How does E3 Lithium’s discovery in Alberta’s Bashaw district impact Canada’s lithium production. What are the implications of this breakthrough for the global battery metals market. Why is the Leduc aquifer significant for E3 Lithium’s commercialization plans.

E3 Lithium’s Groundbreaking Discovery in Alberta

E3 Lithium has made a significant breakthrough in Alberta’s Bashaw district, establishing it as Canada’s largest brine project. This discovery has the potential to position Canada as a formidable competitor in the global battery metals market. The project’s impressive resources include:

- 6.6 million measured tonnes of Lithium Carbonate Equivalent (LCE)

- 9.4 million indicated tonnes of LCE

- A combined total of 16 million tonnes of LCE

These figures have put this previously overlooked region of Alberta on the map within the resource sector, attracting attention from investors and industry experts alike.

The Significance of Canada’s Resource Upgrade

Canada has recently completed one of its largest resource upgrades in history, with far-reaching implications on a global scale. This upgrade has provided invaluable insights into the Leduc aquifer, significantly increasing confidence in E3 Lithium’s commercialization plans.

What makes this resource upgrade so important? The extensive data and geological research conducted have provided a comprehensive understanding of the Leduc aquifer’s potential, allowing for more accurate assessments of lithium extraction feasibility and long-term sustainability.

Key Aspects of the Resource Upgrade:

- Comprehensive geological mapping of the Bashaw district

- Detailed analysis of brine composition and lithium concentrations

- Assessment of extraction techniques and their potential yields

- Evaluation of environmental impacts and mitigation strategies

Collaboration between Imperial Oil and the Canadian Government

The significance of E3 Lithium’s discovery has not gone unnoticed by major players in the industry. Imperial Oil and the Canadian government have joined forces to invest in the Bashaw project, recognizing its potential to revolutionize Canada’s position in the global lithium market.

How will this collaboration benefit the project? The partnership brings together Imperial Oil’s expertise in resource extraction and the Canadian government’s support for sustainable development, creating a powerful synergy that could accelerate the project’s progress.

The Leduc Aquifer: A Game-Changer for Lithium Extraction

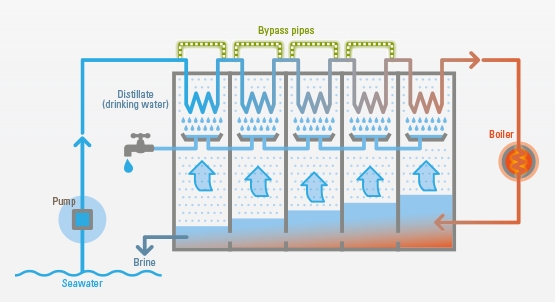

The Leduc aquifer plays a crucial role in E3 Lithium’s commercialization plans. This vast underground reservoir contains lithium-rich brines that can be extracted using innovative technologies. Understanding the aquifer’s characteristics is essential for developing efficient and sustainable extraction methods.

Why is the Leduc aquifer particularly suitable for lithium extraction? The aquifer’s unique geological properties, including its porosity and permeability, make it an ideal source for lithium-rich brines. Additionally, the aquifer’s extensive size ensures a long-term supply of lithium, supporting sustainable production for years to come.

Advantages of the Leduc Aquifer:

- High lithium concentration in brine

- Large volume and extensive coverage

- Favorable geological conditions for extraction

- Potential for sustainable, long-term production

Implications for Canada’s Lithium Production

E3 Lithium’s breakthrough in Alberta’s Bashaw district has significant implications for Canada’s lithium production. This discovery could potentially transform Canada into a major player in the global lithium market, reducing dependence on foreign sources and strengthening the country’s position in the battery supply chain.

How might this impact Canada’s economy? The development of a thriving lithium industry could create numerous job opportunities, attract foreign investment, and contribute to the country’s overall economic growth. Moreover, it aligns with Canada’s commitment to sustainable resource development and the transition to clean energy technologies.

Potential Economic Benefits:

- Job creation in mining, processing, and related industries

- Increased export revenues from lithium products

- Development of a domestic battery manufacturing sector

- Enhanced energy security and reduced reliance on imports

Global Impact on the Battery Metals Market

The emergence of Canada as a significant lithium producer could have far-reaching effects on the global battery metals market. With the growing demand for electric vehicles and energy storage solutions, the need for lithium is expected to surge in the coming years.

How might E3 Lithium’s project influence global lithium prices? As a new major supplier enters the market, it could potentially help stabilize lithium prices and ensure a more reliable supply chain for battery manufacturers worldwide. This increased competition could also drive innovation in extraction technologies and production processes.

Potential Market Impacts:

- Diversification of global lithium supply

- Increased competition among lithium producers

- Potential stabilization of lithium prices

- Acceleration of technological advancements in lithium extraction

Sustainable Extraction Technologies and Environmental Considerations

As E3 Lithium moves forward with its project in the Bashaw district, the focus on sustainable extraction technologies and environmental considerations becomes paramount. The company is committed to developing innovative methods that minimize the environmental impact of lithium production.

What sustainable technologies are being considered for lithium extraction? E3 Lithium is exploring direct lithium extraction (DLE) techniques, which offer several advantages over traditional evaporation pond methods. These technologies can potentially reduce water consumption, minimize land disturbance, and accelerate the production process.

Benefits of Direct Lithium Extraction:

- Reduced water consumption compared to evaporation ponds

- Smaller environmental footprint

- Faster production timelines

- Higher recovery rates of lithium from brine

- Potential for co-production of other valuable minerals

How does E3 Lithium plan to address environmental concerns? The company is committed to conducting thorough environmental impact assessments and implementing best practices in resource extraction. This includes measures to protect local ecosystems, minimize greenhouse gas emissions, and ensure responsible water management throughout the project’s lifecycle.

Future Prospects and Challenges for E3 Lithium

While E3 Lithium’s discovery in the Bashaw district presents enormous potential, the company faces several challenges as it moves towards commercialization. Addressing these challenges will be crucial for the project’s success and its ability to contribute significantly to Canada’s lithium production.

What are the main hurdles E3 Lithium needs to overcome? Some of the key challenges include:

- Scaling up extraction technologies from pilot to commercial scale

- Securing necessary permits and regulatory approvals

- Developing infrastructure for processing and transportation

- Managing capital costs and securing long-term financing

- Navigating market fluctuations and competition from established producers

How is E3 Lithium positioning itself to address these challenges? The company is taking a proactive approach by:

- Collaborating with industry partners and research institutions to refine extraction technologies

- Engaging with local communities and stakeholders to build support for the project

- Exploring strategic partnerships for financing and offtake agreements

- Investing in research and development to maintain a competitive edge

- Developing a phased approach to project implementation to manage risks and costs

As E3 Lithium continues to progress its project in Alberta’s Bashaw district, the company’s success could have far-reaching implications for Canada’s role in the global lithium market. The development of this resource has the potential to not only boost the country’s economy but also contribute significantly to the global transition towards clean energy and sustainable transportation solutions.

With ongoing support from the Canadian government, collaboration with industry partners, and a commitment to sustainable practices, E3 Lithium is well-positioned to leverage this breakthrough discovery and establish Canada as a major player in the lithium industry. As the project moves forward, it will be crucial to monitor its progress and its impact on both the local and global scales, potentially reshaping the landscape of battery metal production in North America and beyond.

E3 Metals: Sampling of Petrolithium Brine from First 43 Wells Complete; Analysis Undergoing

Mr. Chris Doornbos reports:

Vancouver, BC (FSCwire) – E3 METALS CORP. (TSX-V: ETMC, FSE: OU7A) (the “Company” or “E3 Metals”) is pleased to announce the completion of the first round of sampling of Petro-Lithium brine water from petroleum wells, located over several of E3 Metals’ Metallic and Industrial Minerals (MIM) Permits in Alberta. Samples have been collected in collaboration with 11 oil and gas operators. The samples have been received at the accredited laboratories and are undergoing analysis.

Sampling locations were chosen to confirm historical testing results outlined in the E3 Metals NI 43-101 Report, dated May 18. 2017, available under the Company’s profile at www.sedar.com and at www.e3metalscorp.com. Historical results in the sampling area ranged as high as 74.1 mg/L lithium within E3 Metals MIM Permit areas across this small portion of the reservoir. Additionally, E3 Metals has sampled several locations where no historical lithium concentration data is available. The consistency of the lithium concentrations found within the reservoir is a critical component in allowing for commercialization of the Company’s project. This, combined with the ability to produce large volumes of water, the size of the reservoir and the extraction technology efficiency, forms the fundamentals for developing the Company’s Petro-Lithium Project. E3 Metals is working on all four of these metrics simultaneously to drive this project forward as effectively as possible.

Additionally, E3 Metals has sampled several locations where no historical lithium concentration data is available. The consistency of the lithium concentrations found within the reservoir is a critical component in allowing for commercialization of the Company’s project. This, combined with the ability to produce large volumes of water, the size of the reservoir and the extraction technology efficiency, forms the fundamentals for developing the Company’s Petro-Lithium Project. E3 Metals is working on all four of these metrics simultaneously to drive this project forward as effectively as possible.

“We are pleased to have delivered samples from the first 43 wells to the lab for analysis, collected during the first round of our ongoing sampling program” said E3 Metals’ CEO, Chris Doornbos, “This is an increase of almost double our expected number of wells and I would like acknowledge the cooperation of the oil and gas operators E3 has been collaborating with during this sampling round. Our sampling will continue into the fall with planning of additional programs currently underway.”

Our sampling will continue into the fall with planning of additional programs currently underway.”

RECENT & RELEVANT

NV Gold Announces Completion of Drill Program at Triple T Gold Project in Nevada

Fathom Nickel Announces Further Increase to Land Package at the Gochager Lake…

Gold Basin Resources Reports Initial Soil and Rock Assays, Bolsters Team with…

MORE MINING NEWS

FireFox Gold Reports Results from Reconnaissance Drill Program at Sarvi Project, Lapland, Finland

Labrador Gold Intersects 31.86g/t over 0.45 Metres in Fourth Hole at New Dropkick Target 3.4 Kilometres Northeast of Big Vein

Kodiak Copper Adds Second Drill Rig at MPD Copper-Gold Porphyry Project in Southern British Columbia

Calibre’s 2023 Exploration Drill Program Along Panteon VTEM Corridor Yields Multiple New Exciting High-Grade Discoveries in Untapped Regions; Additional Drilling Intersects…

Timberline Resources Announces Updated Mineral Resource Estimate at Eureka Project under SEC Regulation S-K 1300

Vizsla Silver Reports Additional High-grade Intercepts on Copala and Copala 2 Structures

New Age Metals Delivers New Positive Preliminary Economic Assessment of the River Valley Palladium Project

FireFox Gold Drills 20. 4 metres at 5.1 g/t Gold and Extends the Footprint of Mineralization at Mustajärvi East Target in Finland

4 metres at 5.1 g/t Gold and Extends the Footprint of Mineralization at Mustajärvi East Target in Finland

Arras Minerals Commences Regional Field Program on 3,300 sq. km License Package in Pavlodar, Kazakhstan

HighGold Mining Announces Start of 8,000-meter Drill Program and Outlines Advanced Exploration Plans at Johnson Tract Project, Alaska

NV Gold Announces Completion of Drill Program at Triple T Gold Project in Nevada

Prismo Metals Samples 10.3 g/t Au and 104 g/t Ag over 4 Meters at Los Pavitos

E3 Lithium Supercharges Canada’s Largest Brine Project

- 22-Mar-2023 4:17 PM

- Journalist: Nina Jiang

Canada: E3 Lithium has made a breakthrough in Alberta’s Bashaw district, making this area the largest brine project in Canada and a potential rival to some of the world’s biggest suppliers of battery metals. The project boasts 6.6 million measured tonnes of Lithium Carbonate equivalent (LCE) and 9.4 million indicated tonnes of LCE for a combined total of 16 million tonnes — an impressive figure that has placed this previously-unknown corner of Alberta firmly on the map within the resource sector.

The project boasts 6.6 million measured tonnes of Lithium Carbonate equivalent (LCE) and 9.4 million indicated tonnes of LCE for a combined total of 16 million tonnes — an impressive figure that has placed this previously-unknown corner of Alberta firmly on the map within the resource sector.

Canada recently made one of its largest resource upgrades in history and this upgrade has far-reaching implications on a global scale. The tremendous amount of data and geological research conducted for this upgrade is remarkable, giving us invaluable insight into the Leduc aquifer, thus increasing our confidence in our commercialization plans.

Imperial Oil and the Canadian government have joined forces in investing in Bashaw, one of the world’s largest direct Lithium extraction brine projects. This new resource is a giant compared to Canada’s estimated 3.2 million tonnes of Lithium in hard rock deposits, according to Natural Resources Canada.

Calgary-based E3 recently underwent an upgrade thanks to data and core sample analysis from its 2022 drill program. The company also developed a comprehensive geological model of the Bashaw district that provides details on reservoir properties.

The company also developed a comprehensive geological model of the Bashaw district that provides details on reservoir properties.

A recent breakdown of resources for a project’s Clearwater and Bashaw districts revealed that 11.1 billion cubic metres of brine with a median Lithium concentration of 74.5 mg per litre can be found in the Clearwater area, which equates to 4.3 million tonnes LCE contained metal. Meanwhile, the Bashaw district has 29.2 billion cubic metres of similarly concentrated brine, amounting to 11.7 million tonnes LCE contained metal.

E3 Metals Corp. announced an expansion of the Clearwater area and a new inferred estimate of Lithium Carbonate equivalent (LCE) resources in its Rocky area west of Bashaw district, Alberta. The project is designed to tap Lithium-enriched brine from the Leduc Aquifer, an ancient reef complex that spans hundreds of square kilometres and is over 200 metres thick. Inferred LCE resources estimated at 900,000 tonnes give a glimpse of the potential offered by this massive resource. The Exshaw area within the Bashaw district adds further potential to leverage resources in the region.

The Exshaw area within the Bashaw district adds further potential to leverage resources in the region.

The Clearwater area is estimated to produce 20,000 tonnes of Lithium hydroxide annually, upon the completion of a preliminary economic assessment. The initial capital cost for this project was set at $602 million, and the assessment showed an after-tax net present value of $820 million utilizing an 8% discount rate and 27% internal rate of return.

The federal government of Canada has awarded E3 with a C$27 million grant from the Strategic Innovation Fund in November. This follows Imperial Oil, the Canadian arm of ExxonMobil, investing C$6.4 million into researching extraction of Lithium from beneath its iconic Leduc oil field – one of the earliest crude oil discoveries in Western Canada, announced back in June.

E3 metals closer to recovering lithium from oilfield brine.-industry-news

Best lithium battery 18650

Cylindrical lithium-ion battery

Lithium Ion Battery Best Guide

The Best Guide to LiPo Batteries

Best Guide to Lifepo4 Battery

12V lithium battery manual

48 V Li-ion battery

Connecting lithium batteries in parallel and in series

Best Li-Ion Battery 26650

APR 01, 2019Page view:472

E3 Metal’s proprietary lithium pre-metallurgical recovery technology yields up to 1206 mg per liter of lithium concentrate with a concentration factor of 16 times. This company is located in Calgary.

This company is located in Calgary.

process is also successful for key metal impurities decreased by 99%, at the same time show lithium recovery rate as high as 81%.

Tested by the University of Alberta and CIMIC minerals processing group Sedgman Canada Limited, independently verified.

“The E3MetalsAlbertaLithium project is a big step forward,” E3Metals CEO ChrisDoornbos said in a statement.

“In order to develop a simple and efficient process for concentrating brine to significantly reduce impurities, we set out to test the economic and technical feasibility of Alberta’s large lithium petroleum oil resources. By continuously optimizing the adsorbent, our goal is to achieve higher recovery rates. “We are actively developing the next phase of work to advance the technology to extract lithium from Alberta oil,” he said.

Project area in the western company Exshaw E3 Metal six rich in lithium, whose formation water enrichment technology (brine) small-scale metallurgical testing. In less than three hours, the entire enrichment process will be completed. The company is expected to release a related technical report, NI43-101, in the next four weeks.

In less than three hours, the entire enrichment process will be completed. The company is expected to release a related technical report, NI43-101, in the next four weeks.

According to the results, E3Metals will seek to optimize and expand its enrichment technology to further improve lithium concentration and recovery efficiency. The enrichment technology will become a company in the production of lithium two main stages of extraction the first stage.

The company, in collaboration with the University of Alberta, is currently in a provisional patent filed to protect intellectual property rights related to its enrichment technology.

To date, E3Metals has identified 6.7 million tonnes of integrated lithium carbonate equivalent (LCE) resources across the three resources, including Alberta holdings up to 34% of the allowance.

Highly porous and permeable, the formation of which has been shown to allow the transport of large quantities of hot brine (70 to 100 degrees Celsius). The company said that with a wide range of oil and gas well infrastructure, including processing, production base and pipelines, as well as an advanced regulatory system, Alberta lithium for oil development has great appeal.

The company said that with a wide range of oil and gas well infrastructure, including processing, production base and pipelines, as well as an advanced regulatory system, Alberta lithium for oil development has great appeal.

Six trials produced lithium recovery, lithium concentration and reduction of critical (impurity) ion concentration of a series of results. The maximum recovery of lithium has increased from 66% to 81%, while the concentration of lithium varies from 13 to 16 times. The key is to significantly reduce impurities, averaging over 99%.

E3Metals advised that while the project is still at concept level, its concentration can be processed into lithium carbonate and/or lithium hydroxide. Further development of ion-exchange technology will be continued in tests of synthesis and extraction of the optimal adsorbent. The company stated that the goal is to achieve a higher recovery and increase the lithium enrichment ratio while maintaining a high level of impurities.

The page contains machine translated content.

- Previous article:

Huizhou Yiwei Lithium Energy Shares opened a subsidiary - Next article:

Three Tips for Eliminating the Hazards of Incompatible Lithium Batteries

Most Popular Categories

Custom solutions

11.1 V 6600 mAh Battery Construction Diagram for Portable Supersonic Diagnostic Kit B

7.4 V 10 Ah Medical Infusion Pump Backup Circuit

Solutions for Lithium Ion batteries AGV 25.6 V, 38.4 Ah

Lutetia T3 Mixer Used equipment

- Description

- Detailed information

- About this seller

– Vacuum meat churn.

– Manufacturer: Lutetia

– TYPE 3

– Meat + brine capacity: 1400 to 1500 kg.

– 415 V + 50 Hz + 4 kW.

– Volume: 2500 l.

– Weight: 1100 kg.

– Total length: 2650 mm.

– Width: 1450 mm.

– Diameter with tire: 1340 mm.

– Height: 2020 mm.

This description can be translated automatically. Contact us for further details. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

| Capacity | 2500L |

| Tank diameter | 1340 mm |

| Tank material | inox |

| ——————- | |

| L x W x H | 2650. 0 × 1450.0 × 2020.0 0 × 1450.0 × 2020.0 |

| Weight | 1100kg |

| Operating hours | |

| Switching hours | |

| Status | in good condition |

| CE marked | ——— |

| Status | possibility of inspection |

| Customer type | Dealer |

| Active with | 2007 |

| Offers online | 87 |

| Last activity | July 19, 2023 |

Description

– Vacuum meat churn.

– Manufacturer: Lutetia

– TYPE 3

– Meat + brine capacity: 1400 to 1500 kg.

– 415 V + 50 Hz + 4 kW.

– Volume: 2500 l.

– Weight: 1100 kg.

– Total length: 2650 mm.

– Width: 1450 mm.

– Diameter with tire: 1340 mm.

– Height: 2020 mm.

This description can be translated automatically. Contact us for further details. The information in this announcement is for guidance only. Exapro recommends that you check with the seller before buying a machine.

Details

| Capacity | 2500L |

| Tank diameter | 1340 mm |

| Tank material | inox |

| ——————- | |

| L x W x H | 2650. Related Stories |