradients. It starts to crack and peel over time with frequent washing and wear.

Overall, vinyl works well for adding names and numbers to complete a uniform on a budget. It may not withstand heavy use over multiple seasons like screen printing would.

Dye Sublimation

Dye sublimation printing uses specialized inks and a heat press to infuse designs into polyester fabrics. The process permanently dyesthe fibers of the garment for an all-over print with no background box outline. This gives a lightweight, professional feel.

Since the dye fully integrates into the polyester, the prints stretch well without cracking or fading. The colors come out incredibly vibrant and realistic. However, dye sub is not effective on natural fibers like cotton. It also requires a high initial investment for special equipment and inks.

Dye sublimation excels at replicating the look and feel of professional sports jerseys. It’s ideal for esports teams, uniforms, and polyester athleticwear when high quality and durability are essential.

Choosing the Best Printing Method

When deciding between heat pressing, screen printing, vinyl lettering, and sublimation, consider factors like your budget, order quantity, jersey materials, and printing needs. Heat pressing strikes the best balance for most small team orders with its quick turnaround time, easy customization, and minimal startup costs. For large bulk orders, screen printing may provide better durability over the long run.

No matter the printing method, working with a knowledgeable shirt printing company is key. They can provide guidance to match the right technique with the right fabric and design elements to meet your team’s needs. Comparing samples of each printing method can help inform your decision. With the right process, you can get sleek customized jerseys your team will love!